IEC 61857-22:2008

(Main)Electrical insulation systems - Procedures for thermal evaluation - Part 22: Specific requirements for encapsulated-coil model - Wire-wound electrical insulation system (EIS)

Electrical insulation systems - Procedures for thermal evaluation - Part 22: Specific requirements for encapsulated-coil model - Wire-wound electrical insulation system (EIS)

IEC 61857-22:2008 provides a general-purpose procedure for the evaluation of wire-wound systems using a general purpose encapsulated-coil model (ECM) where the application is unknown. This second edition cancels and replaces the first edition published in 2002, and constitutes editorial revisions to make this standard compatible with Parts 1 and 21.

Systèmes d'isolation électriques - Procédures d'évaluation thermique - Partie 22: Exigences particulières pour modèle de bobine encapsulée - Système d'isolation électrique (SIE) à enroulements à fil

La CEI 61857-22:2008 indique une procédure d'usage général pour l'évaluation des systèmes d'enroulement à fil utilisant un modèle de bobine encapsulée (ECM: Encapsulated Coil Model) pour usage général lorsque l'application est inconnue. Cette deuxième édition annule et remplace la première édition publiée en 2002, et elle constitue une révision rédactionnelle pour rendre la présente norme compatible avec les Parties 1 et 21.

General Information

- Status

- Published

- Publication Date

- 24-Jul-2008

- Technical Committee

- TC 112 - Evaluation and qualification of electrical insulating materials and systems

- Drafting Committee

- WG 6 - TC 112/WG 6

- Current Stage

- PPUB - Publication issued

- Start Date

- 25-Jul-2008

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61857-22:2008 is an international standard published by the International Electrotechnical Commission (IEC) that specifies procedures for the thermal evaluation of wire-wound electrical insulation systems (EIS) using a specific encapsulated-coil model (ECM). As Part 22 of the IEC 61857 series, this standard provides a general-purpose methodology applicable when the exact application of the wire-wound system is unknown.

This second edition, published in 2008, supersedes the 2002 first edition and includes editorial revisions to harmonize it with Parts 1 and 21 of the IEC 61857 series. The standard aims to evaluate the thermal endurance and electrical integrity of encapsulated coil systems-a key component in many electrical devices-ensuring reliable performance over their service life.

Key Topics

Encapsulated-coil model (ECM) construction

The ECM replicates wire-wound insulation systems, comprising essential parts such as a bobbin, winding wire (typically 0.4 mm to 0.6 mm diameter), connectors, and an encapsulant material that completely envelops the coil except for external connections. It simulates actual manufacturing processes including winding, impregnation, and encapsulation.Materials and Components

Electrical insulating materials (EIM) used as bobbin and encapsulant play a vital role in coil-to-earth insulation. The standard defines key terms like encapsulant, coil-to-coil insulation, and earth insulation to clarify the scope of materials tested.Thermal evaluation procedure

Test objects, referring to assembled ECMs, undergo rigorous thermal and dielectric stress testing through defined cycles:- Initial screening tests to exclude defective specimens.

- Thermal ageing subcycles involving elevated temperature exposure.

- Mechanical stress subcycles simulating operational stresses.

- Moisture exposure tests.

- Dielectric diagnostic tests to assess insulation integrity.

Test object requirements

A minimum of ten specimens per electrical insulation system and ageing temperature must be tested to ensure statistically significant results.Similarity criteria

The reference and candidate ECMs must be physically similar, especially in winding wire diameter (within ±0.2 mm), to ensure valid comparative evaluations.End-of-life criteria and classification

The standard provides guidance on defining failure points and reporting results that classify the thermal endurance capabilities of electrical insulation systems.

Applications

IEC 61857-22:2008 is extensively applied by manufacturers and testing laboratories involved in:

Quality assurance and design verification of wire-wound electrical insulation systems used in motors, transformers, inductors, relays, and other coil-based electrical components.

Material qualification for encapsulants and insulating materials that impact thermal performance and durability.

Reliability testing where simulating real-life manufacturing processes and operational stresses is essential to predict lifespan and ensure safety.

Standardized communication between material suppliers, manufacturers, and regulatory bodies regarding thermal performance criteria.

This standard aids in minimizing insulation failure risks and facilitates improved design practices for electrical machinery and equipment that rely on wire-wound components.

