IEC 60300-3-3:2004

(Main)Dependability management - Part 3-3: Application guide - Life cycle costing

Dependability management - Part 3-3: Application guide - Life cycle costing

This part of IEC 60300 provides a general introduction to the concept of life cycle costing and covers all applications. This standard is intended for general application by both customers (users) and suppliers of products. It explains the purpose and value of life cycle costing and outlines the general approaches involved. It also identifies typical life cycle cost elements to facilitate project and programme planning.

Gestion de la sûreté de fonctionnement - Partie 3-3: Guide d'application - Evaluation du coût du cycle de vie

La présente partie de la CEI 60300 fournit une introduction générale au concept de l'évaluation du coût du cycle de vie et couvre toutes les applications. Cette norme est destinée à une application générale à la fois par les clients (utilisateurs) et par les fournisseurs de produits. Elle explique l'objet et la valeur de l'évaluation du cycle de vie et donne les lignes principales des approches générales impliquées. Elle identifie aussi les éléments du coût du cycle de vie typique pour faciliter la planification du programme et du projet.

General Information

- Status

- Published

- Publication Date

- 11-Jul-2004

- Technical Committee

- TC 56 - Dependability

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 27-Jan-2017

- Completion Date

- 14-Feb-2026

Relations

- Revised

IEC 60300-3-3:2017 - Dependability management - Part 3-3: Application guide - Life cycle costing - Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60300-3-3:2004 - Dependability management - Part 3-3: Application guide - Life cycle costing (LCC) - is an international application guide that introduces the concept of life cycle costing for products. Intended for both customers (users) and suppliers, the standard explains the purpose and value of LCC and outlines general approaches to assess total costs of acquisition, ownership and disposal over a product’s life cycle. This second edition (2004) expands practical guidance and includes illustrative examples, cost breakdowns and model development advice.

Key topics

The standard covers practical, technical topics relevant to LCC and dependability management:

- Objectives of life cycle costing and its role in decision-making during design, procurement and operation.

- Product life cycle phases and timing of LCC analyses (whole life or selected phases).

- Relationship between dependability (reliability, maintainability) and LCC, including dependability-related costs and consequential costs.

- LCC concept and cost element breakdown - identification of typical cost elements to support project and programme planning.

- Estimation methods and parametric approaches for deriving cost values.

- Sensitivity analysis and the impact of discounting, inflation and taxation on LCC.

- LCC process steps: planning, model selection/development, model application, documentation, review and update.

- Uncertainty, risk assessment in cost estimates and environmental aspects related to life cycle costs.

- Informative annexes with worked examples, LCC calculations, model development guidance and a product breakdown structure (including a railway vehicle example).

Practical applications

IEC 60300-3-3 is practical for:

- Product designers and systems engineers who need to optimize design choices for lower total cost of ownership.

- Procurement and contract managers evaluating bids using life cycle cost criteria.

- Maintenance planners and reliability engineers assessing trade-offs between improved dependability and LCC.

- Programme managers and project teams preparing LCC plans and models to support financial and technical decision-making.

- Sustainability and environmental teams integrating disposal and environmental cost elements into product costing.

Typical uses include design trade-off studies, evaluation of maintenance concepts, procurement comparisons, and program-level cost planning using LCC models and sensitivity analysis.

Related standards

Relevant normative references cited in IEC 60300-3-3:

- IEC 60050-191 (Dependability vocabulary)

- IEC 60300-3-12 (Integrated logistic support guide)

- IEC 61703 (Mathematical expressions for reliability/maintainability)

- IEC 62198 (Project risk management - application guidelines)

Keywords: IEC 60300-3-3, life cycle costing, LCC, life cycle cost, dependability management, cost elements, LCC model, sensitivity analysis, product life cycle.

Buy Documents

IEC 60300-3-3:2004 - Dependability management - Part 3-3: Application guide - Life cycle costing Released:7/12/2004

IEC 60300-3-3:2004 - Dependability management - Part 3-3: Application guide - Life cycle costing Released:7/12/2004

Frequently Asked Questions

IEC 60300-3-3:2004 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Dependability management - Part 3-3: Application guide - Life cycle costing". This standard covers: This part of IEC 60300 provides a general introduction to the concept of life cycle costing and covers all applications. This standard is intended for general application by both customers (users) and suppliers of products. It explains the purpose and value of life cycle costing and outlines the general approaches involved. It also identifies typical life cycle cost elements to facilitate project and programme planning.

This part of IEC 60300 provides a general introduction to the concept of life cycle costing and covers all applications. This standard is intended for general application by both customers (users) and suppliers of products. It explains the purpose and value of life cycle costing and outlines the general approaches involved. It also identifies typical life cycle cost elements to facilitate project and programme planning.

IEC 60300-3-3:2004 is classified under the following ICS (International Classification for Standards) categories: 21.020 - Characteristics and design of machines, apparatus, equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60300-3-3:2004 has the following relationships with other standards: It is inter standard links to IEC 60300-3-3:2017, IEC 60300-3-3:1996. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60300-3-3:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 60300-3-3

Second edition

2004-07

Dependability management –

Part 3-3:

Application guide –

Life cycle costing

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/searchpub) enables you to

search by a variety of criteria including text searches, technical committees

and date of publication. On-line information is also available on recently issued

publications, withdrawn and replaced publications, as well as corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/online_news/ justpub)

is also available by email. Please contact the Customer Service Centre (see

below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD 60300-3-3

Second edition

2004-07

Dependability management –

Part 3-3:

Application guide –

Life cycle costing

© IEC 2004 ⎯ Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale XA

International Electrotechnical Commission

ɆɟɠɞɭɧɚɪɨɞɧɚɹɗɥɟɤɬɪɨɬɟɯɧɢɱɟɫɤɚɹɄɨɦɢɫɫɢɹ

For price, see current catalogue

– 2 – 60300-3-3 © IEC:2004(E)

