IEC 60903:2014

(Main)Live working - Electrical insulating gloves

Live working - Electrical insulating gloves

IEC 60903:2014 is applicable to electrical insulating gloves and mitts that provide protection of the worker against electric shock. This standard also covers electrical insulating gloves with additional integrated mechanical protection referred to in this document as "composite gloves". This third edition cancels and replaces the second edition of IEC 60903, published in 2002. It constitutes a technical revision which includes the following major changes:

- clarification of the requirements and tests for long gloves;

- introduction of a new special property for gloves resistant to leakage current;

- removal of the requirement for an area to mark the date of inspection;

- the d.c. electric tests are no longer included in the normative part of the document but a proof test is suggested at the production level in a new informative Annex E;

- preparation of the elements of evaluation of defects, and general application of IEC 61318:2007;

- introduction of a new normative Annex H on classification of defects;

- and introduction of a new informative Annex I on the rationale for the classification of defects.

Travaux sous tension - Gants isolants électriques

L'IEC 60903:2014 est applicable aux gants isolants électriques et moufles qui fournissent aux travailleurs une protection contre le choc électrique. La présente norme est aussi applicable aux gants isolants électriques offrant une protection mécanique supplémentaire incorporée et qui sont désignés dans ce document par le terme "gants composites". Cette édition annule et remplace la deuxième édition publiée en 2002. Elle constitue une révision technique qui inclut les modifications majeures suivantes:

- la clarification des exigences et des essais pour les gants longs;

- l'introduction d'une nouvelle propriété spéciale pour les gants qui résistent au courant de fuite;

- le retrait de l'exigence pour une bande permettant l'inscription de la date de vérification;

- la disparition de la partie normative du document des essais électriques en courant continu, mais l'introduction d'une nouvelle Annexe E informative la préparation des éléments d'évaluation des défauts et de l'application générale de la IEC 61318:2007;

- l'introduction d'une nouvelle Annexe H normative traitant de la classification des défauts;

- et l'introduction d'une nouvelle Annexe I informative présentant le raisonnement ayant conduit à la classification des défauts.

General Information

- Status

- Published

- Publication Date

- 27-Jul-2014

- Technical Committee

- TC 78 - Live working

- Drafting Committee

- WG 13 - TC 78/WG 13

- Current Stage

- PPUB - Publication issued

- Start Date

- 28-Jul-2014

- Completion Date

- 31-Aug-2014

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60903:2014 is the international standard issued by the International Electrotechnical Commission (IEC) that specifies requirements for electrical insulating gloves and mitts used during live working to protect workers from electric shock. This third edition supersedes the 2002 version, offering a comprehensive technical revision to enhance safety standards and reflect new developments in glove technology.

The standard applies not only to traditional insulating gloves but also to composite gloves, which integrate additional mechanical protection. IEC 60903:2014 serves as an essential reference for manufacturers, safety professionals, and electrical workers involved in the use, testing, and certification of protective insulating gloves.

Key Topics

Scope and Classification

Covers gloves and mitts designed for live working to prevent electrical shock across various voltage levels. Classification includes different glove classes based on their dielectric performance and resistance properties.Physical and Mechanical Requirements

Specifies glove composition, dimensions, thickness limitations, workmanship quality, and finish. Special attention is given to mechanical resilience including abrasion resistance, cutting resistance, and tear resistance, primarily for composite gloves.Electrical Requirements and Testing

Details dielectric tests including type tests and production-level tests. Introduces a new special property category for gloves resistant to leakage current. The DC electrical tests moved to an informative annex, recommending proof testing during production.Marking and Packaging

Requirements for durable, clear markings including glove class, size, and special properties. Guidelines on packaging to ensure safe storage and transport are covered.Inspection and Defect Evaluation

Introduces a new normative annex on the classification of defects and an informative annex explaining the rationale behind these classifications. Emphasizes inspection prior to and during usage for ongoing safety.Special Properties

Includes acid resistance, oil resistance, ozone resistance, extremely low temperature resistance, and leakage current resistance, providing specifications for gloves designed to operate under specific environmental and chemical conditions.Annexes for Practical Guidance

Informative annexes offer recommendations for in-service use, storage, temperature considerations, and procedures for selecting glove class according to system voltage.

