IEC 63190:2023

(Main)Railway applications - Fixed installations - Electric traction - Copper and copper alloy catenary wires for overhead contact line systems

Railway applications - Fixed installations - Electric traction - Copper and copper alloy catenary wires for overhead contact line systems

IEC 63190:2023 specifies the characteristics of copper and copper alloy catenary wires for use on overhead contact lines. This document also covers auxiliary catenary wires. It establishes the product characteristics, the test methods, checking procedures to be used with the catenary wires, together with packing, ordering and delivery conditions.

Applications ferroviaires - Installations fixes - Traction électrique - Câbles porteurs longitudinaux en cuivre et en alliage de cuivre destinés aux réseaux de lignes aériennes de contact

L'IEC 63190:2023 spécifie les caractéristiques des câbles porteurs longitudinaux en cuivre et en alliage de cuivre destinés aux lignes aériennes de contact. Le présent document couvre également les câbles porteurs auxiliaires. Le présent document définit les caractéristiques du produit, les méthodes d'essai et les procédures de contrôle à employer avec les câbles porteurs longitudinaux, ainsi que les conditions de conditionnement, de commande et de livraison applicables.

General Information

- Status

- Published

- Publication Date

- 29-Aug-2023

- Technical Committee

- TC 9 - Electrical equipment and systems for railways

- Drafting Committee

- PT 63190 - TC 9/PT 63190

- Current Stage

- PPUB - Publication issued

- Start Date

- 30-Aug-2023

- Completion Date

- 08-Sep-2023

Overview

IEC 63190:2023 is an international standard published by the International Electrotechnical Commission (IEC) that specifies the technical requirements for copper and copper alloy catenary wires used in overhead contact line (OCL) systems for railway electric traction. These fixed installations are critical components in railway electrification, providing the electrical connection between overhead wires and trains. The standard covers the product characteristics, test methods, checking procedures, packaging, ordering, and delivery conditions to ensure quality, performance, and safety in railway applications.

This first edition (Edition 1.0, August 2023) of IEC 63190 aims to harmonize requirements internationally for catenary wires used in railway electric traction systems. It addresses both primary catenary wires and auxiliary catenary wires, ensuring consistency and interoperability across rail networks and suppliers. The standard also details designations, mechanical and electrical properties, testing protocols, and specific national conditions where applicable.

Key Topics

Material Designation and Wire Types

IEC 63190 defines a clear system for designating copper and copper alloy materials and catenary wire types. This includes specifications for the cross-sectional area, configuration, and allowed sizes of these wires, ensuring they meet the mechanical and electrical requirements for overhead contact lines.Mechanical and Electrical Characteristics

The standard specifies performance requirements such as tensile strength, elongation, unit mass, diameter, breaking load, electrical resistivity, and conductivity of individual wires and assembled catenary wire constructions. It also provides formulas and calculation methods for alternative wire sizes and constructions.Testing and Verification

Comprehensive testing protocols are included, such as:- Individual wire diameter and structure assessment

- Tensile strength and elongation testing

- DC electrical resistivity measurements

- Reverse bend and winding tests for durability

- Heat resistance and vibration tests under specific national conditions

These procedures ensure wires comply with performance criteria before deployment.

Packaging, Handling, and Marking

IEC 63190 sets out requirements for packaging and marking wire drums, including length tolerances and delivery conditions, facilitating proper storage, transport, and identification of catenary wires.National Variants and Additional Requirements

Informative annexes detail special conditions or additional tests required by some countries and regions (e.g., Russia, China, Australia, New Zealand). This ensures wires meet local operating environments and regulatory demands.

Applications

IEC 63190:2023 is essential for manufacturers, railway infrastructure operators, and procurement specialists involved in the design, supply, installation, and maintenance of overhead contact line systems. Key applications include:

Railway Electrification Projects

Ensuring reliable and durable copper-based catenary wires are used in fixed installations for electric traction systems.Quality Assurance and Compliance

Applying standardized test methods and acceptance criteria helps maintain safety and operational efficiency of overhead lines in rail transport.Material Selection and Procurement

Providing clear guidelines for ordering copper and copper alloy wires that meet international performance benchmarks facilitates vendor selection and contract specifications.Engineering Design and Maintenance

Guidelines for wire size, strength, and electrical characteristics support design optimizations and upkeep of overhead systems in different rail network conditions worldwide.

Related Standards

Organizations involved in railway electrification and electric traction systems often refer to IEC 63190 alongside other international and regional standards, including:

- IEC 60077 – Railway applications – Electric equipment for rolling stock

- IEC 60850 – Railway applications – Power supply and earthing

- ISO/IEC Directives – Framework for developing international standards

- National railway electrification standards (e.g., EN standards in Europe, AREMA standards in North America)

These complementary standards form an integrated framework supporting safe, efficient, and interoperable railway electrification infrastructure.

