IEC 60670-1:2002

(Main)Boxes and enclosures for electrical accessories for household and similar fixed electrical installations - Part 1: General requirements

Boxes and enclosures for electrical accessories for household and similar fixed electrical installations - Part 1: General requirements

This part of IEC 60670 applies to boxes, enclosures and parts of enclosures (hereafter called "boxes" and "enclosures") for electrical accessories with a rated voltage not exceeding 1 000 V a.c. and 1 500 V d.c. intended for household or similar fixed electrical installations, either indoors or outdoors. This edition cancels and replaces the second edition of IEC 60670 published in 1989 and its amendment 1 (1994). This edition constitutes a technical revision. The contents of the corrigendum of February 2003 have been included in this copy.

Boîtes et enveloppes pour appareillage électrique pour installations électriques fixes pour usages domestiques et analogues - Partie 1: Règles générales

La présente partie de la CEI 60670 s'applique aux boîtes, parties d'enveloppes et enveloppes (ci-après désignées par les termes «boîtes» et «enveloppes») destinées à des appareillages électriques ayant une tension assignée ne dépassant pas 1 000 V alternatifs et 1 500 V continus prévus pour des installations électriques fixes à usages domestiques ou analogues, pour l'intérieur ou l'extérieur. Cette édition annule et remplace la deuxième édition de la CEI 60670 parue en 1989 ainsi que son amendement 1 (1994). Cette édition constitue une révision technique. Le contenu du corrigendum de février 2003 a été pris en considération dans cet exemplaire.

General Information

- Status

- Published

- Publication Date

- 07-Jul-2011

- Technical Committee

- SC 23B - Plugs, socket-outlets and switches

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 10-Mar-2015

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

IEC 60670-1:2002 – General Requirements for Boxes and Enclosures for Electrical Accessories

Overview

IEC 60670-1:2002, published by the International Electrotechnical Commission (IEC), defines the general requirements for boxes and enclosures used with electrical accessories in household and similar fixed electrical installations. Applicable to rated voltages up to 1,000 V AC and 1,500 V DC, this standard ensures the safe and effective design, testing, and classification of enclosures intended for both indoor and outdoor use.

This standard replaces previous editions from 1989 and 1994 and includes updates from amendment 1 (2011) and the 2003 corrigendum, reflecting a comprehensive technical revision.

Key Topics

Scope and Application

Covers enclosures for electrical devices installed in homes or similar fixed electrical setups. Suitable for ambient temperatures typically not exceeding 25 °C.Classification and Ratings

Includes detailed classifications of boxes and enclosures based on dimensions, materials, and intended use. Ratings address electrical parameters and protection levels.Construction Requirements

Specifies requirements for mechanical strength, durability, resistance to aging, heat, corrosion, and ingress protection against solids and water.Safety Measures

Requirements include protection against electric shock, earthing provisions, insulation resistance, creepage distances, and fire resistance.Marking and Identification

Standard mandates clear markings for correct identification, including classification, ratings, and manufacturer information.Testing Protocols

Defines rigorous tests for mechanical strength, resistance to heat, electrical insulation, ingress protection, corrosion, and electromagnetic compatibility (EMC).Accessories and Components

Covers parts integral to the boxes/enclosures such as membranes, grommets, covers, mounting blocks, and cable anchorages to ensure holistic compliance.Documentation and Visual Aids

Includes examples of typical enclosures, test apparatus diagrams, and measurement examples to facilitate standardized design and verification.

Applications

Residential Electrical Installations

Ensures safety and reliability for electrical switch boxes, socket enclosures, junction boxes, and protective housings inside homes.Similar Fixed Installations

Applies to commercial and light-industrial settings sharing similar environmental conditions and voltage ratings.Indoor and Outdoor Usage

Designed for enclosures placed in protected indoor areas as well as outdoor locations requiring additional ingress protection.Manufacturing and Quality Assurance

Guides manufacturers in producing IEC-compliant electrical enclosures, enabling consistent quality and facilitating international market acceptance.Certification and Regulatory Compliance

Reference for conformity assessment bodies evaluating electrical ancillary equipment for adherence to global safety standards.

Related Standards

IEC 60670 Series

Additional parts of IEC 60670 address specific types of enclosures and specialized requirements beyond general provisions in Part 1.IEC 60529

Related standard detailing IP (Ingress Protection) ratings to assess enclosure sealing against solids and liquids.IEC 61850 and IEC 61439

Pertinent for enclosures used with communication and low-voltage switchgear systems, complementing IEC 60670 requirements.ISO/IEC Directives

Governs the preparation and maintenance of IEC standards including IEC 60670-1.

Why IEC 60670-1 Matters

Adhering to IEC 60670-1 ensures that boxes and enclosures for electrical accessories meet internationally recognized safety, durability, and performance criteria. This provides manufacturers, installers, and end-users with confidence in the protection and longevity of electrical installations, reducing risks of electrical shock, fire, and equipment failure. Compliance also supports interoperability and global market access for electrical products.

For detailed technical specifications, test methods, and classification criteria, professionals should reference the full IEC 60670-1:2002+A1:2011 document available through the IEC Webstore.

Keywords: IEC 60670-1, electrical enclosures, electrical boxes, household electrical installations, fixed electrical installations, electrical safety standards, IEC standards, ingress protection, electrical accessories, construction requirements

Buy Documents

IEC 60670-1:2002 - Boxes and enclosures for electrical accessories for household and similar fixed electrical installations - Part 1: General requirements Released:12/5/2002

IEC 60670-1:2002+AMD1:2011 CSV - Boxes and enclosures for electrical accessories for household and similar fixed electrical installations - Part 1: General requirements Released:7/8/2011

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60670-1:2002 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Boxes and enclosures for electrical accessories for household and similar fixed electrical installations - Part 1: General requirements". This standard covers: This part of IEC 60670 applies to boxes, enclosures and parts of enclosures (hereafter called "boxes" and "enclosures") for electrical accessories with a rated voltage not exceeding 1 000 V a.c. and 1 500 V d.c. intended for household or similar fixed electrical installations, either indoors or outdoors. This edition cancels and replaces the second edition of IEC 60670 published in 1989 and its amendment 1 (1994). This edition constitutes a technical revision. The contents of the corrigendum of February 2003 have been included in this copy.

This part of IEC 60670 applies to boxes, enclosures and parts of enclosures (hereafter called "boxes" and "enclosures") for electrical accessories with a rated voltage not exceeding 1 000 V a.c. and 1 500 V d.c. intended for household or similar fixed electrical installations, either indoors or outdoors. This edition cancels and replaces the second edition of IEC 60670 published in 1989 and its amendment 1 (1994). This edition constitutes a technical revision. The contents of the corrigendum of February 2003 have been included in this copy.

IEC 60670-1:2002 is classified under the following ICS (International Classification for Standards) categories: 29.120.10 - Conduits for electrical purposes. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60670-1:2002 has the following relationships with other standards: It is inter standard links to IEC 60670:1989, IEC 60670-1:2002/AMD1:2011, IEC 60670-1:2002/COR1:2003, IEC 60670-1:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60670-1:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

����� CEI

�������������� IEC

60670-1

�������������

����������������

��������

�������������

�������

Boîtes et enveloppes pour appareillage électrique

pour installations électriques fixes pour usages

domestiques et analogues –

Partie 1:

Règles générales

Boxes and enclosures for electrical accessories

for household and similar fixed electrical

installations –

Part 1:

General requirements

������������ ����!�

�� ����!�����"��

#��$��#�%�%&���’����

����������������������������� ��������������������

��(����)������*+�,�����--&.�)���(�")�!+���������)+�#�� ��� ���� �� =+��+�9� �--&� +))� ��#� (�")�!+������ +��

����������������/�(+��������%����0������.�)+�#���12�� ������� <��6� +� ����8�+����� ��� �6�� %����� ������0� ���

��,�����)+�#���%��12��0 �3+�()�.���#�12��������<��� ���������+����#�%��12��0

�������������������� ���������������������

����,��������!����)���������!���+�����(�")�!+���������)+ �6����#������<�(�")��6��8�!����)��+����,��������� ����

#�����!��(��+���)���+�������������������(���")��0��+� (�")�!+�����0� ���� �3+�()�.� �������� ���"���� �0�.� �0�

�3��()�.�)������������4���������0�.��0������0������5���� +��� �0�� �� ��.� ���(�!��,�)9.� ��� �6�� "+��� (�")�!+����.

