IEC 60286-3:2007

(Main)Packaging of components for automatic handling - Part 3: Packaging of surface mount components on continuous tapes

Packaging of components for automatic handling - Part 3: Packaging of surface mount components on continuous tapes

IEC 60286-3:2007 is applicable to the tape packaging of electronic components without leads or with lead stumps which are intended to be connected to electronic circuits. It includes only those dimensions that are essential for the taping of components intended for the above-mentioned purposes. This fourth edition cancels and replaces the third edition issued in 1997. It constitutes a technical revision. It contains the following significant technical changes with respect to the previous edition:

a) implementation of Type IV (adhesive-backed punched plastic carrier tape for singulated bare die and other surface mount components);

b) minor revisions related to tables, figures and references.

Emballage de composants pour opérations automatisées - Partie 3: Emballage des composants appropriés au montage en surface en bandes continues

La CEI 60286-3:2007 est applicable à la mise en bande des composants électroniques sans fils de sortie ou avec tronçons de sortie destinés à être connectés à des circuits électroniques. Elle fournit uniquement les dimensions essentielles pour la mise sur bande de composants destinés aux opérations mentionnées ci-dessus. Cette quatrième édition annule et remplace la troisième édition publiée en 1997 dont elle constitue une révision technique. Elle contient les importantes modifications techniques suivantes par rapport à la précédente édition:

a) mise en oeuvre du Type IV (bande d'entraînement perforée en plastique avec adhésif au dos pour puce nue isolée et autres composants pour montage en surface);

b) révisions mineures des tableaux, valeurs et références.

General Information

- Status

- Published

- Publication Date

- 05-Jun-2007

- Technical Committee

- TC 40 - Capacitors and resistors for electronic equipment

- Drafting Committee

- MT 60286-3 - TC 40/MT 60286-3

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 17-May-2013

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60286-3:2007 - "Packaging of components for automatic handling - Part 3: Packaging of surface mount components on continuous tapes" defines tape packaging formats, essential dimensions and handling requirements for surface-mount devices (SMDs), singulated die and other leadless or lead-stub components intended for automatic assembly. This fourth edition (2007) is a technical revision of the 1997 edition and introduces Type IV adhesive-backed punched carrier tape for bare die and similar products. The standard focuses on dimensions and packaging features that ensure reliable feeding into automatic placement machines and protection during storage and transport.

Key topics

- Tape types and dimensions

- Type I: Punched carrier tape with top and bottom cover tape (commonly 8 mm and 12 mm).

- Type II: Blister carrier tape with single sprocket holes (8, 12, 16, 24 mm).

- Type III: Blister carrier tape with double sprocket holes (32 mm to 200 mm).

- Type IV: Adhesive-backed punched plastic carrier tape for singulated bare die and other SMDs (8–24 mm).

- Component positioning and orientation

- Target position referencing, allowable tilt, rotation and lateral displacement tolerances to support automatic pick-and-place accuracy.

- Tape and cover-tape requirements

- Fixing methods, peel force for cover tape, break force and minimum bending radius to ensure consistent machine feed and component retention.

- Packing and reels

- Leader/trailer specifications, reel dimensions and reel-hole presentations for compatibility with standard feeders.

- Specifics for die products

- Cleanliness, tape design and reduced lateral movement requirements for bare die and flip-chip components.

- Documentation and marking

- Labeling, bar-code symbology guidance and traceability recommendations.

- Safety and handling

- References to ESD protection and good handling practice for semiconductor die.

Applications

IEC 60286-3 is used by:

- SMT manufacturers and contract assemblers to ensure tape-fed components are compatible with pick-and-place equipment.

- Component and packaging suppliers designing carrier tapes, cover tapes and reels.

- Test houses and component distributors packaging devices for shipment and in-line testing.

- Quality and process engineers implementing tape specification checks, incoming inspection and automated feeder configuration.

Benefits include improved feeder reliability, fewer placement errors, better protection for fragile die products, and standardization that simplifies global sourcing and automation.

Related standards

- IEC 60191-2 (mechanical dimensions of semiconductor devices)

- IEC 61340-5-1 / IEC 61340-5-2 (electrostatics / ESD protection)

- IEC 62258-3 (handling, packing and storage of semiconductor die)

- ISO/IEC 16388 (Code 39 bar-code symbology)

- ISO 11469 (plastic identification and marking)

Keywords: IEC 60286-3, tape packaging, surface mount components, carrier tape, adhesive-backed tape, Type IV, SMT, automatic placement machines, blister tape, punched tape, reel dimensions, cover tape peel force.

Buy Documents

IEC 60286-3:2007 - Packaging of components for automatic handling - Part 3: Packaging of surface mount components on continuous tapes Released:6/6/2007

IEC 60286-3:2007 - Packaging of components for automatic handling - Part 3: Packaging of surface mount components on continuous tapes Released:6/6/2007

Frequently Asked Questions

IEC 60286-3:2007 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Packaging of components for automatic handling - Part 3: Packaging of surface mount components on continuous tapes". This standard covers: IEC 60286-3:2007 is applicable to the tape packaging of electronic components without leads or with lead stumps which are intended to be connected to electronic circuits. It includes only those dimensions that are essential for the taping of components intended for the above-mentioned purposes. This fourth edition cancels and replaces the third edition issued in 1997. It constitutes a technical revision. It contains the following significant technical changes with respect to the previous edition: a) implementation of Type IV (adhesive-backed punched plastic carrier tape for singulated bare die and other surface mount components); b) minor revisions related to tables, figures and references.

IEC 60286-3:2007 is applicable to the tape packaging of electronic components without leads or with lead stumps which are intended to be connected to electronic circuits. It includes only those dimensions that are essential for the taping of components intended for the above-mentioned purposes. This fourth edition cancels and replaces the third edition issued in 1997. It constitutes a technical revision. It contains the following significant technical changes with respect to the previous edition: a) implementation of Type IV (adhesive-backed punched plastic carrier tape for singulated bare die and other surface mount components); b) minor revisions related to tables, figures and references.

IEC 60286-3:2007 is classified under the following ICS (International Classification for Standards) categories: 31.020 - Electronic components in general; 31.240 - Mechanical structures for electronic equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60286-3:2007 has the following relationships with other standards: It is inter standard links to IEC 60286-3:2013, IEC 60286-3:1997. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60286-3:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 60286-3

Fourth edition

2007-06

Packaging of components for automatic handling –

Part 3:

Packaging of surface mount components

on continuous tapes

Reference number

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email:

csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD 60286-3

Fourth edition

2007-06

Packaging of components for automatic handling –

Part 3:

Packaging of surface mount components

on continuous tapes

PRICE CODE

Commission Electrotechnique Internationale U

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

– 2 – 60286-3 © IEC:2007(E)