For further information on IEC 63190:2023 and related documents, visit the IEC Webstore or contact the IEC Secretariat in Geneva. Ensure you have the latest edition for compliance and up-to-date technical guidance in railway electric traction overhead contact line installations.

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

IEC 63190:2023 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Railway applications - Fixed installations - Electric traction - Copper and copper alloy catenary wires for overhead contact line systems". This standard covers: IEC 63190:2023 specifies the characteristics of copper and copper alloy catenary wires for use on overhead contact lines. This document also covers auxiliary catenary wires. It establishes the product characteristics, the test methods, checking procedures to be used with the catenary wires, together with packing, ordering and delivery conditions.

IEC 63190:2023 specifies the characteristics of copper and copper alloy catenary wires for use on overhead contact lines. This document also covers auxiliary catenary wires. It establishes the product characteristics, the test methods, checking procedures to be used with the catenary wires, together with packing, ordering and delivery conditions.

IEC 63190:2023 is classified under the following ICS (International Classification for Standards) categories: 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 63190:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 63190 ®

Edition 1.0 2023-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Railway applications – Fixed installations – Electric traction – Copper and

copper alloy catenary wires for overhead contact line systems

Applications ferroviaires – Installations fixes – Traction électrique – Câbles

porteurs longitudinaux en cuivre et en alliage de cuivre destinés aux réseaux de

lignes aériennes de contact

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur les adapté à vos besoins.

projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au monde,

Restez informé sur les nouvelles publications IEC. Just

avec plus de 22 300 articles terminologiques en anglais et en

Published détaille les nouvelles publications parues.

français, ainsi que les termes équivalents dans 19 langues

Disponible en ligne et une fois par mois par email.

additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 63190 ®

Edition 1.0 2023-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Railway applications – Fixed installations – Electric traction – Copper and

copper alloy catenary wires for overhead contact line systems

Applications ferroviaires – Installations fixes – Traction électrique – Câbles

porteurs longitudinaux en cuivre et en alliage de cuivre destinés aux réseaux de

lignes aériennes de contact

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 45.060.01 ISBN 978-2-8322-7370-8