Applications

IEC 60903:2014 is crucial for industries where live electrical working is performed, such as:

- Power generation and distribution

- Electrical maintenance and repair services

- Utilities and telecommunications

- Industrial plants with high-voltage equipment

- Occupational safety and health programs targeting electrical hazards

By adhering to this standard, organizations ensure workers are protected with gloves that meet stringent electrical insulating requirements while also considering mechanical durability and environmental challenges.

Related Standards

- IEC 61318:2007 – for evaluation elements regarding electrical insulating gloves defects, referenced in IEC 60903 to enhance defect classification.

- IEC 60417-5216 – graphical symbol for gloves suitable for live working, used for marking conformity.

- ISO Standards on Personal Protective Equipment (PPE) – complementary standards covering gloves and broader PPE specifications.

- National Electrical Safety Codes – may reference IEC 60903 or include similar requirements structured around local regulations.

Summary

IEC 60903:2014 is the authoritative standard for electrical insulating gloves used in live working, addressing safety through comprehensive requirements on physical, electrical, and mechanical properties. It facilitates systematic testing, clear marking, and proper maintenance protocols to ensure high reliability and protection against electrical hazards. Compliance with IEC 60903:2014 supports safer work environments and aligns with international best practices in electrical safety equipment.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

NSF International

Global independent organization facilitating standards development and certification.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC 60903:2014 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Live working - Electrical insulating gloves". This standard covers: IEC 60903:2014 is applicable to electrical insulating gloves and mitts that provide protection of the worker against electric shock. This standard also covers electrical insulating gloves with additional integrated mechanical protection referred to in this document as "composite gloves". This third edition cancels and replaces the second edition of IEC 60903, published in 2002. It constitutes a technical revision which includes the following major changes: - clarification of the requirements and tests for long gloves; - introduction of a new special property for gloves resistant to leakage current; - removal of the requirement for an area to mark the date of inspection; - the d.c. electric tests are no longer included in the normative part of the document but a proof test is suggested at the production level in a new informative Annex E; - preparation of the elements of evaluation of defects, and general application of IEC 61318:2007; - introduction of a new normative Annex H on classification of defects; - and introduction of a new informative Annex I on the rationale for the classification of defects.

IEC 60903:2014 is applicable to electrical insulating gloves and mitts that provide protection of the worker against electric shock. This standard also covers electrical insulating gloves with additional integrated mechanical protection referred to in this document as "composite gloves". This third edition cancels and replaces the second edition of IEC 60903, published in 2002. It constitutes a technical revision which includes the following major changes: - clarification of the requirements and tests for long gloves; - introduction of a new special property for gloves resistant to leakage current; - removal of the requirement for an area to mark the date of inspection; - the d.c. electric tests are no longer included in the normative part of the document but a proof test is suggested at the production level in a new informative Annex E; - preparation of the elements of evaluation of defects, and general application of IEC 61318:2007; - introduction of a new normative Annex H on classification of defects; - and introduction of a new informative Annex I on the rationale for the classification of defects.

IEC 60903:2014 is classified under the following ICS (International Classification for Standards) categories: 13.260 - Protection against electric shock. Live working; 29.240.20 - Power transmission and distribution lines; 29.260.99 - Other electrical equipment for working in special conditions. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60903:2014 has the following relationships with other standards: It is inter standard links to IEC 60903:2002/COR1:2003, IEC 60903:2002, IEC 60903:2002/COR2:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60903:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60903 ®

Edition 3.0 2014-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Live working – Electrical insulating gloves

Travaux sous tension – Gants isolants électriques

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

14 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 55 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 60903 ®

