IEC TR 63141:2020

(Main)Damp heat, steady state (unsaturated pressurized vapour with air)

Damp heat, steady state (unsaturated pressurized vapour with air)

IEC TR 63141:2020(E) describes a new test method to control the volume of air injected into a conventional HAST chamber filled with water vapour. This document provides an overview of the conventional HAST chamber, an overview of the air-HAST equipment where air is incorporated into the HAST chamber, an example of an air-HAST test apparatus, and application examples of air-HAST.

General Information

- Status

- Published

- Publication Date

- 08-Apr-2020

- Technical Committee

- TC 104 - Environmental conditions, classification and methods of test

- Drafting Committee

- PT 63141 - TC 104/PT 63141

- Current Stage

- PPUB - Publication issued

- Start Date

- 09-Apr-2020

- Completion Date

- 13-Feb-2026

Overview

IEC TR 63141:2020 - Damp heat, steady state (unsaturated pressurized vapour with air) - is a Technical Report from the IEC (Edition 1.0, 2020-04) that describes a new test method to control the volume of air injected into a conventional HAST (Highly Accelerated Stress Test) chamber filled with water vapour. The report provides an overview of conventional HAST chambers, the structure and operation of air‑HAST equipment, example test apparatus, and multiple applied case studies illustrating how air‑HAST is used in reliability evaluations.

Key topics and technical coverage

- Air‑HAST concept and scope - rationale for introducing air into pressurized vapour to create an unsaturated steady‑state humidity environment.

- HAST chamber overview - structure and function of conventional HAST chambers, venting and air injection processes.

- Air‑HAST equipment structures - descriptions of both two‑vessel and one‑vessel air‑HAST chamber designs and their control elements.

- Air concentration, partial pressure and relative humidity - guidance on monitoring and controlling gas composition and vapour partial pressures inside the test chamber.

- Test apparatus examples - illustrative test vehicles, instrumentation and test condition tables (temperature, humidity, partial pressures).

- Applied evaluation methods - documented case studies including:

- Tin whisker growth assessment for lead‑free plating and solder joints under air‑HAST vs saturated HAST.

- Acceleration testing of electrically‑conductive adhesives under humidity stress.

- Crystalline silicon (c‑Si) photovoltaic (PV) module degradation comparisons across DHT, saturated HAST and air‑HAST.

- Supporting figures, tables and analysis methods (e.g., temperature/RH profiles, microscopy, ion chromatography) are included to illustrate results and interpretation.

Practical applications

- Reliability and environmental stress testing of semiconductor packages, PCB assemblies and solder joints where controlled air content affects corrosion or whisker growth.

- Qualification of lead‑free solder and plating processes for automotive, aerospace and industrial electronics.

- Accelerated humidity testing for PV module materials and lamination processes to predict moisture‑related power loss and material degradation.

- Evaluating performance and lifetime of conductive adhesives used in surface mount and flexible electronics.

Who should use this Technical Report

- Reliability engineers, test laboratory managers and standards engineers planning accelerated humidity tests.

- OEMs and component manufacturers (semiconductor, PCB, PV, automotive electronics) seeking guidance on implementing air‑HAST.

- R&D teams studying humidity‑induced failure modes such as tin whiskers, corrosion, ionic contamination and adhesive degradation.

Keywords: IEC TR 63141:2020, air‑HAST, HAST chamber, damp heat steady state, unsaturated pressurized vapour, tin whisker growth, lead‑free solder testing, PV module humidity testing, environmental stress testing.

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

IEC TR 63141:2020 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Damp heat, steady state (unsaturated pressurized vapour with air)". This standard covers: IEC TR 63141:2020(E) describes a new test method to control the volume of air injected into a conventional HAST chamber filled with water vapour. This document provides an overview of the conventional HAST chamber, an overview of the air-HAST equipment where air is incorporated into the HAST chamber, an example of an air-HAST test apparatus, and application examples of air-HAST.

IEC TR 63141:2020(E) describes a new test method to control the volume of air injected into a conventional HAST chamber filled with water vapour. This document provides an overview of the conventional HAST chamber, an overview of the air-HAST equipment where air is incorporated into the HAST chamber, an example of an air-HAST test apparatus, and application examples of air-HAST.