– 2 – IEC 63190:2023 © IEC 2023

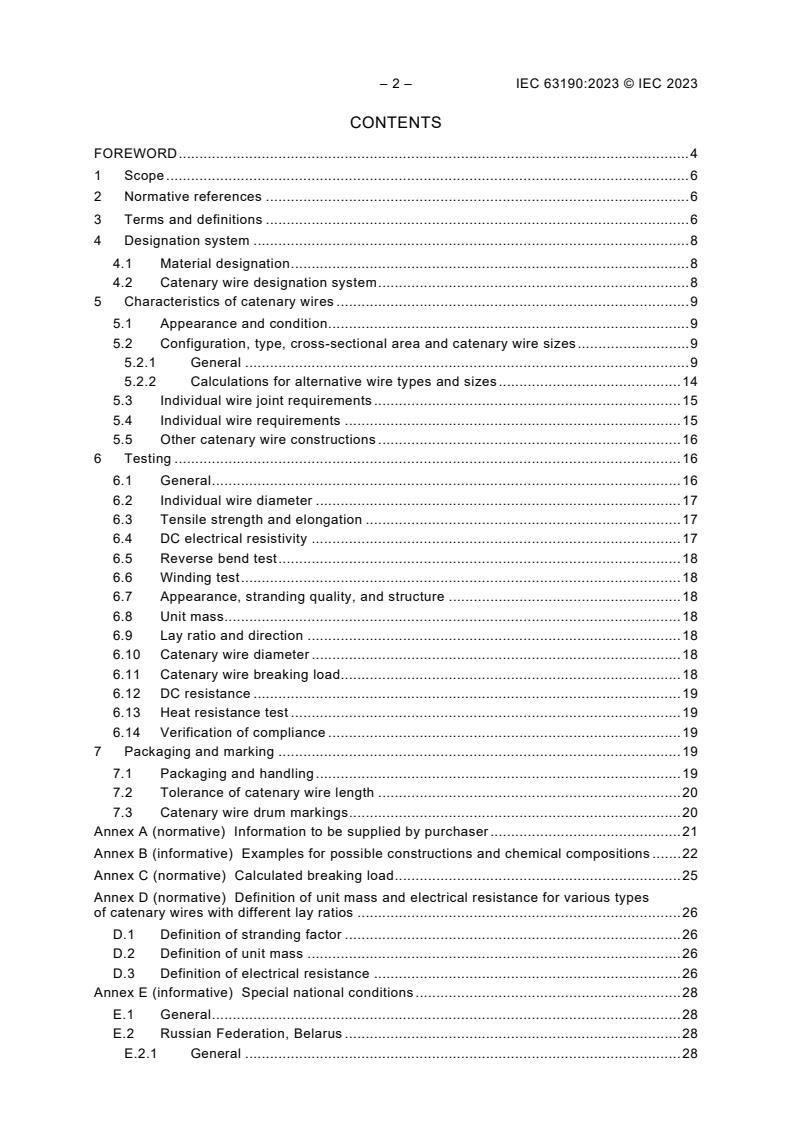

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Designation system . 8

4.1 Material designation . 8

4.2 Catenary wire designation system . 8

5 Characteristics of catenary wires . 9

5.1 Appearance and condition . 9

5.2 Configuration, type, cross-sectional area and catenary wire sizes . 9

5.2.1 General . 9

5.2.2 Calculations for alternative wire types and sizes . 14

5.3 Individual wire joint requirements . 15

5.4 Individual wire requirements . 15

5.5 Other catenary wire constructions . 16

6 Testing . 16

6.1 General . 16

6.2 Individual wire diameter . 17

6.3 Tensile strength and elongation . 17

6.4 DC electrical resistivity . 17

6.5 Reverse bend test . 18

6.6 Winding test . 18

6.7 Appearance, stranding quality, and structure . 18

6.8 Unit mass. 18

6.9 Lay ratio and direction . 18

6.10 Catenary wire diameter . 18

6.11 Catenary wire breaking load. 18

6.12 DC resistance . 19

6.13 Heat resistance test . 19

6.14 Verification of compliance . 19

7 Packaging and marking . 19

7.1 Packaging and handling . 19

7.2 Tolerance of catenary wire length . 20

7.3 Catenary wire drum markings . 20

Annex A (normative) Information to be supplied by purchaser . 21

Annex B (informative) Examples for possible constructions and chemical compositions . 22

Annex C (normative) Calculated breaking load . 25

Annex D (normative) Definition of unit mass and electrical resistance for various types

of catenary wires with different lay ratios . 26

D.1 Definition of stranding factor . 26

D.2 Definition of unit mass . 26

D.3 Definition of electrical resistance . 26

Annex E (informative) Special national conditions . 28

E.1 General . 28

E.2 Russian Federation, Belarus . 28

E.2.1 General . 28

E.2.2 Relative creep test . 30

E.2.3 Vibration test . 31

E.3 China . 31

E.3.1 Vibration and fatigue test . 31

E.3.2 Indoors current-carrying capacity test . 32

E.4 Australia and New Zealand . 33

E.4.1 Joint requirements . 33

E.4.2 Verification of compliance . 33

E.4.3 Additional tests . 33

Bibliography . 34

Figure 1 – Direction of lay . 8

Figure E.1 – Connecting clamps . 31

Figure E.2 – Example of vibration and fatigue test rig arrangement . 32

Table 1 – Example wire designations . 9

Table 2 – Individual wire mechanical characteristics . 11

Table 3 – Individual wire electrical resistivity characteristics . 12

Table 4 – Individual wire electrical conductivity characteristics . 12

Table 5 – Reference constructions . 13

Table 6 – Lay ratio . 16

Table 7 – Types of testing . 17

Table B.1 – Examples for possible chemical compositions . 23

Table B.2 – Examples of common conductor constructions . 24

Table E.1 – Example compacted catenary wires . 29

Table E.2 – Compacted catenary wire construction . 30

– 4 – IEC 63190:2023 © IEC 2023

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

RAILWAY APPLICATIONS – FIXED INSTALLATIONS –

ELECTRIC TRACTION – COPPER AND COPPER ALLOY

CATENARY WIRES FOR OVERHEAD CONTACT LINE SYSTEMS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of

(a) patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights

in respect thereof. As of the date of publication of this document, IEC had received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

IEC 63190 has been prepared by IEC technical committee 9: Electrical equipment and systems

for railways. It is an International Standard.

The text of this International Standard is based on the following documents:

Draft Report on voting

9/2973/FDIS 9/2994/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 63190:2023 © IEC 2023

RAILWAY APPLICATIONS – FIXED INSTALLATIONS –

ELECTRIC TRACTION – COPPER AND COPPER ALLOY

CATENARY WIRES FOR OVERHEAD CONTACT LINE SYSTEMS

1 Scope

This document specifies the characteristics of copper and copper alloy catenary wires for use

on overhead contact lines.

