IEC 61747-1-1:2014

(Main)Liquid crystal display devices - Part 1-1: Generic - Generic specification

Liquid crystal display devices - Part 1-1: Generic - Generic specification

IEC 61747-1-1:2014 is a generic specification for liquid crystal display devices. It defines general procedures for testing and gives general rules for the measuring methods of the electrical and optical characteristics, the rules for climatic and mechanical tests, and the rules for endurance tests. This first edition cancels and replaces the first edition of IEC 61747-1 published in 1998 and Amendment 1:2003. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

a) IEC 61747-1, has been divided into IEC 61747-1-1, Liquid crystal display devices - Part 1-1: Generic - Generic specification and IEC 61747-1-2, Liquid crystal display devices - Part 1-2: Generic - Terminology and letter symbols;

b) the contents of the terminology have been transferred to IEC 61747-1-2;

c) Annex C has been changed from normative to informative, because Tables C.1 and C.2 mismatch some of the large scale production practices of recent date;

d) References cited have been updated.

General Information

- Status

- Published

- Publication Date

- 11-Aug-2014

- Technical Committee

- TC 110 - Electronic displays

- Drafting Committee

- WG 2 - TC 110/WG 2

- Current Stage

- PPUB - Publication issued

- Start Date

- 12-Aug-2014

- Completion Date

- 15-Nov-2014

Relations

- Effective Date

- 05-Sep-2023

- Replaces

IEC 61747-1:1998 - Liquid crystal and solid-state display devices - Part 1: Generic specification - Effective Date

- 05-Sep-2023

Overview

IEC 61747-1-1:2014 - "Liquid crystal display devices - Part 1-1: Generic - Generic specification" is the IEC’s generic specification for liquid crystal display (LCD) devices. It defines general test procedures and measurement rules for electrical and optical characteristics, climatic and mechanical tests, and endurance tests. This first edition (2014) is a technical revision of the earlier IEC 61747-1 and separates generic specification (Part 1-1) from terminology (now in IEC 61747-1-2).

Key topics and technical requirements

This standard sets out general, high-level requirements and procedures rather than device-specific parameters. Major technical topics include:

- General test procedures for LCD evaluation, including order of precedence and standard environmental conditions for measurements.

- Electrical and optical measurement rules, with guidance on precision, alternative methods and measurement precautions.

- Climatic and mechanical tests, covering environmental conditioning and mechanical stress procedures relevant to LCD reliability.

- Endurance tests and procedures when failure rates are specified, including sample selection and actions when failures exceed acceptance numbers.

- Quality assessment and inspection procedures, such as formation of inspection lots, screening, handling, and granting of qualification approval.

- Statistical sampling methods: reference to AQL and LTPD sampling plans, single-lot and small-lot (hypergeometric) approaches; Annex C provides informative LTPD sampling plans.

- Physical examination and documentation: visual inspection, dimensional checks, device identification, traceability, and packing rules.

- Annexes: Examples of outline drawings (Annex A), module orientation (Annex B), and informative sampling guidance (Annex C).

Practical applications and who uses this standard

IEC 61747-1-1 is used by organizations involved in the design, manufacture, testing, procurement and certification of LCD modules and display systems:

- LCD manufacturers - to standardize test and inspection regimes during development and production.

- Test laboratories and QA teams - to perform electrical, optical, environmental and mechanical tests consistently.

- OEMs and integrators - to set procurement specifications and supplier acceptance criteria.

- Certification bodies and compliance engineers - to reference generic testing procedures when assessing conformity.

- Supply-chain and procurement - for lot formation, sampling and acceptance procedures (AQL/LTPD) used in incoming inspection.

Related standards

- IEC 61747-1-2 (Terminology and letter symbols)

- IEC 61747-5 (Environmental, endurance and mechanical test methods)

- IEC 61747-10-1 (Environmental and endurance aspects for specific parts)

- IEC 60410, IEC 60747, IEC 60748, IEC 60749 (sampling, semiconductor/test-method references)

For implementation, obtain the latest edition and any corrigenda from the IEC webstore to ensure you use current normative references and test method details.

