IEC 62220-1:2003

(Main)Medical electrical equipment - Characteristics of digital X-ray imaging devices - Part 1: Determination of the detective quantum efficiency

Medical electrical equipment - Characteristics of digital X-ray imaging devices - Part 1: Determination of the detective quantum efficiency

Specifies the method for the determination of the detective quantum efficiency (DQE) of digital X-ray imaging devices as a function of exposure and of spatial frequency for the working conditions in the range of the medical application as specified by the manufacturer. Is applicable to projection digital X-ray imaging devices producing images in digital format that are used for medical diagnosis. It is restricted to digital X-ray imaging devices that are used for radiographic imaging, such as CR systems, selenium-based systems, flat panel detectors, optically coupled CCD detectors, and digital X-ray image intensifiers used for single exposures.

General Information

- Status

- Replaced

- Publication Date

- 22-Oct-2003

- Technical Committee

- SC 62B - Medical imaging equipment, software, and systems

- Drafting Committee

- WG 33 - TC 62/SC 62B/WG 33

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 12-Mar-2015

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Sponsored listings

Frequently Asked Questions

IEC 62220-1:2003 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Medical electrical equipment - Characteristics of digital X-ray imaging devices - Part 1: Determination of the detective quantum efficiency". This standard covers: Specifies the method for the determination of the detective quantum efficiency (DQE) of digital X-ray imaging devices as a function of exposure and of spatial frequency for the working conditions in the range of the medical application as specified by the manufacturer. Is applicable to projection digital X-ray imaging devices producing images in digital format that are used for medical diagnosis. It is restricted to digital X-ray imaging devices that are used for radiographic imaging, such as CR systems, selenium-based systems, flat panel detectors, optically coupled CCD detectors, and digital X-ray image intensifiers used for single exposures.

Specifies the method for the determination of the detective quantum efficiency (DQE) of digital X-ray imaging devices as a function of exposure and of spatial frequency for the working conditions in the range of the medical application as specified by the manufacturer. Is applicable to projection digital X-ray imaging devices producing images in digital format that are used for medical diagnosis. It is restricted to digital X-ray imaging devices that are used for radiographic imaging, such as CR systems, selenium-based systems, flat panel detectors, optically coupled CCD detectors, and digital X-ray image intensifiers used for single exposures.

IEC 62220-1:2003 is classified under the following ICS (International Classification for Standards) categories: 11.040.50 - Radiographic equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62220-1:2003 has the following relationships with other standards: It is inter standard links to IEC 62220-1-1:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62220-1:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD

62220-1

First edition

2003-10

Medical electrical equipment –

Characteristics of digital X-ray imaging devices –

Part 1: Determination of the detective quantum

efficiency

Appareils électromédicaux –

Caractéristiques des appareils d'imagerie à rayonnement X –

Partie 1: Détermination de l'efficacité quantique de détection

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/searchpub) enables you to

search by a variety of criteria including text searches, technical committees

and date of publication. On-line information is also available on recently issued

publications, withdrawn and replaced publications, as well as corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/online_news/ justpub)

is also available by email. Please contact the Customer Service Centre (see

below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD

62220-1

First edition

2003-10

Medical electrical equipment –

Characteristics of digital X-ray imaging devices –

Part 1: Determination of the detective quantum

efficiency

Appareils électromédicaux –

Caractéristiques des appareils d'imagerie à rayonnement X –

Partie 1: Détermination de l'efficacité quantique de détection

IEC 2003 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale

U

International Electrotechnical Commission

Международная Электротехническая Комиссия

For price, see current catalogue

– 2 – 62220-1 IEC:2003(E)