Edition 3.0 2014-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Live working – Electrical insulating gloves

Travaux sous tension – Gants isolants électriques

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX XA

ICS 13.260; 29.240.20; 29.260.99 ISBN 978-2-8322-1781-8

– 2 – IEC 60903:2014 © IEC 2014

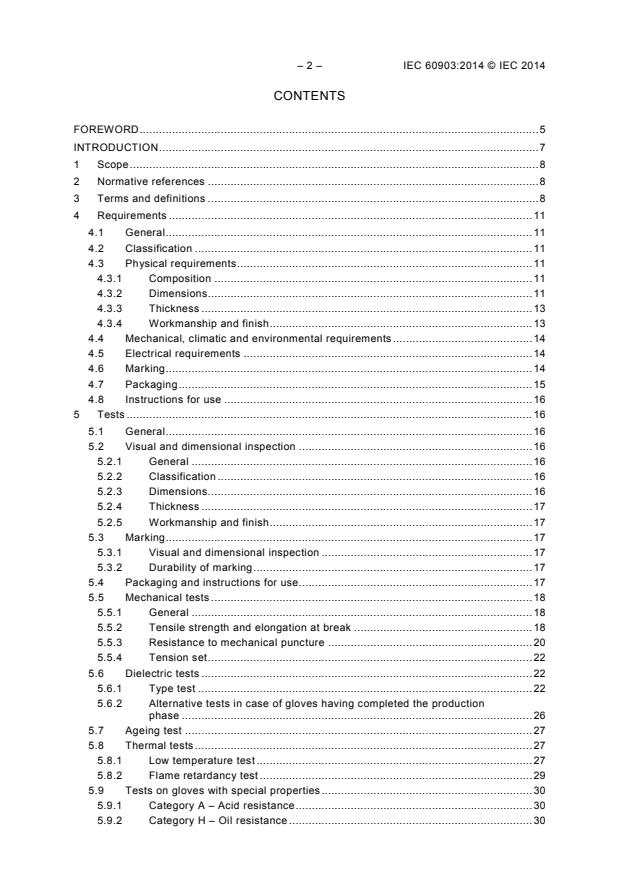

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 8

4 Requirements . 11

4.1 General . 11

4.2 Classification . 11

4.3 Physical requirements . 11

4.3.1 Composition . 11

4.3.2 Dimensions . 11

4.3.3 Thickness . 13

4.3.4 Workmanship and finish . 13

4.4 Mechanical, climatic and environmental requirements . 14

4.5 Electrical requirements . 14

4.6 Marking . 14

4.7 Packaging . 15

4.8 Instructions for use . 16

5 Tests . 16

5.1 General . 16

5.2 Visual and dimensional inspection . 16

5.2.1 General . 16

5.2.2 Classification . 16

5.2.3 Dimensions . 16

5.2.4 Thickness . 17

5.2.5 Workmanship and finish . 17

5.3 Marking . 17

5.3.1 Visual and dimensional inspection . 17

5.3.2 Durability of marking . 17

5.4 Packaging and instructions for use. 17

5.5 Mechanical tests . 18

5.5.1 General . 18

5.5.2 Tensile strength and elongation at break . 18

5.5.3 Resistance to mechanical puncture . 20

5.5.4 Tension set . 22

5.6 Dielectric tests . 22

5.6.1 Type test . 22

5.6.2 Alternative tests in case of gloves having completed the production

phase . 26

5.7 Ageing test . 27

5.8 Thermal tests . 27

5.8.1 Low temperature test . 27

5.8.2 Flame retardancy test . 29

5.9 Tests on gloves with special properties . 30

5.9.1 Category A – Acid resistance . 30

5.9.2 Category H – Oil resistance . 30

5.9.3 Category Z – Ozone resistance . 31

5.9.4 Category C – Extremely low temperature resistance . 31

5.9.5 Category F – Leakage current resistance. 31

5.10 Specific mechanical testing for composite gloves . 33

5.10.1 Abrasion resistance . 33

5.10.2 Cutting resistance . 35

5.10.3 Tear resistance . 38

6 Conformity assessment of gloves having completed the production phase . 40

7 Modifications . 40

Annex A (informative) In-service recommendations . 41

A.1 General . 41

A.2 Storage prior to issue and between use . 41

A.3 Examination before use . 41

A.4 Temperature . 41

A.5 Precautions in use . 41

A.6 Periodic inspection and electrical re-testing . 42

Annex B (normative) Suitable for live working; double triangle (IEC 60417-5216:2002-