Frequently Asked Questions

IEC 61747-1-1:2014 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Liquid crystal display devices - Part 1-1: Generic - Generic specification". This standard covers: IEC 61747-1-1:2014 is a generic specification for liquid crystal display devices. It defines general procedures for testing and gives general rules for the measuring methods of the electrical and optical characteristics, the rules for climatic and mechanical tests, and the rules for endurance tests. This first edition cancels and replaces the first edition of IEC 61747-1 published in 1998 and Amendment 1:2003. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) IEC 61747-1, has been divided into IEC 61747-1-1, Liquid crystal display devices - Part 1-1: Generic - Generic specification and IEC 61747-1-2, Liquid crystal display devices - Part 1-2: Generic - Terminology and letter symbols; b) the contents of the terminology have been transferred to IEC 61747-1-2; c) Annex C has been changed from normative to informative, because Tables C.1 and C.2 mismatch some of the large scale production practices of recent date; d) References cited have been updated.

IEC 61747-1-1:2014 is a generic specification for liquid crystal display devices. It defines general procedures for testing and gives general rules for the measuring methods of the electrical and optical characteristics, the rules for climatic and mechanical tests, and the rules for endurance tests. This first edition cancels and replaces the first edition of IEC 61747-1 published in 1998 and Amendment 1:2003. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) IEC 61747-1, has been divided into IEC 61747-1-1, Liquid crystal display devices - Part 1-1: Generic - Generic specification and IEC 61747-1-2, Liquid crystal display devices - Part 1-2: Generic - Terminology and letter symbols; b) the contents of the terminology have been transferred to IEC 61747-1-2; c) Annex C has been changed from normative to informative, because Tables C.1 and C.2 mismatch some of the large scale production practices of recent date; d) References cited have been updated.

IEC 61747-1-1:2014 is classified under the following ICS (International Classification for Standards) categories: 31.120 - Electronic display devices. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61747-1-1:2014 has the following relationships with other standards: It is inter standard links to IEC 61747-1:1998/AMD1:2003, IEC 61747-1:1998. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61747-1-1:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61747-1-1 ®