CONTENTS

FOREWORD.4

INTRODUCTION.6

1 Scope.7

2 Normative references.7

3 Terms and definitions .7

4 Life cycle costing.8

4.1 Objectives of life cycle costing .8

4.2 Product life cycle phases and LCC .8

4.3 Timing of LCC analysis.10

4.4 Dependability and LCC relationship.10

4.4.1 General.10

4.4.2 Dependability related costs.10

4.4.3 Consequential costs.11

4.5 LCC concept.13

4.5.1 General.13

4.5.2 LCC breakdown into cost elements.14

4.5.3 Estimation of cost.15

4.5.4 Sensitivity analysis.18

4.5.5 Impact of discounting, inflation and taxation on LCC.18

4.6 Life cycle costing process .18

4.6.1 General.18

4.6.2 Life cycle costing plan .19

4.6.3 LCC model selection or development.19

4.6.4 LCC model application.20

4.6.5 Life cycle costing documentation .20

4.6.6 Review of life cycle costing results .21

4.6.7 Analysis update.21

4.7 Uncertainty and risks.21

5 LCC and environmental aspects .22

Annex A (informative) Typical cost-generating activities.23

Annex B (informative) LCC calculations and economic factors .26

Annex C (informative) Example of a life cycle cost analysis .29

Annex D (informative) Examples of LCC model development .49

Annex E (informative) Example of a product breakdown structure and LCC summary

for a railway vehicle .57

Figure 1 – Sample applications of life cycle costing .9

Figure 2 – Typical relationship between dependability and LCC for the operation and

maintenance phase.11

Figure 3 – Cost element concept .15

Figure 4 – Example of cost elements used in the parametric cost method.17

Figure C.1 – Structure of DCN .30

Figure C.2 – Cost breakdown structure used for the example in Figure C.1 .31

60300-3-3 © IEC:2004(E) – 3 –

Figure C.3 – Definition of cost elements.33

Figure C.4 – Comparison of the costs of investment, annual operation and

maintenance .41

Figure C.5 – Net present value (10 % discount rate) .47

Figure C.6 – Net present value (5 % discount rate) .48

Figure C.7 – NPV with improved data store reliability (5 % discount rate) .48

Figure D.1 – Hierarchical structure .53

Figure E.1 – Vehicle system product breakdown structure .58

Table C.1 – First indenture level – Data communication network.32

Table C.2 – Second indenture level – Communication system.32

Table C.3 – Third indenture level – Power supply system .32

Table C.4 – Third indenture level – Main processor .32

Table C.5 – Third indenture level – Fan system .32

Table C.6 – Cost categories.33

Table C.7 – Investments in spare replaceable units .35

Table E.1 – Life cycle cost summary by Product Breakdown Structure.59

– 4 – 60300-3-3 © IEC:2004(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

DEPENDABILITY MANAGEMENT –

Part 3-3: Application guide –

Life cycle costing

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60300-3-3 has been prepared by IEC technical committee 56:

Dependability.

This second edition cancels and replaces the first edition published in 1996, and constitutes a

full technical revision.

This edition expands upon the technical guidance in response to requests from practitioners.

The examples in particular have been enhanced.

The text of this standard is based on the following documents:

FDIS Report on voting

56/942/FDIS 56/962/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

60300-3-3 © IEC:2004(E) – 5 –

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

IEC 60300 consists of the following parts, under the general title Dependability management:

Part 1: Dependability management systems

Part 2: Dependability programme elements and tasks

Part 3: Application guide

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

A bilingual version may be issued at a later date.

– 6 – 60300-3-3 © IEC:2004(E)

INTRODUCTION

Products today are required to be reliable. They have to perform their functions safely with no

undue impact on the environment and be easily maintainable throughout their useful lives.

The decision to purchase is not only influenced by the product's initial cost (acquisition cost)

but also by the product's expected operating and maintenance cost over its life (ownership

cost) and disposal cost. In order to achieve customer satisfaction, the challenge for suppliers

is to design products that meet requirements and are reliable and cost competitive by

optimizing acquisition, ownership and disposal costs. This optimization process should ideally

start at the product's inception and should be expanded to take into account all the costs that

will be incurred throughout its lifetime. All decisions made concerning a product's design and

manufacture may affect its performance, safety, reliability, maintainability, maintenance

support requirements, etc., and ultimately determine its price and ownership and disposal

costs.

Life cycle costing is the process of economic analysis to assess the total cost of acquisition,

ownership and disposal of a product. This analysis provides important inputs in the decision-

making process in the product design, development, use and disposal. Product suppliers can

optimize their designs by evaluation of alternatives and by performing trade-off studies. They

can evaluate various operating, maintenance and disposal strategies (to assist product users)

to optimize life cycle cost (LCC). Life cycle costing can also be effectively applied to evaluate

the costs associated with a specific activity, for example, the effects of different maintenance

concepts/approaches, to cover a specific part of a product, or to cover only selected phase or

phases of a product’s life cycle.

Life cycle costing is most effectively applied in the product’s early design phase to optimize

the basic design approach. However, it should also be updated and used during the

subsequent phases of the life cycle to identify areas of significant cost uncertainty and risk.

The necessity for formal application of the life cycle costing process to a product will normally

depend on contractual requirements. However, life cycle costing provides a useful input to

any design decision-making process. Therefore, it should be integrated with the design

process, to the extent feasible, to optimize product characteristics and costs.

60300-3-3 © IEC:2004(E) – 7 –

DEPENDABILITY MANAGEMENT –

Part 3-3: Application guide –

Life cycle costing

1 Scope

This part of IEC 60300 provides a general introduction to the concept of life cycle costing and

covers all applications. Although the life cycle costs consist of many contributing elements,

this standard particularly highlights the costs associated with dependability of the product.

This standard is intended for general application by both customers (users) and suppliers of

products. It explains the purpose and value of life cycle costing and outlines the general

approaches involved. It also identifies typical life cycle cost elements to facilitate project and

programme planning.

General guidance is provided for conducting a life cycle cost analysis, including life cycle cost

model development. Illustrative examples are provided to explain the concepts.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60050-191:1990, International Electrotechnical Vocabulary (IEV) – Chapter 191: Depend-

ability and quality of service

IEC 60300-3-12, Dependability management – Part 3-12: Application guide – Integrated

logistic support

IEC 61703, Mathematical expressions for reliability, maintainability and maintenance support

terms

IEC 62198, Project risk management – Application guidelines

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-191 and

IEC 61703, together with the following definitions, apply.

3.1

life cycle

time interval between a product’s conception and its disposal

3.2

life cycle costing

process of economic analysis to assess the life cycle cost of a product over its life cycle or a

portion thereof

– 8 – 60300-3-3 © IEC:2004(E)

3.3

life cycle cost

LCC

cumulative cost of a product over its life cycle

3.4

base date

fixed point in time set as the common cost reference

4 Life cycle costing

4.1 Objectives of life cycle costing

Life cycle costing is the process of economic analysis to assess the total cost of acquisition,

ownership and disposal of a product. It can be applied to the whole life cycle of a product or

to parts or combinations of different life cycle phases.

The primary objective of life cycle costing is to provide input to decision making in any or all

phases of a product’s life cycle.

An important objective in the preparation of LCC models is to identify costs that may have a

major impact on the LCC or may be of special interest for that specific application. Equally

important is to identify costs that may only influence the LCC to a very small extent.

