IEC TS 62332-2:2014

(Main)Electrical insulation systems (EIS) - Thermal evaluation of combined liquid and solid components - Part 2: Simplified test

Electrical insulation systems (EIS) - Thermal evaluation of combined liquid and solid components - Part 2: Simplified test

IEC TS 62332-2:2014 is applicable to EIS containing solid and liquid components where the thermal stress is the dominant ageing factor, without restriction to voltage class. This part specifies a sealed tube test procedure for the thermal evaluation and qualification of electrical insulation systems (EIS). One aspect of this procedure is to also provide a method to assign thermal classifications to materials used in EIS where solid and liquid components are both used. This procedure describes a comparative ageing method whereby a reference system composed of kraft paper and mineral oil is compared to a candidate system of any combination of solid and insulating liquid. The test procedures in this part are specifically applicable to liquid immersed transformer insulation systems.

Systèmes d'isolation électrique (SIE) - Evaluation thermique de composants liquides et solides combinés - Partie 2: Essai simplifié

L'IEC TS 62332-2:2014 est applicable aux SIE contenant des composants solides et liquides, où la contrainte thermique est le facteur de vieillissement prédominant, sans restriction de la classe de tension. La présente partie indique une procédure d'essai à tube scellé pour l'évaluation et la qualification thermiques des systèmes d'isolation électrique (SIE). Un aspect de cette procédure est également de fournir une méthode d'attribution de classifications thermiques aux matériaux utilisés dans les SIE qui utilisent tant des composants solides que des composants liquides. Cette procédure décrit une méthode de vieillissement comparative où un système de référence composé de papier kraft et d'huile minérale est comparé à un système candidat de toute combinaison de composant solide et de liquide isolant. Les procédures d'essai décrites dans la présente partie s'appliquent spécifiquement aux systèmes d'isolation à transformateurs de puissance immergés dans un liquide.

General Information

- Status

- Published

- Publication Date

- 23-Apr-2014

- Technical Committee

- TC 112 - Evaluation and qualification of electrical insulating materials and systems

- Drafting Committee

- WG 6 - TC 112/WG 6

- Current Stage

- PPUB - Publication issued

- Start Date

- 24-Apr-2014

- Completion Date

- 30-Jun-2014

Overview

IEC TS 62332-2:2014 is a technical specification published by the International Electrotechnical Commission (IEC) focusing on the thermal evaluation of electrical insulation systems (EIS) that contain both solid and liquid components. This standard applies particularly to insulation systems where thermal stress is the dominant aging factor, without restriction to voltage class. It provides a simplified sealed tube test procedure for the thermal aging and qualification of EIS, mainly targeting liquid-immersed transformer insulation systems.

The document outlines a comparative aging method where a reference system (kraft paper and mineral oil) is tested alongside candidate systems made from various combinations of solid and insulating liquid materials. The procedure allows manufacturers and researchers to assign thermal classifications to insulation materials and evaluate the durability of combined liquid-solid insulation systems under thermal stress.

Key Topics

- Scope of Applicability: Applies to electrical insulation systems (EIS) with combined solid and liquid components subjected to thermal stresses.

- Sealed Tube Test Setup: Detailed description of the apparatus including sealed tubes, gas blanketing, pressure relief, and aging ovens to simulate and control thermal environments.

- Test Object Construction: Guidelines on preparing test samples with accurate component weight ratios to reflect real operational conditions.

- Reference and Candidate Systems: Comparative testing between a standard reference insulation system (kraft paper and mineral oil) and various candidate materials for evaluation.

- Thermal Aging Procedures: Step-by-step methods detailing sample preparation, aging durations, temperature settings, and diagnostic testing for both solid and liquid insulation.

- Data Analysis: Criteria for interpreting results, determining end-of-life for materials, and extrapolating data to assess thermal class and aging behavior.

- Simplified One-Point Test: An accelerated aging test method enabling quicker thermal evaluation without extensive time-consuming procedures.

Applications

IEC TS 62332-2:2014 serves as a critical tool for industries involved in designing, producing, and assessing electrical insulation systems with combined liquid and solid components, including but not limited to:

- Transformer Manufacturing: Especially for liquid-immersed transformer insulation systems, ensuring reliable operation and longevity under thermal stresses.