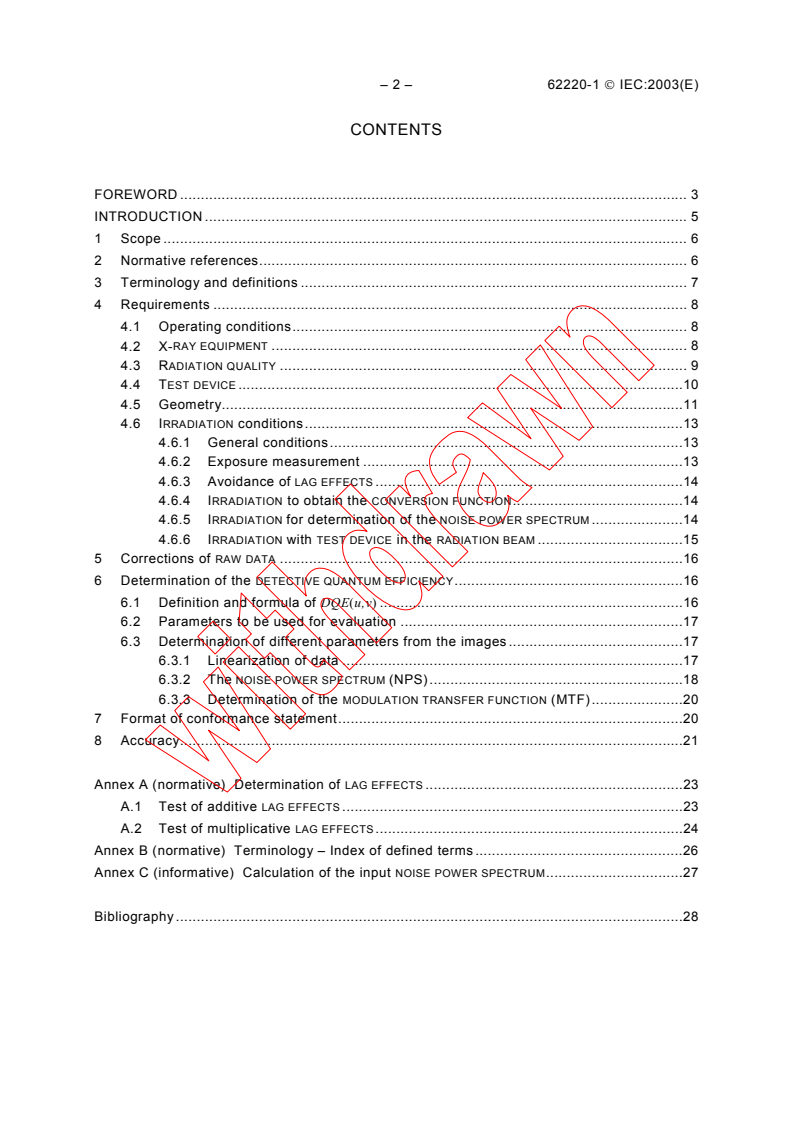

CONTENTS

FOREWORD . 3

INTRODUCTION .5

1 Scope . 6

2 Normative references. 6

3 Terminology and definitions . 7

4 Requirements . 8

4.1 Operating conditions. 8

4.2 X-RAY EQUIPMENT . 8

4.3 RADIATION QUALITY . 9

4.4 TEST DEVICE .10

4.5 Geometry.11

4.6 IRRADIATION conditions.13

4.6.1 General conditions.13

4.6.2 Exposure measurement .13

4.6.3 Avoidance of LAG EFFECTS .14

4.6.4 IRRADIATION to obtain the CONVERSION FUNCTION.14

4.6.5 IRRADIATION for determination of the NOISE POWER SPECTRUM .14

4.6.6 IRRADIATION with TEST DEVICE in the RADIATION BEAM .15

5 Corrections of RAW DATA .16

6 Determination of the DETECTIVE QUANTUM EFFICIENCY.16

6.1 Definition and formula of DQE(u,v) .16

6.2 Parameters to be used for evaluation .17

6.3 Determination of different parameters from the images .17

6.3.1 Linearization of data .17

6.3.2 The NOISE POWER SPECTRUM (NPS).18

6.3.3 Determination of the MODULATION TRANSFER FUNCTION (MTF).20

7 Format of conformance statement.20

8 Accuracy.21

Annex A (normative) Determination of LAG EFFECTS .23

A.1 Test of additive LAG EFFECTS .23

A.2 Test of multiplicative LAG EFFECTS.24

Annex B (normative) Terminology – Index of defined terms.26

Annex C (informative) Calculation of the input NOISE POWER SPECTRUM.27

Bibliography.28

62220-1 IEC:2003(E) – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MEDICAL ELECTRICAL EQUIPMENT –

CHARACTERISTICS OF DIGITAL X-RAY IMAGING DEVICES –

Part 1: Determination of the detective quantum efficiency

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62220-1 has been prepared by subcommittee 62B: Diagnostic

imaging equipment, of IEC technical committee 62: Electrical equipment in medical practice.

The text of this standard is based on the following documents:

FDIS Report on voting

62B/493/FDIS 62B/506/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 4 – 62220-1 IEC:2003(E)

In this standard, terms printed in SMALL CAPITALS are used as defined in IEC 60788, in

Clause 3 of this standard or other IEC publications referenced in Annex B. Where a defined

term is used as a qualifier in another defined or undefined term it is not printed in SMALL

CAPITALS, unless the concept thus qualified is defined or recognized as a “derived term

without definition”.

NOTE Attention is drawn to the fact that, in cases where the concept addressed is not strongly confined to the

definition given in one of the publications listed above, a corresponding term is printed in lower-case letters.

The committee has decided that the contents of this publication will remain unchanged until

2006-12. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

62220-1 IEC:2003(E) – 5 –

INTRODUCTION

DIGITAL X-RAY IMAGING DEVICES are increasingly used in medical diagnosis and will widely

replace conventional (analogue) imaging devices such as screen-film systems or analogue X-

RAY IMAGE INTENSIFIER television systems in the future. It is necessary, therefore, to define

parameters that describe the specific imaging properties of these DIGITAL X-RAY IMAGING

DEVICES and to standardize the measurement procedures employed.

There is growing consensus in the scientific world that the DETECTIVE QUANTUM EFFICIENCY

(DQE) is the most suitable parameter for describing the imaging performance of an X-ray

imaging device. The DQE describes the ability of the imaging device to preserve the signal-to-

NOISE ratio from the radiation field to the resulting digital image data. Since in X-ray imaging,

the NOISE in the radiation field is intimately coupled to the exposure level, DQE values can

also be considered to describe the dose efficiency of a given imaging device.

NOTE 1 In spite of the fact that the DQE is widely used to describe the performance of imaging devices, the

connection between this physical parameter and the decision performance of a human observer is not yet

1)

completely understood [1], [3].

