IEC 60076-15:2008

(Main)Power transformers - Part 15: Gas-filled power transformers

Power transformers - Part 15: Gas-filled power transformers

Applies to gas-filled power transformers (including auto-transformers) and to all construction technologies. May be applicable as a whole or in parts to other transformers.

Transformateurs de puissance - Partie 15: Transformateurs de puissance à isolation gazeuse

S'applique aux transformateurs de puissance à isolation gazeuse (y compris les autotransformateurs) et à toutes les technologies de construction. Peut être appliquée en totalité ou en partie à d'autres transformateurs.

General Information

- Status

- Published

- Publication Date

- 26-Feb-2008

- Technical Committee

- TC 14 - Power transformers

- Drafting Committee

- WG 30 - TC 14/WG 30

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 22-Apr-2015

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60076-15:2008 is an international standard published by the International Electrotechnical Commission (IEC) that specifically addresses gas-filled power transformers, including auto-transformers and various construction technologies. This standard provides a comprehensive framework for the design, testing, operation, and performance evaluation of gas-filled transformers, ensuring uniformity and safety in their manufacture and use. It applies broadly to gas-filled transformers with rated powers above specified thresholds and is vital for manufacturers, operators, and engineers working with gas-insulated transformer technologies.

The standard sets requirements on key aspects such as insulation, service conditions, temperature rise, gas tightness, and electrical testing-ensuring reliability and durability of transformers in high-voltage applications. Although focused on gas-filled transformers, many provisions can also be applied to transformers using gas-liquid hybrid insulation systems.

Key Topics

Scope and Applicability: Defines the transformer types covered, excluding small single-phase and three-phase transformers below 1 kVA and 5 kVA respectively, as well as dry-type, instrument, traction, and special transformers.

Service Conditions and Ratings: Details operating conditions including rated power, voltage, loading cycles, and temperature rise limits tailored for gas insulation, ensuring optimal transformer longevity.

Gas Requirements and Tightness: Specifies the qualities and type of insulating gases (such as sulfur hexafluoride SF6), emphasizing strict leak-proof design and maintenance protocols to maintain gas integrity.

Electrical Tests: Encompasses routine and special electrical testing procedures including:

- Winding resistance measurement

- Voltage ratio and phase displacement verification

- Short-circuit withstand capability

- Lightning impulse and switching impulse tests

- Partial discharge measurements

Temperature and Cooling: Sets temperature-rise limits considering different insulation classes and cooling methods, accounting for factors like high altitude and elevated ambient temperatures.

Mechanical and Safety Features: Includes requirements for earthing terminals, pressure tests, sound level measurement, and identification according to cooling method.

Applications

IEC 60076-15 serves as a critical reference for the design, manufacture, quality assurance, and testing of gas-filled power transformers used widely in:

Electric Power Transmission and Distribution: Ensures transformers meet international performance and safety standards for high-voltage substations and grid infrastructure.

Renewable Energy Integration: Offers guidelines for transformers in solar and wind power plants where gas-filled designs help manage thermal performance and environmental conditions.

Industrial Power Systems: Supports reliable transformer operation in heavy industries requiring robust and gas-insulated units.

Utility Equipment Procurement: Provides clear technical specifications to assist utilities in defining requirements for gas-filled transformers during tendering and supplier evaluation.

Related Standards

IEC 60076 Series: This series governs different aspects of power transformers including general requirements (Part 1), temperature rise (Part 2), insulation and dielectric tests (Part 3), and short-circuit withstand (Part 5).

IEC 60076-11: Pertains to dry-type transformers, complementing Part 15 by covering alternatives to gas-filled insulation.

IEC 60044 Series: Covers instrument transformers, useful in conjunction with gas-filled power transformer standards for complete substation design.

IEC 60376 and IEC 60480: Define specifications, treatment, and handling guidelines for sulfur hexafluoride (SF6) gas, critical for gas-filled transformer insulation reliability.

IEC 60085: Addresses thermal classification of electrical insulation materials to assist in temperature-rise assessments.

By following IEC 60076-15:2008, industry stakeholders ensure that gas-filled power transformers meet stringent safety, reliability, and performance standards vital for modern electric power systems. Adherence to this standard facilitates interoperability, promotes international trade, and supports advances in gas insulation technology for transformer applications.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60076-15:2008 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Power transformers - Part 15: Gas-filled power transformers". This standard covers: Applies to gas-filled power transformers (including auto-transformers) and to all construction technologies. May be applicable as a whole or in parts to other transformers.

