IEC 60092-350:2020

(Main)Electrical installations in ships - Part 350: General construction and test methods of power, control and instrumentation cables for shipboard and offshore applications

Electrical installations in ships - Part 350: General construction and test methods of power, control and instrumentation cables for shipboard and offshore applications

IEC 60092-350:2020 provides the general constructional requirements and test methods for use in the manufacture of electric power, control and instrumentation cables with copper conductors intended for fixed electrical systems at voltages up to and including 18/30(36) kV on board ships and offshore (mobile and fixed) units.

The reference to fixed systems includes those that are subjected to vibration (due to the movement of the ship or installation) or movement (due to motion of the ship or installation) and not to those that are intended for frequent flexing. Cables suitable for frequent or continual flexing use are detailed in other IEC standards, for example IEC 60227 (all parts) and IEC 60245 (all parts), and their uses are restricted to those situations which do not directly involve exposure to a marine environment, for example, portable tools and domestic appliances.

The following types of cables are not included:

- optical fibre;

- sub-sea and umbilical cables;

- data and communication cables;

- coaxial cables.

This fifth edition cancels and replaces the fourth edition published in 2014 and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

a) more detailed description of the test procedures in 7.7.6 and 7.7.7;

b) description of the relationship between Annex A and Annex D.

Installations électriques à bord des navires – Partie 350: Construction générale et méthodes d'essai des câbles d'énergie, de commande et d'instrumentation des navires et des unités mobiles et fixes en mer

L'IEC 60092-350:2020 fournit les exigences générales de construction et les méthodes d'essai à utiliser lors de la fabrication des câbles d'énergie, de commande et d'instrumentation à âmes en cuivre destinés à la connexion de systèmes électriques fixes à une tension au plus égale à 18/30(36) kV installés à bord des navires et des unités en mer (mobiles et fixes).

Les installations fixes incluent les systèmes qui sont soumis à des vibrations (sous l'action du mouvement du navire ou de l'installation) ou des mouvements (sous l'action du déplacement du navire ou de l'installation), mais pas ceux qui sont prévus pour subir des flexions fréquentes. Les câbles prévus pour subir des flexions fréquentes ou continues sont décrits dans d'autres normes IEC (IEC 60227 (toutes les parties) et IEC 60245 (toutes les parties), par exemple), et leurs utilisations se limitent à celles n'impliquant pas directement une exposition à un environnement marin (outils portatifs et appareils domestiques, par exemple).

Les types de câbles suivants ne sont pas couverts:

- câbles à fibres optiques;

- câbles sous-marins et ombilicaux;

- câbles de données et de communication;

- câbles coaxiaux.

Cette cinquième édition annule et remplace la quatrième édition parue en 2014. Cette édition constitue une révision technique.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) description plus détaillée des procédures d'essai données en 7.7.6 et 7.7.7;

b) description de la relation entre l'Annexe A et l'Annexe D.

General Information

- Status

- Published

- Publication Date

- 27-Jan-2020

- Technical Committee

- SC 18A - Electric cables for ships and mobile and fixed offshore units

- Drafting Committee

- MT 2 - TC 18/SC 18A/MT 2

- Current Stage

- PPUB - Publication issued

- Start Date

- 28-Jan-2020

- Completion Date

- 21-Jan-2020

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60092-350:2020 - part of the IEC 60092 series - defines the general constructional requirements and test methods for copper-conductor power, control and instrumentation cables intended for fixed shipboard and offshore installations up to and including 18/30(36) kV. The standard covers cables for fixed systems that may be exposed to ship or platform movement or vibration, but excludes cables intended for frequent flexing and several cable types (see Related Standards). The fifth edition (2020) is a technical revision with more detailed test procedure descriptions (notably clauses 7.7.6 and 7.7.7) and clarifies the relationship between Annex A and Annex D.

Key Topics and Requirements

- Scope and voltage designation: copper conductors for fixed marine/offshore electrical systems up to 18/30(36) kV.

- Constructional requirements:

- Conductor material, class and form, and resistance limits.

- Insulation systems: permitted materials and insulation thickness rules.

- Screens/shields for low- and high-voltage cables.

- Cabling arrangements, fillers, inner coverings and inner sheath.

- Metal braid armour, outer sheath materials (including halogen-free options) and dimensional limits.

- Core identification, marking and voltage designations.

- Test methods:

- Routine tests: conductor resistance, voltage tests, partial discharge checks.

- Sample tests: insulation/sheath thickness, hot-set, insulation resistance.

- Type tests (electrical): insulation resistance at ambient and max temperatures, high-voltage sequence tests, partial discharge, tan δ (dissipation factor) vs. temperature/voltage, impulse withstand and 4-hour HV tests.

- Type tests (non-electrical): mechanical properties before/after ageing, hot oil immersion, low/high temperature behaviour, ozone resistance, galvanizing and compatibility tests.

- Exclusions: optical fibre, subsea and umbilical cables, data/communication and coaxial cables.

Practical Applications and Who Uses This Standard

IEC 60092-350 is used to:

- Specify and procure shipboard and offshore power, control and instrumentation cables.

- Guide cable manufacturers in design and factory testing to meet marine requirements.

- Provide acceptance criteria for classification societies, shipbuilders, naval architects, offshore EPC contractors, procurement teams, testing laboratories, and marine surveyors.

- Support maintenance, retrofits and compliance documentation for maritime electrical installations.

Keywords: IEC 60092-350, shipboard cables, offshore cables, power cables, control cables, instrumentation cables, marine cable test methods, halogen-free sheath, high-voltage marine cabling.

Related Standards

- IEC 60092 (other parts) - broader electrical installations in ships.

- IEC 60227 and IEC 60245 - cables designed for frequent flexing (portable equipment/domestic appliances).

- National rules and classification society regulations often reference IEC 60092 series for shipboard cable approval.