- Electrical Equipment Testing Facilities: Performing thermal evaluation tests to qualify insulation materials and systems according to international standards.

- Material Development and Research: Evaluating new insulating liquids and solid materials combined in EIS for enhanced thermal performance.

- Quality Control and Certification: Supporting manufacturers in demonstrating compliance with thermal aging requirements and classification for electrical insulation products.

- Thermal Aging Assessment: Allowing comparative ageing studies that can predict insulation system performance and service life based on thermal stress factors.

Related Standards

- IEC 60216 – Electrical insulating materials - Thermal endurance properties, which provides the general framework for thermal aging and classification of insulating materials.

- IEC TS 62332-1 – Electrical insulation systems (EIS) – Thermal evaluation of combined liquid and solid components – Part 1: General procedures, covering comprehensive thermal evaluation guidelines that complement this simplified test method.

- IEC 60076 series – Power transformers standards that relate to insulation design and testing, including thermal testing procedures for transformer insulation systems.

- ISO/IEC Directives, Part 2 – Guidelines on the structure and drafting of international technical standards and specifications.

Keywords: IEC TS 62332-2, electrical insulation systems, thermal evaluation, liquid and solid components, sealed tube test, transformer insulation, thermal aging, insulation thermal classification, electrical insulation testing, liquid immersed transformers, thermal stress, insulation system qualification, insulation aging test.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC TS 62332-2:2014 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Electrical insulation systems (EIS) - Thermal evaluation of combined liquid and solid components - Part 2: Simplified test". This standard covers: IEC TS 62332-2:2014 is applicable to EIS containing solid and liquid components where the thermal stress is the dominant ageing factor, without restriction to voltage class. This part specifies a sealed tube test procedure for the thermal evaluation and qualification of electrical insulation systems (EIS). One aspect of this procedure is to also provide a method to assign thermal classifications to materials used in EIS where solid and liquid components are both used. This procedure describes a comparative ageing method whereby a reference system composed of kraft paper and mineral oil is compared to a candidate system of any combination of solid and insulating liquid. The test procedures in this part are specifically applicable to liquid immersed transformer insulation systems.

IEC TS 62332-2:2014 is applicable to EIS containing solid and liquid components where the thermal stress is the dominant ageing factor, without restriction to voltage class. This part specifies a sealed tube test procedure for the thermal evaluation and qualification of electrical insulation systems (EIS). One aspect of this procedure is to also provide a method to assign thermal classifications to materials used in EIS where solid and liquid components are both used. This procedure describes a comparative ageing method whereby a reference system composed of kraft paper and mineral oil is compared to a candidate system of any combination of solid and insulating liquid. The test procedures in this part are specifically applicable to liquid immersed transformer insulation systems.

IEC TS 62332-2:2014 is classified under the following ICS (International Classification for Standards) categories: 29.080.30 - Insulation systems. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 62332-2:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TS 62332-2 ®

Edition 1.0 2014-04

TECHNICAL

SPECIFICATION

SPECIFICATION

TECHNIQUE

colour

inside

Electrical insulation systems (EIS) –Thermal evaluation of combined liquid and

solid components –

Part 2: Simplified test

Systèmes d'isolation électrique (SIE) – Évaluation thermique de composants

liquides et solides combines –

Partie 2: Essai simplifié

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

14 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 55 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC TS 62332-2 ®