The more common types of decisions to which the life cycle costing process provides input

include, for example:

– evaluation and comparison of alternative design approaches and disposal options

technologies;

– assessment of economic viability of projects/products;

– identification of cost contributors and cost effective improvements;

– evaluation and comparison of alternative strategies for product use, operation, test,

inspection, maintenance, etc.;

– evaluation and comparison of different approaches for replacement, rehabilitation/life

extension or retirement of ageing facilities;

– allocation of available funds among the competing priorities for product development/

improvement;

– assessment of product assurance criteria through verification tests and its trade-off;

– long-term financial planning.

Life cycle costing can be used to provide input to integrated logistic support analysis. See

IEC 60300-3-12 for detailed information on integrated logistic support analysis.

4.2 Product life cycle phases and LCC

Fundamental to the concept of life cycle costing is a basic understanding of a product life

cycle and the activities that are performed during these phases. Also essential is an

understanding of the relationship of these activities to the product performance, safety,

reliability, maintainability and other characteristics contributing to life cycle costs.

There are six major life cycle phases of a product as follows:

a) concept and definition;

b) design and development;

c) manufacturing;

60300-3-3 © IEC:2004(E) – 9 –

d) installation;

e) operation and maintenance;

f) disposal.

The appropriate life cycle phases, or parts or combinations of these phases, should be

selected to suit the special needs of each specific analysis. In a general way, the total costs

incurred during the above phases can also be divided into acquisition cost, ownership cost

and disposal cost.

LCC = Cost + Cost + Cost

acquisition ownership disposal

Acquisition costs are generally visible, and can be readily evaluated before the acquisition

decision is made and may or may not include installation cost.

The ownership costs, which are often a major component of LCC, in many cases, exceed

acquisition costs and are not readily visible. These costs are difficult to predict and may also

include the cost associated with installation.

Disposal costs may represent a significant proportion of total LCC. Legislation may require

activities during the disposal phase that for major projects, e.g. nuclear power stations,

involve a significant expenditure.

Figure 1 shows the life cycle phases of a product, together with some of the topics that should

be addressed by a life cycle costing study.

Life cycle phases

Concept and Operation and

Design and

Installation

Manufacturing Disposal

maintenance

definition development

• Retirement cost impact

• System integration and

• New product opportunities • Design trade-offs

verification

• Replacement/renewal

• •

Analysis of system Source selection

schemes

• Cost avoidance/cost

concept and options

• Configuration and change

reduction benefits

• Disposal and salvage

• Product selection controls

value

• Operating and

• Technology selection • Test strategies

maintenance cost

monitoring

• •

Make/buy decisions Repair/throwaway

decisions

• Product modifications and

• Identify cost drivers

service enhancements

• Performance tailoring

• Construction assessment

•

Maintenance support

• Support strategies

resource allocation and

• Manufacturability

optimization

•

assessments New product introduction

• Warranty incentive

schemes

IEC 715/04

Figure 1 – Sample applications of life cycle costing

– 10 – 60300-3-3 © IEC:2004(E)

4.3 Timing of LCC analysis

Early identification of acquisition, ownership and disposal costs enables the decision-maker to

balance dependability factors against life cycle costs. Decisions made early in a product’s life

cycle have a much greater influence on LCC than those made later in a product’s life cycle.

Experience has shown that by the end of the concept and definition phases, more than half of

a product's LCC may be committed by decisions. The opportunity to perform trade-offs

becomes increasingly limited as the product advances in its life cycle.

Life cycle costing may address the whole life cycle of a product or only part of it. The life

cycle costing should be tailored to suit a particular product/project in order to obtain the

maximum benefit from the analysis effort.

4.4 Dependability and LCC relationship

4.4.1 General

Dependability of a product is the collective term used to describe the product’s availability

performance and its influencing factors, i.e. reliability performance, maintainability perform-

ance and maintenance support performance. Performance in all these areas can have a

significant impact on the LCC. Higher initial costs may result in improved reliability and/or

maintainability, and thus improved availability with resultant lower operating and maintenance

costs.

Dependability considerations should be an integral part of the design process and LCC

evaluations. These considerations should be critically reviewed when preparing product

specifications, and be continually evaluated throughout the design phases in order to optimize

product design and the life cycle cost.

4.4.2 Dependability related costs

Costs associated with dependability elements may include the following, as appropriate:

– system recovery cost including corrective maintenance cost;

– preventive maintenance cost;

– consequential cost.

Figure 2 highlights some dependability elements translated into operation and maintenance

costs.

60300-3-3 © IEC:2004(E) – 11 –

Availability

U A

Dependability

Reliability

Maint. support

Maintainability

MTTF

MRT MLD, MAD

Replaceable

Failures

F Cost of

Repairs Preventative

units, spares

λ

, z investment for

maintenance

and facilities

logistic support

Quantity x ((MPH × cost/h) +

(material cost per unit))

Cost of preventive

maintenance

z × [(average cost of maintenance support per failure) + Cost of corrective

maintenance

(MPH × cost/h) + (MPH × cost/h) +

SITE WORKSHOP

(average cost of spares per failure)]

Consequential

Damage to image and reputation, loss of revenue,

cost

service provision, warranty cost, liability cost

IEC 716/04

Symbols and abbreviations apply in accordance with IEC 60050(191).

Figure 2 – Typical relationship between dependability and

LCC for the operation and maintenance phase

4.4.3 Consequential costs

4.4.3.1 General

When a product or service becomes unavailable, a series of consequential costs may be

incurred. These costs may include:

– warranty cost;

– liability cost;

– cost due to loss of revenue;

– costs for providing an alternative service.

In addition, further consequential costs should be identified by applying risk analysis

techniques to determine costs of adverse impacts on the company's:

– image,

– reputation,

– prestige,

which in turn may result in loss of clients.

– 12 – 60300-3-3 © IEC:2004(E)

Costs of recovering from, or mitigating against these risks should be included in

consequential costs.

In most cases, these costs are difficult to assess, but sometimes it is possible to quantify

them. For example, these costs may be estimated based on publicity campaign costs and

costs of marketing efforts or compensations in order to retain the clients. Where applicable,

these costs should be accounted for.

The unavailability of a product can significantly affect its LCC. Therefore, the availability

performance of a product and associated life cycle cost needs to be optimized. With

increasing reliability (all other factors held constant), the acquisition costs will generally

increase but maintenance and support costs will decrease. The LCC is optimized when the

incremental increase in acquisition costs due to reliability improvements equals the

incremental savings in maintenance and support costs, and in consequential costs. At a

certain point, an optimum product reliability, which corresponds to the lowest life cycle cost, is

achieved.

It should be noted that the results of LCC calculations might not match the actual/observed

costs. This is because there are many influencing random factors, such as environmental

conditions and human errors during operation, which cannot be accurately modelled in the

calculations.