���(�!��,������)+�(�")�!+��������"+��.�)+�(�")�!+������� �6�� "+��� (�")�!+����� ��!��(��+���8� +��������� �� +��

"+��� ��!��(��+��� )4+���������� �.� ��� )+� (�")�!+����� �� �6�� "+��� (�")�!+����� ��!��(��+���8� +���������� �

"+�����!��(��+���)���+�����������������0 +����0

���������������������������� "��������������������������������������

������������������������������

��� !������� ��!6��5��� ���� (�")�!+������ ��� )+� #��� ��� �6�� ��!6��!+)� !������� � � ��#� (�")�!+������ ��� B�(�

!����+������ ��,�� (+�� )+� #��� + ��� 5�7�)� �� )���� )7��+� ������ !����+��� ��,��<� "9� �6�� ��#.� �6��� �������8� �6+�

+!���)� ��� )+� ��!6��5��0� ���� ������8�������� ��)+�� �� / �6�� !������� �� )�!��� !������� ��!6��)�890� �� ���+����

!����� (�")�!+����.� 9� !��(���� �+� ,+)�����.� ����� ���(�� ��)+���8� ��� �6��� (�")�!+����.� ��!)����8� ���� ,+)����9.� ��

��")��� �+��� )�� #+�+)�8��� ���� (�")�!+������ ��� )+� #�� +,+�)+")�� ��� �6�� ��#� #+�+)�8��� � � (�")�!+�����

:,���� !���������;� ��� ()��� ���� ���,�))��� ��������. :����"�)�<;� ��� +�������� ��� ��<� ��������.� +���������

+����������� ���!����8���+0� ������ ���+������ ���� )�� +���!����8���+0� �� ���+����� ��� �6�� ��"*�!��� �����

��*����/�)4���������)4+,+�!������������+,+�3� �����(��� !�������+�����+���<��B����(��8�����������+B���"9��6�

(+��)��!�������4�������5���+��)+"����!�����(�")�!+����. ��!6��!+)� !��������� <6�!6� 6+�� (��(+���� �6��

+����� 5��� )+� )����� ���� (�")�!+������ (+����.� ���� (�")�!+����.� +�� <�))� +�� �6�� )���� � � (�")�!+������ ������.

�8+)���������(���")���(+��)4���������+������’ ���+)���+,+�)+")�� �����6�� �))�<��8’

�� ������������������������������� �� ����#��������������������

�� ������������������������������������ �� �����������������������������

��� !+�+)�8��� ��� )�8��� ���� )�� ����� <�"� ��� )+� #�� �6�� ���)���� !+�+)�8��� ��� �6�� ��#� <�"� ����

:<<<0��!0!6$!+�)8� 06��;�,����(��������� +������� :<<<0��!0!6$!+�)8��06��;� ��+")��� 9��� ��� ��+�!6

��!6��!6��� ��� ���)��+��� ��� ���"���3� !�������. "9� +� ,+����9� � � !������+� ��!)����8� ��3�� ��+�!6��.

!��(���+���������!6��!6�����3���))��.�(+��!����� ��!6��!+)�!����������+����+���� �(�")�!+����0����

�4�����������+������(�")�!+����0������� ���+����� )���� �� ���+����� ��� +)��� +,+�)+")�� ��� ��!���)9

��� )�8��� ����� �8+)������ ���(���")��� ���� )�� ������� (�")�!+�����.� <��6��+<�� +��� ��()+!��

���,�))��� (�")�!+�����.� )��� (�")�!+������ ���()+� (�")�!+�����.�+��<�))�+��!����8���+0

!���������������.�+�����5�������)���!����8���+0

�� ��������� ��������

�� ��������� ��������

#�� ������� ���� ���������� (�")�!+������ (+����

�6��� ����+�9� � � ��!���)9� ������� (�")�!+�����

:<<<0��!0!6$=�06��;� ���� +����� ���(���")�� (+�

:<<<0��!0!6$=�06��;� ��� +)��� +,+�)+")�� "9� ��+�)0

!�������� �)�!�����5��0� >���))�?� (������� !���+!�

�)�+���!���+!���6��#�����������,�!��#������:���

+,�!� )�� ���,�!�� !)����� :,���� !���������;� (���� ()��

"�)�<;� ��� ���6����� ���+����0

�4�� ���+�����0

�� ���!�����������

�� ������������!����������

��� ,���� +,�?� ���� 5��������� +�� ��*��� ��� !����

� � 9��� 6+,�� +�9� 5��������� ��8+����8� �6��

(�")�!+����� ��� +,�?� "������ ��� ������8�������

(�")�!+����� ��� ����� ���6��� +�����+�!�.� ()�+��

��(()�����+����.� (����?� !���+!�� +,�!� )�� ���,�!�

!���+!���6��#�����������,�!��#�����’

!)�����’

��+�)’�!������,@��!0!6

��+�)’ !������,@��!0!6

��)’� A2�����-�-������

��)’� A2�����-�-������

�+3’� A2�����-�-��1���

�+3’� A2�����-�-��1���

����� CEI

�������������� IEC

60670-1

�������������

����������������

��������

�������������

�������

Boîtes et enveloppes pour appareillage électrique

pour installations électriques fixes pour usages

domestiques et analogues –

Partie 1:

Règles générales

Boxes and enclosures for electrical accessories

for household and similar fixed electrical

installations –

Part 1:

General requirements

©���#�������������������(����!����������,����⎯��#�(9��86����+))���86��������,��

Aucune partie de cette publication ne peut être reproduite ni No part of this publication may be reproduced or utilized in any

utilisée sous quelque forme que ce soit et par aucun procédé, form or by any means, electronic or mechanical, including

électronique ou mécanique, y compris la photocopie et les photocopying and microfilm, without permission in writing from

microfilms, sans l'accord écrit de l'éditeur. the publisher.

������+����+)� �)�!�����!6��!+)� #���������.� � 1.� ���� ��� >+���"�.� ��� C�3� �1�.� #D������ E���,+� ��.� �<��?��)+��

��)�(6���’�A2�����-�-�������� ��)� +3’�A2�����-�-��1����� ���+�)’����+�)@��!0!6��� F�"’�<<<0��!0!6

#�������G

G�

#�����������)�!�����!6��5���������+����+)� ���#��#���

������+����+)��)�!�����!6��!+)�#���������

�����������������������������������������

Pour prix, voir catalogue en vigueur

For price, see current catalogue

– 2 – 60670-1 � CEI:2002

SOMMAIRE

AVANT-PROPOS . 6

1 Domaine d’application .10

2 Références normatives .10

3 Définitions.12

4 Règles générales .16

5 Notes générales sur les essais.16

6 Caractéristiques assignées .16

7 Classification .18

8 Marquage .20

9 Dimensions.22

10 Protection contre les chocs électriques.22

11 Dispositions pour la mise à la terre.24

12 Construction .26

13 Résistance au vieillissement, protection contre la pénétration de corps solides et

contre la pénétration nuisible de l’eau.46

14 Résistance d’isolement et rigidité diélectrique.56

15 Résistance mécanique .58

16 Résistance à la chaleur .66

17 Lignes de fuite, distances d’isolement dans l’air et distances à travers le matériau

d’étanchéité .70

18 Résistance du matériau isolant à la chaleur anormale et au feu .70

19 Résistance au cheminement .72

20 Résistance à la corrosion .72

21 Compatibilité électromagnétique (CEM).74

Annexe A (informative) Exemples d'enveloppes et de leurs éléments .110

Bibliographie .112

Figure 1 – Exemples de membranes et de passe-fil .76

Figure 2 – Bande de mise à la terre (voir 11.2) .78

Figure 3 – Languette d'essai (voir 11.2) .80

Figure 4 – Mesure du volume (voir 12.12.4) .80

Figure 5 – Paroi d'essai (voir 13.3) .82

Figure 6 – Surfaces de référence pour boîtes et enveloppes .84

Figure 7 – Bloc de montage pour matériel encastré pour application des coups

sur l'arrière (voir 15.3) .86

Figure 8 – Appareil pour l'essai de choc à basse température (voir 15.1) .88

Figure 9 – Points d’application des coups pour la partie A (voir 15.3) .90

Figure 10 – Séquence des coups pour les parties A, B, C, D, E, F et G (voir 15.3) .92

