IEC TS 62332-3:2016

(Main)Electrical insulation systems (EIS) - Thermal evaluation of combined liquid and solid components - Part 3: Hermetic motor-compressors

Electrical insulation systems (EIS) - Thermal evaluation of combined liquid and solid components - Part 3: Hermetic motor-compressors

IEC TS 62332-3:2016 is applicable to EIM and EIS containing solid and liquid components where the refrigerant, oil and thermal stresses are the dominant ageing factor, without restriction to voltage class.

Systèmes d'isolation électrique (SIE) - Évaluation thermique de composants liquides et solides combinés - Partie 3: Motocompresseurs hermétiques

L'IEC TS 62332-3:2016 est applicable aux MIE et aux SIE contenant des composants solides et liquides, et pour lesquels le fluide frigorigène, l'huile et les contraintes thermiques constituent les facteurs de vieillissement prédominants, indépendamment de la classe de tension.

General Information

- Status

- Published

- Publication Date

- 20-Jul-2016

- Technical Committee

- TC 112 - Evaluation and qualification of electrical insulating materials and systems

- Drafting Committee

- WG 6 - TC 112/WG 6

- Current Stage

- PPUB - Publication issued

- Start Date

- 21-Jul-2016

- Completion Date

- 30-Sep-2016

Overview

IEC TS 62332-3:2016 is a Technical Specification published by the International Electrotechnical Commission (IEC) that focuses on the thermal evaluation of electrical insulation systems (EIS) combining liquid and solid components, specifically for hermetic motor-compressors. This standard applies to electrical insulation materials (EIM) and systems where the ageing effects are dominated by refrigerant, oil, and thermal stresses, regardless of the voltage class used.

This document provides standardized methods for testing and evaluating the thermal endurance and ageing behavior of EIS in hermetic motor-compressors, which are essential components in refrigeration and air conditioning systems. The standard outlines test equipment, specimen preparation, test procedures, diagnostic tests, data analysis, and reporting requirements to ensure reliable performance and prolonged operational life.

Key Topics

Scope and Application

Covers electrical insulation systems consisting of combined liquid (refrigerant oil) and solid insulation components in hermetic motor-compressors.Test Equipment and Procedures

Describes use of specialized test apparatus like autoclaves and ageing ovens to simulate operational thermal and chemical conditions for accelerated ageing tests.Specimen Preparation

Includes guidelines on selecting test specimens from insulation materials, with details on dimensions, volume, and weight to ensure consistency.Thermal Ageing Tests

Defines procedures to assess insulation degradation under controlled temperature and chemical exposure, including initial screening, ageing cycles, and sample handling protocols.Diagnostic Testing

Provides tailored diagnostics for solid insulation materials (e.g., electrical resistance, mechanical strength) and liquid insulation materials like refrigerant oils (e.g., chemical stability tests).Data Analysis and End-of-Life Criteria

Explains methods to analyze test results, determine ageing end-points, and extrapolate thermal life expectancy of combined insulation systems.Reporting

Details the format and essential content for standardized test reports, improving transparency and comparability of results.

Applications

Refrigeration Industry

Ensures reliable insulation performance in hermetic motor-compressors, critical for household refrigerators, commercial cooling units, and industrial chillers.HVAC Systems

Supports design and validation of insulation materials in air conditioning compressors exposed to combined thermal and chemical stresses.Insulation Material Development

Assists manufacturers in testing new solid and liquid insulating materials under realistic operating conditions to optimize durability.Quality Assurance and Compliance

Helps manufacturers and certification bodies verify compliance with international thermal endurance requirements for combined insulation systems.Research and Innovation

Provides a scientific basis for studying ageing mechanisms in complex EIS setups, enabling improvements in motor-compressor efficiency and lifespan.

Related Standards

IEC 60034 Series - Covers rotating electrical machines, including thermal and insulation testing methods relevant to motor-compressors.

IEC TS 62332-1 and 2 - Complementary Technical Specifications on thermal evaluation of electrical insulation systems with combined liquid and solid components in other applications.

