IEC 61318:2021

(Main)Live working - Methods for assessment of defects and verification of performance applicable to tools, devices and equipment

Live working - Methods for assessment of defects and verification of performance applicable to tools, devices and equipment

IEC 61318:2021 This document defines methods to assess defects and to verify that products after the manufacturer process meet the requirements of the corresponding product standard.

The principles of assessment of defects for live working products are detailed in this document to assist product standard developers in prescribing the best means to achieve suitable quality of every finished tool, device and piece of equipment.

The following elements are not covered by the present document, but are included in each product standard:

– type tests;

– provisions and description for routine, sampling and acceptance tests;

– identification and classification of defects;

– risk analysis.

This document does not cover conformity assessment of commercial shipments or certifications.

This fourth edition cancels and replaces the third edition published in 2007. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

a) change of the purpose of the document from a prescriptive testing standard to a standard assisting the project team in the conformance to respective product standard.

b) introduction of conformance test, record of process, quality control documentation, adapted to the standard product.

c) change of prescribed sampling procedure to adapted sampling tests to the product standard.

d) suppression of the term “conformity assessment”.

e) Introduction of the term “verification method” replacing “conformity assessment application”.

Travaux sous tension - Méthodes d'évaluation des défauts et vérification des performances applicables aux outils, dispositifs et équipement

IEC 61318:2021 Le présent document définit des méthodes d’évaluation des défauts et comment vérifier que des produits satisfont aux exigences de la norme de produit correspondante, après le processus de fabrication.

Les principes d'évaluation des défauts des produits pour travaux sous tension sont détaillés dans le présent document afin d'aider les développeurs de normes de produit à prescrire les meilleurs moyens pour obtenir une qualité adaptée de chaque outil, dispositif et équipement fini.

Les éléments suivants ne sont pas couverts par le présent document, mais sont inclus dans chaque norme de produit:

- essais de type;

- dispositions et description des essais individuels de série, des essais sur prélèvement et des essais de réception;

- identification et classification des défauts;

- analyse du risque.

Le présent document ne couvre pas l'évaluation de la conformité des livraisons commerciales ou des certifications.

Cette quatrième édition annule et remplace la troisième édition parue en 2007. Cette édition constitue une révision technique.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) modification de l'objet du présent document qui, de norme d'essai prescriptive, devient une norme destinée à aider les équipes de projets à atteindre la conformité à chaque norme de produit;

b) introduction d'un essai de conformité, d'un enregistrement de processus, d'une documentation de contrôle de la qualité, adaptés à la norme de produit;

c) modification de la procédure d'échantillonnage prescrite qui est remplacée par des essais sur prélèvement adaptés à la norme de produit;

d) suppression du terme “évaluation de la conformité”;

e) introduction du terme “méthode de vérification” pour remplacer “application de l'évaluation de la conformité”.

General Information

- Status

- Published

- Publication Date

- 28-Jun-2021

- Technical Committee

- TC 78 - Live working

- Drafting Committee

- MT 61318 - TC 78/MT 61318

- Current Stage

- PPUB - Publication issued

- Start Date

- 29-Jun-2021

- Completion Date

- 16-Jul-2021

Relations

- Revises

IEC 61318:2007 - Live working - Conformity assessment applicable to tools, devices and equipment - Effective Date

- 05-Sep-2023

Overview

IEC 61318:2021 is an international standard published by the International Electrotechnical Commission (IEC) that provides methods for assessment of defects and verification of performance for tools, devices, and equipment used in live working. The standard is designed to assist manufacturers and product standard developers in ensuring that products meet the quality and safety requirements outlined in their respective product standards.

The 2021 edition, the fourth revision of this standard and a technical update from the 2007 edition, shifts from a prescriptive testing standard to a framework supporting conformance verification tailored to individual product standards. It replaces previous terminology such as “conformity assessment” with “verification methods” to better reflect modern quality control practices.

Key Topics

Scope: IEC 61318:2021 defines procedures for defect assessment and performance verification after manufacturing processes to confirm compliance with corresponding product standards. It excludes conformity assessments of shipment or certification processes.

Defect assessment: The standard categorizes defects as:

- Critical defects – likely to cause hazardous or unsafe conditions.

- Major defects – likely to cause failure or significant reduction in functionality.

- Minor defects – unlikely to significantly impact product functionality.

Testing methods: It covers different types of tests including:

- Type tests – on representative samples to verify design.

- Routine tests – on each product unit during or post-manufacture.

- Sampling tests – tests on samples taken from production lots.

- Acceptance tests – contractual checks to ensure the product meets specific requirements.