NOTE 2 The standard IEC 61262-5 specifies a method to determine the DQE of X-RAY IMAGE INTENSIFIERS at

nearly zero SPATIAL FREQUENCY. It focuses only on the electro-optical components of X-RAY IMAGE INTENSIFIERS, not

on the imaging properties as this standard does. As a consequence, the output is measured as an optical quantity

(luminance), and not as digital data. Moreover, IEC 61262-5 prescribes the use of a RADIATION SOURCE ASSEMBLY,

whereas this standard prescribes the use of an X-RAY TUBE. The scope of IEC 61262-5 is limited to X-RAY IMAGE

INTENSIFIERS and does not interfere with the scope of this standard.

The DQE is already widely used by manufacturers to describe the performance of their

equipment. The specification of the DQE is also required by regulatory agencies (such as the

Food and Drug Administration (FDA)) for admission procedures. However, there is presently

no standard governing either the measurement conditions or the measurement procedure with

the consequence that values from different sources may not be comparable.

This standard has therefore been developed in order to specify the measurement procedure

together with the format of the conformance statement for the DETECTIVE QUANTUM EFFICIENCY

of DIGITAL X-RAY IMAGING DEVICES.

In the DQE calculations proposed in this standard, it is assumed that system response is

measured for objects that attenuate all energies equally (task-independent) [5].

The standard will be beneficial for manufacturers, users, distributors and regulatory agencies.

It can be regarded as the first of a series describing all the relevant parameters of DIGITAL X-

RAY IMAGING DEVICES.

———————

1)

Figures in square brackets refer to the bibliography.

– 6 – 62220-1 IEC:2003(E)

MEDICAL ELECTRICAL EQUIPMENT –

CHARACTERISTICS OF DIGITAL X-RAY IMAGING DEVICES –

Part 1: Determination of the detective quantum efficiency

1 Scope

This part of IEC 62220 specifies the method for the determination of the DETECTIVE QUANTUM

EFFICIENCY (DQE) of DIGITAL X-RAY IMAGING DEVICES as a function of exposure and of SPATIAL

FREQUENCY for the working conditions in the range of the medical application as specified by

the MANUFACTURER.

This part of IEC 62220 is applicable to projection DIGITAL X-RAY IMAGING DEVICES producing

IMAGES in digital format that are used for medical diagnosis. It is restricted to DIGITAL X-RAY

IMAGING DEVICES that are used for radiographic imaging, such as CR systems, selenium-based

systems, flat panel detectors, optically coupled CCD detectors, and digital X-RAY IMAGE

INTENSIFIERS used for single exposures.

This part of IEC 62220 is not applicable to

– DIGITAL X-RAY IMAGING DEVICES intended to be used in mammography or in dental

radiography;

– COMPUTED TOMOGRAPHY:

– systems in which the X-ray field is scanned across the patient; and

– devices for dynamic imaging (where series of images are acquired, as in fluoroscopic or

cardiac imaging).

NOTE The devices noted above are excluded because they contain many parameters (for instance, beam

qualities, geometry, time dependence, etc.) which differ from those important for general radiography. It is intended

to treat some of these techniques in separate standards as has been done for other topics, for instance for speed

and contrast, in IEC and ISO standards.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60336:1993, X-ray tube assemblies for medical diagnosis – Characteristics of focal spots

IEC 60601-2-7: Medical electrical equipment – Part 2-7: Particular requirements for the safety

of high-voltage generators of diagnostic X-ray generators

IEC 60788:1984, Medical radiology – Terminology

IEC 61267:1994, Medical diagnostic X-ray equipment – Radiation conditions for use in the

determination of characteristics

ISO 12232:1998, Photography – Electronic still-picture cameras – Determination of ISO speed

62220-1 IEC:2003(E) – 7 –

3 Terminology and definitions

For the purposes of this part of IEC 62220 the following terms and definitions apply.

3.1

CENTRAL AXIS

line perpendicular to the ENTRANCE PLANE passing through the centre of the entrance field

3.2

CONVERSION FUNCTION

plot of the large area output level (ORIGINAL DATA) of a DIGITAL X-RAY IMAGING DEVICE versus

the number of exposure quanta per unit area (Q) in the DETECTOR SURFACE plane

NOTE 1 Q is to be calculated by multiplying the measured exposure excluding back scatter by the value given in

column 2 of Table 2.

NOTE 2 Usually AIR KERMA is substituted for exposure.

NOTE 3 Many calibration laboratories, such as national metrology institutes, calibrate RADIATION METERS to

measure AIR KERMA.

3.3

DETECTIVE QUANTUM EFFICIENCY

DQE(u,v)

ratio of two NOISE POWER SPECTRUM (NPS) functions with the numerator being the NPS of the

input signal at the DETECTOR SURFACE of a digital X-ray detector after having gone through the

deterministic filter given by the system transfer function, and the denominator being the

measured NPS of the output signal (ORIGINAL DATA)

NOTE Instead of the two-dimensional DETECTIVE QUANTUM EFFICIENCY, often a cut through the two-

dimensional DETECTIVE QUANTUM EFFICIENCY along a specified SPATIAL FREQUENCY axis is published.