IEC 60721 - Environmental conditions standards which impact ageing and performance testing of electrical insulation materials.

ISO 5149 and AHRI Standards - Pertinent for refrigeration system safety and performance where hermetic motor-compressors are commonly used.

By adhering to IEC TS 62332-3:2016, manufacturers and testing laboratories can ensure comprehensive evaluation of insulation systems subjected to complex thermal and chemical stressors in hermetic motor-compressors, thus enhancing product safety, reliability, and international market acceptance.

Keywords: IEC TS 62332-3, electrical insulation systems, thermal evaluation, hermetic motor-compressors, refrigerant oil ageing, solid insulation, autoclave testing, thermal endurance, motor-compressor insulation, electrical insulation material testing.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC TS 62332-3:2016 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Electrical insulation systems (EIS) - Thermal evaluation of combined liquid and solid components - Part 3: Hermetic motor-compressors". This standard covers: IEC TS 62332-3:2016 is applicable to EIM and EIS containing solid and liquid components where the refrigerant, oil and thermal stresses are the dominant ageing factor, without restriction to voltage class.

IEC TS 62332-3:2016 is applicable to EIM and EIS containing solid and liquid components where the refrigerant, oil and thermal stresses are the dominant ageing factor, without restriction to voltage class.

IEC TS 62332-3:2016 is classified under the following ICS (International Classification for Standards) categories: 29.080.30 - Insulation systems. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 62332-3:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TS 62332-3 ®

Edition 1.0 2016-07

TECHNICAL

SPECIFICATION

SPECIFICATION

TECHNIQUE

colour

inside

Electrical insulation systems (EIS) – Thermal evaluation of combined liquid and

solid components –

Part 3: Hermetic motor-compressors

Systèmes d'isolation électrique (SIE) – Évaluation thermique de composants

liquides et solides combinés –

Partie 3: Motocompresseurs hermétiques

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 15

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC 65 000 entrées terminologiques électrotechniques, en anglais

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC TS 62332-3 ®

Edition 1.0 2016-07

TECHNICAL

SPECIFICATION

SPECIFICATION

TECHNIQUE

colour

inside

Electrical insulation systems (EIS) – Thermal evaluation of combined liquid and

solid components –

Part 3: Hermetic motor-compressors

Systèmes d'isolation électrique (SIE) – Évaluation thermique de composants

liquides et solides combinés –

Partie 3: Motocompresseurs hermétiques

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.080.30 ISBN 978-2-8322-3527-0