Figure 11 – Appareil pour l'essai des serre-câble (voir 12.6) .94

60670-1 © IEC:2002 – 3 –

CONTENTS

FOREWORD . 7

1 Scope .11

2 Normative references.11

3 Definitions .13

4 General requirements .17

5 General notes on tests.17

6 Ratings .17

7 Classification .19

8 Marking .21

9 Dimensions.23

10 Protection against electric shock.23

11 Provision for earthing.25

12 Construction .27

13 Resistance to ageing, protection against ingress of solid objects and against

harmful ingress of water.47

14 Insulation resistance and electric strength .57

15 Mechanical strength.59

16 Resistance to heat .67

17 Creepage distances, clearances and distances through sealing compound.71

18 Resistance of insulating material to abnormal heat and fire.71

19 Resistance to tracking .73

20 Resistance to corrosion .73

21 Electromagnetic compatibility (EMC).75

Annex A (informative) Examples of enclosures and parts thereof .111

Bibliography.113

Figure 1 – Examples of membranes and grommets .77

Figure 2 – Earthing strap (see 11.2) .79

Figure 3 – Test strap (see 11.2) .81

Figure 4 – Volume measurement (see 12.12.5) .81

Figure 5 – Test wall in accordance (see 13.3) .83

Figure 6 – Reference surfaces for boxes and enclosures .85

Figure 7 – Mounting block for flush-type equipment in order to apply blows on the rear

surface (see 15.3) .87

Figure 8 – Apparatus for impact test at low temperature (see 15.1) .89

Figure 9 – Application points for blows for part A (see 15.3).91

Figure 10 – Sequence of blows for parts A, B, C, D, E, F and G (see 15.3) .93

Figure 11 – Apparatus for testing the cable anchorage (see 12.6) .95

– 4 – 60670-1 � CEI:2002

Figure 12 – Disposition pour l'essai des capots ou plaques de recouvrement

(voir 12.1.2.2).96

Figure 13 – Calibre (épaisseur 2 mm environ) pour la vérification du contour des

couvercles, capots ou plaques de recouvrement (voir 12.1.2.3).96

Figure 14 – Exemples d'applications du calibre de la Figure 13 sur des capots fixés

sans vis sur une surface de montage ou de support (voir 12.1.2.3) .98

Figure 15 – Exemples d'application du calibre de la Figure 13 (voir 12.1.2.3) .100

Figure 16 – Calibre pour la vérification des rainures, trous et dépouilles inverses

(voir 12.1.2.4).102

Figure 17 – Schéma montrant la direction d'application du calibre de la Figure 16

(voir 12.1.2.4).102

Figure 18 – Vérification des moyens de fixation des boîtes et enveloppes classifiées

selon 7.7.1 (voir 12.11).104

Figure 19 – Essai selon 12.14.3.106

Figure 20 – Barre rigide (voir 16.3) .108

Figure 21 – Représentation schématique de l’essai au fil incandescent (voir Article 18).108

Figure A.1 – Exemples d'enveloppes et de leurs éléments .110

Tableau 1 – Classification des boîtes et enveloppes .18

Tableau 2 – Forces à appliquer aux capots, plaques de recouvrement ou aux organes

de manœuvre dont la fixation ne dépend pas de vis .28

Tableau 3 – Forces et couples à appliquer aux serre-câble .34

Tableau 4 – Couples de serrage pour la vérification de la résistance mécanique des vis .40

Tableau 5 – Valeurs de l'essai de couple pour les presse-étoupe .44

Tableau 6 – Tension d'essai pour l'essai de rigidité diélectrique .58

Tableau 7 – Détermination des parties A, B, C, D, E, F et G.64

Tableau 8 – Hauteur de chute pour l'essai de choc .64

60670-1 © IEC:2002 – 5 –

Figure 12 – Arrangement for test on covers or cover-plates (see 12.1.2.2) .97

Figure 13 – Gauge (thickness about 2 mm) for the verification of the outline of lids,

covers or cover-plates (see 12.1.2.3) .97

Figure 14 – Examples of application of the gauge of Figure 13 on covers fixed without

screws on a mounting surface or supporting surface (see 12.1.2.3).99

Figure 15 – Examples of application of the gauge of Figure 13 (see 12.1.2.3) .101

Figure 16 – Gauge for verification of grooves, holes and reverse tapers (see 12.1.2.4) .103

Figure 17 – Sketch showing the direction of application of the gauge of Figure 16

(see 12.1.2.4).103

Figure 18 – Verification of fixing means for boxes and enclosures classified according

to 7.7.1 (see 12.11).105

Figure 19 – Test according to 12.14.3 .107

Figure 20 – Rigid crossbar (see 16.3) .109

Figure 21 – Diagrammatic representation of the glow-wire test (see Clause 18) .109

Figure A.1 – Examples of enclosures and parts of thereof.111

Table 1 – Classification of boxes and enclosures .19

Table 2 – Forces to be applied to covers, cover-plates or actuating members whose

fixing is not dependent on screws.29

Table 3 – Forces and torques to be applied to cable anchorages .35

Table 4 – Tightening torques for the verification of the mechanical strength of screws .41

Table 5 – Torque test values for cable glands .45

Table 6 – Test voltage for electric strength test .59

Table 7 – Determination of parts A, B, C, D E, F and G .65

Table 8 – Height of fall for impact test.65

– 6 – 60670-1 � CEI:2002

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

BOÎTES ET ENVELOPPES POUR APPAREILLAGE ÉLECTRIQUE

POUR INSTALLATIONS ÉLECTRIQUES FIXES

POUR USAGES DOMESTIQUES ET ANALOGUES –

Partie 1: Règles générales

AVANT-PROPOS

1) La CEI (Commission Electrotechnique Internationale) est une organisation mondiale de normalisation composée

de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a pour objet de

favoriser la coopération internationale pour toutes les questions de normalisation dans les domaines de

l'électricité et de l'électronique. A cet effet, la CEI, entre autres activités, publie des Normes internationales.

Leur élaboration est confiée à des comités d'études, aux travaux desquels tout Comité national intéressé par le

sujet traité peut participer. Les organisations internationales, gouvernementales et non gouvernementales, en

liaison avec la CEI, participent également aux travaux. La CEI collabore étroitement avec l'Organisation

Internationale de Normalisation (ISO), selon des conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux intéressés

sont représentés dans chaque comité d’études.

3) Les documents produits se présentent sous la forme de recommandations internationales. Ils sont publiés

comme normes, spécifications techniques, rapports techniques ou guides, et agréés comme tels par les

Comités nationaux.

