IEC 60092-353:2011

(Main)Electrical installations in ships - Part 353: Power cables for rated voltages 1 kV and 3 kV

Electrical installations in ships - Part 353: Power cables for rated voltages 1 kV and 3 kV

IEC 60092-353:2011 is applicable to shipboard and offshore non radial field power cables with extruded solid insulation, having a voltage rating of 0,6/1 (1,2) kV and 1,8/3 (3,6) kV intended for fixed installations. Cables for use in circuits requiring resistance to fire are included. The various types of power cables are given in 5.1. The constructional requirements and test methods shall comply with those indicated in IEC 60092-350, unless otherwise specified in this standard. The object of this standard is:

- to standardize cables whose safety and reliability is ensured when they are installed in accordance with the requirements of IEC 60092-352 or IEC 61892-4;

- to lay down standard manufacturing requirements and characteristics of such cables directly or indirectly bearing on safety;

- to specify test methods for checking conformity with those requirements.

This edition includes the following significant technical changes with respect to the previous edition:

a) Rationalization of the number of insulating and sheathing materials. In particular polyvinyl chloride based insulation (PVC) and sheath (ST1) have been removed. PVC sheath ST2 is permitted even though it releases harmful fumes under fire conditions;

b) Modification of construction requirements in line with IEC 60092-350;

c) Requirements and test methods have been divided in several tables for clarification. Requirements for enhanced cold properties, oil resistance and resistance to drilling fluids have been aligned to IEC 60092-350;

d) The new testing methods for fire resistant cables are referenced in the standard.

Installations électriques à bord des navires - Partie 353: Câbles d'énergie pour les tensions assignées 1 kV et 3 kV

La CEI 60092-353:2011 est applicable aux câbles pour installations à bord des navires et à champ non radial, à isolement massif extrudé, pour tension assignée 0,6/1 (1,2) kV et 1,8/3 (3,6) kV destinés aux installations fixes. Les câbles utilisés dans les circuits devant résister au feu sont inclus. Les différents types de câbles d'énergie sont indiqués en 5.1. Leurs exigences de fabrication et leurs méthodes d'essai doivent être conformes à celles qui sont indiquées dans la CEI 60092-350 sauf spécification contraire dans la présente norme. L'objet de la présente norme est:

- de normaliser des câbles qui soient sûrs et fiables lorsqu'ils sont installés conformément aux exigences de la CEI 60092-352 ou de la CEI 61892-4;

- d'établir les caractéristiques pour de tels câbles et les exigences normalisées relatives à leur fabrication se référant directement ou indirectement à la sécurité;

- de préciser les méthodes d'essai pour vérifier la conformité à ces exigences.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) Rationalisation du nombre de matériaux d'isolation et de gainage. En particulier, l'isolation à base de PVC (polychlorure de vinyle) et la gaine (ST1) ont été supprimées. La gaine ST2 en PVC est autorisée même si elle diffuse des fumées nocives en cas d'incendie;

b) Modification des exigences de construction en accord avec la CEI 60092-350;

c) Les exigences et méthodes d'essai ont été séparées pour des raisons de clarification dans plusieurs tableaux. Les exigences en matière de propriétés à froid améliorées, de résistance à l'huile et de résistance aux boues de forage ont été alignées sur celles de la CEI 60092-350;

d) Les nouvelles méthodes d'essai des câbles résistant au feu sont référencées dans la norme.

General Information

- Status

- Published

- Publication Date

- 25-Aug-2011

- Technical Committee

- SC 18A - Electric cables for ships and mobile and fixed offshore units

- Drafting Committee

- MT 2 - TC 18/SC 18A/MT 2

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 19-Sep-2016

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60092-353:2011 is an international standard published by the International Electrotechnical Commission (IEC) that specifies the requirements for power cables used in shipboard and offshore fixed electrical installations. It applies to non-radial field power cables with extruded solid insulation designed for rated voltages of 0.6/1 (1.2) kV and 1.8/3 (3.6) kV. This standard ensures that power cables used in ships and offshore units meet stringent safety, reliability, and performance criteria, including resistance to fire for circuits where such properties are essential.

The key objectives of IEC 60092-353 are:

- Standardization of power cables to maintain safety and operational reliability.

- Defining manufacturing requirements and characteristics directly related to cable safety.

- Specifying rigorous test methods to verify compliance.

This third edition of the standard integrates significant updates, such as rationalized insulating and sheathing materials, elimination of certain polyvinyl chloride (PVC) types, alignment of construction requirements with IEC 60092-350, and updated testing procedures for fire resistance.

Key Topics

Scope and Application

- Covers shipboard and offshore non-radial field power cables with extruded solid insulation.

- Intended for fixed electrical installations in marine and offshore environments.

- Voltage ratings covered include 0.6/1 (1.2) kV and 1.8/3 (3.6) kV.

- Includes cables designed to be fire resistant, suitable for safety-critical applications.

Constructional Requirements

- Specifies conductor types, insulation materials, inner and outer sheathing, armor options, and core marking.

- Prohibits certain PVC insulations (ST1), while allowing PVC sheath ST2 with disclaimers on fire-generated fumes.

- Covers cable screening and armoring to ensure durability and electromagnetic compatibility.

- Details minimum thicknesses for insulation, sheaths, and coverings to guarantee mechanical and electrical integrity.

Testing and Compliance

- Defines standard tests and criteria to validate cable construction and performance.

- Applies general cable tests as per IEC 60092-350, with additional specialized fire-resistance test methods.

- Describes tests for enhanced cold properties, oil resistance, and resistance to drilling fluids.

- Uses tabulated performance requirements for clarity and ease of reference.