Buy Documents

IEC 60092-350:2020 - Electrical installations in ships - Part 350: General construction and test methods of power, control and instrumentation cables for shipboard and offshore applications Released:1/28/2020 Isbn:9782832277836

IEC 60092-350:2020 RLV - Electrical installations in ships - Part 350: General construction and test methods of power, control and instrumentation cables for shipboard and offshore applications Released:1/28/2020 Isbn:9782832278192

IEC 60092-350:2020 - Electrical installations in ships - Part 350: General construction and test methods of power, control and instrumentation cables for shipboard and offshore applications Released:1/28/2020 Isbn:9782832281529

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Sponsored listings

Frequently Asked Questions

IEC 60092-350:2020 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electrical installations in ships - Part 350: General construction and test methods of power, control and instrumentation cables for shipboard and offshore applications". This standard covers: IEC 60092-350:2020 provides the general constructional requirements and test methods for use in the manufacture of electric power, control and instrumentation cables with copper conductors intended for fixed electrical systems at voltages up to and including 18/30(36) kV on board ships and offshore (mobile and fixed) units. The reference to fixed systems includes those that are subjected to vibration (due to the movement of the ship or installation) or movement (due to motion of the ship or installation) and not to those that are intended for frequent flexing. Cables suitable for frequent or continual flexing use are detailed in other IEC standards, for example IEC 60227 (all parts) and IEC 60245 (all parts), and their uses are restricted to those situations which do not directly involve exposure to a marine environment, for example, portable tools and domestic appliances. The following types of cables are not included: - optical fibre; - sub-sea and umbilical cables; - data and communication cables; - coaxial cables. This fifth edition cancels and replaces the fourth edition published in 2014 and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) more detailed description of the test procedures in 7.7.6 and 7.7.7; b) description of the relationship between Annex A and Annex D.

IEC 60092-350:2020 provides the general constructional requirements and test methods for use in the manufacture of electric power, control and instrumentation cables with copper conductors intended for fixed electrical systems at voltages up to and including 18/30(36) kV on board ships and offshore (mobile and fixed) units. The reference to fixed systems includes those that are subjected to vibration (due to the movement of the ship or installation) or movement (due to motion of the ship or installation) and not to those that are intended for frequent flexing. Cables suitable for frequent or continual flexing use are detailed in other IEC standards, for example IEC 60227 (all parts) and IEC 60245 (all parts), and their uses are restricted to those situations which do not directly involve exposure to a marine environment, for example, portable tools and domestic appliances. The following types of cables are not included: - optical fibre; - sub-sea and umbilical cables; - data and communication cables; - coaxial cables. This fifth edition cancels and replaces the fourth edition published in 2014 and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) more detailed description of the test procedures in 7.7.6 and 7.7.7; b) description of the relationship between Annex A and Annex D.

IEC 60092-350:2020 is classified under the following ICS (International Classification for Standards) categories: 29.060.20 - Cables; 47.020.60 - Electrical equipment of ships and of marine structures. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60092-350:2020 has the following relationships with other standards: It is inter standard links to IEC 60092-350:2014/COR1:2018, IEC 60092-350:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60092-350:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60092-350 ®

Edition 5.0 2020-01

INTERNATIONAL

STANDARD

Electrical installations in ships –

Part 350: General construction and test methods of power, control

and instrumentation cables for shipboard and offshore applications

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60092-350 ®

Edition 5.0 2020-01

INTERNATIONAL

STANDARD

Electrical installations in ships –

Part 350: General construction and test methods of power, control

and instrumentation cables for shipboard and offshore applications

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.060.20; 47.020.60 ISBN 978-2-8322-7783-6