Applies to gas-filled power transformers (including auto-transformers) and to all construction technologies. May be applicable as a whole or in parts to other transformers.

IEC 60076-15:2008 is classified under the following ICS (International Classification for Standards) categories: 29.180 - Transformers. Reactors. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60076-15:2008 has the following relationships with other standards: It is inter standard links to IEC 60076-15:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60076-15:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60076-15

Edition 1.0 2008-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Power transformers –

Part 15: Gas-filled power transformers

Transformateurs de puissance –

Partie 15: Transformateurs de puissance à isolation gazeuse

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60076-15

Edition 1.0 2008-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Power transformers –

Part 15: Gas-filled power transformers

Transformateurs de puissance –

Partie 15: Transformateurs de puissance à isolation gazeuse

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

T

CODE PRIX

ICS 29.180 ISBN 2-8318-9633-9

– 2 – 60076-15 © IEC:2008

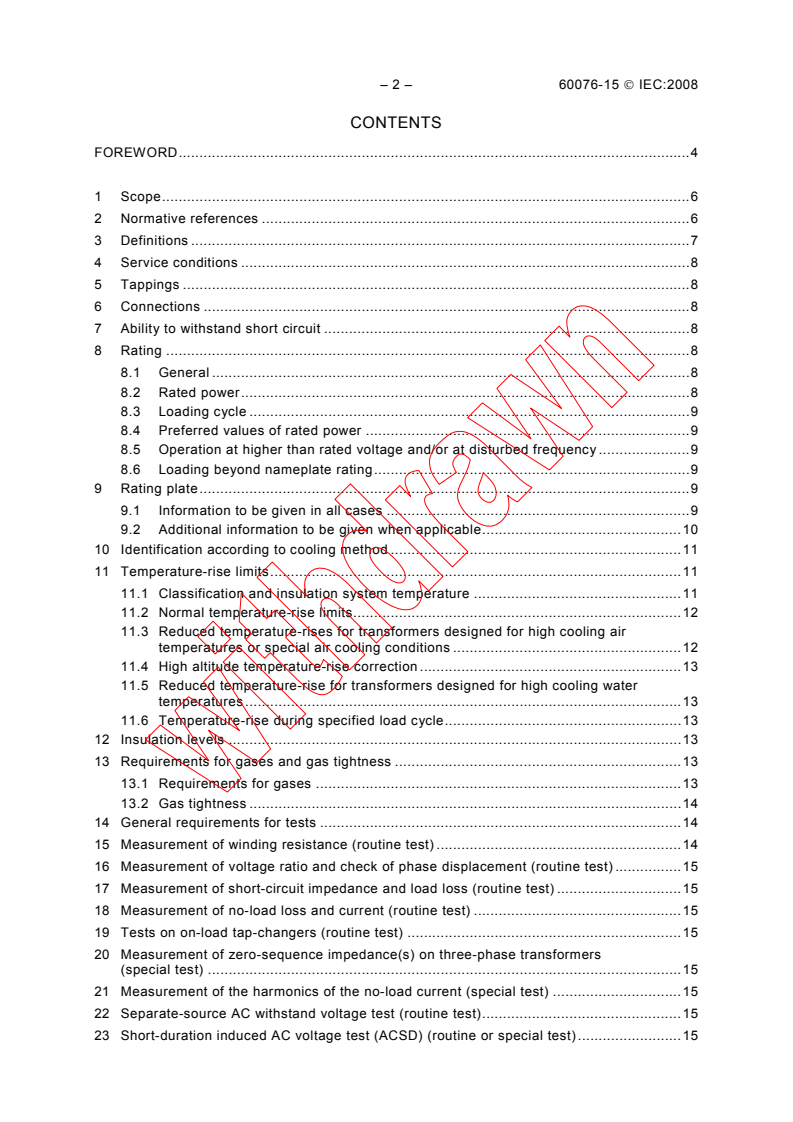

CONTENTS

FOREWORD.4

1 Scope.6

2 Normative references .6

3 Definitions .7

4 Service conditions .8

5 Tappings .8

6 Connections .8

7 Ability to withstand short circuit .8

8 Rating .8

8.1 General .8

8.2 Rated power.8

8.3 Loading cycle .9

8.4 Preferred values of rated power .9

8.5 Operation at higher than rated voltage and/or at disturbed frequency .9

8.6 Loading beyond nameplate rating.9

9 Rating plate.9

9.1 Information to be given in all cases .9

9.2 Additional information to be given when applicable.10

10 Identification according to cooling method .11

11 Temperature-rise limits.11

11.1 Classification and insulation system temperature .11

11.2 Normal temperature-rise limits.12

11.3 Reduced temperature-rises for transformers designed for high cooling air

temperatures or special air cooling conditions .12

11.4 High altitude temperature-rise correction .13

11.5 Reduced temperature-rise for transformers designed for high cooling water

temperatures .13

11.6 Temperature-rise during specified load cycle.13

12 Insulation levels .13

13 Requirements for gases and gas tightness .13

13.1 Requirements for gases .13

13.2 Gas tightness .14

14 General requirements for tests .14

15 Measurement of winding resistance (routine test) .14

16 Measurement of voltage ratio and check of phase displacement (routine test) .15

17 Measurement of short-circuit impedance and load loss (routine test) .15

18 Measurement of no-load loss and current (routine test) .15

19 Tests on on-load tap-changers (routine test) .15