This document also covers auxiliary catenary wires. It establishes the product characteristics,

the test methods, checking procedures to be used with the catenary wires, together with packing,

ordering and delivery conditions.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60468, Method of measurement of resistivity of metallic materials

ISO 6892-1, Metallic materials – Tensile testing – Part 1: Method of test at room temperature

ISO 7801, Metallic materials – Wire – Reverse bend test

ISO 7802, Metallic materials – Wire – Wrapping test

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

stranded conductor

conductor consisting of a number of individual uninsulated wires laid up together in left- and

right-hand alternating helical layers

[SOURCE: IEC 60050-466:1990, 466-10-03]

3.2

catenary wire

messenger wire

longitudinal stranded conductor supporting the contact wire or wires either directly or indirectly

Note 1 to entry: The term "catenary wires" used in this document includes auxiliary catenary wires.

[SOURCE: IEC 60050-811:2017, 811-33-06, modified – In the definition, "cable" has been

replaced with "stranded conductor". Note 1 to entry has been added.]

3.3

individual wire

one of the wires of a catenary wire

3.4

compacted catenary wire

catenary wire in which the interstices between the individual wires have been reduced by

mechanical compression, or by drawing, or by suitable choice of the shape and disposition of

individual wires

3.5

length of lay

axial length of one complete turn of the helix of a wire in a stranded conductor

[SOURCE: IEC 60050-466:1990, 466-10-05]

3.6

lay ratio

ratio of the length of lay to the outer diameter of the helix

[SOURCE: IEC 60050-466:1990, 466-10-06, modified – In the definition, "outer" has been

added.]

3.7

measured wire diameter

diameter, determined from measurements

3.8

calculated cross-sectional area

sum of the cross-sectional areas of individual wires

3.9

nominal cross-sectional area

value used for designation purposes based on the calculated cross-sectional area rounded to

the nearest multiple of 5 mm

Note 1 to entry: Regional exceptions exist.

3.10

direction of lay

direction of twist of a layer of wires of a stranded conductor as viewed from the end

Note 1 to entry: The lay is said to be right-hand when the visible portion of the helix, together with the two cross-

sections limiting it, form the shape of a letter Z, and left-hand when they form the shape of a letter S, see Figure 1.

– 8 – IEC 63190:2023 © IEC 2023

Figure 1 – Direction of lay

[SOURCE: IEC 60050-466:1990, 466-10-07, modified – Note 1 to entry from

IEC 60050-461:2008, 461-04-03 and Figure 1 have been added.]

3.11

stranding factor

relative increased ratio in unit mass and electrical resistance due to stranding, dependent on

the lay ratio

3.12

fill factor

ratio of the unit mass of the catenary wire to the unit mass of a rod made of the same length,

diameter and material

4 Designation system

4.1 Material designation

The catenary wires, as described in this document, shall consist of a copper or copper alloy.

The user shall specify explicitly the alloying material(s) to be used in the construction. Chemical

composition, mechanical characteristics, conductivity class and % IACS shall be agreed

between purchaser and supplier. Mechanical characteristics are designated C0 to C7, where

C0 represents pure copper and C1 to C7 are designations given to represent characteristics of

materials, which can be achieved with commonly used copper alloys worldwide. They have

been grouped in Table 2 with increasing tensile strength so that shared mechanical

characteristics are common within each category. Examples for some possible chemical

compositions and some common conductor constructions of the copper and copper alloy

catenary wire are presented in Annex B.

4.2 Catenary wire designation system

The catenary wire designation shall consist of:

– "Catenary wire" (as shown in the examples in Table 1, but not in Annex B or Annex E);

– reference of this document;

– nominal cross-sectional area;

– number of individual wires;

– individual wire diameter;

– conductivity class and % IACS conductivity (as per Table 3 and Table 4);

– mechanical characteristics (C0 to C7 as per Table 2);

– alloying elements.

The formatting of this combined designation system is shown in Table 1.

Table 1 – Example wire designations

Catenary Wire IEC 63190-60-19x2,00-S96-C1 CuAg

IEC 63190 - 60 - 19 x 2,00 - S96 - C1 CuAg

Catenary Wire IEC 63190-180-37x2,50-H59-С6 CuMg

IEC 63190 - 180 - 37 x 2,50 - H59 - C6 CuMg

Further alloy compositions and example catenary wires are listed in Annex B.

5 Characteristics of catenary wires

5.1 Appearance and condition

The catenary wires shall not present any imperfections (roughness, sliver, seam, inclusion or

cracks) liable to affect the mechanical and electrical properties specified in this document or to

cause difficulties during installation and operation.