Edition 1.0 2014-08

INTERNATIONAL

STANDARD

Liquid crystal display devices –

Part 1–1: Generic – Generic specification

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC 61747-1-1 ®

Edition 1.0 2014-08

INTERNATIONAL

STANDARD

Liquid crystal display devices –

Part 1–1: Generic – Generic specification

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

U

ICS 31.120 ISBN 978-2-8322-1805-1

– 2 – IEC 61747-1-1:2014 © IEC 2014

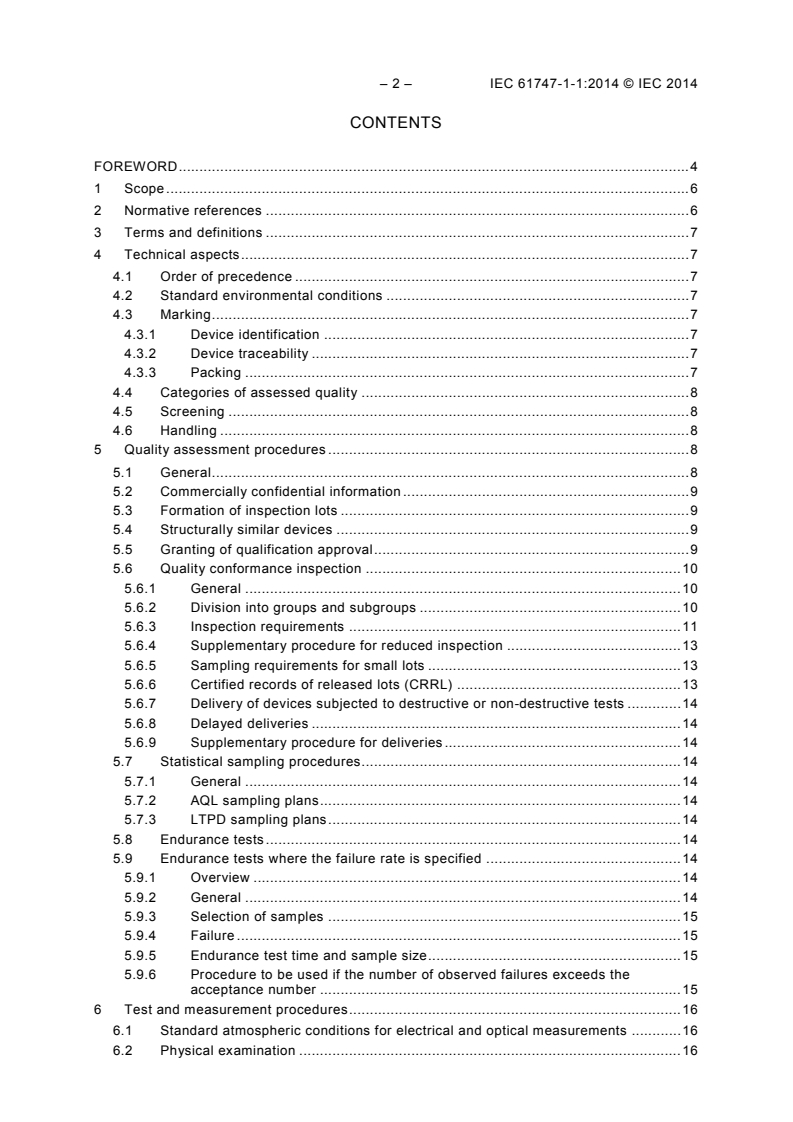

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Technical aspects . 7

4.1 Order of precedence . 7

4.2 Standard environmental conditions . 7

4.3 Marking . 7

4.3.1 Device identification . 7

4.3.2 Device traceability . 7

4.3.3 Packing . 7

4.4 Categories of assessed quality . 8

4.5 Screening . 8

4.6 Handling . 8

5 Quality assessment procedures . 8

5.1 General . 8

5.2 Commercially confidential information . 9

5.3 Formation of inspection lots . 9

5.4 Structurally similar devices . 9

5.5 Granting of qualification approval . 9

5.6 Quality conformance inspection . 10

5.6.1 General . 10

5.6.2 Division into groups and subgroups . 10

5.6.3 Inspection requirements . 11

5.6.4 Supplementary procedure for reduced inspection . 13

5.6.5 Sampling requirements for small lots . 13

5.6.6 Certified records of released lots (CRRL) . 13

5.6.7 Delivery of devices subjected to destructive or non-destructive tests . 14

5.6.8 Delayed deliveries . 14

5.6.9 Supplementary procedure for deliveries . 14

5.7 Statistical sampling procedures . 14

5.7.1 General . 14

5.7.2 AQL sampling plans . 14

5.7.3 LTPD sampling plans . 14

5.8 Endurance tests . 14

5.9 Endurance tests where the failure rate is specified . 14

5.9.1 Overview . 14

5.9.2 General . 14

5.9.3 Selection of samples . 15

5.9.4 Failure . 15

5.9.5 Endurance test time and sample size . 15

5.9.6 Procedure to be used if the number of observed failures exceeds the

acceptance number . 15

6 Test and measurement procedures . 16

6.1 Standard atmospheric conditions for electrical and optical measurements . 16

6.2 Physical examination . 16

6.2.1 Visual examination . 16

6.2.2 Dimensions . 16

6.3 Electrical and optical measurements . 17

6.3.1 Alternative methods . 17

6.3.2 Precision of measurements . 17

6.3.3 General precautions . 17

6.4 Environmental tests . 17

6.5 Mechanical tests . 17

Annex A (informative) Examples of outline drawings of liquid crystal display cells . 18

Annex B (normative) Orientation of LCD modules . 21

Annex C (informative) Lot tolerance percentage defective (LTPD) sampling plans . 22

C.1 General . 22

C.1.1 Overview . 22

C.1.2 Selection of samples . 22

C.1.3 Failures . 22

C.2 Single-lot sampling method . 22

C.2.1 General . 22

C.2.2 Sample size . 22

C.2.3 Acceptance procedure . 22

C.3 Additional sample . 23

C.4 Multiple criteria . 23

C.5 100 % inspection . 23

C.6 Tightened inspection . 23

Bibliography . 28

Figure A.1 – Example of outline drawings of liquid crystal display cells . 18

Figure A.2 – Example of outline drawings of liquid crystal display cells . 19

Figure B.1 – Orientation of LCD modules . 21

Table A.1 – Example of table for dimension of each element . 19

Table C.1 – LTPD sampling plans . 24

Table C.2 – Hypergeometric sampling plans for small lot sizes of 200 or less . 26

Table C.3 – AQL and LTPD sampling plans . 27

– 4 – IEC 61747-1-1:2014 © IEC 2014

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LIQUID CRYSTAL DISPLAY DEVICES –

Part 1–1: Generic – Generic specification

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61747-1-1 was prepared by IEC technical committee 110:

Electronic display devices.