20 Measurement of zero-sequence impedance(s) on three-phase transformers

(special test) .15

21 Measurement of the harmonics of the no-load current (special test) .15

22 Separate-source AC withstand voltage test (routine test).15

23 Short-duration induced AC voltage test (ACSD) (routine or special test) .15

60076-15 © IEC:2008 – 3 –

24 Long-duration induced AC voltage test with partial discharge measurement (ACLD)

(routine or special test).15

25 Lightning impulse test (LI) (routine or type test).16

26 Test with lightning impulse chopped on the tail (LIC) (special test) .16

27 Switching impulse test (SI) (routine test for the transformers having highest voltage

higher than 170 kV) .16

28 Temperature-rise test (type test) .16

28.1 General .16

28.2 Corrections.16

29 Measurement of sound level (special test).16

29.1 General .16

29.2 Prescribed contour .16

30 Short-circuit test (special test) .17

31 Tightness tests (routine test) .17

32 Pressure tests for tanks (routine test) .18

33 Other special tests .18

34 Tolerances .18

35 Earthing terminal .18

36 Information required with enquiry and order.18

Annex A (informative) Information required with enquiry and order .19

Annex B (informative) Transient loading – Mathematical model.22

Bibliography.24

Figure B.1 – Temperature distribution model.22

Table 1 – Classification and insulation system temperature .12

Table 2 – Winding temperature-rise limits .12

Table 3 – Maximum permissible values of the average temperature of each winding.17

– 4 – 60076-15 © IEC:2008

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

POWER TRANSFORMERS –

Part 15: Gas-filled power transformers

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60076-15 has been prepared by IEC technical committee 14:

Power transformers.

The text of this standard is based on the following documents:

FDIS Report on voting

14/567/FDIS 14/571/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 60076 series, under the general title Power transformers, can

be found on the IEC website.

60076-15 © IEC:2008 – 5 –

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 60076-15 © IEC:2008

POWER TRANSFORMERS –

Part 15: Gas-filled power transformers

1 Scope

This standard applies to gas-filled power transformers (including auto-transformers). The

standard applies to all construction technologies.

This standard does not apply to

– single-phase transformers with rated power less than 1 kVA and three-phase

transformers less than 5 kVA;

– dry-type transformers (see IEC 60076-11);

– instrument transformers (see IEC 60044);

– starting transformers;

– testing transformers;

– traction transformers mounted on rolling stock;

– welding transformers.

Where IEC standards do not exist for the transformers mentioned above or for other special

transformers, this standard may be applicable as a whole or in parts.