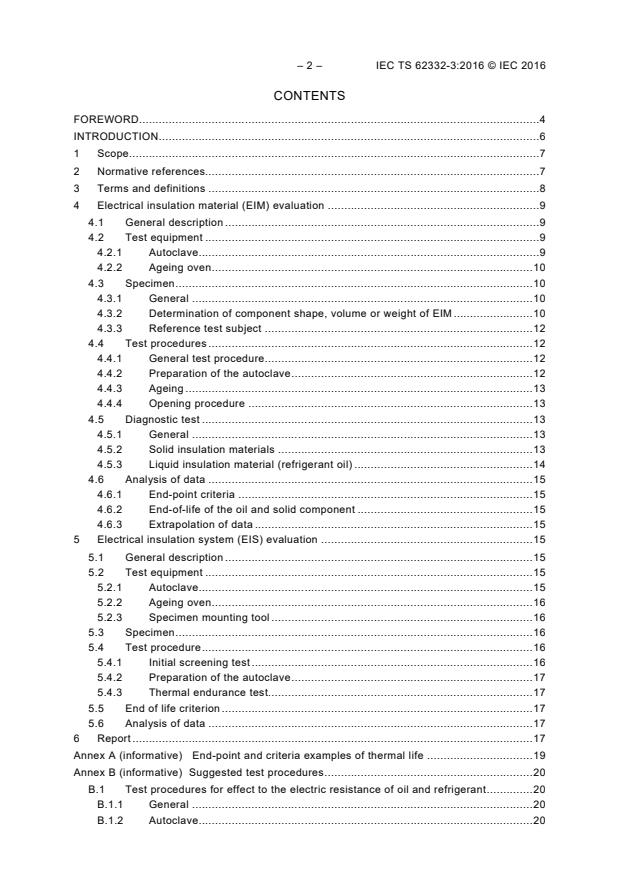

– 2 – IEC TS 62332-3:2016 © IEC 2016

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references. 7

3 Terms and definitions . 8

4 Electrical insulation material (EIM) evaluation . 9

4.1 General description . 9

4.2 Test equipment . 9

4.2.1 Autoclave . 9

4.2.2 Ageing oven . 10

4.3 Specimen . 10

4.3.1 General . 10

4.3.2 Determination of component shape, volume or weight of EIM . 10

4.3.3 Reference test subject . 12

4.4 Test procedures . 12

4.4.1 General test procedure . 12

4.4.2 Preparation of the autoclave . 12

4.4.3 Ageing . 13

4.4.4 Opening procedure . 13

4.5 Diagnostic test . 13

4.5.1 General . 13

4.5.2 Solid insulation materials . 13

4.5.3 Liquid insulation material (refrigerant oil) . 14

4.6 Analysis of data . 15

4.6.1 End-point criteria . 15

4.6.2 End-of-life of the oil and solid component . 15

4.6.3 Extrapolation of data . 15

5 Electrical insulation system (EIS) evaluation . 15

5.1 General description . 15

5.2 Test equipment . 15

5.2.1 Autoclave . 15

5.2.2 Ageing oven . 16

5.2.3 Specimen mounting tool . 16

5.3 Specimen . 16

5.4 Test procedure . 16

5.4.1 Initial screening test . 16

5.4.2 Preparation of the autoclave . 17

5.4.3 Thermal endurance test. 17

5.5 End of life criterion . 17

5.6 Analysis of data . 17

6 Report . 17

Annex A (informative) End-point and criteria examples of thermal life . 19

Annex B (informative) Suggested test procedures . 20

B.1 Test procedures for effect to the electric resistance of oil and refrigerant . 20

B.1.1 General . 20

B.1.2 Autoclave . 20

B.1.3 Test subject . 20

B.1.4 Test process . 20

B.2 Blister test of winding wire . 20

B.2.1 Overview . 20

B.2.2 General . 20

B.2.3 Autoclave . 20

B.2.4 Test subject . 21

B.2.5 Test process . 21

B.2.6 Test result . 21

B.3 Refrigerant extract test for solid insulating materials . 21

B.3.1 General . 21

B.3.2 Autoclave . 21

B.3.3 Test subject . 21

B.3.4 Test process . 22

B.3.5 Test result . 22

B.4 Metal surface contamination test . 22

B.4.1 General . 22

B.4.2 Test procedure . 22

Bibliography . 23

Figure 1 – Autoclave example for ageing test of EIM . 9

Figure 2 – Examples of the autoclave for EIS ageing . 16

Figure 3 – Mounting tool . 16

Figure 4 – Example of GPM mounting . 16

Table 1 – Hermetic motor-compressor EIM and diagnostic test items . 10

Table 2 – Diagnostic test and its method for solid insulation . 14

Table 3 – Diagnostic test and its method for liquid insulation . 14

Table A.1 – End-point and criteria example of thermal life . 19

– 4 – IEC TS 62332-3:2016 © IEC 2016

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRICAL INSULATION SYSTEMS (EIS) –

THERMAL EVALUATION OF COMBINED LIQUID

AND SOLID COMPONENTS –

Part 3: Hermetic motor-compressors

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In

exceptional circumstances, a technical committee may propose the publication of a Technical

Specification when

• the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

• the subject is still under technical development or where, for any other reason, there is the

future but no immediate possibility of an agreement on an International Standard.

Technical Specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

IEC TS 62332-3, which is a Technical Specification, has been prepared by IEC technical

committee 112: Evaluation and qualification of electrical insulating materials and systems.