Edition 1.0 2014-04

TECHNICAL

SPECIFICATION

SPECIFICATION

TECHNIQUE

colour

inside

Electrical insulation systems (EIS) –Thermal evaluation of combined liquid and

solid components –

Part 2: Simplified test

Systèmes d'isolation électrique (SIE) – Évaluation thermique de composants

liquides et solides combines –

Partie 2: Essai simplifié

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX T

ICS 29.080.30 ISBN 978-2-8322-1514-2

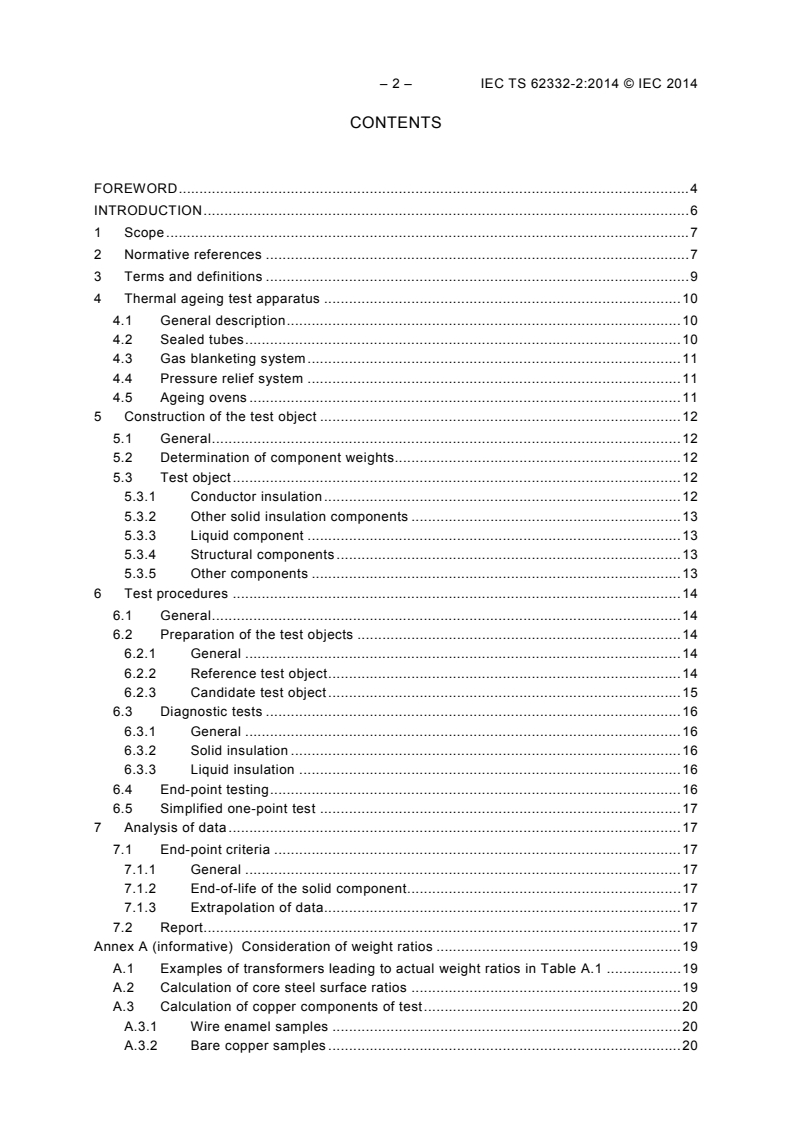

– 2 – IEC TS 62332-2:2014 © IEC 2014

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 9

4 Thermal ageing test apparatus . 10

4.1 General description . 10

4.2 Sealed tubes . 10

4.3 Gas blanketing system . 11

4.4 Pressure relief system . 11

4.5 Ageing ovens . 11

5 Construction of the test object . 12

5.1 General . 12

5.2 Determination of component weights. 12

5.3 Test object . 12

5.3.1 Conductor insulation . 12

5.3.2 Other solid insulation components . 13

5.3.3 Liquid component . 13

5.3.4 Structural components . 13

5.3.5 Other components . 13

6 Test procedures . 14

6.1 General . 14

6.2 Preparation of the test objects . 14

6.2.1 General . 14

6.2.2 Reference test object . 14

6.2.3 Candidate test object . 15

6.3 Diagnostic tests . 16

6.3.1 General . 16

6.3.2 Solid insulation . 16

6.3.3 Liquid insulation . 16

6.4 End-point testing . 16

6.5 Simplified one-point test . 17

7 Analysis of data . 17

7.1 End-point criteria . 17

7.1.1 General . 17

7.1.2 End-of-life of the solid component. 17

7.1.3 Extrapolation of data . 17

7.2 Report. 17

Annex A (informative) Consideration of weight ratios . 19

A.1 Examples of transformers leading to actual weight ratios in Table A.1 . 19

A.2 Calculation of core steel surface ratios . 19

A.3 Calculation of copper components of test . 20

A.3.1 Wire enamel samples . 20

A.3.2 Bare copper samples . 20

Annex B (informative) Consideration of ageing time and temperature . 21

Annex C (informative) Aging example . 22

C.1 Reference system test . 22

C.2 Candidate system test . 22

Bibliography . 25

Figure 1 – Sealed tube example. 11

Figure B.1 – Reference EIS system . 21

Figure C.1 – Example of aging result at a temperature of 165 °C . 23

Figure C.2 – Aging life curve . 24

Table 1 – Reference component weight ratio calculations . 12

Table 2 – Reference EIS ageing conditions and candidate EIS ageing temperatures . 15

