IEC 61375-2:2007

(Main)Electric railway equipment - Train bus - Part 2: Train communication network conformance testing

Electric railway equipment - Train bus - Part 2: Train communication network conformance testing

Applies to all equipment and devices implemented according to IEC 61375-1, that is covers the procedures to be applied to such equipment and devices when the conformance should be proven. The applicability of this standard to a TCN implementation allows for individual conformance checking of the implementation itself and is a pre-requisite for further interoperability checking between different TCN implementations.

General Information

- Status

- Replaced

- Publication Date

- 10-Apr-2007

- Technical Committee

- TC 9 - Electrical equipment and systems for railways

- Drafting Committee

- MT 43 - TC 17/SC 17C/MT 43

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 21-Jun-2012

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

IEC 61375-2:2007 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electric railway equipment - Train bus - Part 2: Train communication network conformance testing". This standard covers: Applies to all equipment and devices implemented according to IEC 61375-1, that is covers the procedures to be applied to such equipment and devices when the conformance should be proven. The applicability of this standard to a TCN implementation allows for individual conformance checking of the implementation itself and is a pre-requisite for further interoperability checking between different TCN implementations.

Applies to all equipment and devices implemented according to IEC 61375-1, that is covers the procedures to be applied to such equipment and devices when the conformance should be proven. The applicability of this standard to a TCN implementation allows for individual conformance checking of the implementation itself and is a pre-requisite for further interoperability checking between different TCN implementations.

IEC 61375-2:2007 is classified under the following ICS (International Classification for Standards) categories: 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61375-2:2007 has the following relationships with other standards: It is inter standard links to IEC 61375-2-2:2012, IEC 61375-3-2:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61375-2:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 61375-2

First edition

2007-04

Electric railway equipment –

Train bus –

Part 2:

Train communication network conformance testing

Reference number

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD 61375-2

First edition

2007-04

Electric railway equipment –

Train bus –

Part 2:

Train communication network conformance testing

PRICE CODE

Commission Electrotechnique Internationale XH

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

– 2 – 61375-2 © IEC:2007(E)