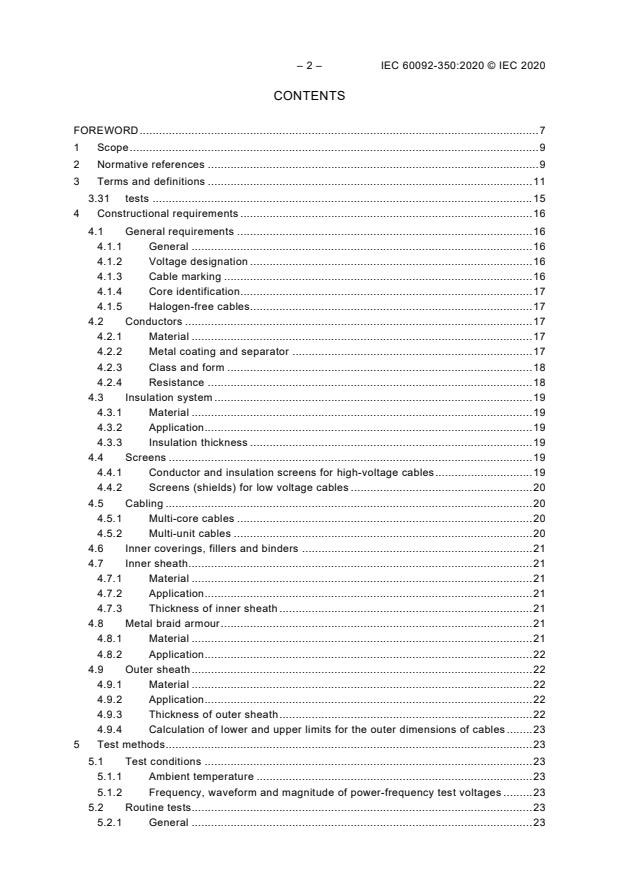

– 2 – IEC 60092-350:2020 © IEC 2020

CONTENTS

FOREWORD . 7

1 Scope . 9

2 Normative references . 9

3 Terms and definitions . 11

3.31 tests . 15

4 Constructional requirements . 16

4.1 General requirements . 16

4.1.1 General . 16

4.1.2 Voltage designation . 16

4.1.3 Cable marking . 16

4.1.4 Core identification . 17

4.1.5 Halogen-free cables. 17

4.2 Conductors . 17

4.2.1 Material . 17

4.2.2 Metal coating and separator . 17

4.2.3 Class and form . 18

4.2.4 Resistance . 18

4.3 Insulation system . 19

4.3.1 Material . 19

4.3.2 Application . 19

4.3.3 Insulation thickness . 19

4.4 Screens . 19

4.4.1 Conductor and insulation screens for high-voltage cables . 19

4.4.2 Screens (shields) for low voltage cables . 20

4.5 Cabling . 20

4.5.1 Multi-core cables . 20

4.5.2 Multi-unit cables . 20

4.6 Inner coverings, fillers and binders . 21

4.7 Inner sheath . 21

4.7.1 Material . 21

4.7.2 Application . 21

4.7.3 Thickness of inner sheath . 21

4.8 Metal braid armour . 21

4.8.1 Material . 21

4.8.2 Application . 22

4.9 Outer sheath . 22

4.9.1 Material . 22

4.9.2 Application . 22

4.9.3 Thickness of outer sheath . 22

4.9.4 Calculation of lower and upper limits for the outer dimensions of cables . 23

5 Test methods . 23

5.1 Test conditions . 23

5.1.1 Ambient temperature . 23

5.1.2 Frequency, waveform and magnitude of power-frequency test voltages . 23

5.2 Routine tests. 23

5.2.1 General . 23

5.2.2 Measurement of the electrical resistance of the conductors . 23

5.2.3 Voltage test . 24

5.2.4 Partial discharge test . 25

6 Sample tests . 26

6.1 General . 26

6.2 Frequency of sample tests . 26

6.3 Repetition of tests . 26

6.4 Conductor examination . 26

6.5 Measurement of thickness of insulation . 27

6.5.1 General . 27

6.5.2 Procedure . 27

6.5.3 Requirements . 27

6.6 Measurements of thickness of non-metallic sheaths . 27

6.6.1 General . 27

6.6.2 Procedure . 27

6.6.3 Requirements . 27

6.7 Measurement of external diameter . 27

6.8 Hot-set test for insulations and sheaths . 27

6.8.1 General procedure . 27

6.8.2 Requirements . 28

6.9 Insulation resistance test (volume resistivity determination) . 28

7 Type tests, electrical. 29

7.1 General . 29

7.2 Insulation resistance measurement . 29

7.2.1 Measurement at ambient temperature . 29

7.2.2 Measurement at maximum rated temperature . 29

7.3 Increase in AC capacitance after immersion in water . 30

7.3.1 General . 30

7.3.2 Preparation of test specimens. 30

7.3.3 Apparatus . 30

7.3.4 Procedure . 30

7.3.5 Requirements . 30

7.4 High-voltage test for 4 h for cables rated up to 1,8/3 kV . 31

7.4.1 General . 31

7.4.2 Requirement . 31

7.5 Mutual capacitance (control and instrumentation cables only) . 31

7.6 Inductance to resistance ratio (control and instrumentation cables only) . 31

7.7 High voltage sequence test (cables having a voltage rating higher than

3,6/6 (7,2) kV) . 31

7.7.1 General . 31

7.7.2 Special provisions . 31

7.7.3 Partial discharge test . 32

7.7.4 Bending test . 32

7.7.5 Tan δ measurement as a function of the voltage . 32

7.7.6 Tan δ measurement as a function of the temperature . 32

7.7.7 Heating cycle test plus partial discharge test . 33

7.7.8 Impulse withstand test, followed by a power-frequency voltage test . 33

7.7.9 High-voltage test for 4 h . 33

8 Type tests (non-electrical) . 33

– 4 – IEC 60092-350:2020 © IEC 2020

8.1 General . 33

8.2 Measurement of thickness of insulation . 34

8.3 Measurement of thickness of non-metallic sheaths (excluding inner

coverings) . 34

8.4 Tests for determining the mechanical properties of insulation before and

after ageing . 34

8.4.1 Sampling . 34

8.4.2 Ageing treatments . 34

8.4.3 Conditioning and mechanical tests . 34

8.4.4 Requirements . 34

8.5 Tests for determining the mechanical properties of sheaths before and after

ageing. 34

8.5.1 Sampling . 34

8.5.2 Ageing treatments . 34

8.5.3 Conditioning and mechanical tests . 34

8.5.4 Requirements . 34

8.6 Additional ageing test on pieces of completed cables (compatibility test) . 35

8.6.1 General . 35

8.6.2 Sampling . 35

8.6.3 Ageing treatment . 35

8.6.4 Mechanical tests . 35

8.6.5 Requirements . 35

8.7 Loss of mass test on PVC ST 2 sheath . 35

8.7.1 Procedure . 35

8.7.2 Requirements . 35

8.8 Test for the behaviour of PVC ST 2 and halogen-free SHF 1 sheaths at high

temperature (hot pressure test) . 35

8.8.1 Procedure . 35

8.8.2 Requirements . 35

8.9 Test for the behaviour of PVC sheath ST 2 and halogen-free SHF 1 and

SHF 2 sheaths at low temperature . 36

8.9.1 Procedure . 36

8.9.2 Requirements . 36

8.10 Special test for low temperature behaviour (when required) . 36

8.11 Test of the metal coating of copper wires . 36

8.12 Galvanizing test . 36

8.13 Test for resistance of PVC ST 2 and halogen-free SHF 1 sheaths to cracking

(heat shock test) . 36

8.13.1 Procedure . 36

8.13.2 Requirements . 36

8.14 Ozone resistance test for insulation and for sheaths . 36

8.14.1 Procedure . 36

8.14.2 Requirements . 36

8.15 Hot oil immersion test and enhanced hot oil immersion test for sheaths . 37

8.15.1 Hot oil immersion test . 37

8.15.2 Enhanced hot oil immersion test (when required) . 37

8.16 Mud drilling fluid test (when required) . 37

8.17 Fire tests . 37

8.17.1 Flame-spread test on single cables . 37

8.17.2 Flame-spread test on bunched cables. 37

8.17.3 Smoke emission test . 37

8.17.4 Acid gas emission test . 37

8.17.5 pH and conductivity test. 37

8.17.6 Fluorine content test . 38

8.17.7 Fire-resistance test (test for circuit integrity cables) . 38

8.18 Determination of hardness for HEPR. 38

8.19 Determination of elastic modulus for HEPR . 38

8.20 Durability of print . 38

Annex A (normative) Fictitious calculation method for determination of dimensions of

protective coverings . 39

A.1 Overview. 39

A.2 General . 39

A.3 Method . 39

A.3.1 Conductors . 39

A.3.2 Cores . 40

A.3.3 Diameter over laid-up cores . 41

A.3.4 Inner coverings . 43

A.3.5 Sheath . 43

A.3.6 Braid armour . 44

Annex B (informative) Recommended minimum spark test voltage levels

(according to IEC 62230) . 45

B.1 General . 45

B.2 Test voltages . 45

B.2.1 General . 45

B.2.2 Contact electrodes . 45

B.2.3 Non-contact electrodes . 46

Annex C (normative) Rounding of numbers . 47

C.1 Rounding of numbers for the purpose of the fictitious calculation method . 47

C.1.1 Rules . 47

C.1.2 Illustrations . 47

C.2 Rounding of numbers for other purposes . 47

Annex D (normative) Calculation of the lower and upper limits for the outer

dimensions of cables with circular copper conductors . 48

D.1 General . 48

D.2 Lower limit for the outer diameter . 48

D.3 Upper limit for the outer diameter . 48

D.4 Thickness of the mandatory or optional coverings other than the insulation

and the sheath(s) . 49

Annex E (normative) Cold bend test and impact test for low temperature behaviour . 50