Table 3 – Recommended ageing temperatures and periods for expected thermal class . 15

Table A.1 – Examples obtained from industry sources . 19

Table A.2 – Examples of component volume ratio calculations . 19

Table C.1 – Calculation of end-of-life criteria for comparative evaluation . 22

Table C.2 – Example of aging experiment . 23

– 4 – IEC TS 62332-2:2014 © IEC 2014

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRICAL INSULATION SYSTEMS (EIS) –

THERMAL EVALUATION OF COMBINED LIQUID

AND SOLID COMPONENTS –

Part 2: Simplified test

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In

exceptional circumstances, a technical committee may propose the publication of a technical

specification when

• the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

• the subject is still under technical development or where, for any other reason, there is the

future but no immediate possibility of an agreement on an International Standard.

Technical specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

IEC TS 62332-2, which is a technical specification, has been prepared by IEC technical

committee 112: Evaluation and qualification of electrical insulating materials and systems.

The text of this technical specification is based on the following documents:

Enquiry draft Report on voting

112/256/DTS 112/268/RVC

Full information on the voting for the approval of this technical specification can be found in

the report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 62332 series, published under the general title Electrical

insulation systems (EIS) – Thermal evaluation of combined liquid and solid components, can

be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• transformed into an International standard,

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC TS 62332-2:2014 © IEC 2014

INTRODUCTION

This technical specification describes a method for the thermal evaluation of electrical

insulation systems (EIS) for electrotechnical products with combined liquid and solid

components. More specifically, this part addresses liquid immersed power transformers.

Part 1 covers general test requirements. This Part 2 covers a simplified test method which

can be used as a screening test prior to conducting Part 1 testing or it can be used to

determine a thermal classification of an EIS. This method can also be used as a quality

control test to evaluate minor product changes.

This specification provides a standardized test method for sealed tube testing. The sealed

tube should contain all the primary EIS elements, and in relative component ratios which

compare with actual liquid immersed power transformers.

This technical specification has been prepared in conjunction with IEC TC 14, Power

transformers and IEC TC 10, Fluids for electrotechnical applications. Any comments or

suggestions from other technical committees to make this technical specification more general

are welcome.

ELECTRICAL INSULATION SYSTEMS (EIS) –

THERMAL EVALUATION OF COMBINED LIQUID

AND SOLID COMPONENTS –

Part 2: Simplified test

1 Scope

This part of IEC 62332, which is a technical specification, is applicable to EIS containing solid

and liquid components where the thermal stress is the dominant ageing factor, without

restriction to voltage class.

This part specifies a sealed tube test procedure for the thermal evaluation and qualification of

electrical insulation systems (EIS). One aspect of this procedure is to also provide a method

to assign thermal classifications to materials used in EIS where solid and liquid components

are both used. This procedure describes a comparative ageing method whereby a reference

system composed of kraft paper and mineral oil is compared to a candidate system of any

combination of solid and insulating liquid. The test procedures in this part are specifically

applicable to liquid immersed transformer insulation systems.

Similar procedures should also work for other electrotechnical devices with a combination of

liquid and solid components, such as bushings, cables or capacitors, but this will be added as

additional parts once experience is gained using this technical specification.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60085, Electrical insulation – Thermal evaluation and designation

IEC 60156, Insulating liquids – Determination of the breakdown voltage at power frequency –

Test method

IEC 60216-2:2005, Electrical insulating materials – Thermal endurance properties – Part 2:

Determination of thermal endurance properties of electrical insulating materials – Choice of

test criteria

IEC 60216-3, Electrical insulating materials – Thermal endurance properties – Part 3:

Instructions for calculating thermal endurance characteristics

IEC 60216-4-1, Electrical insulating materials – Thermal endurance properties – Part 4-1:

Ageing ovens – Single-chamber ovens

IEC 60216-5, Electrical insulating materials – Thermal endurance properties – Part 5:

Determination of relative thermal endurance index (RTE) of an insulating material