NOTE This standard can be applicable to the gas parts of a transformer in which an insulating gas is used with an

insulating liquid.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60050, International Electrotechnical Vocabulary

IEC 60076-1:1993, Power transformers – Part 1: General

IEC 60076-2:1993, Power transformers – Part 2: Temperature rise

IEC 60076-3:2000, Power transformers – Part 3: Insulation levels, dielectric tests and external

clearances in air

IEC 60076-5, Power transformers – Part 5: Ability to withstand short circuit

IEC 60076-10, Power transformers – Part 10: Determination of sound levels

IEC 60085, Electrical insulation – Thermal classification and designation

IEC 60376, Specification of technical grade sulfur hexafluoride SF for use in electrical

equipment

60076-15 © IEC:2008 – 7 –

IEC 60480, Guidelines for the checking and treatment of sulfur hexafluoride (SF6) taken from

electrical equipment and specification for its re-use

IEC 62271-1, High-voltage switchgear and controlgear – Part 1: Common specifications

ISO 9001:2000, Quality management systems – Requirements

3 Definitions

For the purpose of this document, the following definitions apply. Other terms used have the

meanings ascribed to them in IEC 60076-1, or IEC 60050.

3.1

gas-filled transformer

a transformer of which the magnetic circuit and windings are placed in an enclosure filled with

an insulating gas. Generally sulfur hexafluoride (SF ) gas is used, and sometimes this

transformer is called a gas-insulated transformer.

3.2

rated gas pressure

gas pressure (gauge pressure) at 20 °C designed for use in a gas-filled transformer

3.3

guaranteed minimum gas pressure

the minimum gas pressure (gauge pressure) at 20 °C, which is able to guarantee the

insulation of a gas-filled transformer

NOTE A transformer of which the magnetic circuit and windings are placed in an enclosure or a vessel filled with

an insulating liquid such as perfluorocarbon, natural ester, synthetic ester, silicon oil and vegetable oil should be

considered a liquid immersed type transformer.

3.4

design pressure of tanks

relative pressure used to determine the design of the tanks

NOTE It is at least equal to the maximum pressure in the tank at the highest temperature that the gas can reach

under specified maximum service condition.

3.5 Definitions, symbols and units relating to gas and vacuum tightness

3.5.1

absolute leakage rate

F

the amount of gas escaped by time unit at rated filling pressure (or density), expressed in Pa

/s

m

3.5.2

permissible leakage rate

F

p

the maximum permissible absolute leakage rate of gas at rated filling pressure (or density)

specified by the manufacturer, expressed in Pa m /s

3.5.3

relative leakage rate

F

rel

the absolute leakage rate related to the total amount of gas in the transformer at rated filling

pressure (or density). It is expressed in percentage per year or per day.

– 8 – 60076-15 © IEC:2008

4 Service conditions

The requirements in IEC 60076-1 apply. With regard to cooling reference, requirement of

IEC 60076-2 apply.

5 Tappings

The requirements in IEC 60076-1 apply.

6 Connections

The requirements in IEC 60076-1 apply.

7 Ability to withstand short circuit

Transformers shall fulfil the requirements in IEC 60076-5. If the purchaser requires a test to

demonstrate this fulfilment, this shall be stated in the contract.

8 Rating

8.1 General

The manufacturer shall assign ratings to the transformer, which shall be marked on the rating

plate, see Clause 9. These ratings shall be such that the transformer can deliver its rated

current under steady loading conditions without exceeding the limits of temperature-rise

specified in Clause 11, assuming that the applied primary voltage is equal to the rated voltage,

that the supply is at rated frequency and that the transformer is operating at rated gas

pressure.

8.2 Rated power

The transformer shall have an assigned rated power for each winding which shall be marked

on the rating plate. The rated power refers to continuous loading. This is a reference value for

guarantees and tests concerning load losses, temperature-rises and short-circuit impedance.

If different values of apparent power are assigned under different circumstances, for example,

with different methods of cooling, the highest of these values is the rated power.

NOTE A two-winding transformer has only one value of rated power, identical for both windings. When the

transformer has rated voltage applied to the primary winding, and rated current flows through the terminals of that

winding, the transformer receives the relevant rated power for both windings.

The transformer shall be capable of carrying, in continuous service, the rated power (for a

multi-winding transformer: the specified combination(s) of winding rated powers) under

conditions listed in Clause 4 and without exceeding the temperature-rise limitations specified

in Clause 11.

60076-15 © IEC:2008 – 9 –

8.3 Loading cycle

If specified in the enquiry or the contract, the transformer may, in addition to its rated power

for continuous loading, be assigned a temporary load cycle which it shall be capable of

performing under conditions specified in Clause 11.

NOTE This option is to be used in particular to give a basis for design and guarantees concerning short-time

emergency loading of large power transformers.