IEC TR 63141:2020 is classified under the following ICS (International Classification for Standards) categories: 19.040 - Environmental testing. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 63141:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TR 63141 ®

Edition 1.0 2020-04

TECHNICAL

REPORT

colour

inside

Damp heat, steady state (unsaturated pressurized vapour with air)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC TR 63141 ®

Edition 1.0 2020-04

TECHNICAL

REPORT

colour

inside

Damp heat, steady state (unsaturated pressurized vapour with air)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 19.040 ISBN 978-2-8322-8090-4

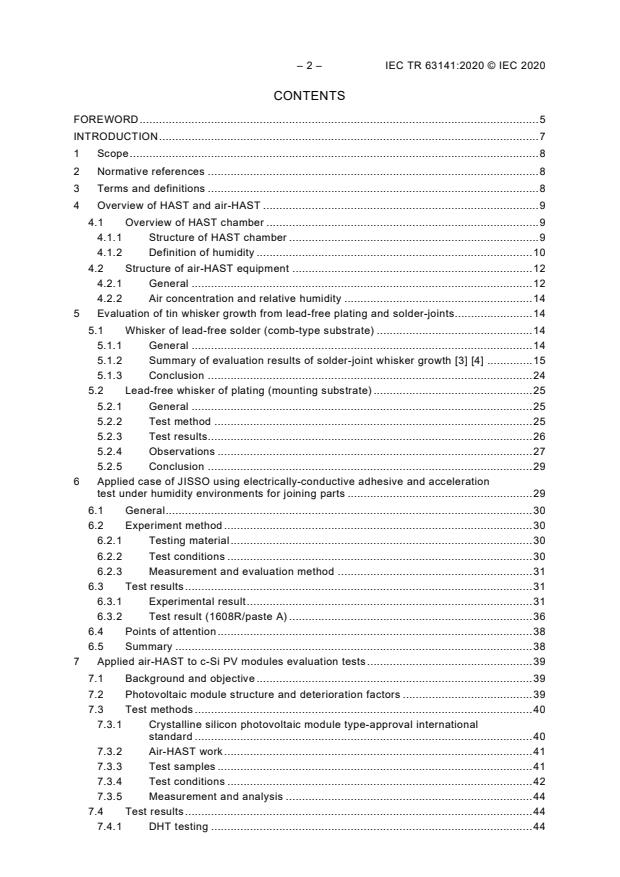

– 2 – IEC TR 63141:2020 © IEC 2020

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 8

4 Overview of HAST and air-HAST . 9

4.1 Overview of HAST chamber . 9

4.1.1 Structure of HAST chamber . 9

4.1.2 Definition of humidity . 10

4.2 Structure of air-HAST equipment . 12

4.2.1 General . 12

4.2.2 Air concentration and relative humidity . 14

5 Evaluation of tin whisker growth from lead-free plating and solder-joints . 14

5.1 Whisker of lead-free solder (comb-type substrate) . 14

5.1.1 General . 14

5.1.2 Summary of evaluation results of solder-joint whisker growth [3] [4] . 15

5.1.3 Conclusion . 24

5.2 Lead-free whisker of plating (mounting substrate) . 25

5.2.1 General . 25

5.2.2 Test method . 25

5.2.3 Test results. 26

5.2.4 Observations . 27

5.2.5 Conclusion . 29

6 Applied case of JISSO using electrically-conductive adhesive and acceleration

test under humidity environments for joining parts . 29

6.1 General . 30

6.2 Experiment method . 30

6.2.1 Testing material . 30

6.2.2 Test conditions . 30

6.2.3 Measurement and evaluation method . 31

6.3 Test results . 31

6.3.1 Experimental result . 31

6.3.2 Test result (1608R/paste A) . 36

6.4 Points of attention . 38

6.5 Summary . 38

7 Applied air-HAST to c-Si PV modules evaluation tests . 39

7.1 Background and objective . 39

7.2 Photovoltaic module structure and deterioration factors . 39

7.3 Test methods . 40

7.3.1 Crystalline silicon photovoltaic module type-approval international

standard . 40

7.3.2 Air-HAST work . 41

7.3.3 Test samples . 41

7.3.4 Test conditions . 42

7.3.5 Measurement and analysis . 44

7.4 Test results . 44

7.4.1 DHT testing . 44

7.4.2 Saturated HAST. 46

7.4.3 Air-HAST . 47

7.4.4 External appearance comparison . 48

