IEC 60404-4:1995

(Main)Magnetic materials - Part 4: Methods of measurement of d.c. magnetic properties of iron and steel

Magnetic materials - Part 4: Methods of measurement of d.c. magnetic properties of iron and steel

Describes the terminology and two measuring methods, namely: the ring method and the permeameter method. Both methods use a test specimen in a closed magnetic circuit. Description of the test equipment and the electric circuits is given.

Matériaux magnétiques - Partie 4: Méthodes de mesure en courant continu des propriétés magnétiques du fer et de l'acier

Définit la terminologie et les deux méthodes de mesure, notamment la méthode du tore et la méthode du perméamètre. Les deux méthodes utilisent une éprouvette dans un circuit magnétique fermé. La description de l'équipement d'essai et des circuits électriques est également mentionnée.

General Information

- Status

- Published

- Publication Date

- 14-Feb-1995

- Technical Committee

- TC 68 - Magnetic alloys and steels

- Drafting Committee

- WG 2 - TC 68/WG 2

- Current Stage

- PPUB - Publication issued

- Start Date

- 15-Feb-1995

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60404-4:1995 is an international standard published by the International Electrotechnical Commission (IEC) that specifies methods for the measurement of direct current (d.c.) magnetic properties of magnetically soft iron and steel materials. The standard focuses on two primary measurement techniques utilizing a closed magnetic circuit: the ring method and the permeameter method. It provides detailed guidance on specimen preparation, test equipment setup, electric circuits, measurement procedures, and data interpretation. This standard is essential for accurate characterization of magnetic materials used in electrical and electronic applications.

Key Topics

Scope and Objective: The standard addresses measurements of d.c. magnetic characteristics of magnetically soft materials, primarily iron and steel, using either ring-shaped specimens or bar specimens. It covers magnetic field strengths ranging from very low values up to 200 kA/m, depending on the method.

Ring Method:

- Suitable for measuring up to 10 kA/m magnetic field strength, with considerations to avoid specimen heating.

- Involves winding coils around laminated, solid, or sintered ring specimens to form a closed magnetic circuit.

- Provides measurement of the normal magnetization curve, hysteresis loop, remanent flux density, and coercive field strength.

- Requires temperature control of the specimen (ambient at 23 ± 5 °C and specimen temperature not exceeding 50 °C).

Permeameter Method:

- Capable of measuring a broader range of magnetic field strengths, from 1 kA/m up to 200 kA/m.

- Uses bar-shaped specimens placed in a magnetically closed circuit within a permeameter.

- Allows characterization of magnetic flux density and field strength through specialized coil arrangements and magnetic circuits.

Measurement Parameters & Calculations:

- Determination of magnetic field strength (H).

- Measurement and integration of magnetic flux density (B).

- Analysis of hysteresis loops for magnetic behavior and material performance.

- Calibration methods for search coils and flux integrators are provided.

Test Report Requirements: Ensures measurement repeatability and confidence by recommending standardized formats for documenting test results and conditions.

Applications

IEC 60404-4:1995 is critical for industries and sectors involving:

Electromagnetic Device Manufacturing: Accurate magnetic property data enables optimization of transformers, inductors, electric motors, and generators.

Material Quality Control: Helps manufacturers verify magnetic properties of iron and steel alloys to meet performance standards.

Research & Development: Enables material scientists and engineers to characterize magnetic soft materials under different magnetic field conditions.

Magnetic Component Design: Facilitates design engineers in selecting appropriate materials and predicting device behaviors under direct current magnetization.

Standards Compliance Testing: Laboratories use this standard to ensure conformity of magnetic materials with international and national specifications.

Related Standards

To complement IEC 60404-4:1995, relevant IEC standards include:

IEC 60404-7: Specifies measurement of coercivity in open magnetic circuits.

IEC 60404-8 series: Defines specifications for various types of magnetic materials such as cold-rolled magnetic alloyed steel strips, non-alloyed steel strips, non-oriented magnetic steel sheets, and grain-oriented steel.

IEC 60404-8-6: Covers soft magnetic metallic materials specifically.

Applying IEC 60404-4 alongside these standards ensures comprehensive evaluation of magnetic properties, from material specifications to measurement techniques.

Keywords: IEC 60404-4, magnetic materials, d.c. magnetic properties, magnetically soft materials, ring method, permeameter method, iron and steel, magnetic field measurement, hysteresis loop, coercive field strength, magnetic flux density, closed magnetic circuit, magnetic test methods, magnetic material standards.

Buy Documents

IEC 60404-4:1995+AMD1:2000 CSV - Magnetic materials - Part 4: Methods of measurement of d.c. magnetic properties of magnetically soft materials Released:11/28/2000 Isbn:2831854296

IEC 60404-4:1995+AMD1:2000+AMD2:2008 CSV - Magnetic materials - Part 4: Methods of measurement of d.c. magnetic properties of magnetically soft materials Released:11/13/2008 Isbn:9782889101887

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60404-4:1995 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Magnetic materials - Part 4: Methods of measurement of d.c. magnetic properties of iron and steel". This standard covers: Describes the terminology and two measuring methods, namely: the ring method and the permeameter method. Both methods use a test specimen in a closed magnetic circuit. Description of the test equipment and the electric circuits is given.

Describes the terminology and two measuring methods, namely: the ring method and the permeameter method. Both methods use a test specimen in a closed magnetic circuit. Description of the test equipment and the electric circuits is given.

IEC 60404-4:1995 is classified under the following ICS (International Classification for Standards) categories: 17.220.20 - Measurement of electrical and magnetic quantities; 29.030 - Magnetic materials. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60404-4:1995 has the following relationships with other standards: It is inter standard links to IEC 60404-4:1995/AMD1:2000, IEC 60404-4:1995/AMD2:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60404-4:1995 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60404-4

Edition 2.1 2000-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Magnetic materials –

Part 4: Methods of measurement of d.c. magnetic properties of magnetically soft

materials

Matériaux magnétiques –

Partie 4: Méthodes de mesure en courant continu des propriétés magnétiques

des matériaux magnétiquement doux

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60404-4

Edition 2.1 2000-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Magnetic materials –