Verification methods: The standard guides how to collect objective evidence to confirm that all specified requirements are fulfilled, through processes customized for the standard product.

Process documentation: Emphasis is placed on maintaining records of manufacturing processes and quality control documentation to support verification activities.

Exclusions: Specific product standards will handle:

- Risk analysis,

- Identification and classification of defects,

- Provisions for routine, sampling, and acceptance tests.

Applications

IEC 61318:2021 is applicable primarily to the live working sector, where tools, devices, and equipment are used in electrical environments that remain energized. The standard is vital for:

- Manufacturers ensuring their products are defect-free and meet stringent quality requirements before release.

- Product standard developers leveraging IEC 61318’s principles to define defect classifications and test methods specific to their product types.

- Quality assurance teams implementing verification methods aligned with international best practices.

- Safety auditors and inspectors reviewing test records and verification reports to validate compliance with electrical safety standards.

By adopting IEC 61318:2021, stakeholders can significantly reduce risks associated with live working, including electric shock and equipment failure, thereby improving overall workplace safety and reliability.

Related Standards

IEC 61318:2021 interacts with and complements several other standards in the live working and electrotechnical domains, including but not limited to:

- Specific product standards for live working tools, such as insulating gloves, live line tools, and hot sticks, which may define detailed type tests and classification criteria.

- IEC 60050 series - International Electrotechnical Vocabulary (IEV), which provides terms and definitions related to defects and testing.

- ISO/IEC Guide 51:2014 - offering guidance on risk analysis and safety principles related to hazard identification in electrotechnical products.

- IEC 61318 predecessors (e.g., the 2007 edition) for historical context and evolution of verification practices.

- National and regional certification standards where manufacturers may additionally seek compliance validation.

Implementing IEC 61318:2021 empowers manufacturers and stakeholders to establish rigorous quality control systems focused on defect management and performance verification. This international standard enhances product safety in live working environments, supporting global harmonization of testing and quality assurance processes.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

NSF International

Global independent organization facilitating standards development and certification.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC 61318:2021 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Live working - Methods for assessment of defects and verification of performance applicable to tools, devices and equipment". This standard covers: IEC 61318:2021 This document defines methods to assess defects and to verify that products after the manufacturer process meet the requirements of the corresponding product standard. The principles of assessment of defects for live working products are detailed in this document to assist product standard developers in prescribing the best means to achieve suitable quality of every finished tool, device and piece of equipment. The following elements are not covered by the present document, but are included in each product standard: – type tests; – provisions and description for routine, sampling and acceptance tests; – identification and classification of defects; – risk analysis. This document does not cover conformity assessment of commercial shipments or certifications. This fourth edition cancels and replaces the third edition published in 2007. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) change of the purpose of the document from a prescriptive testing standard to a standard assisting the project team in the conformance to respective product standard. b) introduction of conformance test, record of process, quality control documentation, adapted to the standard product. c) change of prescribed sampling procedure to adapted sampling tests to the product standard. d) suppression of the term “conformity assessment”. e) Introduction of the term “verification method” replacing “conformity assessment application”.

IEC 61318:2021 This document defines methods to assess defects and to verify that products after the manufacturer process meet the requirements of the corresponding product standard. The principles of assessment of defects for live working products are detailed in this document to assist product standard developers in prescribing the best means to achieve suitable quality of every finished tool, device and piece of equipment. The following elements are not covered by the present document, but are included in each product standard: – type tests; – provisions and description for routine, sampling and acceptance tests; – identification and classification of defects; – risk analysis. This document does not cover conformity assessment of commercial shipments or certifications. This fourth edition cancels and replaces the third edition published in 2007. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) change of the purpose of the document from a prescriptive testing standard to a standard assisting the project team in the conformance to respective product standard. b) introduction of conformance test, record of process, quality control documentation, adapted to the standard product. c) change of prescribed sampling procedure to adapted sampling tests to the product standard. d) suppression of the term “conformity assessment”. e) Introduction of the term “verification method” replacing “conformity assessment application”.

IEC 61318:2021 is classified under the following ICS (International Classification for Standards) categories: 13.260 - Protection against electric shock. Live working; 29.240.20 - Power transmission and distribution lines; 29.260.99 - Other electrical equipment for working in special conditions. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61318:2021 has the following relationships with other standards: It is inter standard links to IEC 61318:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61318:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61318 ®

Edition 4.0 2021-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Live working – Methods for assessment of defects and verification of

performance applicable to tools, devices and equipment

Travaux sous tension – Méthodes d'évaluation des défauts et vérification des

performances applicables aux outils, dispositifs et équipement

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC online collection - oc.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur adapté à vos besoins.

les projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au

Restez informé sur les nouvelles publications IEC. Just

monde, avec plus de 22 000 articles terminologiques en

Published détaille les nouvelles publications parues.

anglais et en français, ainsi que les termes équivalents dans

Disponible en ligne et une fois par mois par email.