The surface shall be clean and free of oxide inclusions or sulphide generated during the

manufacturing process or foreign substances such as pickling residue. Slight changes in the

colour of the bright metallic surface due to atmospheric influence immediately after

manufacturing are acceptable.

The catenary wire shall not have any crossings, protrusions, breaks, burrs, scratches,

indentations, dents or cracks in accordance with good technical practice.

The catenary wire shall be coiled carefully in orderly layers on the drum. The two ends of the

wire shall be fastened to the flanges of the drum. There shall be no twist or cross-over of turns

within a layer or between layers in the winding.

5.2 Configuration, type, cross-sectional area and catenary wire sizes

5.2.1 General

The catenary wires are composed of a number of individual wires laid up together. Mechanical

characteristics of typical individual wires are shown in Table 2, and electrical characteristics

are shown in Table 3 and Table 4.

Table 5 details reference round wire concentric lay catenary wires. There are four different

constructions with 7, 19, 37 and 61 individual wires. Each conductor is composed of a central

individual wire surrounded by one or more adjacent layers of wires that are laid helically in

opposite directions.

The measured wire diameter of the catenary wire shall not vary by more than:

• ±1 % for diameters larger than or equal to 10 mm;

• ±0,1 mm for diameters smaller than 10 mm.

Document

reference

Nominal

cross-sectional

area

Number of

individual wires

Individual wire

diameter

Conductivity

class and

% IACS

Mechanical

characteristics

Alloying

elements

– 10 – IEC 63190:2023 © IEC 2023

Other designs can be allowed by agreement between purchaser and supplier, in accordance

with 5.5.

Table 2 – Individual wire mechanical characteristics

Minimum tensile strength (MPa) before stranding and after stranding, and reduction coefficient

Diameter Material

mm C0 C1 C2 C3 C4 C5 C6 C7

Before After Before After Before After Before After Before After Before After Before After Before After

up to 1 430 409 430 409 490 466 520 494 620 589 736 714

>1,00 to 1,25 430 409 430 409 490 466 520 494 620 589 736 714

>1,25 to 1,50 430 409 430 409 490 466 520 494 620 589 718 696

>1,50 to 1,75 430 409 430 409 490 466 520 494 620 589 697 679 718 696

>1,75 to 2,00 430 409 430 409 490 466 520 494 620 589 660 640 697 676 776 760

>2,00 to 2,25 430 409 430 409 490 466 520 494 620 589 639 620 686 665 776 760

>2,25 to 2,50 430 409 430 409 490 466 520 494 620 589 622 603 652 641 750 735

>2,50 to 2,75 430 409 430 409 490 466 520 494 620 589 622 603 638 617 750 735

>2,75 to 3,00 430 409 430 409 490 466 520 494 620 589

>3,00 to 3,25 424 402 424 402 485 460 520 494 620 589

>3,25 to 3,50 424 402 424 402 485 460 500 475 600 570

>3,50 to 3,75 418 397 418 397 479 455 500 475 600 570

>3,75 to 4,00 418 397 418 397 479 455 500 475 600 570

>4,00 to 4,25 413 392 413 392 474 450 500 475 600 570

Reduction

95 % 95 % 95 % 95 % 95 % 97 % 97 % 98 %

coefficient

Heat

No Yes Yes Yes Yes Yes Yes Yes

a

resistance

a

The heat resistance indicates whether the alloy resists changes in its physical properties when subjected to changes in temperature and if requested by purchaser shall comply

with the test procedure in 6.13.

– 12 – IEC 63190:2023 © IEC 2023

Table 3 – Individual wire electrical resistivity characteristics

Maximum material resistivity

(nΩm)

Conductivity class

C0 C1 C2 C3 C4 C5 C6 C7

Standard (S) 17,77 17,96 24,63 25,73 27,78 31,35 57,47 66,30

High (H) 21,55 21,55 22,99 24,40 29,30 50,80

Extra High (E) 20,28 20,48 21,55 22,99 24,40

Ultra High (U) 19,16 19,82 20,28 21,55 23,00

Table 4 – Individual wire electrical conductivity characteristics

Minimum material conductivity

Conductivity class (% IACS)

C0 C1 C2 C3 C4 C5 C6 C7

Standard (S) 97 96 70 67 62 55 30 26

High (H) 80 80 75 71 59 34

Extra High (E) 85 84 80 75 71

Ultra High (U) 90 87 85 80 75

Table 5 – Reference constructions

Calculated Calculated breaking load

Individual Catenary

Calculated Unit cross-

wire wire

resistance mass sectional

C0 C1 C2 C3 C4 C5 C6 C7

diameter diameter

Stranding

area

factor

mm mm Ω/km kg/km

mm

kN kN kN kN kN kN kN kN

±1 % ±1 % ±3 % ±2 %

35 7 2,5 7,5 0,508 3 309,4 34,4 1,012 96 13,33 13,33 15,20 16,13 19,23 19,69 23,99