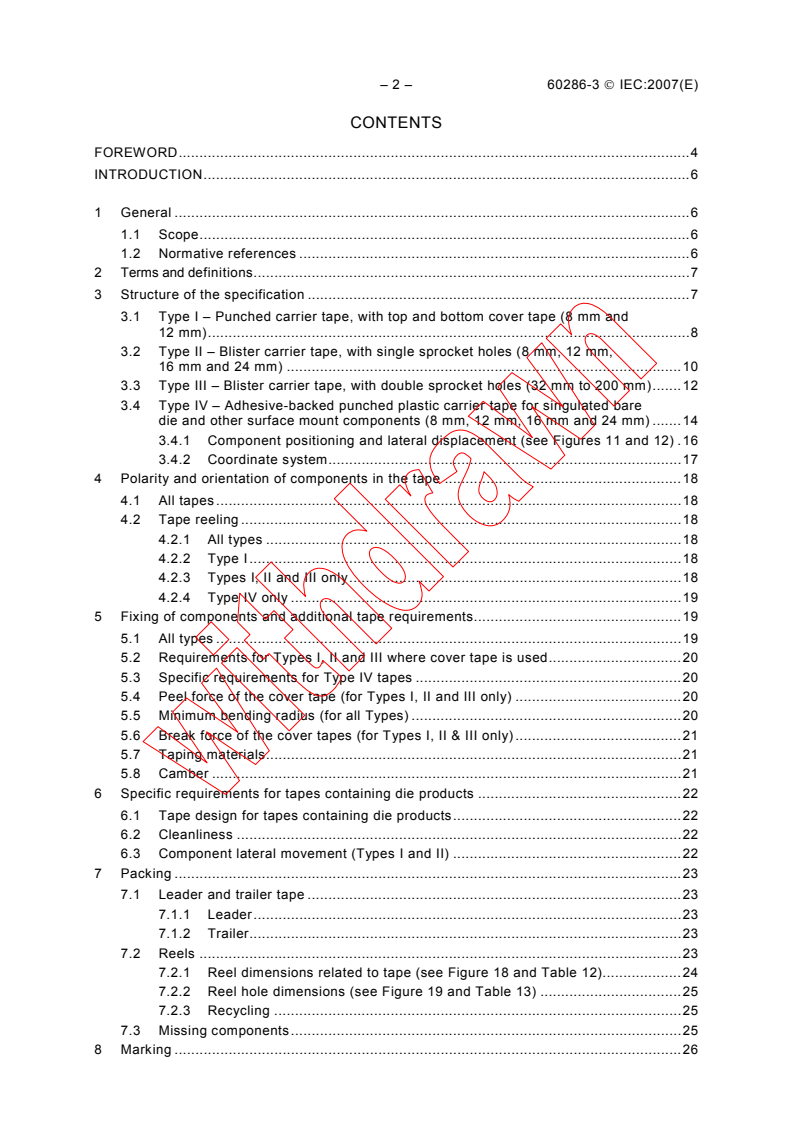

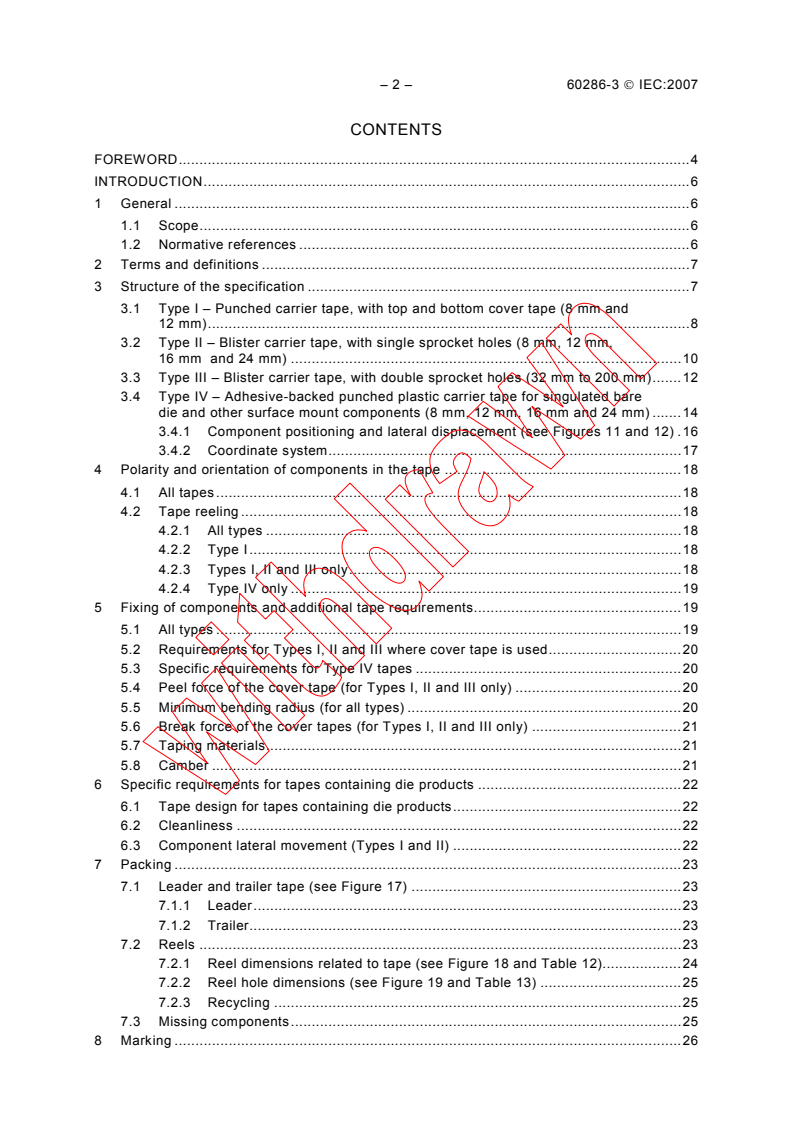

CONTENTS

FOREWORD.4

INTRODUCTION.6

1 General .6

1.1 Scope.6

1.2 Normative references .6

2 Terms and definitions.7

3 Structure of the specification .7

3.1 Type I – Punched carrier tape, with top and bottom cover tape (8 mm and

12 mm).8

3.2 Type II – Blister carrier tape, with single sprocket holes (8 mm, 12 mm,

16 mm and 24 mm) .10

3.3 Type III – Blister carrier tape, with double sprocket holes (32 mm to 200 mm).12

3.4 Type IV – Adhesive-backed punched plastic carrier tape for singulated bare

die and other surface mount components (8 mm, 12 mm, 16 mm and 24 mm) .14

3.4.1 Component positioning and lateral displacement (see Figures 11 and 12) .16

3.4.2 Coordinate system.17

4 Polarity and orientation of components in the tape .18

4.1 All tapes.18

4.2 Tape reeling .18

4.2.1 All types .18

4.2.2 Type I.18

4.2.3 Types I, II and III only.18

4.2.4 Type IV only .19

5 Fixing of components and additional tape requirements.19

5.1 All types .19

5.2 Requirements for Types I, II and III where cover tape is used.20

5.3 Specific requirements for Type IV tapes .20

5.4 Peel force of the cover tape (for Types I, II and III only) .20

5.5 Minimum bending radius (for all Types) .20

5.6 Break force of the cover tapes (for Types I, II & III only) .21

5.7 Taping materials.21

5.8 Camber .21

6 Specific requirements for tapes containing die products .22

6.1 Tape design for tapes containing die products.22

6.2 Cleanliness .22

6.3 Component lateral movement (Types I and II) .22

7 Packing .23

7.1 Leader and trailer tape .23

7.1.1 Leader.23

7.1.2 Trailer.23

7.2 Reels .23

7.2.1 Reel dimensions related to tape (see Figure 18 and Table 12).24

7.2.2 Reel hole dimensions (see Figure 19 and Table 13) .25

7.2.3 Recycling .25

7.3 Missing components.25

8 Marking .26

60286-3 © IEC:2007(E) – 3 –

Table 1 – Constant dimensions of 8 mm and 12 mm punched carrier tape .9

Table 2 – Variable dimensions of 8 mm and 12 mm punched carrier tape .9

Table 3 – Constant dimensions of 8 mm to 24 mm blister carrier tape.11

Table 4 – Variable dimensions of 8 mm to 24 mm blister carrier tape.11

Table 5 – Constant dimensions of 32 mm to 200 mm blister carrier tape .13

Table 6 – Variable dimensions of 32 mm to 200 mm blister carrier tape .13

Table 7 – Constant dimensions of adhesive backed punched carrier tape .15

Table 8 – Variable dimensions of adhesive-backed punched carrier tape.15

Table 9 – Absolute referencing data for component target position .17

Table 10 – Peel force.20

Table 11 – Minimum bending radius.21

Table 12 – Reel dimensions.24

Table 13 – Reel hole dimensions .25

Figure 1 – 8 mm and 12 mm punched carrier-tape dimensions.8

Figure 2 – Illustration of 2 mm cavity pitch .8

Figure 3 – Maximum component tilt, rotation and lateral movement .8

Figure 4 – Blister carrier tape dimensions (8 mm, 12 mm, 16 mm and 24 mm).10

Figure 5 – Illustration of 2 mm cavity pitch .10

Figure 6 – Maximum component tilt, rotation and lateral movement .10

Figure 7 – Blister carrier tape .12

Figure 8 – Maximum component tilt, rotation and lateral movement .12

Figure 9 – Adhesive-backed punched carrier-tape dimensions (4 mm compartment pitch) .14

Figure 10 – Illustration of 2 mm compartment pitch .14

Figure 11 – Component clearance and positioning method .16

Figure 12 – Maximum component tilt and lateral displacement.16

Figure 13 – Type IV coordinate system .17

Figure 14 – Tape reeling and label area on the reel .19

Figure 15 – Bending radius .21

Figure 16 – Camber (top view).22

Figure 17 – Leader and trailer.23

Figure 18 – Reel dimensions.24

Figure 19 – Reel hole presentation .25

– 4 – 60286-3 © IEC:2007(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PACKAGING OF COMPONENTS FOR AUTOMATIC HANDLING –

Part 3: Packaging of surface mount components

on continuous tapes

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60286-3 has been prepared by IEC technical committee 40:

Capacitors and resistors for electronic equipment.

This fourth edition cancels and replaces the third edition issued in 1997. It constitutes a

technical revision.

This edition contains the following significant technical changes with respect to the previous

edition:

a) implementation of Type IV (adhesive-backed punched plastic carrier tape for singulated

bare die and other surface mount components);

b) minor revisions related to tables, figures and references.