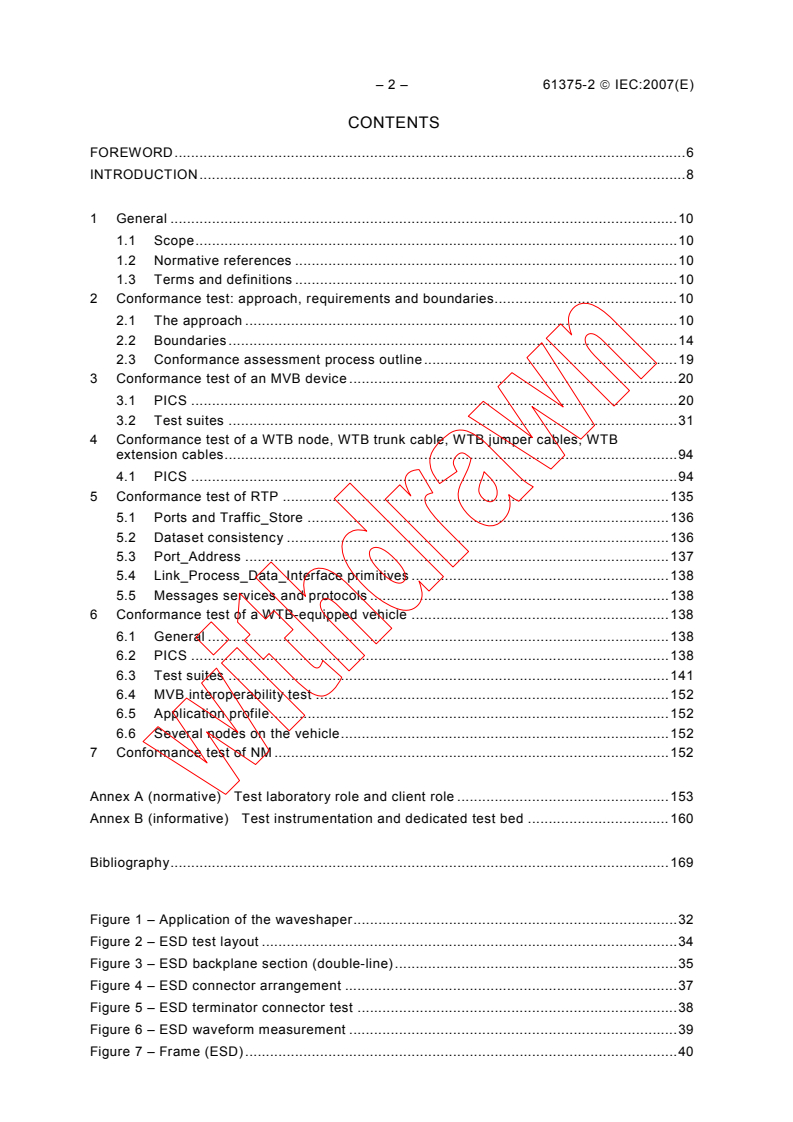

CONTENTS

FOREWORD.6

INTRODUCTION.8

1 General .10

1.1 Scope.10

1.2 Normative references .10

1.3 Terms and definitions .10

2 Conformance test: approach, requirements and boundaries.10

2.1 The approach .10

2.2 Boundaries .14

2.3 Conformance assessment process outline.19

3 Conformance test of an MVB device .20

3.1 PICS .20

3.2 Test suites .31

4 Conformance test of a WTB node, WTB trunk cable, WTB jumper cables, WTB

extension cables.94

4.1 PICS .94

5 Conformance test of RTP .135

5.1 Ports and Traffic_Store .136

5.2 Dataset consistency .136

5.3 Port_Address .137

5.4 Link_Process_Data_Interface primitives .138

5.5 Messages services and protocols .138

6 Conformance test of a WTB-equipped vehicle .138

6.1 General .138

6.2 PICS .138

6.3 Test suites .141

6.4 MVB interoperability test .152

6.5 Application profile.152

6.6 Several nodes on the vehicle.152

7 Conformance test of NM .152

Annex A (normative) Test laboratory role and client role .153

Annex B (informative) Test instrumentation and dedicated test bed .160

Bibliography.169

Figure 1 – Application of the waveshaper.32

Figure 2 – ESD test layout .34

Figure 3 – ESD backplane section (double-line).35

Figure 4 – ESD connector arrangement .37

Figure 5 – ESD terminator connector test .38

Figure 6 – ESD waveform measurement .39

Figure 7 – Frame (ESD).40

61375-2 © IEC:2007(E) – 3 –

Figure 8 – Measurement of insertion loss.42

Figure 9 – EMD transmitter heavy load circuit .42

Figure 10 – EMD transmitter light test circuit.43

Figure 11 – Example of pulse waveform at EMD transmitter.44

Figure 12 – EMD transmitter idling test circuit .45

Figure 13 – Signal with end delimiter .45

Figure 14 – Example of end delimiter for EMD medium .45

Figure 15 – Example of test hardware implementation .56

Figure 16 – F_code + Address .60

Figure 17 – Concept of message data testing .67

Figure 18 – Model of the relation between TE and IUT for message data testing.67

Figure 19 – Relation between TE and IUT in case of test of IUT as caller .68

Figure 20 – Packet formats (transport layer body).69

Figure 21 – Test message task of IUT.70

Figure 22 – Caller timeout identification .73

Figure 23 – Nesting address with 0x83 .79

Figure 24 – Block diagram of a line.85

Figure 25 – Frames in test RP-1.2 .86

Figure 26 – Inter-frame spacing .86

Figure 27 – Pulse distortion .88

Figure 28 – Frame with out-of-place transition .88

Figure 29 – Frames in test RP-1.4 .89

Figure 30 – Insertion loss measurement.104

Figure 31 – Measurement of the input resistance .105

Figure 32 – End setting measurement setup 1 .105

Figure 33 – End setting measurement setup 2 .106

Figure 34 – Switches measurement setup 1 .107

Figure 35 – Direct attachment switches measurements Fixture 1 .107

Figure 36 – Indirect attachment switches measurements Fixture 1.108

Figure 37 – Transmitter fixtures .109

Figure 38 – Transmitter output signal.110

Figure 39 – Intermediate transmitted noise test fixture .110

Figure 40 – End node transmitted noise test fixture.111

Figure 41 – Signal and idling at transmitter .112

Figure 42 – RF resistor example .113

Figure 43 – Short-circuit test Fixture 1 .113

Figure 44 – Receiver signal envelope .115

Figure 45 – Receiver edge distortion.116

Figure 46 – Example of relay switch logic diagram for line A.119

Figure 47 – WTB orientation .122

Figure 48 – Line switch identification in position P01 .123

Figure 49 – Line switch identification in position P10 .123

Figure 50 – Line switch identification in position P32 .123

– 4 – 61375-2 © IEC:2007(E)