10) . 44

Annex C (normative) Chronological order for type tests . 45

C.1 General . 45

C.2 Group size requirements . 48

C.2.1 Group 1 . 48

C.2.2 Group 2 . 48

C.2.3 Group 3 . 48

C.2.4 Group 4 – Additional tests for composite gloves . 48

C.2.5 Group 5 – Additional tests for gloves of category A . 48

C.2.6 Group 6 – Additional tests for gloves of category H . 49

C.2.7 Group 7 – Additional tests for gloves of category Z . 49

C.2.8 Group 8 – Additional tests for gloves of category F . 49

Annex D (informative) Guidelines for the selection of the class of glove in relation to

a.c. nominal voltage of a system . 50

Annex E (informative) Recommendations for d.c. electrical tests and voltage use . 51

E.1 General . 51

E.2 DC dielectric tests . 51

E.2.1 General . 51

E.2.2 Test equipment . 51

E.2.3 Voltage dielectric test procedure . 51

E.2.4 DC proof test . 51

E.3 Recommended maximum use voltage in d.c. installations . 52

Annex F (normative) Liquid for tests on gloves of category H – Oil resistance . 53

F.1 Particularities of liquid 102 . 53

F.2 Characteristics of oil no. 1 . 53

Annex G (informative) Cotton canvas additional characteristics . 54

Annex H (normative) Classification of defects and tests to be allocated . 56

Annex I (informative) Rationale for the classification of defects . 57

Bibliography . 58

Figure 1 – Contour of glove . 12

– 4 – IEC 60903:2014 © IEC 2014

Figure 2 – Illustration of the working area . 14

Figure 3 – Composite glove symbol – Hammer . 15

Figure 4 – Dumb-bell test piece for mechanical tests (plan view) . 19

Figure 5 – Test plates and needle for resistance to mechanical puncture . 21

Figure 6 – Test set up for the dielectric test on glove . 25

Figure 7 – Bend (fold) line for low and extremely low temperature test . 28

Figure 8 – Set-up for low and extremely low temperature folding tests . 28

Figure 9 – Set-up for the flame retardancy test . 30

Figure 10 – Test arrangement for leakage current resistance . 32

Figure 11 – Abrasion resistance tester . 34

Figure 12 – Apparatus for testing cutting resistance . 36

Figure 13 – Test piece direction and location for tear resistance . 39

Figure 14 – Shape of test piece for tear resistance . 39

Table 1 – Special properties . 11

Table 2 – Standard lengths of gloves . 12

Table 3 – Maximum thickness of the gloves . 13

Table 4 – Sampling plan . 19

Table 5 – Clearance from open part of the glove to water line . 24

Table 6 – Proof test and withstand test . 26

Table 7 – Clearance from open part of the gloves / long gloves to water line for

alternative routine proof test . 27

Table 8 – Test voltage for gloves of category F . 33

Table 9 – Presentation of test results on glove test piece. 38

Table A.1 – Distances between the cuff of the protector glove and the top of the cuff

of the glove . 42

Table C.1 – General type test procedure . 46

Table D.1 – Designation of maximum use a.c. voltage . 50

Table E.1 – Clearance from open part of the glove to water line . 51

Table E.2 – Proof test voltage . 52

Table E.3 – Designation of maximum use voltage . 52

Table F.1 – Characteristics of oil no. 1 . 53

Table G.1 – Identification sheet – Reference test piece – Cotton weave fabric . 55

Table H.1 – Classification of defects and associated requirements and tests . 56

Table I.1 – Justification for the type of defect . 57

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LIVE WORKING –

ELECTRICAL INSULATING GLOVES

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60903 has been prepared by IEC technical committee 78: Live

working.