Environmental issues, as well as traditional factors such as cost and time, have to be

considered in LCC calculations. Therefore, methods have to be used to evaluate and rank

environmental consequences of different activities. These evaluations can provide the bases

for environmental planning and integrating environmental issues with decision making.

4.4.3.2 Warranty costs

Warranties provide protection to the customers, insulating them from the cost of correcting

product failures, in particular during the early stages of product operations. The cost of

warranties is usually borne by the suppliers, and may be affected by reliability, maintainability

and maintenance support characteristics of the product. Suppliers can exercise significant

control over these characteristics during design and development, and manufacturing phases

thus influencing the warranty costs.

Warranties usually apply for a limited period of time, and a number of conditions generally

apply. Warranties rarely include protection against consequential costs incurred by the

customer due to product unavailability.

Warranties may be supplemented or replaced by service contracts whereby the supplier

performs, in addition to any arrangements made by the customer, all preventive and

corrective maintenance for a fixed period of time that can be renewed for any period up to the

whole product lifetime. In the latter case, the suppliers are motivated to build an optimum

level of reliability and maintainability into their product, usually at higher acquisition costs.

4.4.3.3 Liability costs

A liability will arise where, for example, a supplier fails to comply with his legal obligations.

The cost of compensating for a breach of the law needs to be considered as part of the LCC.

This is especially important in the case of products that have a high potential to cause human

injury and/or environmental damage. Liability costs are also important for new products for

which risks involved may not be fully apparent and/or well understood. Where required, a risk

analysis, together with past experience and expert judgement, may be used to provide an

estimate of these costs. For guidance on risk analysis, see IEC 62198.

60300-3-3 © IEC:2004(E) – 13 –

4.5 LCC concept

4.5.1 General

An LCC model, like any other model, is a simplified representation of the real world. It

extracts the salient features and aspects of the product and translates them into cost

estimating relationships. In order for the model to be realistic, it should:

a) represent the characteristics of the product being analysed, including its intended use

environment, maintenance concept, operating and maintenance support scenarios as well

as any constraints or limitations;

b) be comprehensive in order to include and highlight all factors that are relevant to LCC;

c) be simple enough to be easily understood and allow for its timely use in decision making,

and future update and modification;

d) be designed in such a way as to allow for the evaluation of specific elements of LCC

independent from other elements.

A simple LCC model is basically an accounting structure that contains mathematical

expressions for the estimation of cost associated with each of the cost elements constituting

the LCC. Examples are given in Annex D.

In some cases, a model may need to be specifically developed for the problem under study,

while for some other cases commercially available models may be used. Each LCC model has

its own flexibility and application. Knowledge of the contents and the conditions under which

they apply are important in order to assure adequacy of their use. Before selecting a model,

the amount of information needed should be identified together with the results expected from

using the model. Someone familiar with the details of the model is needed to review it so as to

determine the applicability of all cost factors, empirical relationships, elements and other

constants and variables in the model. Therefore, before using any existing LCC model, it

should be suitably validated for the life cycle costing study under consideration. To do this,

the cost factors and other parameters from a known example, along with the operational

scenario, should be used to assess the extent to which the model provides realistic results.

Many products are designed to have a very long life, for example buildings or power stations.

For such products, a number of costs, for instance for functional changes or product

enhancement, will occur at intervals during the life of the product and techniques to deal with

these should be incorporated in the model.

LCC modelling includes:

– cost breakdown structure,

– product/work breakdown structure,

– selection of cost categories,

– selection of cost elements,

– estimation of costs,

– presentation of results.

When applicable it may also include:

– environmental and safety aspects,

– uncertainties and risks,

– sensitivity analysis to identify cost drivers.

The cost breakdown structure presents a breakdown of costs incurred over the major phases

(or phases of interest) of the life cycle of a product. Annex C includes examples of

presentation of costs related to cost breakdown structure.

– 14 – 60300-3-3 © IEC:2004(E)

The product/work breakdown structure is composed of a detailed breakdown of hardware,

services and data identifying all major tasks and supporting work packages. Annex E gives an

example of a product breakdown structure and LCC summary for a railway vehicle.

Detailed expressions for costs for the different phases can be developed separately. The cost

elements, factors, etc. should have unique identities. In a situation where analyses cover

several phases, the identities of cost elements, factors, etc. should be unique in the total LCC

model. It is normally an advantage to maintain the product/work breakdown structure unvaried

for the particular study.

4.5.2 LCC breakdown into cost elements

In order to estimate the total life cycle cost, it is necessary to break down the total LCC into

its constituent cost elements. These cost elements should be individually identified so that

they can be distinctly defined and estimated. The identification of the elements and their

corresponding scope should be based on the purpose and scope of the LCC study.

The cost element is the link between cost categories and the product/work breakdown

structure. The selection of cost elements should be related to the complexity of the product,

as well as to the cost categories of interest in accordance with the required cost breakdown

structure. See the example in Annex C.

One approach often used to identify the required cost elements involves the breakdown of the

product to lower indenture levels, cost categories and life cycle phases. This approach can

best be illustrated by the use of a three-dimensional matrix shown in Figure 3. This matrix

involves identification of the following aspects of the product:

– breakdown of the product to lower indenture levels (i.e. the product/work breakdown

structure);

– the time in the life cycle when the work/activity is to be carried out (i.e. the life cycle

phases);

– the cost category of applicable resources such as labour, materials, fuel/energy,

overhead, transportation/travel (i.e. the cost categories).

This kind of approach has the advantage of being systematic and orderly, thus giving a high

level of confidence that all cost elements have been included.

Annex A identifies typical activities for which the costs should be addressed.

An example of a product breakdown structure and LCC summary for a railway vehicle is

presented in Annex E.

Costs associated with LCC elements may be further allocated between recurring and non-

recurring costs so that the total of all recurring and non-recurring costs equals LCC. LCC

elements may also be estimated in terms of fixed and variable costs. The latter costs, for

example, will vary with the number of copies of the product to be produced and put into use.

To facilitate control and decision making, and to support the life cycle cost process, the costs

information should be collected and reported to be consistent with the defined LCC

breakdown structure. A database should be established and maintained to capture results of

previous LCC studies in order to serve as a source of experience feedback.

60300-3-3 © IEC:2004(E) – 15 –

Cost

categories

Product/work

breakdown

structure

Labour

cost

Example of

Life cycle phases

a life cycle

cost element

Power supply

Manufacturing

IEC 717/04

Figure 3 – Cost element concept

4.5.3 Estimation of cost

4.5.3.1 General

Examples of methods that may be used to estimate the parameters of a cost element include:

– engineering cost method;

– analogous cost method;

– parametric cost method.