4) Dans le but d'encourager l'unification internationale, les Comités nationaux de la CEI s'engagent à appliquer de

façon transparente, dans toute la mesure possible, les Normes internationales de la CEI dans leurs normes

nationales et régionales. Toute divergence entre la norme de la CEI et la norme nationale ou régionale

correspondante doit être indiquée en termes clairs dans cette dernière.

5) La CEI n’a fixé aucune procédure concernant le marquage comme indication d’approbation et sa responsabilité

n’est pas engagée quand un matériel est déclaré conforme à l’une de ses normes.

6) L’attention est attirée sur le fait que certains des éléments de la présente Norme internationale peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La Norme internationale CEI 60670-1 a été établie par le sous-comité 23B: Prises de courant

et interrupteurs, du comité d'études 23 de la CEI: Petit appareillage.

Cette édition annule et remplace la deuxième édition de la CEI 60670 parue en 1989 ainsi que

son amendement 1 (1994). Cette édition constitue une révision technique.

Le texte de cette norme est issu de la deuxième édition de la CEI 60670, son amendement 1 et

des documents suivants:

FDIS Rapport de vote

23B/681/FDIS 23B/693/RVD

Le rapport de vote indiqué dans le tableau ci-dessus donne toute information sur le vote ayant

abouti à l'approbation de cette norme.

Cette publication a été rédigée selon les Directives ISO/CEI, Partie 2.

60670-1 © IEC:2002 – 7 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

BOXES AND ENCLOSURES FOR ELECTRICAL ACCESSORIES

FOR HOUSEHOLD AND SIMILAR FIXED ELECTRICAL INSTALLATIONS –

Part 1: General requirements

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International

Organization for Standardization (ISO) in accordance with conditions determined by agreement between the

two organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60670-1 has been prepared by subcommittee 23B: Plugs, socket-

outlets and switches, of IEC technical committee 23: Electrical accessories.

This edition cancels and replaces the second edition of IEC 60670 published in 1989 and its

amendment 1 (1994). This edition constitutes a technical revision.

The text of this standard is based on the second edition of IEC 60670, its amendment 1 and

on the following documents:

FDIS Report on voting

23B/681/FDIS 23B/693/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 8 – 60670-1 � CEI:2002

Le comité a décidé que le contenu de cette publication ne sera pas modifié avant 2005.

A cette date, la publication sera

reconduite;

supprimée;

remplacée par une édition révisée, ou

amendée.

Dans la présente norme, les caractères d'imprimerie suivants sont employés:

– prescriptions proprement dites: caractères romains

– modalités d'essais: caractères italiques

– notes: petits caractères romains.

Le contenu du corrigendum de février 2003 a été pris en considération dans cet exemplaire.

60670-1 © IEC:2002 – 9 –

The committee has decided that the contents of this publication will remain unchanged

until 2005. At this date, the publication will be

reconfirmed;

withdrawn;

replaced by a revised edition, or

amended.

In this publication, the following print types are used:

− requirements proper: in roman type

− test specifications: in italic type

− notes: in smaller roman type.

The contents of the corrigendum of Februray 2003 have been included in this copy.

– 10 – 60670-1 � CEI:2002

BOÎTES ET ENVELOPPES POUR APPAREILLAGE ÉLECTRIQUE

POUR INSTALLATIONS ÉLECTRIQUES FIXES

POUR USAGES DOMESTIQUES ET ANALOGUES –

Partie 1: Règles générales

1 Domaine d’application

La présente partie de la CEI 60670 s'applique aux boîtes, parties d'enveloppes et enveloppes

(ci-après désignées par les termes «boîtes» et «enveloppes») destinées à des appareillages

électriques ayant une tension assignée ne dépassant pas 1 000 V alternatifs et 1 500 V

continus prévus pour des installations électriques fixes à usages domestiques ou analogues,

pour l'intérieur ou l'extérieur.

NOTE 1 Les règles concernant des types de boîtes et d’enveloppes particuliers sont spécifiées dans la Partie 2

applicable de la CEI 60670.

Les boîtes et enveloppes conformes à la présente norme sont utilisables à des températures

ambiantes ne dépassant pas habituellement 25 °C, mais pouvant atteindre occasionnellement

35 °C.

La présente Norme internationale est prévue pour s'appliquer aux boîtes et enveloppes pour

appareillages électriques du domaine du comité d'étude 23 de la CEI.

NOTE 2 La présente norme peut aussi être utilisée comme document de référence pour d'autres comités et sous-

comités d'études de la CEI.

Les boîtes et enveloppes qui constituent une partie intégrante d'un appareillage électrique dont

elles assurent la protection contre des influences externes (par exemple chocs mécaniques,

pénétration de corps solides ou de l'eau, etc.) sont couvertes par la norme applicable à cet

appareillage.

Cette norme ne s’applique pas aux

– rosaces de plafond;

– connecteurs supports de luminaires;

– boîtes, enveloppes et parties d’enveloppes spécifiquement conçues pour être utilisées dans

les systèmes de goulottes et de conduits profilés conformes à la CEI 61084 et qui ne sont

pas prévues pour être installées en dehors de ces systèmes.

2 Références normatives

Les documents de référence suivants sont indispensables pour l'application du présent

document. Pour les références datées, seule l'édition citée s'applique. Pour les références non

datées, la dernière édition du document de référence s'applique (y compris les éventuels

amendements).

CEI 60068-2-75:1997, Essais d’environnement – Partie 2-75: Essais – Essai Eh: Essais aux

marteaux

CEI 60112:1979, Méthode pour déterminer les indices de résistance et de tenue au chemine-

ment des matériaux isolants solides dans des conditions humides

CEI 60423:1993, Conduits de protection des conducteurs – Diamètres extérieurs des conduits

pour installations électriques et filetages pour conduits et accessoires

60670-1 © IEC:2002 – 11 –

BOXES AND ENCLOSURES FOR ELECTRICAL ACCESSORIES

FOR HOUSEHOLD AND SIMILAR FIXED ELECTRICAL INSTALLATIONS –

Part 1: General requirements

1 Scope

This part of IEC 60670 applies to boxes, enclosures and parts of enclosures (hereafter called

“boxes” and “enclosures”) for electrical accessories with a rated voltage not exceeding

1 000 V a.c. and 1 500 V d.c. intended for household or similar fixed electrical installations,

either indoors or outdoors.

NOTE Requirements for particular types of boxes and enclosures are given in the relevant parts 2 of IEC 60670.

Boxes and enclosures complying with this standard are suitable for use at ambient tem-

perature not normally exceeding 25 °C but occasionally reaching 35 °C.

This International Standard is intended to apply to boxes and enclosures for electrical

accessories within the scope of IEC technical committee 23.

NOTE This standard may also be used as a reference document for other IEC technical committees and

subcommittees.

A box or an enclosure which is an integral part of an electrical accessory and provides

protection for that accessory against external influences (for example mechanical impact,

ingress of solid objects or water, etc.) is covered by the relevant standard for such an

accessory.

This standard does not apply to

– ceiling roses;

– luminaire supporting couplers;

– boxes, enclosures and parts of enclosures specifically designed to be used for cable

trunking and ducting systems complying with IEC 61084 and which are not intended to be

installed outside of these systems.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60068-2-75:1997, Environmental testing – Part 2-75: Tests – Test Eh: Hammer tests

IEC 60112:1979, Method for determining the comparative and the proof-tracking indices of

solid insulating materials under moist conditions

IEC 60423:1993, Conduits for electrical purposes – Outside diameters of conduits for

electrical installations and threads for conduits and fittings

– 12 – 60670-1 � CEI:2002

CEI 60529:1989, Degrés de protection procurés par les enveloppes (Code IP)

CEI 60695-2-11:2000, Essais relatifs aux risques du feu – Partie 2-11: Essais au fil

incandescent/chauffant – Méthode d'essai d'inflammabilité pour produits finis

CEI 60695-10-2:1995, Essais relatifs aux risques du feu – Partie 10-2: Guide et méthodes

d'essai pour la minimalisation des effets de chaleurs anormales sur des produits

électrotechniques impliqués dans des feux – Méthode pour vérifier la résistance à la chaleur

des produits en matériaux non métalliques au moyen de l'essai à la bille

CEI 60981:1989, Conduits très lourds rigides en acier pour installations électriques

CEI 61032:1997, Protection des personnes et des matériels par les enveloppes – Calibres

d'essai pour la vérification

CEI 61084 (toutes les parties), Systèmes de goulottes et de conduits profilés pour installations

électriques

CEI 61140: 2001, Protection contre les chocs électriques – Aspects communs aux installations

et aux matériels

3 Définitions

Pour les besoins de la présente partie de la CEI 60670, les définitions suivantes s’appliquent.