This third edition cancels and replaces the second edition of IEC 60903, published in 2002. It

constitutes a technical revision.

The major changes are:

– clarification of the requirements and tests for long gloves;

– introduction of a new special property for gloves resistant to leakage current;

– removal of the requirement for an area to mark the date of inspection;

– for the thickness measurement, no other instrument than the micrometer with specified

parameters is allowed;

– the d.c. electric tests are no longer included in the normative part of the document but a

proof test is suggested at the production level where a d.c. use of gloves is expected, as

presented in a new informative Annex E;

– 6 – IEC 60903:2014 © IEC 2014

– preparation of the elements of evaluation of defects, and general application of

IEC 61318:2007;

– the normative Annex C on sampling plans and procedure has been deleted (not applicable

according to IEC 61318:2007);

– in the new normative Annex F, updating of the characteristics of the liquid specified for

tests on gloves of category H, according to the latest edition of ISO 1817;

– the informative Annex H on acceptance tests has been deleted (consideration now

included in IEC 61318:2007);

– introduction of a new normative Annex H on classification of defects;

– introduction of a new informative Annex I on the rationale for the classification of defects;

– review of the annex on in-service recommendations.

The text of this standard is based on the following documents:

FDIS Report on voting

78/1043/FDIS 78/1056/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

Terms defined in Clause 3 are given in italic print throughout this standard.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

INTRODUCTION

In this document, the clauses on requirements and testing are reorganized in order to bring

together the common requirements and tests, then to lay down separately those which are

specific to insulating gloves for electrical protection normally worn under leather protector

gloves as opposed to those specific to insulating gloves for combined electrical and

mechanical protection. This arrangement meets the basic necessity that a same quality level

of electrical insulation is achieved for all types of electrical insulating gloves.

This document has been prepared according to the requirements of IEC 61477 where

applicable.

The product covered by this standard may have an impact on the environment during some or

all stages of its life cycle. These impacts can range from slight to significant, be of short-term

or long-term, and occur at the global, regional or local level.

Except for a disposal statement in the Instructions for use, this standard does not include

requirements and test provisions for the manufacturers of the product, or recommendations to

the users of the product for environmental improvement. However, all parties intervening in its

design, manufacture, packaging, distribution, use, maintenance, repair, reuse, recovery and

disposal are invited to take account of environmental considerations.

– 8 – IEC 60903:2014 © IEC 2014

LIVE WORKING –

ELECTRICAL INSULATING GLOVES

1 Scope

This International Standard is applicable to electrical insulating gloves and mitts that provide

protection of the worker against electric shock.

Unless otherwise stated, the use of the term “glove” includes both gloves and mitts.

This standard also covers electrical insulating gloves with additional integrated mechanical

protection referred to in this document as “composite gloves”.

The products designed and manufactured according to this standard contribute to the safety

of the users provided they are used by skilled persons, in accordance with safe methods of

work and the instructions for use.

NOTE Insulating gloves are normally to be used in conjunction with leather protector gloves to provide

mechanical protection. Composite insulating gloves are normally used without over-gloves.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60060-1, High-voltage test techniques – Part 1: General definitions and test requirements

IEC 60060-2, High-voltage test techniques – Part 2: Measuring systems

IEC 60212, Standard conditions for use prior to and during the testing of solid electrical

insulating materials

IEC 60417, Graphical symbols for use on equipment

IEC 61318:2007, Live working – Conformity assessment applicable to tools, devices and

equipment

IEC 61477, Live working – Minimum requirements for the utilization of tools, devices and

equipment

ISO 23529, Rubber – General procedures for preparing and conditioning test pieces for

physical test methods

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 61318 as well as

the following apply.