60286-3 © IEC:2007(E) – 5 –

The text of this standard is based on the following documents:

FDIS Report on voting

40/1838/FDIS 40/1847/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The list of all the parts of the IEC 60286 series, under the general title Packaging of

components for automatic handling, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date

– 6 – 60286-3 © IEC:2007(E)

PACKAGING OF COMPONENTS FOR AUTOMATIC HANDLING –

Part 3: Packaging of surface mount components

on continuous tapes

INTRODUCTION

Tape packaging meets the requirements of automatic component placement machines and

also covers the use of tape packaging for components for test purposes and other operations.

1 General

1.1 Scope

This part of IEC 60286 is applicable to the tape packaging of electronic components without

leads or with lead stumps which are intended to be connected to electronic circuits. It includes

only those dimensions that are essential for the taping of components intended for the above-

mentioned purposes.

This standard also includes requirements related to the packaging of singulated die products

including bare die and bumped die (flip chips).

1.2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60191-2:1966, Mechanical standardization of semiconductor devices – Part 2:

Dimensions

IEC 61340-5-1:1998, Electrostatics – Part 5-1: Protection of electronic devices from

electrostatic phenomena – General requirements

IEC 61340-5-2:1999, Electrostatics – Part 5-2: Protection of electronic devices from

electrostatic phenomena – User guide

IEC 62258-3:2005, Semiconductor die products – Part 3: Recommendations for good practice

in handling, packing and storage

ISO/IEC 16388:1999, Information technology – Automatic identification and data capture

techniques – Bar code symbology specifications – Code 39

ISO 11469:2000, Plastics – Generic identification and marking of plastics products

60286-3 © IEC:2007(E) – 7 –

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1

packaging

product made of any material of any nature to be used for the containment, protection,

structured alignment for automatic assembly, handling and delivery

3 Structure of the specification

The various types of tapes are as follows.

Type I - Punched carrier tape, with top and bottom cover tape (8 mm and 12 mm)

Type II - Blister carrier tape, with single sprocket holes (8 mm, 12 mm, 16 mm and

24 mm)

Type III - Blister carrier tape, with double sprocket holes (32 mm to 200 mm)

Type IV - Adhesive-backed punched plastic carrier tape for singulated bare die and

other surface mount components

Type V - Continuous pressed carrier tapes (in development)

Type VI - Blister carrier tapes 4 mm in width (in development)

All dimensions in the tables are in millimetres.

– 8 – 60286-3 © IEC:2007(E)

3.1 Type I – Punched carrier tape, with top and bottom cover tape (8 mm and 12 mm)

P

T

D P

0 2

Top Bottom

cover cover

E

tape tape

F

W

E

B

T

T

G

A P

0 1

Direction of unreeling

IEC 625/07

Figure 1 – 8 mm and 12 mm punched carrier-tape dimensions

P

P

P

Pocket off-set: 0,05 mm max.

IEC 629/07

Figure 2 – Illustration of 2 mm cavity pitch

0,3 mm max. (P = 2 )

20° max.

0,5 mm max. (P ≥ 4 )

See also Table 2, Note d

Typical

cavity

centre line

(design value)

10° max.

B

Typical

component

centre line

A

Component tilt Component planar Component lateral

movements

rotation

Side or front

sectional view Top view

Top view

Sketch A Sketch B

Sketch C

IEC 627/07

Figure 3 – Maximum component tilt, rotation and lateral movement

60286-3 © IEC:2007(E) – 9 –

Table 1 – Constant dimensions of 8 mm and 12 mm punched carrier tape

Tape size D E P P G T T Cumulative

0 1 0 2 min max 1max

pitch (over

10 pitches)

+0,1

1,5

8 and 12 1,75 ± 0,1 4,0 ± 0,1 2,0 ± 0,05 0,75 1,1 paper 0,1 ± 0,2

(P ≥ 4)

1,6 non-

4,0 ± 0,05

paper

(P = 2)

Table 2 – Variable dimensions of 8 mm and 12 mm punched carrier tape

Tape size E F P W A , B , T

2 min 1 0 0

+0,3

8 6,25 3,5 ± 0,05 4,0 ± 0,1 See note

8,0

−0,1

(P ≥ 4)

2,0 ± 0,05

(P = 2)

+0,3

4,0 ± 0,1

12 10,25 5,5 ± 0,05 12,0

−0,1

(P ≥ 4)

2,0 ± 0,05

(P = 2)

NOTE The nominal dimensions of the component compartment should be derived from the relevant component

specification. The tolerances on the nominal dimensions of the compartment should be chosen so that the

components cannot change their orientation within the tape and can be easily removed from the tape, with the

following characteristics.