E.1 Cold bend test at any specified low temperature . 50

E.1.1 Method no. 1 . 50

E.1.2 Method no. 2 . 50

E.1.3 Examination and requirements . 51

E.2 Impact test at any specified low temperature . 51

E.2.1 Apparatus . 51

E.2.2 Procedures . 51

E.2.3 Requirements . 51

Bibliography . 52

– 6 – IEC 60092-350:2020 © IEC 2020

Table 1 – Minimum size of conductors . 18

Table 2 – Routine test voltage . 25

Table 3 – Number of samples according to cable length . 26

Table 4 – Tan δ versus voltage . 32

Table 5 – Tan δ versus temperature . 33

Table 6 – Impulse withstand voltages . 33

Table 7 – Test methods and requirements for halogen-free components . 38

Table A.1 – Fictitious diameter of conductor . 40

Table A.2 – Increase of diameter for concentric conductors and metallic screens made

of tape or wire . 40

Table A.3 – Assembly coefficient k for laid-up . 42

Table A.4 – Coefficient c . 43

f

Table B.1 – Recommended minimum spark-test voltages for cables having rated

voltage (U ) between 150 V and 1 800 V . 45

Table D.1 – Lower and upper limits of circular copper conductors for cables for fixed

installations . 49

Table E.1 – Details of low temperature bending test . 50

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRICAL INSTALLATIONS IN SHIPS –

Part 350: General construction and test methods of power, control

and instrumentation cables for shipboard and offshore applications

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60092-350 has been prepared by subcommittee 18A: Electric

cables for ships and mobile and fixed offshore units, of IEC technical committee 18: Electrical

installations of ships and of mobile and fixed offshore units.

This fifth edition cancels and replaces the fourth edition published in 2014 and constitutes a

technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) more detailed description of the test procedures in 7.7.6 and 7.7.7;

b) description of the relationship between Annex A and Annex D.

– 8 – IEC 60092-350:2020 © IEC 2020

The text of this International Standard is based on the following documents:

CDV Report on voting

18A/420/FDIS 18A/423/RVC

Full information on the voting for the approval of this document can be found in the report on

voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

The list of all the parts of the IEC 60092 series, under the general title Electrical installations

in ships, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

ELECTRICAL INSTALLATIONS IN SHIPS –

Part 350: General construction and test methods of power, control

and instrumentation cables for shipboard and offshore applications

1 Scope

This part of IEC 60092 provides the general constructional requirements and test methods for

use in the manufacture of electric power, control and instrumentation cables with copper

conductors intended for fixed electrical systems at voltages up to and including 18/30(36) kV

on board ships and offshore (mobile and fixed) units.

The reference to fixed systems includes those that are subjected to vibration (due to the

movement of the ship or installation) or movement (due to motion of the ship or installation)

and not to those that are intended for frequent flexing. Cables suitable for frequent or

continual flexing use are detailed in other IEC standards, for example IEC 60227 (all parts)

and IEC 60245 (all parts), and their uses are restricted to those situations which do not

directly involve exposure to a marine environment, for example, portable tools and domestic

appliances.

The following types of cables are not included:

– optical fibre;

– sub-sea and umbilical cables;

– data and communication cables;

– coaxial cables.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60050-461, International Electrotechnical Vocabulary – Part 461: Electric cables

(available at www.electropedia.org)

IEC 60092-360:2014, Electrical installations in ships – Part 360: Insulating and sheathing

materials for shipboard and offshore units, power, control, instrumentation and

telecommunication cables

IEC 60228, Conductors of insulated cables

IEC 60230, Impulse tests on cables and their accessories

IEC 60331-1, Tests for electric cables under fire conditions – Circuit integrity – Part 1: Test

method for fire with shock at a temperature of at least 830 °C for cables of rated voltage up to

and including 0,6/1,0 kV and with an overall diameter exceeding 20 mm

IEC 60331-2, Tests for electric cables under fire conditions – Circuit integrity – Part 2: Test

method for fire with shock at a temperature of at least 830 °C for cables of rated voltage up to

and including 0,6/1,0 kV and with an overall diameter not exceeding 20 mm

– 10 – IEC 60092-350:2020 © IEC 2020

IEC 60331-11, Tests for electric cables under fire conditions – Circuit integrity – Part 11:

Apparatus – Fire alone at a flame temperature of at least 750 °C

IEC 60331-21, Tests for electric cables under fire conditions – Circuit integrity – Part 21:

Procedures and requirements – Cables of rated voltage up to and including 0,6/1,0 kV

IEC 60332-1-2, Tests on electric and optical fibre cables under fire conditions – Part 1-2: Test

for vertical flame propagation for a single insulated wire or cable – Procedure for 1 kW pre-

mixed flame

IEC 60332-3-22, Tests on electric and optical fibre cables under fire conditions – Part 3-22:

Test for vertical flame spread of vertically-mounted bunched wires or cables – Category A

IEC 60684-2, Flexible insulating sleeving – Part 2: Methods of test

IEC 60754-1, Test on gases evolved during combustion of materials from cables – Part 1:

Determination of the halogen acid gas content

IEC 60754-2, Test on gases evolved during combustion of materials from cables – Part 2:

Determination of acidity (by pH measurement) and conductivity

IEC 60811-201, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 201: General tests – Measurement of insulation thickness

IEC 60811-202, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 202: General tests – Measurement of thickness of non-metallic sheath

IEC 60811-203, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 203: General tests – Measurement of overall dimensions

IEC 60811-401, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 401: Miscellaneous tests – Thermal ageing methods – Ageing in an air oven

IEC 60811-403, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 403: Miscellaneous tests – Ozone resistance test on cross-linked compounds

IEC 60811-404, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 404: Miscellaneous tests – Mineral oil immersion tests for sheaths

IEC 60811-409, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 409: Miscellaneous tests – Loss of mass test for thermoplastic insulations and sheaths

IEC 60811-501, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 501: Mechanical tests – Tests for determining the mechanical properties of insulating and

sheathing compounds

IEC 60811-504, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 505: Mechanical tests – Bending tests at low temperature for insulations and sheaths

IEC 60811-505, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 505: Mechanical tests – Elongation at low temperature for insulations and sheaths

IEC 60811-506, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 505: Mechanical tests – Impact test at low temperature for insulations and sheaths

IEC 60811-507, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 507: Mechanical tests – Hot set test for cross-linked materials

IEC 60811-508, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 508: Mechanical tests – Pressure test at high temperature for insulation and sheaths

IEC 60811-509, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 509: Mechanical tests – Test for resistance of insulations and sheaths to cracking (heat

shock test)

IEC 60885-3, Electrical test methods for electric cables – Part 3: Test methods for partial

discharge measurements on lengths of extruded power cables

IEC 61034-1, Measurement of smoke density of cables burning under defined conditions –

Part 1: Test apparatus

IEC 61034-2, Measurement of smoke density of cables burning under defined conditions –

Part 2: Test procedure and requirements

ISO 7989-2:2007, Steel wire and wire products – Non-ferrous metallic coatings on steel wire –

Part 2: Zinc or zinc-alloy coating

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-461 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

approximate value

value which is neither guaranteed nor checked

Note 1 to entry: It is used, for example, for the calculation of other dimensional values.