Examples of application of each method are given below.

When carrying out life cycle costing analysis for a certain product, one or more of these

methods, or other methods, may be used as appropriate.

In order to reduce different types of uncertainties involved in the analyses, it should be

possible to perform sensitivity analyses, for example by introducing minimum and maximum

values to the parameters of the model into the cost estimation equations.

4.5.3.2 Engineering cost method

When using the engineering cost method, the cost attributes for the particular cost elements

are directly estimated by examining the product component by component or part by part.

Often, standard established cost factors, e.g. the current engineering and manufacturing

estimates, are used to develop the cost of each element and its relationship to other

elements. Older estimates available may be updated to the present time by the use of

appropriate factors, e.g. annual discounting and escalation factors.

The engineering cost method can be illustrated by the following example concerning the cost

related to a recurring cost element:

– 16 – 60300-3-3 © IEC:2004(E)

The labour cost for the manufacture of a power supply is to be estimated. The following

information is given:

Product: power supply

Life cycle phase: manufacturing phase

Cost category: labour cost.

According to detailed assessment of manufacturing steps provided by the manufacturing

department, the time consumption for the production of one unit of the particular power supply

is 38,80 person hours. Suppose the labour cost is currency unit (CU) 54,50/person hours. The

total labour cost for the production of one unit is then 38,80 x 54,50 = CU 2 114,60.

4.5.3.3 Analogous cost method

In this method, cost estimations based on experience from a similar product or technology are

used. Historical data, updated to reflect cost escalation, effects of technology advances, etc.

are utilized. This technique may be one of the least complex and least time-consuming

methods. It is easily applied to components of the product for which there is some experience

and actual data.

The analogous cost method can be illustrated by the following example where an estimate of

the cost for parts and materials for a power supply, using experience from an older power

unit, is used.

The following information is given:

Product: power supply

Life cycle phase: manufacturing phase

Cost category: parts and materials.

For a somewhat less complex power supply produced 4 years ago, the cost for parts and

materials was CU 220. Overall cost escalation over 4 years is taken to be 5 %.

The cost for additional parts will be about CU 50.

Therefore, cost for parts and materials for the new power supply unit is estimated to be

Cost of parts and material for the old unit (1+0,05) + cost for additional parts =

= 220 x 1,05 + 50 = CU 281.

4.5.3.4 Parametric cost method

The parametric cost method uses parameters and variables to develop cost estimating

relationships. The method might be used differently in other areas.

The relationships are usually in the form of equations where, for example, person hours are

converted into costs.

An example of the parametric cost method used for a calculation of active corrective

maintenance cost for a subsystem P , is given in Figure 4.

60300-3-3 © IEC:2004(E) – 17 –

Product breakdown

structure (P)

P

max

Cost element (CE): R ; P

7 14

-

-

P

-

-

P

Cost categories (R)

- R - - R - R - - R - R - - R

2 5 7 10 12 n

IEC 718/04

Figure 4 – Example of cost elements used in the parametric cost method

In Figure 4

R is the investment cost in test equipment, workshop (non-recurring);

R is the investment cost in spares, workshop (non-recurring);

R is the labour cost, site (recurring);

R is the labour cost, workshop (recurring);

R is the spares consumption cost, workshop (recurring);

P is subsystem P .

14 14

Cost of active corrective maintenance for subsystem P for a 10 year period =

Cost(R P ) + Cost(R P ) + {Cost(R P ) + Cost(R P ) + Cost(R P )} x 10

; ; ; ; ;

2 14 5 14 7 14 10 14 12 14

(ignoring the effects of inflation, etc.)

NOTE Active corrective maintenance time is defined in IEC 60050(191), see definition 191-08-07 and

Figure 191-10.

where, for example, the cost related to element (R P ) is calculated as follows:

;

7 14

Cost(R P ) is the labour cost, active corrective maintenance at site for sub-system P

;

7 14 14

Cost(R P ) = QP x ZP x C x n x MRT cost/year

;

7 14 14 14 L

where

QP is the quantity or number of items, in this example QP = 1;

14 14

ZP is the expected number of failures/year for subsystem P ;

14 14

C is the labour cost/hour;

L

n is the number of persons required to carry out the repair;

MRT is the mean repair time in h/action.

Assume:

QP = one item /system

ZP = 0,3 failures/year

C = CU 50/hour

L

n = one person

– 18 – 60300-3-3 © IEC:2004(E)

MRT = 2,4 h/action.

Then

Cost(R P ) = 1 x 0,3 x 50 x 1 x 2,4 = CU 36/year.

;

7 14

To calculate the labour cost over 10 years, the result should be multiplied by 10 (ignoring the

effects of inflation, etc.).

If different factors, for instance inflation or discounting, have to be taken into account, this

could be included in the estimation of cost related to each element or at a higher cost element

level in the LCC model.

Cost(R ; P ), etc. are calculated in a similar way.

10 14

4.5.4 Sensitivity analysis

In order to identify significant cost contributors, sensitivity analyses should be performed.

Data may be varied to establish their impact on the total LCC or part of it.

To facilitate the sensitivity analysis, it is important that the LCC model is developed in such a

manner that, when a common parameter, for instance person hour cost, is varied, this is

automatically reflected wherever this parameter is used.

It may be desirable to use minimum or maximum values of certain data or even a distribution.

The LCC model in that case should be developed to meet these needs.

4.5.5 Impact of discounting, inflation and taxation on LCC

Several factors complicate the life cycle costing process; for example, the real value of money

changes constantly and factors such as opportunity costs, inflation and taxation may need to

be taken into account.

Annex B introduces these concepts and briefly indicates the methods that may be used to

take account of them.

4.6 Life cycle costing process

4.6.1 General

The life cycle costing process involves identification and evaluation of the costs associated

with acquisition, ownership and disposal of a product during its life cycle. In order to produce

results which can be usefully and correctly employed, any life cycle costing analysis should

be conducted in a structured and well-documented manner using the following steps:

a) life c

...