This Part 1-1 forms the generic specification for liquid crystal display devices.

This first edition cancels and replaces the first edition of IEC 61747-1 published in 1998 and

Amendment 1:2003. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) IEC 61747-1, has been divided into IEC 61747-1-1, Liquid crystal display devices – Part 1-

1: Generic – Generic specification and IEC 61747-1-2, Liquid crystal display devices –

Part 1-2: Generic – Terminology and letter symbols;

b) the contents of the terminology have been transferred to IEC 61747-1-2;

c) Annex C has been changed from normative to informative, because Tables C.1 and C.2

mismatch some of the large scale production practices of recent date;

d) References cited have been updated.

The text of this standard is based on the following documents:

CDV Report on voting

110/527/CDV 110/563/RVC

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 61747 series, under the general title Liquid crystal display

devices, can be found on the IEC website.

NOTE The structure of the IEC 61747 series and the changes in the numbering are shown in Annex D of

IEC 61747-30-1:2012.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

– 6 – IEC 61747-1-1:2014 © IEC 2014

LIQUID CRYSTAL DISPLAY DEVICES –

Part 1–1: Generic – Generic specification

1 Scope

This part of IEC 61747 is a generic specification for liquid crystal display devices. It defines

general procedures for testing and gives general rules for the measuring methods of the

electrical and optical characteristics, the rules for climatic and mechanical tests, and the rules

for endurance tests.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60410:1973, Sampling plans and procedures for inspection by attributes

IEC 60747 (all parts), Semiconductor devices – Discrete devices

IEC 60747-1:2006, Semiconductor devices – Part 1: General

IEC 60747-10:1991, Semiconductor devices – Part 10: Generic specification for discrete

devices and integrated circuits

IEC 60748 (all parts), Semiconductor devices – Integrated circuits

IEC 60749, Semiconductor devices – Mechanical and climatic test methods

IEC 61747-1-2, Liquid crystal display devices – Part 1-2: Terminology and letter symbols

IEC 61747-5, Liquid crystal and solid-state display devices – Part 5: Environmental,

endurance and mechanical test methods

IEC 61747-10-1, Liquid crystal display devices – Part 10-1: Environmental, endurance and

mechanical test methods – Mechanical

IEC 61747-10-2, Liquid crystal display devices – Part 10-2: Environmental and endurance

measurements

IEC 61747-20 (all parts), Liquid crystal display devices – Visual inspection

IEC 61747-30-1, Liquid crystal display devices – Part 30-1: Measuring methods for liquid

crystal display modules – Transmissive type

ISO 2859 (all parts), Sampling procedures for inspection by attributes

ISO 2859-1, Sampling procedures for inspection by attributes – Part 1: Sampling schemes

indexed by acceptance quality limit (AQL) for lot-by-lot inspection

ISO 2859-10, Sampling procedures for inspection by attributes – Part 10: Introduction to the

ISO 2859 series of standards for sampling for inspection by attributes

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 61747-1-2 apply.

4 Technical aspects

4.1 Order of precedence

Where there are conflicting requirements, documents shall rank in the following order of

authority:

a) the detail specification;

b) the blank detail specification;

c) the family specification, if any;

d) the sectional specification;

e) the generic specification;

f) the basic specification;

g) international (e.g. IEC) documents to which reference is made;

h) a national document.

The same order of precedence shall apply to equivalent national documents.

4.2 Standard environmental conditions

The preferred values of temperature, humidity and pressure for the measurement of charac-

teristics, for tests and for operating conditions, are a temperature of 25 ºC ± 5 ºC, a relative

humidity of 45 %RH to 75 %RH, and a pressure of 86 kPa to 106 kPa.

4.3 Marking

4.3.1 Device identification

The marking on the device shall enable clear identification of the device.

4.3.2 Device traceability

The device shall be provided with a traceability code which enables back-tracing of the device

to a certain production or inspection lot.

4.3.3 Packing

The marking on the packing shall state:

a) the device identification code;

b) the traceability code(s) of the enclosed devices;

c) the number of enclosed devices;

d) the required precautions, if any.

This marking shall be in accordance with custom regulations.

NOTE Additional requirements can be specified in the relevant detail specification.