50 7 3,0 9,0 0,353 0 445,6 49,5 1,012 96 19,20 19,20 21,88 23,22 27,69

65 7 3,5 10,5 0,259 3 606,5 67,3 1,012 96 25,77 25,77 29,48 30,39 36,47

90 7 4,0 12,0 0,198 5 792,1 88,0 1,012 96 33,18 33,18 38,03 39,69 47,63

35 19 1,5 7,5 0,522 8 303,9 33,6 1,018 11 13,03 13,03 14,85 15,76 18,79 22,21

60 19 2,0 10,0 0,294 1 540,3 59,7 1,018 11 23,16 23,16 26,40 28,01 33,40 36,30 38,34 43,12

95 19 2,5 12,5 0,188 2 844,2 93,3 1,018 11 36,19 36,19 41,24 43,77 52,19 53,46 65,12

135 19 3,0 15,0 0,130 7 1 215,6 134,3 1,018 11 52,12 52,12 59,39 63,03 75,15

185 19 3,5 17,5 0,096 0 1 654,5 182,8 1,018 11 69,95 69,95 80,01 82,49 98,99

240 19 4,0 20,0 0,073 5 2 161,0 238,8 1,018 11 90,07 90,07 103,22 107,74 129,29

30 37 1,0 7,0 0,605 6 263,7 29,1 1,020 68 11,28 11,28 12,85 13,64 16,26

65 37 1,5 10,5 0,269 1 593,3 65,4 1,020 68 25,37 25,37 28,91 30,68 36,59 43,26

115 37 2,0 14,0 0,151 4 1 054,7 116,2 1,020 68 45,11 45,11 51,40 54,55 65,04 70,70 74,66 83,98

180 37 2,5 17,5 0,096 9 1 648,0 181,6 1,020 68 70,48 70,48 80,32 85,24 101,63 104,10 126,82

260 37 3,0 21,0 0,067 3 2 373,2 261,5 1,020 68 101,50 101,50 115,66 122,74 146,34

355 37 3,5 24,5 0,049 4 3 230,1 356,0 1,020 68 136,22 136,22 155,82 160,64 192,76

50 61 1,0 9,0 0,367 8 435,3 47,9 1,022 10 18,59 18,59 21,19 22,48 26,81

110 61 1,5 13,5 0,163 5 979,5 107,8 1,022 10 41,83 41,83 47,67 50,59 60,32 71,32

190 61 2,0 18,0 0,092 0 1 741,3 191,6 1,022 10 74,37 74,37 84,75 89,94 107,23 116,55 123,09 138,45

300 61 2,5 22,5 0,058 9 2 720,8 299,4 1,022 10 116,20 116,20 132,42 140,52 167,55 171,63 209,08

NOTE All values are calculated based on a conductivity of 100 % IACS or resistivity of 17,241 nΩm, the reference lay ratios of Table 6 and a density of 8,89 g/cm .

The deviations on unit mass and resistance resulting from extreme length of lay values result in a deviation less than 0,9 % from the tabled values, and these deviations can be

considered as part of the tolerance. The combined tolerance has been rounded up to 3 % for convenience for unit mass.

The calculated breaking load is in accordance with Annex C. The values for unit mass are calculated in accordance with Annex D.

Definition of unit mass and electrical resistance for various types of catenary wires with different lay ratios is given in Annex D.

Nominal

cross-sectional

area

Number of wires

– 14 – IEC 63190:2023 © IEC 2023

5.2.2 Calculations for alternative wire types and sizes

5.2.2.1 Calculation of cross-sectional area ratio

There are many alternative types and sizes of catenary wire used around the world. It is

necessary to calculate a cross-sectional area ratio to determine the related material

characteristics for alternative conductor sizes:

d

a

r =

s

d

t

where

r is the cross-sectional area ratio;

s

d is the alternative conductor diameter, mm;

a

d is the closest conductor diameter for comparison in Table 5, mm.

t

5.2.2.2 Calculation of DC resistance

To calculate DC resistance using the resistivity of the actual copper alloy:

r

a

RR ×

at

r

Cu

where

R is the DC resistance of the wire, Ω/km;

a

R is the stated wire resistance from Table 5, Ω/km;

t

r is the actual copper alloy wire resistivity, nΩm;

a

r is the resistivity of soft annealed copper corresponding to 100 % IACS, 17,241 nΩm.