The text of this Technical Specification is based on the following documents:

Enquiry draft Report on voting

112/353/DTS 112/362/RVC

Full information on the voting for the approval of this Technical Specification can be found in

the report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62332 series, published under the general title Electrical insulation

systems (EIS) – Thermal evaluation of combined liquid and solid components, can be found

on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• transformed into an International Standard,

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC TS 62332-3:2016 © IEC 2016

INTRODUCTION

This part of IEC 62332, which is a Technical Specification, describes a method for the thermal

evaluation of electrical insulation systems (EIS) for electrotechnical products with combined

liquid and solid components. IEC TS 62332-1 covers general test requirements.

IEC TS 62332-2 covers a simplified test method which can be used as a screening test prior

to conducting IEC TS 62332-1 testing or can be used as a quality control test to evaluate

minor product changes. This part of IEC 62332 covers the evaluation and qualification of

electrical insulation materials (EIM) and EIS which are applied to motor-compressors for the

refrigerator or air conditioner. This document contains the evaluation items which are

important to maintain the equipment performances in the refrigerator oil and refrigerant at

high temperature and high pressure.

This document has been prepared in conjunction with IEC 60335-2-34.

IEC TS 62332-3 is applicable to EIM and EIS evaluation for hermetic motor-compressors

which are applied to the refrigerator and the air conditioner. The main procedures consist in

the evaluation of EIM and EIS endurance for refigerator and oil at high temperature and high

pressure. It describes how to evaluate the mechanical, thermal and chemical degradation of

the performances of EIM which have deep relation to keep the sound condition of the

equipment.

This simplified Technical Specification provides a test method for sealed tube testing. The

sealed tube should contain all the primary EIM elements in relative component ratios which

compare with the actual electrotechnical device.

ELECTRICAL INSULATION SYSTEMS (EIS) –

THERMAL EVALUATION OF COMBINED LIQUID

AND SOLID COMPONENTS –

Part 3: Hermetic motor-compressors

1 Scope

This part of IEC 62332, which is a Technical Specification, is applicable to EIM and EIS

containing solid and liquid components where the refrigerant, oil and thermal stresses are the

dominant ageing factor, without restriction to voltage class.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60216-1, Electrical insulating materials – Thermal endurance properties – Part 1: Ageing

procedures and evaluation of test results

IEC 60216-3, Electrical insulating materials – Thermal endurance properties – Part 3:

Instructions for calculating thermal endurance characteristics

IEC 60216-4-1:2006, Electrical insulating materials – Thermal endurance properties – Part 4-1:

Ageing ovens – Single-chamber ovens

IEC 60216-5, Electrical insulating materials – Thermal endurance properties – Part 5:

Determination of relative thermal endurance index (RTE) of an insulating material

IEC 60247, Insulating liquids – Measurement of relative permittivity, dielectric dissipation

factor (tan δ) and d.c. resistivity

IEC 60250, Recommended methods for the determination of the permittivity and dielectric

dissipation factor of electrical insulating materials at power, audio and radio frequencies

including metre wavelengths

IEC 60317-0-1, Specifications for particular types of winding wires – Part 0-1: General

requirements – Enamelled round copper wire

IEC 60505, Evaluation and qualification of electrical insulation systems

IEC 60674-2, Specification for plastic films for electrical purposes. Part 2: Methods of test

IEC 60684-2, Flexible insulating sleeving – Part 2: Methods of test

IEC 60851-5, Winding wires – Test methods – Part 5: Electrical properties

IEC 61857-1:2008, Electrical insulation systems– Procedures for thermal evaluation – Part 1:

General requirements – Low voltage

– 8 – IEC TS 62332-3:2016 © IEC 2016

IEC 61857-21:2009, Electrical insulation systems – Procedures for thermal evaluation –

Part 21: Specific requirements for general-purpose models – Wire-wound applications

IEC 62021 (all parts), Insulating liquids – Determination of acidity

ISO 178, Plastics – Determination of flexural properties

ASTM D4603, Standard Test Method for Determining Inherent Viscosity of Poly(Ethylene

Terephthalate) (PET) by Glass Capillary Viscometer

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60505, as well as

the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

acidity

quantity of base, expressed in milligrams of potassium hydroxide per gram of sample,

required to titrate potentiometrically or colourimetrically a test portion in a specified solvent to

the end point

[SOURCE: IEC 62021-3: 2014, 3.1]

3.2

breakdown voltage

voltage at which a specimen suffers destructive discharges under the prescribed test

conditions

Note 1 to entry: It is used in tests with continuously rising voltage.