3.2

braid

covering formed from braided metallic or non-metallic material

[SOURCE: IEC 60050-461:2008, 461-05-10]

3.3

braid armour

covering formed from braided metal wires used to protect a cable from external mechanical

effects

Note 1 to entry: Where the rules of the applicable national, regulatory or approval body permit the practice, it is

also possible to use the braid armour as an earth conductor.

Note 2 to entry: Copper-wire braid armour may also provide a limited function of an electrostatic collective

screen, provided it is effectively earthed.

– 12 – IEC 60092-350:2020 © IEC 2020

3.4

compatibility test

test intended to check that the insulation and sheath are not liable to deteriorate in operation

due to contact either with each other or with other components in the cable

3.5

conductor

part of a cable which has the specific function of carrying current

[SOURCE: IEC 60050-461:2008, 461-01-01]

3.6

conductor screen

non-metallic conducting layer applied between the conductor and insulation to equalise the

electrical stress between these components

Note 1 to entry: It may also provide smooth surfaces at the boundaries of the insulation and assist in the

elimination of spaces at these boundaries

3.7

core-insulated conductor, US

assembly comprising a conductor and its own insulation (and screens, if any)

Note 1 to entry: In North American usage, the core of a cable has been defined as the assembly of components of

a cable lying under a common covering such as the sheath (jacket).

3.8

drain wire

un-insulated wire laid in contact with an electrical screen or an electrical shield which has the

specific function of earthing an electrostatic screen by ensuring a low resistive path

throughout the length of the cable

3.9

electrostatic screen

electrostatic shield, US

earthed metallic layer surrounding a cable which confines the electric field generated by the

cable within the cable cores, pair(s), triples(s) or quad(s), and/or protects the core(s), pair(s),

triple(s) or quad(s) from external influence

Note 1 to entry: Metallic sheaths, foils, braids, armours and earthed concentric conductors may also serve as an

electrostatic screen, provided they are effectively grounded or earthed.

3.10

fictitious value

value calculated according to the "fictitious method" described in Annex A

3.11

filler

material used to fill the interstices between the cores of a multi-conductor cable

[SOURCE: IEC 60050-461:2008, 461-04-05]

3.12

fire resistance

circuit integrity

ability of an electric cable to continue to operate in a designated manner whilst subjected to a

specified flame source for a specified period of time under specified conditions

3.13

flexible cable

cable which is required to be capable of being flexed while in service and of which the

structure and materials are such as to fulfil this requirement

[SOURCE: IEC 60050-461:2008, 461-06-14]

3.14

individually screened cable

radial field cable

cable in which each core is covered with an individual screen

[SOURCE: IEC 60050-461:2008, 461-06-12]

3.15

inner covering

non-metallic covering which surrounds the core or the assembly of the cores or the cabling

elements (and fillers, if any) of a multi-conductor cable and over which further layers are

applied and which has no mechanical or electrical functions

Note 1 to entry: The inner covering can be either extruded or taped, and in either case forms a continuous layer,

which has only an approximate value of thickness and no defined mechanical requirements.

Note 2 to entry: Taped inner coverings are also sometimes called "lapped beddings".

3.16

inner sheath

inner jacket, US

non-metallic sheath generally applied under a metallic sheath, reinforcement

...

IEC 60092-350 ®

Edition 5.0 2020-01

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Electrical installations in ships –

Part 350: General construction and test methods of power, control

and instrumentation cables for shipboard and offshore applications

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and once 67 000 electrotechnical terminology entries in English and

a month by email. French extracted from the Terms and Definitions clause of IEC

publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or need CISPR.

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60092-350 ®

Edition 5.0 2020-01

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Electrical installations in ships –

Part 350: General construction and test methods of power, control

and instrumentation cables for shipboard and offshore applications

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.060.20; 47.020.60 ISBN 978-2-8322-7819-2

