IEC TS 62736:2016

(Main)Ultrasonics - Pulse-echo scanners - Simple methods for periodic testing to verify stability of an imaging system's elementary performance

Ultrasonics - Pulse-echo scanners - Simple methods for periodic testing to verify stability of an imaging system's elementary performance

IEC TS 62736:2016(E) specifies requirements and methods for periodic testing of the quality of diagnostic medical ultrasound systems with linear array, curved linear array, single element, annular array, phased array, matrix linear array transducers and two-dimensional arrays.

General Information

- Status

- Published

- Publication Date

- 11-Jul-2016

- Technical Committee

- TC 87 - Ultrasonics

- Drafting Committee

- WG 9 - TC 87/WG 9

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 13-Jan-2023

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC TS 62736:2016 - Ultrasonics - Pulse‑echo scanners - Simple methods for periodic testing to verify stability of an imaging system’s elementary performance - provides practical, repeatable test methods for periodic quality control (QC) of diagnostic medical ultrasound imaging systems. The Technical Specification covers a broad range of transducer types (linear, curved linear, single element, annular, phased array, matrix linear and 2‑D arrays) and focuses on simple measurement procedures to verify ongoing stability of basic imaging performance.

Key Topics

- Scope and purpose: Periodic testing methods to confirm stability of elementary performance of pulse‑echo scanners used in clinical practice.

- Quality control levels: A tiered approach with Level 1 (basic visual/operational checks), Level 2 (simple measurement tests using phantoms and image analysis), and Level 3 (quantitative measurements for depth penetration, distance accuracy and display).

- Test methods and procedures: Mechanical inspection, image uniformity and transducer/channel integrity checks, maximum relative depth of penetration assessments, distance measurement verification, and display/archiving considerations.

- Equipment and data requirements: Use of tissue‑mimicking phantoms, recommended image acquisition settings, digital image data handling and image‑archiving systems for QC records.

- Environmental and operational recommendations: Consideration of environmental conditions and system settings to ensure repeatable measurements.

- Analysis and documentation: Guidance on image analysis, examples of phantoms, and use of control charts/software for tracking performance over time.

Applications

- Routine periodic QC for ultrasound departments in hospitals and clinics to ensure consistent diagnostic image quality and patient safety.

- Preventive maintenance and service verification by biomedical engineers and service technicians to detect transducer element or channel failures.

- Quality assurance programs led by clinical physicists or imaging managers to meet institutional or regulatory expectations for medical imaging equipment.

- Manufacturers and suppliers can use the TS to define basic performance checks and expectations for field support and warranty servicing.

Who Should Use This Standard

- Biomedical engineers and service personnel

- Clinical medical physicists and QA technologists

- Ultrasound department managers and sonographers involved in QC programs

- Manufacturers and suppliers of diagnostic ultrasound equipment

Related Standards (if applicable)

IEC TS 62736 complements other IEC and international guidance on medical ultrasound and medical electrical equipment performance and safety. Users should consult their national requirements and additional IEC publications on ultrasound test methods and medical device standards for comprehensive compliance.

Keywords: IEC TS 62736:2016, ultrasonics, pulse‑echo scanners, ultrasound QC, periodic testing, image uniformity, depth of penetration, transducer testing, diagnostic medical ultrasound.

IEC TS 62736:2016 - Ultrasonics - Pulse-echo scanners - Simple methods for periodic testing to verify stability of an imaging system's elementary performance

IEC TS 62736:2016 - Ultrasonics - Pulse-echo scanners - Simple methods for periodic testing to verify stability of an imaging system's elementary performance Released:7/12/2016 Isbn:9782832235294

Get Certified

Connect with accredited certification bodies for this standard

BSMI (Bureau of Standards, Metrology and Inspection)

Taiwan's standards and inspection authority.

Sponsored listings

Frequently Asked Questions

IEC TS 62736:2016 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Ultrasonics - Pulse-echo scanners - Simple methods for periodic testing to verify stability of an imaging system's elementary performance". This standard covers: IEC TS 62736:2016(E) specifies requirements and methods for periodic testing of the quality of diagnostic medical ultrasound systems with linear array, curved linear array, single element, annular array, phased array, matrix linear array transducers and two-dimensional arrays.

IEC TS 62736:2016(E) specifies requirements and methods for periodic testing of the quality of diagnostic medical ultrasound systems with linear array, curved linear array, single element, annular array, phased array, matrix linear array transducers and two-dimensional arrays.

IEC TS 62736:2016 is classified under the following ICS (International Classification for Standards) categories: 17.140.50 - Electroacoustics. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 62736:2016 has the following relationships with other standards: It is inter standard links to IEC TS 62736:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TS 62736:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TS 62736 ®

Edition 1.0 2016-07

TECHNICAL

SPECIFICATION

colour

inside

Ultrasonics – Pulse-echo scanners –

Simple methods for periodic testing to verify stability of an imaging system’s

elementary performance

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC TS 62736 ®

Edition 1.0 2016-07

TECHNICAL

SPECIFICATION

colour

inside

Ultrasonics – Pulse-echo scanners –

Simple methods for periodic testing to verify stability of an imaging system’s

elementary performance

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 17.140.50 ISBN 978-2-8322-3529-4