3.1

enveloppe

combinaison de parties, telles que boîtes, capots, plaques de recouvrement, couvercles,

extensions de boîtes, appareillages, etc., assurant, après assemblage et montage comme en

usage normal, un degré approprié de protection contre les influences externes et un degré

déterminé de protection contre les contacts avec les parties actives enfermées, dans toutes les

directions accessibles (voir l’Annexe A)

3.2

boîte

partie d’une enveloppe pourvue de moyens pour fixer un capot, une plaque de recouvrement,

un appareillage, etc., et qui est prévue pour recevoir des appareillages (tels que socles de

prises, interrupteurs, etc.)

3.3

extension de boîte

partie d’une enveloppe destinée à l’extension d’une boîte dans le but soit d'accroître son

volume interne soit de l'ajuster lors du montage encastré ou semi-encastré avec la surface

finie du mur ou élément similaire

3.4

couvercle, capot ou plaque de recouvrement

partie d’une enveloppe ne faisant pas partie intégrante ou partie de l’appareillage, qui peut soit

maintenir un appareillage dans sa position soit l’enfermer

3.5

couvercle de rehausse

couvercle destiné à être monté directement sur la boîte pour permettre la fixation d’appa-

reillages et pour augmenter le volume interne de l’enveloppe

NOTE La partie centrale du couvercle est rehaussée afin de s’ajuster à l’épaisseur du mur ou du plafond et pour

permettre le montage d’un appareillage au ras de la surface du mur ou du plafond.

60670-1 © IEC:2002 – 13 –

IEC 60529:1989, Degrees of protection provided by enclosures (IP Code)

IEC 60695-2-11:2000, Fire hazard testing – Part 2-11: Glowing/hot-wire based test methods -

Glow-wire flammability test method for end-products

IEC 60695-10-2:1995, Fire hazard testing – Part 10-2: Guidance and test methods for the

minimization of the effects of abnormal heat on electrotechnical products involved in fires –

Method for testing products made from non-metallic materials for resistance to heat using the

ball pressure test

IEC 60981:1989, Extra-heavy duty rigid steel conduits for electrical installations

IEC 61032:1997, Protection of persons and equipment by enclosures – Probes for verification

IEC 61084 (all parts), Cable trunking and ducting systems for electrical installations

IEC 61140:2001, Protection against electric shock – Common aspects for installation and

equipment

3 Definitions

For the purposes of this part of IEC 60670, the following definitions apply.

3.1

enclosure

combination of parts, such as boxes, covers, cover-plates, lids, box extensions, accessories,

etc., providing after assembly and installation as in normal use, an appropriate protection

against external influences, and a defined protection against contact with enclosed live parts

from any accessible direction (see Annex A)

3.2

box

part of an enclosure provided with means for fixing a cover, cover-plate, accessory, etc., and

intended to receive accessories (such as socket-outlets, switches, etc.)

3.3

box extension

part of an enclosure which is intended to extend a box for the purpose of either increasing the

internal volume of the box or enclosure or to adjust for mounting the box flush or semi-flush

with the finished surface of a wall or the like

3.4

lid, cover or cover-plate

part of an enclosure, not integral with or part of an accessory, which may either retain an

accessory in position or enclose it

3.5

raised cover

cover intended for mounting directly onto a box to provide for the attachment of accessories

and to increase the internal volume of the enclosure

NOTE The centre portion of the cover is raised to accommodate a specific wall or ceiling thickness and to permit

the mounting of the accessory on it, flush with the surface of the wall or ceiling.

– 14 – 60670-1 � CEI:2002

3.6

partie conductrice accessible

partie conductrice d’un équipement électrique que l’on peut toucher, qui n’est normalement pas

active, mais qui peut devenir active lorsque l’isolation de base fait défaut

3.7

boîte ou enveloppe pour montage en saillie

boîte ou enveloppe destinée à être montée en saillie sur une surface (voir l’Annexe A)

3.8

boîte ou enveloppe pour montage encastré

boîte ou enveloppe destinée à être encastrée de façon à affleurer la surface de montage (voir

l’Annexe A)

3.9

boîte ou enveloppe pour montage semi-encastré

boîte ou enveloppe destinée à être encastrée dans une surface de montage et qui fait

partiellement saillie au niveau de la surface de montage

3.10

presse-étoupe

dispositif conçu pour permettre l'entrée d'un câble dans une enveloppe et qui assure l'étan-

chéité et la retenue. Il peut également assurer d'autres fonctions telles que mise à la terre,

liaison de continuité, isolement, protège-câble, détensionnement du câble, séparément ou en

combinaison

3.11

joint (garniture)

matériau utilisé pour remplir l’espace compris entre l’intérieur d’un presse-étoupe et le câble

qui le traverse, habituellement comprimé par le presse-étoupe et formant donc un joint

3.12

joint d’étanchéité

matériau introduit entre deux surfaces conjuguées d’une boîte qui forme un joint par

compression

3.13

passe-fil

composant utilisé pour soutenir et protéger le câble ou le conduit au point d’entrée. Il peut

également prévenir la pénétration de l’humidité ou de polluants (voir Figure 1)

3.14

membrane d’entrée

composant ou partie intégrante d’une enveloppe utilisé(e) pour protéger le câble et qui peut

être utilisé(e) pour soutenir le câble ou le conduit au point d’entrée

NOTE Une membrane d'entrée peut également prévenir la pénétration de l’humidité ou de polluants et elle peut

faire partie d’un passe-fil (voir Figure 1).

3.15

membrane de protection

composant ou partie intégrante d’une enveloppe qui n’est pas destiné(e) à être traversé(e) en

utilisation normale et est prévu(e) pour assurer une protection contre la pénétration d’eau ou

de corps solides et/ou permettre le fonctionnement d’un appareillage (voir Figure 1)

3.16

matériau composite

combinaison d’un métal et d’un matériau isolant

60670-1 © IEC:2002 – 15 –

3.6

exposed conductive part

conductive part of electrical equipment, which can be touched and which is not normally live,

but which can become live when basic insulation fails

3.7

surface mounting box or enclosure

box or enclosure which is intended for mounting on a surface (see Annex A)

3.8

flush-mounting box or enclosure

box or enclosure which is intended for mounting flush with the surface (see Annex A)

3.9

semi-flush mounting box or enclosure

box or enclosure which is intended to fit within a mounting surface and partially projects from

the mounting surface

3.10

cable gland

device designed to permit the entry of a cable into an enclosure and which provides sealing

and retention. It may also provide other functions such as earthing, bonding, insulation, cable

guarding, strain relief or a combination of these

3.11

seal (packing)

material used to fill up the space between the inside of a gland and the cable passing

through, usually compressed by the gland and thereby forming a joint

3.12

gasket

material introduced between mating surfaces of an enclosure which in compression forms a

joint

3.13

grommet

component used to support and protect the cable or conduit at the point of entry. It may also

prevent the ingress of moisture or contaminants (see Figure 1)

3.14

entry membrane

component or an integral part of an enclosure used to protect the cable which may be used to

support the cable or conduit at the point of entry

NOTE An entry membrane may also prevent the ingress of moisture or contaminants and may be part of a grommet (see

Figure 1).