IEC 60300-3-3

Edition 2.0 2004-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Dependability management –

Part 3-3: Application guide – Life cycle costing

Gestion de la sûreté de fonctionnement –

Partie 3-3: Guide d’application – Evaluation du coût du cycle de vie

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60300-3-3

Edition 2.0 2004-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Dependability management –

Part 3-3: Application guide – Life cycle costing

Gestion de la sûreté de fonctionnement –

Partie 3-3: Guide d’application – Evaluation du coût du cycle de vie

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

XB

CODE PRIX

ICS 21.020 ISBN 2-8318-8173-0

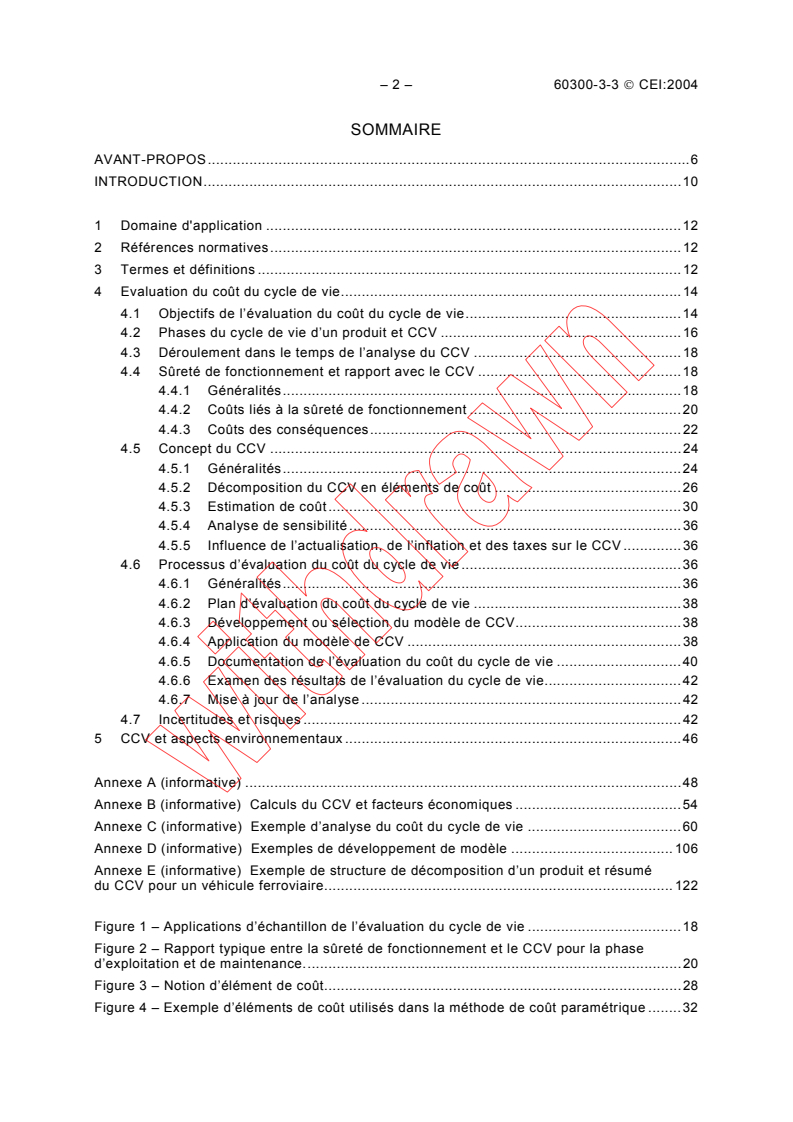

– 2 – 60300-3-3 © CEI:2004

SOMMAIRE

AVANT-PROPOS.6

INTRODUCTION.10

1 Domaine d'application .12

2 Références normatives.12

3 Termes et définitions .12

4 Evaluation du coût du cycle de vie.14

4.1 Objectifs de l’évaluation du coût du cycle de vie.14

4.2 Phases du cycle de vie d’un produit et CCV .16

4.3 Déroulement dans le temps de l’analyse du CCV .18

4.4 Sûreté de fonctionnement et rapport avec le CCV .18

4.4.1 Généralités.18

4.4.2 Coûts liés à la sûreté de fonctionnement .20

4.4.3 Coûts des conséquences.22

4.5 Concept du CCV .24

4.5.1 Généralités.24

4.5.2 Décomposition du CCV en éléments de coût .26

4.5.3 Estimation de coût.30

4.5.4 Analyse de sensibilité.36

4.5.5 Influence de l’actualisation, de l’inflation et des taxes sur le CCV .36

4.6 Processus d’évaluation du coût du cycle de vie .36

4.6.1 Généralités.36

4.6.2 Plan d’évaluation du coût du cycle de vie .38

4.6.3 Développement ou sélection du modèle de CCV.38

4.6.4 Application du modèle de CCV .38

4.6.5 Documentation de l’évaluation du coût du cycle de vie .40

4.6.6 Examen des résultats de l’évaluation du cycle de vie.42

4.6.7 Mise à jour de l’analyse .42

4.7 Incertitudes et risques .42

5 CCV et aspects environnementaux .46

Annexe A (informative) .48

Annexe B (informative) Calculs du CCV et facteurs économiques .54

Annexe C (informative) Exemple d’analyse du coût du cycle de vie .60

Annexe D (informative) Exemples de développement de modèle .106

Annexe E (informative) Exemple de structure de décomposition d’un produit et résumé

du CCV pour un véhicule ferroviaire.122

Figure 1 – Applications d’échantillon de l’évaluation du cycle de vie .18

Figure 2 – Rapport typique entre la sûreté de fonctionnement et le CCV pour la phase

d’exploitation et de maintenance.20

Figure 3 – Notion d’élément de coût.28

Figure 4 – Exemple d’éléments de coût utilisés dans la méthode de coût paramétrique .32

60300-3-3 © IEC:2004 – 3 –

CONTENTS

FOREWORD.7

INTRODUCTION.11

1 Scope.13

2 Normative references.13

3 Terms and definitions .13

4 Life cycle costing.15

4.1 Objectives of life cycle costing .15

4.2 Product life cycle phases and LCC .17

4.3 Timing of LCC analysis.19

4.4 Dependability and LCC relationship.19

4.4.1 General.19

4.4.2 Dependability related costs.21

4.4.3 Consequential costs.23

4.5 LCC concept.25

4.5.1 General.25

4.5.2 LCC breakdown into cost elements.27

4.5.3 Estimation of cost.31

4.5.4 Sensitivity analysis.37

4.5.5 Impact of discounting, inflation and taxation on LCC.37

4.6 Life cycle costing process .37

4.6.1 General.37

4.6.2 Life cycle costing plan .39

4.6.3 LCC model selection or development.39

4.6.4 LCC model application.39

4.6.5 Life cycle costing documentation .41

4.6.6 Review of life cycle costing results .43

4.6.7 Analysis update.43

4.7 Uncertainty and risks.43

5 LCC and environmental aspects .47

Annex A (informative) Typical cost-generating activities.49

Annex B (informative) LCC calculations and economic factors .55

Annex C (informative) Example of a life cycle cost analysis .61

Annex D (informative) Examples of LCC model development .107

Annex E (informative) Example of a product breakdown structure and LCC summary

for a railway vehicle .123

Figure 1 – Sample applications of life cycle costing .19

Figure 2 – Typical relationship between dependability and LCC for the operation and

maintenance phase.21

Figure 3 – Cost element concept .29

Figure 4 – Example of cost elements used in the parametric cost method.33

– 4 – 60300-3-3 © CEI:2004

Figure C.1 – Structure du DCN .62

Figure C.2 – Structure de décomposition de coût utilisée dans l’exemple de la figure C.1.64