– 2 – IEC TS 62736:2016 © IEC 2016

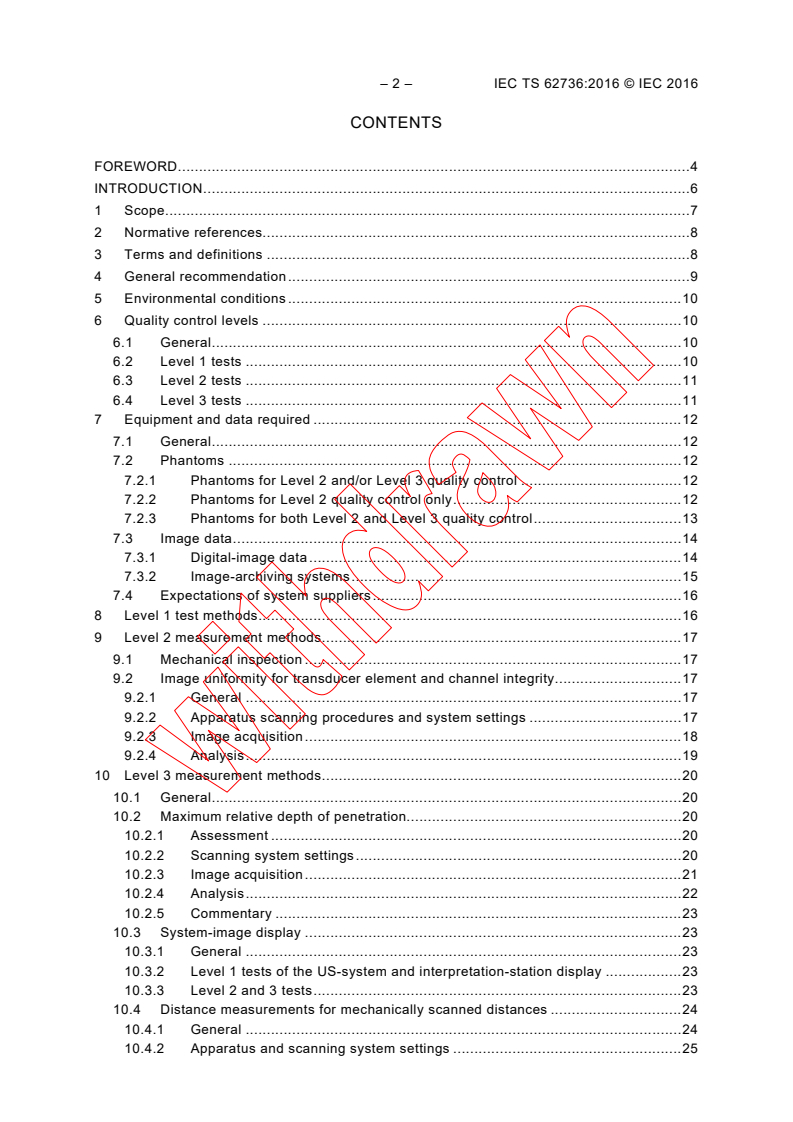

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references. 8

3 Terms and definitions . 8

4 General recommendation . 9

5 Environmental conditions . 10

6 Quality control levels . 10

6.1 General . 10

6.2 Level 1 tests . 10

6.3 Level 2 tests . 11

6.4 Level 3 tests . 11

7 Equipment and data required . 12

7.1 General . 12

7.2 Phantoms . 12

7.2.1 Phantoms for Level 2 and/or Level 3 quality control . 12

7.2.2 Phantoms for Level 2 quality control only . 12

7.2.3 Phantoms for both Level 2 and Level 3 quality control . 13

7.3 Image data . 14

7.3.1 Digital-image data . 14

7.3.2 Image-archiving systems . 15

7.4 Expectations of system suppliers . 16

8 Level 1 test methods . 16

9 Level 2 measurement methods . 17

9.1 Mechanical inspection . 17

9.2 Image uniformity for transducer element and channel integrity. 17

9.2.1 General . 17

9.2.2 Apparatus scanning procedures and system settings . 17

9.2.3 Image acquisition . 18

9.2.4 Analysis . 19

10 Level 3 measurement methods . 20

10.1 General . 20

10.2 Maximum relative depth of penetration. 20

10.2.1 Assessment . 20

10.2.2 Scanning system settings . 20

10.2.3 Image acquisition . 21

10.2.4 Analysis . 22

10.2.5 Commentary . 23

10.3 System-image display . 23

10.3.1 General . 23

10.3.2 Level 1 tests of the US-system and interpretation-station display . 23

10.3.3 Level 2 and 3 tests . 23

10.4 Distance measurements for mechanically scanned distances . 24

10.4.1 General . 24

10.4.2 Apparatus and scanning system settings . 25

10.4.3 Image acquisition . 25

10.4.4 Analysis . 25

Annex A (informative) Example phantoms for image uniformity and/or maximum

relative depth of penetration . 26

Annex B (informative) Available analysis software . 29

B.1 Open source software for assessment for QC of ultrasound image uniformity . 29

B.2 Example of QC control chart: . 31

Annex C (informative) Display test patterns . 33

Annex D (informative) Electronic test methods and test methods provided by the

manufacturers; relation to clinical significance . 35

Bibliography . 36

Figure 1 – Median-averaged image (right) and its lateral profile (left) . 19

Figure 2 – A) Image of a uniform section in a tissue-mimicking phantom, bright

rectangle; B) Image displaying electronic noise only, obtained with the operating

controls set the same as for A but with the transducer decoupled from the phantom

[SOURCE: University of Wisconsin] . 21

Figure 3 – Mean digitized image-data value vs. depth for the phantom image data (A(j))

and for the noise-image data (Aʹ(j)) . 22

Figure A.1 – Example phantom for image-uniformity and/or maximum-relative-depth-

of-penetration tests . 26

Figure A.2 – Example compact phantom for image-uniformity tests . 27

Figure A.3 – Photograph and drawing of a three-in-one phantom which provides for

determination of distance measurement precision and bias, image uniformity and

depth of penetration [37] . 27

Figure A.4 – A compact uniformity phantom of relatively durable rubber material . 28

Figure B.1 – On the left the profile of median pixel value is plotted for each image

column in the analysis box shown in the median image on the right for the transducer

in Figure 1, but without the nylon filament obstructing some central elements . 30

Figure B.2 – Control chart for a dip in the middle of the profile for one transducer (TD)

mode C9-4 and the specified serial number (S/N) . 32

Figure C.1 – AAPM TG18-UN10 (left) and TG18-UN80 (right) patterns for luminance

uniformity, colour uniformity, and angular response evaluations [35] . 33

Figure C.2 – Example data entry form for visual display evaluation: left for Figure C.1;

right for Figure C.3. 34

Figure C.3 – TG18-CT low-contrast test pattern for the evaluation of the luminance

response of display systems [35] . 34

Table 1 – Outline of Level 1 tests . 10

Table 2 – Outline of Level 3 tests additional to those in Table 1 . 11

Table B.1 – Output of analysis . 31

– 4 – IEC TS 62736:2016 © IEC 2016

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ULTRASONICS – PULSE-ECHO SCANNERS –

Simple methods for periodic testing to verify stability

of an imaging system’s elementary performance

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In

exceptional circumstances, a technical committee may propose the publication of a Technical

Specification when

• the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

• the subject is still under technical development or where, for any other reason, there is the

future but no immediate possibility of an agreement on an International Standard.

Technical Specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

IEC TS 62736, which is a Technical Specification, has been prepared by IEC technical

committee 87: Ultrasonics.

The text of this Technical Specification is based on the following documents:

Enquiry draft Report on voting

87/576/DTS 87/592A/RVC

Full information on the voting for the approval of this Technical Specification can be found in

the report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

Terms in bold in the text are defined in Clause 3. Symbols and formulae are in Times New

Roman italic.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• transformed into an International Standard,

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC TS 62736:2016 © IEC 2016

INTRODUCTION

An ultrasonic pulse-echo scanner produces images of tissue in a scan plane by sweeping a

narrow pulsed beam of ultrasound through the section of interest and detecting the echoes

generated by reflection at tissue boundaries and by scattering within tissues. Various

transducer types are employed to operate in a transmit/receive mode to generate/detect the

ultrasonic signals. Ultrasonic scanners are widely used in medical practice to produce images

of soft-tissue organs throughout the human body. As ultrasound systems are usually

employed under rigorous time restrictions and in diverse environments to help make decisions

often critical to patients’ well being, it is important that the systems perform consistently at the

level provided and accepted in initial tests, e.g. those of IEC 61391-1 and IEC 61391-2. This

document provides methods to verify the stability of an imaging system’s elementary

performance.