3.15

protecting membrane

component or an integral part of an enclosure that is not intended to be penetrated in normal

use and is intended to provide protection against ingress of water or solid objects and/or to

allow the operation of an accessory (see Figure 1).

3.16

composite material

combination of metal and insulating material

– 16 – 60670-1 � CEI:2002

3.17

orifice à manchon

entrée ouverte d’une boîte permettant l’insertion et le logement d’un conduit

3.18

retenue de câble

capacité à limiter le déplacement d’un câble contre les forces de traction

3.19

serre-câble

capacité à limiter le déplacement d’un câble flexible contre les forces de traction et pression et

les torsions

4 Règles générales

Chacune des parties de l’enveloppe doit être conçue et construite de façon que l’enveloppe

procure, lorsqu'elle est montée et installée comme en usage normal, une protection électrique

et mécanique adéquate aux parties qu'elle enferme et réduise au minimum les dangers pour

l'usager et l'environnement.

La conformité est vérifiée par la réalisation des essais applicables spécifiés.

5 Notes générales sur les essais

5.1 Les essais selon cette norme sont des essais de type.

Sauf spécification contraire, les boîtes et enveloppes sont soumises aux essais telles qu’elles

sont fournies.

Les appareillages conformes à d'autres normes ne sont pas soumis à de nouveaux essais.

Les essais sur les boîtes et enveloppes en matériau isolant doivent être effectués après une

période de conditionnement préalable d’au moins 10 jours à la température ambiante et à une

humidité relative de l’air comprise entre 45 % et 85 %.

Sauf spécification contraire, les essais doivent être effectués dans l’ordre des articles à une

température ambiante de (20 ± 5) °C sur un lot de trois échantillons neufs.

5.2 Si l’un des échantillons ne satisfait pas à un essai en raison d’un défaut de montage ou

de fabrication, cet essai de même que ceux qui l’ont précédé et qui ont pu avoir une influence

sur le résultat de cet essai doivent être répétés sur un autre lot complet d’échantillons. Les

essais qui suivent doivent eux aussi être réalisés, sur ce même lot d’échantillons, dans l’ordre

demandé. Au terme de ces essais, les échantillons doivent tous être conformes aux exigences.

NOTE Lorsqu’il présente le premier lot d’échantillons, le demandeur peut aussi soumettre le lot supplémentaire

qui peut s’avérer nécessaire si un échantillon est défaillant. Le laboratoire d’essais peut alors, sans autre demande,

essayer le lot supplémentaire d’échantillons et ne le rejeter qu’en cas de nouveau défaut. Si le lot supplémentaire

d’échantillons n’est pas fourni

...

IEC 60670-1 ®

Edition 1.1 2011-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Boxes and enclosures for electrical accessories for household and similar fixed

electrical installations –

Part 1: General requirements

Boîtes et enveloppes pour appareillage électrique pour installations électriques

fixes pour usages domestiques et analogues –

Partie 1: Règles générales

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60670-1 ®

Edition 1.1 2011-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Boxes and enclosures for electrical accessories for household and similar fixed

electrical installations –

Part 1: General requirements

Boîtes et enveloppes pour appareillage électrique pour installations électriques

fixes pour usages domestiques et analogues –

Partie 1: Règles générales

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX CS

ICS 29.120.10 ISBN 978-2-88912-514-2

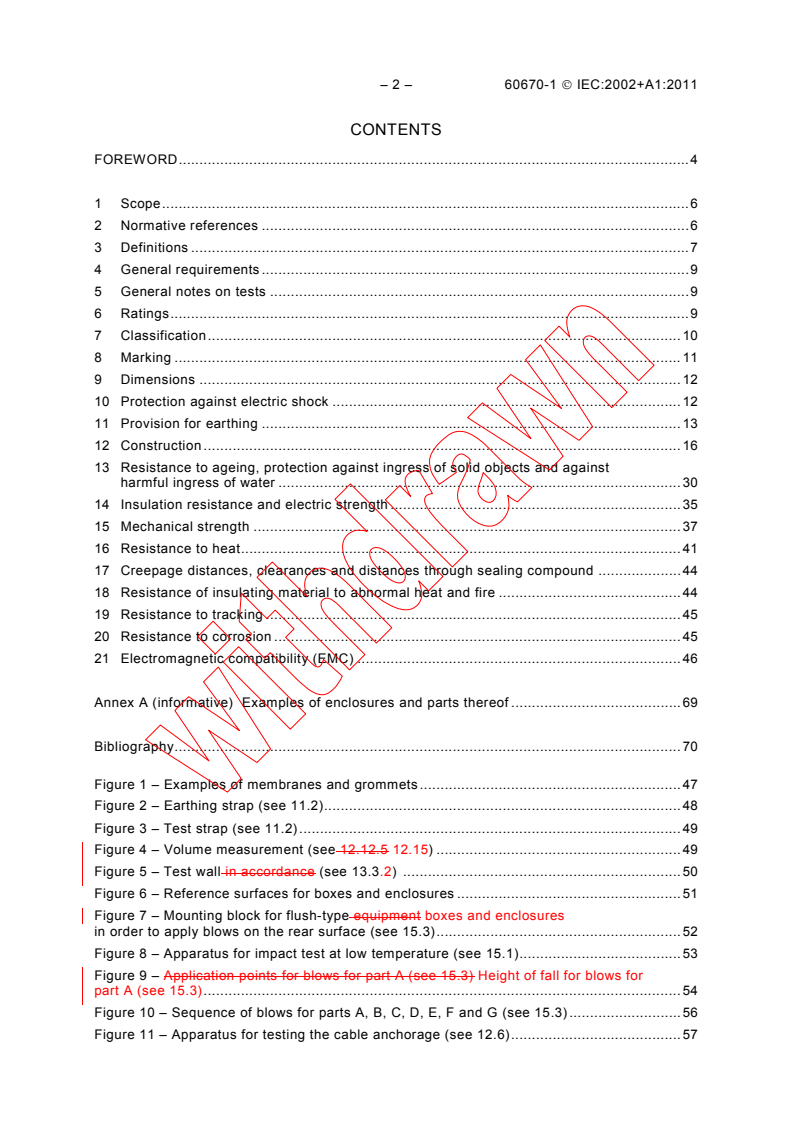

– 2 – 60670-1 IEC:2002+A1:2011

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Definitions . 7

4 General requirements . 9

5 General notes on tests . 9

6 Ratings . 9

7 Classification . 10

8 Marking . 11

9 Dimensions . 12

10 Protection against electric shock . 12

11 Provision for earthing . 13

12 Construction . 16

13 Resistance to ageing, protection against ingress of solid objects and against

harmful ingress of water . 30

14 Insulation resistance and electric strength . 35

15 Mechanical strength . 37

16 Resistance to heat . 41

17 Creepage distances, clearances and distances through sealing compound . 44

18 Resistance of insulating material to abnormal heat and fire . 44

19 Resistance to tracking . 45

20 Resistance to corrosion . 45

21 Electromagnetic compatibility (EMC) . 46

Annex A (informative) Examples of enclosures and parts thereof . 69

Bibliography . 70

Figure 1 – Examples of membranes and grommets . 47

Figure 2 – Earthing strap (see 11.2) . 48

Figure 3 – Test strap (see 11.2) . 49

Figure 4 – Volume measurement (see 12.12.5 12.15) . 49

Figure 5 – Test wall in accordance (see 13.3.2) . 50

Figure 6 – Reference surfaces for boxes and enclosures . 51

Figure 7 – Mounting block for flush-type equipment boxes and enclosures

in order to apply blows on the rear surface (see 15.3) . 52

Figure 8 – Apparatus for impact test at low temperature (see 15.1) . 53

Figure 9 – Application points for blows for part A (see 15.3) Height of fall for blows for

part A (see 15.3) . 54

Figure 10 – Sequence of blows for parts A, B, C, D, E, F and G (see 15.3) . 56

Figure 11 – Apparatus for testing the cable anchorage (see 12.6) . 57

60670-1 IEC:2002+A1:2011 – 3 –

Figure 12 – Arrangement for test on covers or cover-plates (see 12.1.2.2) . 58

Figure 13 – Gauge (thickness about 2 mm) for the verification of the outline of lids,

covers or cover-plates (see 12.1.2.3) . 58

Figure 14 – Examples of application of the gauge of Figure 13 on covers fixed without

screws on a mounting surface or supporting surface (see 12.1.2.3) . 59

Figure 15 – Examples of application of the gauge of Figure 13 (see 12.1.2.3) . 60