In the absence of such specification, guidance on loading of transformers complying with this

part are subjected to agreement between the purchaser and the manufacturer.

The bushings, tap-changers and other auxiliary equipment shall be selected so as not to

restrict the loading capability of the transformer.

8.4 Preferred values of rated power

The requirements in IEC 60076-1 apply.

8.5 Operation at higher than rated voltage and/or at disturbed frequency

The requirements in IEC 60076-1 apply.

8.6 Loading beyond nameplate rating

Unless specified in the enquiry or the contract, temporary loading beyond nameplate rating

capability is subjected to agreement between the supplier and the purchaser.

NOTE The concept of IEC 60076-7 can be applicable to the consideration of the loading beyond nameplate rating

capability of gas-filled transformers, but IEC 60076-7 cannot be applied directly because the cooling characteristics

of oil and gas are different.

9 Rating plate

9.1 General

Each transformer shall be provided with a rating plate of weatherproof material, fitted in a

visible position, showing the items indicated below. The entries on the plate shall be indelibly

marked (that is, by etching, engraving, stamping or by a photo-chemical process).

9.2 Information to be given in all cases

a) Kind of transformer (for example gas-filled transformer, gas-filled auto-transformer, etc.).

b) Number and year of this standard.

c) Manufacturer’s name.

d) Manufacturer’s serial number.

e) Year of manufacture.

f) Number of phases.

g) Rated power (in kVA or MVA). (For multi-winding transformers, the rated power of each

winding should be given.)

h) Rated frequency (in Hz).

i) Rated voltages and tapping range (in V or kV).

j) Rated currents (in A or kA).

– 10 – 60076-15 © IEC:2008

k) Connection symbol.

l) Connection diagram.

m) Short-circuit impedance, measured value in percentage. For multi-winding transformers,

several impedances for different two-winding combinations are to be given with the

respective reference power values. For transformers having a tapped winding, see also

IEC 60076-1.

n) Type of cooling. (If the transformer has several assigned cooling methods, the respective

power values may be expressed as percentages of rated power, for example GNAN/GDAF

30/100 %.)

o) Insulation system temperature for each winding (for multi-winding transformers, the

insulation system temperature of each winding should be given).

p) Temperature-rise limits of windings (only in the case of specifying limits other than the

limits in Table 2).

q) Kind of insulating gas.

r) Rated gas pressure (in MPa-gauge).

s) Guaranteed minimum gas pressure (in MPa-gauge).

t) Vacuum withstand capability of the tank.

u) Total mass.

v) Mass of gas.

w) Transportation mass (for transformers exceeding 5 t total mass).

x) Untanking mass (for transformers exceeding 5 t total mass).

y) Insulation levels (the rated withstand voltages for all windings shall appear on the rating

plate. The principles of the standard notation are illustrated in IEC 60076-3.).

aa) If the transformer has more than one set of ratings, depending upon different connections

of windings which have been specially allowed for in the design, the additional ratings

shall all be given on the rating plate, or separate rating plates shall be fitted for each set.

9.3 Additional information to be given when applicable

a) For transformers having one or more windings with ‘highest voltage for equipment’ U

m

equal to or above 3,6 kV:

– short notation of insulation levels (withstand voltages) as described in Clause 3 of

IEC 60076-3.

b) For transformers having a tapped winding, particulars about the tappings are as follows:

– for transformers having a tapping range not exceeding ±5 %: tapping voltages on the

tapped winding for all tappings. This applies in particular to distribution transformers;

– for transformers having a tapping range exceeding ±5 %: a table stating tapping

voltage, tapping current and tapping power for all tappings. In addition the short-circuit

impedance values for the principal tapping and at least the extreme tappings shall be

given, preferably in ohms per phase referred to a specific winding.

c) Temperature rises of top gas and windings (if not normal values). When a transformer is

specified for installation at high altitude, this shall be indicated, together with information

on either the reduced temperature-rise figures valid under normal ambient conditions, or

the reduced loading which will result in normal temperature-rise at the high altitude

(standard transformer with normal cooling capacity).

d) Connection diagram (in cases where the connection symbol will not give complete

information regarding the internal connections). If the connections can be changed inside

the transformer, this shall be indicated on a separate plate or with duplicate rating plates.

The connection fitted at the works shall be indicated.