Related Standards

IEC 61857-22 forms part of the broader IEC 61857 series focused on thermal evaluation of electrical insulation systems. Other parts relevant to this standard include:

IEC 61857-1:2004 – General requirements for thermal evaluation procedures, establishing foundational definitions and testing principles for low-voltage EIS.

IEC 61857-21 – Procedures for evaluation of similar encapsulated coil models, ensuring consistency across different coil constructions.

For comprehensive thermal evaluation and material assessment, practitioners should refer to the full IEC 61857 series and coordinate with related standards on electrical insulating materials and system testing.

Keywords: IEC 61857-22, electrical insulation systems, thermal evaluation, encapsulated-coil model, wire-wound coil, encapsulant, electrical insulating materials, thermal endurance testing, dielectric diagnostics, encapsulated coil model, coil-to-earth insulation.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 61857-22:2008 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electrical insulation systems - Procedures for thermal evaluation - Part 22: Specific requirements for encapsulated-coil model - Wire-wound electrical insulation system (EIS)". This standard covers: IEC 61857-22:2008 provides a general-purpose procedure for the evaluation of wire-wound systems using a general purpose encapsulated-coil model (ECM) where the application is unknown. This second edition cancels and replaces the first edition published in 2002, and constitutes editorial revisions to make this standard compatible with Parts 1 and 21.

IEC 61857-22:2008 provides a general-purpose procedure for the evaluation of wire-wound systems using a general purpose encapsulated-coil model (ECM) where the application is unknown. This second edition cancels and replaces the first edition published in 2002, and constitutes editorial revisions to make this standard compatible with Parts 1 and 21.

IEC 61857-22:2008 is classified under the following ICS (International Classification for Standards) categories: 29.080.30 - Insulation systems. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61857-22:2008 has the following relationships with other standards: It is inter standard links to IEC 61857-22:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61857-22:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61857-22

Edition 2.0 2008-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electrical insulation systems – Procedures for thermal evaluation –

Part 22: Specific requirements for encapsulated-coil model – Wire-wound

electrical insulation system (EIS)

Systèmes d’isolation électriques – Procédures d’évaluation thermique –

Partie 22: Exigences particulières pour modèle de bobine encapsulée – Système

d’isolation électrique (SIE) à enroulements à fil

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61857-22

Edition 2.0 2008-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electrical insulation systems – Procedures for thermal evaluation –

Part 22: Specific requirements for encapsulated-coil model – Wire-wound

electrical insulation system (EIS)