IEC 60243-1, Electrical strength of insulating materials – Test methods – Part 1: Tests at

power frequencies

– 8 – IEC TS 62332-2:2014 © IEC 2014

IEC 60247, Insulating liquids – Measurement of relative permittivity, dielectric dissipation

factor (tan δ) and d.c. resistivity

IEC 60296, Fluids for electrotechnical applications – Unused mineral insulating oils for

transformers and switchgear

IEC 60317 (all parts), Specifications for particular types of winding wires

IEC 60450, Measurement of the average viscometric degree of polymerization of new and

aged cellulosic electrically insulating materials

IEC 60505:2011, Evaluation and qualification of electrical insulation systems

IEC 60554-2, Cellulosic papers for electrical purposes – Part 2: Methods of test

IEC 60567, Oil-filled electrical equipment – Sampling of gases and of oil for analysis of free

and dissolved gases – Guidance

IEC 60599, Mineral oil-impregnated electrical equipment in service – Guide to the

interpretation of dissolved and free gases analysis

IEC 60763-2, Specification for laminated pressboard – Part 2: Methods of test

IEC 60814, Insulating liquids – Oil-impregnated paper and pressboard – Determination of

water by automatic coulometric Karl Fischer titration

IEC 60851-5, Winding wires – Test methods – Part 5: Electrical properties

IEC 61198, Mineral insulating oils– Methods for the determination of 2-furfural and related

compounds

IEC 61620, Insulating liquids – Determination of dielectric dissipation factor by measurement

of the conductance and capacitance – Test method

IEC 62021-1, Insulating liquids – Determination of acidity – Part 1: Automatic potentiometric

titration

IEC 62021-2, Insulating liquids – Determination of acidity – Part 2: Colourimetric titration

IEC 62021-3, Insulating liquids – Determination of acidity – Part 3: Test methods for non

mineral insulating oils

IEC TS 62332-1:2011, Electrical insulation systems (EIS) – Thermal evaluation of combined

liquid and solid components – Part 1: General requirements

ISO 2049, Petroleum products – Determination of colour (ASTM scale)

ISO 2211, Liquid chemical products – Measurement of colour in Hazen units (platinum-cobalt

scale)

ASTM D971, Standard Test Method for Interfacial Tension Of Oil Against Water By The Ring

Method

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply, some of which

are taken from IEC 60505.

3.1

electrical insulation system

EIS

insulating structure containing one or more electrical insulating materials (EIM) together with

associated conducting parts employed in an electrotechnical device

Note 1 to entry: EIMs with different temperature indices (ATE RTE according to IEC 60216-5) may be combined to

form an EIS, which has a thermal class that may be higher or lower than that of any of the individual components

according to IEC 60505.

[SOURCE: IEC 60505:2011, 3.1.1 – modified, the Note 1 to entry has been added]

3.2

candidate EIS

EIS under evaluation to determine its service capability (thermal)

3.3

reference EIS

evaluated and established EIS with either a known service experience record or a known

comparative functional evaluation as a basis

3.4

thermal class

designation of an EIS that is equal to the numerical value of the maximum temperature in

degrees Celsius for which the EIS is appropriate according to IEC 60085

Note 1 to entry: An EIS may be subjected to operating temperatures exceeding its thermal class, which can result

in shorter expected life.

3.5

EIS assessed thermal endurance index

EIS ATE

numerical value of the temperature in degrees Celsius for the reference EIS as derived from

known service experience or a known comparative functional evaluation

3.6

EIS relative thermal endurance index

EIS RTE

numerical value of the temperature in degrees Celsius for the candidate EIS which is relative

to the known EIS ATE of a reference EIS when both EIS are subjected to the same ageing

and diagnostic procedures in a comparative test

3.7

test object

piece of original equipment, a representation (model) of equipment, a component of or part of

equipment, including the EIS, intended for use in a functional test

3.8

thermal ageing factor

thermal stress that causes irreversible changes in the EIS

– 10 – IEC TS 62332-2:2014 © IEC 2014

3.9

diagnostic test

periodic application of a specified level of a diagnostic factor to a test object to determine

whether the end-point criterion has been reached

3.10

end-point criterion

selected value of either a property or a change of property that defines the end of a

component’s life

[SOURCE: IEC 61857-1:2008, 3.11, modified – "component's life" replaces "test object in a

functional test]