Safety and Standardization

- Ensures cables meet safety thresholds for installation per IEC 60092-352 and IEC 61892-4.

- Supports global harmonization of marine power cable manufacturing and testing practices.

- Addresses toxic fume release and cable behavior under fire to protect personnel and cargo.

Applications

IEC 60092-353:2011 power cables are integral to electrical installations on:

- Merchant Ships and Cargo Vessels: Providing reliable power distribution across fixed installations.

- Offshore Oil and Gas Platforms: Where harsh environmental conditions and safety-critical performance demand robust cable constructions.

- Passenger Ships and Ferries: Including circuits requiring fire-resistant cables to ensure evacuation safety.

- Marine Construction and Maintenance: For fixed electrical networks powering equipment and instrumentation.

These cables ensure:

- Safe transmission of electrical power in complex marine environments.

- Compliance with international maritime electrical standards.

- Resistance to environmental stressors such as oils, cold temperatures, and mechanical abrasion.

- Enhanced fire safety properties critical for passenger and crew protection.

Related Standards

For comprehensive marine electrical system design and installation, IEC 60092-353 should be used in conjunction with the following standards:

- IEC 60092-350: General construction and test methods for shipboard power, control, and instrumentation cables.

- IEC 60092-351: Insulating materials applicable to shipboard and offshore cables.

- IEC 60092-352: Guidelines for the choice and installation of electrical cables on ships.

- IEC 60092-359: Specification of sheathing materials for power and telecommunication cables in the marine environment.

- IEC 61892-4: Mobile and fixed offshore units-Design and construction requirements for electrical installations.

These interconnected standards form a complete framework to guide the selection, manufacture, testing, installation, and maintenance of marine electrical cables, promoting safety and reliability throughout the vessel or offshore unit lifecycle.

Keywords: IEC 60092-353, shipboard power cables, marine electrical cables, offshore power cables, rated voltage 1 kV, rated voltage 3 kV, extruded solid insulation cables, fire resistant cables, IEC marine standards, electrical installations in ships, offshore electrical installations, cable construction, marine cable testing, electrical cable safety.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Sponsored listings

Frequently Asked Questions

IEC 60092-353:2011 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electrical installations in ships - Part 353: Power cables for rated voltages 1 kV and 3 kV". This standard covers: IEC 60092-353:2011 is applicable to shipboard and offshore non radial field power cables with extruded solid insulation, having a voltage rating of 0,6/1 (1,2) kV and 1,8/3 (3,6) kV intended for fixed installations. Cables for use in circuits requiring resistance to fire are included. The various types of power cables are given in 5.1. The constructional requirements and test methods shall comply with those indicated in IEC 60092-350, unless otherwise specified in this standard. The object of this standard is: - to standardize cables whose safety and reliability is ensured when they are installed in accordance with the requirements of IEC 60092-352 or IEC 61892-4; - to lay down standard manufacturing requirements and characteristics of such cables directly or indirectly bearing on safety; - to specify test methods for checking conformity with those requirements. This edition includes the following significant technical changes with respect to the previous edition: a) Rationalization of the number of insulating and sheathing materials. In particular polyvinyl chloride based insulation (PVC) and sheath (ST1) have been removed. PVC sheath ST2 is permitted even though it releases harmful fumes under fire conditions; b) Modification of construction requirements in line with IEC 60092-350; c) Requirements and test methods have been divided in several tables for clarification. Requirements for enhanced cold properties, oil resistance and resistance to drilling fluids have been aligned to IEC 60092-350; d) The new testing methods for fire resistant cables are referenced in the standard.

IEC 60092-353:2011 is applicable to shipboard and offshore non radial field power cables with extruded solid insulation, having a voltage rating of 0,6/1 (1,2) kV and 1,8/3 (3,6) kV intended for fixed installations. Cables for use in circuits requiring resistance to fire are included. The various types of power cables are given in 5.1. The constructional requirements and test methods shall comply with those indicated in IEC 60092-350, unless otherwise specified in this standard. The object of this standard is: - to standardize cables whose safety and reliability is ensured when they are installed in accordance with the requirements of IEC 60092-352 or IEC 61892-4; - to lay down standard manufacturing requirements and characteristics of such cables directly or indirectly bearing on safety; - to specify test methods for checking conformity with those requirements. This edition includes the following significant technical changes with respect to the previous edition: a) Rationalization of the number of insulating and sheathing materials. In particular polyvinyl chloride based insulation (PVC) and sheath (ST1) have been removed. PVC sheath ST2 is permitted even though it releases harmful fumes under fire conditions; b) Modification of construction requirements in line with IEC 60092-350; c) Requirements and test methods have been divided in several tables for clarification. Requirements for enhanced cold properties, oil resistance and resistance to drilling fluids have been aligned to IEC 60092-350; d) The new testing methods for fire resistant cables are referenced in the standard.