– 8 – IEC 61747-1-1:2014 © IEC 2014

4.4 Categories of assessed quality

This generic specification provides three categories of quality control. The devices are

grouped in an identified and date-coded inspection lot, which is tested to the specified quality

categories. The AQLs (acceptance quality levels) or LTPDs (lot tolerance percentage

defectives) associated with the same inspection group may vary for each category and shall

be as specified in the detail specification.

The minimum requirements of the categories are as follows:

Category I The type meets the requirements of categories II or III. Each lot meets the

inspection requirements of group A which includes functional tests. Every three

months, one lot meets the inspection requirements for interconnection ability.

Annually, one lot meets the group B and group C inspection requirements.

Category II The lot meets the inspection requirements of group A and group B on a lot-

by-lot basis, and of group C on a periodic basis.

Category III The lot is 100 % screened and meets the inspection requirements of group A

and group B on a lot-by-lot basis, and of group C on a periodic basis.

The sectional or blank detail specifications shall define the minimum requirements for each

category. A detail specification may contain requirements, including screening requirements,

additional to those given in the generic, sectional or blank detail specification.

4.5 Screening

A screening is an examination or test applied to all devices in a lot.

When required by the detail specification, all devices in the lot shall be screened by

submitting them to one of the sequences given in the relevant table of the sectional or blank

detail specification, and all defectives removed. Other sequences not specified in this

standard are applicable only where the above sequences are not correlated or are in

contradiction with recognized failure mechanisms. When a part of the screening process as

given in the relevant table of the sectional or blank detail specification forms part of the

manufacturing process in the prescribed sequence, these procedures need not be repeated.

For the purpose of this specification, burn-in is defined as thermal and electrical stress

applied to all devices in a lot for a specified period of time for the purpose of detecting and

removing potential early failures.

4.6 Handling

See IEC 60747-1:2006, Clause 8.

Adequate warning shall be displayed in the case of harmful products (e.g. Be0).

5 Quality assessment procedures

5.1 General

Quality assessment comprises the procedure for obtaining qualification approval as defined

in 5.6, followed by quality conformance inspection on a lot-by-lot basis (including screening if

required) and on a periodic basis as qualified in the detail specification.

The quality assessment tests are subdivided into group A, B and C tests; these are performed

lot-by-lot or periodically. In some cases, group D tests may also be specified, for example, for

qualification approval.

5.2 Commercially confidential information

If any part of the manufacturing process is commercially confidential, this shall be suitably

identified, and the designated management representative (DMR) shall demonstrate that the

requirements of the rules of procedure given in the specified quality assessment system have

been complied with.

5.3 Formation of inspection lots

An inspection lot may be formed by the aggregation of several production lots provided that

a) the production lots are manufactured under essentially the same conditions (materials,

processes, machines, personnel, etc.), and,

b) quality control and inspection during manufacture is performed to the extent necessary, in

accordance with directives established by the appropriate departments of the

manufacturer in consultation with the DMR, and,

c) the results of this inspection indicate for each production lot that the quality of materials

and processing is maintained within the limits necessary for the production of components

satisfying the requirements of the specification, and,

d) the period over which production lots may be aggregated into one inspection lot should

normally not exceed one week, and shall not exceed one month unless permitted by the

relevant specification.

The programme for the aggregation of production lots into inspection lots shall be determined

by the DMR and shall be submitted for approval.

5.4 Structurally similar devices

Structurally similar components are components produced by the same manufacturer with

essentially the same design, materials, processes and methods. They are such that the

results of a given test carried out on one of these components can be recognised as being

valid for the others of the group. They are separately identifiable.

The relevant specification shall give the requirements for grouping structurally similar

components for the purpose of testing for QA and quality conformance inspection.

Details concerning grouping are given in the relevant sectional or blank detail specifications.

5.5 Granting of qualification approval

The CB shall validate the recommendation and grant the QA, when the requirements of the

specific quality assessment system have been met.

Method a) or b) of the rules of procedure may be used at the manufacturer's discretion in

accordance with the inspection requirements given in the sectional or blank detail

specifications. Samples may be composed of appropriate structurally similar devices. In some

cases, group D tests are required for qualification approval. All variables measurements

called for as post-test end-points in the detail specification shall be recorded as variables data.

The qualification report shall include a summary of all the test results for each group and

subgroup, including number of devices tested and number of devices failed. This summary

shall be derived from variables and/or attributes data.

The manufacturer shall retain all data for submission on demand.