7.4.5 Use of dark I-V measurement to infer deterioration factors . 50

7.4.6 Use of ion chromatography to quantify residual acetic acid ions . 50

7.5 Discussion . 51

7.5.1 Environment test method comparisons . 51

7.5.2 Power-loss profiles by moisture permeation . 52

7.5.3 Comparisons by ion chromatography acetic acid quantification . 52

7.6 Conclusion . 53

8 Summary . 54

Bibliography . 55

Figure 1 – Two types of HAST equipment and their structures . 9

Figure 2 – Image of air vent process . 11

Figure 3 – Saturated test . 11

Figure 4 – Unsaturated test. 12

Figure 5 – Structure of two-vessel type air-HAST chamber . 13

Figure 6 – Structure of one-vessel type air-HAST chamber . 14

Figure 7 – Example of test vehicle with comb pattern . 15

Figure 8 – Process flow for sample build . 16

Figure 9 – Temperature/relative humidity profiles of HAST and air-HAST . 17

Figure 10 – Whisker generation situation in air-HAST . 19

Figure 11 – Mapping of the cross-section at the solder fillet in HAST . 20

Figure 12 – Mapping of the cross-section at the solder fillet in air-HAST . 20

Figure 13 – Arrhenius plot of the bromine-based flux . 22

Figure 14 – Reciprocal of relative humidity of whisker generation on solder . 22

Figure 15 – Humidity properties of whisker generation on solder (pt.2) . 23

Figure 16 – Evaluated sample . 25

Figure 17 – Whisker formation (Substrate: Cu) . 27

Figure 18 – Cross-section inspection results with electron-imaging (Substrate: Cu) . 28

Figure 19 – Elements analysis . 29

Figure 20 – Substrate for conductive resistance measurement and example of

component mounting . 30

Figure 21 – Humidity test conductive resistance monitor test status . 31

Figure 22 – Example of the conductive resistance value change . 32

Figure 23 – Weibull plot of temperature acceleration (under fixed humidity conditions) . 32

Figure 24 – Arrhenius plot (fixed humidity) . 33

Figure 25 – Weibull plot of humidity acceleration (under fixed temperature conditions) . 34

Figure 26 – Arrhenius plot (fixed temperature) . 35

Figure 27 – Eyring plot of all conditions . 35

Figure 28 – Comparison of paste (120 °C/85 % RH Air-HAST) . 36

Figure 29 – Cross-section analysis of 1608R after a humidity test (SEM image) . 37

Figure 30 – Magnified image of cross-section analysis of 1608R after a humidity test

(SEM image) . 37

– 4 – IEC TR 63141:2020 © IEC 2020

Figure 31 – Cross-section analysis of 1608R after a humidity test (SEM image) and