IEC 60092-353:2011 is classified under the following ICS (International Classification for Standards) categories: 29.060.20 - Cables; 47.020.60 - Electrical equipment of ships and of marine structures. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60092-353:2011 has the following relationships with other standards: It is inter standard links to IEC 60092-353:1995/AMD1:2001, IEC 60092-353:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60092-353:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60092-353 ®

Edition 3.0 2011-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electrical installations in ships –

Part 353: Power cables for rated voltages 1 kV and 3 kV

Installations électriques à bord des navires –

Partie 353: Câbles d’énergie pour les tensions assignées 1 kV et 3 kV

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60092-353 ®

Edition 3.0 2011-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electrical installations in ships –

Part 353: Power cables for rated voltages 1 kV and 3 kV

Installations électriques à bord des navires –

Partie 353: Câbles d’énergie pour les tensions assignées 1 kV et 3 kV

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX S

ICS 29.060.20; 47.020.60 ISBN 978-2-88912-639-2

– 2 – 60092-353 © IEC:2011

CONTENTS

FOREWORD . 4

1 Scope and object . 6

2 Normative references. 6

3 Terms and definitions . 7

4 General requirements . 8

4.1 Rated voltage . 8

4.2 Markings . 8

4.2.1 Indication of origin and voltage identification . 8

4.2.2 Continuity . 8

4.2.3 Core identification . 8

5 Constructional requirements . 9

5.1 General description . 9

5.1.1 Overview . 9

5.1.2 Unarmoured cables (excluding 1,8/3 kV) . 9

5.1.3 Armoured cables . 9

5.2 Conductors . 10

5.3 Insulation . 10

5.3.1 Material . 10

5.3.2 Application . 10

5.3.3 Thickness of insulation . 10

5.4 Cabling (including fillers & binders) . 11

5.5 Inner covering. 11

5.5.1 General . 11

5.5.2 Thickness of inner covering . 11

5.6 Screen. 12

5.6.1 Construction . 12

5.6.2 Application . 13

5.7 Inner sheath . 13

5.7.1 Material . 13

5.7.2 Application . 13

5.7.3 Thickness of inner sheath . 13

5.8 Braid armour . 13

5.8.1 General . 13

5.8.2 Braid wire diameter . 14

5.8.3 Coverage density . 14

5.8.4 Application of the armour . 14

5.9 Outer sheath . 14

5.9.1 Material . 14

5.9.2 Application . 14

5.9.3 Thickness of outer sheath . 14

5.9.4 Colour of outer sheath . 15

6 Tests – methods and requirements . 15

Annex A (informative) Alternative enhanced insulation thickness for 0,6/1 kV . 18

Annex B (informative) Identification of cores of multicore cables . 19

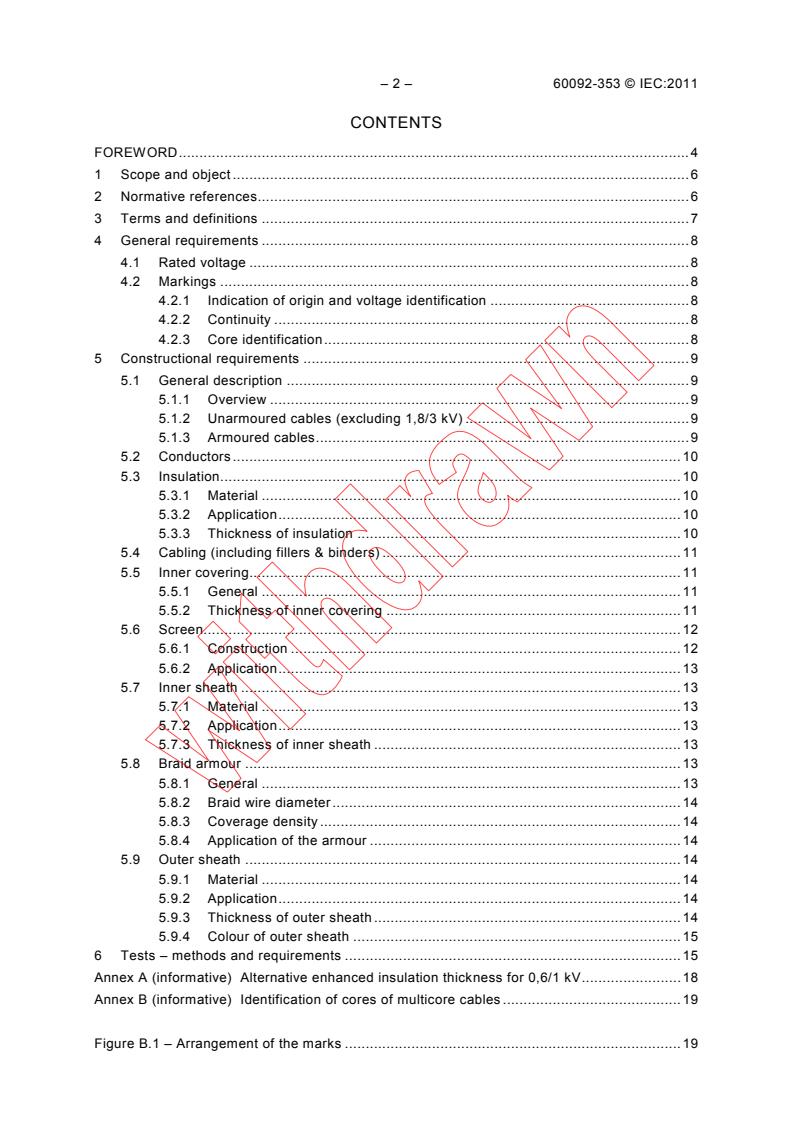

Figure B.1 – Arrangement of the marks . 19

60092-353 © IEC:2011 – 3 –

Table 1 – Insulation thickness . 11

Table 2 – Thickness of extruded inner covering and fictitious diameters . 12

Table 3 – Requirements of drain wire . 12

Table 4 – Tests applicable to all cables . 15

Table 5 – Additional tests required for halogen-free cables . 16

Table 6 – Additional test required for low smoke cables . 17

Table 7 – Additional tests required for fire resistant cables . 17

Table 8 – Additional tests required for specific performances . 17

Table A.1 – Alternative enhanced insulation thickness for 0,6/1 kV . 18

Table B.1 – Dimensions of the marks . 20

– 4 – 60092-353 © IEC:2011

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRICAL INSTALLATIONS IN SHIPS –

Part 353: Power cables for rated voltages 1 kV and 3 kV

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60092-353 has been prepared by Subcommittee 18A: Electric

cables for ships and mobile and fixed offshore units of IEC Technical Committee 18: Electrical

installations of ships and of mobile and fixed offshore units.