– 10 – IEC 61747-1-1:2014 © IEC 2014

5.6 Quality conformance inspection

5.6.1 General

Quality conformance inspection shall consist of the examinations and tests of groups A, B, C

and D, as specified.

For groups B and C inspection, samples may be composed of structurally similar devices.

Samples for periodic tests shall be drawn from one or more lots which have passed groups A

and B inspection. Individual devices shall have passed the group A measurements called for

in the detail specification.

5.6.2 Division into groups and subgroups

5.6.2.1 General

The following guidelines shall be used in the preparation of detail specifications.

5.6.2.2 Group A inspection (lot-by-lot)

This group prescribes the visual inspection and the electrical measurements to be made on a

lot-by-lot basis to assess the principal properties of a device. Unless otherwise specified,

structural similarity groupings are not permitted.

Group A Inspection is divided into appropriate subgroups as follows:

Subgroup A1 This subgroup comprises a visual examination as specified in 6.2.1.

Subgroup A2 This subgroup comprises measurements of primary characteristics of

the device.

Subgroups A3 and A4 These subgroups may not be required. They comprise

measurements of secondary characteristics of the device. The

correct requirements for each device category are given in the

relevant sectional or blank detail specification. The choice between

subgroups A3 or A4 for given measurements is essentially governed

by the desirability of performing them at a given quality level.

5.6.2.3 Group B inspection (lot-by-lot, except for category I)

This group prescribes the procedures to be used to assess certain additional properties of the

device, and includes mechanical, climatic, electrical and optical endurance tests that can

normally be performed in one week or as specified in the relevant sectional or blank detail

specification.

5.6.2.4 Group C inspection (periodic)

This group prescribes the procedures to be used on a periodic basis to assess certain

additional properties of the devices, and includes electrical and optical measurements,

mechanical, climatic and endurance tests appropriate for checking at intervals of either three

months (categories II and III) or one year (category I), or as specified in the relevant sectional

or blank detail specification.

5.6.2.5 Division of group B and group C into subgroups

To enable comparison and to facilitate change from group B to group C and vice versa when

necessary, tests in these groups have been divided into subgroups bearing the same number

for corresponding tests.

The division is as given below.

Subgroups B1/C1 Comprise measurements that control the dimensional interchange-

ability of the devices.

Subgroups B2a/C2a Comprise the measurements that assess the electrical and optical

properties of the devices of a design nature.

Subgroups B2b/C2b Comprise measurements that further assess some of the electrical

and optical characteristics of the device already measured in group A

by measurement under different voltage, current, temperature or

optical conditions.

Subgroups B2c/C2c Comprise the verification of ratings of the device, where appropriate.

Subgroups B3/C3 Comprise the tests intended to assess the mechanical robustness of

the device.

Subgroups B4/C4 Comprise the tests intended to assess the interconnection ability of

the device.

Subgroups B5/C5 Comprise the tests intended to assess the ability of the device to

withstand climatic stresses, for example change of temperature,

sealing.

Subgroups B6/C6 Comprise the tests intended to assess the ability of the device to

withstand mechanical stresses, for example vibration, shock.

Subgroups B7/C7 Comprise the tests intended to assess the ability of the device to

withstand long-term humidity.

Subgroups B8/C8 Comprise the tests intended to assess the failure characteristics of the

device under endurance testing.

Subgroups B9/C9 Comprise the tests intended to assess the electrical and optical

properties of the device under storage conditions at extremes of

temperature.

Subgroups B10/C10 Comprise the tests intended to assess the performance of the device

during variations of air pressure.

Subgroups B11/C11 Comprise the tests on the permanence of marking.

Subgroup CRRL Lists a selection of tests and/or measurements made in the preceding

subgroups, the results of which shall be presented in the certified

record of released lots (CRRL).

These subgroups may not all be required.

5.6.2.6 Group D inspection

This group prescribes the procedures to be carried out at intervals of 12 months or for

qualification approval only.

5.6.3 Inspection requirements

5.6.3.1 General

The statistical sampling procedures described in 5.7 shall be used.

5.6.3.2 Criteria for lot rejection

Lots failing to meet the quality conformance inspection of either group A or group B inspection

shall not be accepted. If, during quality conformance inspection, devices fail a test in a

subgroup which would result in the lot being rejected, the quality conformance inspection can

be terminated, and the lot shall be considered a rejected lot in group A and B. If a lot is

withdrawn in a state of failing to meet quality conformance requirements and is not re-

submitted, it shall be considered a rejected lot.