Figure C.3 – Définition des éléments de coût .70

Figure C.4 – Comparaison des coûts d’investissement, maintenance et exploitation

annuels.88

Figure C.5 – Valeur présente nette (10% du taux d’actualisation) .100

Figure C.6 – Valeur présente nette (5 % du taux d’actualisation) .102

Figure C.7 – NPV avec une fiabilité de stockage de données augmentée

(5 % de taux d’actualisation).104

Figure D.1 – Structure hiérarchique .112

Figure E.1 – Structure de décomposition de produit de système de véhicule.124

Tableau C.1 – Premier niveau de découpage – Réseau de communication de données.66

Tableau C.2 – Second niveau de découpage – Système de communication.66

Tableau C.3 – Troisième niveau de découpage – Système d’alimentation électrique.66

Tableau C.4 – Troisième niveau de découpage – Processeur principal .66

Tableau C.5 – Troisième niveau de découpage – Système de ventilation.68

Tableau C.6 – Catégories de coût.68

Tableau C.7 – Investissements en unités de remplacement de pièce .74

Tableau E.1 – Résumé du coût du cycle de vie par la structure de décomposition du

produit .125

60300-3-3 © IEC:2004 – 5 –

Figure C.1 – Structure of DCN .63

Figure C.2 – Cost breakdown structure used for the example in Figure C.1 .65

Figure C.3 – Definition of cost elements.71

Figure C.4 – Comparison of the costs of investment, annual operation and

maintenance .89

Figure C.5 – Net present value (10 % discount rate) .101

Figure C.6 – Net present value (5 % discount rate) .103

Figure C.7 – NPV with improved data store reliability (5 % discount rate) .105

Figure D.1 – Hierarchical structure .113

Figure E.1 – Vehicle system product breakdown structure .125

Table C.1 – First indenture level – Data communication network.67

Table C.2 – Second indenture level – Communication system.67

Table C.3 – Third indenture level – Power supply system .67

Table C.4 – Third indenture level – Main processor .67

Table C.5 – Third indenture level – Fan system .69

Table C.6 – Cost categories.69

Table C.7 – Investments in spare replaceable units .75

Table E.1 – Life cycle cost summary by Product Breakdown Structure.127

– 6 – 60300-3-3 © CEI:2004

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

GESTION DE LA SÛRETÉ DE FONCTIONNEMENT –

Partie 3-3: Guide d’application –

Evaluation du coût du cycle de vie

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (CEI) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les

domaines de l'électricité et de l'électronique. A cet effet, la CEI – entre autres activités – publie des Normes

internationales, des Spécifications techniques, des Rapports techniques, des Spécifications accessibles au

public (PAS) et des Guides (ci-après dénommés "Publication(s) de la CEI"). Leur élaboration est confiée à des

comités d'études, aux travaux desquels tout Comité national intéressé par le sujet traité peut participer. Les

organisations internationales, gouvernementales et non gouvernementales, en liaison avec la CEI, participent

également aux travaux. La CEI collabore étroitement avec l'Organisation Internationale de Normalisation (ISO),

selon des conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux de la CEI

intéressés sont représentés dans chaque comité d’études.

3) Les Publications de la CEI se présentent sous la forme de recommandations internationales et sont agréées

comme telles par les Comités nationaux de la CEI. Tous les efforts raisonnables sont entrepris afin que la CEI

s'assure de l'exactitude du contenu technique de ses publications; la CEI ne peut pas être tenue responsable

de l'éventuelle mauvaise utilisation ou interprétation qui en est faite par un quelconque utilisateur final.

4) Dans le but d'encourager l'uniformité internationale, les Comités nationaux de la CEI s'engagent, dans toute la

mesure possible, à appliquer de façon transparente les Publications de la CEI dans leurs publications

nationales et régionales. Toutes divergences entre toutes Publications de la CEI et toutes publications

nationales ou régionales correspondantes doivent être indiquées en termes clairs dans ces dernières.

5) La CEI n’a prévu aucune procédure de marquage valant indication d’approbation et n'engage pas sa

responsabilité pour les équipements déclarés conformes à une de ses Publications.

6) Tous les utilisateurs doivent s'assurer qu'ils sont en possession de la dernière édition de cette publication.

7) Aucune responsabilité ne doit être imputée à la CEI, à ses administrateurs, employés, auxiliaires ou

mandataires, y compris ses experts particuliers et les membres de ses comités d'études et des Comités

nationaux de la CEI, pour tout préjudice causé en cas de dommages corporels et matériels, ou de tout autre

dommage de quelque nature que ce soit, directe ou indirecte, ou pour supporter les coûts (y compris les frais

de justice) et les dépenses découlant de la publication ou de l'utilisation de cette Publication de la CEI ou de

toute autre Publication de la CEI, ou au crédit qui lui est accordé.

8) L'attention est attirée sur les références normatives citées dans cette publication. L'utilisation de publications

référencées est obligatoire pour une application correcte de la présente publication.

9) L’attention est attirée sur le fait que certains des éléments de la présente Publication de la CEI peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La Norme internationale CEI 60300-3-3 a été établie par le Comité d’Etudes 56: Sûreté de

fonctionnement.

Cette seconde édition annule et remplace la première édition publiée en 1996. Elle constitue

une révision technique complète.

Cette édition peut s’étendre à un guide technique en réponse à des demandes pratiques. Les

exemples en particulier ont été mis en valeur.

Cette version bilingue, publiée en 2005-08, correspond à la version anglaise.

60300-3-3 © IEC:2004 – 7 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

DEPENDABILITY MANAGEMENT –

Part 3-3: Application guide –

Life cycle costing

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60300-3-3 has been prepared by IEC technical committee 56:

Dependability.

This second edition cancels and replaces the first edition published in 1996, and constitutes a

full technical revision.

This edition expands upon the technical guidance in response to requests from practitioners.

The examples in particular have been enhanced.

The bilingual version, published in 2005-08, corresponds to the English version.

– 8 – 60300-3-3 © CEI:2004

Le texte anglais de cette norme est issu des documents 56/942/FDIS et 56/962/RVD.

Le rapport de vote 56/962/RVD donne toute information sur le vote ayant abouti à

l’approbation de cette norme.