Part 4: Methods of measurement of d.c. magnetic properties of magnetically soft

materials

Matériaux magnétiques –

Partie 4: Méthodes de mesure en courant continu des propriétés magnétiques

des matériaux magnétiquement doux

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CK

CODE PRIX

ICS 17.220.20; 29.030 ISBN 2-8318-5429-6

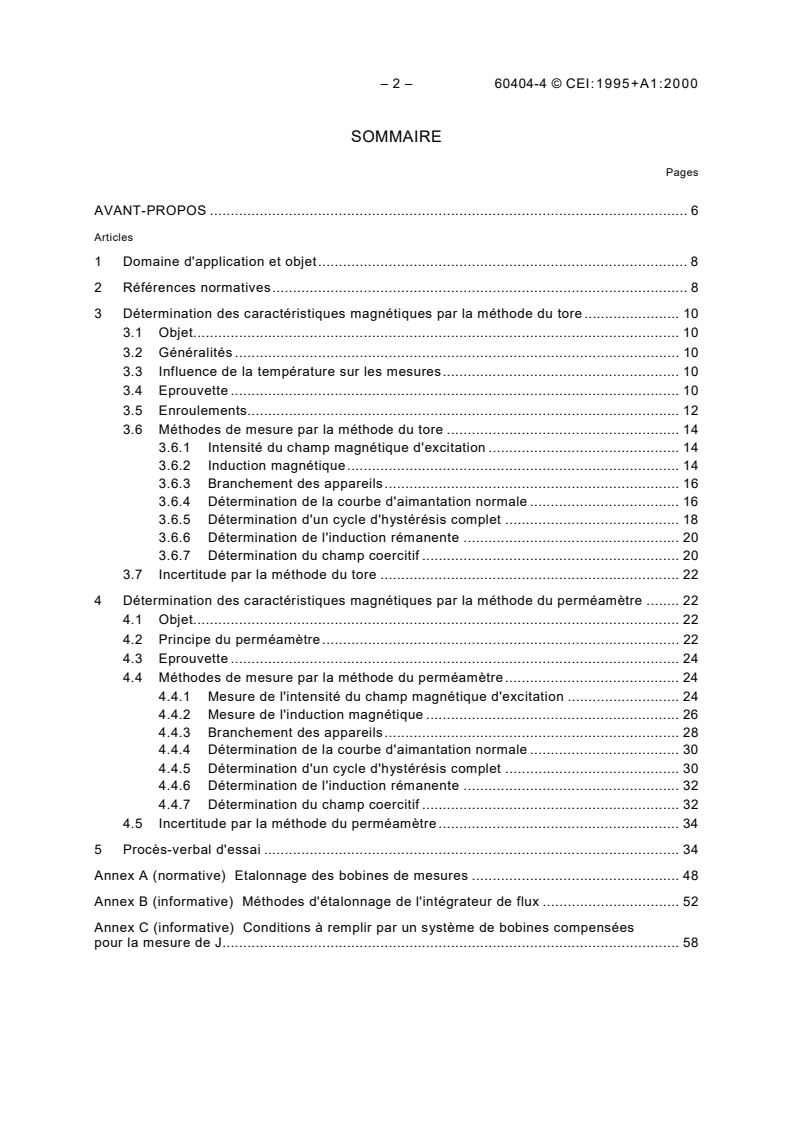

– 2 – 60404-4 © CEI:1995+A1:2000

SOMMAIRE

Pages

AVANT-PROPOS . 6

Articles

1 Domaine d'application et objet. 8

2 Références normatives. 8

3 Détermination des caractéristiques magnétiques par la méthode du tore . 10

3.1 Objet. 10

3.2 Généralités . 10

3.3 Influence de la température sur les mesures. 10

3.4 Eprouvette . 10

3.5 Enroulements. 12

3.6 Méthodes de mesure par la méthode du tore . 14

3.6.1 Intensité du champ magnétique d'excitation . 14

3.6.2 Induction magnétique. 14

3.6.3 Branchement des appareils. 16

3.6.4 Détermination de la courbe d'aimantation normale . 16

3.6.5 Détermination d'un cycle d'hystérésis complet . 18

3.6.6 Détermination de l'induction rémanente . 20

3.6.7 Détermination du champ coercitif . 20

3.7 Incertitude par la méthode du tore . 22

4 Détermination des caractéristiques magnétiques par la méthode du perméamètre . 22

4.1 Objet. 22

4.2 Principe du perméamètre. 22

4.3 Eprouvette . 24

4.4 Méthodes de mesure par la méthode du perméamètre. 24

4.4.1 Mesure de l'intensité du champ magnétique d'excitation . 24

4.4.2 Mesure de l'induction magnétique . 26

4.4.3 Branchement des appareils. 28

4.4.4 Détermination de la courbe d'aimantation normale . 30

4.4.5 Détermination d'un cycle d'hystérésis complet . 30

4.4.6 Détermination de l'induction rémanente . 32

4.4.7 Détermination du champ coercitif . 32

4.5 Incertitude par la méthode du perméamètre. 34

5 Procès-verbal d'essai . 34

Annex A (normative) Etalonnage des bobines de mesures . 48

Annex B (informative) Méthodes d'étalonnage de l'intégrateur de flux . 52

Annex C (informative) Conditions à remplir par un système de bobines compensées

pour la mesure de J. 58

60404-4 © IEC:1995+A1:2000 – 3 –

CONTENTS

Page

FOREWORD . 7

Clause

1 Scope and object . 9

2 Normative references. 9

3 Determination of the magnetic characteristics by the ring method . 11

3.1 Object. 11

3.2 General. 11

3.3 Effect of temperature on the measurements. 11

3.4 Test specimen . 11

3.5 Windings. 13

3.6 Methods of measurement by the ring method. 15

3.6.1 Magnetic field strength. 15

3.6.2 Magnetic flux density . 15

3.6.3 Connection of apparatus . 17

3.6.4 Determination of normal magnetization curve. 17

3.6.5 Determination of a complete hysteresis loop . 19

3.6.6 Determination of remanent flux density . 21

3.6.7 Determination of coercive field strength . 21

3.7 Uncertainty by the ring method . 23

4 Determination of the magnetic characteristics by the permeameter method. 23

4.1 Object. 23

4.2 Principle of the permeameter . 23

4.3 Test specimen . 25

4.4 Methods of measurement by the permeameter method . 25

4.4.1 Measurement of magnetic field strength. 25

4.4.2 Measurement of magnetic flux density . 27

4.4.3 Connection of apparatus . 29

4.4.4 Determination of the normal magnetization curve. 31

4.4.5 Determination of a complete hysteresis loop . 31

4.4.6 Determination of remanent flux density . 33

4.4.7 Determination of coercive field strength . 33

4.5 Uncertainty by the permeameter method. 35

5 Test report . 35

Annex A (normative) Calibration of search coils . 49

Annex B (informative) Methods of calibrating the flux integrator . 53

Annex C (informative) Requirements for the J-compensated coil system . 59

– 4 – 60404-4 © CEI:1995+A1:2000

Pages

Figure 1 – Circuit pour la détermination des caractéristiques magnétiques par

la méthode du tore . 36

Figure 2 – Cycle d'hystérésis. 36

Figure 3 – Configuration typique d'un perméamètre de type A. 38

Figure 4 – Configuration typique d'un perméamètre de type B. 40

Figure 5 – Configuration des bobines de mesure. 44

Figure 6 – Circuit pour la détermination de la courbe d'aimantation normale et du cycle

d'hystérésis à l'aide d'un perméamètre à double culasse (échantillon en barreau). 46

Figure A.1 – Circuit pour l'étalonnage des bobines de mesure. 50

Figure B.1 – Circuit d'étalonnage de l'intégrateur de flux par la méthode de

la décharge d'un condensateur étalon . 56

Tableau 1 – Séquence des commutations nécessaires au maintien de l'éprouvette

dans un état cyclique stable . 20

60404-4 © IEC:1995+A1:2000 – 5 –

Page

Figure 1 – Circuit for the determination of the magnetic characteristics

by the ring method . 37

Figure 2 – Hysteresis loop. 37

Figure 3 – Typical arrangement of a type A permeameter. 39

Figure 4 – Typical arrangement of a type B permeameter. 41

Figure 5 – Arrangement of search coils . 45

Figure 6 – Circuit for the determination of the normal magnetization curve and

hysteresis loop of bar specimens using a double yoke permeameter . 47

Figure A.1 – Circuit for the calibration of search-coils. 51

Figure B.1 – Circuit for calibration the flux integrator by the capacitor

discharge method. 57

Table 1 – Switching sequence to maintain the test specimen in a steady cyclic state . 21

– 6 – 60404-4 © CEI:1995+A1:2000

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

MATÉRIAUX MAGNÉTIQUES –

Partie 4: Méthodes de mesure en courant continu

des propriétés magnétiques des matériaux magnétiquement doux

AVANT-PROPOS

1) La CEI (Commission Électrotechnique Internationale) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les

domaines de l'électricité et de l'électronique. A cet effet, la CEI, entre autres activités, publie des Normes

internationales. Leur élaboration est confiée à des comités d'études, aux travaux desquels tout Comité national

intéressé par le sujet traité peut participer. Les organisations internationales, gouvernementales et non

gouvernementales, en liaison avec la CEI, participent également aux travaux. La CEI collabore étroitement

avec l'Organisation Internationale de Normalisation (ISO), selon des conditions fixées par accord entre les

deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux intéressés

sont représentés dans chaque comité d’études.