This third edition cancels and replaces the second edition published in 1995 and Amendment 1

(2001). This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Rationalization of the number of insulating and sheathing materials. In particular polyvinyl

chloride based insulation (PVC) and sheath (ST1) have been removed. PVC sheath ST2 is

permitted even though it releases harmful fumes under fire conditions;

b) Modification of construction requirements in line with IEC 60092-350;

60092-353 © IEC:2011 – 5 –

c) Requirements and test methods have been divided in several tables for clarification.

Requirements for enhanced cold properties, oil resistance and resistance to drilling fluids

have been aligned to IEC 60092-350;

d) The new testing methods for fire resistant cables are referenced in the standard.

The text of this standard is based on the following documents:

FDIS Report on voting

18A/316A/FDIS 18A/319/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts of the IEC 60092 series, under the general title Electrical installations in

ships, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until the

stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data related to

the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 60092-353 © IEC:2011

ELECTRICAL INSTALLATIONS IN SHIPS –

Part 353: Power cables for rated voltages 1 kV and 3 kV

1 Scope and object

This part of the IEC 60092 series is applicable to shipboard and offshore non radial field power

cables with extruded solid insulation, having a voltage rating of 0,6/1 (1,2) kV and

1,8/3 (3,6) kV intended for fixed installations.

Cables for use in circuits requiring resistance to fire are included.

The various types of power cables are given in 5.1. The constructional requirements and test

methods shall comply with those indicated in IEC 60092-350, unless otherwise specified in this

standard.

The object of this standard is:

– to standardize cables whose safety and reliability is ensured when they are installed in

accordance with the requirements of IEC 60092-352 or IEC 61892-4;

– to lay down standard manufacturing requirements and characteristics of such cables

directly or indirectly bearing on safety;

– to specify test methods for checking conformity with those requirements.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60038:2009, IEC standard voltages

IEC 60050-461:2008, International electrotechnical vocabulary – Part 461: Electric cables

IEC 60092-350, Electrical installations in ships – Part 350: General construction and test

methods of power, control and instrumentation cables for shipboard and offshore applications

IEC 60092-351, Electrical installations in ships – Part 351: Insulating materials for shipboard

and offshore units, power, control, instrumentation, telecommunication and data cables

IEC 60092-352, Electrical installations in ships – Part 352: Choice and installation of electrical

cables

IEC 60092-359, Electrical installations in ships – Part 359: Sheathing materials for shipboard

power and telecommunication cables

IEC 60228:2004, Conductors of insulated cables

IEC 60331-1:2009, Tests for electric cables under fire conditions – Circuit integrity – Part 1:

Test method for fire with shock at a temperature of at least 830 °C for cables of rated voltage

up to and including 0,6/1,0 kV and with an overall diameter exceeding 20 mm

60092-353 © IEC:2011 – 7 –

IEC 60331-2:2009, Tests for electric cables under fire conditions – Circuit integrity – Part 2:

Test method for fire with shock at a temperature of at least 830 °C for cables of rated voltage

up to and including 0,6/1,0 kV and with an overall diameter not exceeding 20 mm

IEC 60331-11:1999, Tests for electric cables under fire conditions – Circuit integrity – Part 11:

Apparatus – Fire alone at a flame temperature of at least 750 °C

Amendment 1 (2009)

IEC 60331-21:1999, Tests for electric cables under fire conditions – Circuit integrity – Part 21:

Procedures and requirements – Cables of rated voltage up to and including 0,6/1,0 kV

IEC 60332-1-2:2004, Tests on electric and optical fibre cables under fire conditions – Part 1-2:

Test for vertical flame propagation for a single insulated wire or cable – Procedure for 1 kW

pre-mixed flame

IEC 60332-3-22:2000, Tests on electric cables under fire conditions – Part 3-22: Test for

vertical flame spread of vertically-mounted bunched wires or cables – Category A

Amendment 1 (2008)

IEC 60445:2010, Basic and safety principles for man-machine interface, marking and

identification – Identification of equipment terminals, conductor terminations and conductors

IEC 60684-2:1997, Flexible insulating sleeving – Part 2: Methods of test

Amendment 1 (2003)

IEC 60754-1:1994, Test on gases evolved during combustion of materials from cables – Part 1:

Determination of the amount of halogen acid gas

IEC 60754-2:1991, Test on gases evolved during combustion of electric cables – Part 2:

Determination of degree of acidity of gases evolved during the combustion of materials taken

from electric cables by measuring pH and conductivity

Amendment 1 (1997)

IEC 61034-1:2005, Measurement of smoke density of cables burning under defined conditions

– Part 1: Test apparatus

IEC 61034-2:2005, Measurement of smoke density of cables burning under defined conditions

– Part 2: Test procedure and requirements

IEC 61892-4, Mobile and fixed offshore units – Electrical installations – Part 4: Cables

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60092-350 as well as

in IEC 60050-461 apply.

___________

There exists a consolidated edition (1.1) which includes IEC 60331-11:1999 and its amendment 1.

There exists a consolidated edition (1.1) which includes IEC 60332-3-22:2000 and its amendment 1.

There exists a consolidated edition (2.1) which includes IEC 60684-2:1997 and its amendment 1 and its

corrigendum.