3.3

extract

substance or resource obtained from a given element by a special method

3.4

thermal ageing factor

thermal stress that causes irreversible changes in the EIS

3.5

interfacial tension

adhesive forces between the liquid phase of one substance and either a solid, liquid or gas

phase of another substance

3.6

autoclave

sealed tube

sealed container partially filled with the liquid EIM and which includes the solid EIM in relative

component ratios which compare with the actual electrotechnical device

3.7

blister

small foam which is produced in the inner enamel layer of a winding wire

4 Electrical insulation material (EIM) evaluation

4.1 General description

This test procedure is useful for evaluating the chemical compatibility of insulation material

(EIM) with the liquid (oil) and refrigerant at high temperature and high pressure.

The reference and candidate EIM shall be exposed to test periods at selected elevated

temperatures and pressures. These test periods consist of a specific time exposure at the

selected temperature and pressure followed by diagnostic tests.

A specific material is sealed in a stainless steel autoclave, subjected to a specified thermal

ageing cycle and then subjected to each test. Candidate autoclave test results are then

compared to the reference autoclave test results for qualification of the acceptability of the

candidate EIM.

The test system consists of the following elements:

• autoclaves;

• ageing ovens;

• test objects.

4.2 Test equipment

4.2.1 Autoclave

Each autoclave is a container constructed of stainless steel. The size or the volume shall be

determined by the size or the volume of the test objects, oil and refrigerant, excluding the

3 3

electric resistance test and extract test. In general, 300 cm to 500 cm volume of autoclave

is convenient and enough for each EIM test.

Either one or both ends of the cell shall be fitted with removable, sealable bolt-on covers.

The autoclave parts shall be provided for the pressure gage, pressure relief system, needle

valve and gas sealing packing.

For specific details, see Figure 1.

IEC

Figure 1 – Autoclave example for ageing test of EIM

– 10 – IEC TS 62332-3:2016 © IEC 2016

4.2.2 Ageing oven

An air circulating oven or oil bath can be used.

In case of an air circulating oven, the ovens used shall meet the requirements of

IEC 60216-4-1:2006, 5.2 to 5.4 (temperature difference, fluctuation on variation).

In case of an oil bath, the oil level shall be maintained at a level high enough to provide

appropriate heat transfer during the test. The oil shall have enough thermal endurance for the

ageing test in this case.

4.3 Specimen

4.3.1 General

The following EIMs and components are applied as test subjects and evaluated by each

diagnostic test as shown in Table 1.

Table 1 – Hermetic motor-compressor EIM and diagnostic test items

Winding Varnish Film Molding Tube Tie cord Oil Refriger Process

a

wire part ant oil

Breakdown voltage

〇 〇 〇 〇

Dielectric constant (ε)

〇

Electric resistivity

〇 〇

Effect to electric

〇

resistivity of oil

Effect to electric

〇

resistivity of refrigerant

Tensile strength

〇 〇

Flexual strength

〇

Elongation

〇

Blister

〇

Molecular weight

〇

change

Extract

〇 〇 〇 〇 〇 〇

Acidity

〇

Metal Surface

〇

contamination

Key:

〇 = EIM that is applied to the qualification test.

a

For example: winding wire winding lubricant, iron punching oil, die casting oil.