Figure 16 – Gauge for verification of grooves, holes and reverse tapers (see 12.1.2.4) . 61

Figure 17 – Sketch showing the direction of application of the gauge of Figure 16

(see 12.1.2.4) . 61

Figure 18 – Verification of fixing means for boxes and enclosures classified according

to 7.7.1 (see 12.11) . 62

Figure 19 – Test according to to 12.14.3 12.12.3 . 63

Figure 20 – Rigid crossbar (see 16.3) . 64

Figure 21 – Diagrammatic representation of the glow-wire test (see Clause 18) . 64

Figure 22 – Example of mounting block for boxes to be embedded in masonry (flush

type and semi-flush type) according to 12.10 . 65

Figure 23 – Example of the fixing of the auxiliary device mounted on a specimen

according to 12.10 . 66

Figure 24 – Example of test apparatus for the test according to 12.10 . 67

Figure 25 – Example of the protected volume (see 13.3.4) . 68

Figure 26 – Demonstration of the non-penetration of the internal volume . 68

Figure A.1 – Examples of enclosures and parts of thereof . 69

Table 1 – Classification of boxes and enclosures . 10

Table 2 – Forces to be applied to covers, cover-plates or actuating members whose

fixing is not dependent on screws . 17

Table 3 – Forces and torques to be applied to cable anchorages . 20

Table 4 – Tightening torques for the verification of the mechanical strength of screws . 24

Table 5 – Torque test values for cable glands . 29

Table 6 – Test voltage for electric strength test . 37

Table 7 – Determination of parts A, B, C, D E, F and G. 40

Table 8 – Height of fall for impact test . 40

– 4 – 60670-1 IEC:2002+A1:2011

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

BOXES AND ENCLOSURES FOR ELECTRICAL ACCESSORIES

FOR HOUSEHOLD AND SIMILAR FIXED ELECTRICAL INSTALLATIONS –

Part 1: General requirements

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of IEC 60670-1 consists of the first edition (2002) [documents

23B/681/FDIS and 23B/693/RVD], its amendment 1 (2011) [documents 23B/981/FDIS and

23B/991/RVD] and its corrigendum of February 2003. It bears the edition number 1.1.

The technical content is therefore identical to the base edition and its amendment and

has been prepared for user convenience. A vertical line in the margin shows where the

base publication has been modified by amendment 1. Additions and deletions are

displayed in red, with deletions being struck through.

60670-1 IEC:2002+A1:2011 – 5 –

International Standard IEC 60670-1 has been prepared by subcommittee 23B: Plugs, socket-

outlets and switches, of IEC technical committee 23: Electrical accessories.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

In this publication, the following print types are used:

− requirements proper: in roman type

− test specifications: in italic type

− notes: in smaller roman type.

The committee has decided that the contents of the base publication and its amendments will

remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date, the

publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

– 6 – 60670-1 IEC:2002+A1:2011

BOXES AND ENCLOSURES FOR ELECTRICAL ACCESSORIES

FOR HOUSEHOLD AND SIMILAR FIXED ELECTRICAL INSTALLATIONS –

Part 1: General requirements

1 Scope

This part of IEC 60670 applies to boxes, enclosures and parts of enclosures (hereafter called

“boxes” and “enclosures”) for electrical accessories with a rated voltage not exceeding

1 000 V a.c. and 1 500 V d.c. intended for household or similar fixed electrical installations,

either indoors or outdoors.

NOTE Requirements for particular types of boxes and enclosures are given in the relevant parts 2 of IEC 60670.

Boxes and enclosures complying with this standard are suitable for use at ambient tem-

perature not normally exceeding 25 °C but occasionally reaching 35 °C.

This International Standard is intended to apply to boxes and enclosures for electrical

accessories within the scope of IEC technical committee 23.

NOTE This standard may also be used as a reference document for other IEC technical committees and

subcommittees.

A box or an enclosure which is an integral part of an electrical accessory and provides

protection for that accessory against external influences (for example mechanical impact,

ingress of solid objects or water, etc.) is covered by the relevant standard for such an

accessory.

This standard does not apply to

– ceiling roses;

– luminaire supporting couplers;

– boxes, enclosures and parts of enclosures specifically designed to be used for cable

trunking and ducting systems complying with IEC 61084 and which are not intended to be

installed outside of these systems.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60068-2-75:1997, Environmental testing – Part 2-75: Tests – Test Eh: Hammer tests

IEC 60112:1979, Method for determining the comparative and the proof-tracking indices of

solid insulating materials under moist conditions

IEC 60423:1993, Conduits for electrical purposes – Outside diameters of conduits for

electrical installations and threads for conduits and fittings

IEC 60529:1989, Degrees of protection provided by enclosures (IP Code)

IEC 60695-2-11:2000, Fire hazard testing – Part 2-11: Glowing/hot-wire based test methods -

Glow-wire flammability test method for end-products

60670-1 IEC:2002+A1:2011 – 7 –

IEC 60695-10-2:1995, Fire hazard testing – Part 10-2: Guidance and test methods for the

minimization of the effects of abnormal heat on electrotechnical products involved in fires –

Method for testing products made from non-metallic materials for resistance to heat using the

ball pressure test

IEC 60981:1989, Extra-heavy duty rigid steel conduits for electrical installations

IEC 61032:1997, Protection of persons and equipment by enclosures – Probes for verification

IEC 61084 (all parts), Cable trunking and ducting systems for electrical installations

IEC 61140:2001, Protection against electric shock – Common aspects for installation and

equipment

IEC 62444:2010, Cable glands for electrical installations

3 Definitions

For the purposes of this part of IEC 60670, the following definitions apply.

3.1

enclosure

combination of parts, such as boxes, covers, cover-plates, lids, box extensions, accessories,

etc., providing after assembly and installation as in normal use, an appropriate protection

against external influences, and a defined protection against contact with enclosed live parts

from any accessible direction (see Annex A)

3.2

box

part of an enclosure provided with means for fixing a cover, cover-plate, accessory, etc., and

intended to receive accessories (such as socket-outlets, switches, etc.)

3.3

box extension

part of an enclosure which is intended to extend a box for the purpose of either increasing the

internal volume of the box or enclosure or to adjust for mounting the box flush or semi-flush

with the finished surface of a wall or the like

3.4

lid, cover or cover-plate

part of an enclosure, not integral with or part of an accessory, which may either retain an

accessory in position or enclose it

3.5

raised cover

cover intended for mounting directly onto a box to provide for the attachment of accessories

and to increase the internal volume of the enclosure

NOTE The centre portion of the cover is raised to accommodate a specific wall or ceiling thickness and to permit

the mounting of the accessory on it, flush with the surface of the wall or ceiling.