examples of componential analysis by EDX . 38

Figure 32 – Structure of c-Si PV module . 40

Figure 33 – Qualification test sequence in IEC 61215-1 [23] . 41

Figure 34 – Appearance of modules . 42

Figure 35 – EL images after DHT . 45

Figure 36 – Degradation profiles with DHT . 46

Figure 37 – EL images of HAST 105 °C/100 % RH . 46

o

Figure 38 – EL images after HAST 120 C/100 % RH . 47

Figure 39 – Degradation profiles with HAST . 47

Figure 40 – EL images after air-HAST . 48

Figure 41 – Degradation profiles with air-HAST . 48

Figure 42 – Appearance of modules after each test . 49

Figure 43 – Dark I-V . 50

Figure 44 – Residue of acetate ion and retention of P after each test . 51

max

Table 1 – Test conditions . 15

Table 2 – Influence of fluxes and circumstances to whisker growth . 18

Table 3 – Whisker generation in HAST. 18

Table 4 – Whisker generation in air-HAST . 19

Table 5 – Comparison of coefficients for Equations (5), (6) and (7) . 24

Table 6 – Details of evaluated samples . 26

Table 7 – Lead frames composition . 26

Table 8 – Environmental test conditions . 26

Table 9 – Electrically-conductive adhesives . 30

Table 10 – Testing material . 31

Table 11 – Test conditions . 36

Table 12 – Example of failure modes of PV module via materials . 40

Table 13 – Specifications of materials used in PV module . 42

Table 14 – Test conditions . 43

Table 15 – Test conditions and partial pressures . 43

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

DAMP HEAT, STEADY STATE

(UNSATURATED PRESSURIZED VAPOUR WITH AIR)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a Technical Report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC TR 63141, which is a Technical Report, has been prepared by IEC technical committee

104: Environmental conditions, classification and methods of test.

The text of this Technical Report is based on the following documents:

Draft TR Report on voting

104/834/DTR 104/853A/RVDTR

Full information on the voting for the approval of this Technical Report can be found in the

report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 6 – IEC TR 63141:2020 © IEC 2020

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

Highly accelerated stress test (HAST), is a high temperature (100 °C or more), high humidity

steady test of unsaturated pressurized steam of 85 % RH, and is the original test method that

was developed for the evaluation of corrosion of packaged semiconductor wiring. This test

method, often referred to as HAST, is applied to primarily non-hermetically sealed small

electronic components, and has been standardized as a standard test method for evaluating,

in an accelerated manner, the resistance to the deteriorative effect of high temperature and

high humidity (IEC 60068-2-66). The equipment used for this test method is a chamber, filled

with unsaturated water vapour, called a HAST chamber.

However, in life evaluation test conditions, acceleration cannot be obtained without air from

the environment being incorporated into the HAST chamber. This test method is referred to as

air-HAST.

Examples of the application of air-HAST are whiskers evaluation of lead-free solder,

deterioration life evaluation of conductive paste, and deterioration life evaluation of solar cells

and are given in this document in order to provide an understanding of air-HAST with the aim,

in future, to standardize air-HAST.

The International Electrotechnical Commission (IEC) draws attention to the fact that it is

claimed that compliance with this document may involve the use of a patent concerning

whisker evaluation given in Clause5.

IEC takes no position concerning the evidence, validity and scope of this patent right.

The holder of this patent right has assured the IEC that he/she is willing to negotiate licences

under reasonable and non-discriminatory terms and conditions with applicants throughout the

world. In this respect, the statement of the holder of this patent right is registered with IEC.

Information may be obtained from:

ESPEC CORP.

3-5-6,Tenjinbashi,Kita-ku

Osaka,530-8550

Japan

Attention is drawn to the possibility that some of the elements of this document may be the

subject of patent rights other than those identified above. IEC shall not be held responsible for

identifying any or all such patent rights.

ISO (www.iso.org/patents) and IEC (http://patents.iec.ch) maintain on-line data bases of

patents relevant to their standards. Users are encouraged to consult the data bases for the

most up to date information concerning patents.

– 8 – IEC TR 63141:2020 © IEC 2020

DAMP HEAT, STEADY STATE

(UNSATURATED PRESSURIZED VAPOUR WITH AIR)

1 Scope

This document describes a new test method to control the volume of air injected into a

conventional HAST chamber filled with water vapour. This document provides an overview of

the conventional HAST chamber, an overview of the air-HAST equipment where air is

incorporated into the HAST chamber, an example of an air-HAST test apparatus, and

application examples of air-HAST.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

galvanic corrosion

corrosion damage induced when two dissimilar materials are coupled in a corrosive electrolyte

3.2

Kirkendall effect

motion of the boundary layer between two metals that occurs as a consequence of the

difference in diffusion rates of the metal atoms

3.3

whisker

metallic protrusion which grows up naturally during storage or in use

3.4

HAST

highly accelerated stress test

original test method developed to evaluate the corrosion of the semiconductor wiring at a high

temperature of 100 °C or more

3.5

air-HAST

HAST test method with the addition of further air partial pressure in a HAST chamber