Systèmes d’isolation électriques – Procédures d’évaluation thermique –

Partie 22: Exigences particulières pour modèle de bobine encapsulée – Système

d’isolation électrique (SIE) à enroulements à fil

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

M

CODE PRIX

ICS 29.080.30 ISBN 2-8318-9945-1

– 2 – 61857-22 © IEC:2008

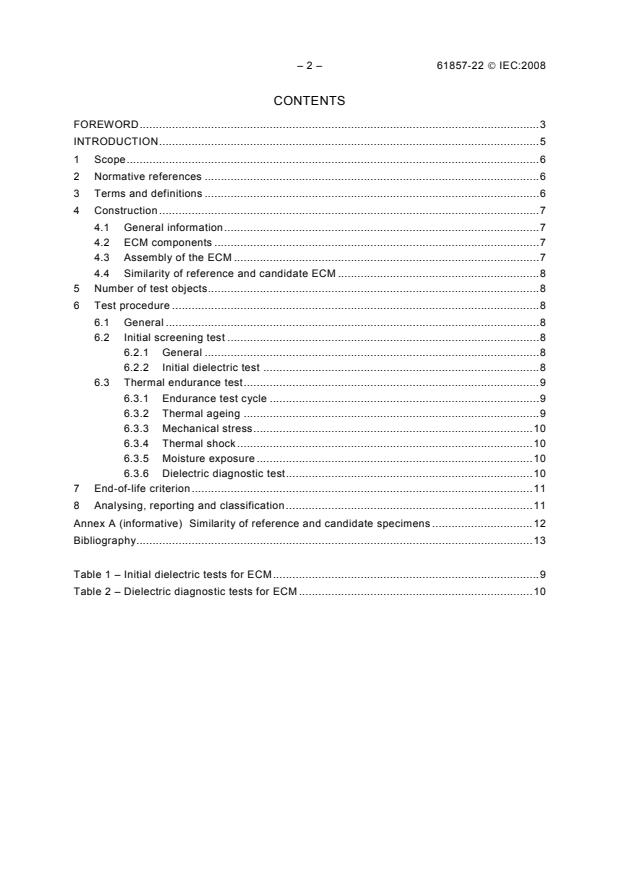

CONTENTS

FOREWORD.3

INTRODUCTION.5

1 Scope.6

2 Normative references .6

3 Terms and definitions .6

4 Construction .7

4.1 General information.7

4.2 ECM components .7

4.3 Assembly of the ECM .7

4.4 Similarity of reference and candidate ECM .8

5 Number of test objects.8

6 Test procedure .8

6.1 General .8

6.2 Initial screening test .8

6.2.1 General .8

6.2.2 Initial dielectric test .8

6.3 Thermal endurance test.9

6.3.1 Endurance test cycle .9

6.3.2 Thermal ageing .9

6.3.3 Mechanical stress.10

6.3.4 Thermal shock.10

6.3.5 Moisture exposure .10

6.3.6 Dielectric diagnostic test.10

7 End-of-life criterion.11

8 Analysing, reporting and classification.11

Annex A (informative) Similarity of reference and candidate specimens .12

Bibliography.13

Table 1 – Initial dielectric tests for ECM.9

Table 2 – Dielectric diagnostic tests for ECM .10

61857-22 © IEC:2008 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRICAL INSULATION SYSTEMS –

PROCEDURES FOR THERMAL EVALUATION –

Part 22: Specific requirements for encapsulated-coil model –

Wire-wound electrical insulation system (EIS)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61857-22 has been prepared by IEC technical committee 112:

Evaluation and qualification of electrical insulating materials and systems.

This second edition cancels and replaces the first edition published in 2002, and constitutes

editorial revisions to make this standard compatible with Parts 1 and 21.

The text of this standard is based on the following documents:

CDV Report on voting

112/91/CDV 112/99/RVC

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 4 – 61857-22 © IEC:2008

A list of all the parts in the IEC 61857 series, under the general title Electrical insulation

systems – Procedures for thermal evaluation, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

61857-22 © IEC:2008 – 5 –

INTRODUCTION

A series of parts that will make up IEC 61857 is currently being developed, each of which will

address a specific test object and/or application with an associated test procedure.

Additional parts will be developed in cooperation with IEC technical committees responsible

for equipment.

– 6 – 61857-22 © IEC:2008

ELECTRICAL INSULATION SYSTEMS –

PROCEDURES FOR THERMAL EVALUATION –

Part 22: Specific requirements for encapsulated-coil model –

Wire-wound electrical insulation system (EIS)

1 Scope

This part of IEC 61857 provides a general-purpose procedure for the evaluation of wire-

wound systems using a general purpose encapsulated-coil model (ECM) where the

application is unknown.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 61857-1:2004, Electrical insulation systems – Procedures for thermal evaluation – Part 1:

General requirements – Low-voltage

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 61857-1, as well as

the following definitions, apply.

3.1

encapsulant

electrical insulating material (EIM) that completely encases the coil except for connections to

the exterior, and is part of the electrical insulation system (EIS)

NOTE The encapsulated-coil model (ECM) does not employ a supplemental shell.

3.2

encapsulation

process of applying an encapsulant

NOTE For the purpose of evaluating an electrical insulation system (EIS), the process may consist of injection

moulding, compression moulding, casting or other techniques.

3.3

bobbin

form around which a coil is wound

3.4

coil

continuous winding of insulated wire

3.5

coil-to-coil insulation

electrical insulating material (EIM) between individual coils

61857-22 © IEC:2008 – 7 –

3.6

earth

ground (US)

make an electric connection between a given point in a system or in an installation or in

equipment and a local earth

[IEV 195-01-08]

3.7

earth (ground) insulation

electrical insulating material (EIM) between a coil and earthed metal

4 Construction

4.1 General information

The ECM is useful in evaluating the compatibility of EIM used in a candidate EIS. It is equally

capable of simulating the influences of actual manufacturing processes such as winding

techniques, termination techniques and encapsulation.

The essential parts of the ECM are a bobbin, winding wire, wire connectors and encapsulant.

The winding wires may be connected to binding posts or to lead wires, either of which extends

through the encapsulant wall.