In addition to the main rating plate with the information listed above, the transformer shall also

carry plates with identification and characteristics of auxiliary equipment according to

60076-15 © IEC:2008 – 11 –

international standards for such components (bushings, tap-changer, current transformers,

special cooling equipment).

10 Identification according to cooling method

Transformers shall be identified according to the cooling method employed. For gas-filled

transformers, this identification is expressed by a four-letter code as described below.

First letter: internal cooling medium in contact with the winding:

G insulating gas;

Second letter: circulation mechanism for internal cooling medium:

N natural/thermosiphon flow through cooling equipment and in windings;

F forced circulation through cooling equipment, thermosiphon flow in windings;

D forced circulation through cooling equipment, directed from the cooling equipment into

at least the main windings.

Third letter: external cooling medium:

A air;

W water.

Fourth letter: circulation mechanism for external cooling medium:

N natural convection;

F forced circulation (fans, air blowers, water pumps).

A transformer may be specified with alternative cooling methods. The specification and the

rating plate shall then carry information about the power figures at which the transformer

fulfils the temperature-rise limitations when these alternatives apply, see n) of Subclause 9.2.

The alternatives are conventionally listed in rising order of cooling capacity.

EXAMPLE

GNAN/GDAF. The transformer has cooling equipment with blowers and fans but is also

specified with a reduced power-carrying under natural cooling.

NOTE The percentage of natural cooling capacity to forced cooling capacity of gas-filled transformers is smaller

than that of oil-immersed transformers. It is not difficult generally in oil-immersed transformers to achieve ONAN

capacity as 50 % of the OFAF or ODAF capacity. But in gas-filled transformers, it is sometimes difficult and not

economical to achieve GNAN capacity as 50 % of the GDAF capacity. It is recommended for the purchaser to

consult with the manufacturer about natural cooling capacity to forced cooling capacity.

11 Temperature-rise limits

11.1 Classification and insulation system temperature

Transformers are classified by the insulation systems shown in Table 1. The maximum

temperature occurring in any part of the winding shall not exceed the insulation system

temperature in Table 1 continuously.

An approximate value for practical purposes of hot-spot temperature can be calculated by

using the concept of Annex B.

– 12 – 60076-15 © IEC:2008

Components used as insulating material may be used separately or in combination providing

that their temperature does not exceed continuously the values given for the appropriate

insulation system temperature.

Table 1 – Classification and insulation system temperature

Insulation system Insulation system temperature

(see note) °C

Class 105 105

Class 120 120

Class 130 130

Class 155 155

Class 180 180

Class 200 200

Class 220 220

NOTE Temperature classifications are given in IEC 60085.

11.2 Normal temperature-rise limits

The temperature rise of each winding of the transformer, designed for operation at normal

service conditions, shall not exceed the corresponding limit specified in Table 2 when tested

in accordance with Clause 28.

The temperature of the core, metallic parts and adjacent materials shall not reach a value that

will cause damage to any part of the transformer.

In most of the gases, the temperature-rise limit of gas is higher than the temperature-rise limit

of winding, so that the temperature-rise limit of gas is not necessary to be specified. If

necessary, it is subjected to agreement between the supplier and the purchaser.

Table 2 – Winding temperature-rise limits

Insulation system Average winding

temperature-rise limits

(see note 1)

K

(see note 2)

Class 105 60

Class 120 75

Class 130 80

Class 155 100

Class 180 125

Class 200 135

Class 220 150

NOTE 1 Temperature classifications are given in IEC 60085.

NOTE 2 Temperature-rise measured in accordance with Clause 28.

11.3 Reduced temperature-rises for transformers designed for high cooling air

temperatures or special air cooling conditions

The requirements in IEC 60076-2 apply.

60076-15 © IEC:2008 – 13 –

11.4 High altitude temperature-rise correction

Unless otherwise agreed between the supplier and the purchaser, for transformers designed

for operation at an altitude greater than 1 000 m but tested at normal altitudes, the limits of

temperature-rise given in Table 2 shall be reduced by the following amounts for each 500 m

by which the intended working altitude exceeds 1 000 m:

natural-air-cooled transformers: 2 %;

forced-air-cooled transformers: 3 %.

A corresponding reverse correction may be applied in cases where the altitude of the factory

is above 1 000 m and the altitude of the installation site is below 1 000 m.