There shall be sufficient clearance surrounding the component so that

a) the component does not protrude beyond either surface of the carrier tape;

b) the component can be removed from the cavity in a vertical direction without mechanical restriction

after the top cover tape has been removed;

c) the rotation of the component is limited to a 10° max. tilt (see Figure 3, sketch A) and a 20°

max. planar rotation (see Figure 3, sketch B);

d) the lateral movement of the component is restricted to 0,5 mm max.(P ≥ 4), 0,3 mm max.(P = 2)

1 1

(see Figure 3, sketch C).

For components with either length or width dimensions of less than 1,2 mm, market trends are towards a planar

rotation limit of 10° max. and a lateral movement of 0,2 mm max. and a component rotation depends on the

agreement between suppliers and users. See also Clause 6 for die products.

For defined component positioning, the pocket positions should be defined to an origin point; in this case, the

index hole. Pockets should be positioned relative to this hole.

Preferred dimensions for components should be taken from the relevant IEC specifications.

Dimensions A ≤ B .

0 0

– 10 – 60286-3 © IEC:2007(E)

3.2 Type II – Blister carrier tape, with single sprocket holes (8 mm, 12 mm, 16 mm

and 24 mm)

P

T

D P

0 2

E

Cover

tape

F

W

E

B

B

G

T

D

1 1

T

2 G

P

K

A

Direction of unreeling

IEC 628/07

Figure 4 – Blister carrier tape dimensions (8 mm, 12 mm, 16 mm and 24 mm)

P

P

P

Pocket off-set: 0,05 mm max.

IEC 629/07

Figure 5 – Illustration of 2 mm cavity pitch

20° max.

(W = 8 mm and 12 mm)

10° max. (W > 12 mm)

See also Table 2, Note d

Typical

cavity

centre line

10° max.

B

Typical

component

centre line

A

Component tilt Component planar Component lateral

rotation movements

Side or front

sectional view Top view

Top view

Sketch D Sketch E

Sketch F

IEC 630/07

Figure 6 – Maximum component tilt, rotation and lateral movement

60286-3 © IEC:2007(E) – 11 –

Table 3 – Constant dimensions of 8 mm to 24 mm blister carrier tape

Tape size D E G P T T Cumulative pitch

0 1 min 0 max 1max

(over 10 pitches)

+0,1

1,5

8 to 24 1,75 ± 0,1 0,75 4,0 ± 0,1 0,6 0,1 ±0,2

(P ≥ 4)

4,0 ± 0,05

(P = 2)

Table 4 – Variable dimensions of 8 mm to 24 mm blister carrier tape

a

Tape B1max. E2 min F P1 P2 T2 max W A0, B0,

D

1 min

size K

+0,3

4,35 0,3 6,25 3,5 ± 0,05 2,0 ± 0,05 2,0 ± 0,05 3,5 8,0 see

−0,1

4,0 ± 0,1 Note

+0,3

12 8,2 1,5 10,25 5,5 ± 0,05 2,0 ± 0,05 2,0 ± 0,05 6,5

12,0

−0,1

4,0 ± 0,1 or

12,0 ± 0,1 in

4,0 increments

+0,3

16 12,1 1,5 14,25 7,5 ± 0,1 4,0 ± 0,1 to 2,0 ± 0,1 9,5 16,0

−0,1

16,0 ± 0,1 in

4,0 increments

+0,3

24 20,1 1,5 22,25 11,5 ± 0,1 4,0 ± 0,1 to 2,0 ± 0,1 12,5 24,0

−0,1

24,0 ± 0,1 in

4,0 increments

NOTE The nominal dimensions of the component compartment should be derived from the relevant component

specification. The tolerances on the nominal sizes of the compartment should be selected so that the

components cannot change their orientation within the tape and can be easily removed from the tape, with the

following characteristics.

There shall be sufficient clearance surrounding the component so that

a) the component does not protrude above the top surface of the carrier tape;

b) the component can be removed from the cavity in a vertical direction without mechanical restriction after the

top cover tape has been removed;

c) the rotation of the component is limited to a 10° max. tilt (see Figure 6, sketch D), a 20° max. planar rotation

for W = 8 mm and 12 mm and a 10° max. planar rotation for W = 16 mm and 24 mm (see Figure 6, sketch E);

d) the lateral movement of the component is restricted to 0,5 mm max. (see Figure 6, sketch F).

For components with either length or width dimensions of less than 1,2 mm, market trends are towards a planar

rotation limit of 10° max. and lateral movements of 0,2 mm max. See also Clause 6 for die products.

The centre of the component compartment is defined by P and F, relative to the sprocket holes, as shown in

Figure 4 with tolerances given in the table above. The centre of the index hole is defined by P and F, relative to

the sprocket holes, as shown in Figure 4 with the tolerances given in the table above.

Preferred dimensions for components shall be taken from the relevant IEC specifications.

Dimensions A ≤ B .

0 0

Dimension K should comply with the component tilt in Sketch D.

In the case of P1 = 2 mm, the off-set between the centre of the component compartment and the centre of the

sprocket hole should not be more than 0,05 mm (see Figure 5).

a

Optionally, for easy and reliable removal of the component, or for component inspection or for any applicable

application, the cavity may have a hole in the centre of the bottom.

– 12 – 60286-3 © IEC:2007(E)

3.3 Type III – Blister carrier tape, with double sp

...

IEC 60286-3

Edition 4.0 2007-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Packaging of components for automatic handling –

Part 3: Packaging of surface mount components on continuous tapes

Emballage de composants pour opérations automatisées –

Partie 3: Emballage des composants appropriés au montage en surface en

bandes continues

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60286-3

Edition 4.0 2007-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Packaging of components for automatic handling –