3) Les documents produits se présentent sous la forme de recommandations internationales. Ils sont publiés

comme normes, spécifications techniques, rapports techniques ou guides et agréés comme tels par les

Comités nationaux.

4) Dans le but d'encourager l'unification internationale, les Comités nationaux de la CEI s'engagent à appliquer de

façon transparente, dans toute la mesure possible, les Normes internationales de la CEI dans leurs normes

nationales et régionales. Toute divergence entre la norme de la CEI et la norme nationale ou régionale

correspondante doit être indiquée en termes clairs dans cette dernière.

5) La CEI n’a fixé aucune procédure concernant le marquage comme indication d’approbation et sa responsabilité

n’est pas engagée quand un matériel est déclaré conforme à l’une de ses normes.

6) L’attention est attirée sur le fait que certains des éléments de la présente Norme internationale peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La Norme internationale CEI 60404-4 a été établie par le comité d'études 68 de la CEI:

Matériaux magnétiques tels qu'alliages et aciers.

Cette deuxième édition annule et remplace la première édition parue en 1982 et constitue une

révision technique.

La présente version consolidée de la CEI 60404-4 comprend la deuxième édition (1995)

[documents 68(BC)95 et 68/117/RVD], et son amendement 1 (2000) [documents 68/215/FDIS

et 68/217/RVD].

Le contenu technique de cette version consolidée est donc identique à celui de l'édition de

base et à son amendement; cette version a été préparée par commodité pour l'utilisateur.

Elle porte le numéro d'édition 2.1.

Une ligne verticale dans la marge indique où la publication de base a été modifiée par

l’amendement 1.

L'annexe A fait partie intégrante de cette norme.

Les annexes B et C sont données uniquement à titre d'information.

Le comité a décidé que le contenu de la publication de base et de ses amendements ne sera

pas modifié avant 2009. A cette date, la publication sera

• reconduite;

• supprimée;

• remplacée par une édition révisée, ou

• amendée.

60404-4 © IEC:1995+A1:2000 – 7 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MAGNETIC MATERIALS –

Part 4: Methods of measurement of d.c.

magnetic properties of magnetically soft materials

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International

Organization for Standardization (ISO) in accordance with conditions determined by agreement between the

two organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60404-4 has been prepared by IEC technical committee 68:

Magnetic alloys and steels.

This second edition cancels and replaces the first edition published in 1982 and constitutes a

technical revision.

This consolidation version of IEC 60404-4 consists of the second edition (1995) [documents

68(CO)95 and 68/117/RVD], and amendment 1 (2000) [documents 68/215/FDIS and 68/217/RVD].

The technical content is therefore identical to the base edition and its amendment and has

been prepared for user convenience.

It bears the edition number 2.1.

A vertical line in the margin shows where the base publication has been modified by

amendment 1.

Annex A forms an integral part of this standard.

Annexes B and C are for information only.

The committee has decided that the contents of the base publication and its amendments will

remain unchanged until 2009. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

– 8 – 60404-4 © CEI:1995+A1:2000

MATÉRIAUX MAGNÉTIQUES –

Partie 4: Méthodes de mesure en courant continu

des propriétés magnétiques des matériaux magnétiquement doux

1 Domaine d'application et objet

Cette partie de la CEI 60404 traite des méthodes de mesure en courant continu des pro-

priétés magnétiques des matériaux magnétiquement doux, en circuit magnétique fermé, en

utilisant la méthode du tore ou celle du perméamètre. L’utilisation de la méthode du tore est

adaptée pour les éprouvettes constituées d’un tore monobloc ou formé de feuilles, de même

que pour les éprouvettes constituées d’un tore obtenues par frittage.

Deux méthodes sont utilisées:

a) la méthode du tore, en particulier pour des intensités de champ d'excitation magnétique

pouvant aller jusqu'à 10 kA/m;

b) la méthode du perméamètre pour des intensités de champ d'excitation magnétique allant

de 1 kA/m à 200 kA/m.

NOTE La mesure de la coercitivité en circuit magnétique ouvert fait l'objet de la CEI 60404-7.

2 Références normatives

Les documents normatifs suivants contiennent des dispositions qui, par suite de la référence

qui y est faite, constituent des dispositions valables pour la présente partie de la CEI 60404.

Pour les références datées, les amendements ultérieurs ou les révisions de ces publications

ne s’appliquent pas. Toutefois, les parties prenantes aux accords fondés sur la présente

partie de la CEI 60404 sont invitées à rechercher la possibilité d'appliquer les éditions les

plus récentes des documents normatifs indiqués ci-après. Pour les références non datées, la

dernière édition du document normatif en référence s’applique. Les membres de la CEI et de

l'ISO possèdent le registre des Normes internationales en vigueur.

CEI 60404-7:1982, Matériaux magnétiques – Septième partie: Méthode de mesure du champ

coercitif des matériaux magnétiques en circuit magnétique ouvert

CEI 60404-8-2:1985, Matériaux magnétiques – Huitième partie: Spécifications pour matériaux

particuliers – Section deux: Spécification des bandes magnétiques en acier allié, laminées à

froid et livrées à l'état semi-fini

CEI 60404-8-3:1985, Matériaux magnétiques – Huitième partie: Spécifications pour matériaux

particuliers – Section trois: Spécification des bandes magnétiques en acier non allié, laminées

à froid et livrées à l'état semi-fini

CEI 60404-8-4:1986, Matériaux magnétiques – Huitième partie: Spécifications pour matériaux

particuliers – Section quatre: Spécification des tôles magnétiques en acier à grains non

orientés, laminées à froid

CEI 60404-8-6:1986, Matériaux magnétiques – Huitième partie: Spécifications pour matériaux

particuliers – Section six: Matériaux métalliques magnétiquement doux

Amendement 1 (1992)

60404-4 © IEC:1995+A1:2000 – 9 –

MAGNETIC MATERIALS –

Part 4: Methods of measurement of d.c.

magnetic properties of magnetically soft materials

1 Scope and object

This part of IEC 60404 specifies the methods of measuring the d.c. magnetic properties of

magnetically soft materials in a closed magnetic circuit using either the ring or the permea-

meter methods. The ring method is suitable for use with laminated or solid ring specimens as

well as ring specimens produced by sintering.

Two methods are used:

a) the ring method, particularly for magnetic field strengths of up to 10 kA/m;

b) the permeameter method for magnetic field strengths in the range 1 kA/m to 200 kA/m.