Cu

To calculate the resistance for alternative catenary wire constructions, divide the resistance of

the closest equivalent catenary wire by the cross-sectional area ratio, r from 5.2.2.1.

s

The resistance for alternative catenary wires with different lay ratios shall be calculated using

the formulae shown in Annex D.

5.2.2.3 Calculation of unit mass

To calculate the unit mass using the density of the actual copper alloy:

ρ

a

mm×

a t

8,89

where

m is the actual unit mass of the wire, kg/km;

a

m is the stated unit mass from Table 5, kg/km;

t

ρ is the actual copper alloy wire density (use Table B.1), g/cm .

a

To calculate the unit mass for alternative catenary wire constructions, multiply the unit mass of

the closest equivalent catenary wire by the cross-sectional area ratio, r .

s

=

=

The unit mass for the actual catenary wire with variant lay ratio shall be calculated using the

formula shown in Clause D.2.

5.2.2.4 Calculation of breaking load

To calculate breaking load, use cross-sectional area ratio (use Table 5) and multiply by the

tensile strength after stranding and the reduction coefficient (use Table 2). The calculation

method shown in Annex C shall be used.

5.3 Individual wire joint requirements

During stranding, no copper or copper alloy wire welds shall be made for the purpose of

achieving the required conductor length.

Joints are permitted in catenary wires unavoidably broken during stranding provided such

breaks are not associated with either inherently defective wire or with the use of short lengths

of copper or copper alloy wires. Joints shall conform to the geometry of the original wire,

i.e. joints shall be dressed smoothly with a diameter equal to that of the parent wires and shall

not be kinked.

Joints shall be made by electric butt welding, electric butt cold upset welding, or cold pressure

welding. These joints shall not be closer than 15 m from a joint in the same wire or in any other

individual wire of the completed conductor.

The manufacturer shall demonstrate that the method used for joining individual wires meets the

required strength agreed between the purchaser and supplier.

The special requirements of joints shall be agreed between purchaser and supplier.

5.4 Individual wire requirements

– Lay ratio of the catenary wire shall be in accordance with Table 6. Any lay ratio shall not

exceed the inner adjacent layer ratio.

– Individual wires of every layer shall be stranded tightly and evenly on the central wire or

inner adjacent layer. A catenary wire shall not contain a broken wire, lack of wire or disorder

of wires.

– All individual wires shall lie naturally in their position after stranding, and when cut, the

individual wire ends shall remain in position or be readily replaced by hand and then remain

approximately in position.

– All individual wires of the catenary wire shall be concentrically stranded.

– Adjacent wire layers shall be stranded with reverse lay directions. The direction of lay of the

external layer shall be right hand except when otherwise specified by the purchaser.

– 16 – IEC 63190:2023 © IEC 2023

Table 6 – Lay ratio

6-wire layer 12-wire layer 18-wire layer 24-wire layer

Stranded wire construction

Min. Max. Ref. Min. Max. Ref. Min. Max. Ref. Min. Max. Ref.

7 10,0 14,0 12,0

19 10,0 15,0 12,5 10,0 14,0 12,0

37 10,0 16,0 13,0 10,0 15,0 12,5 10,0 14,0 12,0

61 10,0 17,0 13,5 10,0 16,0 13,0 10,0 15,0 12,5 10,0 14,0 12,0

Min. Minimum lay ratio

Max. Maximum lay ratio

Ref. Reference lay ratio used in Table 5.

Lay ratio is always rounded to the nearest whole number, but decimals have been used for the reference lay ratio

for the purpose of calculating the construction types.

5.5 Other catenary wire constructions

Alternative construction methods for catenary wires are open for development. Such examples

include stranded conductors with a fill factor greater than 90 %. Specific construction and

testing requirements should be agreed between purchaser and supplier.

Examples of alternative constructions of catenary wires used under special national conditions

are given in Annex E.

6 Testing

6.1 General

To verify compliance with the requirements of Clause 5, type tests and sample tests are

undertaken. The number of repeated type tests shall be agreed between purchaser and supplier.

Catenary wires are accepted in batch quantities. A batch consists of catenary wire of a single

type, produced of the same material by only one manufacturer with a single technology and

should be offered for acceptance with a single document.

Test samples may be the catenary wire or individual wires taken from a drum of the batch to be

tested. The selection of samples shall be carried out to identify them for compliance labelling.

Unless otherwise specified in the details for the particular test, tests shall be carried out at an

ambient temperature between 10 °C and 30 °C.

The tests to be performed on the catenary wire or individual wires and the type of each test are

shown in Table 7.