– 8 – 60092-353 © IEC:2011

4 General requirements

4.1 Rated voltage

The standard method of designating the rated voltages of cables covered by this standard shall

take the form U /U (U ),

o m

where

U is the rated power-frequency voltage between phase conductor and earth or metallic

o

screen, for which the cable is designed;

U is the rated power-frequency voltage between phase conductors for which the cable is

designed;

U is the maximum value of the “highest system voltage” for which the equipment (including

m

cable) may be used (see IEC 60038).

All voltages are given as r.m.s. values.

The standard rated voltages U /U (U ) of the cables considered in this standard are:

o m

U /U (U ) = 0,6/1 (1,2) kV and 1,8/3 (3,6) kV

o m

For 0,6/1 (1,2) kV cables, d.c. voltage up to a maximum of 1,5 times the a.c. voltage may be

used provided that the voltage to earth does not exceed 0,9 kV.

4.2 Markings

4.2.1 Indication of origin and voltage identification

Cables shall comply with 4.1.2 of IEC 60092-350 with respect to:

a) indication of origin;

b) rated voltage and cable construction;

c) continuity;

d) durability / legibility.

4.2.2 Continuity

The marking is deemed to be continuous if the distance between the end of any marking and

the beginning of the next does not exceed:

a) 550 mm if the marking is on the outer surface of the cable;

b) 275 mm in all other cases.

4.2.3 Core identification

4.2.3.1 General

Cable cores shall be clearly identified by either colours or numbers.

4.2.3.2 Coloured cores

The core colours shall be in accordance with IEC 60445.

60092-353 © IEC:2011 – 9 –

4.2.3.3 Numbered Cores – multicore cables

Identification shall be made by inscription of numbers on each core starting from the centre

beginning with 1 in accordance with Annex B.

5 Constructional requirements

5.1 General description

5.1.1 Overview

Shipboard and offshore cables for fixed installations shall be single or multicore cables

generally constructed as follows:

5.1.2 Unarmoured cables (excluding 1,8/3 kV)

a) Single-core unarmoured unsheathed cable

• copper conductor, see 5.2;

• insulation applied as a single layer of insulating compound of one of the types described

in 5.3 with an enhanced thickness equivalent to that of a combined insulation and outer

sheath for use in unarmoured cables installed in an adequately protected environment

(see 5.3.3 for the thickness).

b) Unarmoured single- or double-sheathed cable

• copper conductor, see 5.2;

• insulation, see 5.3;

• cabling (for multicore cables), see 5.4;

• inner covering (optional, but mandatory when a braided or a metal tape electrostatic

screening is applied over the core lay-up), see 5.5;

• electrostatic screening (optional), see 5.6;

• inner sheath (optional), see 5.7;

• outer sheath applied as either one or two layer systems, see 5.9.

5.1.3 Armoured cables

a) Armoured single-sheathed cable with outer sheath only

• copper conductor, see 5.2;

• insulation, see 5.3;

• cabling (for multicore cables), see 5.4;

• inner covering below electrostatic screening (optional, but mandatory when a braided or

a metal tape electrostatic screening is applied over the core lay-up), see 5.5;

• electrostatic screening (optional), see 5.6;

• inner covering (optional, but mandatory in case of a braid armour of galvanised steel

wires in which case the inner covering shall be extruded), see 5.5;

• braid armour, see 5.8;

• outer sheath applied as either one or two layer systems, see 5.9.

b) Armoured double-sheathed cable with inner and outer sheath

• copper conductor, see 5.2;

• insulation, see 5.3;

• cabling (for multicore cables), see 5.4;

– 10 – 60092-353 © IEC:2011

• inner covering (optional, but mandatory when a braided or a metal tape electrostatic

screening is applied over the core lay-up), see 5.5;

• electrostatic screening (optional), see 5.6;

• inner sheath, see 5.7;

• braid armour, see 5.8;

• outer sheath applied as either one or two layer systems, see 5.9.

NOTE The use of a thermoplastic inner sheath (ST2 or SHF1) is not recommended if the outer sheath consists of

an elastomeric crosslinked material.

c) Armoured single-sheathed cable with inner sheath only

• copper conductor, see 5.2;

• insulation, see 5.3;

• cabling (for multicore cables), see 5.4;

• inner covering (optional, but mandatory when a braided or a metal tape electrostatic

screening is applied over the core lay-up), see 5.5;

• electrostatic screening (optional), see 5.6;

• inner sheath, see 5.7;

• braid armour, see 5.8.

NOTE Cables for installation in spaces where corrosion may occur, for example weather decks, wet locations,

battery compartments, refrigeration rooms, etc., should have an outer sheath over the braid, if any, unless the braid

itself is corrosion-resistant.

5.2 Conductors

Material, metal coating, class and form of the conductors shall be in accordance with

IEC 60092-350. For cables having rated voltage 1,8/3 kV only circular stranded compacted or

non-compacted conductors with a minimum cross-section of 10 mm² are permitted. A separator

between conductors and insulation is permitted.

5.3 Insulation

5.3.1 Material

The insulating compounds and their designations shall be as given in IEC 60092-351 thus:

– for 0,6/1 (1,2) kV cables, types EPR, HEPR, XLPE, HF 90 or S 95 shall be used;

– for 1,8/3 (3,6) kV cables, types only EPR, HEPR, XLPE shall be used.

The insulation system shall consist of one of the options (a) to (d) as listed in IEC 60092-350,

4.3.1.

5.3.2 Application

The application shall be as detailed in IEC 60092-350, 4.3.2.

5.3.3 Thickness of insulation

The thickness of the insulation shall be as specified in Table 1 hereinafter and meet the

requirements of IEC 60092-350, 4.3.3.