4 Overview of HAST and air-HAST

4.1 Overview of HAST chamber

4.1.1 Structure of HAST chamber

HAST is an evaluation test at a high-temperature and high-humidity unsaturated pressurized

steam atmosphere environment of more than 100 °C. The test apparatus is roughly divided

into a one-vessel type and a two-vessel type, as shown in Figure 1.

a) One-vessel type b) Two-vessel type

Key

1 pressure gauge

2 pressure vessel

2 temperature sensor for moisture

4 safety valve

5 door

6 working space

7 heater for humidifying water

8 humidifying water

9 temperature sensor for humidifying water

10 air-exhaust valve

11 fan

12 heater for moisture fan for air

13 magnetic coupling

14 pressure vessel 2

Figure 1 – Two types of HAST equipment and their structures

The configuration of the one-vessel type and the configuration of the two-vessel type are

explained as follows.

a) Configuration of the one-vessel type (See Figure 1 a))

This type of chamber is called a one-vessel type because it has only one pressure vessel.

The inner cylinder provided inside the pressure vessel is divided into a steam generator

for supplying humidifying water vapour and a working space to set the sample. A fan for

generating a flow of steam from the steam generator to the working space is provided in

the back of the inner cylinder. Heaters are arranged outside of this fan and in the steam

generator. Steam flow rate of this system is suppressed to about the flow rate of natural

convection.

b) Configuration of the two-vessel type (See Figure 1 b))

– 10 – IEC TR 63141:2020 © IEC 2020

This type of chamber is called a two-vessel type because it is composed of two different

pressure vessels: the test chamber which sets the sample and the steam generation chamber

which supplies humidifying water vapour. Heaters are respectively located in the test chamber

and the steam generation chamber. Water vapour is fed by boiling water vapour pressure to

the test chamber from the steam generation chamber holding the humidifying water, the

amount that was the condensed water goes back into the steam generation chamber. There is

an inner cylinder in the test chamber, and a heater is provided on the outside of this inner

cylinder. Heat from the heater is transmitted to the inner cylinder, keeping the temperature of

the entire working space at a constant level. This system is also referred to as a natural

convection because it does not require a fan for the circulation of water vapour.

4.1.2 Definition of humidity

HAST is carried out in a closed vessel which is isolated from the atmosphere of the

atmospheric pressure (pressure vessel), under the assumption that air is absent from the

filled water vapour atmosphere. Therefore during the start of HAST, steps to eliminate air

(Figure 2 air vent process) are always taken. The humidifying water is heated and boiled by

the heater, the exhaust valve is opened and the test vessel is filled with 100 % water vapour

until all air is discharged. Then the exhaust valve is closed to perform heating until the test

temperature in the vessel is reached again. The difference between the saturated test and

unsaturated test in the working space in the chamber is then recorded. The state of the

saturated test is shown in Figure 3. The state of the unsaturated test is shown in Figure 4.

The air vent process is executed in both the saturated test and unsaturated test, the chamber

needs to be filled with 100 % water vapour without air.

In saturation conditions, the working space is kept at a constant temperature by water vapour

generated from the humidifying water because the heating source is only humidifying the

water heater.

T : is the humidification water temperature;

T : is the test space temperature.

= T .

In this case the vessel temperature is T

1 2

In the case of the unsaturated test, a heater for heating the working space is installed in the

chamber. In the apparatus, water vapour generated from the humidifying water enters the

working space, it is re-heated by the heater to a higher temperature than the water vapour in

the surroundings. When the temperature in the vessel is controlled to T < T , the working

1 2

space is an unsaturated vapour atmosphere. At this stage, the relative humidity (RH) of the

working space is determined by the following equation:

H = P / P × 100

1 2

where

H: is the relative humidity, RH (%);

P : is the saturated water vapour pressure in the humidification water temperature T (MPa);

1 1

P : is the saturated water vapour pressure in the test space temperature T (MPa).

2 2

At this stage the vessel pressure, P , is the test pressure because it is determined by the

temperature of the humidification water (T ).

a) Air-exhaust valve open b) Air-exhaust valve close

Key

1 water vapour

2 humidifying water

3 heater

4 air-exhaust valve

Figure 2 – Image of air vent process

Key

1 working space

2 humidifying water

Figure 3 – Saturated test

– 12 – IEC TR 63141:2020 © IEC 2020

Key

1 working space

2 humidifying water

Figure 4 – Unsaturated test

4.2 Structure of air-HAST equipment

4.2.1 General

In the case of air-HAST, it is necessary to leave the air into a traditional HAST chamber.