3.11

end-of-life

end of a test object’s life, as determined by any selected component meeting its end-point

criterion

3.12

sealed tube

sealed container partially filled with the liquid EIM and in which includes the solid EIM in

relative component ratios which compare with the actual electrotechnical device

3.13

halving value

HIC

numerical value of the temperature interval in Kelvins which expresses the halving of the time

to end-point taken at the temperature equal to TI

[SOURCE: IEC 60050-212:2010, 212-12-13, modified – "equal to TI" replaces the original

"corresponding to the temperature index or the relative temperature index"]

4 Thermal ageing test apparatus

4.1 General description

The thermal ageing test apparatus shall be designed to allow the ageing of solid and liquid

components. The reference and candidate EIS shall be exposed to test periods at selected

elevated temperatures. These test periods consist of a specific time exposure at the selected

temperature followed by diagnostic tests. The test system consists of the following elements:

• sealed tubes

• ageing ovens

• test objects.

4.2 Sealed tubes

Each sealed tube is a container constructed of stainless steel or other suitable materials such

as glass, the size to be determined by the size of the test objects. Additionally, the material

for the tube shall either not affect the ageing (such as glass or stainless steel) or identically

constructed tubes shall be used for all sets of experiments. The cell volume shall consider the

space required for thermal expansion of the liquid at ageing temperatures, as well as space

for the EIM to be evaluated. The EIM to be evaluated should be fully immersed in the liquid

during the entire test period. Either one or both ends of the cell shall be fitted with removable,

sealable bolt-on covers.

Ports shall be provided for

• sampling of the liquid,

• gas blanketing and associated pressure relief system.

For example, see Figure 1.

IEC 1019/14

Figure 1 – Sealed tube example

4.3 Gas blanketing system

A gas blanketing system shall be provided which simulates the insulation system used in the

transformer being evaluated. This can be a sealed gas system, which maintains a gas blanket

over the liquid in the cell for the purpose of reducing oxidation of the liquid. In each case, the

gas blanket in each cell shall be regulated to maintain a positive pressure as is described in

below in 4.4.

Free breathing liquid preservation systems are not included due to safety hazard of testing

liquids at temperatures above their flashpoints where additional oxygen is available. In the

case of a sealed test, the amount of available oxygen is limited.

NOTE Oxygen is known to increase ageing of insulation systems, so a test with air would be expected to be more

severe than one sealed with nitrogen.

4.4 Pressure relief system

A pressure relief valve shall be installed on each cell to prevent the internal cell pressure from

rising above the capability of the sealed tube. Additionally, the test should simulate the end

application which is under evaluation. As an example, for liquid-immersed transformer

applications, the transformer tanks are designed to operate at a pressure of up to 150 kPa.

The technical evaluation for this design should use a method (such as a pressure relief valve)

to control the pressure in the cells at a level consistent with the end use application being

evaluated. If not otherwise specified, choose a level of 150 kPa for this test pressure.

Pressure control has two functions. The first is for safety and the second is to control the

pressure at a low consistent level to better model the actual transformer application. This

pressure control can be accomplished by using a pressure relief value equal to that used on

the transformer for which the evaluation is being conducted, or by the means of an expanding

bellows which allows increasing gas space of the test cell without an increase of pressure.

4.5 Ageing ovens

The ageing ovens used shall meet the requirements of IEC 60216-4-1.

– 12 – IEC TS 62332-2:2014 © IEC 2014

5 Construction of the test object

5.1 General

The test object is designed to model the EIS portion of the transformer under evaluation and

usually consists of

• a conductor insulation,

• other solid insulation components,

• structural components,

• metallic materials (typically copper or aluminium and steel),

• an insulating liquid,

• other components in the candidate if they differ from the reference system and if they

reasonably affect the outcome of the test.

5.2 Determination of component weights

It is important that the ratios of weights of components used to construct the test object shall

be representative of the candidate transformer being modelled. Determine the percentage of

each individual component as a part of the total weight. The percentages shall be used to

determine the weight of those individual components to be used in the construction of the test

object. In a family of products with the same specific EIS, the ratio of weight of the individual

components to the total weight should be similar. Other components which affect aging based

on surface area are included on this basis.

Table 1 provides the weights and dimensions of the components to be used in the reference

test. This table is based on the ratio of materials assuming 100 g of solid for each type of EIS.