Any temperature-rise correction in dependence on altitude shall be rounded to the nearest

whole number of Kelvin.

The influence of differing ambient temperature or altitude on the air cooling of the tank is

disregarded for the water-cooled transformers.

11.5 Reduced temperature-rise for transformers designed for high cooling water

temperatures

The requirements in IEC 60076-2 apply.

11.6 Temperature rise during specified load cycle

If guarantees and/or a special test regarding a load cycle are to be specified, this shall involve

the following parameters:

– the initial temperature condition of the transformer, either at ambient temperature or with

steady-state temperature-rises corresponding to a specified fraction of rated current

(‘preload’);

– the (constant) magnitude of the test current, expressed as a multiple of rated current, and

its duration;

– the maximum permissible temperature-rise values for top gas and winding average (by

resistance) at the termination of the test. This statement is optional. The test may be

executed for information only, without any limits being agreed on beforehand;

– any special observations or measurements to be performed, for example direct hot-spot

temperature measurements, thermal imaging of tank-wall heating, and possible limitations

in relation to them.

For further recommendations and discussion regarding temperature rise during specified load

cycle – particularly measurements and evaluation – temperature rise during specified load

cycle is subjected to agreement between the supplier and the purchaser.

12 Insulation levels

The requirements in IEC 60076-3 apply.

13 Requirements for gases and gas tightness

13.1 Requirements for gases

The manufacturer shall specify the type and the required quantity, quality and density of the

gas to be used in a gas-filled transformer.

– 14 – 60076-15 © IEC:2008

For sulfur hexafluoride-filled transformers, new SF in accordance with IEC 60376 and used

SF in accordance with IEC 60480 can be used.

The maximum allowable moisture content within gas-filled transformer filled with gas at rated

gas pressure shall be such that the dew-point is not higher than –20 °C for a measurement at

20 °C. Adequate correction shall be made for measurement made at other temperatures. For

the measurement and determination of the dew point, refer to IEC 60376 and IEC 60480.

NOTE In gas compartments which are separated from transformer winding, a dew point of –5 °C for measurement

at 20 °C is acceptable.

13.2 Gas tightness

IEC 62271-1 gives general rules to the gas tightness of high-voltage switchgears. This rule

can be applicable to the gas-filled transformers.

The tightness characteristic shall be consistent with a minimum maintenance and inspection

philosophy. The tightness for gas is specified by the relative leakage rate F .

rel

For sulfur hexafluoride-filled transformers, the relative leakage rate of SF shall not exceed

0,5 percent per year. For transformers filled with the mixture, consisting of SF and other

gases, the relative leakage rate of the mixture shall not exceed 0,5 percent per year.

14 General requirements for tests

New transformers shall be subjected to tests as specified below.

Tests shall be made at any ambient temperature between 10 °C and 40 °C. For water cooled

transformer, tests shall be made at any water temperature not exceeding 25 °C.

Tests shall be made at the manufacturer's works, unless otherwise agreed between the

supplier and the purchaser.

All external components and fittings that are likely to affect the performance of the

transformer during the test shall be in place.

Tapped windings shall be connected on their principal tapping, unless the relevant test clause

requires otherwise or unless the supplier and the purchaser agree otherwise.

The test basis for all characteristics other than insulation is the rated condition, unless the

test clause states otherwise. Dielectric tests shall be performed in guaranteed minimum gas

pressure.

All measuring systems used for the tests shall have certified, traceable accuracy and be

subjected to periodic calibration, according to the rules of 7.6 of ISO 9001.

NOTE Specific requirements on the accuracy and verification of the measuring systems are under consideration

(see IEC 60076-8).

If test methods are not prescribed in this standard, or if tests other than those listed in this

standard are specified in the contract, such test methods are subjected to agreement between

the supplier and the purchaser.

15 Measurement of winding resistance (routine test)

The test described in IEC 60076-1 applies.

60076-15 © IEC:2008 – 15 –

16 Measurement of voltage ratio and check of phase displacement (routine test)

The test described in IEC 60076-1 applies.

17 Measurement of short-circuit impedance and load loss (routine test)

The test described in IEC 60076-1 applies.

The reference temperature of the short-circuit impedance and load loss shall be

– 75 °C for an insulation system temperature of 105 °C;

– average winding temperature-rise plus 20 °C for other average winding temperature-rise.