– 12 – IEC 61747-1-1:2014 © IEC 2014

5.6.3.3 Re-submitted lots

Failing lots, that have been reworked when technically possible and are resubmitted for

quality conformance inspection, shall contain only devices that were included in the original

lot and shall be re-submitted only once for each inspection group (group A and B). Re-

submitted lots shall be kept separate from new lots and shall be clearly identified as re-

submitted lots. Re-submitted lots shall be randomly re-sampled and inspected for all the

inspection criteria of group A.

5.6.3.4 Procedure in case of test equipment failure or operator error

If any devices are believed to have failed as a result of faulty test equipment or operator error,

the failures shall be entered in the test record (but may be excluded from the CRRL) and shall

be submitted along with a complete explanation of why the failures are believed to be invalid.

The chief inspector shall decide whether replacement devices from the same inspection lot

may be added to the sample. Replacement devices shall be subjected to the same tests to

which the discarded devices were subjected prior to failure and to any remaining specified

tests to which the discarded devices were not subjected prior to failure.

5.6.3.5 Procedure in case of failure in periodic tests

When a group B failure occurs, the corresponding group C tests are invalid. In the event of

failing periodic inspection tests for causes other than faults or an operator error, see the rules

of procedure given in the specified quality assessment system.

Case 1) When a sample fails to satisfy the requirements of a periodic test the DMR (or,

where applicable, the local DMR) shall immediately

– suspend further releases under the mark, or certificate of conformity of the

component in question,

– initiate an investigation to determine the reasons for failure, and

– report the situation.

Case 2) The DMR (or, where applicable, the local DMR) shall maintain this suspension

until the investigation has been concluded. The DMR (or, where applicable, the

local DMR) shall then proceed according to the appropriate conditions in case 3),

case 4) or case 5).

Case 3) If the failure is concluded to have been due solely to an error in test procedure,

a) release under the mark, or certificate of conformity shall be resumed

immediately, and

b) the correct test procedure shall be applied to a sample drawn from the first

available inspection lot. If the sample fails the corrected test, action shall be

taken as in case-1).

Case 4) If the failure is concluded to be due to an identified manufacturing fault which can

immediately be corrected,

a) release under the mark, or certificate of conformity of corrected lots shall be

resumed immediately,

b) the test shall be repeated on the first available corrected lot, and

c) if the result of the repeated test is unsatisfactory, the procedure defined in

Case-5) or Case-6) shall be applied as appropriate.

Case 5) If the failure is concluded to be due to an identified manufacturing fault which

cannot be corrected immediately, but defective components can be detected and

rejected by an appropriate eliminating test acceptable to the DMR (or, where

applicable, the local DMR),

a) release under the mark, or certificate of conformity of accepted components

shall be resumed immediately, and

b) elimination before submission for acceptance shall be continued until the

necessary steps to correct the manufacturing fault have been taken, and until

satisfactory results for the periodic test in question have been obtained on a

sample from the first available lot presented for inspection after correction.

Case 6) If the failure is concluded to be due to an identified manufacturing fault which

cannot be corrected immediately and defective components cannot be removed by

the application of an eliminating test, the CB shall suspend the QA and withdraw

the right to use the mark, or certificate, of conformity for the component in

question. QA and the right to use the Mark, or Certificate, of Conformity shall be

reinstated when the manufacturer can demonstrate, by the successful submission

of a sample from a production lot to the periodic test, that the manufacturing fault

has been eliminated.

Case 7) If the failure cannot be attributed with certainty to a specific error in test procedure

or to an identified manufacturing fault, samples from subsequent lots shall then be

subjected to all tests in the subgroup of the periodic test in which the failure

occurred, on a lot-by-lot basis, and released if these samples pass the test

successfully. The sample size shall be that designated for the subgroup.

Except where otherwise specified in the generic specification, normal periodic

testing shall be resumed when two successive lots have successfully passed the

tests in the subgroup in question, or as otherwise specified in the generic

specification.

Case 8) If the requirements of Case-4), Case-5) or Case-6) are not fulfilled within a

reasonable period of time, QA shall be re-examined and may be withdrawn.