La version française de cette norme n’a pas été soumise au vote.

Cette publication a été rédigée selon les Directives ISO/CEI, Partie 2.

La CEI 60300 comprend les parties suivantes, présentées sous le titre général Gestion de la

sûreté de fonctionnement:

Partie 1: Systèmes de gestion de la sûreté de fonctionnement

Partie 2: Tâches et éléments du programme de sûreté de fonctionnement

Partie 3: Guide d’application

Le comité a décidé que le contenu de cette publication ne sera pas modifié avant la date de

maintenance indiquée sur le site web de la CEI sous "http://webstore.iec.ch" dans les

données relatives à cette publication spécifique. A cette date, la publication sera

• reconduite;

• supprimée;

• remplacée par une édition révisée, ou

• amendée.

60300-3-3 © IEC:2004 – 9 –

The text of this standard is based on the following documents:

FDIS Report on voting

56/942/FDIS 56/962/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

IEC 60300 consists of the following parts, under the general title Dependability management:

Part 1: Dependability management systems

Part 2: Dependability programme elements and tasks

Part 3: Application guide

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

– 10 – 60300-3-3 © CEI:2004

INTRODUCTION

Aujourd’hui les produits sont tenus d’être fiables. Il faut qu’ils remplissent leurs fonctions de

façon sûre sans trop d’impact sur l’environnement et soient d’un entretien facile durant toute

leur durée d’utilisation. La décision d’achat n’est pas influencée uniquement par le coût initial

du produit (coût d’acquisition) mais aussi par le coût de l’utilisation et de la maintenance du

produit pendant sa durée (coût de propriété) et coût de démantèlement. Pour satisfaire le

client, le défi pour les fournisseurs est de concevoir des produits qui répondent aux

exigences, sont fiables et à un prix compétitif, en optimisant les coûts d’acquisition, de

propriété et de démantèlement. Idéalement, il convient que ce processus d’optimisation

commence dès la conception du produit et se développe pour prendre en compte tous les

coûts relatifs à sa durée de vie. Toutes les décisions prises concernant la conception et la

fabrication d’un produit peuvent affecter sa rentabilité, sa sécurité, sa fiabilité, sa

maintenabilité, les exigences du support de maintenance, etc., et en dernier lieu, déterminer

son prix et les coûts de propriété et de démantèlement.

L’évaluation du coût du cycle de vie est le procédé d’analyse économique pour déterminer le

coût total de l’acquisition, de la propriété et du démantèlement d’un produit. Cette analyse

fournit d’importants apports pour la prise de décision dans la conception, le développement,

l’utilisation et le démantèlement du produit. Les fournisseurs de produits peuvent optimiser

leurs conceptions par l’évaluation d’alternatives et en réalisant des études de compromis. Ils

peuvent évaluer diverses stratégies de fonctionnement, de maintenance et de démantèlement

(pour aider les utilisateurs) pour optimiser le coût du cycle de vie (CCV). L’évaluation du coût

du cycle de vie peut effectivement être appliquée pour déterminer les coûts associés à une

activité spécifique, par exemple, les effets de différentes approches/concepts de

maintenance, pour couvrir une partie spécifique d’un produit, ou pour couvrir seulement une

phase sélectionnée ou des phases du cycle de vie d’un produit.

L’évaluation du cycle de vie est plus efficacement appliquée, dans la phase précoce de la

conception pour optimiser l’approche de conception de base. Cependant, il convient

également de la tenir à jour et de l’utiliser pendant les phases ultérieures du cycle de vie pour

identifier les zones de risques et d’incertitudes de coût significatives.

La nécessité d’une application formelle du processus d’évaluation du coût du cycle de vie

d’un produit dépendra normalement des exigences contractuelles. Cependant, l’évaluation du

coût du cycle de vie fournit des données utiles pour toute prise de décision sur la conception.

Par conséquent, il convient de l’intégrer au processus de conception, dans la mesure du

possible, pour optimiser les coûts et les caractéristiques du produit.

60300-3-3 © IEC:2004 – 11 –

INTRODUCTION

Products today are required to be reliable. They have to perform their functions safely with no

undue impact on the environment and be easily maintainable throughout their useful lives.

The decision to purchase is not only influenced by the product's initial cost (acquisition cost)

but also by the product's expected operating and maintenance cost over its life (ownership

cost) and disposal cost. In order to achieve customer satisfaction, the challenge for suppliers

is to design products that meet requirements and are reliable and cost competitive by

optimizing acquisition, ownership and disposal costs. This optimization process should ideally

start at the product's inception and should be expanded to take into account all the costs that

will be incurred throughout its lifetime. All decisions made concerning a product's design and

manufacture may affect its performance, safety, reliability, maintainability, maintenance

support requirements, etc., and ultimately determine its price and ownership and disposal

costs.

Life cycle costing is the process of economic analysis to assess the total cost of acquisition,

ownership and disposal of a product. This analysis provides important inputs in the decision-

making process in the product design, development, use and disposal. Product suppliers can

optimize their designs by evaluation of alternatives and by performing trade-off studies. They

can evaluate various operating, maintenance and disposal strategies (to assist product users)

to optimize life cycle cost (LCC). Life cycle costing can also be effectively applied to evaluate

the costs associated with a specific activity, for example, the effects of different maintenance

concepts/approaches, to cover a specific part of a product, or to cover only selected phase or

phases of a product’s life cycle.

Life cycle costing is most effectively applied in the product’s early design phase to optimize

the basic design approach. However, it should also be updated and used during the

subsequent phases of the life cycle to identify areas of significant cost uncertainty and risk.

The necessity for formal application of the life cycle costing process to a product will normally

depend on contractual requirements. However, life cycle costing provides a useful input to

any design decision-making process. Therefore, it should be integrated with the design

process, to the extent feasible, to optimize product characteristics and costs.

– 12 – 60300-3-3 © CEI:2004

GESTION DE LA SÛRETÉ DE FONCTIONNEMENT –

Partie 3-3: Guide d’application –

Evaluation du coût du cycle de vie

1 Domaine d'application

La présente partie de la CEI 60300 fournit une introduction générale au concept de

l’évaluation du coût du cycle de vie et couvre toutes les applications. Bien que les coûts du

cycle de vie consistent en la contribution de plusieurs éléments, cette norme met

particulièrement l’accent sur les coûts associés à la sûreté de fonctionnement du produit.

Cette norme est destinée à une application générale à la fois par les clients (utilisateurs) et

par les fournisseurs de produits. Elle explique l’objet et la valeur de l’évaluation du cycle de

vie et donne les lignes principales des approches générales impliquées. Elle identifie aussi

les éléments du coût du cycle de vie typique pour faciliter la planification du programme et du