3.4

DETECTOR SURFACE

area which is closest to the IMAGE RECEPTOR PLANE with all protecting parts (including the

ANTI-SCATTER GRID and components for AUTOMATIC EXPOSURE CONTROL, if applicable) that can

be safely removed out of the RADIATION BEAM without damaging the digital X-ray detector

3.5

DIGITAL X-RAY IMAGING DEVICE

device consisting of a digital X-ray detector including the protective layers installed for use in

practice, the amplifying and digitizing electronics, and a computer providing the ORIGINAL DATA

(DN) of the image

3.6

IMAGE MATRIX

arrangement of matrix elements in a preferably Cartesian coordinate system

3.7

LAG EFFECT

influence from a previous image on the current one

3.8

LINEARIZED DATA

ORIGINAL DATA to which the inverse CONVERSION FUNCTION has been applied

NOTE The LINEARIZED DATA are directly proportional to the exposure.

– 8 – 62220-1 IEC:2003(E)

3.9

MODULATION TRANSFER FUNCTION

MTF(u,v)

modulus of the generally complex optical transfer function, expressed as a function of SPATIAL

FREQUENCIES u and v

3.10

NOISE

fluctuations from the expected value of a stochastic process

3.11

NOISE POWER SPECTRUM

(NPS)

W(u,v)

modulus of the Fourier transform of the NOISE auto-covariance function. The power of NOISE,

contained in a two-dimensional SPATIAL FREQUENCY interval, as a function of the two-

dimensional frequency

NOTE In literature, the NOISE POWER SPECTRUM is often named “Wiener spectrum” in honour of the mathematician

Norbert Wiener.

3.12

ORIGINAL DATA

DN

RAW DATA to which the corrections allowed in this standard have been applied

3.13

PHOTON FLUENCE

Q

mean number of photons per unit area

3.14

RAW DATA

pixel values read directly after the analogue-digital-conversion from the DIGITAL X-RAY IMAGING

DEVICE without any software corrections

3.15

SPATIAL FREQUENCY

u or v

inverse of the period of a repetitive spatial phenomenon. The dimension of the SPATIAL

FREQUENCY is inverse length

4 Requirements

4.1 Operating conditions

The DIGITAL X-RAY IMAGING DEVICE shall be stored and operated according to the

MANUFACTURER’S recommendations. The warm-up time shall be chosen according to the

recommendation of the MANUFACTURER. The operating conditions shall be the same as those

intended for clinical use and shall be maintained during evaluation as required for the specific

tests described herein.

Ambient climatic conditions in the room where the DIGITAL X-RAY IMAGING DEVICE is operated

shall be stated together with the results.

4.2 X-RAY EQUIPMENT

For all tests described in the following subclauses, a CONSTANT POTENTIAL HIGH-VOLTAGE

GENERATOR shall be used (IEC 60601-2-7). The PERCENTAGE RIPPLE shall be equal to, or less

than, 4.

62220-1 IEC:2003(E) – 9 –

The NOMINAL FOCAL SPOT VALUE (IEC 60336) shall be not larger than 1,2.

For the measurement of exposure, calibrated RADIATION METERS shall be used. The

uncertainty (coverage factor 2)[2] of the readings shall be less than 5 %.

NOTE 1 “Uncertainty” and “coverage factor” are terms defined in the ISO Guide to the expression of uncertainty in

measurement [2].

NOTE 2 RADIATION METERS to read AIR KERMA are, for instance, calibrated by many national metrology institutes.

4.3 RADIATION QUALITY

The RADIATION QUALITIES shall be one or more out of four selected RADIATION QUALITIES

specified in IEC 61267 (see Table 1). If only a single RADIATION QUALITY is used, RADIATION

QUALITY RQA5 should be preferred.

For the application of the RADIATION QUALITIES, refer to IEC 61267:1994.

NOTE 1 According to IEC 61267, RADIATION QUALITIES are defined by a fixed ADDITIONAL FILTRATION and a

HALF-VALUE LAYER that is realized with this filtration by a suitable adaptation of the X-RAY TUBE VOLTAGE,

starting from the approximate X-RAY TUBE VOLTAGE (Table 1).

Table 1 – RADIATION QUALITY (IEC 61267:1994) for the determination

of DETECTIVE QUANTUM EFFICIENCY and corresponding parameters

Approximate HALF-VALUE ADDITIONAL

RADIATION

X-RAY TUBE LAYER (HVL) FILTRATION

QUALITY No.

VOLTAGE

kV mm Al mm Al

RQA 3 50 4,0 10,0

RQA 5 70 7,1 21,0

RQA 7 90 9,1 30,0

RQA 9 120 11,5 40,0

NOTE 2 The additional filtration is the filtration added to the inherent filtration of the X-RAY TUBE.

NOTE 3 The capability of X-RAY GENERATORS to produce low exposure levels may not be sufficient, especially for

RQA9. In this case, it is recommended that the distance FOCAL SPOT to DETECTOR SURFACE be increased.

– 10 – 62220-1 IEC:2003(E)

4.4 TEST DEVICE

The TEST DEVICE for the determination of the MODULATION TRANSFER FUNCTION and the

magnitude of LAG EFFECTS shall consist of a 1,0 mm thick tungsten plate (purity higher than

90 %) 100 mm long and at least 75 mm wide (see Figure 1). Inadequate purity of tungsten

shall be compensated by increased thickness.