16 langues additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 61318 ®

Edition 4.0 2021-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Live working – Methods for assessment of defects and verification of

performance applicable to tools, devices and equipment

Travaux sous tension – Méthodes d'évaluation des défauts et vérification des

performances applicables aux outils, dispositifs et équipement

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 13.260; 29.240.20; 29.260.99 ISBN 978-2-8322-9907-4

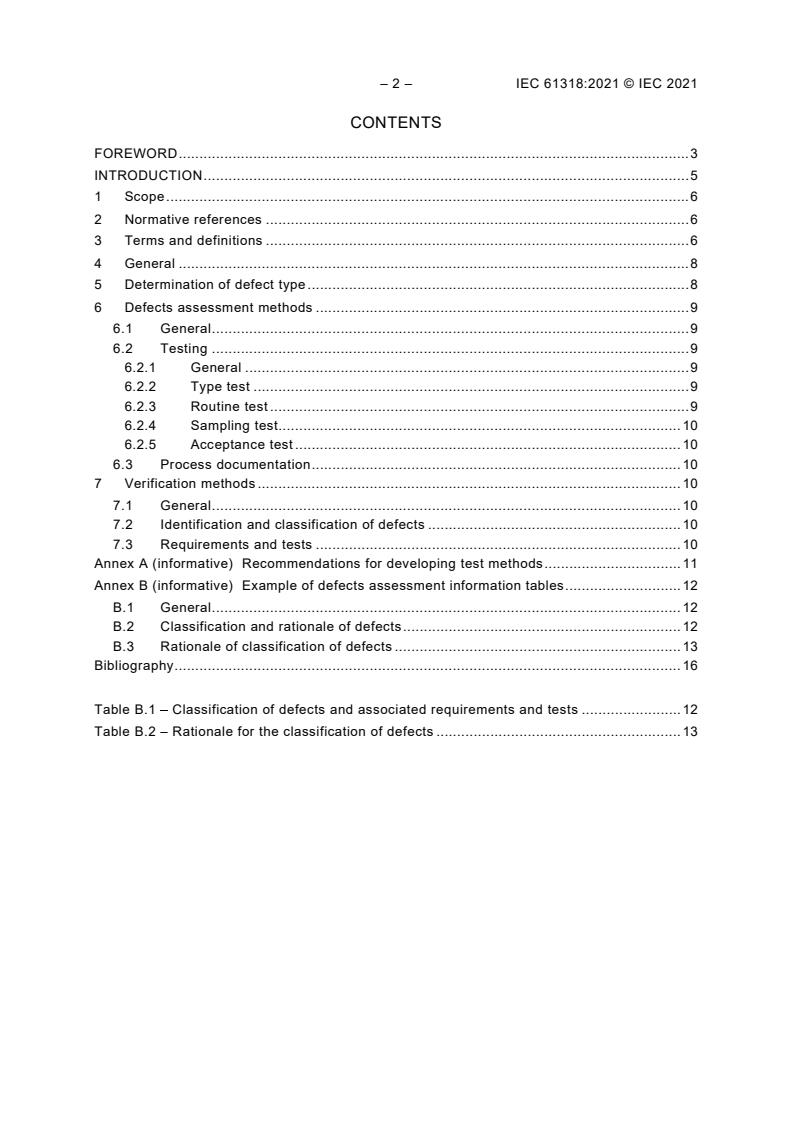

– 2 – IEC 61318:2021 © IEC 2021

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 General . 8

5 Determination of defect type . 8

6 Defects assessment methods . 9

6.1 General . 9

6.2 Testing . 9

6.2.1 General . 9

6.2.2 Type test . 9

6.2.3 Routine test . 9

6.2.4 Sampling test. 10

6.2.5 Acceptance test . 10

6.3 Process documentation . 10

7 Verification methods . 10

7.1 General . 10

7.2 Identification and classification of defects . 10

7.3 Requirements and tests . 10

Annex A (informative) Recommendations for developing test methods . 11

Annex B (informative) Example of defects assessment information tables . 12

B.1 General . 12

B.2 Classification and rationale of defects . 12

B.3 Rationale of classification of defects . 13

Bibliography . 16

Table B.1 – Classification of defects and associated requirements and tests . 12

Table B.2 – Rationale for the classification of defects . 13

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LIVE WORKING –

METHODS FOR ASSESSMENT OF DEFECTS AND

VERIFICATION OF PERFORMANCE APPLICABLE

TO TOOLS, DEVICES AND EQUIPMENT

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61318 has been prepared by IEC technical committee 78: Live

working.