NOTE The measurement of coercivity in an open magnetic circuit is specified in IEC 60404-7.

2 Normative references

The following normative documents contain provisions which, through reference in this text,

constitute provisions of this part of IEC 60404. For dated references, subsequent amend-

ments to, or revisions of, any of these publications do not apply. However, parties to

agreements based on this part of IEC 60404 are encouraged to investigate the possibility of

applying the most recent editions of the normative documents indicated below. For undated

references, the latest edition of the normative document referred to applies. Members of IEC

and ISO maintain registers of currently valid International Standards.

IEC 60404-7:1982, Magnetic materials – Part 7: Method of measurement of the coercivity of

magnetic materials in an open magnetic circuit

IEC 60404-8-2:1985, Magnetic materials – Part 8: Specifications for individual materials –

Section Two: Specification for cold-rolled magnetic alloyed steel strip delivered in the semi-

processed state

IEC 60404-8-3:1985, Magnetic materials – Part 8: Specifications for individual materials –

Section Three: Specification for cold-rolled magnetic non-alloyed steel strip delivered in the

semi-processed state

IEC 60404-8-4:1986, Magnetic materials – Part 8: Specifications for individual materials –

Section Four: Specification for cold-rolled non-oriented magnetic steel sheet and strip

IEC 60404-8-6:1986, Magnetic materials – Part 8: Specifications for individual materials –

Section Six: Soft magnetic metallic materials

Amendment 1 (1992)

– 10 – 60404-4 © CEI:1995+A1:2000

CEI 60404-8-7:1988, Matériaux magnétiques – Huitième partie: Spécifications pour matériaux

particuliers – Section sept: Spécification des tôles magnétiques en acier à grains orientés

Amendement 1 (1991)

CEI 60404-8-8:1991, Matériaux magnétiques – Partie 8: Spécifications pour matériaux

particuliers – Section 8: Spécification des tôles magnétiques extra-minces en acier pour

utilisation à moyennes fréquences

3 Détermination des caractéristiques magnétiques par la méthode du tore

3.1 Objet

Cet article décrit la méthode du tore utilisée pour déterminer la courbe d'aimantation normale

et le cycle d'hystérésis.

3.2 Généralités

Cette méthode est utilisée en particulier pour les intensités du champ magnétique d'excitation

jusqu'à 10 kA/m. Toutefois, à condition de prendre des précautions pour éviter d'échauffer

l'éprouvette, cette méthode reste valable pour des champs magnétiques plus intenses.

3.3 Influence de la température sur les mesures

Des précautions doivent être prises pour éviter tout échauffement excessif de l'éprouvette.

Les mesures doivent être faites à une température ambiante de (23 ± 5) ° C. La température

de l'éprouvette ne doit pas dépasser 50 °C. Elle doit être contrôlée par une sonde de

température.

Pour des matériaux qui sont particulièrement sensibles à la température, les normes de

produits peuvent définir des températures limites de l'éprouvette plus hautes ou plus basses.

3.4 Eprouvette

L'éprouvette est constituée par un tore homogène, sans soudure, de section rectangulaire ou

circulaire. L'aire de la section du tore est déterminée par les dimensions du produit,

l'uniformité de ses propriétés magnétiques, la sensibilité des instruments de mesure, et

2 2

l'espace requis pour les enroulements. Une section comprise entre 100 mm et 500 mm est

utilisée couramment.

Des précautions doivent être prises dans la préparation de l'éprouvette pour éviter un

écrouissage ou un échauffement du matériau qui pourraient en altérer les caractéristiques

magnétiques. L'éprouvette peut être usinée par tournage, suivi d'une légère rectification, avec

assez de liquide de refroidissement pour prévenir tout échauffement du matériau. Les bords

des tores doivent être ébavurés.

Pour limiter l'effet d'une variation radiale de l'intensité du champ magnétique d'excitation, on

doit veiller à satisfaire la relation:

D ≤ 1,1 d (1)

où

D est le diamètre extérieur de l'éprouvette, en mètres;

d est le diamètre intérieur de l'éprouvette, en mètres.

60404-4 © IEC:1995+A1:2000 – 11 –

IEC 60404-8-7:1988, Magnetic materials – Part 8: Specifications for individual materials –

Section Seven: Specification for grain-oriented magnetic steel sheet and strip

Amendment 1 (1991)

IEC 60404-8-8:1991, Magnetic materials – Part 8: Specifications for individual materials –

Section 8: Specification for thin magnetic steel strip for use at medium frequencies

3 Determination of the magnetic characteristics by the ring method

3.1 Object

This clause describes the ring method used to obtain the normal magnetization curve and the

hysteresis loop.

3.2 General

This method is used particularly for magnetic field strengths of up to 10 kA/m. However, if

care is taken to avoid heating the test specimen, this method may be used at higher magnetic

field strengths.

3.3 Effect of temperature on the measurements

Care shall be taken to avoid unduly heating the test specimen. The measurements shall be

made at an ambient temperature of (23 ± 5) °C. The temperature of the test specimen shall

not exceed 50 °C which shall be monitored by means of a temperature sensor.

For materials which are particularly temperature sensitive, product standards may define

lower or higher test specimen temperatures.

3.4 Test specimen

The test specimen is a homogeneous unwelded ring of rectangular or circular cross-section.

The cross-sectional area of the ring is determined by the product dimensions, uniformity of

magnetic properties, instrumentation sensitivity and space required for the test windings.

2 2

Usually the cross-sectional area is in the range of 100 mm to 500 mm .

Care shall be taken in the preparation of the test specimen to avoid work hardening or heating

of the material which might affect the magnetic characteristics. The test specimen can be

prepared by turning and finished by light grinding with sufficient coolant to prevent heating the

material. The edges of the rings shall be deburred.

To reduce the effect of the radial variation of the magnetic field strength, the following

relationship shall apply:

D ≤ 1,1 d (1)

where

D is the outside diameter of test specimen, in metres;

d is the inside diameter of test specimen, in metres.

– 12 – 60404-4 © CEI:1995+A1:2000

La présente relation doit s’appliquer pour les mesures sur les éprouvettes constituées d’un

tore monobloc ou formé de feuilles. Pour les matériaux frittés magnétiquement doux, pour

lesquels les dimensions finies sont généralement petites, la relation suivante peut être

utilisée:

D ≤ 1,4 d (1a)

Dans ce cas, il y aura une plus grande variation radiale du champ magnétique d’excitation.

Les dimensions de l'éprouvette doivent être déterminées par la mesure des diamètres

extérieur et intérieur du tore, ainsi que sa hauteur ou son diamètre, à l'aide d'un micromètre

ou d'une jauge à vernier appropriés. L'aire de la section moyenne doit être calculée avec une

incertitude de ±0,5 % ou meilleure.

La longueur moyenne du circuit magnétique de l'éprouvette doit être également calculée avec

une incertitude de ±0,5 % ou meilleure à partir de la relation:

+

D d

l = π (2)

où

l est la longueur moyenne du circuit magnétique de l'éprouvette, en mètres.

3.5 Enroulements

Avant réalisation des bobinages, une liaison électrique avec l'éprouvette doit être mise en

place afin de vérifier ultérieurement l'isolation des enroulements, une sonde thermique doit

être fixée à l'éprouvette, et ensuite une couche mince d'isolant doit être déposée sur le tore.