The tungsten plate is used as an edge TEST DEVICE. Therefore, the edge which is used for the

test IRRADIATION shall be carefully polished straight and at 90° to the plate. If the edge is

irradiated by X-rays in contact with a screenless film, the image on the film shall show no

ripples on the edge larger than 5 μm.

The tungsten plate shall be fixed on a 3 mm thick lead plate (see Figure 1). This arrangement

is suitable to measure the MODULATION TRANSFER FUNCTION of the DIGITAL X-RAY IMAGING

DEVICE in one direction.

Pb (2)

b

W (1)

a

e

b

c

d

f

IEC 2253/03

NOTE The TEST DEVICE consists of a 1,0 mm thick tungsten plate (1) fixed on a 3 mm thick lead plate (2).

Dimension of the lead plate: a: 200 mm, d: 70 mm, e: 90 mm, f: 100 mm.

Dimension of the tungsten plate: 100 mm × 75 mm.

The region of interest (ROI) used for the determination of the MTF is defined by b × c, 50 mm × 100 mm (inner long

dashed line).

The irradiated field on the detector (outer dashed line) is at least 160 mm × 160 mm.

Figure 1 – TEST DEVICE

62220-1 IEC:2003(E) – 11 –

4.5 Geometry

The geometrical set-up of the measuring arrangement shall comply with Figure 2. The X-RAY

EQUIPMENT is used in that geometric configuration in the same way as it is used for normal

diagnostic applications. The distance between the FOCAL SPOT of the X-RAY TUBE and the

DETECTOR SURFACE should be not less than 1,50 m. If, for technical reasons, the distance

cannot be 1,50 m or more, a smaller distance can be chosen but has to be explicitly declared

when reporting results.

The TEST DEVICE is placed immediately in front of the DETECTOR SURFACE. The centre of the

edge of the TEST DEVICE should be aligned to the CENTRAL AXIS of the X-ray beam.

Displacement from the CENTRAL AXIS will lower the measured MTF. The CENTRAL AXIS can be

located by maximizing the MTF as a function of TEST DEVICE displacement.

The recommended procedure is that the TEST DEVICE and the X-ray field be centred on the

detector. If this is not done, the position of the centre of the X-ray field and of the TEST DEVICE

needs to be stated.

In the set-up of Figure 2, the DIAPHRAGM B1 and the ADDED FILTER shall be positioned near the

FOCAL SPOT of the X-RAY TUBE. The diaphragms B2 and B3 should be used, but may be

omitted if it is proven that this does not change the result of the measurements. The

DIAPHRAGMS B1 and - if applicable - B2 and the ADDED FILTER shall be in a fixed relation to the

position of the FOCAL SPOT. The DIAPHRAGM B3 - if applicable - and the DETECTOR SURFACE

shall be in a fixed relation at each distance from the FOCAL SPOT. The square DIAPHRAGM B3 –

if applicable – shall be 120 mm in front of the DETECTOR SURFACE and shall be of a size to

allow an irradiated field at the DETECTOR SURFACE of at least 160 mm × 160 mm. The

RADIATION APERTURE of DIAPHRAGM B2 may be made variable so that the beam remains tightly

collimated as the distance is changed. The irradiated field at the DETECTOR SURFACE shall be

at least 160 mm × 160 mm.

The attenuating properties of the DIAPHRAGMS shall be such that their transmission into

shielded areas does not contribute to the results of the measurements. The RADIATION

APERTURE of the DIAPHRAGM B1 shall be large enough so that the PENUMBRA of the RADIATION

BEAM will be outside the sensitive volume of the monitor detector R1 and the RADIATION

APERTURE of DIAPHRAGM B2 – if applicable.

A monitor detector should be used to assure the precision of the X-RAY GENERATOR. The

monitor detector R1 may be inside the beam that irradiates the DETECTOR SURFACE if it is

suitably transparent and free of structure; otherwise, it shall be placed outside the beam. The

precision (standard deviation 1σ) of the monitor detector shall be better than 2 %. The

relationship between the monitor reading and the exposure at the DETECTOR SURFACE shall be

calibrated for each RADIATION QUALITY used (see also 4.6.2). To minimize the effect of back-

scatter from layers behind the detector a minimum distance of 500 mm to other objects should

be provided.

NOTE The calibration of the monitor detector may be sensitive to the positioning of the ADDED FILTER and to the

adjustment of the shutters built into the X-RAY SOURCE. Therefore, these items should not be altered without re-

calibration of the monitor detector.

This geometry is used either to irradiate the DETECTOR SURFACE uniformly for the

determination of the CONVERSION FUNCTION and the NOISE POWER SPECTRUM or to irradiate the

DETECTOR SURFACE behind a TEST DEVICE (see 4.6.6). For all measurements, the same area of

the DETECTOR SURFACE shall be irradiated. The centre of this area, with respect to either the

centre or the border of the digital X-ray detector, shall be recorded.

For the determination of the NOISE POWER SPECTRUM and the CONVERSION FUNCTION, the TEST

DEVICE shall be moved out of the beam.

– 12 – 62220-1 IEC:2003(E)

B1

Added filter

Monitor detector R1

B2

1,5 m min.