3.1

bell cuff glove

glove with an enlarged shape from the wrist to the cuff in such a way as to facilitate pull-on

over a thick garment

3.2

composite glove

electrical insulating glove made with additional integrated mechanical protection of the glove

[SOURCE: IEC 60050-651:2014, 651-23-03 and IEC 60743:2013, 8.2.1, modified – The

definition clarifies that the mechanical protection is an additional one]

3.3

contour glove

glove shaped at the upper part of the gauntlet in such a way as to facilitate the bending of the

arm and intended for gloves that extend to or above the elbow

3.4

cuff

open part of a glove

3.5

cuff roll

roll or reinforced edge of a glove at the cuff

3.6

disruptive discharge

passage of an arc following dielectric breakdown

Note 1 to entry: The term “flashover” (in French “contournement”) is used when a disruptive discharge occurs at

least partly along the surface of a solid dielectric surrounded by a gaseous or liquid medium.

Note 2 to entry: The term “puncture” (in French “perforation”) is used when a disruptive discharge occurs through

a solid dielectric producing permanent damage.

[SOURCE: IEC 60050-604:1987, 604-03-38 modified – the content of the original note has

been reduced, modified to suit the application and presented in the form of two notes to entry]

3.7

elastomer

macromolecular material which returns rapidly to its initial dimensions and shape after

substantial deformation by a weak stress and release of the stress

Note 1 to entry: The definition applies under room temperature test conditions.

[SOURCE: ISO 472:2013, 2.327]

3.8

electrical insulating glove

glove made of elastomer, used for the protection of the worker against electric shock

[SOURCE: IEC 60050-651:2014, 651-23-02 and IEC 60743:2013, 8.1.3, modified – The

definition is in line with the composition requirements of the standard for the type of insulating

material. The note 1 to entry has been deleted]

3.9

fork

part of glove at the junction of two fingers, or finger and thumb

– 10 – IEC 60903:2014 © IEC 2014

3.10

formally trained and qualified person

competent person possessing the appropriate practical and theoretical knowledge and having

adequate skill and experience to enable the person to perform the required periodic testing,

interpret the resultant information and from that information determine that the electrical

insulating glove is safe to use, and report the importance of any defect found or suspected in

relation to the safety and continued use of the electrical insulating glove

3.11

gauntlet

part of a glove from the wrist to the open part of the glove

3.12

lined glove

glove with an inside lining of textile attached to the elastomer

3.13

long glove

electrical insulating glove used to extend the protection to the upper arm

Note 1 to entry: The length of the glove does not include protection up to the armpit.

[SOURCE: IEC 60743:2013, 8.1.5, modified – The whole document is about insulating glove

protecting against electric shock so that does not need to be repeated in the term and its

definition. The note 1 to entry has been added to clarify the type of protection offered]

3.14

mitt

glove with multiple fingers enclosed in one covering

3.15

nominal voltage of a system

suitable approximate value of voltage used to designate or identify a system

[SOURCE: IEC 60050-601:1985, 601-01-21]

3.16

palm

part of glove covering the face of the central inside hand

3.17

proof test voltage

specified voltage that is applied to a glove for the time defined under specified conditions to

assure that the electrical strength of the insulation is above a specified value

3.18

withstand test voltage

voltage that the glove withstands without disruptive discharge when voltage is applied under

specified conditions

3.19

wrist

narrowest part of the glove between the cuff and the hand

4 Requirements

4.1 General

The following requirements have been prepared in order that the products covered by this

standard are designed and manufactured to contribute to the safety of the users, provided

they are used by persons skilled for live working, in accordance with safe method of work and

the instructions for use.

4.2 Classification

The gloves covered by this standard shall be designated as follows:

– by class, as class 00, class 0, class 1, class 2, class 3 and class 4;

– by special properties, by the addition of a suffix to the class of the glove as shown in

Table 1.

Guidance as to temperature range at which gloves can be used is given in Annex A.