4.3.2 Determination of component shape, volume or weight of EIM

Excluding the resistance test and the extract test, the specimen shall be prepared as follows:

a) Winding wire:

• breakdown voltage: specimen shall be prepared in accordance with IEC 60851-5,

• relative permittivity (ε ) and dielectric loss (tanδ): in accordance with IEC 60250,

r

• blister test: 100 mm in length,

• extract test: see 4.4.2.

b) Varnish:

• breakdown voltage: if included in the EIS, the impregnating varnish shall be applied to

the winding wire samples as twisted pair and cured in accordance with the

manufacturer’s specifications,

• extract test: see 4.4.2.

c) Film:

• breakdown voltage: size 250 mm × 250 mm,

• relative permittivity (ε ): size 100 mm × 100 mm,

r

• tensile strength and elongation: width = 10 mm to 25 mm, length = 100 mm,

• molecular weight; about 1,0 g,

• extract test: see Clause B.3

d) Molding part:

• bending strength: apply the practical part which is used in the compressor,

• extract test: see Clause B.3.

e) Tube:

• breakdown voltage: enough length that it does not cause flashover when the surface

test pole length is 100 mm,

• extract test: see Article B.3.

f) Tie cord:

• tensile strength and elongation: enough length to chuck when the elongation

measurement is 25 mm long,

• effect on the electric resistance of oil: the same ratio of the weight to the oil in the

compressor is applied,

• effect on the electric resistance of refrigerant: the same ratio of the weight to the

refrigerant in the compressor is applied,

• extract test: see Clause B.3.

g) Metallic part:

• surface contamination test: capillary tube longer than 100 mm ,

• see Clause B.4.

h) Oil:

• half the volume of the autoclave container shall be supplied for each ageing test,

• after the ageing, the test subject shall be removed from the autoclave and the oil shall

be supplied to each diagnostic test.

i) Refrigerant:

• the refrigerant weight which is supplied to the autoclave shall be decided by the ageing

pressure at the ageing temperature. The relation between the temperature and the

pressure depends on the quality of each refrigerant.

NOTE The amount of the refrigerant ratio to the oil is different according to the ageing test temperatures for

keeping the settled autoclave inner pressure.

– 12 – IEC TS 62332-3:2016 © IEC 2016

4.3.3 Reference test subject

The reference test subject shall be composed of EIMs that have an established performance

in combination with the same compressor component, oil and refrigerant.

4.4 Test procedures

4.4.1 General test procedure

The general test procedure shall be applied to the evaluation tests, excluding the electrical

resistance of refrigerant test and extract test.

A three-temperature ageing test shall be completed to establish the thermal rating of the new

EIM. A reference EIM shall be used to validate the testing of the candidate EIM.

A simplified single-point ageing can also be conducted for the purpose of quality control,

minor product changes or for screening prior to a full three-point evaluation. The setup would

be similar to that described for the three-point ageing.

While a complete thermal index may not be determined based on such a single-point test, this

test could be used to understand the expected capability of a proposed candidate EIS without

the time and effort of completing a full evaluation.

4.4.2 Preparation of the autoclave

The preparation of the autoclave assembly is as follows.

a) Cleaning of the autoclave: it shall be filled with an effective solvent, such as acetone, for

24 h or longer, scrubbed well with a detergent brush, rinsed thoroughly with tap water and

then with distilled water, and finally dried.

b) Drying of the autoclave: the taps, nuts, and bolts shall be conditioned for at least 1 h in an

oven maintained at 105 °C ± 2 K, and shall then be removed from the oven and the

samples immediately inserted.

c) Setting of the specimen: the twisted pairs of wire shall be prepared in accordance with

IEC 60851-5 before insertion in the autoclave. The other materials shall then be

positioned inside the autoclave, avoiding contact with each other, if possible, so that there

is no sticking during the ageing period.

d) The twisted pair shall be set up in the autoclave so that half of the twisted part is

immersed into the oil. In case there are other EIMs, it is better to separate into two groups.

One of the group (about half the amount of the specimen) shall be kept in oil, and the

effect of oil checked.

e) Drying of the specimen: after the EIMs are set in the autoclave, the tube, gaskets, taps,

nuts and bolts shall be dried for at least 1 h in an oven maintained at 105 °C ± 2 K.