Part 3: Packaging of surface mount components on continuous tapes

Emballage de composants pour opérations automatisées –

Partie 3: Emballage des composants appropriés au montage en surface en

bandes continues

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

U

CODE PRIX

ICS 31.020; 31.240 ISBN 2-8318-9920-6

– 2 – 60286-3 © IEC:2007

CONTENTS

FOREWORD.4

INTRODUCTION.6

1 General .6

1.1 Scope.6

1.2 Normative references .6

2 Terms and definitions .7

3 Structure of the specification .7

3.1 Type I – Punched carrier tape, with top and bottom cover tape (8 mm and

12 mm).8

3.2 Type II – Blister carrier tape, with single sprocket holes (8 mm, 12 mm,

16 mm and 24 mm) .10

3.3 Type III – Blister carrier tape, with double sprocket holes (32 mm to 200 mm).12

3.4 Type IV – Adhesive-backed punched plastic carrier tape for singulated bare

die and other surface mount components (8 mm, 12 mm, 16 mm and 24 mm) .14

3.4.1 Component positioning and lateral displacement (see Figures 11 and 12) .16

3.4.2 Coordinate system.17

4 Polarity and orientation of components in the tape .18

4.1 All tapes.18

4.2 Tape reeling .18

4.2.1 All types .18

4.2.2 Type I.18

4.2.3 Types I, II and III only.18

4.2.4 Type IV only .19

5 Fixing of components and additional tape requirements.19

5.1 All types .19

5.2 Requirements for Types I, II and III where cover tape is used.20

5.3 Specific requirements for Type IV tapes .20

5.4 Peel force of the cover tape (for Types I, II and III only) .20

5.5 Minimum bending radius (for all types) .20

5.6 Break force of the cover tapes (for Types I, II and III only) .21

5.7 Taping materials.21

5.8 Camber .21

6 Specific requirements for tapes containing die products .22

6.1 Tape design for tapes containing die products.22

6.2 Cleanliness .22

6.3 Component lateral movement (Types I and II) .22

7 Packing .23

7.1 Leader and trailer tape (see Figure 17) .23

7.1.1 Leader.23

7.1.2 Trailer.23

7.2 Reels .23

7.2.1 Reel dimensions related to tape (see Figure 18 and Table 12).24

7.2.2 Reel hole dimensions (see Figure 19 and Table 13) .25

7.2.3 Recycling .25

7.3 Missing components.25

8 Marking .26

60286-3 © IEC:2007 – 3 –

Figure 1 – 8 mm and 12 mm punched carrier-tape dimensions.8

Figure 2 – Illustration of 2 mm cavity pitch .8

Figure 3 – Maximum component tilt, rotation and lateral movement .8

Figure 4 – Blister carrier tape dimensions (8 mm, 12 mm, 16 mm and 24 mm).10

Figure 5 – Illustration of 2 mm cavity pitch .10

Figure 6 – Maximum component tilt, rotation and lateral movement .10

Figure 7 – Blister carrier tape .12

Figure 8 – Maximum component tilt, rotation and lateral movement .12

Figure 9 – Adhesive-backed punched carrier-tape dimensions (4 mm compartment

pitch) .14

Figure 10 – Illustration of 2 mm compartment pitch .14

Figure 11 – Component clearance and positioning method .16

Figure 12 – Maximum component tilt and lateral displacement.16

Figure 13 – Type IV coordinate system .17

Figure 14 – Tape reeling and label area on the reel .19

Figure 15 – Bending radius .21

Figure 16 – Camber (top view).22

Figure 17 – Leader and trailer.23

Figure 18 – Reel dimensions.24

Figure 19 – Reel hole presentation .25

Table 1 – Constant dimensions of 8 mm and 12 mm punched carrier tape .9

Table 2 – Variable dimensions of 8 mm and 12 mm punched carrier tape .9

Table 3 – Constant dimensions of 8 mm to 24 mm blister carrier tape.11

Table 4 – Variable dimensions of 8 mm to 24 mm blister carrier tape.11

Table 5 – Constant dimensions of 32 mm to 200 mm blister carrier tape .13

Table 6 – Variable dimensions of 32 mm to 200 mm blister carrier tape .13

Table 7 – Constant dimensions of adhesive backed punched carrier tape .15

Table 8 – Variable dimensions of adhesive-backed punched carrier tape.15

Table 9 – Absolute referencing data for component target position .17

Table 10 – Peel force.20

Table 11 – Minimum bending radius.21

Table 12 – Reel dimensions.24

Table 13 – Reel hole dimensions .25

– 4 – 60286-3 © IEC:2007

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PACKAGING OF COMPONENTS FOR AUTOMATIC HANDLING –

Part 3: Packaging of surface mount components

on continuous tapes

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60286-3 has been prepared by IEC technical committee 40:

Capacitors and resistors for electronic equipment.

This fourth edition cancels and replaces the third edition issued in 1997. It constitutes a

technical revision.

This edition contains the following significant technical changes with respect to the previous

edition:

a) implementation of Type IV (adhesive-backed punched plastic carrier tape for singulated

bare die and other surface mount components);

b) minor revisions related to tables, figures and references.

60286-3 © IEC:2007 – 5 –

This bilingual version, published in 2008-08, corresponds to the English version.

The text of this standard is based on the following documents:

FDIS Report on voting

40/1838/FDIS 40/1847/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

The French version of this standard has not been voted upon.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The list of all the parts of the IEC 60286 series, under the general title Packaging of

components for automatic handling, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 60286-3 © IEC:2007

PACKAGING OF COMPONENTS FOR AUTOMATIC HANDLING –

Part 3: Packaging of surface mount components

on continuous tapes

INTRODUCTION

Tape packaging meets the requirements of automatic component placement machines and

also covers the use of tape packaging for components for test purposes and other operations.

1 General

1.1 Scope

This part of IEC 60286 is applicable to the tape packaging of electronic components without

leads or with lead stumps which are intended to be connected to electronic circuits. It includes

only those dimensions that are essential for the taping of components intended for the above-

mentioned purposes.

This standard also includes requirements related to the packaging of singulated die products

including bare die and bumped die (flip chips).

1.2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60191-2:1966, Mechanical standardization of semiconductor devices – Part 2:

Dimensions

IEC 61340-5-1:1998, Electrostatics – Part 5-1: Protection of electronic devices from

)

electrostatic phenomena – General requirements

IEC 61340-5-2:1999, Electrostatics – Part 5-2: Protection of electronic devices from

1)

electrostatic phenomena – User guide

IEC 62258-3:2005, Semiconductor die products – Part 3: Recommendations for good practice

in handling, packing and storage

ISO/IEC 16388:1999, Information technology – Automatic identification and data capture

1)

techniques – Bar code symbology specifications – Code 39

ISO 11469:2000, Plastics – Generic identification and marking of plastics products

___________

)

A new edition of this publication exists.

60286-3 © IEC:2007 – 7 –

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1

packaging

product made of any material of any nature to be used for the containment, protection,

structured alignment for automatic assembly, handling and delivery

3 Structure of the specification

The various types of tapes are as follows.

Type I - Punched carrier tape, with top and bottom cover tape (8 mm and 12 mm)

Type II - Blister carrier tape, with single sprocket holes (8 mm, 12 mm, 16 mm and

24 mm)

Type III - Blister carrier tape, with double sprocket holes (32 mm to 200 mm)

Type IV - Adhesive-backed punched plastic carrier tape for singulated bare die and

other surface mount components

Type V - Continuous pressed carrier tapes (in development)

Type VI - Blister carrier tapes 4 mm in width (in development)

All dimensions in the tables are in millimetres.

– 8 – 60286-3 © IEC:2007

3.1 Type I – Punched carrier tape, with top and bottom cover tape (8 mm and 12 mm)

P

T

D P

0 2

Top Bottom

cover cover

E

tape tape

F

W

E

B

T

T

G

A P

0 1

Direction of unreeling

IEC 625/07

Figure 1 – 8 mm and 12 mm punched carrier-tape dimensions

P

P

P

Pocket off-set: 0,05 mm max.

IEC 629/07

Figure 2 – Illustration of 2 mm cavity pitch

0,3 mm max. (P = 2 )

20° max.

0,5 mm max. (P ≥ 4 )

See also Table 2, Note d

Typical

cavity

centre line

(design value)

10° max.