This fourth edition cancels and replaces the third edition published in 2007. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) change of the purpose of the document from a prescriptive testing standard to a standard

assisting the project team in the conformance to respective product standard;

b) introduction of conformance test, record of process, quality control documentation,

adapted to the standard product;

c) change of prescribed sampling procedure to adapted sampling tests to the product

standard;

– 4 – IEC 61318:2021 © IEC 2021

d) suppression of the term “conformity assessment”;

e) Introduction of the term “verification method” replacing “conformity assessment

application”.

The text of this International Standard is based on the following documents:

FDIS Report on voting

78/1339/FDIS 78/1353/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement,

available at www.iec.ch/members_experts/refdocs. The main document types developed by

IEC are described in greater detail at www.iec.ch/standardsdev/publications.

In this document, the following characters are used:

– requirements: roman characters;

– terms defined in Clause 3: italics.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

INTRODUCTION

This document is applied by each IEC Live Working product standard for the purpose of

assessing whether or not each product meets the requirements of the relevant product

standard.

– 6 – IEC 61318:2021 © IEC 2021

LIVE WORKING –

METHODS FOR ASSESSMENT OF DEFECTS AND

VERIFICATION OF PERFORMANCE APPLICABLE

TO TOOLS, DEVICES AND EQUIPMENT

1 Scope

This document defines methods to assess defects and to verify that products after the

manufacturer process meet the requirements of the corresponding product standard.

The principles of assessment of defects for live working products are detailed in this

document to assist product standard developers in prescribing the best means to achieve

suitable quality of every finished tool, device and piece of equipment.

The following elements are not covered by the present document, but are included in each

product standard:

– type tests;

– provisions and description for routine, sampling and acceptance tests;

– identification and classification of defects;

– risk analysis.

This document does not cover conformity assessment of commercial shipments or

certifications.

2 Normative references

There are no normative referenced documents.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

acceptance test

contractual test to prove to the customer that the item meets certain conditions of its

specification

[SOURCE: IEC 60050-151:2001, 151-16-23, modified – The main term "hand-over test" has

been deleted.]

3.2

critical defect

any defect where judgement and experience indicate that it is likely to result in hazardous or

unsafe conditions for individuals using or depending on the product

3.3

harm

physical injury or damage to the health of people, or damage to property or the environment

[SOURCE: ISO IEC Guide 51:2014, 3.1, modified – Addition of "physical".]

3.4

hazard

potential source of harm

Note 1 to entry: The term hazard can be qualified in order to define its origin or the nature of the expected harm

(e.g. electric shock hazard, electric arc hazard, crushing hazard, cutting hazard, toxic hazard, fire hazard, drowning

hazard).

[SOURCE ISO IEC Guide 51:2014, 3.2, modified – Addition of Note 1 to entry.]

3.5

major defect

defect of product, other than critical, that is likely to result in failure, or to reduce significantly

the functionality of the product

3.6

minor defect

defect of product that is not likely to reduce significantly the functionality of the product

3.7

non-conformance

non-fulfilment of a requirement

[SOURCE: ISO 16426:2002, 3.15]

3.8

risk

combination of the probability of occurrence of harm and the severity of that harm

[SOURCE: ISO IEC Guide 51:2014, 3.9, modified – The note 1 to entry was deleted.]

3.9

risk analysis

systematic use of available information to identify hazards and to estimate the risk

[SOURCE: ISO IEC Guide 51:2014, 3.10]

3.10

routine test

test made on each individual item during or after manufacture

[SOURCE: IEC 60050-151:2001, 151-16-17, modified – the term “conformity” was deleted]

– 8 – IEC 61318:2021 © IEC 2021

3.11

sampling plan

combination of sample size(s) to be used and associated lot acceptability criteria

[SOURCE: ISO 2859-1:1999, 3.1.17, modified – Deletion of the notes.]

3.12

sampling test

test on a sample

[SOURCE: IEC 60050-151:2001, 151-16-20]

3.13

type test

test made on one or more items representative of the production

[SOURCE: IEC 60050-151:2001, 151-16-16, modified – the term “conformity”]

3.14

verification

confirmation, through the provision of objective evidence, that specified requirements have

been fulfilled

Note 1 to entry: The term “verified” is used to designate the corresponding status.

Note 2 to entry: Design verification is the application of tests and evaluation to assess that the design meets the

specified requirements.