Table 1 – Special properties

Category Resistant to

A Acid

H Oil

Z Ozone

R Acid, oil, ozone

C Extremely low temperature

F Leakage current

NOTE 1 Category R combines the characteristics of categories A, H and Z.

NOTE 2 Category F is for long gloves only.

NOTE 3 Any combination of categories may be used.

4.3 Physical requirements

4.3.1 Composition

All gloves may be lined or unlined. They may have an exterior covering and may be specially

compounded to reduce the effects of chemical attack. If gloves have an exterior covering, it

shall be of a contrasting colour to assist in visual inspection.

Gloves are made of elastomer.

Gloves may be manufactured with or without cuff roll.

4.3.2 Dimensions

Gloves shall be of the length specified in Table 2.

– 12 – IEC 60903:2014 © IEC 2014

Table 2 – Standard lengths of gloves

Standard length

Class

b

mm

a

00 280 360 – – 800

a

0 280 360 410 460 800

a

1 – 360 410 460 800

a

2 – 360 410 460 800

a

3 – 360 410 460 800

a

4 – – 410 460 800

a

Long gloves.

b

The tolerance in length shall be ±15 mm for any class, except for long gloves where tolerance shall be

±20 mm.

For contour-cuff gloves, the difference between the maximum and minimum lengths (see

Figure 1) shall be 50 mm ± 6 mm except for long gloves where this difference shall be

100 mm ± 12 mm.

NOTE 1 There are different shapes of gloves on the market including bell cuff gloves, contour gloves and

gauntlets.

IEC

a) Side view

IEC

b) Flat view

Key

L

maximum length

max

L minimum length

min

C

contour shall be 50 mm ± 6 mm

Figure 1 – Contour of glove

Palm circumferences shall be defined as follows:

178 mm (size 7), 191 mm (size 7.5), 203 mm (size 8), 216 mm (size 8.5), 229 mm (size 9),

241 mm (size 9.5), 254 mm (size 10), 267 mm (size 10.5), 279 mm (size 11), 292 mm

(size 11.5) and 305 mm (size 12).

The tolerance in size shall be ± 13 mm.

NOTE 2 Additional sizes may be available following agreement between manufacturer and client.

4.3.3 Thickness

The minimum thickness shall be determined only by the ability to pass the dielectric tests

defined in 5.6.

The maximum thickness on the flat surface of a glove (no ribbed area if present) shall be as

given in Table 3 in order to obtain the appropriate flexibility.

Table 3 – Maximum thickness of the gloves

Thickness

mm

Class

Gloves Composite gloves

00 0,50 1,8

0 1,00 2,3

1 1,50 2,8

2 2,30 3,3

3 2,90 3,6

4 3,60 4,2

Long gloves may require additional thickness which shall not exceed 0,6 mm.

Gloves of categories A, H, Z and R may require additional thickness which shall not exceed

0,6 mm.

4.3.4 Workmanship and finish

Gloves shall be free on both inner and outer surfaces from harmful physical irregularities that

can be detected by thorough test and inspection.

Harmful physical irregularities shall be defined as any feature that disrupts the uniform,

smooth surface contour, such as pinholes, cracks, blisters, cuts, conductive embedded

foreign matter, creases, pinch marks, voids (entrapped air), prominent ripples and prominent

mould marks.

Non-harmful physical irregularities shall be defined as surface irregularities present on the

inner and outer surfaces of the glove due to imperfections on molds and inherent difficulties in

the manufacturing process. These irregularities may appear as mould marks that look like

cuts even though they are actually a raised ridge of material, indentations, protuberances,

embedded foreign matter, or colour splashes that are acceptable provided that:

a) the indentations, protuberance or mould marks tend to blend into a smooth slope upon

stretching of the material;

b) foreign material remains in place when the glove is folded and stretched with the material

surrounding it;

– 14 – IEC 60903:2014 © IEC 2014

c) colour splashes are no larger than 1 mm in any direction on the inner surface of the

working area.