Considering the possibility that a residual air volume greatly affects test results, it becomes

necessary to accurately control the amount of air. Using a conventional HAST chamber, to

ensure the air-HAST environment contains air, the following two methods are used:

a) keeping a certain amount of air during start-up, and

b) injecting a predetermined amount of air after discharging air to the outside of the chamber.

Technically, either method is possible. Method a) can be realized simply by omitting the vent

process, but it is difficult to control the amount of air to be discharged when adjusting the air

volume. Method b) injects air after discharging air, so that the entire process becomes

complicated but the control of the amount of air is easy. A dual-vessel type air-HAST chamber

is shown in Figure 5. This equipment, which is a wet bulb installed and provided with a pan

and wick temperature sensor in the working space of a conventional two-vessel type chamber,

has become a mechanism for controlling the humidification water heater (steam generator) at

the specified temperature. This air-HAST system is easily obtained from a dual-vessel type

HAST equipment and has the advantage of facilitating experimentation. The method consists

in injecting a predetermined amount of air from the air pressure port after the system has

reached a steady state and all air in the chamber has been evacuated. The air remaining in

the chamber is controlled by a pressure controller, so the constant partial pressure can be

held.

Key

1 pressure gauge 2 door 3 working space

4 pressure vessel 2 5 humidifying water 6 heater for humidifying water

7 solenoid valve for drain 8 heater for water vapour 9 wet bulb pan

10 cloth wick 11 sensor for humidifying water 12 sensor for water vapour

13 safety valve 14 pressure vessel 1 15 pressure sensor

16 pressure regulator 17 inlet 18 flow controller

19 check valve 20 solenoid valve

Figure 5 – Structure of two-vessel type air-HAST chamber

A one-vessel air-HAST chamber (Figure 6) is used for whiskers, electrically-conducting

adhesives and photovoltaic modules reliability tests. A one-vessel air-HAST chamber is of a

less complex constitution providing reproducible and compatible test results. At first, the

specimen is set in the vessel at room temperature, the door is closed, the test is started to

create heat and humidity. This way there is no pressure damage by a sudden change in

pressure and no condensation on the specimen. In addition, a forced steam of water-vapour is

normally generated by means of a fan installed in the chamber to create air velocity and

accurately detect humidity by a dry and wet bulb.

– 14 – IEC TR 63141:2020 © IEC 2020

Key

1 door 2 specimen 3 cloth wick

4 humidifying water 5 humidifying water temperature sensor 6 wet bulb temperature sensor

7 humidifying heater 8 air circulating fan motor 9 magnetic coupling

10 chamber temperature sensor 11 heater 12 air circulating fan

13 inner cylinder 14 pressure vessel

Figure 6 – Structure of one-vessel type air-HAST chamber

4.2.2 Air concentration and relative humidity

Initially the intention was to determine the exact concentration of oxygen using an oxygen

concentration meter. However, since the inside of the HAST equipment reaches a high

pressure up to 1 atm or more, a commercial oxygen concentration meter operating in such an

environment was not available.

Therefore, the amount of air is calculated based on the gauge pressure. Moreover, since it is

difficult to measure the correct relative humidity directly in an air-HAST chamber, relative

humidity is controlled by the temperature in the same way as for a conventional HAST

chamber.

5 Evaluation of tin whisker growth from lead-free plating and solder-joints

5.1 Whisker of lead-free solder (comb-type substrate)

5.1.1 General

Lead-free manufacturing of electronic products has now reached its implementation stage and

around 2 000, the focus was moved to finding a solution to suppress tin whisker growth.

Related studies are still on-going.

Clause 5 describes the results of the studies, and how the whiskers generated from the

corrosion of solder joints or plated surface are accelerated by high-temperature and high-

humidity conditions; conventional HAST with temperatures exceeding 100 °C does not give

the expected further acceleration and good acceleration is achieved only with air-HAST with

additional air partial pressure [1] to [11] .