This document is deemed necessary because substandard ultrasound system performance is

often accepted, or remains undetected in the absence of unequivocal and documented tests.

The most common of the failures, in all but the oldest systems nearing retirement, are

subperformance of a transducer-array element or lens or of a cable or electronic channel.

Sensitive image uniformity tests for these transducer- and channel-failures are presented in

this document for use monthly (Level 1), biannually (Level 2) and biennially (Level 3). With

approximately 14 % transducer-failure rate and 10 % system-failure rate per year on first

testing [1],[2],[3],[4],[5],[6],[7],[8],[9],[10],[11],[12], there are, very approximately, 100 000

systems worldwide routinely performing suboptimal diagnostic exams for part of the year.

This common occurrence of suboptimal diagnostic examinations has created an urgent need

to standardize quality-control (QC) and performance-evaluation procedures to promote

improved efficacy of diagnostic examinations through widespread use of effective QC

procedures and to dispel myths as to their utility. Proposers believe, however, that existing

national standards and guides [13],[14] specify too many tests and inappropriate tests for

detecting and discriminating the common flaws in diagnostic ultrasound systems during

routine QC. These practices include tests, such as spatial resolution, which are low-yield and

belong in performance-evaluation procedures, rather than QC.

Modern flat-panel display technology is more stable than, and generally far superior to, earlier

CRT displays. However, LCD displays can still exhibit luminance drift, as well as problems

such as defective pixels. It is still necessary to evaluate them periodically.

ULTRASONICS – PULSE-ECHO SCANNERS –

Simple methods for periodic testing to verify stability

of an imaging system’s elementary performance

1 Scope

This document specifies requirements and methods for periodic testing of the quality of

diagnostic medical ultrasound systems with linear array, curved linear array, single element,

annular array, phased array, matrix linear array transducers and two-dimensional arrays.

Image interpretation and measurement workstations are included. Usually, “periodic testing” is

referred to here as “quality control”. This document represents a minimum set of such tests

intended for frequent users of medical ultrasound systems, for quality control professionals in

their organization, or those hired from other quality-control and/or service-provider

organizations. System-manufacturing and repair companies might well employ other or

additional tests. The tests are defined in three levels, with the simplest and most cost-

effective performed most frequently, similarly to [1]. More complete tests for acceptance

testing and for assessment at times of particular importance or concern are specified in

IEC 61391-1, IEC 61391-2 and IEC TS 62791 [15]. These more complete tests are

categorized as performance evaluation, rather than quality control or frequent periodic testing.

This document also defines terms and specifies methods for measuring (for quality

maintenance or quality control) the maximum relative depth of penetration of real-time

ultrasound B-MODE scanners, though this penetration measure is listed as less frequently

applied.

Frequent distance-measurement accuracy tests are recommended only for certain classes of

position encoding that are not now known to be highly stable and without bias.

The types of transducers used with these scanners include:

• mechanical probes;

• electronic phased arrays;

• linear arrays;

• curved arrays;

• two-dimensional arrays;

• three-dimensional scanning probes based on a combination of the above types.

Transducers not readily amenable to transducer-element testing by the simple image-

uniformity procedures specified (for example, phased array and 2D-array transducers) are

tested only partially by maximum relative depth of penetration. System manufacturers are

encouraged to provide pulsing patterns of the transducer elements to allow testing of

individual elements or small-enough groups of elements to enable users to detect significant

element failure or to provide access to another implemented and explained element-test

program. Dedicated Doppler systems are excluded from coverage here as specialized

equipment is required to test them. This test equipment can be specific to the intended

application of the Doppler system.

All scanners considered include basic pulse-echo techniques. The failures to be detected by

the recommended pulse-echo tests also will affect the operation of other modes, such as

colour-flow, harmonic-, elasticity- and compound imaging. The test methodology is applicable

for transducers operating in the 1 MHz to 17 MHz frequency range and could be made

applicable up to 40 MHz, if the depth of penetration were allowed to be relative, rather than

– 8 – IEC TS 62736:2016 © IEC 2016

absolute, and phantom stability were verified [15]. Image-uniformity QC is applicable to

transducers operating in the 1 MHz to 40 MHz frequency range as the requirements for

phantoms are not stringent.

NOTE Phantom manufacturers are encouraged to extend the frequency range to which phantoms are specified to

enable relative depth-of-penetration tests of systems operating at fundamental and harmonic frequencies above

17 MHz.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60050-802, International Electrotechnical Vocabulary – Part 802: Ultrasonics (available at

)

IEC 61391-1, Ultrasonics – Pulse-echo scanners – Part 1: Techniques for calibrating spatial

measurement systems and measurement of system point spread function response

IEC 61391-2, Ultrasonics – Pulse-echo scanners – Part 2: Measurement of maximum depth of

penetration and local dynamic range

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-802 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

addressable patch

smallest addressable group of transducer elements

3.2

echo from weakly reflecting, background scatterers

echoes from many small targets in which the scattered field is much less intense than the

incident field

3.3

maximum depth of penetration

maximum range at which the ratio of the mean, digitized, B-mode-image data corresponding

to images displaying echoes from weakly reflecting, background scatterers to the mean,

digitized, B-mode-image data corresponding to images displaying only electronic noise equals

1,4, when the echoes from weakly reflecting, background scatterers are generated in a

phantom with properties meeting the specifications of IEC 61391-2.

Note 1 to entry: The maximum depth of penetration is expressed in metres (m) and conventionally in

centimetres (cm).

3.4

maximum relative depth of penetration

maximum range at which the ratio of the mean, digitized, B-mode-image data corresponding

to images displaying echoes from weakly reflecting, background scatterers to the mean,

digitized, B-mode-image data corresponding to images displaying only electronic noise equals

1,4, when the echoes from weakly reflecting, background scatterers are generated in a

phantom with properties meeting specifications more relaxed than those of IEC 61391-2

Note 1 to entry: The adjective “relative” is used because the phantom specifications defined in this document are

so loose that measurements of the “maximum range” with different phantoms cannot be compared. The

measurements are only for tests of stability, i.e. comparisons between measurements on the same phantom over

time.