En premier lieu, un enroulement secondaire constitué d'un fil de cuivre isolé doit être bobiné

régulièrement tout au long de l'anneau. On doit déterminer les dimensions, et calculer la

section moyenne, A , de cet enroulement secondaire.

c

Un enroulement d'excitation constitué par un fil de section suffisante pour supporter le

courant maximal d'excitation doit être ensuite bobiné régulièrement sur l'anneau, en une ou

plusieurs couches, avec un nombre de spires suffisant pour permettre d'appliquer l'intensité

spécifiée du champ magnétique d'excitation. L'enroulement d'excitation peut comporter:

a) un grand nombre de spires d'un fil unique, disposées au plus près et réparties uniformé-

ment tout au long du tore, ou

b) un nombre de spires plus réduit, d'un câble multifils, ces spires étant disposées au plus

près et réparties uniformément tout au long du tore et les extrémités de chaque fil étant

reliées entre elles de façon à produire l'effet d'un enroulement multicouches, ou

c) un système de conducteurs rigides, ou un système constitué de conducteurs en partie

rigides et en partie flexibles, qui peut être ouvert pour permettre la mise en place du tore

(comportant l'enroulement secondaire et l'isolation) et refermé ensuite pour constituer un

enroulement torique régulièrement réparti.

Si nécessaire, le tore bobiné est immergé dans un bain d'huile ou soumis à un courant d'air

pour assurer son refroidissement.

NOTE Quand on utilise les dispositifs décrits ci-dessus avec un enroulement secondaire uniformément réparti,

une erreur peut être présente dans tout essai sur tore, erreur susceptible d'être amplifiée et de prendre une

importance considérable. Cette erreur provient du fait qu'en bobinant sur un anneau une couche toroïdale, on

ajoute en fait une spire circulaire effective de diamètre égal au diamètre moyen du tore.

60404-4 © IEC:1995+A1:2000 – 13 –

This relationship shall apply for measurements on laminated or solid ring test specimens. For

sintered magnetically soft materials, where the finished dimensions are usually small, the

following relationship can be used:

D ≤ 1,4 d (1a)

In this case there will be a greater radial variation in the magnetic field strength.

The dimensions of the test specimen shall be determined by measuring the outside and inside

diameters of the ring together with the height or diameter using a suitable micrometer

or vernier gauge. The mean cross-sectional area shall be calculated with an uncertainty

of ±0,5 % or better.

The mean magnetic path length of the test specimen shall also be calculated with an

uncertainty of ±0,5 % or better from the relationship:

D + d

l = π (2)

where

l is the mean magnetic path length of test specimen, in metres.

3.5 Windings

Before winding, a connection shall be made to the core in order to check subsequently the

insulation of the windings, a temperature sensor shall be attached to the test specimen and

then the ring shall be overlaid with a thin layer of insulating material.

Firstly, a secondary winding of insulated copper wire shall be wound evenly round the core.

The dimensions of the secondary winding shall be determined and the mean cross-sectional

area, A , of the secondary winding shall be calculated.

c

A magnetizing winding of wire capable of carrying the maximum magnetizing current and of a

sufficient number of turns to produce the maximum required magnetic field strength shall be

evenly wound in one or more layers on the core. The magnetizing winding can consist of:

a) a large number of turns of a single conductor applied closely and uniformly round the

whole ring, or

b) a smaller number of turns of a multicore cable applied closely and uniformly round the

whole ring, the ends of the conductor in the individual cores being interconnected to give

the effect of one multilayer winding, or

c) an arrangement of rigid, or part rigid and part flexible, conductors which can be opened to

admit the ring (carrying the secondary winding and insulation) and then closed to form a

uniformly wound toroid round the ring.

If necessary, the wound ring is immersed in an oil bath or subjected to an air blast in order to

cool it.

NOTE If the above arrangements are used with a uniformly distributed secondary winding, an error, which may be

present in any ring test, is liable to be magnified and to become of considerable importance. This error arises

because, in winding a ring specimen toroidally, an effective circular turn of diameter equal to the mean diameter of

the ring is produced.

– 14 – 60404-4 © CEI:1995+A1:2000

Le flux d'induction mutuelle entre ces spires circulaires effectives qui appartiennent à l'enroulement d'excitation et

à l'enroulement secondaire, et qui circule parallèlement à l'axe du tore, s'ajoute ou se retranche au flux

circonférenciel principal. Quand un câble multiconducteur est utilisé pour l'enroulement d'excitation, le nombre de

spires effectives dans le primaire de l'inductance mutuelle supplémentaire est augmenté proportionnellement au

nombre de conducteurs, et l'erreur qui en résulte peut atteindre plusieurs pour cent, en particulier dans les champs

intenses où la perméabilité de l'éprouvette est réduite. Pour éliminer cette erreur, il convient d'ajouter une spire

appartenant à l'enroulement secondaire en retour le long de la circonférence moyenne du tore, ou, mieux, il

convient que le câble d'excitation soit réparti en un nombre pair de couches alternativement enroulées en tournant

sur l'anneau dans le sens des aiguilles d'une montre et dans le sens contraire.

3.6 Méthodes de mesure par la méthode du tore

3.6.1 Intensité du champ magnétique d'excitation

L'intensité du courant d'excitation doit être mesurée avec une incertitude de ±0,5 % ou

meilleure. L'intensité du champ magnétique d'excitation doit être calculée à partir de la

relation suivante:

N I

H = (3)

l

où

H est l'intensité du champ magnétique d'excitation, en ampères par mètre;

N est le nombre de spires de l'enroulement d'excitation du tore;

l est la longueur moyenne du circuit magnétique, en mètres;

I est l'intensité du courant d'excitation, en ampères.

3.6.2 Induction magnétique

L'enroulement secondaire N (bobine B) doit être relié à un intégrateur de flux (intégrateur

électronique, galvanomètre balistique ou fluxmètre) étalonné en suivant l'une des procédures

définies à l'annexe B avec une incertitude de ±1 % ou meilleure.

Les variations de l'induction magnétique doivent être calculées à partir de la relation suivante:

K .

b b

ΔB = (4)

N A

où

ΔB est la variation mesurée de l'induction magnétique, en teslas;

K est la constante d'étalonnage de l'intégrateur de flux, en volts secondes;

B

α est l'indication de l'intégrateur de flux;

B

N est le nombre de spires de l'enroulement secondaire du tore;

A est la section du tore, en mètres carrés.

Pour obtenir ΔB en lecture directe, l'intégrateur de flux peut être réglé de telle façon que

K /(N A) soit une puissance de 10.

B 2

A condition que l'enroulement secondaire soit bobiné étroitement sur l'éprouvette, le flux

d'induction dans l'air que le bobinage secondaire prend en compte sera négligeable dans la

gamme des champs d'excitation allant de 0 à 4 kA/m et aucune correction n'apparaît

nécessaire. Pour des champs d'excitation plus importants, une correction de flux dans l'air

doit être effectuée selon l'équation (8).

60404-4 © IEC:1995+A1:2000 – 15 –

The flux between the effective mutually inductive circular turns of the magnetizing winding and secondary winding,

associated with flux parallel to the axis of the ring, is added to, or subtracted from the circumferential flux. When a

multiconductor cable is used for the magnetizing winding, the number of turns in the primary of the supplementary

mutual inductance is increased in proportion to the number of cores, and the error from this source, particularly at

high field-strengths where the permeability of the test specimen is reduced, may amount to several per cent. To

eliminate this error a turn should be wound back on the secondary winding along the mean circumference of the

ring, or, preferably, the magnetizing cable should be wound in pairs of layers, alternate layers being wound

clockwise and anti-clockwise around the ring.