Figure 51 – Test suite identifier TTS1 .124

Figure 52 – Test suite identifier TTS2 .125

Figure 53 – Test suite identifier TTS3 .126

Figure 54 – Line resistance.143

Figure 55 – Crosstalk.144

Figure 56 – Propagation delay and attenuation .145

Figure 57 – Coach tester nodes .150

Figure B.1 – Hardware test bed architecture .161

Figure B.2 – Test bed configuration MRTB1.162

Figure B.3 – Test bed configuration MRTB2.162

Figure B.4 – Coach tester architecture.163

Figure B.5 – Configuration of the coach tester .167

Figure B.6 – WTB line redundancy switch-over .168

Table 1 – Document structure .9

Table 2 – Continuance indication .17

Table 3 – Weak statements.18

Table 4 – Relation to interoperability.19

Table 5 – Relation to performance test .19

Table 6 – ESD basic interconnection tests .33

Table 7 – EMD basic interconnection tests.33

Table 8 – Measurement idle.35

Table 9 – Measurement with load for minimum current.36

Table 10 – Measurement with load for maximum current.36

Table 11 – Measurement with load for overcurrent.36

Table 12 – Pin assignment for the ESD connector .37

Table 13 – ESD measurements pin to pin .38

Table 14 – Event poll strategy.71

Table 15 – Abbreviations .75

Table 16 – Addressing type.76

Table 17 – Test function directory.78

Table 18 – Test station directory.78

Table 19 – Nesting address .79

Table 20 – Read_Memory and Write_Memory sequence.81

Table 21 – Configuration of periodic data in BA .91

Table 22 – Configuration of periodic ports in CU-1 .92

Table 23 – Configuration of periodic ports in CU-2 .93

Table 24 – WTB pin to pin measurement.108

Table 25 – Fault tolerance parameters.112

Table 26 – Frequency sinusoidal signal .117

Table 27 – WTB devices configuration .120

Table 28 – TNM agent services.121

61375-2 © IEC:2007(E) – 5 –

Table 29 – Test suite .123

– 6 – 61375-2 © IEC:2007(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRIC RAILWAY EQUIPMENT –

TRAIN BUS –

Part 2: Train communication network conformance testing

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical

Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt

with may participate in this preparatory work. International, governmental and non-governmental organizations

liaising with the IEC also participate in this preparation. IEC collaborates closely with the International

Organization for Standardization (ISO) in accordance with conditions determined by agreement between the two

organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61375-2 has been prepared by IEC technical committee 9:

Electrical equipment and systems for railways.

This standard is to be read in conjunction with IEC 61375-1, second edition.

The text of this standard is based on the following documents:

FDIS Report on voting

9/1014/FDIS 9/1034/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

61375-2 © IEC:2007(E) – 7 –

A list of all parts of IEC 61375 series, published under the general title Electric railway

equipment – Train bus can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in the

data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

Following the decision of the committee, some parts of the text and some figures of this

publication are copied from the IEC 61375-1 for keeping the maximum of clarity.

A bilingual version of this standard may be issued at a later date.

– 8 – 61375-2 © IEC:2007(E)

INTRODUCTION

TCN is an International Standard with the aim of defining interfaces so as to achieve plug-in

compatibility:

a) between equipment located in different vehicles, and

b) between equipment and devices located within the same vehicle.

One of the key success factors for deployment of any technology is the standardisation and

the ensuring interoperability among various implementations. To facilitate interoperability a

conformance test should be implemented.

In this part of IEC 61375, the TCN hierarchical structure deals with two levels of busses:

a) the train bus called the Wire Train Bus (WTB);

b) the vehicle bus called the Multifunction Vehicle Bus (MVB).

No other busses are taken into consideration even though they are foreseen by IEC 61375-1,

see the note below.

WTB and MVB share the same real-time protocols, which offer two communication services:

a) process variables, a distributed, real-time database, periodically refreshed through

broadcasting;

b) messages, transmitted on demand either as:

0. unicast messages (point-to-point) or/and

1. multicast messages.

WTB and MVB share a common network management, which allows debugging,

commissioning and maintenance over the network.

NOTE TCN states that several vehicle busses may apply, provided that such busses are able to provide the

services of Real_Time Protocols. However, this part of IEC 61375 is focused on MVB as vehicle bus, even if the

conformance test may apply to other busses, the exact conformance test should be derived upon.

This standard is structured into 7 clauses and 2 annexes.