Note 2 to entry: For available phantoms and specifications see [16] and for a potential alternative measure of

depth of penetration see [17]

Note 3 to entry: The maximum relative depth of penetration is expressed in metres (m) and conventionally in

centimetres (cm).

3.5

median absolute deviation

MAD

median of the absolute value of the deviations from the median of a data set

Note 1 to entry: The MAD is similar to the standard deviation but, as the median of linear deviations rather than

squared deviations, it is more resilient to outliers [18].

3.6

performance evaluation

tests performed to assess specific absolute performance of the object tested

Note 1 to entry: Typical times for ultrasound system performance evaluation are at pre-purchase evaluation, new

and repaired system acceptance testing [19],[20],[21],[22],[1] at time of performance difficulties, and end of useful

life evaluations. They are recommended for performance in Level 3 QC tests, though that is not required.

3.7

phantom

device designed to mimic some aspects of the human body for the purposes of testing or

training

3.8

specific attenuation coefficient

attenuation coefficient divided by the frequency

Note 1 to entry: The specific attenuation coefficient, expressed in decibels per centimetre per megahertz

–1 -1

(dB cm MHz ), makes the explicit assumption of linear dependence of the attenuation coefficient on frequency.

3.9

quality control

QC

regularly performed procedures to assure consistent performance

Note 1 to entry: A more descriptive term is quality maintenance; quality assurance is also used.

3.10

equivalent sensitivity

sensitivity that is statistically the same or has smaller variance and bias

4 General recommendation

The manufacturer’s specification should allow comparison with the results obtained from the

tests described in this document.

– 10 – IEC TS 62736:2016 © IEC 2016

5 Environmental conditions

All measurements should be performed within the following ranges of ambient conditions:

– temperature, 23 °C ± 16 °C for uniformity tests; 23 °C ± 3 °C for other measurements;

– relative humidity, 10 % to 95 %; 45 % to 75 % for relative depth of penetration;

– atmospheric pressure, 66 kPa to 106 kPa; 86 kPa to 106 kPa for relative depth of

penetration.

Properties of ultrasound phantoms, such as speed of sound, backscatter coefficient and

attenuation coefficient, are known to vary with temperature. The specifications published by

the phantom manufacturer should be consulted to determine whether the expected acoustic

properties are maintained under the above environmental conditions. If not, the environmental

conditions over which expected and reproducible results can be obtained from the phantom or

test object should be adopted for tests.

6 Quality control levels

6.1 General

These levels are based on the time required for performance and the interval between tests.

Small facilities with a single ultrasound system might not be expected to perform Level 3 tests

except for distance-measurement variance and bias or when problems are suspected that are

not rapidly addressed by a service call. These levels are similar to those recommended by the

European Federation of Societies in Ultrasound in Medicine and Biology [1].

6.2 Level 1 tests

Level 1 tests are short-duration (approximately 5 min) checks, to be performed monthly by the

ultrasound system users, which require no special equipment, only record keeping. They are

simple to perform and record with limited practice. Alternative methods of proven and at least

equivalent sensitivity, as well as interpretability to end users, may be employed.

See Table 1.

Table 1 – Outline of Level 1 tests

Test Evaluation Possible subsequent actions

Inspection for: Visual Level 2 tests or maintenance

(immediately or at interval specified

Damage to transducer face or

by the manufacturer)

housing

Damage to cable

Stable wheel mounts

Clean air filters

Image uniformity Visual with clean transducer face Level 2 tests or maintenance

held in air

Monitor function Visual Level 3 tests, adjustments or

maintenance

Hard copy and image storage Visual Adjustments or maintenance

function

Performance in clinical use Ask users whether any changes in Level 2 or 3 tests, adjustments or

or insufficiencies in the system maintenance

performance have been observed.

Record and investigate any

observations mentioned by users or

interpreters

While both Level 1 and Level 2 tests are simple, it may be helpful to have a quality control

professional, such as a medical physicist or hospital engineer, involved, to assure initiation of

the tests and adequate record maintenance over an extended period of time.

6.3 Level 2 tests

Level 2 tests are performed every six months by users or QC professionals. They are simply

Level 1 tests plus a more sensitive version of the image-uniformity test and any other tests

indicated for special conditions such as mechanically scanned transducers. This more

sensitive image-uniformity test is performed with a phantom and averaging of a cine loop. See

Clause 9. Alternative methods of proven and at least equivalent sensitivity and

interpretability to end users may be employed.

6.4 Level 3 tests

Level 3 tests are performed by QC professionals every two years. They are designed to

detect or verify defects that are less frequent than those detected by the image-uniformity test

and they require more specialized, stable phantoms. These tests include as a minimum:

Levels 1 and 2 tests, plus measurement of maximum relative depth of penetration, and

system- and interpretation-image displays. Distance-measurement variance and bias tests are

required initially on some systems and regularly on others. See Table 2 and Clause 10. The

maximum relative depth of penetration and optional measures are recommended to be

absolute, as in performance evaluations, to allow comparison with results from other sites,

but this is not required. These measures should be self-consistent to detect changes in the

ultrasound systems tested over many years. Acceptance tests and other full-performance

evaluations are part of complete quality control but are treated separately because they are

covered by other standards already described. Several Level 3 procedures are specified by

reference. In large medical systems with many inexpensive ultrasound systems, Level 3 and

even Level 2 tests on all scanners might be hard to justify. In these situations, rapid

replacement followed by repair or recycling in response to concerns from Level 1 tests might

be appropriate, with Level 3 tests of perhaps 10 or 20 of the units every other year. In small,

possibly isolated, practices, Level 1 tests should be performed and every effort made to

obtain Levels 2 and 3 quality control and correction of malfunctions.

Table 2 – Outline of Level 3 tests additional to those in Table 1

Test Evaluation Possible subsequent actions

maximum relative depth of See 10.2; Preferably absolute as in Adjustment or maintenance

penetration IEC 61391-2:2010, 7.1

System- and interpretation-image Tests listed here Adjustment or maintenance

displays

Distance-measurement and bias See 10.4 and IEC 61391-1:2006, 7.4 Adjustment or maintenance

Contrast-detail detectability IEC TS 61390:1996, 6.3.2.3 [23] Adjustment or maintenance

(optional)

Spatial resolution (optional) IEC TS 62791 [15] or, in lateral, axial Adjustment or maintenance

and elevational directions, IEC TS

61390:1996, 3.12, 6.3.2 [23], or, in

lateral and elevational directions

combined, IEC TS 62558 [24].

Evaluation of QC program Assess the QC program, check that Adjustment of procedures

appropriate actions are taken to correct

problems, identify areas where QC

testing may be improved.