5.1.2 Summary of evaluation results of solder-joint whisker growth [3] [4]

5.1.2.1 Test method

Figure 7 shows examples of the test vehicles with comb pattern conductors. The conductor

width and the conductor spacing in Figure 7 a) are both 0,318 mm. In Figure 7 b) the

conductor width and the conductor spacing are both 0,165 mm. These vehicles are submitted

to preconditioning as described in Figure 8 with Sn-3Ag-0,5Cu solder. The coated flux on the

comb pattern substrate consists of a mass fraction of 75 % of IPA (isopropyl alcohol) and a

mass fraction of 25 % of WW (water white) rosin with the addition of a varied amount of

diethylamine hydrobromide as an activator. Environmental test conditions are given in Table 1

and Figure 9 shows pressure, temperature and humidity profiles for both the HAST

(Figure 9 a)) and air-HAST test chambers (Figure 9 b)).

a) Large pitch (comb pattern 1) b) Small pitch (comb pattern 2)

Figure 7 – Example of test vehicle with comb pattern

Table 1 – Test conditions

Test type Test condition

55 °C/85 % RH

High temperature/high humidity 75 °C/85 % RH

85 °C/85 % RH

110 °C/85 % RH

HAST

(Air partial pressure 0 kPa)

110 °C/85 % RH

Air-HAST

a

(Air partial pressure 130 kPa)

a

Theoretical value.

___________

Numbers in square brackets refer to the bibliography.

– 16 – IEC TR 63141:2020 © IEC 2020

Figure 8 – Process flow for sample build

HAST (wet and dry bulb controlled) conditions are:

Total pressure: 0,121 8 MPa abs, 0,03 MPa G.

Air-HAST conditions are:

Total pressure: 0,251 8 MPa abs, 0,15 MPa G.

a) HAST temperature/relative humidity profiles

b) Air-HAST temperature/relative humidity profiles

NOTE 1 Both absolute pressure (abs) and gauge pressure (G) are shown.

NOTE 2 Total pressure of air-HAST is set at 0,251 8 MPa, as the sum of partial pressure of air (0,130 MPa) and

water vapour (0,121 8 MPa).

NOTE 3 Gauge pressure = Absolute pressure – 0,101 3 MPa (atmospheric pressure).

Figure 9 – Temperature/relative humidity profiles of HAST and air-HAST

5.1.2.2 Test results

The results of the temperature-humidity tests are shown in Table 2. Growth of whiskers was

observed in early stages with a bromine-based flux. The acceleration by temperature was also

observed from the test with varied temperatures. Air-HAST equipment with a single test

chamber as shown in Figure 6 was used for an acceleration property study. Although

conventional HAST in the region of 110 °C/85 % RH for test vehicles with a bromine-based

flux exhibited no whisker growth as shown in Table 3, air-HAST – with added air partial

pressure – exhibited whisker growth from an early stage as shown in Table 4 [3] [4].

Examples of such whiskers are shown in Figure 10.

– 18 – IEC TR 63141:2020 © IEC 2020

Table 2 – Influence of fluxes and circumstances to whisker growth

Activator Diethyl amine HBr salt

Content wt % 0,1 2 2 2 4

Temperature (°C) 85 85 70 55 85

Humidity (% RH) 85 85 85 85 85

500 h None 40 μm - - 45 μm

1 000 h None 67 μm None None 44 μm

1 500 h None 91 μm None None 63 μm

2 000 h None 83 μm 16 μm None 87 μm

3 000 h - 102 μm 35 μm None -

4 000 h - 125 μm 86 μm None -

5 000 h - 153 μm 64 μm None -

7 000 h - 160 μm 110 μm 20 μm -

10 000 h - 208 μm 112 μm 17 μm -

Table 3 – Whisker generation in HAST

No. Flux Solder Pattern HAST (110 °C /85 % RH)

composition

200 h 300 h 400 h 600 h

1 Flux none Sn-3Ag-0,5Cu Large None None None None

2 Small None None None None

3 Bromine Large None None None None

system flux

4 Small None None None None

Table 4 – Whisker generation in air-HAST

No. Flux Solder Pattern Air-HAST (110 °C 85 % RH)

composition

50 h 100 h 150 h 200 h 300 h 400 h

1 Flux Sn-3Ag- Large None None None None None None

None 0,5Cu

(A)