Certain materials may require additional conditioning to remove all moisture, if agreed

upon by interested parties. Higher temperatures and times may be used to condition these

materials prior to insertion in the autoclave.

f) Supplying of the oil: the oil is supplied into the autoclave. Oil volume is at about half the

volume of the autoclave's inner volume. In this case, the water content of the oil shall be

controlled.

g) Assembly of the autoclave: immediately after the supplying of the oil, the autoclave shall

be closed, to prevent the oil from absorbing water.

h) Supplying of the refrigerant: in the autoclave a vacuum of 1 000 Pa to 2 000 Pa is

generated and the pre-fixed amount of refrigerant is supplied.

i) Pressure control: the autoclave is inserted into the oven or the oil bath and the

temperature is maintained at a settled temperature. After the autoclave temperature has

settled, the autoclave pressure is set to the settled pressure by controlling the refrigerant

amount using the needle valve of the autoclave. Inspection of the autoclave sealing could

be done by checking the pressure gauge.

4.4.3 Ageing

The autoclave shall be placed in the pre-heated thermal conditioning oven. The thermal

conditioning oven shall not be opened during the conditioning cycle as this can affect the

thermal ageing of the EIS under evaluation.

The ageing temperature and time shall be in accordance with IEC 60216-1.

The ageing temperature shall be selected at the temperature where the refrigerant oil or

refrigerant is stable.

4.4.4 Opening procedure

After thermal conditioning of the autoclave, the oven shall be turned off and allowed to cool to

room temperature before the autoclave is removed.

The autoclave shall be kept sealed, prior to evaluation, which is not to be delayed for more

than three days. The autoclave shall then be opened and the EIMs components carefully

removed and separated so as to reduce mechanical damage.

4.5 Diagnostic test

4.5.1 General

Samples of both the solid insulation and the liquid insulation shall be tested prior to start-up.

After the ageing, each property of the solid insulation and the liquid shall be measured.

Changes between the initial and final states shall be used to determine the amount of

degradation occurring during the testing cycle. The results of the initial moisture content

measurements shall be used to determine whether or not the materials are adequately dried

prior to start-up.

4.5.2 Solid insulation materials

At start-up, the solid insulation samples shall be tested using one or more diagnostic tests to

be chosen by the equipment technical committee to determine the end of life. Additional tests

may be used for monitoring purposes. Evaluation tests and their method are shown in Table 2.

– 14 – IEC TS 62332-3:2016 © IEC 2016

Table 2 – Diagnostic test and its method for solid insulation

Evaluation test Test EIM Test method

Electric property Breakdown voltage Winding wire IEC 60317-0-1

Varnish IEC 60317-0-1

Film IEC 60674-2

Tube IEC 60684-2

Relative permittivity (ε ) Film IEC 60250

r

Effect on oil electric Tie cord Clause B.1

resistivity

Effect on refrigerant

electric resistivity

Mechanical property Tensile strength Film IEC 60674-2

Tie cord IEC 60684-2

Elongation Film IEC 60674-2

a

Flexural strength Molding part ISO 178

Blister Winding wire Clause B.2

Chemical property Extract Winding wire Clause B.3

Varnish

Film

Molding part

Tie cord

Molecular weight Film ASTM D4603

Metal surface EIMs and process oil Clause B.4

contamination

NOTE For solid insulation which includes enamel coated wires, most of the above test methods are not

appropriate. In such cases, the key characteristic to monitor for the enamel coated wires is the dielectric

strength retention. There has only been limited experience using such coated wires with this test method.

a

The support span shall be decided by the examiner.

4.5.3 Liquid insulation material (refrigerant oil)

At start-up, the liquid insulation pre-conditioned according to 4.4.2 shall be tested using one

or more diagnostic tests to be chosen by the equipment technical committee to determine the

end of life. Additional tests may be used for monitoring purposes. Examples of typical

diagnostic test for liquids are as follows (see Table 3):

Table 3 – Diagnostic test and its method for liquid insulation

Evaluation test Test EIM Test method

Electric resistivity Oil IEC 60247

Refrigerant IEC 60247

Acidity Oil IEC 62021 (all parts)

4.6 Analysis of data

4.6.1 End-point criteria

The criteria by which a test object is considered to have failed shall be fully defined prior to

the start of the test. An adequate test shall be included in the test period to detect when a

failure occurs, denoting the end of life for each test object. The use of more than one end-

point criterion will tend to make interpretation of the test results more difficult. It is

recommended that only one end-point criterion be used for each component in the test object

(solid/liquid). The equipment technical committee for the EIS being modelled shall define the

specific end-point criterion.