B

Typical

component

centre line

A

Component tilt Component planar Component lateral

movements

rotation

Side or front

sectional view Top view

Top view

Sketch A Sketch B

Sketch C

IEC 627/07

Figure 3 – Maximum component tilt, rotation and lateral movement

60286-3 © IEC:2007 – 9 –

Table 1 – Constant dimensions of 8 mm and 12 mm punched carrier tape

Tape size D E P P G T T Cumulative

0 1 0 2 min max 1max

pitch (over

10 pitches)

+0,1

1,5

8 and 12 0,75 1,1 paper 0,1

0 1,75 ± 0,1 4,0 ± 0,1 2,0 ± 0,05 ± 0,2

(P ≥ 4)

1,6 non-

4,0 ± 0,05

paper

(P = 2)

Table 2 – Variable dimensions of 8 mm and 12 mm punched carrier tape

Tape size E F P W A , B , T

2 min 1 0 0

+0,3

4,0 ± 0,1

8 6,25 3,5 ± 0,05 8,0 See note

−0,1

(P ≥ 4)

2,0 ± 0,05

(P = 2)

+0,3

12 10,25 4,0 ± 0,1

5,5 ± 0,05 12,0

−0,1

(P ≥ 4)

2,0 ± 0,05

(P = 2)

NOTE The nominal dimensions of the component compartment should be derived from the relevant component

specification. The tolerances on the nominal dimensions of the compartment should be chosen so that the

components cannot change their orientation within the tape and can be easily removed from the tape, with the

following characteristics.

There shall be sufficient clearance surrounding the component so that

a) the component does not protrude beyond either surface of the carrier tape;

b) the component can be removed from the cavity in a vertical direction without mechanical restriction after the

top cover tape has been removed;

c) the rotation of the component is limited to a 10° max. tilt (see Figure 3, sketch A) and a 20° max. planar

rotation (see Figure 3, sketch B);

d) the lateral movement of the component is restricted to 0,5 mm max.(P ≥ 4), 0,3 mm max.(P = 2) (see Figure 3,

1 1

sketch C).

For components with either length or width dimensions of less than 1,2 mm, market trends are towards a planar

rotation limit of 10° max. and a lateral movement of 0,2 mm max. and a component rotation depends on the

agreement between suppliers and users. See also Clause 6 for die products.

For defined component positioning, the pocket positions should be defined to an origin point; in this case, the

index hole. Pockets should be positioned relative to this hole.

Preferred dimensions for components should be taken from the relevant IEC specifications.

Dimensions A ≤ B .

0 0

– 10 – 60286-3 © IEC:2007

3.2 Type II – Blister carrier tape, with single sprocket holes (8 mm, 12 mm, 16 mm

and 24 mm)

P

T

D P

0 2

E

Cover

tape

F

W

E

B

B

G

T

D

1 1

T

2 G

P

K

A

Direction of unreeling

IEC 628/07

Figure 4 – Blister carrier tape dimensions (8 mm, 12 mm, 16 mm and 24 mm)

P

P

P

Pocket off-set: 0,05 mm max.

IEC 629/07

Figure 5 – Illustration of 2 mm cavity pitch

20° max.

(W = 8 mm and 12 mm)

10° max. (W > 12 mm)

See also Table 2, Note d

Typical

cavity

centre line

10° max.

B

Typical

component

centre line

A

Component tilt Component planar Component lateral

rotation movements

Side or front

sectional view Top view

Top view

Sketch D Sketch E

Sketch F

IEC 630/07

Figure 6 – Maximum component tilt, rotation and lateral movement

60286-3 © IEC:2007 – 11 –

Table 3 – Constant dimensions of 8 mm to 24 mm blister carrier tape

Tape size D E G P T T Cumulative pitch

0 1 min 0 max 1max

(over 10 pitches)

+0,1

1,5

8 to 24 1,75 ± 0,1 0,75 4,0 ± 0,1 0,6 0,1 ±0,2

(P ≥ 4)

4,0 ± 0,05

(P = 2)

Table 4 – Variable dimensions of 8 mm to 24 mm blister carrier tape

a

Tape B E F P P T W A , B ,

1max. 2 min 1 2 2 max 0 0

D

1 min

size K

+0,3

8 4,35 0,3 6,25 3,5 8,0 See

3,5 ± 0,05 2,0 ± 0,05 2,0 ± 0,05

−0,1

Note

4,0 ± 0,1

+0,3

12 8,2 1,5 10,25 6,5 12,0

5,5 ± 0,05 2,0 ± 0,05 2,0 ± 0,05

−0,1

4,0 ± 0,1 or

12,0 ± 0,1 in

4,0 increments

+0,3

16 12,1 1,5 14,25 9,5 16,0

7,5 ± 0,1 4,0 ± 0,1 to 2,0 ± 0,1

−0,1

16,0 ± 0,1 in

4,0 increments

+0,3

24 20,1 1,5 22,25 12,5 24,0

11,5 ± 0,1 4,0 ± 0,1 to 2,0 ± 0,1

−0,1

24,0 ± 0,1 in

4,0 increments

NOTE The nominal dimensions of the component compartment should be derived from the relevant component

specification. The tolerances on the nominal sizes of the compartment should be selected so that the

components cannot change their orientation within the tape and can be easily removed from the tape, with the

following characteristics.

There shall be sufficient clearance surrounding the component so that

a) the component does not protrude above the top surface of the carrier tape;

b) the component can be removed from the cavity in a vertical direction without mechanical restriction after the

top cover tape has been removed;

c) the rotation of the component is limited to a 10° max. tilt (see Figure 6, sketch D), a 20° max. planar rotation

for W = 8 mm and 12 mm and a 10° max. planar rotation for W = 16 mm and 24 mm (see Figure 6, sketch E);

d) the lateral movement of the component is restricted to 0,5 mm max. (see Figure 6, sketch F).

For components with either length or width dimensions of less than 1,2 mm, market trends are towards a planar

rotation limit of 10° max. and lateral movements of 0,2 mm max. See also Clause 6 for die products.

The centre of the component compartment is defined by P and F, relative to the sprocket holes, as shown in

Figure 4 with tolerances given in the table above. The centre of the index hole is defined by P and F, relative to

the sprocket holes, as shown in Figure 4 with the tolerances given in the table above.

Preferred dimensions for components shall be taken from the relevant IEC specifications.

Dimensions A ≤ B .

0 0

Dimension K should comply with the component tilt in sketch D.

In the case of P = 2 mm, the off-set between the centre of the component compartment and the centre of the

sprocket hole should not be more than 0,05 mm (see Figure 5).

a

Optionally, for easy and reliable removal of the component, or for component inspection or for any applicable

application, the cavity may have a hole in the centre of the bottom.

– 12 – 60286-3 © IEC:2007

3.3 Type III – Blister carrier tape, with double sprocket holes (32 mm to 200 mm)

P

T

D P

0 2

E

Cover

tape

F

W

B B

S

d

D

T 0

D

T

Skew

K

A P

Direction of unreeling

IEC 631/07

Figure 7 – Blister carrier tape

10° max.

1,0 mm max.