B3

TEST DEVICE

120 mm

Detector surface

IEC 2254/03

NOTE No TEST DEVICE is used for the measurement of the CONVERSION FUNCTION and the NOISE POWER SPECTRUM.

Figure 2 – Geometry for exposing the DIGITAL X-RAY IMAGING DEVICE in order to determine

the CONVERSION FUNCTION, the NOISE POWER SPECTRUM and the MODULATION TRANSFER

FUNCTION

62220-1 IEC:2003(E) – 13 –

4.6 IRRADIATION conditions

4.6.1 General conditions

The calibration of the digital X-ray detector shall be carried out prior to any testing, i.e., all

operations necessary for corrections according to Clause 5 shall be effected. No re-calibration

of the digital X-ray detector shall be allowed between any measurement of the series.

The exposure level shall be chosen as that used when the digital X-ray detector is operated

for the intended use in clinical practice. This is called the “normal“ level and shall be specified

by the MANUFACTURER. At least two additional exposure levels shall be chosen, one 3,2 times

the normal level and one at 1/3,2 of the normal level. No change of system settings (such as

gain etc.) shall be allowed when changing exposure levels.

NOTE 1 A factor of three in the exposure above and below the “normal” level approximately corresponds to the

bright and dark parts within one clinical radiation image.

To cover the range of various different clinical examinations, additional “normal” levels may

be chosen. For these additional “normal” levels other system settings may be chosen and

kept constant during the test procedure.

Each IRRADIATION shall be made without interruption. The variation of exposure shall be

carried out by variation of the X-RAY TUBE CURRENT or the IRRADIATION TIME or both. The

IRRADIATION TIME and exposure level shall be similar to the conditions for clinical application of

the digital X-ray detector. LAG EFFECTS shall be avoided (see 4.6.3).

The IRRADIATION conditions shall be stated together with the results (see Clause 7).

The RADIATION QUALITY shall be assured when varying the X-RAY TUBE CURRENT or the

IRRADIATION TIME and shall be checked at the lowest exposure level.

4.6.2 Exposure measurement

The exposure at the DETECTOR SURFACE is measured with an appropriate RADIATION METER.

For this purpose, the digital X-ray detector is removed from the beam and the RADIATION

DETECTOR of the RADIATION METER is placed behind APERTURE B3 in the DETECTOR SURFACE

plane. Care shall be taken to minimize the back-SCATTERED RADIATION. The correlation

between the readings of the RADIATION METER and the monitoring detector, if used, shall be

noted, and shall be used for the exposure calculation at the DETECTOR SURFACE when

irradiating the DETECTOR SURFACE to determine the CONVERSION FUNCTION, the NOISE POWER

SPECTRUM and the MODULATION TRANSFER FUNCTION. It is recommended that about five

exposures be monitored and that the average be used for the correct exposure.

NOTE 2 To reduce back-SCATTERED RADIATION, a lead screen of 4 mm in thickness may be placed 450 mm behind

the RADIATION DETECTOR. It has been proven by experiments that, under these conditions, the back-SCATTERED

RADIATION is not more than 0,5 %. If the lead screen is at a distance of 250 mm, the back-SCATTERED RADIATION is

not more than 2,5 %.

If it is not possible to remove the digital X-ray detector out of the beam, the exposure at the

DETECTOR SURFACE may be calculated via the inverse square distance law. For that purpose,

the exposure is measured at different distances from the FOCAL SPOT in front of the DETECTOR

SURFACE. For this measurement, radiation, back-scattered from the DETECTOR SURFACE, shall

be avoided. Therefore, a minimum distance between the DETECTOR SURFACE and the

RADIATION DETECTOR of 450 mm is recommended.

If a monitoring detector is used, the following equation shall be plotted as a function of the

distance d between the FOCAL SPOT and the RADIATION DETECTOR:

monitor detector reading

f (d) =

radiation detector reading

– 14 – 62220-1 IEC:2003(E)

By extrapolating this approximately linear curve up to the distance between the FOCAL SPOT

and the DETECTOR SURFACE r , the ratio of the readings at r can be obtained and the

SID SID

exposure at the DETECTOR SURFACE for any monitoring detector reading can be calculated.

If no monitoring detector is used, the square root of the inverse RADIATION METER reading is

plotted as a function of the distance between the FOCAL SPOT and the RADIATION DETECTOR.

The extrapolation etc. is carried out as in the preceding paragraph.

NOTE 3 To reduce back-SCATTERED RADIATION, a lead shield of 4 mm thickness may be placed in front of the

DETECTOR SURFACE.

4.6.3 Avoidance of LAG EFFECTS

LAG EFFECTS may influence the measurement of the CONVERSION FUNCTION and the NOISE

POWER SPECTRUM. They may, therefore, influence the measurement of DETECTIVE QUANTUM

EFFICIENCY.

The influence may be split into an additive component (additional offset) and a multiplicative

component (change of gain). The magnitude of both components shall be estimated.

For the determination of possible LAG EFFECTS, the digital X-ray detector shall be operated

according to the specifications of the MANUFACTURER. The minimum time interval between two

successive exposures (as determined by the tests given in Annex A) must be maintained to

prevent the contaminating LAG EFFECTS on the measurement of the DETECTIVE QUANTUM

EFFICIENCY.