For single core unsheathed unarmoured cables (see 5.1.2 a)), the total insulation thickness

shall be the sum of:

a) the thickness t as specified in Table 1, and

j

60092-353 © IEC:2011 – 11 –

b) the thickness as calculated in accordance with 5.9.3 a), with fictitious diameter D = d +2 t

L i

(see also IEC 60092-350, Annex A). The total thickness shall meet the requirements of

IEC 60092-350, 4.3.3.

Table 1 – Insulation thickness

0,6/1 kV 1,8/3 kV

Nominal cross EPR HEPR XLPE EPR HEPR XLPE

sectional

S 95 HF 90

area of conductor

mm mm mm mm mm mm mm

1 1,0 0,7 0,7 – – –

1,5 1,0 0,7 0,7 – – –

2,5 1,0 0,7 0,7 – – –

4 1,0 0,7 0,7 – – –

6 1,0 0,7 0,7 – – –

10 1,0 0,7 0,7 2,2 2,0 2,0

16 1,0 0,7 0,7 2,2 2,0 2,0

25 1,2 0,9 0,9 2,2 2,0 2,0

35 1,2 0,9 0,9 2,2 2,0 2,0

50 1,4 1,0 1,0 2,2 2,0 2,0

70 1,4 1,1 1,1 2,2 2,0 2,0

95 1,6 1,1 1,1 2,4 2,0 2,0

120 1,6 1,2 1,2 2,4 2,0 2,0

150 1,8 1,4 1,4 2,4 2,0 2,0

185 2,0 1,6 1,6 2,4 2,0 2,0

240 2,2 1,7 1,7 2,4 2,0 2,0

300 2,4 1,8 1,8 2,4 2,0 2,0

400 2,6 2,0 2,0 2,6 2,0 2,0

500 2,8 2,2 2,2 2,8 2,2 2,2

630 2,8 2,4 2,4 2,8 2,4 2,4

NOTE Alternative enhanced insulation thickness may be given in some countries for legal reasons. These

are based on those given in Annex A.

5.4 Cabling (including fillers & binders)

Cores of a multicore cable shall be laid up, and the interstices filled if necessary with fillers,

inner covering or inner sheath (outer sheath in the case of unarmoured cables) according to

IEC 60092-350, 4.5.

5.5 Inner covering

5.5.1 General

The inner covering, if any, may be extruded (mandatory below galvanized steel wire braid) or

lapped. The relevant material and characteristics shall be in accordance with 4.6 of

IEC 60092-350.

5.5.2 Thickness of inner covering

The values of the (approximate) thickness of extruded inner covering for the calculation of

fictitious diameters are given in Table 2.

– 12 – 60092-353 © IEC:2011

Table 2 – Thickness of extruded inner covering and fictitious diameters

Fictitious diameter over laid up cores Thickness of extruded inner

covering

Above Up to and including (approximate value)

mm mm mm

- 25 1,0

25 35 1,2

35 45 1,4

45 60 1,6

60 80 1,8

80 - 2,0

The values of the (approximate) thickness of lapped covering for the calculation of the fictitious

diameters are 0,4 mm for fictitious diameter over laid-up cores up to and including 40 mm and

0,6 mm for larger diameters.

NOTE For the calculation of fictitious diameter, see Annexes A and C of IEC 60092-350.

5.6 Screen

5.6.1 Construction

5.6.1.1 General

The screen if any, shall be a collective metallic screen and shall be in accordance with

IEC 60092-350, 4.4.2 and shall consist of one or more tapes, a braid or a combination of a

braid with tape(s).

5.6.1.2 Metal/polyester tape

The laminated electrostatic screening tape shall be applied with the metallic side in electrical

contact with a drain wire. The minimum overlap of the laminated tape shall be 15 % of its total

width, to ensure coverage in case of bending the cable. The laminated tape shall be either

aluminium bonded to polyester having a minimum thickness of aluminium of 0,008 mm and a

minimum thickness of polyester of 0,010 mm, or copper bonded to polyester having a minimum

thickness of copper of 0,018 mm and a minimum thickness of polyester of 0,023 mm.

The drain wire shall be composed of a number of strands of tinned annealed copper wires in

the case of aluminium laminate tape and either plain or tinned annealed copper wires in the

case of copper laminate tape. The drain wire shall have a maximum resistance in accordance

with Table 3.

Table 3 – Requirements of drain wire

Nominal area of conductor of the cores Maximum drain wire resistance

mm ohm/km

1 28,3

1,5 28,3

2,5 and above 21,2

Polyester tape of either 0,023 mm or 0,050 mm nominal thickness shall be applied over the

screen with a minimum overlap of 15 % of its total width.

60092-353 © IEC:2011 – 13 –

NOTE A screen consisting of a laminated electrostatic screening tape and a drain wire is not suitable for carrying

large short-circuit currents and should not be grounded with the protective earth conductor of the applicable power

circuit.

5.6.1.3 Metal tape

The specified nominal thickness for a plain metal tape shall be at least 0,1 mm.

5.6.1.4 Braid

The specified nominal thickness for the braiding wires shall be at least 0,2 mm.

5.6.2 Application

The screen, if any, shall be applied over the inner covering in case of a braided or a metal tape

screen (see 5.1.2 and 5.1.3).

5.7 Inner sheath

5.7.1 Material

The inner sheathing compound and its designation shall be one of those given in

IEC 60092-359 except that PVC type ST1 is not permitted.

5.7.2 Application

The application shall be as detailed in IEC 60092-350, 4.7.2.