3.6

exposed conductive part

conductive part of electrical equipment, which can be touched and which is not normally live,

but which can become live when basic insulation fails

3.7

surface mounting box or enclosure

box or enclosure which is intended for mounting on a surface (see Annex A)

– 8 – 60670-1 IEC:2002+A1:2011

3.8

flush-mounting box or enclosure

box or enclosure which is intended for mounting flush with the surface (see Annex A)

3.9

semi-flush mounting box or enclosure

box or enclosure which is intended to fit within a mounting surface and partially projects from

the mounting surface

3.10

cable gland

device designed to permit the entry of a cable into an enclosure and which provides sealing

and retention. It may also provide other functions such as earthing, bonding, insulation, cable

guarding, strain relief or a combination of these

a device designed to permit the entry of a cable, flexible cable or insulated conductor into an

enclosure, and which provides sealing and retention. It may also provide other functions such

as earthing, bonding, insulation, cable guarding, strain relief or a combination of these

3.11

seal (packing)

material used to fill up the space between the inside of a gland and the cable passing

through, usually compressed by the gland and thereby forming a joint

3.12

gasket

material introduced between mating surfaces of an enclosure which in compression forms a

joint

3.13

grommet

component used to support and protect the cable or conduit at the point of entry. It may also

prevent the ingress of moisture or contaminants (see Figure 1)

3.14

entry membrane

component or an integral part of an enclosure used to protect the cable which may be used to

support the cable or conduit at the point of entry

NOTE An entry membrane may also prevent the ingress of moisture or contaminants and may be part of a grommet (see

Figure 1).

3.15

protecting membrane

component or an integral part of an enclosure that is not intended to be penetrated in normal

use and is intended to provide protection against ingress of water or solid objects and/or to

allow the operation of an accessory (see Figure 1).

3.16

composite material

combination of metal and insulating material

3.17

spout (hub)

open entry of a box permitting the insertion and containment of a conduit

3.18

cable retention

ability to limit the displacement of a fitted cable against pull forces

60670-1 IEC:2002+A1:2011 – 9 –

3.19

cable anchorage

ability to limit the displacement of a fitted flexible cable against pull and push forces and

torques

3.20

blanking-plug

a blanking-plug is a component used to close an open inlet or an open knock out

4 General requirements

Each part of the enclosure shall be so designed and constructed that, when mounted and

installed as for normal use, the enclosure ensures adequate electrical and mechanical

protection to the parts so enclosed and minimizes the risk of danger to the user or

surroundings.

Compliance is checked by carrying out the relevant tests specified.

5 General notes on tests

5.1 Tests according to this standard are type tests.

Unless otherwise specified boxes and enclosures are tested as delivered.

Accessories complying with other standards are not tested.

Tests on boxes and enclosures of insulating material shall be performed after a precondi-

tioning of at least 10 days at ambient temperature and relative air humidity of between 45 %

and 85 %.

Unless otherwise specified the tests shall be carried out in the order of the clauses at an

ambient temperature of (20 ± 5) °C on a set of three new specimens.

5.2 If one of the specimens does not satisfy a test due to an assembly or a manufacturing

fault, that test and any preceding ones which may have influenced the results of the test shall

be repeated and also the tests which follow shall be made in the required sequence on

another full set of specimens, all of which shall comply with the requirements.

NOTE When submitting the first set of specimens, the applicant may also submit the additional set of specimens

which may be necessary, should one specimen fail. The testing station will then, without further request, test the

additional set of specimens and will only reject if a further failure occurs. If the additional set of specimens is not

submitted at the same time, the failure of one specimen will entail rejection.

6 Ratings

See relevant parts 2 of this standard.

– 10 – 60670-1 IEC:2002+A1:2011

7 Classification

Boxes and enclosures are classified according to Table 1.

Table 1 – Classification of boxes and enclosures

Classification criteria

7.1 The nature of their material 7.1.1 Insulating

7.1.2 Metallic

7.1.3 Composite

a

7.2.1 Flush, semi-flush or 7.2.1.1 Non-combustible walls,

7.2 The method of installation

embedded in non-combustible ceilings or non-

combustible floors

7.2.1.2 Combustible walls,

combustible ceilings or combustible

floors

7.2.1.3 Hollow walls, hollow

ceilings, hollow floors or furniture

7.2.2 Surface mounting on 7.2.2.1 Non-combustible walls,

non-combustible ceilings, non-

combustible floors or

non-combustible furniture

7.2.2.2 Combustible walls,

combustible ceilings, combustible

floors or combustible furniture

7.2.3 Placement 7.2.3.1 Suitable for installation into

concrete during the casting process

(see 7.6)

7.2.3.2 Suitable for all types of

installation except into concrete

b

7.3 The type(s) of inlets (outlets) 7.3.1 With inlets for sheathed

cables for fixed installations

7.3.2 With inlets for flexible cables

7.3.3 With inlets for plain or

corrugated conduits

7.3.4 With inlets for threaded

conduits

7.3.5 With inlets for other types of

conductors/cables or conduits

7.3.6 With spouts (hub)

7.3.7 Without inlets. Inlet openings

will be made during installation

7.4 The clamping means 7.4.1 With cable retention

7.4.2 With cable anchorage

7.4.3 With clamping means for

flexible conduit

7.4.4 Without clamping means

7.5 The minimum and maximum 7.5.1 –5 °C to +60 °C

temperatures during installation

7.5.2 –15 °C to +60 °C

7.5.3 –25 °C to +60 °C

7.6 The maximum temperature 7.6.1 +60 °C

c

during the casting process

d

7.6.2 +90 °C

60670-1 © IEC:2002+A1:2011 – 11 –

Table 1 (continued)

Classification criteria

7.7 Boxes and enclosures for 7.7.1 Class Ha

hollow walls and the like according

7.7.2 Class Hb 7.7.2.1 Class Hb for walls

to 7.2.1.3 are classified as

7.7.2.2 Class Hb for ceilings

7.7.3 According to the degree of 7.7.3.1 IP2X

protection of the part mounted in the

hollow wall

7.7.3.2 >IP2X

7.8 The provision for fixing 7.8.1 Boxes supplied with screws

accessories to boxes

7.8.2 Boxes intended to receive

screws

7.8.3 Boxes intended to receive

claws

7.8.4 Boxes intended to receive

other means

a

Boxes and enclosures may be suitable for more than one method of installation.

b

Boxes and enclosures may have more than one type of inlet.

c

These apply only to boxes and enclosures classified according to 7.2.3.1.

d

These types are for use in concrete and will temporarily withstand temperatures up to +90 °C during the casting

process.

8 Marking

8.1 Boxes and enclosures shall be marked with

a) the name, trade mark or identification mark of the manufacturer or the responsible vendor.

In addition enclosures shall be marked with

b) the IP code against ingress of solid objects if higher than IP2X in which case the second

IP numeral shall also be marked;

c) the IP code against harmful ingress of water if higher than IPX0 in which case the first IP

numeral shall also be marked.

IPXX

d) the following marking on cover of flush enclosures intended to be mounted on rough

surfaces and where the IP is dependent on the surface (see Figure 5).

The IP code, if applicable, shall be marked on the outside of the enclosure so as to be easily

discernible when the enclosure is mounted and wired as for normal use.

e) the type reference, which may be a catalogue number;

NOTE In the following country the marking of the type reference is not used: UK.

The following information shall be marked on the boxes and enclosures or provided by the

manufacturer on the smallest package unit or in the instructions of the manufacturer:

f) the maximum temperature during the building process if 90 °C;

g) the necessary information concerning the openings which can be made during installation

in the case of boxes and enclosures classified according to 7.3.7;

h) the minimum temperature during installation for boxes classified according to 7.5.2

and 7.5.3;

– 12 – 60670-1 IEC:2002+A1:2011

i) for boxes and enclosures classified as in 7.7.2, the minimum internal volume in cm as

determined by the test in 12.15 2.5. The internal volume shall be marked on the inside of

the box or enclosure. The marking on a box or enclosure shall be such that the value can

be read after installation of the box in the normal manner but before the installation of the

wiring devices and wiring;