4.6.2 End-of-life of the oil and solid component

The preferred end-point criterion for the solid or oil insulation shall be the degradation of the

original value of the selected mechanical, electrical and chemical properties.

Other choices for the end-point criterion are described in IEC 60216-2:2005, Table 1. The end

of life value for the candidate EIS (such as 50 % tensile strength retention) shall be

determined based on the test of the same component in the reference EIS.

The end point and criteria examples of thermal life are shown in Table A.1.

The total number of hours to end of life shall be recorded for the solid component in the test

object at each ageing temperature. The life (in hours) at each ageing temperature shall be

calculated according to IEC 60216-3.

4.6.3 Extrapolation of data

Linear regression analysis on the solid component data shall be carried out in accordance

with IEC 60216-5.

5 Electrical insulation system (EIS) evaluation

5.1 General description

EIS evaluation uses the same method in accordance with IEC 61857-1 and IEC 61857-21

except the ageing environment which is applied to the refrigerant and refrigerant oil in the

autoclave.

5.2 Test equipment

5.2.1 Autoclave

Each autoclave is a container constructed of stainless steel. The size or the volume shall be

determined by the size or the volume of the test objects. Either one or both ends of the cell

shall be fitted with removable, sealable bolt-on covers.

The autoclave parts shall be provided for pressure gauge, pressure relief system, needle

valve and gas sealing packing.

Two examples of the autoclave for EIS ageing are shown in Figure 2.

– 16 – IEC TS 62332-3:2016 © IEC 2016

IEC

Source: ELTEK International Laboratories

Figure 2 – Examples of the autoclave for EIS ageing

5.2.2 Ageing oven

The air circulating oven shall be used and meet the requirements of IEC 60216-4-1:2006, 5.2

through 5.4 (temperature difference, fluctuation on variation).

5.2.3 Specimen mounting tool

The GPM (general purpose model) specimen is mounted in the autoclave by using an

adequate tool for keeping the oil immersion length and avoiding contact with each other.

Examples of mounting tool for EIS and of GPM mounting are shown in Figure 3, and Figure 4

IEC

IEC

Source: ELTEK International Laboratories. Source: ELTEK International Laboratories.

Figure 3 – Mounting tool Figure 4 – Example of GPM mounting

5.3 Specimen

For the evaluation of EIS, the GPM shall be applied in accordance with IEC 61857-21.

The minimum number of test objects in a group for each ageing temperature shall be 5.

5.4 Test procedure

5.4.1 Initial screening test

Prior to the ageing test, all test objects shall be subjected to the initial screening test in

accordance with IEC 61857-21:2009, 6.2.2.

5.4.2 Preparation of the autoclave

The preparation of the autoclave shall be done in accordance with 4.4.2.

In this case, the volume of the oil is controlled to about half of the autoclave volume so that

the GPM shall be capable of being immersed to half of its length.

5.4.3 Thermal endurance test

5.4.3.1 General

Following the mounting of the GPM in the autoclave, the autoclave shall be placed in the pre-

heated thermal conditioning oven. All test objects shall be subjected to repeated thermal

endurance test cycles consisting of sub-cycle in the following order:

a) thermal ageing by exposure to refrigerant and refrigerant oil;

b) mechanical stress;

c) thermal shock;

d) dielectric diagnostic test.

5.4.3.2 Thermal ageing by exposure to refrigerant and refrigerant oil (5.4.3.1 a))

The thermal conditioning oven shall not be opened during the conditioning cycle as this can

affect the thermal ageing of the EIS under evaluation. The agei

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...