NOTE Reference temperature with an insulation system of class 200 or above shall be subjected to agreement

between the supplier and the purchaser.

When a transformer has windings of different insulation system temperatures, the reference

temperature relating to the winding having the higher insulation system temperature shall be

used.

18 Measurement of no-load loss and current (routine test)

The test described in IEC 60076-1 applies.

19 Tests on on-load tap-changers (routine test)

The test described in IEC 60076-1 applies.

20 Measurement of zero-sequence impedance(s) on three-phase transformers

(special test)

The test described in IEC 60076-1 applies.

21 Measurement of the harmonics of the no-load current (special test)

The test described in IEC 60076-1 applies.

22 Separate-source AC withstand voltage test (routine test)

The test described in IEC 60076-3 applies.

23 Short-duration induced AC voltage test (ACSD) (routine or special test)

The test described in IEC 60076-3 applies. Routine or special test is in accordance with

IEC 60076-3.

24 Long-duration induced AC voltage test with partial discharge measurement

(ACLD) (routine or special test)

The test described in IEC 60076-3 applies. Routine or special test is in accordance with

IEC 60076-3.

– 16 – 60076-15 © IEC:2008

25 Lightning impulse test (LI) (routine or type test)

The test described in IEC 60076-3 applies. Routine or type test is in accordance with

IEC 60076-3.

26 Test with lightning impulse chopped on the tail (LIC) (special test)

The test described in IEC 60076-3 applies.

27 Switching impulse test (SI) (routine test for the transformers having highest

voltage higher than 170 kV)

The test described in IEC 60076-3 applies.

28 Temperature-rise test (type test)

28.1 General

The relevant requirements in IEC 60076-2 apply with the translation of oil to gas.

28.2 Corrections

The gas temperature-rise above ambient during the test is multiplied by the following factors.

x

total losses

⎛ ⎞

⎜ ⎟

test losses

⎝ ⎠

– x = 0,8 for distribution gas-filled transformers (natural cooling, maximum rated power

2 500 kVA);

– x = 0,9 for larger gas-filled transformers with GN. cooling;

– x = 1,0 for larger gas-filled transformers with GF. or GD. cooling.

The average winding temperature-rise above gas temperature during the test is multiplied by

the following factors.

y

rated current

⎛ ⎞

⎜ ⎟

test current

⎝ ⎠

– y = 1,6 for gas-filled transformers with GN. or GF. cooling;

– y = 2,0 for gas-filled transformers with GD. cooling.

29 Measurement of sound level (special test)

29.1 General

The relevant requirements in IEC 60076-10 apply.

29.2 Prescribed contour

For measurement made with forced air cooling and forced gas cooling auxiliaries (if any) out

of service, the prescribed contour shall be spaced 0,3 m away from the principal radiating

surface.

For measurement made with forced air cooling or forced gas cooling auxiliaries in service, the

prescribed contour shall be spaced 2 m away from the principal radiating surface.

60076-15 © IEC:2008 – 17 –

30 Short-circuit test (special test)

The relevant requirements in IEC 60076-5 apply.

The average temperature of each winding after loading with a symmetrical short-circuit

current I of a value and duration as specified in IEC 60076-5, respectively, shall not exceed

the maximum value stated in Table 3 at any tapping position.

Table 3 – Maximum permissible values of the average temperature of each winding

Maximum permissible value of temperature

°C

Insulation system

Copper winding Aluminum winding

Class 105 180 180

Class 120 250 200

Class 130 350 200

Class 155 350 200

Class 180 350 200

Class 200 350 200

Class 220 350 200

NOTE In case of windings made of high tensile strength aluminum alloys, higher

maximum values of temperature, but not exceeding those relevant to copper, may

be allowed by agreement between the manufacturer and the purchaser.

31 Tightness tests (routine test)

IEC 62271-1 gives a general test method of the gas tightness of high-voltage switchgears.

This method can be applicable to the gas-filled transformers.

The purpose of the tightness tests is to demonstrate that the absolute leakage rate F does not

exceed the specified value of the permissible leakage rate F .

p

Where possible, the tests should be performed at normal ambient temperature on a complete

system filled at rated gas pressure. If this is not practical, the tests may be performed on

parts, components or sub-assemblies. In such cases, the leakage rate of the total system

shall be determined by summation of the compon

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...