3.6 Methods of measurement by the ring method

3.6.1 Magnetic field strength

The magnetizing current shall be measured with an uncertainty of ±0,5 % or better. The

magnetic field strength shall be calculated from the following relationship:

N I

H = (3)

l

where

H is the magnetic field strength, in amperes per metre;

N is the number of turns of magnetizing winding of the ring;

l is the mean magnetic path length, in metres;

I is the magnetizing current, in amperes.

3.6.2 Magnetic flux density

The secondary winding N (B coil) shall be connected to a flux integrator (electronic

integrator, ballistic galvanometer or fluxmeter) the calibration of which shall be established in

accordance with one of the procedures given in annex B with an uncertainty of ±1 % or better.

The changes of the magnetic flux density shall be calculated from the following relationship:

K .

b b

ΔB = (4)

N A

where

ΔB is the measured change of the magnetic flux density, in teslas;

K is the flux integrator calibration constant, in volts seconds;

B

α is the reading of the flux integrator;

B

N is the number of turns on the secondary winding of the ring;

A is the cross-sectional area of the ring, in square metres.

For direct reading of the ΔB, the flux integrator may be adjusted so that K /(N A) becomes a

B 2

power of 10.

Provided that the secondary winding is

...

IEC 60404-4 ®

Edition 2.2 2008-11

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Magnetic materials –

Part 4: Methods of measurement of d.c. magnetic properties of magnetically soft

materials

Matériaux magnétiques –

Partie 4: Méthodes de mesure en courant continu des propriétés magnétiques

des matériaux magnétiquement doux

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 15

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC

65 000 entrées terminologiques électrotechniques, en anglais

en utilisant différents critères (numéro de référence, texte,

et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les

publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées.

antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Restez informé sur les nouvelles publications IEC. Just Service Clients - webstore.iec.ch/csc

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 60404-4 ®

Edition 2.2 2008-11

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Magnetic materials –

Part 4: Methods of measurement of d.c. magnetic properties of magnetically

soft materials

Matériaux magnétiques –

Partie 4: Méthodes de mesure en courant continu des propriétés magnétiques

des matériaux magnétiquement doux

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 17.220.20; 29.030 ISBN 978-2-8891-0188-7

– 2 – 60404-4 © IEC:1995+A1:2000

+A2:2008

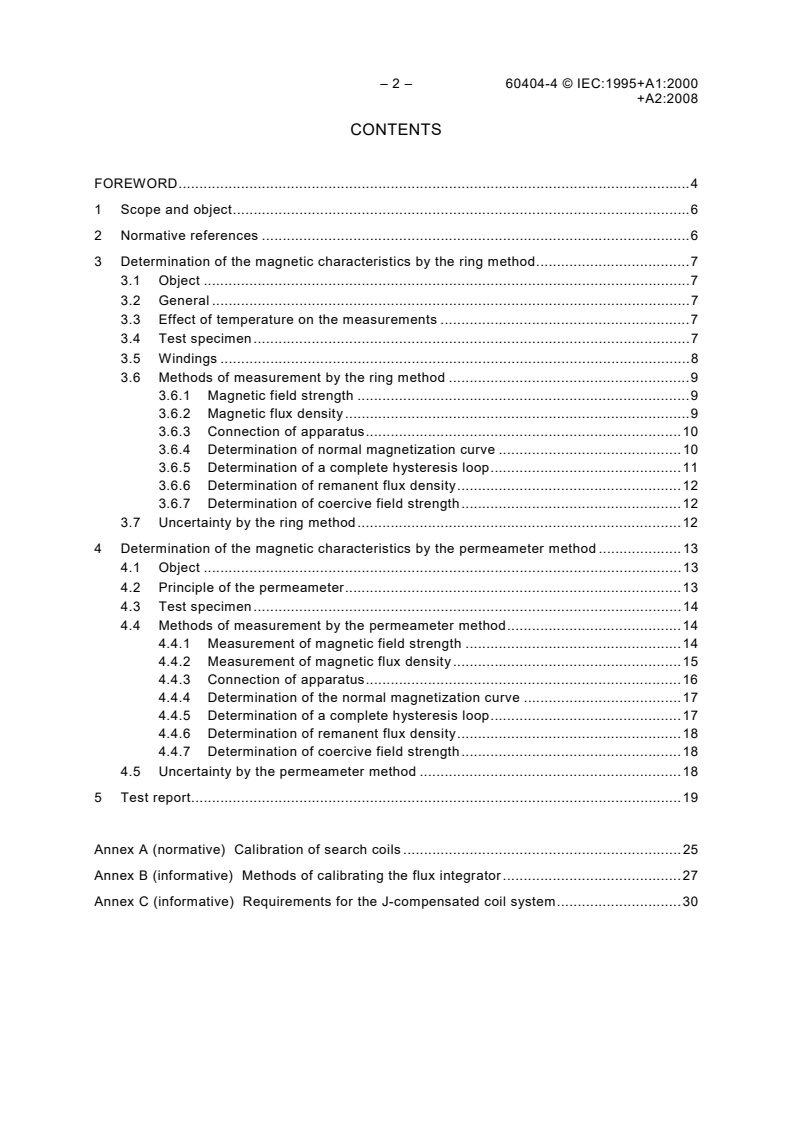

CONTENTS

FOREWORD.4

1 Scope and object.6

2 Normative references.6

3 Determination of the magnetic characteristics by the ring method.7

3.1 Object.7

3.2 General.7

3.3 Effect of temperature on the measurements .7

3.4 Test specimen.7

3.5 Windings.8

3.6 Methods of measurement by the ring method .9

3.6.1 Magnetic field strength .9

3.6.2 Magnetic flux density.9

3.6.3 Connection of apparatus.10

3.6.4 Determination of normal magnetization curve .10

3.6.5 Determination of a complete hysteresis loop.11

3.6.6 Determination of remanent flux density.12

3.6.7 Determination of coercive field strength.12

3.7 Uncertainty by the ring method.12

4 Determination of the magnetic characteristics by the permeameter method .13

4.1 Object.13

4.2 Principle of the permeameter.13

4.3 Test specimen.14

4.4 Methods of measurement by the permeameter method.14

4.4.1 Measurement of magnetic field strength .14

4.4.2 Measurement of magnetic flux density .15

4.4.3 Connection of apparatus.16

4.4.4 Determination of the normal magnetization curve .17

4.4.5 Determination of a complete hysteresis loop.17

4.4.6 Determination of remanent flux density.18

4.4.7 Determination of coercive field strength.18

4.5 Uncertainty by the permeameter method .18

5 Test report.19

Annex A (normative) Calibration of search coils .25

Annex B (informative) Methods of calibrating the flux integrator.27

Annex C (informative) Requirements for the J-compensated coil system.30

60404-4 © IEC:1995+A1:2000 – 3 –

+A2:2008

Figure 1 – Circuit for the determination of the magnetic characteristics

by the ring method .20

Figure 2 – Hysteresis loop .20

Figure 3 – Typical arrangement of a type A permeameter .21

Figure 4 – Typical arrangement of a type B permeameter .22

Figure 5 – Arrangement of search coils.24

Figure 6 – Circuit for the determination of the normal magnetization curve and

hysteresis loop of bar specimens using a double yoke permeameter.24

Figure A.1 – Circuit for the calibration of search-coils .26

Figure B.1 – Circuit for calibration the flux integrator by the capacitor

discharge method .29

Table 1 – Switching sequence to maintain the test specimen in a steady cyclic state.12

– 4 – 60404-4 © IEC:1995+A1:2000

+A2:2008

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MAGNETIC MATERIALS –

Part 4: Methods of measurement of d.c.

magnetic properties of magnetically soft materials

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

m of its technical committees and IEC National Committees for any personal injury, property damage or

embers

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendments has been

prepared for user convenience.