2 Small None None None None None None

(B)

3 Bromine Large None None 38 μm 15 μm 28 μm 46 μm

system

(A)

flux

4 Small None 30 μm 37μm 36 μm 53 μm 90 μm

(B)

Figure 10 – Whisker generation situation in air-HAST

Ohno et al reported that the whisker growth is accelerated by localized solder corrosion

enhanced by the residue of bromine-based activator [5].

– 20 – IEC TR 63141:2020 © IEC 2020

a) Reflected electron image b) Elementary analysis

Test conditions:

110 °C/85 % RH 200 h

Solder: Sn-3Ag-0,5Cu

Flux: Bromine system flux

Figure 11 – Mapping of the cross-section at the solder fillet in HAST

a) Reflected electron image b) Elementary analysis

Test conditions:

110 °C/85 % RH 200 h

Solder: Sn-3Ag-0,5Cu

Flux: Bromine system flux

Figure 12 – Mapping of the cross-section at the solder fillet in air-HAST

Cross-section observation of samples from these HAST and air-HAST tests are shown in

Figure 11 and Figure 12. Figure 11 shows no corrosion in the solder layer, even after 200 h of

HAST exposure with no apparent whisker growth, while in Figure 12, showing the result of the

air-HAST test, oxygen penetration into the solder layer was observed. These results

correspond to whisker growth [3].

5.1.2.3 Effect of oxygen on solder whisker generation [3]

The previous results indicate that, in addition to humidity, the presence of oxygen is

necessary for the generation of whisker. Electrochemical reactions of tin, with the effect of

oxygen included, were derived as follows. Tin transfers to oxide by way of hydroxide as these

formulae indicate.

2+ −

Sn ⇌ Sn + 2e (1)

− −

O + 2H O + 4e ⇌ 4OH (2)

2 2

2+ −

Sn + 2OH ⇌ Sn(OH) (3)

− −

Sn(OH) + 2OH ⇌ SnO + 2H O + 2e (4)

2 2 2

Tests to evaluate electrochemical migration (ECM) was also conducted, and ECM was

observed without any air partial pressure, thus indicating its mechanism is different from that

of whisker generation [7].

5.1.2.4 Acceleration property from varied humidity test [3]

5.1.2.4.1 General

Whisker generation evaluation was conducted on test boards with comb-pattern conductors,

with Sn-3Ag-0,5Cu solder and a mass fraction of 2 % flux with a bromine-based activator. The

environmental test conditions were based on standard conditions of 85 °C/85 % RH.

Temperatures ranging from 55 °C to 110 °C (typical air-HAST conditions) with a constant

humidity of 85 % RH were used. Humidity ranging from 65 % RH to 85 % RH with a constant

temperature of 85 °C was applied. The time needed for whisker growth of approximately

20 µm was defined as time-to-whisker L (hours) and used throughout the study.

5.1.2.4.2 Time-to-whisker versus temperature with constant humidity

The results of the test with a constant relative humidity of 85 % RH and varied temperatures

are shown in Figure 13. The figure shows good linearity on an Arrhenius plot (relationship

between reciprocal of absolute temperature and time-to-whisker on a logarithmic scale). Air-

HAST was employed at a temperature of 110 °C. Good linearity was obtained over a wide

range of test temperatures. Activation energy E was calculated from the slope of this plot as

a

0,84 eV.

– 22 – IEC TR 63141:2020 © IEC 2020

Figure 13 – Arrhenius plot of the bromine-based flux

5.1.2.5 Discussion on lifetime characteristic formulae

Various formulae were proposed for lifetime characteristics. The Arrhenius plot, among others,

is widely known for temperature changes, using the reciprocal of absolute temperature, and

exhibited good linearity as shown in Figure 13.

Conditions:

Solder: Sn-3Ag-0,5Cu

Temperature: 85 °C

Figure 14 – Reciprocal of relative humidity of whisker generation on solder

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...