In large hospitals and clinics with many inexpensive, as well as high end, ultrasound systems,

Level 3 and even Level 2 tests on all scanners might be hard to justify. In these situations,

rapid replacement followed by repair or recycling in response to concerns from Level 1 tests

might be appropriate, with Level 3 tests of perhaps 10 or 20 of the units every other year. In

– 12 – IEC TS 62736:2016 © IEC 2016

small, possibly isolated, practices, Level 1 tests should be performed and every effort made to

obtain Levels 2 and 3 quality control and correction of malfunctions.

7 Equipment and data required

7.1 General

The test procedures described in this document should be carried out using tissue-mimicking

phantoms and electronic test equipment, together with digital-image data acquired from the

ultrasound scanner.

7.2 Phantoms

7.2.1 Phantoms for Level 2 and/or Level 3 quality control

See Annex A for example geometries of a phantom for both image-uniformity and maximum

relative depth of penetration testing (Figure A.1) and a more compact and less expensive

phantom for image-uniformity testing only (Figure A.2). Figure A.3 shows a phantom for

assessing all three parameters, namely uniformity, maximum relative depth of penetration,

and distance-measurement variance and bias. Suitable phantoms for these tests can be

constructed using, for example, water-based gels, open-pore sponges or urethane rubbers

having microscopic inhomogeneities that are uniformly distributed throughout, to produce the

desired attenuation level [19],[25],[26],[27],[28],[29],[30]. Phantoms without other backscatter

generators require particles, such as 40-micrometre-diameter glass beads to provide

)

backscattered signals at a controlled amplitude [31],[32]. Several manufacturers can

produce tissue-mimicking materials and phantoms that comply with the following

specifications in 7.2.2 and 7.2.3.

7.2.2 Phantoms for Level 2 quality control only

These specifications should be met in the 1 MHz to 17 MHz frequency range except as noted.

More stringent requirements are listed in 7.2.2 for Level 3 tests other than image uniformity:

–1

Speed of sound: (1 500 ± 100) m s at 3 MHz for image uniformity

testing only.

Speed of sound for distance measurement shall meet

specifications for Level 3 tests, below.

−3

Density: (1,00 ± 0,3) g cm

–1 –1

Specific attenuation coefficient: (0,3 to 0,9) dB cm MHz or

–1 –1

(1,4 ± 0,4) dB cm MHz for a compact image-

uniformity phantom. The high value minimizes

reverberation artifacts.

–4 –1 –1

Backscatter coefficient: (3 × 10 cm sr ) ± 10 dB relative to that number at

n

3 MHz with dependence on “frequency to the n” (f ),

where 1 ≤ n < 4 from 1 MHz to 17 MHz for a

combination image-uniformity and relative-depth-of-

penetration phantom.

Scanning surface: The scanning surface should allow acoustic contact of

the entire active area of the transducer with the

phantom.

___________

)

These include, for example, ATS Labs; Bridgeport, CT, USA (www.atslabs.com); CIRS, Norfolk, VA, USA

(www.cirsinc.com); Gammex/RMI, Middleton, WI, USA (www.gammex.com), and Kyoto Kagaku Co., Ltd, Kyoto,

Japan (http://www.kyotokagaku.com). This information is given for the convenience of users of this document and

does not constitute an endorsement by IEC of these products.

Dimensions: The phantom should provide a uniformly scattering

and attenuating field that extends to a depth of at

least 6 cm.

7.2.3 Phantoms for both Level 2 and Level 3 quality control

“Maximum relative depth of penetration” is used here, rather than “maximum depth of

penetration”, as defined in the referenced standard (IEC 61391-2), because more expensive

and perhaps less robust test objects, which are required for the absolute measurements

defined in that standard, are not absolutely required for quality control. However, absolute

measures are recommended, using phantoms defined in IEC 61391-2 to allow comparison of

a user’s current system performance with published values and those values obtained in that

user’s own system with other phantoms. The tissue-mimicking material should have the

following properties, similar to those specified in IEC 61391-2 except that a phantom’s

acoustic-properties requirements, though not its stability requirements, are relaxed here for

facilities using the same phantom for a long period of quality-control testing, or a series of

phantoms having consistent properties.

Phantom material requirements for Level 3 QC over 1 MHz to 17 MHz are:

–1

Speed of sound (SOS): (1 540 ± 20) m s , to avoid substantial complications.

When speed of sound in the phantom is not as assumed by the ultrasound system, the

focus will be displaced and degraded. These are minor effects in the consistency checks

of quality control. However, speed of sound is of great concern in checking for distance

measurement error unless that has been tested carefully in Level 3 performance tests and

consistency tracked carefully in quality control. When filaments are included with

–1

appropriate spacing to simulate 1 540 m s SOS for each of the scan geometries

–1

available on the ultrasound system, then (1 500 ± 80) m s at 3 MHz is tolerable. This

latter extreme flexibility is allowed with great warnings because of the convenience and

–1

longevity of urethane rubber phantoms at, typically, 1 450 m s . However, for the majority

–1

of ultrasound systems, those that assume 1 540 m s propagation speed, different groups

of filaments are required, carefully spaced for their depth in the phantom to give unbiased

distance measurements for phased arrays and linear arrays. Filament placement on an

angular arc specifically matched to the curvature and placement of curved linear arrays or

to the placement of phased arrays is necessary. With any deviation of machine-assumed

SOS from the phantom SOS, deviation of the assumed angle or location of view of the

filaments, or in assumed curvature of the linear array will cause errors in lateral distance

)

measurements . In other words, it is impossible for a single set of filaments to provide

correct lateral distance measurements for different curved linear-array curvatures or for

curved arrays and linear arrays. These lateral/azimuthal and axial distance measurement

problems are not encountered for the increasing number of ultrasound systems that have

an adjustment for speed of sound that can be set to that of the phantom when the

filaments or other targets are placed at their expected distances. It is best to have the

lateral distance filaments on arcs with radii of curvature that match those of the arrays for

which they are designed. Users should be instructed to use a filament group with

curvature close to that (within a certain tolerance) of the transducer, as can be seen easily

on the image of the filaments.

Phantom stability:

Specifications should be met for a period of at least 5 years, warranted for that period by

the phantom’s manufacturer. The warranty can include the expectation of regeneration, for

example, via replacement of solution lost to desiccation, if procedures and costs are

specified. A method of testing for stability of the phantom within specifications should be

provided. In many cases, a manufacturer’s labelling of the mass of the phantom and time

interval at which weight should be tested can meet this need. When a phantom is starting

to desiccate, as water-based phantoms do, or otherwise decay, transition of existing QC

___________

)

Lateral is referred to as azimuthal with phased arrays.

– 14 – IEC TS 62736:2016 © IEC 2016

data to that with a new phantom is possible, if the two phantoms have consistent acoustic

properties. If such a transition is attempted, note clearly the time of the change.