– 2 – IEC 60092-350:2020 RLV © IEC 2020

CONTENTS

FOREWORD . 7

1 Scope . 9

2 Normative references . 9

3 Terms and definitions . 11

3.31 tests . 15

4 Constructional requirements . 16

4.1 General requirements . 16

4.1.1 General . 16

4.1.2 Voltage designation . 16

4.1.3 Cable marking . 16

4.1.4 Core identification . 17

4.1.5 Halogen-free cables. 18

4.2 Conductors . 18

4.2.1 Material . 18

4.2.2 Metal coating and separator . 18

4.2.3 Class and form . 18

4.2.4 Resistance . 19

4.3 Insulation system . 19

4.3.1 Material . 19

4.3.2 Application . 19

4.3.3 Insulation thickness . 19

4.4 Screens . 20

4.4.1 Conductor and insulation screens for high-voltage cables . 20

4.4.2 Screens (shields) for low voltage cables . 20

4.5 Cabling . 21

4.5.1 Multi-core cables . 21

4.5.2 Multi-unit cables . 21

4.6 Inner coverings, fillers and binders . 21

4.7 Inner sheath . 21

4.7.1 Material . 21

4.7.2 Application . 21

4.7.3 Thickness of inner sheath . 22

4.8 Metal braid armour . 22

4.8.1 Material . 22

4.8.2 Application . 22

4.9 Outer sheath . 23

4.9.1 Material . 23

4.9.2 Application . 23

4.9.3 Thickness of outer sheath . 23

4.9.4 Calculation of lower and upper limits for the outer dimensions of cables . 23

5 Test methods . 23

5.1 Test conditions . 23

5.1.1 Ambient temperature . 23

5.1.2 Frequency, waveform and magnitude of power-frequency test voltages . 23

5.2 Routine tests. 23

5.2.1 General . 23

5.2.2 Measurement of the electrical resistance of the conductors . 24

5.2.3 Voltage test . 24

5.2.4 Partial discharge test . 26

6 Sample tests . 26

6.1 General . 26

6.2 Frequency of sample tests . 26

6.3 Repetition of tests . 27

6.4 Conductor examination . 27

6.5 Measurement of thickness of insulation . 27

6.5.1 General . 27

6.5.2 Procedure . 27

6.5.3 Requirements . 27

6.6 Measurements of thickness of non-metallic sheaths . 28

6.6.1 General . 28

6.6.2 Procedure . 28

6.6.3 Requirements . 28

6.7 Measurement of external diameter . 28

6.8 Hot-set test for insulations and sheaths . 28

6.8.1 General procedure . 28

6.8.2 Requirements . 28

6.9 Insulation resistance test (volume resistivity determination) . 28

7 Type tests, electrical. 29

7.1 General . 29

7.2 Insulation resistance measurement . 29

7.2.1 Measurement at ambient temperature . 29

7.2.2 Measurement at maximum rated temperature . 30

7.3 Increase in AC capacitance after immersion in water . 30

7.3.1 General . 30

7.3.2 Preparation of test specimens. 30

7.3.3 Apparatus . 30

7.3.4 Procedure . 31

7.3.5 Requirements . 31

7.4 High-voltage test for 4 h for cables rated up to 1,8/3 kV . 31

7.4.1 General . 31

7.4.2 Requirement . 31

7.5 Mutual capacitance (control and instrumentation cables only) . 31

7.6 Inductance to resistance ratio (control and instrumentation cables only) . 31

7.7 High voltage sequence test (cables having a voltage rating higher than

3,6/6 (7,2) kV) . 32

7.7.1 General . 32

7.7.2 Special provisions . 32

7.7.3 Partial discharge test . 32

7.7.4 Bending test . 32

7.7.5 Tan δ measurement as a function of the voltage . 33

7.7.6 Tan δ measurement as a function of the temperature . 33

7.7.7 Heating cycle test plus partial discharge test . 33

7.7.8 Impulse withstand test, followed by a power-frequency voltage test . 33

7.7.9 High-voltage test for 4 h . 34

8 Type tests (non-electrical) . 34

– 4 – IEC 60092-350:2020 RLV © IEC 2020

8.1 General . 34

8.2 Measurement of thickness of insulation . 34

8.3 Measurement of thickness of non-metallic sheaths (excluding inner

coverings) . 34

8.4 Tests for determining the mechanical properties of insulation before and

after ageing . 34

8.4.1 Sampling . 34

8.4.2 Ageing treatments . 34

8.4.3 Conditioning and mechanical tests . 34

8.4.4 Requirements . 35

8.5 Tests for determining the mechanical properties of sheaths before and after

ageing. 35

8.5.1 Sampling . 35

8.5.2 Ageing treatments . 35

8.5.3 Conditioning and mechanical tests . 35

8.5.4 Requirements . 35

8.6 Additional ageing test on pieces of completed cables (compatibility test) . 35

8.6.1 General . 35

8.6.2 Sampling . 35

8.6.3 Ageing treatment . 35

8.6.4 Mechanical tests . 35

8.6.5 Requirements . 36

8.7 Loss of mass test on PVC ST 2 sheath . 36

8.7.1 Procedure . 36

8.7.2 Requirements . 36

8.8 Test for the behaviour of PVC ST 2 and halogen-free SHF 1 sheaths at high

temperature (hot pressure test) . 36

8.8.1 Procedure . 36

8.8.2 Requirements . 36

8.9 Test for the behaviour of PVC sheath ST 2 and halogen-free SHF 1 and

SHF 2 sheaths at low temperature . 36

8.9.1 Procedure . 36

8.9.2 Requirements . 36

8.10 Special test for low temperature behaviour (when required) . 36

8.11 Test of the metal coating of copper wires . 36

8.12 Galvanizing test . 37

8.13 Test for resistance of PVC ST 2 and halogen-free SHF 1 sheaths to cracking

(heat shock test) . 37

8.13.1 Procedure . 37

8.13.2 Requirements . 37

8.14 Ozone resistance test for insulation and for sheaths . 37

8.14.1 Procedure . 37

8.14.2 Requirements . 37

8.15 Hot oil immersion test and enhanced hot oil immersion test for sheaths . 37

8.15.1 Hot oil immersion test . 37

8.15.2 Enhanced hot oil immersion test (when required) . 37

8.16 Mud drilling fluid test (when required) . 37

8.17 Fire tests . 37

8.17.1 Flame-spread test on single cables . 37

8.17.2 Flame-spread test on bunched cables. 38

8.17.3 Smoke emission test . 38

8.17.4 Acid gas emission test . 38

8.17.5 pH and conductivity test. 38

8.17.6 Fluorine content test . 38

8.17.7 Fire-resistance test (test for circuit integrity cables) . 39

8.18 Determination of hardness for HEPR. 39

8.19 Determination of elastic modulus for HEPR . 39

8.20 Durability of print . 39

Annex A (normative) Fictitious calculation method for determination of dimensions of

protective coverings . 40

A.1 Overview. 40

A.2 General . 40

A.3 Method . 40

A.3.1 Conductors . 40

A.3.2 Cores . 41

A.3.3 Diameter over laid-up cores . 42

A.3.4 Inner coverings . 44

A.3.5 Sheath . 44

A.3.6 Braid armour . 45

Annex B (informative) Recommended minimum spark test voltage levels

(according to IEC 62230) . 46

B.1 General . 46

B.2 Test voltages . 46

B.2.1 General . 46

B.2.2 Contact electrodes . 46

B.2.3 Non-contact electrodes . 47

Annex C (normative) Rounding of numbers . 48

C.1 Rounding of numbers for the purpose of the fictitious calculation method . 48

C.1.1 Rules . 48

C.1.2 Illustrations . 48

C.2 Rounding of numbers for other purposes . 48

Annex D (normative) Calculation of the lower and upper limits for the outer

dimensions of cables with circular copper conductors . 49

D.1 General . 49

D.2 Lower limit for the outer diameter . 49

D.3 Upper limit for the outer diameter . 49

D.4 Thickness of the mandatory or optional coverings other than the insulation

and the sheath(s) . 50

Annex E (normative) Cold bend test and impact test for low temperature behaviour . 52