4.2 ECM components

The components of the encapsulated-coil model are as follows:

a) Coil: the coils may be wound with two wires in parallel (bifilar winding) or may be wound

with a single wire.

b) Wire: winding wire, heavy film coated; 0,4 mm to 0,6 mm diameter wire size is preferred.

c) Earth insulation: the EIM used as the bobbin and the EIM used as the encapsulant

function as coil-to-earth insulation. An EIM evaluated only as a coil bobbin shall not also

be used as an encapsulant material. An EIM used as an encapsulant shall be evaluated as

such.

d) Tape: electrical tape may be used but unless electrically stressed and evaluated is not

part of the EIS.

e) Connectors: the winding wires are connected inside the encapsulant to binding posts or

lead wires. These connections are essential parts of the ECM.

f) Electrical impregnating resin/varnish: this may be part of the EIS if applied prior to the

encapsulation process.

NOTE A metal frame or a lamination stack that may be incorporated into the test object is not an essential part of

the test object if it does not function as a fault path.

4.3 Assembly of the ECM

Assemble the ECM as follows:

a) Wind the winding wire over the bobbin using accepted winding techniques.

b) As appropriate, use electrical grade tape or other components to secure the winding wire

in place.

c) Connect the winding wire to the binding posts or lead wires.

d) If part of the candidate EIS, apply impregnating resin/varnish.

e) Apply the encapsulant material.

– 8 – 61857-22 © IEC:2008

4.4 Similarity of reference and candidate ECM

The physical shape and assembly of the reference and candidate ECM must be similar. It is

essential that the size of the winding wire used in the reference and candidate ECM be within

±0,2 mm of each other. Refer to Annex A for more information. Details of the construction of

the reference and candidate ECM shall be reported according to 7.4 of IEC 61857-1:2004.

5 Number of test objects

The minimum number of test objects for each EIS and for each ageing temperature shall be

ten.

6 Test procedure

6.1 General

All test objects shall be subjected to initial screening tests followed by repeated thermal

endurance test cycles in the following order:

a) a thermal ageing subcycle;

b) a subcycle of pre-diagnostic mechanical stress, other pre-diagnostic requirements and

moisture exposure, in that order;

c) a dielectric diagnostic test.

6.2 Initial screening test

6.2.1 General

Prior to exposure to an elevated temperature on the first thermal ageing subcycle, all test

objects shall be subjected to initial screening tests in order to eliminate defective test objects.

The initial screening tests shall consist of the following steps and shall be conducted in the

order given:

a) visual inspection;

b) initial dielectric test (see 6.2.2);

c) mechanical stress (see 6.3.3);

d) thermal shock, as required (see 6.3.4)

e) moisture exposure (see 6.3.5);

f) dielectric diagnostic test (see 6.3.6).

6.2.2 Initial dielectric test

An initial screening test using dielectric techniques shall be performed on each ECM test

object prior to application of other prediagnostic stresses and thermal ageing, see Table 1.

61857-22 © IEC:2008 – 9 –

Table 1 – Initial dielectric tests for ECM

Voltage Acceptance

Test Method

V criteria

Wire in a single Change of Apply a direct current voltage that will result <3 % reduction of

strand coil resistance in a maximum admissible current density at

the resistance for

which the active resistance of the winding can

the coil design

a

be measured.

Wires in bifilar coils Conductor to 0,5 A to 0,75 A

400 ± 40

conductor

Coil-to-coil (for Dielectric

2 000 ± 100 (40 ± 10) mA

multiple coil withstand

constructions)

Earth insulation Dielectric

2 000 ± 100 (40 ± 10) mA

withstand

a 2

Maximum 1 A/mm of cross-section.

The following procedure shall then be followed:

• an initial dielectric test voltage shall be applied for a minimum of 60 s;

• failure shall be current flow as defined above prior to completion of the time period;

• frequency of the test voltage shall be between 48 Hz and 62 Hz.

NOTE Instantaneous application of full voltage is not recommended. It is recommended that surge protectors be

included in the test circuit to eliminate unintended high voltage spikes.

For test objects evaluated by applied voltage, pre-calibrated electromechanical over-current

circuit-breakers with a trip time of 2 s to 3 s have been used successfully to detect failure.

The cause of failure shall be determined. When the failure is within the EIS, it shall eliminate

that ECM from further testing. When the failure is not within the EIS and it can be repaired

without disturbing the EIS, the ECM may be retested and returned to the test programme

if it passes.

6.3 Thermal endurance test

6.3.1 Endurance test cycle

Following the initial screening tests, all test objects shall be subjected to repeated thermal

endurance test cycles in the following order:

a) thermal ageing subcycle;

b) mechanical stress subcycle;

c) thermal shock subcycle;

d) moisture exposure subcycle;

e) dielectric diagnostic test.