Typical

cavity

centre line

10° max. (32 mm to 56 mm tape)

5° max. (72 mm to 200 mm tape)

Design value

B

Typical

component

centre line

A

Component lateral

Component tilt Component planar

rotation movements

Side or front

sectional view Top view

Top view

Sketch D

Sketch E

Sketch F

IEC 632/07

Figure 8 – Maximum component tilt, rotation and lateral movement

60286-3 © IEC:2007 – 13 –

Table 5 – Constant dimensions of 32 mm to 200 mm blister carrier tape

a

Tape size D D d E P T T Cumulative

0 1 min 0 max 1 max

pitch (over

10 pitches)

+0,1

1,5

32 to 200

0 2,0 1,0 0,1

0,2 ± 0,05 1,75 ± 0,1 4,0 ± 0,1 ±0,2

a

Optionally, for easy and reliable removal of the component from the compartment of the tape by

automatic pick-up equipment, the cavity may have a hole in the centre of the bottom.

Table 6 – Variable dimensions of 32 mm to 200 mm blister carrier tape

Tape B F P P S Skew T W A , B ,

1 max 1 2 2 max 0 0

size max. K

32 23,0 0,05 12,5 See

14,2 ± 0,1 4,0 ± 0,1 2,0 ± 0,1 28,4 ± 0,1 32,0 ± 0,3

note

to 32,0 ± 0,1

in 4,0 increments

44 35,0 16,0

20,2 ± 0,1 4,0 ± 0,1 2,0 ± 40,4 ± 0,1 44,0 ± 0,3

0,15

to 44,0 ± 0,1

in 4,0 increments

46,0 26,2 ± 0,1 4,0 ± 0,1 2,0 ± 52,4 ± 0,1 20,0 56,0 ± 0,3

0,15

to 56,0 ± 0,1

in 4,0 increments

72 60,0 34,2 ± 0,30 4,0 ± 0,15 2,0 ± 0,2 68,4 ± 0,1 0,1 30,0 72,0

- 0,3/ +0,4

to 72,0 ± 0,15

in 4,0 increments

88 76,0 42,2 ± 0,30 84,4 ± 0,1 88,0

- 0,3/ +0,4

104 91,0 50,2 ± 0,35 4,0 ± 0,20 2,0 ± 100,4 ± 0,2 0,15 35,0 104,0

0,25 - 0,3/ +0,5

to 72,0 ± 0,20

in 4,0 increments

107,0 58,2 ± 0,35 116,4 ± 0,2 40,0 120,0

- 0,3/ +0,5

136 123,0 136,0

66,2 ± 0,40 4,0 ± 0,25 2,0 ± 0,3 132,4 ± 0,2

- 0,3/ +0,5

to 72,0 ± 0,25

in 4,0 increments

152 139,0 152,0

74,2 ± 0,40 148,4 ± 0,3

- 0,3/ +0,6

168 153,0 0,2 168,0

82,2 ± 0,45 4,0 ± 0,30 2,0 ± 164,4 ± 0,3

- 0,3/ +0,6

0,35

to 72,0 ± 0,30

in 4,0 increments

184 169,0 184,0

90,2 ± 0,45 180,4 ± 0,3

- 0,3/ +0,6

200 185,0 200,0

98,2 ± 0,50 4,0 ± 0,35 2,0 ± 0,4 196,4 ± 0,3

- 0,3/ +0,6

to 72,0 ± 0,35

in 4,0 increments

NOTE The nominal dimension of the component compartment should be derived from the relevant component

specification. The tolerances on the nominal sizes of the compartment should be selected so that the components

cannot change their orientation within the tape and can be easily removed from the tape, with the following

characteristics.

There shall be sufficient clearance surrounding the component so that

a) the component does not protrude above the top surface of the carrier tape;

b) the component can be removed from the cavity in a vertical direction without mechanical restriction after the top

cover tape has been removed;

c) the rotation of the component is limited to 10° max. (see Figure 8, sketches D and E);

d) the lateral movement of the component is restricted to 1,0 mm max. (see Figure 8, sketch F).

Preferred dimensions for components shall be taken from the relevant IEC specifications.

Dimensions A ≤ B .

0 0

Dimension K should comply with the component tilt in sketch D.

R for 72 mm to 200 mm tape: 75.

min

The centre of the component compartment is defined by P and F, relative to the sprocket holes, as shown in Figure 6

with the tolerances given in the table above. The centre of the index hole is defined by P and F, relative to the sprocket

holes, as shown in Figure 6 with the tolerances given in the table above.

– 14 – 60286-3 © IEC:2007

3.4 Type IV – Adhesive-backed punched plastic carrier tape for singulated bare die

and other surface mount components (8 mm, 12 mm, 16 mm and 24 mm)

Type IV requires some explanation of the coordinate system and tape parameters. It is similar

to Type I, but, whereas Type I has cavities sized to the component dimensions, Type IV uses

a standard compartment size much larger than the component, the orientation and

displacement of which is fixed by being placed on a backing of adhesive film.

Component placement accuracy is determined during component taping, when the component

is placed into the tape. Therefore, parameters P and F are absolute when determining the

2A A

displacement of the component in the tape relative to the drive sprocket hole (see 3.4.1 and

Table 9).

P

T

D

0 P

Adhesive

E

tape

F

W

V

T

V P

1 G

Direction of unreeling

IEC 633/07

Figure 9 – Adhesive-backed punched carrier-tape dimensions

(4 mm compartment pitch)

P

V

V P

1 1

IEC 634/07

Figure 10 – Illustration of 2 mm compartment pitch

60286-3 © IEC:2007 – 15 –

Table 7 – Constant dimensions of adhesive backed punched carrier tape

Tape size D E P P T G T

o 1 o 2 1 max min max

2,0 ± 0,05

(W = 8 and 12)

+0,05

8 to 24

1,5 1,75 ± 0,05 4,0 ± 0,025 0,1 0,75 1,1

0 2,0 ± 0,1

(W = 16 and

24)

Table 8 – Variable dimensions of adhesive-backed punched carrier tape

Tape size F P V V W

1 1 2

1,5 3,1

2,0 ± 0,05

3,50 ± 0,05 8,1 ± 0,1

4,0 ± 0,1

3,1 3,1

1,5 6,35

2,0 ± 0,05

4,0 ± 0,1 to

12 5,50 ± 0,05 3,1 6,35 12,1 ± 0,1

12,0 ± 0,1 in

4,0 increments

6,35 6,35

4,0 ± 0,1 to

6,35 10,2

16 7,50 ± 0,05 16,1 ± 0,1

16,0 ± 0,1 in

4,0 increments 10,2 10,2

4,0 ± 0,1 to

10,2 17,3

11,50 ± 0,05 24,0 ± 0,1 in 24,1 ± 0,1

14,0 17,3

4,0 increments

NOTE 1 The virtual boundary (comprising an area of maximum size, irrespective of component size)

is defined by V , V , and T. These dimensions should be selected to provide sufficient clearance

1 2

surrounding the component so that

a) the component does not protrude beyond the top of the carrier tape;

b) the component can be removed from the compartment in a vertical direction by vacuum pick-up or

by non-surface contact means;

c) the component may be precisely positioned laterally and rotationally at the target coordinates and

remain immobilized when affixed to the adhesive backing.

NOTE 2 The minimum bending radius for the tape with components is proportional to the component

dimension in the V direction of the carrier tape compartment. A minimum bending radius of 100 mm is

recommended for 24 mm tapes containing singulated bare die when the component/compartment pitch

P (Figure 9) is 16 mm. When required, a length of carrier tape trailer can be spooled on the reel to

increase effective reel hub diameter (N, Figure 18).