NOTE The following parameters may contribute to LAG EFFECTS: time of IRRADIATION relative to read-out, method

of erasure of remnants of previous IRRADIATION, time from erase to re-IRRADIATION, time from read-out to re-

IRRADIATION, or the inclusion of intervening “dummy” read-outs used to erase the effects of a previous IRRADIATION.

To test the magnitude of LAG EFFECTS, the test procedures as given in Annex A shall be used.

4.6.4 IRRADIATION to obtain the CONVERSION FUNCTION

The settings of the DIGITAL X-RAY IMAGING DEVICE shall be the same as those used when

exposing the TEST DEVICE. The IRRADIATION shall be carried out using the geometry of Figure 2

but without any TEST DEVICE in the beam. The exposure is measured according to 4.6.2. The

CONVERSION FUNCTION shall be determined from exposure level zero up to four times the

normal exposure level.

The CONVERSION FUNCTION for exposure level zero shall be determined from a dark image,

realized under the same conditions as an X-ray image. The minimum X-ray exposure level

shall not be greater than one-fifth of the normal exposure level.

Depending on the form of the CONVERSION FUNCTION the number of different exposures varies;

if only the linearity of the CONVERSION FUNCTION has to be checked, five exposures, uniformly

distributed within the desired range, are sufficient. If the complete CONVERSION FUNCTION has

to be determined, the exposure shall be varied in such a way that the maximum increments of

logarithmic (to the base 10) exposure is not greater than 0,1. The RADIATION QUALITY for all

exposure levels shall be assured and shall be checked at the lowest exposure level. In case

of deviations from this requirement, the FOCAL SPOT to DETECTOR SURFACE distance may have

to be increased.

4.6.5 IRRADIATION for determination of the NOISE POWER SPECTRUM

The settings of the DIGITAL X-RAY IMAGING DEVICE shall be the same as those used when

exposing the TEST DEVICE. The IRRADIATION shall be carried out using the geometry of Figure 2

but without any TEST DEVICE in the beam. The exposure is measured according to 4.6.2.

62220-1 IEC:2003(E) – 15 –

A square area of approximately 125 mm × 125 mm located centrally behind the 160 mm

square DIAPHRAGM is used for the evaluation of an estimate for the NOISE POWER SPECTRUM to

be used later on to calculate the DQE.

For this purpose, the set of input data shall consist of at least four million independent image

PIXELS arranged in one or several independent flat-field images, each having at least 256

PIXELS in either spatial direction. If more than one image is necessary, all individual images

shall be taken at the same RADIATION QUALITY and AIR KERMA. The standard deviation of the

IRRADIATIONS used to get the different images shall be less than 10 % of the mean.

NOTE The minimum number of required independent image PIXELS is determined by the required accuracy which

defines the minimum number of ROIs. For an accuracy of the two-dimensional NOISE POWER SPECTRUM of 5 %, a

minimum of 960 (overlapping) ROIs are needed meaning 16 million independent image pixels with the given ROI

size. The averaging and binning process applied afterwards to obtain a one-dimensional cut reduces the minimum

number of required independent image PIXELS to four million, still assuring the necessary accuracy.

Care shall be taken that there is no correlation between the subsequent images (LAG EFFECT;

see 4.6.3). No change of system setting is allowed when making the IRRADIATIONS.

The images for the determination of the NOISE POWER SPECTRUM shall be taken at three

exposure levels (see 4.6.1): the normal one and two others, each differing by a factor of 3,2

from the normal one.

4.6.6 IRRADIATION with TEST DEVICE in the RADIATION BEAM

The IRRADIATION shall be carried out using the geometry of Figure 2. The TEST DEVICE is

placed directly on the DETECTOR SURFACE. The TEST DEVICE is positioned in such a way that

the edge is tilted by an angle α relative to the axis of the PIXEL columns or PIXEL rows, where

α is between 1,5° and 3°.

NOTE 1 The method of tilting the TEST DEVICE relative to the rows or columns of the IMAGE MATRIX is common in

other standards (ISO 15529 and ISO 12233) and reported in numerous publications when the pre-sampling

MODULATION TRANSFER FUNCTION has to be determined.

The TEST DEVICE has to be adjusted in such a way that it is perpendicular to the CENTRAL AXIS

of the RADIATION BEAM and the edge of the TEST DEVICE is aligned as closely as possible to the

CENTRAL AXIS of the RADIATION BEAM.

NOTE 2 Deviations from this ideal set-up will result in a lower measured MTF.

Two IRRADIATIONS shall be made with the TEST DEVICE in the RADIATION BEAM, one with the

TEST DEVICE oriented approximately along the columns, the other with the TEST DEVICE

approximately along the rows of the IMAGE MATRIX. The positions of the other components

shall not be changed. For the new position, a new adjustment of the TEST DEVICE shall be

made.

The images for the determination of the MTF shall be taken at one of the three exposure

levels (see 4.6.1).

– 16 – 62220-1 IEC:2003(E)

5 Corrections of RAW DATA

The following linear and image-independent corrections of the RAW DATA are allowed in

advance of the processing of the data for the determination of the CONVERSION FUNCTION, the

NOISE POWER SPECTRUM, and the MODULATION TRANSFER FUNCTION:

– The RAW DATA of bad or defective pixels may be replaced by appropriate data as in normal

clinical use.