−3 −3

Density: (1,00 ± 0,11) g cm stable to within ± 0,02 g cm

–1 –1

Specific attenuation coefficient: (0,7 + 0,2 / – 0,05) dB cm MHz in the 1 MHz to

17 MHz frequency range

–4 –1 –1

Backscatter coefficient: (3 × 10 cm sr ) ± 10 dB relative to this number

at 3 MHz with dependence on “frequency to the n”

n

(f ), where 1 ≤ n < 4 from 1 MHz to 17 MHz for a

combination image-u

...

IEC TS 62736 ®

Edition 1.0 2016-07

TECHNICAL

SPECIFICATION

colour

inside

Ultrasonics – Pulse-echo scanners –

Simple methods for periodic testing to verify stability of an imaging system’s

elementary performance

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC TS 62736 ®

Edition 1.0 2016-07

TECHNICAL

SPECIFICATION

colour

inside

Ultrasonics – Pulse-echo scanners –

Simple methods for periodic testing to verify stability of an imaging system’s

elementary performance

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 17.140.50 ISBN 978-2-8322-3529-4

– 2 – IEC TS 62736:2016 © IEC 2016

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references. 8

3 Terms and definitions . 8

4 General recommendation . 9

5 Environmental conditions . 10

6 Quality control levels . 10

6.1 General . 10

6.2 Level 1 tests . 10

6.3 Level 2 tests . 11

6.4 Level 3 tests . 11

7 Equipment and data required . 12

7.1 General . 12

7.2 Phantoms . 12

7.2.1 Phantoms for Level 2 and/or Level 3 quality control . 12

7.2.2 Phantoms for Level 2 quality control only . 12

7.2.3 Phantoms for both Level 2 and Level 3 quality control . 13

7.3 Image data . 14

7.3.1 Digital-image data . 14

7.3.2 Image-archiving systems . 15

7.4 Expectations of system suppliers . 16

8 Level 1 test methods . 16

9 Level 2 measurement methods . 17

9.1 Mechanical inspection . 17

9.2 Image uniformity for transducer element and channel integrity. 17

9.2.1 General . 17

9.2.2 Apparatus scanning procedures and system settings . 17

9.2.3 Image acquisition . 18

9.2.4 Analysis . 19

10 Level 3 measurement methods . 20

10.1 General . 20

10.2 Maximum relative depth of penetration. 20

10.2.1 Assessment . 20

10.2.2 Scanning system settings . 20

10.2.3 Image acquisition . 21

10.2.4 Analysis . 22

10.2.5 Commentary . 23

10.3 System-image display . 23

10.3.1 General . 23

10.3.2 Level 1 tests of the US-system and interpretation-station display . 23

10.3.3 Level 2 and 3 tests . 23

10.4 Distance measurements for mechanically scanned distances . 24

10.4.1 General . 24

10.4.2 Apparatus and scanning system settings . 25

10.4.3 Image acquisition . 25

10.4.4 Analysis . 25

Annex A (informative) Example phantoms for image uniformity and/or maximum

relative depth of penetration . 26

Annex B (informative) Available analysis software . 29

B.1 Open source software for assessment for QC of ultrasound image uniformity . 29

B.2 Example of QC control chart: . 31

Annex C (informative) Display test patterns . 33

Annex D (informative) Electronic test methods and test methods provided by the

manufacturers; relation to clinical significance . 35

Bibliography . 36

Figure 1 – Median-averaged image (right) and its lateral profile (left) . 19

Figure 2 – A) Image of a uniform section in a tissue-mimicking phantom, bright

rectangle; B) Image displaying electronic noise only, obtained with the operating

controls set the same as for A but with the transducer decoupled from the phantom

[SOURCE: University of Wisconsin] . 21

Figure 3 – Mean digitized image-data value vs. depth for the phantom image data (A(j))

and for the noise-image data (Aʹ(j)) . 22

Figure A.1 – Example phantom for image-uniformity and/or maximum-relative-depth-

of-penetration tests . 26

Figure A.2 – Example compact phantom for image-uniformity tests . 27

Figure A.3 – Photograph and drawing of a three-in-one phantom which provides for

determination of distance measurement precision and bias, image uniformity and

depth of penetration [37] . 27

Figure A.4 – A compact uniformity phantom of relatively durable rubber material . 28

Figure B.1 – On the left the profile of median pixel value is plotted for each image

column in the analysis box shown in the median image on the right for the transducer

in Figure 1, but without the nylon filament obstructing some central elements . 30

Figure B.2 – Control chart for a dip in the middle of the profile for one transducer (TD)

mode C9-4 and the specified serial number (S/N) . 32

Figure C.1 – AAPM TG18-UN10 (left) and TG18-UN80 (right) patterns for luminance

uniformity, colour uniformity, and angular response evaluations [35] . 33

Figure C.2 – Example data entry form for visual display evaluation: left for Figure C.1;

right for Figure C.3. 34

Figure C.3 – TG18-CT low-contrast test pattern for the evaluation of the luminance

response of display systems [35] . 34

Table 1 – Outline of Level 1 tests . 10

Table 2 – Outline of Level 3 tests additional to those in Table 1 . 11

Table B.1 – Output of analysis . 31

– 4 – IEC TS 62736:2016 © IEC 2016

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ULTRASONICS – PULSE-ECHO SCANNERS –

Simple methods for periodic testing to verify stability

of an imaging system’s elementary performance

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In

exceptional circumstances, a technical committee may propose the publication of a Technical

Specification when

• the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

• the subject is still under technical development or where, for any other reason, there is the

future but no immediate possibility of an agreement on an International Standard.

Technical Specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

IEC TS 62736, which is a Technical Specification, has been prepared by IEC technical

committee 87: Ultrasonics.

The text of this Technical Specification is based on the following documents:

Enquiry draft Report on voting

87/576/DTS 87/592A/RVC

Full information on the voting for the approval of this Technical Specification can be found in

the report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

Terms in bold in the text are defined in Clause 3. Symbols and formulae are in Times New

Roman italic.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• transformed into an International Standard,

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC TS 62736:2016 © IEC 2016

INTRODUCTION

An ultrasonic pulse-echo scanner produces images of tissue in a scan plane by sweeping a

narrow pulsed beam of ultrasound through the section of interest and detecting the echoes

generated by reflection at tissue boundaries and by scattering within tissues. Various

transducer types are employed to operate in a transmit/receive mode to generate/detect the

ultrasonic signals. Ultrasonic scanners are widely used in medical practice to produce images

of soft-tissue organs throughout the human body. As ultrasound systems are usually

employed under rigorous time restrictions and in diverse environments to help make decisions

often critical to patients’ well being, it is important that the systems perform consistently at the

level provided and accepted in initial tests, e.g. those of IEC 61391-1 and IEC 61391-2. This

document provides methods to verify the stability of an imaging system’s elementary

performance.