NOTE 3 Dimension E , as defined in 3.1, is for Type IV tape minimum value only but can be derived

as a reference dimension by subtracting E from W .

1 max

– 16 – 60286-3 © IEC:2007

P

2A

Punched tape thickness T >

component thickness Z

F

A

Z < T

Virtual component Centroid of component is

boundary (ref.) targeted on centre of

Not to be used as

abscissa and ordinate, F

A

a datum for component

and P

2A

placement

Side or front Component

sectional view location

Sketch A Sketch B

Direction of reeling during

component placement into

tape

IEC 635/07

Figure 11 – Component clearance and positioning method

P P

2A 2A

± 0,05 mm (P = 2)

± 0,1 mm (P = 4)

5° max.

F

A

F

A

Typical component

centre lines

Component planar

Component lateral

rotation displacement

(top view)

(top view)

Direction of reeling during

component placement into

Sketch C

Sketch D

tape

IEC 636/07

Figure 12 – Maximum component tilt and lateral displacement

3.4.1 Component positioning and lateral displacement (see Figures 11 and 12)

The component position in Type IV tape is not measured with respect to the compartment, as

in Types I, II and III, but relative to a virtual target point at an absolute position given by P

2A

and F . Table 9 gives the absolute position of this target point relative to the sprocket-hole

A

centroid for different tape sizes.

The maximum displacement of the actual component position from this target location is

shown in sketch D of Figure 12 and may be negative or positive. This displacement is a

function of the accuracy of the component placement system and not the tape.

It is normal for the user drawing to specify the maximum component rotational and lateral

displacement of the component when delivered in Type IV, which may have a tighter tolerance

60286-3 © IEC:2007 – 17 –

than that shown in sketches C and D, where the repeatability of the component position at the

pick point is critical.

Table 9 – Absolute referencing data for component target position

Tape size F P

A 2A

3,5 2,0

12 5,5 2,0

16 7,5 2,0

24 11,5 2,0

Punched plastic

Sprocket drive

Ordinates

carrier tape

holes

P

2A Pressure-sensitive

adhesive tape

F

A

Abscissa

Virtual boundary

Target centre point

compartments

for components

IEC 637/07

Figure 13 – Type IV coordinate system

3.4.2 Coordinate system

3.4.2.1 The coordinate system shown in Figure 13 is established to define carrier tape

dimensioning together with components placements on adhesive-backed punched plastic

carrier tapes.

3.4.2.2 The abscissa is a 0-0 datum straight line of infinite length to align the centres of a

plurality of sprocket drive holes throughout the entire length of the continuous tapes.

3.4.2.3 Ordinates are lines at right angles to the abscissa and uniformly spaced along its

length to position the centre of each sprocket drive hole aligned along the abscissa.

3.4.2.4 Compartments within the punched plastic carrier tape comprise virtual boundaries for

the placement of components at predetermined pitch intervals throughout the length of the

carrier tape.

3.4.2.5 Horizontal and vertical coordinates dimensioned from the abscissa and ordinates

establish target location centre points for the planar centroids of the components placed

within each virtual boundary. See 3.4.2.6 and 3.4.2.7.

3.4.2.6 The centre of the components shall be located within a 0,2 mm diameter of the target

centerpoints within the virtual boundaries. See Figures 11 and 13.

3.4.2.7 Component rotation shall be limited to 5° from the abscissa axis centre line of the

sprocket drive holes (see Figure 12).

– 18 – 60286-3 © IEC:2007

3.4.2.8 Adherence to the tolerances defined in Figure 9 and Table 8 ensures that the

following critical criteria are maintained:

a) precise alignment of all sprocket drive hole centres along abscissa;

b) consistent pitch of sprocket holes throughout the entire length of the tape;

c) uniform diameters of all sprocket drive holes;

d) polarity and orientation of components in the tape.

4 Polarity and orientation of components in the tape

4.1 All tapes

All polarized components shall be oriented in one direction. For components with two

terminations, the cathode side shall be either adjacent to the sprocket hole or the last one to

leave the package, unless otherwise specified in the detail specification.

For components in flat packages (for example, chip carriers and SO-packages) with more

than two terminations, termination No. 1 shall be adjacent to the round sprocket hole, unless

otherwise specified in the detail specification.

For die products (bare die or bumped die) with more than two pads or terminations, pad No. 1

shall be located on the side adjacent to the round sprocket hole, unless otherwise specified in

the detail specification.

For components with a lead configuration corresponding to IEC 60191-2, the component side

from which one single termination emerges shall be at the compartment side closest to the

sprocket holes in the tape and the mounting side shall face the bottom of the component

compartment.

For quartz-crystal units with two terminations located on one side of the package, the

terminations shall be located at the sprocket hole side.

The polarity or orientation of components with other shapes or termination configurations shall

be stated in the detail specification.

4.2 Tape reeling

4.2.1 All types

Tape with components ready for assembly placement shall be spooled in such a way that the

sprocket drive holes shall be on the left-hand side as the tape enters the feeder as viewed

from the back of the feeder looking towards the bed of the assembly machine.

4.2.2 Type I

Type I has effectively a cover tape on either side. Therefore, components may be placed with

the mounting side orientated to the bottom or the top side of the tape. If the mounting side

needs to be reversed (as is the case for some surface mounted components), then the tape is

re-spooled and the alternate cover tape removed, effectively inverting the component.

4.2.3 Types I, II and III only

The mounting side of the components shall be oriented to the bottom side of the tape. The

bottom side is defined as the invisible side of the tape when reeled (see Figure 14).

60286-3 © IEC:2007 – 19 –

Tape

Label

upper side

Tape bottom side

Direction of unreeling

Reel

IEC 638/07

Figure 14 – Tape reeling and label area on the reel

4.2.4 Type IV only

The non-active side of the component is always placed to the bottom side of the tape, i.e.

affixed to the adhesive layer. In the case of flip-chips, the component is placed ‘bumps up’ on

the tape, the reel is then re-spooled and the tape fed into the assembly placement feeder with

the component on the bottom side of the tape, now effectively in the ‘bumps down’ orientation.

5 Fixing of components and additional tape requirements

5.1 All types

5.1.1 Components shall be prevented from falling out of the component window of the tape.

This is normally done by cover tapes on one (blister-tape) or both (punched-tape) sides of the

carrier tape. Requirements for Types I, II and III, which use cover tapes, are listed in 5.2.

Type IV does not require a cover tape, because components are affixed to the adhesive

backing when taped and are held in position.

5.1.2 Tapes in adjacent layers shall not stick together, when wound on the reel.

5.1.3 The tapes shall be suitable to withstand storage of the taped components without

danger of migration of the terminations or the giving off of vapours which would make

soldering difficult or deteriorate the component properties or terminations by chemical action.

5.1.4 The carrier tape material shall not age and lose strength so that it breaks on unreeling

when the taped components are fed from the package by hand into the assembly machines.

Carrier materials shall not delaminate in a manner that would prevent proper delivery of the

component in the assembly process.

5.1.5 The break force of the tape in the direction of unreeling shall be at least 10 N.

Properties of the splice tape should be such that it can be attached to the surface of the

carrier tape and cover tape an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...