Each of the items in this table is described in more detail in the clauses following the table.

The reference should be selected that is most appropriate for the candidate under test.

Table 1 – Reference component weight ratio calculations

Transformer type

Test material descriptions Distribution Power – Core type Power – Shell type

Insulating liquid 1 330 g 760 g 330 g

Conductor insulation 10 g 10 g

Layer insulation 50 g

Low density pressboard 50 g 10 g 80 g

High density pressboard 80 g 10 g

Ratio – Liquid to solid 13,3 to 1 7,6 to 1 3,3 to 1

2 2 2

Surface area of core steel 9,6 cm 9,6 cm 9,6 cm

Enamel wire samples 5 samples 5 samples 5 samples

2 2 2

Surface area of copper 9,6 cm 9,6 cm 9,6 cm

In addition to the ratios of the solid and liquid insulation components shown in Table 1, other

materials as described in 5.3.4 and 5.3.5 should be included as well, but are not included

here for simplicity. Enamel wire samples are described in Annex A.

5.3 Test object

5.3.1 Conductor insulation

Depending on the type of transformer, the conductors can range from small round wires, to

larger rectangular wires or metal foils. The insulation for each of these may differ. The

insulation may be either enamel coating, conductors wrapped with thin insulating materials or,

in the case of the metal foils, thicker papers/films, sometimes with adhesive coatings.

The conductor insulation should be tested in a way that can allow estimation of the expected

thermal capability of the material when combined with a fluid. For thin wire wrap materials, the

test specimens can be pre-cut tensile strips. A minimum of 20 test specimens per ageing cell

should be included in each cell. For enamel coated round wires, twisted wire pairs of can be

aged, again with a minimum of 20 test specimens per ageing cell. For applications such as

distribution transformers, the thicker layer papers or films used with metal foils, can be

evaluated similar to the thin wire wrap materials.

For papers/films with adhesive coatings, a separate test to evaluate the technical

characteristic of the adhesive should be conducted. The failure mode for this test may be

bond strength retention of the adhesive rather than a tensile retention test of the base

paper/film insulation.

Include the same ratio of exposed surface area of the conductor metal (copper or aluminium)

as in the transformer being evaluated for paper/film wrapped conductors.

5.3.2 Other solid insulation components

Other solid materials are typically used in the transformers. These components include

pressboard products that are adjacent to the conductors (spacer materials), and as such

experience the same temperature extremes as the conductor insulation or other materials

which are used in the cooler part of the transformer (such as cylinders or oil-flow barriers). In

other type of designs, the insulated conductors may be separated by insulating papers which

again experience the same extreme temperatures as the conductor insulation. Each of these

materials should be included in the correct ratio as described in 5.2.

5.3.3 Liquid component

The cell shall be filled with the liquid component used in the transformer being evaluated. The

weight of the liquid shall be determined from requirements in 5.2 based on weight and

temperature calculations. Care shall be taken to allow space for expansion of the liquid in the

cell at elevated temperatures.

5.3.4 Structural components

Other materials are used in the transformer that are for “mechanical purposes” only, and have

no direct impact on electrical performance of the insulation system, but if they fail in the

application, could cause a degradation of the insulation system. Examples of such

components include, but are not limited to, tie cords, netting tapes, adhesive tapes, etc. Many

of these components are manufacturing aids, so a failure in operation is not a design problem,

as long as the components degrade in a way that does not affect the other materials

(chemical compatibility) or affect design parameters, e.g. block cooling.

These materials could be included in the test consistent with 5.2.

NOTE At present, no method has been developed as to how to evaluate the addition of these materials into the

test object. Once experience with this test specification has been obtained, a method to evaluate these materials

will be added.

5.3.5 Other components

For products being simulated, representative components that are not included in the EIS but

are expected to affect it, shall be included. Examples include pieces of core steel, material

supporting the leads, coatings, solder and enclosure materials. The relative weights of these

components should match those of the evaluated product, with the exception of magnetic core

steel and tank material. The relative quantity of magnetic core steel and tank shall be

determined, based on the surface area exposed to the liquid component. An example is given

– 14 – IEC TS 62332-2:2014 © IEC 2014

in Annex A. Core steel is considered a surface area rather than a weight ratio since only the

surface is available to affect the aging of the insulation system.