E.1 Cold bend test at any specified low temperature . 52

E.1.1 Method no. 1 . 52

E.1.2 Method no. 2 . 52

E.1.3 Examination and requirements . 53

E.2 Impact test at any specified low temperature . 53

E.2.1 Apparatus . 53

E.2.2 Procedures . 53

E.2.3 Requirements . 53

Bibliography . 54

– 6 – IEC 60092-350:2020 RLV © IEC 2020

Table 1 – Minimum size of conductors . 18

Table 2 – Routine test voltage . 25

Table 3 – Number of samples according to cable length . 27

Table 4 – Tan δ versus voltage . 33

Table 5 – Tan δ versus temperature . 33

Table 6 – Impulse withstand voltages . 34

Table 7 – Test methods and requirements for halogen-free components . 39

Table A.1 – Fictitious diameter of conductor . 41

Table A.2 – Increase of diameter for concentric conductors and metallic screens made

of tape or wire . 41

Table A.3 – Assembly coefficient k for laid-up . 43

Table A.4 – Coefficient c . 44

f

Table B.1 – Recommended minimum spark-test voltages for cables having rated

voltage (U ) between 150 V and 1 800 V . 46

Table D.1 – Lower and upper limits of circular copper conductors for cables for fixed

installations . 51

Table E.1 – Details of low temperature bending test . 52

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRICAL INSTALLATIONS IN SHIPS –

Part 350: General construction and test methods of power, control

and instrumentation cables for shipboard and offshore applications

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

– 8 – IEC 60092-350:2020 RLV © IEC 2020

International Standard IEC 60092-350 has been prepared by subcommittee 18A: Electric

cables for ships and mobile and fixed offshore units, of IEC technical committee 18: Electrical

installations of ships and of mobile and fixed offshore units.

This fifth edition cancels and replaces the fourth edition published in 2014 and constitutes a

technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) more detailed description of the test procedures in 7.7.6 and 7.7.7;

b) description of the relationship between Annex A and Annex D.

The text of this International Standard is based on the following documents:

CDV Report on voting

18A/420/FDIS 18A/423/RVC

Full information on the voting for the approval of this document can be found in the report on

voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

The list of all the parts of the IEC 60092 series, under the general title Electrical installations

in ships, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

ELECTRICAL INSTALLATIONS IN SHIPS –

Part 350: General construction and test methods of power, control

and instrumentation cables for shipboard and offshore applications

1 Scope

This part of IEC 60092 provides the general constructional requirements and test methods for

use in the manufacture of electric power, control and instrumentation cables with copper

conductors intended for fixed electrical systems at voltages up to and including 18/30(36) kV

on board ships and offshore (mobile and fixed) units.

The reference to fixed systems includes those that are subjected to vibration (due to the

movement of the ship or installation) or movement (due to motion of the ship or installation)

and not to those that are intended for frequent flexing. Cables suitable for frequent or

continual flexing use are detailed in other IEC standards, for example IEC 60227 (all parts)

and IEC 60245 (all parts), and their uses are restricted to those situations which do not

directly involve exposure to a marine environment, for example, portable tools and domestic

appliances.

The following types of cables are not included:

– optical fibre;

– sub-sea and umbilical cables;

– data and communication cables;

– coaxial cables.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60050-461, International Electrotechnical Vocabulary – Part 461: Electric cables

(available at www.electropedia.org)

IEC 60092-353, Electrical installations in ships – Part 353: Power cables for rated voltages

1 kV and 3 kV

IEC 60092-360:2014, Electrical installations in ships – Part 360: Insulating and sheathing

materials for shipboard and offshore units, power, control, instrumentation, and

telecommunication and data cables

IEC 60228, Conductors of insulated cables

IEC 60230, Impulse tests on cables and their accessories

IEC 60331-1, Tests for electric cables under fire conditions – Circuit integrity – Part 1: Test

method for fire with shock at a temperature of at least 830 °C for cables of rated voltage up to

and including 0,6/1,0 kV and with an overall diameter exceeding 20 mm

– 10 – IEC 60092-350:2020 RLV © IEC 2020

IEC 60331-2, Tests for electric cables under fire conditions – Circuit integrity – Part 2: Test

method for fire with shock at a temperature of at least 830 °C for cables of rated voltage up to

and including 0,6/1,0 kV and with an overall diameter not exceeding 20 mm

IEC 60331-11, Tests for electric cables under fire conditions – Circuit integrity – Part 11:

Apparatus – Fire alone at a flame temperature of at least 750 °C

IEC 60331-21, Tests for electric cables under fire conditions – Circuit integrity – Part 21:

Procedures and requirements – Cables of rated voltage up to and including 0,6/1,0 kV

IEC 60332-1-2, Tests on electric and optical fibre cables under fire conditions – Part 1-2: Test

for vertical flame propagation for a single insulated wire or cable – Procedure for 1 kW pre-

mixed flame

IEC 60332-3-22, Tests on electric and optical fibre cables under fire conditions – Part 3-22:

Test for vertical flame spread of vertically-mounted bunched wires or cables – Category A

IEC 60684-2, Flexible insulating sleeving – Part 2: Methods of test

IEC 60754-1, Test on gases evolved during combustion of materials from cables – Part 1:

Determination of the halogen acid gas content

IEC 60754-2, Test on gases evolved during combustion of materials from cables – Part 2:

Determination of acidity (by pH measurement) and conductivity

IEC 60811-201, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 201: General tests – Measurement of insulation thickness

IEC 60811-202, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 202: General tests – Measurement of thickness of non-metallic sheath

IEC 60811-203, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 203: General tests – Measurement of overall dimensions

IEC 60811-401, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 401: Miscellaneous tests – Thermal ageing methods – Ageing in an air oven

IEC 60811-403, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 403: Miscellaneous tests – Ozone resistance test on cross-linked compounds

IEC 60811-404, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 404: Miscellaneous tests – Mineral oil immersion tests for sheaths

IEC 60811-409, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 409: Miscellaneous tests – Loss of mass test for thermoplastic insulations and sheaths

IEC 60811-501, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 501: Mechanical tests – Tests for determining the mechanical properties of insulating and

sheathing compounds

IEC 60811-504, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 505: Mechanical tests – Bending tests at low temperature for insulations and sheaths

IEC 60811-505, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 505: Mechanical tests – Elongation at low temperature for insulations and sheaths

IEC 60811-506, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 505: Mechanical tests – Impact test at low temperature for insulations and sheaths

IEC 60811-507, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 507: Mechanical tests – Hot set test for cross-linked materials

IEC 60811-508, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 508: Mechanical tests – Pressure test at high temperature for insulation and sheaths

IEC 60811-509, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 509: Mechanical tests – Test for resistance of insulations and sheaths to cracking (heat

shock test)

IEC 60885-2, Electrical test methods for electric cables. Part 2: partial discharge tests

IEC 60885-3, Electrical test methods for electric cables – Part 3: Test methods for partial

discharge measurements on lengths of extruded power cables

IEC 61034-1, Measurement of smoke density of cables burning under defined conditions –

Part 1: Test apparatus

IEC 61034-2, Measurement of smoke density of cables burning under defined conditions –

Part 2: Test procedure and requirements

ISO 7989-2:2007, Steel wire and wire products – Non-ferrous metallic coatings on steel wire –

Part 2: Zinc or zinc-alloy coating

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-461 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

approximate value

value which is neither guaranteed nor checked

Note 1 to entry: It is used, for example, for the calculation of other dimensional values.