– A flat-field correction comprising

• correction of the non-uniformity of the radiation field,

• correction for the offset of the individual pixels and

• gain correction for the individual pixels

may be applied as in normal clinical use.

– A correction for geometrical distortion may be made as in normal clinical use.

NOTE Some detectors execute linear image processing due to their physical concept. As long as this image

processing is linear and image-independent, these operations are allowed.

6 Determination of the DETECTIVE QUANTUM EFFICIENCY

6.1 Definition and formula of DQE(u,v)

The equation for the frequency-dependent DETECTIVE QUANTUM EFFICIENCY DQE(u,v) is :

W (u,v)

2 2 in

DQE(u,v) = G MTF (u,v)

(1)

W (u,v)

out

The source for this equation is the Handbook of Medical Imaging I (equation 2.153) [4],

In this standard, the NOISE POWER SPECTRUM at the output W (u, v) and the MODULATION

out

TRANSFER FUNCTION MTF(u,v) of the DIGITAL X-RAY IMAGING DEVICE shall be calculated on the

LINEARIZED DATA. The LINEARIZED DATA are calculated by applying the inverse CONVERSION

FUNCTION to the ORIGINAL DATA (according to subclause 6.3.1) and are expressed in number of

exposure quanta per unit area. The gain G of the detector at zero SPATIAL FREQUENCY

(equation (1)) is part of the conversion function and does not need to be separately

determined.

Therefore the working equation for the determination of the frequency-dependent DETECTIVE

QUANTUM EFFICIENCY DQE(u,v) according to this standard is :

W (u,v)

in

DQE(u,v) = MTF (u,v) (2)

W (u,v)

out

where

MTF(u,v) is the pre-sampling MODULATION TRANSFER FUNCTION of the DIGITAL X-RAY IMAGING

DEVICE, determined according to subclause 6.3.3;

W (u,v) is the NOISE POWER SPECTRUM of the radiation field at the DETECTOR SURFACE,

in

determined according to subclause 6.2;

W (u,v) is the NOISE POWER SPECTRUM at the output of the DIGITAL X-RAY IMAGING DEVICE,

out

determined according to subclause 6.3.2.

62220-1 IEC:2003(E) – 17 –

6.2 Parameters to be used for evaluation

For the determination of the DETECTIVE QUANTUM EFFICIENCY, the value of the input NOISE

POWER SPECTRUM W (u,v) shall be calculated:

in

W (u,v) = K ⋅ SNR (3)

in a in

where

K is the measured AIR KERMA, unit: µGy;

a

SNR is the squared signal-to-NOISE ratio per AIR KERMA, unit: 1/( mm ⋅µGy) as given in

in

column 2 of Table 2.

The values for SNR in Table 2 shall apply for this standard.

in

Table 2 – Parameters mandatory for the application of this standard

RADIATION QUALITY SNR

in

No.

1/(mm ⋅⋅⋅⋅µGy)

RQA 3 21759

RQA 5 30174

RQA 7 32362

RQA 9 31077

Background information on the calculation of SNR is given in Annex C.

in

6.3 Determination of different parameters from the images

6.3.1 Linearization of data

The LINEARIZED DATA are calculated by applying the inverse CONVERSION FUNCTION to the

ORIGINAL DATA on an individual PIXEL basis. Since the CONVERSION FUNCTION is the output level

(ORIGINAL DATA) as a function of the number of exposure quanta per unit area, the linearized

data have units of exposure quanta per unit area.

NOTE In case of a linear CONVERSION FUNCTION this calculation reduces to the multiplication by a conversion

factor.

The CONVERSION FUNCTION is determined from the images generated according to 4.6.4.

The output is calculated by averaging 100 × 100 pixels of those ORIGINAL DATA in the centre of

the exposed area. The PIXEL values shall be the ORIGINAL DATA, meaning the RAW DATA values

which are corrected according to Clause 5 only. This output is plotted against the input signal

being the number of exposure quanta per unit area Q calculated by multiplying the AIR KERMA

by the value given in column 2 of Table 2 (see 6.2).

The experimental data points shall be fitted by a model function. If the CONVERSION FUNCTION

is assumed to be linear (only 5 exposures made according to 4.6.4) only a linear function

shall be fitted. The fit-result has to fulfil the following requirements:

– Final R ≥ 0,99; and

– no individual experimental data point deviates from its corresponding fit result by more

than 2 % relatively.

– 18 – 62220-1 IEC:2003(E)

6.3.2 The NOISE POWER SPECTRUM (NPS)

The NOISE POWER SPECTRUM at the output of the DIGITAL X-RAY IMAGING DEVICE (W (u,v)) shall

out.

be determined from the images generated according to 4.6.5.

The portion of the uniformly exposed area of the digital X-ray detector used for NPS analysis

shall be divided into square areas, called ROIs. Each ROI for calculating an individual sample

for the NOISE POWER SPECTRUM shall be 256 × 256 PIXELS in size. These areas shall overlap by

128 PIXELS in both, the horizontal and vertical direction (see Figure 3). Let the first area be the

one in the upper left corner of the total region analysed. The next is produced by moving the

rectangular a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...