[SOURCE: ISO 9000:2015, 3.8.12, modified – The Notes to entry have been modified.]

4 General

Principle methods for assessment and verification for live working products are detailed in this

document to assist product standard developers in prescribing the best means to demonstrate

that every finished tool, device and piece of equipment meet the standard requirements.

Non-conformance to product standards may results in defects. Product defects are

categorized into three levels; critical, major and minor defects as defined in Clause 3.

Assessment and verification involve tests, records of processes, sampling plans and quality

control documentation. The required records are determined through risk analysis,

classification of defects and corresponding methods of preventing these defects.

Assessment and verification records shall be kept by the manufacturer for at least five years

and in accordance with national or regional regulations.

5 Determination of defect type

In the application of this document, every significant defect shall be determined and then

classified according to type.

In order to determine the type of defects applicable to each product, it is necessary to

understand the intended functionality. The properties required in the finish product relate to

the application of the product. Where these properties are deficient, the resulting lack of

functionality will have an impact which shall be evaluated.

Critical defects on tools, devices and equipment for live working are not acceptable. Major

defects of tools, devices and equipment for live working are likely to result in failure or in a

significant reduction of functionality, while minor defects do not reduce significantly the

functionality.

The evaluation of impact due to functional or other defects involves a risk analysis. The

ISO/IEC Guide 51 provides a framework for performing risk analysis.

6 Defects assessment methods

6.1 General

The main methods used in product manufacturing to prevent defects and ensure that standard

requirements are met are testing, process documentation and quality assessment. A guide to

developing general test methods (such as alternative test methods) is provided in Annex A.

6.2 Testing

6.2.1 General

Four categories of tests are included within live working product standards:

– type test;

– routine test;

– sampling test;

– acceptance test.

6.2.2 Type test

Type tests are performed on a relatively small number of items which are to be typical of all

products. Tests performed on these few are to determine basic design and functional

capabilities to their mechanical or electrical limits. Significant damage to the test object is

probable.

Type tests often involve rigorous laboratory tests requiring specialized equipment. Products

manufactured to the same specifications and using the same materials are expected to

perform and have the same characteristics as those used in type tests.

While type tests provide design verification, they are not usually suitable to be performed

continuously on production units. To verify some or all of the significant characteristics and

functionality, it may be useful to develop other practicable test methods which could be

applied to a wider number of items.

6.2.3 Routine test

Routine tests demonstrate performance and functionality according to specified levels and are

conducted on each manufactured product. While verifying a level of conformance to standard

requirements, these tests should not degrade or negatively impact the product.

Whenever the standard developer determines routine tests to be necessary those routine

tests should be used to determine critical defects.

– 10 – IEC 61318:2021 © IEC 2021

6.2.4 Sampling test

Sampling tests are performed on either component parts of a product or finished items. These

involve only a prescribed amount or number of items and may involve testing of performance

to any level including destruction. Sampling plan parameters are determined statistically and

shall be followed precisely to yield meaningful results. ISO 2859-1:1999 provides rules to

follow in regard to determine sampling plans for these tests. The adequate acceptable quality

level (AQL) is determined according the risk analysis.

6.2.5 Acceptance test

An acceptance test is a contractual test to prove to the customer that the product meets the

customer’s specification. These tests are performed on a predetermined number of items in

the complete batch of ordered units and are of varying severity.

Acceptance tests may be destructive or potentially damage the product. In this case, the

disposition of the tested products should be considered. The product should be re-built or

destroyed to ensure that worker safety is not jeopardized from use of a damaged product.

6.3 Process documentation

Process documentation is a means of ensuring that all products are manufactured in a

traceable and consistent fashion. In this way, each item produced most exactly replicates

those used in type testing. Where production processes and materials are verified, function

and performance characteristics may be inferred in the finished product.

7 Verification methods

7.1 General

Verification methods involve the systematic means of identifying and preventing possible

product defects and ensuring that manufactured products meet the requirements of the

associated product standard.

Following a risk analysis, information pertaining to verification method including a rationale of

the defects (critical, major and minor) shall be provided in normative annexes of each product

standard. This information is best presented in tables where each defect is identified and

classified along with the required tests and relevant subclauses. An example presentation of

defects assessment information requirements for IEC 61481-2:2014 is presented in Annex B.

7.2 Identification and classification of defects

The classification of possible defects shall be based on a risk analysis, considering:

– the severity of the harm;

– and the probability of occurrence of the harm.

7.3 Requirements and tests

Each live working product standard provides appropriate means for ensuring that all

significant features of the product are measurable and verifiable. These include tests,

documentation, processes and other requirements detailed in each product standard.