In addition to the core steel, these materials could be included in the test consistent with 5.2.

NOTE At present no method has been developed as to how to evaluate the addition of these materials into the

test object. Once experience with this test specification has been obtained, a method to evaluate these materials

will be added.

6 Test procedures

6.1 General

A three-temperature ageing test shall be completed to establish the thermal rating of the new

system. A reference EIS shall be used to validate the testing of the candidate EIS. Unless

otherwise stipulated by the equipment technical committee, the reference system shall be

cellulose solid insulation and mineral oil.

NOTE For transformers which include enamel coated wires, the enamel coated wires to be evaluated as part of

the reference EIS are specified in IEC 60317 – PVF (polyvinyl formal).

6.2 Preparation of the test objects

6.2.1 General

The quantity of samples of solid and liquid insulation should be sufficient to supply all

reference and candidate test objects and requirements for diagnostic testing.

All solid samples shall be pre-conditioned by drying. Lower temperature drying will take longer

than high temperatures, but will prevent damage of the insulation prior to the ageing

experiment. For optimum drying conditions, refer to the relevant material testing standards.

The moisture content of the solid insulation materials shall be between 0,25 % and 0,50 % at

the start of the ageing.

Immediately after drying, the conductor materials, other solid materials and all additional

materials shall be vacuum-impregnated with the liquid under evaluation. The impregnation

process is conducted for 6 h to 24 h, at 70 °C to 90 °C.

Prior to inserting the test objects into the ageing cell, remove the pre-conditioned solid and

liquid diagnostic test samples. Verify the initial moisture content after the impregnation

process to determine whether or not the materials are adequately dried prior to start-up.

A clean, dry ageing cell is then filled with the previously determined weight of liquid and the

impregnated solid components are inserted. The cell is quickly sealed then purged with dry

sealing gas.

Following its assembly, the ageing cell is placed into an ageing oven. The temperature of the

oven is then increased to the ageing temperature.

6.2.2 Reference test object

The reference EIS shall be composed of solid materials and liquid that have an established

performance in combination. At the time of issue of this technical specification, the only

established reference EIS is composed of cellulose solid materials and mineral oil. The EIS

ATE of this reference system is recognized to be 105 °C. However, if the equipment technical

committee has established another EIS with known performance, this may be used as the

reference EIS. The equipment technical committee should provide specific details:

• conductor with Kraft cellulose insulation (samples described in 5.3.1);

• non-inhibited mineral oil according to IEC 60296.

For verification of reference EIS ageing, a single set of three test objects composed of the

reference EIS shall be evaluated along with the candidate test objects. For the reference EIS

cellulose and mineral oil system, the ageing temperatures shall be as shown below.

Testing shall be carried out with three temperatures for the referenced EIS as shown in Table

2 below. Evaluate the per cent tensile strength of the three sets and average them for the

end of life criteria for the candidate system. Ageing times for the reference EIS is based on a

20,000 h life at the ATE (of 105 °C) with a HIC of 6 K.

Table 2 – Reference EIS ageing conditions and candidate EIS ageing temperatures

Insulation Expected increase Ageing time Ageing time Ageing time

system in thermal rating 3 536 h number 2: number 3:

625 h 110 h

°C °C °C °C

Reference EIS 130 145 160

Candidate EIS 10 140 155 170

20 150 165 180

30 160 175 190

40 170 185 200

50 180 195 210

60 190 205 220

The expected value for the reference EIS at the above times and temperatures is in the range

of 25 % tensile strength. For dielectric strength of enamel coated wire, the expected value is

in the range of 80 % retained dielectric strength. In either case, the property retention of the

reference EIS will determine the end of life criteria for the candidate EIS. Unless there is a

good reason for an alternative end of life test (other than tensile strength for solid insulation

and dielectric strength for enamel/wire coatings) these should be chosen.

6.2.3 Candidate test object

At least four ageing cells shall be used for the candidate system for each test temperature. At

least one cell shall have ageing results that extend past the end of life criteria determined

from the reference EIS testing for each test temperature.

Select the ageing temperatures for the candidate EIS, based on the expected thermal class

from IEC 60085, listed below in Table 3. The four ageing period durations are defined for

each ageing temperature.

Table 3 – Recommended agei

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...