This document is deemed necessary because substandard ultrasound system performance is

often accepted, or remains undetected in the absence of unequivocal and documented tests.

The most common of the failures, in all but the oldest systems nearing retirement, are

subperformance of a transducer-array element or lens or of a cable or electronic channel.

Sensitive image uniformity tests for these transducer- and channel-failures are presented in

this document for use monthly (Level 1), biannually (Level 2) and biennially (Level 3). With

approximately 14 % transducer-failure rate and 10 % system-failure rate per year on first

testing [1],[2],[3],[4],[5],[6],[7],[8],[9],[10],[11],[12], there are, very approximately, 100 000

systems worldwide routinely performing suboptimal diagnostic exams for part of the year.

This common occurrence of suboptimal diagnostic examinations has created an urgent need

to standardize quality-control (QC) and performance-evaluation procedures to promote

improved efficacy of diagnostic examinations through widespread use of effective QC

procedures and to dispel myths as to their utility. Proposers believe, however, that existing

national standards and guides [13],[14] specify too many tests and inappropriate tests for

detecting and discriminating the common flaws in diagnostic ultrasound systems during

routine QC. These practices include tests, such as spatial resolution, which are low-yield and

belong in performance-evaluation procedures, rather than QC.

Modern flat-panel display technology is more stable than, and generally far superior to, earlier

CRT displays. However, LCD displays can still exhibit luminance drift, as well as problems

such as defective pixels. It is still necessary to evaluate them periodically.

ULTRASONICS – PULSE-ECHO SCANNERS –

Simple methods for periodic testing to verify stability

of an imaging system’s elementary performance

1 Scope

This document specifies requirements and methods for periodic testing of the quality of

diagnostic medical ultrasound systems with linear array, curved linear array, single element,

annular array, phased array, matrix linear array transducers and two-dimensional arrays.

Image interpretation and measurement workstations are included. Usually, “periodic testing” is

referred to here as “quality control”. This document represents a minimum set of such tests

intended for frequent users of medical ultrasound systems, for quality control professionals in

their organization, or those hired from other quality-control and/or service-provider

organizations. System-manufacturing and repair companies might well employ other or

additional tests. The tests are defined in three levels, with the simplest and most cost-

effective performed most frequently, similarly to [1]. More complete tests for acceptance

testing and for assessment at times of particular importance or concern are specified in

IEC 61391-1, IEC 61391-2 and IEC TS 62791 [15]. These more complete tests are

categorized as performance evaluation, rather than quality control or frequent periodic testing.

This document also defines terms and specifies methods for measuring (for quality

maintenance or quality control) the maximum relative depth of penetration of real-time

ultrasound B-MODE scanners, though this penetration measure is listed as less frequently

applied.

Frequent distance-measurement accuracy tests are recommended only for certain classes of

position encoding that are not now known to be highly stable and without bias.

The types of transducers used with these scanners include:

• mechanical probes;

• electronic phased arrays;

• linear arrays;

• curved arrays;

• two-dimensional arrays;

• three-dimensional scanning probes based on a combination of the above types.

Transducers not readily amenable to transducer-element testing by the simple image-

uniformity procedures specified (for example, phased array and 2D-array transducers) are

tested only partially by maximum relative depth of penetration. System manufacturers are

encouraged to provide pulsing patterns of the transducer elements to allow testing of

individual elements or small-enough groups of elements to enable users to detect significant

element failure or to provide access to another implemented and explained element-test

program. Dedicated Doppler systems are excluded from coverage here as specialized

equipment is required to test them. This test equipment can be specific to the intended

application of the Doppler system.

All scanners considered include basic pulse-echo techniques. The failures to be detected by

the recommended pulse-echo tests also will affect the operation of other modes, such as

colour-flow, harmonic-, elasticity- and compound imaging. The test methodology is applicable

for transducers operating in the 1 MHz to 17 MHz frequency range and could be made

applicable up to 40 MHz, if the depth of penetration were allowed to be relative, rather than

– 8 – IEC TS 62736:2016 © IEC 2016

absolute, and phantom stability were verified [15]. Image-uniformity QC is applicable to

transducers operating in the 1 MHz to 40 MHz frequency range as the requirements for

phantoms are not stringent.

NOTE Phantom manufacturers are encouraged to extend the frequency range to which phantoms are specified to

enable relative depth-of-penetration tests of systems operating at fundamental and harmonic frequencies above

17 MHz.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60050-802, International Electrotechnical Vocabulary – Part 802: Ultrasonics (available at

)

IEC 61391-1, Ultrasonics – Pulse-echo scanners – Part 1: Techniques for calibrating spatial

measurement systems and measurement of system point spread function response

IEC 61391-2, Ultrasonics – Pulse-echo scanners – Part 2: Measurement of maximum depth of

penetration and local dynamic range

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-802 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

addressable patch

smallest addressable group of transducer elements

3.2

echo from weakly reflecting, background scatterers

echoes from many small targets in which the scattered field is much less intense than the

incident field

3.3

maximum depth of penetration

maximum range at which the ratio of the mean, digitized, B-mode-image data corresponding

to images displaying echoes from weakly reflecting, background scatterers to the mean,

digitized, B-mode-image data corresponding to images displaying only electronic noise equals

1,4, when the echoes from weakly reflecting, background scatterers are generated in a

phantom with properties meeting the specifications of IEC 61391-2.

Note 1 to entry: The maximum depth of penetration is expressed in metres (m) and conventionally in

centimetres (cm).

3.4

maximum relative depth of penetration

maximum range at which the ratio of the mean, digitized, B-mode-image data corresponding

to images displaying echoes from weakly reflecting, background scatterers to the mean,

digitized, B-mode-image data corresponding to images displaying only electronic noise equals

1,4, when the echoes from weakly reflecting, background scatterers are generated in a

phantom with properties meeting specifications more relaxed than those of IEC 61391-2

Note 1 to entry: The adjective “relative” is used because the phantom specifications defined in this document are

so loose that measurements of the “maximum range” with different phantoms cannot be compared. The

measurements are only for tests of stability, i.e. comparisons between measurements on the same phantom over

time.

Note 2 to entry: For available phantoms and specifications see [16] and for a potential alternative measure of

depth of penetration see [17]

Note 3 to entry: The maximum relative depth of penetration is expressed in metres (m) and conventionally in

centimetres (cm).

3.5

median absolute deviation

MAD

median of the absolute value of the deviations from the median of a data set

Note 1 to entry: The MAD is similar to the standard deviation but, as the median of linear deviations rather than

squared deviations, it is more resilient to outliers [18].