For each defect identified, an explanation or appropriate clause or subclause of the product

standard shall be identified as shown in Table B.1 and Table B.2.

Annex A

(informative)

Recommendations for developing test methods

The development of test methods should consider the elements of risk analysis of possible

product defects provided by the product standard. These include:

– description of the requirements the product has to meet;

– determination of the classification of defects (critical, major, minor);

– determination of relevant means (test, inspection, calculation, etc.) of addressing

requirements based on the classification of defects.

Test methods developed should provide consistent results and ensure the reproducibility of

the results within specified tolerances.

Non-destructive test methods or other means should be chosen whenever they can replace

destructive test methods while providing the same level of quality.

Test methods typically describe the following:

– functional characteristic to be tested;

– reagent and/or material;

– apparatus, test set-up, measurement instrument;

– preparation, preconditioning and preservation of test pieces;

– procedure;

– expression of results;

– method of calculation and precision of the test method;

– measurement uncertainty.

– 12 – IEC 61318:2021 © IEC 2021

Annex B

(informative)

Example of defects assessment information tables

B.1 General

These examples taken from IEC 61481-2:2014 are provided to demonstrate the proper form of

presentation of defects assessment information required for each product standard.

Types of defects for phase comparators are identified, classified (critical, major or minor) and

associated with the appropriate subclause where the requirements and tests are described.

B.2 Classification and rationale of defects

Table B.1 is derived from Table D.1 of IEC 61481-2:2014.

Table B.1 – Classification of defects and associated requirements and tests

Requirements of IEC 61481-2:2014 Type of defects Test of

IEC 61481-

Critical Major Minor

2:2014

4.4.3 Minimum length of the insulating element for a X 5.4.1.2

phase comparator as a complete device

4.5 Correctness of the marking of the phase X 5.4.1.1

comparator

4.3.5.2 Leakage current along the insulating element of X 5.3.5.2

a phase comparator as a complete device

4.2.1 Clear indication of the status of the phase X 5.2.2

relationship

b

4.2.1.3 Effect of interference fields (continuous X

indication)

Protection against bridging for indoor/outdoor

4.3.2 X 5.3.2

type phase comparator

a

Protection against bridging for outdoor type X

5.3.3

phase comparator

4.3.3 Spark resistance X 5.3.4.3

4.2.5 Response time for phase comparators with one X

active signal

5.2.7.2

Response time for phase comparators with two X

active signals

4.2.4 Frequency dependence X 5.2.6.2

4.2.3 Temperature and humidity dependence of the X 5.4.7.2

indication

4.2.2 Clear perceptibility: only visual X 5.2.5.1.2

Clear perceptibility: visual and audible X 5.2.5.2.2

4.4.5 Vibration resistance X 5.4.4.2

4.4.6 Drop resistance X 5.4.5.2

4.4.7 Shock resistance X 5.4.6.2

4.2.7 Functioning of the testing element X 5.2.9.2

4.2.6 Power source dependability X 5.2.8.2

4.2.1.6 EMC X 5.2.3.2

Requirements of IEC 61481-2:2014 Type of defects Test of

Critical Major Minor IEC 61481-

2:2014

4.2.8 Time rating X 5.2.10.2

4.5 Marking: availability and durability X 5.4.1.1

5.4.8

4.4.4 Grip force and deflection X 5.4.2

4.6 Instructions for use (availability) X 5.4.1.1

4.3.1 Insulating material for tubes and rods of phase X 5.3.1.2

comparator as complete device

4.3.4 Resistive element X 5.2.10.2

4.3.6 Circuit current X 5.3.7.2

4.3.7 Indicator casing (dielectric property) X 5.3.2

a

5.3.3

4.3.8 Insulation of connecting lead X 5.3.6.2

4.4.3

4.4.3 Robustness of connecting lead and connections X 5.4.3.2

a

For outdoor type phase comparators the tests are performed in dry conditions only.

b

At the production level there is no need to perform a test associated with this requirement. The confirmation

of the clear indication according to 5.2.2 confirms the correctness of the performance of the device to give a

correct indication under interference field.

B.3 Rationale of classification of defects

Table B.2 is derived from Table F.1 of IEC 61481-2:2014.

Table B.2 – Rationale for the classification of defects

Justification for the associated defect

Requirement of IEC 61481-2:2014

specified in Annex D of IEC 61481-2:2014

Critical defects

Minimum length of the insulating element A shorter length of the insulating element can result in an

(phase comparator as a complete device) unacceptable value of leakage current and/or can lead to a

breakdown during use.