6.3.2 Thermal ageing

Thermal ageing, comprising selection of ageing temperature, initial ageing periods and ageing

procedures shall be conducted in accordance with 6.3 of IEC 61857-1:2004.

Ovens shall be used in accordance with 6.3.4 of IEC 61857-1:2004.

– 10 – 61857-22 © IEC:2008

6.3.3 Mechanical stress

Mechanical stress shall be applied by mounting the test objects on a vibration table and

exposing them between 55 min to 65 min of sinusoidal vibration at a frequency between 48 Hz

–2

and 62 Hz, with a constant acceleration of (14,7 ± 3) ms . No voltage shall be applied during

this period.

6.3.4 Thermal shock

Unless agreed to by all interested parties, both the reference and candidate EIS shall be

exposed to a low-temperature thermal shock. Thermal shock shall be applied by placing

ECMs directly from ambient conditions into a low-temperature chamber at (–20 ± 5) °C for at

least 2 h. No voltage shall be applied during this period.

6.3.5 Moisture exposure

Moisture exposure with visible condensation shall be applied in accordance with 6.6 of

IEC 61857-1:2004.

6.3.6 Dielectric diagnostic test

Following each ageing cycle and conditioning described in 6.3.3 through 6.3.5, evaluate the

ECM specimens in accordance with the dielectric diagnostic test given in Table 2.

Table 2 – Dielectric diagnostic tests for ECM

Voltage

Test Method End-of-life

V

Wire in a single Change of Apply a direct current voltage that will result ≥10 % reduction of the

strand coil resistance in a maximum admissible current density at resistance for the coil

which the active resistance of the winding can

design

a

be measured.

Wires in bifilar coils Conductor to 0,5 A to 0,75 A

110 ± 10

conductor

Coil-to-coil (for Dielectric 0,5 A to 0,75 A

600 ± 30

multiple coil withstand

constructions)

Earth insulation Dielectric

2 000 ± 100 (40 ± 10 ) mA

withstand

a 2

Maximum 1 A/mm of cross-section.

The following steps shall then be taken:

• dielectric diagnostic test voltages, except for the change of resistance measurement,

shall be applied for a minimum of 10 min.

• dielectric diagnostic test voltage for the change of resistance shall be applied for a

minimum of 60 s;

• failure shall be current flow as defined above prior to completion of the time period.

• the frequency of the test voltage shall be between 48 Hz and 62 Hz.

NOTE Instantaneous application of full voltage is not recommended. It is recommended that surge protectors be

included in the test circuit to eliminate unintended high voltage spikes.

For test objects evaluated by applied voltage, pre-calibrated electromechanical over-current

circuit breakers with a trip time of 2 s to 3 s have been used successfully to detect failure.

61857-22 © IEC:2008 – 11 –

In order to check the condition of the test objects and determine end-of-life, the dielectric

diagnostic test shall be applied after each successive exposure to moisture, either while the

test objects are still in the condensation chamber or immediately after removal while still wet

with moisture.

7 End-of-life criterion

The end-of-life criterion for individual test specimens shall be failure of an ECM to hold the

applied voltage for the required time period shown in Table 2. The cause of failure shall be

determined. When the failure is within the EIS, it shall eliminate that ECM from further testing.

When the failure is not within the EIS and it can be repaired without disturbing the EIS, the

.

ECM may be returned to the test program

8 Analysing, reporting and classification

Analysing, reporting and classification shall be in accordance with Clause 7 of IEC 61857-

1:2004.

– 12 – 61857-22 © IEC:2008

Annex A

(informative)

Similarity of reference and candidate specimens

Technical committee 98 developed this part of IEC 61857 with a focus on trying to keep an

economical approach to the development of the test objects. A major concern of TC 98 was

the high cost that could result by trying to specify a single or a preferred size for the test

object. Such a proposal would require companies to make a major financial investment for a

mould that would, most likely, only be applicable to the moulding of test objects for the

evaluation of a candidate EIS and not be applicable to end use devices. This seemed to be an

unacceptable approach.

Experience has shown that a company interested in evaluating candidate encapsulated EIS

has moulds that can provide usable and acceptable test objects. In order to maintain

reasonable test costs, TC 98 has recognized and supported flexibility in the design of the test

objects.

In addition, all EIS evaluations in accordance with IEC 61857 are relative comparisons

between a reference EIS and a candidate EIS. I

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...