5.7.3 Thickness of inner sheath

The thickness of the inner sheath is given as a function of the internal diameter of the sheath

under consideration, the fictitious diameter being calculated by the method in IEC 60092-350,

Annexes A and C.

The formula is:

a) for double sheathed unarmoured cable as 5.1.2 (b):

t = 0,025 D + 0,6 mm, with a minimum thickness of 0,8 mm

b) for armoured cable as 5.1.3 b) and c):

t = 0,04 D + 0,8 mm, with a minimum thickness of 1,0 mm for construction 5.1.3 b) and 1,4

mm for construction 5.1.3 c)

where

D is the fictitious diameter under the inner sheath.

The thickness at any point shall satisfy the prescriptions given in 4.7.3 of IEC 60092-350.

5.8 Braid armour

5.8.1 General

In this standard only metal braid armours are specified, the braid wires being of copper, copper

alloy or galvanized steel.

Joints in the braiding wires shall be soldered, twisted or woven-in and the complete braid shall

not be jointed. The braid shall be evenly applied.

The armour may serve as a collective metallic screen (see 5.6).

– 14 – 60092-353 © IEC:2011

NOTE In some countries, the use of an armour as an earthing collective metallic screen is prohibited for legal

reasons.

5.8.2 Braid wire diameter

Irrespective of the metal used, the nominal diameter of the braid wire shall be:

0,2 mm, as a minimum, for cables having fictitious diameter under the braid less than or

equal to 10 mm;

0,3 mm, as a minimum, for cables having fictitious diameter under the braid larger than

10 mm and less than or equal to 30 mm;

0,4 mm, as a minimum, for cables having fictitious diameter under the braid larger than

30 mm.

5.8.3 Coverage density

The coverage density of the braid shall be in accordance with IEC 60092-350, 4.8.2.

NOTE In case the alternative method in accordance with IEC 60092-350, 4.8.2 is used to evaluate the coverage

density, the mean diameter of the braid to be used is the fictitious diameter under the braid plus two times the

nominal diameter of the braiding wires.

5.8.4 Application of the armour

The armour shall be applied in such a way that it shall neither adhere to the inner covering or

inner sheath nor to the outer sheath.

5.9 Outer sheath

5.9.1 Material

The outer sheathing compound and its designation shall be one of those given in

IEC 60092-359 except that PVC type ST1 is not permitted.

5.9.2 Application

The application shall be as detailed in IEC 60092-350, 4.9.2.

5.9.3 Thickness of outer sheath

The thickness of outer sheath is given as a function of the internal diameter of the sheath

under consideration, the fictitious diameter being calculated by the method in IEC 60092-350,

Annexes A and C.

The formula is:

a) for unarmoured or armoured single-sheathed cables as 5.1.2 a) and b) and 5.1.3 a):

t = 0,04 D + 0,8 mm with a minimum thickness of 1,0 mm

where D is the fictitious diameter under the sheath

b) for unarmoured double-sheathed cables as 5.1.2 b):

t = 0,025 D + 0,9 mm, with a minimum thickness of 1,0 mm

c) for armoured double-sheathed cables as 5.1.3 b):

t = 0,025 D + 0,6 mm, with a minimum thickness of 0,8 mm

The thickness at any point shall satisfy the prescriptions given in 4.9.3 of IEC 60092-350.

60092-353 © IEC:2011 – 15 –

5.9.4 Colour of outer sheath

The outer sheath shall be coloured black or grey, unless otherwise specified by the purchaser

at the time of ordering.

6 Tests – methods and requirements

The tests shall be carried out according to Tables 4 to 8 where applicable.

Table 4 – Tests applicable to all cables

Test Applicability – Status Method – Requirement – as in

all types of clause number IEC 60092-350 unless

cable unless given in otherwise stated

otherwise IEC 60092-350

stated

Measurement of electrical Routine 5.2.2 IEC 60228

resistance of conductors

Voltage test Routine 5.2.3 -

Voltage test on sheath Armoured Routine 5.2.3.4 -

cables

Insulation resistance test Routine; sample 5.2.4 -

Type 7.2.1

Conductor examination Sample and 6.4 -

Type

Check of cable Sample and

dimensions Type

– Thickness of insulation

6.5 and 8.1 -

– Thickness of non

6.6 and 8.2 -

metallic sheaths

(excluding inner

coverings)

6.7 -

– External diameter

Hot set test HEPR, EPR, Sample 6.8 IEC 60092-351 and

XLPE, HF 90, S IEC 60092- 359

95 insulations

and SE1, SHF2

sheaths

Coverage density of braid Braid armoured Type 4.8.2

cables

Insulation resistance Type 7.2.2 IEC 60092-351

measurement at maximum

rated temperature

Increase in a.c. Type 7.3 IEC 60092-351

capacitance after

immersion in water

High-voltage test for 4 h Type 7.4

Mechanical properties of Type 8.3 IEC 60092-351

insulation before and after

ageing

Mechanical properties of Type 8.4 IEC 60092-359

sheath before and after

ageing

Additional ageing Type 8.5 IEC 60092-351 and

compatibility test IEC 60092- 359

Loss of mass test ST2 sheath Type 8.6 IEC 60092-359

– 16 – 60092-353 © IEC:2011

Table 4 (continued)

Test Applicability – Status Method – Requirement – as in

all types of clause number IEC 60092-350 unless

cable unless given in otherwise stated

otherwise IEC 60092-350

stated

Behaviour at high ST2 and SHF1 Type 8.7 IEC 60092-359

temperature sheaths

Behaviour at low ST2, SHF1 and Type 8.8 IEC 60092-359

temperatures SHF2 sheaths

Test for coating of copper Type 8.10

wires

Galvanizing test Type 8.11

Resistance to cracking ST2 and SHF1 Type 8.12 IEC 60092-359

heat shock sheaths

Ozone resistance Insulations and Type 8.13

sheaths

Hot oil immersion SE1, SH and Type 8.14.1 IEC 60092-359

SHF2 sheaths

Flame-spread tests: Type 8.16.1 IEC 60332-1-2 and

IEC 60332-1-2 and

8.16.2 IEC 60332-3-22 in which

IEC 60332-3-22

case cables shall be installed

in touching configuration on

the front of the ladder.