Case 9) If the duration of the periodic test in question exceeds three months and if special

conditions would be appropriate to the particular type of component and the

nature or extent of the failure, the relevant specification shall prescribe any

special procedure to be followed.

5.6.4 Supplementary procedure for reduced inspection

5.6.4.1 Group B

A special reduced inspection procedure may be used which allows the manufacturer to carry

out the appropriate group B tests at normal inspection on every fourth lot with a maximum

interval of three months instead of on a lot-by-lot basis for the tests in all subgroups of group

B. This special procedure applies to each subgroup which has fulfilled the required conditions.

The condition for this change shall be that 10 successive lots have passed group B inspection.

Reversion to normal inspection in group B shall be made when a sample has failed to meet a

subgroup inspection under the reduced inspection procedure.

5.6.4.2 Group C

When a three-month interval is specified for periodic tests, the test period may be extended to

six months provided that three successive periodic tests have been passed at three-month

intervals. Reversion to the normal three-month interval shall be made when a sample has

failed to meet a subgroup inspection under the extended interval procedure.

5.6.5 Sampling requirements for small lots

Where a lot size is small, the procedures shall refer to 3.6.4 of IEC 60747-10:1991 or 3.5 of

IEC 60410:1973.

5.6.6 Certified records of released lots (CRRL)

Lots released by manufacturers or distributors shall be unambiguously identified by a mark, or

certificate of conformity. This mark, or certificate, means that the components have been

released in accordance with the requirements of the relevant detail specification.

– 14 – IEC 61747-1-1:2014 © IEC 2014

Only components approved against a detail specification registered within the system may

receive the mark, or certificate of conformity.

Authorization to affix, or to issue, the mark, or certificate, of conformity is suspended or

withdrawn if there is persistent non-conformity with the specification.

5.6.7 Delivery of devices subjected to destructive or non-destructive tests

Tests considered as destructive are marked (D) in the sectional or blank detail specifications.

Devices subjected to destructive tests shall not be included in the lot for delivery. Devices

subjected to non-destructive environmental tests may be delivered provided they are re-tested

according to group A requirements and satisfy them.

5.6.8 Delayed deliveries

Before delivery of lots in store for a period and in conditions specified in the relevant sectional

or blank detail specification, the lots or the quantities to be delivered shall undergo the

specified group A inspection and the group B interconnection ability tests. Once this has been

done for the complete lot, no further re-testing is required for another period.

5.6.9 Supplementary procedure for deliveries

The manufacturer may, at his discretion, supply devices that have met a more severe

assessment level than that required.

5.7 Statistical sampling procedures

5.7.1 General

For group A, B and C inspections, either the AQL sampling procedure or the LTPD sampling

procedure shall be used. The detail specification shall specify which of the procedures is to

be used.

5.7.2 AQL sampling plans

See IEC 60410, ISO 2859-1 and ISO 2859-10.

There are three types of sampling plans: single, double and multiple. When several types of

plans are available for a given AQL and code letter, any one may be used.

5.7.3 LTPD sampling plans

See Annex C as an example.

5.8 Endurance tests

Endurance tests shall be specified in the detail specification.

5.9 Endurance tests where the failure rate is specified

5.9.1 Overview

Failure rate as used in this standard is defined as LTPD expressed as a percentage per

thousand hours.

5.9.2 General

Endurance tests shall be conducted in accordance with the procedures mentioned.

Endurance tests performed on devices at, or within, their maximum ratings shall be

considered non-destructive.

5.9.3 Selection of samples

Samples for endurance tests shall be selected at random from the inspection lot (see Annex C

as an example). The sample size for a 1 000 h test shall be chosen by the manufacturer from

the column under the specified failure rate (see Table C.1 as an example) or the actual lot

size (see Table C.2 as an example).

The acceptance number shall be the one associated with the particular sample size chosen.

5.9.4 Failure

A device which fails at one or more of the end-point limits specified for endurance tests at any

specified reading interval shall be considered a failure and be considered as such at any

subsequent reading interval. If the sample fails, the test may be terminated at the discretion of

the manufacturer.

5.9.5 Endurance test time and sample size

Whenever the failure rate is specified, the endurance test time shall be 1 000 h initially. Once

a lot has passed the 1 000 h test, endurance tests can be reduced to a certain period, as

specified in the detail specification.

5.9.6 Procedure to be used if the number of observed failures exceeds the

acceptance number

5.9.6.1 General

In the event that the number of failures o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...