3.6

performance evaluation

tests performed to assess specific absolute performance of the object tested

Note 1 to entry: Typical times for ultrasound system performance evaluation are at pre-purchase evaluation, new

and repaired system acceptance testing [19],[20],[21],[22],[1] at time of performance difficulties, and end of useful

life evaluations. They are recommended for performance in Level 3 QC tests, though that is not required.

3.7

phantom

device designed to mimic some aspects of the human body for the purposes of testing or

training

3.8

specific attenuation coefficient

attenuation coefficient divided by the frequency

Note 1 to entry: The specific attenuation coefficient, expressed in decibels per centimetre per megahertz

–1 -1

(dB cm MHz ), makes the explicit assumption of linear dependence of the attenuation coefficient on frequency.

3.9

quality control

QC

regularly performed procedures to assure consistent performance

Note 1 to entry: A more descriptive term is quality maintenance; quality assurance is also used.

3.10

equivalent sensitivity

sensitivity that is statistically the same or has smaller variance and bias

4 General recommendation

The manufacturer’s specification should allow comparison with the results obtained from the

tests described in this document.

– 10 – IEC TS 62736:2016 © IEC 2016

5 Environmental conditions

All measurements should be performed within the following ranges of ambient conditions:

– temperature, 23 °C ± 16 °C for uniformity tests; 23 °C ± 3 °C for other measurements;

– relative humidity, 10 % to 95 %; 45 % to 75 % for relative depth of penetration;

– atmospheric pressure, 66 kPa to 106 kPa; 86 kPa to 106 kPa for relative depth of

penetration.

Properties of ultrasound phantoms, such as speed of sound, backscatter coefficient and

attenuation coefficient, are known to vary with temperature. The specifications published by

the phantom manufacturer should be consulted to determine whether the expected acoustic

properties are maintained under the above environmental conditions. If not, the environmental

conditions over which expected and reproducible results can be obtained from the phantom or

test object should be adopted for tests.

6 Quality control levels

6.1 General

These levels are based on the time required for performance and the interval between tests.

Small facilities with a single ultrasound system might not be expected to perform Level 3 tests

except for distance-measurement variance and bias or when problems are suspected that are

not rapidly addressed by a service call. These levels are similar to those recommended by the

European Federation of Societies in Ultrasound in Medicine and Biology [1].

6.2 Level 1 tests

Level 1 tests are short-duration (approximately 5 min) checks, to be performed monthly by the

ultrasound system users, which require no special equipment, only record keeping. They are

simple to perform and record with limited practice. Alternative methods of proven and at least

equivalent sensitivity, as well as interpretability to end users, may be employed.

See Table 1.

Table 1 – Outline of Level 1 tests

Test Evaluation Possible subsequent actions

Inspection for: Visual Level 2 tests or maintenance

(immediately or at interval specified

Damage to transducer face or

by the manufacturer)

housing

Damage to cable

Stable wheel mounts

Clean air filters

Image uniformity Visual with clean transducer face Level 2 tests or maintenance

held in air

Monitor function Visual Level 3 tests, adjustments or

maintenance

Hard copy and image storage Visual Adjustments or maintenance

function

Performance in clinical use Ask users whether any changes in Level 2 or 3 tests, adjustments or

or insufficiencies in the system maintenance

performance have been observed.

Record and investigate any

observations mentioned by users or

interpreters

While both Level 1 and Level 2 tests are simple, it may be helpful to have a quality control

professional, such as a medical physicist or hospital engineer, involved, to assure initiation of

the tests and adequate record maintenance over an extended period of time.

6.3 Level 2 tests

Level 2 tests are performed every six months by users or QC professionals. They are simply

Level 1 tests plus a more sensitive version of the image-uniformity test and any other tests

indicated for special conditions such as mechanically scanned transducers. This more

sensitive image-uniformity test is performed with a phantom and averaging of a cine loop. See

Clause 9. Alternative methods of proven and at least equivalent sensitivity and

interpretability to end users may be employed.

6.4 Level 3 tests

Level 3 tests are performed by QC professionals every two years. They are designed to

detect or verify defects that are less frequent than those detected by the image-uniformity test

and they require more specialized, stable phantoms. These tests include as a minimum:

Levels 1 and 2 tests, plus measurement of maximum relative depth of penetration, and

system- and interpretation-image displays. Distance-measurement variance and bias tests are

required initially on some systems and regularly on others. See Table 2 and Clause 10. The

maximum relative depth of penetration and optional measures are recommended to be

absolute, as in performance evaluations, to allow comparison with results from other sites,

but this is not required. These measures should be self-consistent to detect changes in the

ultrasound systems tested over many years. Acceptance tests and other full-performance

evaluations are part of complete quality control but are treated separately because they are

covered by other standards already described. Several Level 3 procedures are specified by

reference. In large medical systems with many inexpensive ultrasound systems, Level 3 and

even Level 2 tests on all scanners might be hard to justify. In these situations, rapid

replacement followed by repair or recycling in response to concerns from Level 1 tests might

be appropriate, with Level 3 tests of perhaps 10 or 20 of the units every other year. In small,

possibly isolated, practices, Level 1 tests should be performed and every effort made to

obtain Levels 2 and 3 quality control and correction of malfunctions.

Table 2 – Outline of Level 3 tests additional to those in Table 1

Test Evaluation Possible subsequent actions

maximum relative depth of See 10.2; Preferably absolute as in Adjustment or maintenance

penetration IEC 61391-2:2010, 7.1

System- and interpretation-image Tests listed here Adjustment or maintenance

displays

Distance-measurement and bias See 10.4 and IEC 61391-1:2006, 7.4 Adjustment or maintenance

Contrast-detail detectability IEC TS 61390:1996, 6.3.2.3 [23] Adjustment or maintenance

(optional)

Spatial resolution (optional) IEC TS 62791 [15] or, in lateral, axial Adjustment or maintenance

and elevational directions, IEC TS

61390:1996, 3.12, 6.3.2 [23], or, in

lateral and elevational directions

combined, IEC TS 62558 [24].

Evaluation of QC program Assess the QC program, check that Adjustment of procedures

appropriate actions are taken to correct

problems, identify areas where QC

testing may be improved.

In large hospitals and clinics with many inexpensive, as well as high end, ultrasound systems,

Level 3 and even Level 2 tests on all scanners might be hard to justify. In these situations,

rapid replacement followed by repair or recycling in response to concerns from Level 1 tests

might be appropriate, with Level 3 tests of perhaps 10 or 20 of the units every other year. In

– 12 – IEC TS 62736:2016 © IEC 2016

small, possibly isolated, practices, Level 1 tests should be performed and every effort made to

obtain Levels 2 and 3 quality control and correction of malfunctions.