Leakage current (phase comparator as a The insulating element of a phase comparator as a complete

complete device) device is the protection of the worker during each use of the

device. On a brand-new device, a value of leakage current

above the limit is a hazard for the initial worker.

Clear indication of the status of the phase If the phase comparator gives a false indication (for example

relationship "Correct" instead of "Incorrect") it can lead to a hazardous

situation.

Effect of interference fields (continuous If the phase comparator gives a false indication (for example

indication) "Correct" instead of "Incorrect") it can lead to a hazardous

situation.

Electromagnetic – Immunity If the phase comparator does not fulfil the EMC requirement, it

can give wrong indications.

Temperature and humidity dependence of the If the phase comparator does not work properly in its

indication temperature range, it could give a false indication and lead to a

hazardous situation for the worker.

Frequency dependence If the phase comparator does not work properly in its frequency

range, it can give a false indication and lead to a hazardous

situation for the worker.

Response time only for phase comparators If for any reasons the response time becomes longer than 1 s,

with one active signal the worker could conclude a non-answer as an indication. This

could lead to a hazardous situation for the worker.

– 14 – IEC 61318:2021 © IEC 2021

Requirement of IEC 61481-2:2014 Justification for the associated defect

specified in Annex D of IEC 61481-2:2014

Power source dependability The purpose of this requirement is to ensure that the phase

comparator will indicate properly until the built-in power source

is exhausted. If not, it could give an incorrect indication and

lead to a hazardous situation.

Insulating material for tubes and rods of The good dielectric performance of the insulating material for

phase comparator as complete device tubes and rods used for complete devices guarantees the

protection of the worker during each use of the device.

Protection against bridging This would be hazardous for the user to have the phase

comparator initiate a fault between two parts at different

potential. Of course, the users would not be in the direct circuit

of the arc but may be close enough to suffer of the arc by-

products.

Resistive element If the resistors are not adequately rated with respect to voltage

and power that can lead to hazardous situation (i.e. initiate a

fault between two phases) or indicate a false indication (i.e.

“correct phase relationship” in case of an open circuit)

Circuit current in case of misuse If the current is not limited to 3,5 mA it could lead to a

hazardous situation in case of misuse.

Indicator casing If the material and dimensioning of the indicator casing are not

adequately rated with respect to voltage and power that can

lead to a hazardous situation.

Insulation of connecting lead If the insulation of the lead is not ensured it could lead to

hazardous situation for the workers.

For example: In case of bad insulation along a connecting lead

making contact with parts of the installation at different

potentials there is a possibility of short-circuit.

Marking – correctness An incorrect marking, for example a wrong nominal voltage or a

wrong operational class, could result in a hazardous situation.

Time rating If a phase comparator does not respect the time rating, it could

result in a short circuit (example: defect of a resistor) and can

lead to hazardous situation.

Circuit current in case of a defect of the If the current is higher than 3,5 mA, in the case of a defect of

connecting lead the connecting lead it could lead to a hazardous situation.

Robustness of connecting lead and If the connecting lead is damaged it could give an incorrect

connections indication and can lead to a hazardous indication.

Vibration resistance If a brand-new device does not have a good mechanical

performance to drop, shock and vibration, it can lead to internal

Drop resistance

defect which can cause hazardous situations.

Shock resistance

Major defects

Clear perceptibility: only visual If the worker cannot see the visual indication, he cannot

conclude.

Testing element (non-functioning) If the testing element does not function, the worker will become

aware of that during the test. This results in a non availability of

the phase comparator.

Instructions for use A phase comparator without its instructions for use is an

incomplete product and should not be used.

Protection against sparking If a phase comparator does not respect this requirement, some

elements could be destroyed. The device does not work any

more. That reduces significantly the functionality of the product.

Marking: availability and durability If the marking is not available or is impaired the worker will not

use the phase comparator.

Requirement of IEC 61481-2:2014 Justification for the associated defect

specified in Annex D of IEC 61481-2:2014

Minor defects

Clear perceptibility: visual and audible We can consider that there is always one active signal

operational and the operator can conclude. It does not affect

significantly the functionality of the device.

Response time for phase comparators with For these types of phase comparator, a “non-response” can

two active signals never be considered as an indication. The worker will conclude

something, only when the device gives an indication. There is

no misunderstanding.

Grip force and deflection Even if the grip force and the deflection do not fulfil the

requirements, it does not reduce significantly the functionality

of the product.

– 16 – IEC 61318:2021 © IEC 2021

Bibliography

IEC 60050-151:2001, International Electrotechnical Vocabulary (IEV) – Part 151: Electrical

and magnetic devices

IEC 61481-2:2014, Live working – Phase comparators – Part 2: Resistive type to be used for

voltages from 1 kV to 36 kV a.c.