Determination of hardness HEPR Type 8.17 IEC 60092-351

insulation

Determination of modulus HEPR Type 8.18 IEC 60092-351

of elasticity insulation

Durability of marking Type 8.19 The marking shall remain

legible following the test as

given in IEC 60092-350, 8.19

Table 5 – Additional tests required for halogen-free cables

Test Status Method – clause Requirement – as in IEC 60092-

number given in 350 unless otherwise stated

IEC 60092-350

Acid gas emission Type 8.16.4 IEC 60754-1

pH and conductivity Type 8.16.5 IEC 60754-2

Fluorine content test Type 8.16.6 IEC 60684-2

60092-353 © IEC:2011 – 17 –

Table 6 – Additional test required for low smoke cables

Test Status Method – clause Requirement – as in

number given in IEC 60092-350 unless

IEC 60092-350 otherwise stated

Smoke emission test for Type 8.16.3 The test is satisfactory for the

cables insulated and finished cables if the levels of

sheathed with halogen-free light transmittance exceeds

materials. When tested 60% throughout the test

according to IEC 61034-1

and IEC 61034-2

NOTE The smoke emission test is in general applicable to halogen-free cables. See also

Table 5.

Table 7 – Additional tests required for fire resistant cables

Test Status Method – clause Requirement – as in IEC 60092-

number given in 350 unless otherwise stated

IEC 60092-350

Test for fire resistance Type 8.16.7 The test shall be carried out in

(limited circuit integrity) accordance with IEC 60331-21 or

IEC 60331-1 or IEC 60331-2 and

the minimum time to failure shall

be 90 min

NOTE The test apparatus for the test procedure defined in IEC 60331-21 is detailed in

IEC 60331-11.

Table 8 – Additional tests required for specific performances

Test Status Method – clause Requirement – as in IEC 60092-

number given in 350 unless otherwise stated

IEC 60092-350

Special test for low Type 8.9

temperature behaviour

Enhanced hot oil immersion Type 8.14.2

Mud fluid drilling test Type 8.15

– 18 – 60092-353 © IEC:2011

Annex A

(informative)

Alternative enhanced insulation thickness for 0,6/1 kV

NOTE 1 For legal reasons in some countries this Annex may become normative.

Table A.1 gives an overview of alternative enhanced insulation thickness for 0,6/1 kV.

Table A.1 – Alternative enhanced insulation thickness for 0,6/1 kV

Rated voltage 0,6/1 kV

Silicone rubber / EPR XLPE

Nominal cross-sectional Insulation thickness Nominal cross-sectional Insulation thickness

area area

a b c

(t) and (t)

mm mm

(S) (S)

mm² mm²

1 1,0 1,0 0,9

1,5 1,0 1,5 0,9

2,5 1,0 2,5 0,9

4 1,1 4 1,0

6 1,1 6 1,0

10 1,2 10 1,1

16 1,3 16 1,2

25 1,4 25 1,3

35 1,5 35 1,3

50 1,6 50 1,4

70 1,7 70 1,6

95 1,9 95 1,7

120 2,0 120 1,8

150 2,1 150 1,9

185 2,3 185 2,0

240 2,4 240 2,2

300 2,6 300 2,4

400 2,9 400 2,6

500 3,1 500 2,8

630 3,4 630 3,1

a

These values of the insulation thickness correspond approximately to the formula:

mm

t = 0,1 S + 0,9

b

All these values may be reduced by 0,1 mm if the rubber wall is covered by an extruded skin of polyamide

or equivalent material.

c

These values of the insulation thickness correspond approximately to the formula:

mm

t = 0,09 S + 0,8

NOTE 2 For cross sections of 185 mm² and above, the insulation thickness is suitable for 3 kV. If in this case a

voltage rating of 3 kV is designated to the cable, this cable should be tested as a 3 kV cable.

60092-353 © IEC:2011 – 19 –

Annex B

(informative)

Identification of cores of multicore cables

B.1 Inscription

The inscription shall be composed of marks at regular intervals along the entire length of core

and comprising of:

a) a reference number in Arabic numerals;

b) a dash which underlines this reference number and indicates the direction in which the

number must be read.

B.2 Arrangement of the marks

Two consecutive marks shall always be placed upside down in relation to one another. The

arrangement of the marks is shown in Figure B.1.

d d

h i

i

IEC 1894/11

Key

Refer to Clause B.3 below

Figure B.1 – Arrangement of the marks

When the reference consists of a single numeral, the dash is placed under it; if the reference

number consists of two numerals, these are disposed one below the other and the dash is

placed underneath the lower numeral.

B.3 Spacing and dimensions of the marks

The dimensions of the marks and the spacing are given in Table B.1, where:

D = nominal diameter of the core;

e = minimum width of a mark;

h = minimum height of a numeral;

i = approximate interval, in a mark, between two consecutive numerals, as well as

between numeral and dash;

d = maximum interval between two consecutive marks.

e/2

e

D

– 20 – 60092-353 © IEC:2011

Table B.1 – Dimensions of the marks

Nominal diameter, D, of the core

e h i d

mm

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...