The working area is defined as all finger and thumb forks, the palm and the palm side of the

fingers and thumb (see Figure 2).

Palm and finger surfaces designed to improve the grip shall not be considered as

irregularities.

IEC

Key

A working area (shaded)

Figure 2 – Illustration of the working area

4.4 Mechanical, climatic and environmental requirements

Gloves shall withstand the mechanical, climatic and environmental stresses specified in this

standard.

Gloves with one or more special categories (see Table 1) shall support any related stresses.

4.5 Electrical requirements

Gloves shall be capable of withstanding the corresponding electrical stresses according to its

electrical class.

4.6 Marking

Each glove which is claimed to comply with the requirements of this standard shall bear a

label and/or marking giving the following information:

– symbol IEC 60417-5216:2002-10 – Suitable for live working; double triangle (see

Annex B);

NOTE The exact ratio of the height of the figure to the base of the triangle is 1,43. For the purpose of

convenience, this ratio can be between the values of 1,4 and 1,5.

– number of the relevant IEC standard immediately adjacent to the symbol (IEC 60903);

– name, trademark or identification of the manufacturer;

– category, if applicable;

– size;

– class;

– month and year of manufacture.

Composite gloves shall also be identified with a mechanical symbol (hammer), adjacent to the

double triangle (see Figure 3). The length of the hammer (x) shall be equal to the length of

one side of the triangles.

IEC

Figure 3 – Composite glove symbol – Hammer

Marking and/or label shall be adjacent to the cuff but not closer than 2,5 mm except for long

gloves for which it shall be not less than 300 mm from the cuff in order to allow users to cut

the glove at the required length.

Marking shall be on the external surface of the glove and shall be clearly visible and legible to

a person with normal or corrected vision without additional magnification.

The marking or label shall not impair the quality of the glove. It shall be durable and shall

remain visible after being subjected to a durability test (see 5.3.2).

Any additional marking or label shall be subject to agreement between the manufacturer and

the customer.

When a colour code for symbols is used, it shall correspond to the following:

class 00 – beige;

class 0 – red;

class 1 – white;

class 2 – yellow;

class 3 – green;

class 4 – orange.

4.7 Packaging

Each pair of gloves shall be packaged in an individual container or package of sufficient

strength to so far as is reasonably practicable, properly protect the gloves from damage when

transported, handled and stored in accordance with the manufacturers instructions. The

– 16 – IEC 60903:2014 © IEC 2014

outside of the container or package shall be marked with the name of the manufacturer or

supplier, the classification, category, size, length and cuff design.

The type of packaging suitable for transport shall be defined by the manufacturer.

4.8 Instructions for use

The manufacturer shall provide written instructions for use with each packaging of gloves

covered by this standard.

The instructions for use shall include information on storage, handling, disposal, periodic

inspection, periodic testing and reference to the standard with its date of publication.

Additional information may be provided.

These instructions shall be prepared in accordance with the general provisions of IEC 61477.

5 Tests

5.1 General

The present standard provides testing provisions to demonstrate compliance of the product to

the requirements of Clause 4. These testing provisions are primarily intended to be used as

type test for validation of the design input. Where relevant, alternative means (calculation,

examination, tests, etc.), are specified within the test subclauses for the purpose of gloves

having completed the production phase.

The allocation of the gloves into various testing groups, the quantity required and the order in

which the type tests are carried out are given in Annex C.

Gloves shall pass all type tests.

Gloves which have been subjected to type tests shall not be reused.

Unless otherwise specified, gloves for type test shall be preconditioned for a period of

2 h ± 0,5 h at a temperature of 23 °C ± 2 °C and 50 % ± 5 % relative humidity.

Where relevant, testing equipments shall comply with IEC 60060-1. Measuring systems shall

comply with IEC 60060-2 unless otherwise specified.

NOTE It is essential that the tests are done by a competent test facility.

5.2 Visual and dimens

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...