ISO IEC 17000:2004, Conformity assessment – Vocabulary and general principles

ISO IEC Guide 51:2014, Safety aspects – Guidelines for their inclusion in standards

ISO 2859-1:1999, Sampling procedures for inspection by attributes – Part 1: Sampling

schemes indexed by acceptance quality limit (AQL) for lot-by-lot inspection

ISO 9000:2015, Quality management systems – Fundamentals and vocabulary

ISO 16426:2002, Fasteners – Quality assurance system

____________

-18 – IEC 61318:2021 © IEC 2021

SOMMAIRE

SOMMAIRE . 18

AVANT-PROPOS . 19

INTRODUCTION . 21

1 Domaine d’application . 22

2 Références normatives . 22

3 Termes et définitions . 22

4 Généralités . 24

5 Détermination du type de défauts . 24

6 Méthodes d’évaluation des défauts . 25

6.1 Généralités . 25

6.2 Essais . 25

6.2.1 Généralités . 25

6.2.2 Essai de type . 25

6.2.3 Essai individuel de série . 25

6.2.4 Essai sur prélèvement . 26

6.2.5 Essai de réception . 26

6.3 Documentation du processus . 26

7 Méthodes de vérification . 26

7.1 Généralités . 26

7.2 Identification et classification des défauts . 26

7.3 Exigences et essais . 27

Annexe A (informative) Recommandations pour le développement de méthodes

d'essai . 28

Annexe B (informative) Exemple de tableau d'informations sur l'évaluation des défauts . 29

B.1 Généralités . 29

B.2 Classification et justification des défauts . 29

B.3 Justification de la classification des défauts. 30

Bibliographie . 33

Tableau B.1 – Classification des défauts et exigences et essais associés . 29

Tableau B.2 – Justifications relatives à la classification des défauts . 30

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

TRAVAUX SOUS TENSION –

MÉTHODES D'ÉVALUATION DES DÉFAUTS ET VÉRIFICATION DES

PERFORMANCES APPLICABLES

AUX OUTILS, DISPOSITIFS ET ÉQUIPEMENTS

AVANT-PROPOS

1) La Commission Électrotechnique Internationale (IEC) est une organisation mondiale de normalisation composée

de l'ensemble des comités électrotechniques nationaux (Comités nationaux de l’IEC). L’IEC a pour objet de

favoriser la coopération internationale pour toutes les questions de normalisation dans les domaines de

l'électricité et de l'électronique. A cet effet, l’IEC – entre autres activités – publie des Normes internationales,

des Spécifications techniques, des Rapports techniques, des Spécifications accessibles au public (PAS) et des

Guides (ci-après dénommés "Publication(s) de l’IEC"). Leur élaboration est confiée à des comités d'études, aux

travaux desquels tout Comité national intéressé par le sujet traité peut participer. Les organisations

internationales, gouvernementales et non gouvernementales, en liaison avec l’IEC, participent également aux

travaux. L’IEC collabore étroitement avec l'Organisation Internationale de Normalisation (ISO), selon des

conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de l’IEC concernant les questions techniques représentent, dans la mesure du

possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux de l’IEC intéressés

sont représentés dans chaque comité d’études.

3) Les Publications de l’IEC se présentent sous la forme de recommandations internationales et sont agréées

comme telles par les Comités nationaux de l’IEC. Tous les efforts raisonnables sont entrepris afin que l’IEC

s'assure de l'exactitude du contenu technique de ses publications; l’IEC ne peut pas être tenue responsable de

l'éventuelle mauvaise utilisation ou interprétation qui en est faite par un quelconque utilisateur final.

4) Dans le but d'encourager l'uniformité internationale, les Comités nationaux de l’IEC s'engagent, dans toute la

mesure possible, à appliquer de façon transparente les Publications de l’IEC dans leurs publications nationales

et régionales. Toutes divergences entre toutes Publications de l’IEC et toutes publications nationales ou

régionales correspondantes doivent être indiquées en termes clairs dans ces dernières.

5) L’IEC elle-même ne fournit aucune attestation de conformité. Des organismes de certification indépendants

fournissent des services d'évaluation de conformité et, dans certains secteurs, accèdent aux marques de

conformité de l’IEC. L’IEC n'est responsable d'aucun des services effectués par les organismes de certification

indépendants.

6) Tous les utilisateurs doivent s'assurer qu'ils sont en possession de la dernière édition de cette publication.

7) Aucune responsabilité ne doit être imputée à l’IEC, à ses administra

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...