Table 7 – Types of testing

Test type

Sub-

Test item

clause

Type Sample

6.2 Diameter ● ●

a

6.3 Tensile strength ● ●

Individual wire

6.3 Elongation ● ●

test (before

6.4 DC electrical resistivity ● ●

stranding)

6.5 Reverse bend test ○ ○

6.6 Winding test ○ ○

6.7 Appearance (including packaging) ● ●

6.7 Stranding quality ● ●

6.7 Stranding structure (e.g. 19 × 2,1) ● ●

6.8 Unit mass (mass/length) ● ●

6.9 Lay direction ● ●

Catenary wire

test

6.9 Lay ratio ● ●

6.10 Diameter ● ●

6.11 Breaking load ● ○

6.12 DC resistance (per unit length) at 20 °C ● ●

6.13 Heat resistance ○ –

6.2 Diameter ● ●

a

6.3 ● ●

Tensile strength

Individual wire

6.3 Elongation ○ ○

test (after

stranding and

6.4 DC electrical resistivity ○ ○

separating)

6.5 Reverse bend test ○ ○

6.6 Winding test ○ ○

● indicates this test item shall be done.

○ indicates this test item is optional.

– indicates this test item is not required.

a

at least the result of one of these two tests should be used for calculating breaking load.

6.2 Individual wire diameter

Measurements shall be made with suitable equipment to read in 0,001 mm or higher accuracy.

The measurement shall be taken twice at the same location and the two measurements shall

be perpendicular to each other. The average of the two measurements, rounded to two decimal

places, shall be recorded as the measured wire diameter.

6.3 Tensile strength and elongation

This test shall be performed in accordance with the requirements of ISO 6892-1. The gauge

length for percentage elongation measurement shall be 200 mm or 250 mm. For other gauge

lengths the values should be agreed between purchaser and supplier. The original gauge length

shall be marked to an accuracy of 1 %.

6.4 DC electrical resistivity

The test shall be performed in accordance with the requirements of IEC 60468. Before the test,

the samples should be straightened properly without causing any change in electrical properties.

It is recommended that the samples are straightened by hand.

For end-users and purchasers For manufacturers

– 18 – IEC 63190:2023 © IEC 2023

6.5 Reverse bend test

The test shall be performed in accordance with the requirements of ISO 7801. Before the test,

the samples should be straightened properly without causing any change in mechanical

properties. It is recommended that the samples are straightened by hand.

6.6 Winding test

The test shall be performed in accordance with the requirements of ISO 7802.

A sample is tightly wound around a mandrel for eight turns. The diameter of the mandrel shall

be equal to the sample’s diameter. If necessary, before the test, the samples should be

straightened properly without causing any change in mechanical properties. It is recommended

that the samples are straightened by hand.

On completion of the test, the sample shall be examined with normal vision and present no

crack, scale, fissure, or incipient break.

6.7 Appearance, stranding quality, and structure

The appearance, stranding quality and structure of the catenary wire shall be inspected with

the unaided eye. The appearance shall comply with the requirements of 5.1. The stranding

quality and structure shall comply with the requirements of 5.4.

6.8 Unit mass

This consists of measuring the mass and the length of a suitable sample at ambient temperature

in accordance with 6.1. The precision of the measurement shall be better than 0,5 % error.

6.9 Lay ratio and direction

The lay ratio of each layer of the conductor shall be obtained. The length of lay should be

measured with suitable equipment to be read in 1 mm or higher accuracy. The diameters of

catenary wires should be measured in accordance with 6.10, Table 5 and Table 6.

The lay direction of catenary wires should be checked with normal vision. To check the inner

lay direction, it is permitted to untwist the outer layer.

6.10 Catenary wire diameter

Measurements shall be made with suitable equipment to be read in 0,01 mm or higher accuracy.

The measurements shall be taken twice at the same location and be perpendicular to each

other. The average of the two measurements, rounded to one decimal place, shall be recorded

as the measured diameter of the wire.

6.11 Catenary wire breaking load

The breaking load shall be determined by pulling a conductor in a suitable tensile testing

machine with an accuracy of at least ±1 %. The sample length shall be agreed between

purchaser and supplier. The rate of increase of load shall be uniform during the test. The time

required to reach 30 % of calculated breaking load shall not be less than 1 min nor more than

2 min. The same rate of loading shall thereafter be maintained throughout the test.

For the purposes of the tensile test, appropriate fittings shall be applied on the ends of the

conductor samples, such as pressing a seamless steel tube. The breaking load is the maximum

load recorded before one or more wires of the conductor are fractured. If wire

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...