IEC 60404-4 edition 2.2 contains the second edition (1995) [documents 68(CO)95 and

68/117/RVD], its amendment 1 (2000) [documents 68/215/FDIS and 68/217/RVD] and its

amendment 2 (2008) [documents 68/363/CDV and 68/375/RVC].

A vertical line in the margin shows where the base publication has been modified by

amendments 1 and 2.

International Standard IEC 60404-4 has been prepared by IEC technical committee 68:

Magnetic alloys and steels.

60404-4 © IEC:1995+A1:2000 – 5 –

+A2:2008

Annex A forms an integral part of this standard.

Annexes B and C are for information only.

The committee has decided that the contents of the base publication and its amendments will

remain unchanged until the maintenance result date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date,

the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 60404-4 © IEC:1995+A1:2000

+A2:2008

MAGNETIC MATERIALS –

Part 4: Methods of measurement of d.c.

magnetic properties of magnetically soft materials

1 Scope and object

This part of IEC 60404 specifies the methods of measuring the d.c. magnetic properties of

magnetically soft materials in a closed magnetic circuit using either the ring or the permea-

meter methods. The ring method is suitable for use with laminated or solid ring specimens as

well as ring specimens produced by sintering.

Two methods are used:

a) the ring method, particularly for magnetic field strengths of up to 10 kA/m;

b) the permeameter method for magnetic field strengths in the range 1 kA/m to 200 kA/m.

NOTE The measurement of coercivity in an open magnetic circuit is specified in IEC 60404-7.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60404-7:1982, Magnetic materials – Part 7: Method of measurement of the coercivity of

magnetic materials in an open magnetic circuit

IEC 60404-8-2:1985, Magnetic materials – Part 8: Specifications for individual materials –

Section Two: Specification for cold-rolled magnetic alloyed steel strip delivered in the semi-

processed state

IEC 60404-8-3:1985, Magnetic materials – Part 8: Specifications for individual materials –

Section Three: Specification for cold-rolled magnetic non-alloyed steel strip delivered in the

semi-processed state

IEC 60404-8-4:1986, Magnetic materials – Part 8: Specifications for individual materials –

Section Four: Specification for cold-rolled non-oriented magnetic steel sheet and strip

IEC 60404-8-6:1986, Magnetic materials – Part 8: Specifications for individual materials –

Section Six: Soft magnetic metallic materials

Amendment 1 (1992)

IEC 60404-8-7:1988, Magnetic materials – Part 8: Specifications for individual materials –

Section Seven: Specification for grain-oriented magnetic steel sheet and strip

Amendment 1 (1991)

IEC 60404-8-8:1991, Magnetic materials – Part 8: Specifications for individual materials –

Section 8: Specification for thin magnetic steel strip for use at medium frequencies

60404-4 © IEC:1995+A1:2000 – 7 –

+A2:2008

3 Determination of the magnetic characteristics by the ring method

3.1 Object

This clause describes the ring method used to obtain the normal magnetization curve and the

hysteresis loop.

3.2 General

This method is used particularly for magnetic field strengths of up to 10 kA/m. However, if

care is taken to avoid heating the test specimen, this method may be used at higher magnetic

field strengths.

3.3 Effect of temperature on the measurements

Care shall be taken to avoid unduly heating the test specimen. The measurements shall be

made at an ambient temperature of (23 ± 5) °C. The temperature of the test specimen shall

not exceed 50 °C which shall be monitored by means of a temperature sensor.

For materials which are particularly temperature sensitive, product standards may define

lower or higher test specimen temperatures.

3.4 Test specimen

The test specimen is a homogeneous unwelded ring of rectangular or circular cross-section.

The cross-sectional area of the ring is determined by the product dimensions, uniformity of

magnetic properties, instrumentation sensitivity and space required for the test windings.

2 2

Usually the cross-sectional area is in the range of 10 mm to 200 mm .

Care shall be taken in the preparation of the test specimen to avoid work hardening or heating

of the material which might affect the magnetic characteristics. The test specimen can be

prepared by turning and finished by light grinding with sufficient coolant to prevent heating the

material. The edges of the rings shall be deburred.

To reduce the effect of radial variation of the magnetic field strength, the ring shall have

dimensions such that the ratio of the outer to inner diameter shall be no greater than 1,4 and

preferably less than 1,25. If the ratio approaches the value 1,4, there will be a greater radial

variation in the magnetic field strength.

For a stack of laminations or a toroidal wound core, the cross-sectional area of the test

specimen shall be calculated from the mass, density and the value of the inner and outer

diameter of the ring. The density can be the conventional density for the material supplied by

the manufacturer. The cross-sectional area shall be calculated from the following equation:

2m

A = (1)

ρ π(D + d)

where

A is the cross-sectional area of the test specimen, in square metres;

D is the outer diameter of the test specimen, in metres;

d is the inner diameter of the test specimen, in metres;

m is the mass of the test specimen, in kilograms;

ρ is the density of the material, in kilograms per cubic metre.

– 8 – 60404-4 © IEC:1995+A1:2000

+A2:2008

The dimensions of the test specimen shall be determined by measuring the outside and inside

diameters of the ring together with the height or diameter using a suitable micrometer

or vernier gauge. The mean cross-sectional area shall be calculated with an uncertainty

of ±0,5 % or better.

The mean magnetic path length of the test specimen shall also be calculated with an

uncertainty of ±0,5 % or better from the relationship:

D + d

l = π (2)

where

l is the mean magnetic path length of test specimen, in metres.

3.5 Windings

Before winding, a connection shall be made to the core in order to check subsequently the

insulation of the windings, a temperature sensor shall be attached to the test specimen and

then the ring shall be overlaid with a thin layer of insulating material.

Firstly, a secondary winding of insulated copper wire shall be wound evenly round the core.

The dimensions of the secondary winding shall be determined and the mean cross-sectional

area, A , of the secondary winding shall be calculated.

c

A magnetizing winding of wire capable of carrying the maximum magnetizing current and of a

sufficient number of turns to produce the maximum required magnetic field strength shall be

evenly wound in one or more layers on the core. The magnetizing winding can consist of:

a) a large number of turns of a single conductor applied closely and uniformly round the

whole ring, or

b) a smaller number of turns of a multicore cable applied closely and uniformly round the

whole ring, the ends of the conductor in the individual cores being interconnected to give

the effect of one multilayer winding, or

c) an arrangement of rigid, or part rigid and part flexible, conductors which can be opened to

admit the ring (carrying the secondary winding and insulation) and then closed to form a

uniformly wound toroid round the ring.

If necessary, the wound ring is immersed in an oil bath or subjected to an air blast in order to

cool it.