3.2

braid

covering formed from braided metallic or non-metallic material

[SOURCE: IEC 60050-461:2008, 461-05-10, modified ("plaited" replaced by "braided")]

3.3

braid armour

covering formed from braided metal wires used to protect a cable from external mechanical

effects

Note 1 to entry: Where the rules of the applicable national, regulatory or approval body permit the practice, it is

also possible to use the braid armour as an earth conductor.

– 12 – IEC 60092-350:2020 RLV © IEC 2020

Note 2 to entry: Copper-wire braid armour may also provide a limited function of an electrostatic collective

screen, provided it is effectively earthed.

3.4

compatibility test

test intended to check that the insulation and sheath are not liable to deteriorate in operation

due to contact either with each other or with other components in the cable

3.5

conductor

part of a cable which has the specific function of carrying current

[SOURCE: IEC 60050-461:2008, 461-01-01]

3.6

conductor screen

non-metallic conducting layer applied between the conductor and insulation to equalise the

electrical stress between these components

Note 1 to entry: It may also provide smooth surfaces at the boundaries of the insulation and assist in the

elimination of spaces at these boundaries

3.7

core-insulated conductor, US

assembly comprising a conductor and its own insulation (and screens, if any)

Note 1 to entry: In North American usage, the core of a cable has been defined as the assembly of components of

a cable lying under a common covering such as the sheath (jacket).

3.8

drain wire

un-insulated wire laid in contact with an electrical screen or an electrical shield which has the

specific function of earthing an electrostatic screen by ensuring a low resistive path

throughout the length of the cable

[SOURCE: IEC 60050-461:2008, 461-03-07, modified (addition of text from "… which has

…")]

3.9

electrostatic screen

electrostatic shield, US

earthed metallic layer surrounding a cable which confines the electric field generated by the

cable within the cable cores, pair(s), triples(s) or quad(s), and/or protects the core(s), pair(s),

triple(s) or quad(s) from external influence

Note 1 to entry: Metallic sheaths, foils, braids, armours and earthed concentric conductors may also serve as an

electrostatic screen, provided they are effectively grounded or earthed.

3.10

fictitious value

value calculated according to the "fictitious method" described in Annex A

[SOURCE: IEC 60502-2:2005, definition 3.1.4]

3.11

filler

material used to fill the interstices between the cores of a multi-conductor cable

[SOURCE: IEC 60050-461:2008, 461-04-05]

3.12

fire resistance

circuit integrity

ability of an electric cable to continue to operate in the a designated manner whilst subjected

to a specified flame source for a specified period of time under specified conditions

[SOURCE: IEC 60331-11:2009, definition 3.1, modified (addition of "fire res

...

IEC 60092-350 ®

Edition 5.0 2020-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electrical installations in ships –

Part 350: General construction and test methods of power, control and

instrumentation cables for shipboard and offshore applications

Installations électriques à bord des navires –

Partie 350: Construction générale et méthodes d'essai des câbles d'énergie,

de commande et d'instrumentation des navires et des unités mobiles et fixes

en mer

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 60092-350 ®

Edition 5.0 2020-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electrical installations in ships –

Part 350: General construction and test methods of power, control and

instrumentation cables for shipboard and offshore applications

Installations électriques à bord des navires –

Partie 350: Construction générale et méthodes d'essai des câbles d'énergie,

de commande et d'instrumentation des navires et des unités mobiles et fixes

en mer

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.060.20; 47.020.60 ISBN 978-2-8322-8152-9

– 2 – IEC 60092-350:2020 © IEC 2020

CONTENTS

FOREWORD . 7

1 Scope . 9

2 Normative references . 9

3 Terms and definitions . 11

3.31 tests . 15

4 Constructional requirements . 16

4.1 General requirements . 16

4.1.1 General . 16

4.1.2 Voltage designation . 16

4.1.3 Cable marking . 16

4.1.4 Core identification . 17

4.1.5 Halogen-free cables. 17

4.2 Conductors . 17

4.2.1 Material . 17

4.2.2 Metal coating and separator . 17

4.2.3 Class and form . 18

4.2.4 Resistance . 18

4.3 Insulation system . 19

4.3.1 Material . 19

4.3.2 Application . 19

4.3.3 Insulation thickness . 19

4.4 Screens . 19

4.4.1 Conductor and insulation screens for high-voltage cables . 19

4.4.2 Screens (shields) for low voltage cables . 20

4.5 Cabling . 20

4.5.1 Multi-core cables . 20

4.5.2 Multi-unit cables . 20

4.6 Inner coverings, fillers and binders . 21

4.7 Inner sheath . 21

4.7.1 Material . 21

4.7.2 Application . 21

4.7.3 Thickness of inner sheath . 21

4.8 Metal braid armour . 21

4.8.1 Material . 21

4.8.2 Application . 22

4.9 Outer sheath . 22

4.9.1 Material . 22

4.9.2 Application . 22

4.9.3 Thickness of outer sheath . 22

4.9.4 Calculation of lower and upper limits for the outer dimensions of cables . 23

5 Test methods . 23

5.1 Test conditions . 23

5.1.1 Ambient temperature . 23

5.1.2 Frequency, waveform and magnitude of power-frequency test voltages . 23

5.2 Routine tests. 23

5.2.1 General . 23

5.2.2 Measurement of the electrical resistance of the conductors . 23

5.2.3 Voltage test . 24

5.2.4 Partial discharge test . 25

6 Sample tests . 26

6.1 General . 26

6.2 Frequency of sample tests . 26

6.3 Repetition of tests . 26

6.4 Conductor examination . 26

6.5 Measurement of thickness of insulation . 27

6.5.1 General . 27

6.5.2 Procedure . 27

6.5.3 Requirements . 27

6.6 Measurements of thickness of non-metallic sheaths . 27

6.6.1 General . 27