NOTE If the above arrangements are used with a uniformly distributed secondary winding, an error, which may be

present in any ring test, is liable to be magnified and to become of considerable importance. This error arises

because, in winding a ring specimen toroidally, an effective circular turn of diameter equal to the mean diameter of

the ring is produced.

The flux between the effective mutually inductive circular turns of the magnetizing winding and secondary winding,

associated with flux parallel to the axis of the ring, is added to, or subtracted from the circumferential flux. When a

multiconductor cable is used for the magnetizing winding, the number of turns in the primary of the supplementary

mutual inductance is increased in proportion to the number of cores, and the error from this source, particularly at

high field-strengths where the permeability of the test specimen is reduced, may amount to several per cent. To

eliminate this error a turn should be wound back on the secondary winding along the mean circumference of the

ring, or, preferably, the magnetizing cable should be wound in pairs of layers, alternate layers being wound

clockwise and anti-clockwise around the ring.

60404-4 © IEC:1995+A1:2000 – 9 –

+A2:2008

3.6 Methods of measurement by the ring method

3.6.1 Magnetic field strength

The magnetizing current shall be measured with an uncertainty of ±0,5 % or better. The

magnetic field strength shall be calculated from the following relationship:

N I

H = (3)

l

where

H is the magnetic field strength, in amperes per metre;

N is the number of turns of magnetizing winding of the ring;

l is the mean magnetic path length, in metres;

I is the magnetizing current, in amperes.

3.6.2 Magnetic flux density

The secondary winding N (B coil) shall be connected to a flux integrator (electronic

integrator, ballistic galvanometer or fluxmeter) the calibration of which shall be established in

accordance with one of the procedures given in annex B with an uncertainty of ±1 % or better.

The changes of the magnetic flux density shall be calculated from the following relationship:

K α

b b

ΔB = (4)

N A

where

ΔB is the measured change of the magnetic flux density, in teslas;

K is the flux integrator calibration constant, in volts seconds;

B

α is the reading of the flux integrator;

B

N is the number of turns on the secondary winding of the ring;

A is the cross-sectional area of the ring, in square metres.

For direct reading of the ΔB, the flux integrator may be adjusted so that K /(N A) becomes a

B 2

power of 10.

Provided that the secondary winding is wound closely on the test specimen, the air flux

included in the secondary winding over the range of magnetic field strength 0 to 4 kA/m will

be insignificant and no correction need be applied. At higher values of magnetic field strength,

an air flux correction shall be applied in accordance with equation (8).

– 10 – 60404-4 © IEC:1995+A1:2000

+A2:2008

3.6.3 Connection of apparatus

The apparatus is connected as shown in figure 1.

A source of direct current E (stabilized d.c. supply with a ripple content of less than 0,1 %, or

a battery) is connected through a current-measuring device A and a reversing switch S to the

magnetizing winding N on the ring specimen. If a bipolar current source is used, reversing

switch S is not required. With switch S closed, the current in the magnetizing circuit is

1 2

controlled by resistor R . If a stabilized supply with a continuously controllable output is used,

resistor R is not required. This is the arrangement of the magnetizing circuit for the

determination of the normal magnetization curve and for the measurement of the tip points of

hysteresis loops. Switch S , together with resistor R are necessary in some arrangements for

2 2

the determination of the complete hysteresis loop. The secondary circuit comprises the

secondary winding N (B coil) connected to the flux integrator.

3.6.4 Determination of normal magnetization curve

The test specimen shall be carefully demagnetized from a magnetic field strength of not less

than 5 kA/m by the repeated reversals of a gradually reducing demagnetizing field. Test

specimens which have been subjected to a higher magnetic field strength shall be

demagnetized from a suitably high field before test (for example, when machined using a

magnetic chuck).

NOTE In order that the magnetic field may completely penetrate the test specimen, the dwell time after each

reversal should be greater than 2 s for a cross-section 10 mm × 10 mm, and 10 s for a cross-section 20 mm × 20 mm.

The flux integrator shall be calibrated by one of the methods described in annex B. With S

closed, the normal magnetization curve shall then be determined by one of the following

methods.

Method A: continuous recording method

To utilize this method, the output from the flux integrator shall be connected to the Y axis of

an X-Y recorder, plotter or computer interface. A low value (e.g. 0,1 Ω or 1 Ω) calibrated

resistor with two current and two voltage terminals shall be connected in series with the

magnetizing winding. The potential terminals of this resistor shall be connected to the X axis

of the recorder, plotter or computer interface. The system can be calibrated overall to give

direct readings of magnetic flux density and magnetic field strength on the recorder, plotter or

computer interface.

The magnetizing current shall be steadily increased from zero to the value to produce the

required maximum magnetic field strength. The magnetization curve is then produced on the

X-Y recorder, plotter or computer interface.

Method B: point-by-point method

A low current corresponding to a low magnetic field strength (see equation 3) shall be passed

through the magnetizing winding N . The current shall be reversed about 10 times by means

of reversing switch S to bring the material into a steady cyclic state. Switch S shall be

1 3

closed during this operation to maintain the flux integrator at zero. With switch S open, the

flux integrator reading corresponding to the reversal of the magnetizing field shall be recorded

and the corresponding magnetic flux density calculated.

By successively increasing the magnetizing current and repeating this procedure,

corresponding values of magnetic field strength and magnetic flux density are obtained from

which the normal magnetization curve can be plotted.

60404-4 © IEC:1995+A1:2000 – 11 –

+A2:2008

The magnetizing current shall never be decreased during the measurements, otherwise the

test specimen shall be demagnetized before resuming measurements.

3.6.5 Determination of a complete hysteresis loop

The test specimen shall be demagnetized in accordance with 3.6.4 and the hysteresis loop

shall be determined by one of the following methods.

Method A: continuous recording method

The additional equipment specified in method A of 3.6.4 is required. The flux integrator shall

be zeroed and then a current of value sufficient to produce the maximum magnetic field

strength required shall be passed through the magnetizing winding N . This current shall be

slowly reduced to zero, reversed, increased to its maximum negative value, reduced to zero,

reversed again and increased to its maximum positive value.

NOTE The cycle should be completed in a time between 30 s to 60 s, although some materials, e.g. pure iron,

may require longer, in order to allow time for the magnetization of the test specimen to follow the applied magnetic

field and yet avoid significant drift of the flux integrator zero with time.

Method B: point-by-point method

The test specimen shall be demagnetized and a current sufficient to produce the maximum

magnetic field strength required shall be passed through the magnetizing winding N . The tip

points of the hysteresis loop shall be determined by measuring the corresponding values of

magnetic field strength and magnetic flux density in accordance with method B of 3.6.4.

Portion PQ of the hysteresis loop (see figure 2) is then determined with switch S closed in

position 1, by opening switch S , and measuring the corresponding magnetic field strength

and change in magnetic flux density. By adjusting resistor R a number of points on the curve

PQ can be obtained. The point Q is obtained with switch S closed and measuring the change

in magnetic flux density when opening switch S .

The value of the magnetic field strength at each point is calculated from the corresponding

measured value of current flowing (see equation (3)).

The value of the magnetic flux density at each point is calculated from the following relation-

ship:

B = B – ΔB (5)

P′ P

where

B is the flux density at the point P′ of curve PQ, in teslas;

P′

B is the magnetic flux density at tip of hysteresis loop, in teslas;