The clauses and annexes are listed and briefly described in the Table 1.

61375-2 © IEC:2007(E) – 9 –

Table 1 – Document structure

Clause/sections Description

1. General This clause describes the scope of this standard and

introduces basic terms and abbreviations not reported in

IEC 61375-1.

2. Conformance test: approach, This clause is an overview of the methods of TCN

requirements and boundaries implementation verification that are available to the

developer and regulatory personnel.

Supplies information concerning the ICS and IXITpPro-

forma(s).

3. Conformance test of an MVB device This clause covers all tests on MVB devices that are

grouped by classes, from Class 0 up to Class 4. The main

contents are:

the MVB PICS and PIXIT;

the MVB test suites;

the MVB test procedures.

4. Conformance test of a WTB device Contents: All tests on WTB are classified by nodes related

to WTB itself and MVB only. The main contents are:

the WTB PICS and PIXIT;

the WTB test suites;

the WTB test procedures.

5 Conformance test of RTP This clause lists the tests covered in Clauses 3 and 4

fulfilling the real time protocol.

6. Conformance test of a WTB- This clause covers the Physical Layer while the Services

equipped vehicle given by the WTB node are covered by the previous

clauses. Application profiles are covered by other bodies,

like UIC for profile UIC 556.

7 Conformance test of NM Partially covered by Clauses 3 and 4. Remaining parts are

not covered.

Annex A – Test laboratory role and This annex is normative.

client role

Annex B – Test instrumentation and This annex is informative.

dedicated test bed

– 10 – 61375-2 © IEC:2007(E)

ELECTRIC RAILWAY EQUIPMENT –

TRAIN BUS –

Part 2: Train communication network conformance testing

1 General

1.1 Scope

This part of IEC 61375 applies to all equipment and devices implemented according to

IEC 61375-1, i.e. it covers the procedures to be applied to such equipment and devices when

the conformance should be proven.

The applicability of this standard to a TCN implementation allows for individual conformance

checking of the implementation itself and is a pre-requisite for further interoperability checking

between different TCN implementations.

NOTE 1 For a definition of TCN implementation see 1.3.

1.2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60571:Electronic equipment used on rail vehicles

IEC 60807, Rectangular connectors for frequencies below 3 MHz

IEC 61375-1: 2007, Electric railway equipment – Train bus – Part 1: Train communication

network

ISO/IEC 9646-1:1994, Information technology – Open Systems Interconnection – Conformance

testing methodology and framework – Part 1: General concepts (Also available as ITU-T

Recommendation X.290 (1995))

ISO/IEC 9646-7:1994, Information technology – Open Systems Interconnection –Conformance

testing methodology and framework – Part 7: Implementation Conformance Statements (Also

available as ITU-T Recommendation X.296 (1995))

UIC 556, Information transmission in trains (train bus)

1.3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO/IEC 9646-1 and

IEC 61375-1 apply.

2 Conformance test: approach, requirements and boundaries

2.1 The approach

This standard specifies a general methodology for testing the conformance to the TCN

protocol standard of products in which the standard is claimed to be implemented.

This standard is organised into clauses structured into different phases of the conformance

testing process, these phases being characterised by the following roles:

61375-2 © IEC:2007(E) – 11 –

a) the specification of abstract test suites for particular TCN protocols according to ISO/IEC

9646-1;

b) the derivation of executable test suites and associated testing tools according to ISO/IEC

9646-7;

Annex A specifies the rules on clients and laboratory specifying:

c) the role of a client of a test laboratory, having an implementation of TCN protocols to be

tested;

d) the operation of conformance testing, culminating in the production of a conformance test

report which gives the results in terms of the test suite(s) used and the relevant

documentation produced.

In all clauses of this standard, the scope is limited in order to meet the following objectives:

e) to achieve an adequate level of confidence in the tests as a guide to conformance;

f) to achieve comparability between the results of the corresponding tests applied in different

places at different times;

g) to facilitate communication between the parties responsible for the roles described above.

Each objective involves the framework for development of TCN test suites, as listed

hereinafter:

h) how they should relate to the various types of conformance requirement;

i) the types of test to be standardised and the types not needing standardisation;

j) the criteria for selecting tests for inclusion in a conformance test suite;

k) the notation to be used for defining tests;

l) the structure of a test suite.

Certification, an administrative procedure which may follow conformance testing, is outside the

scope of this standard.

Requirements for procurement and contracts are outside the scope of this standard.

2.1.1 Requirements

2.1.1.1 General

In the context of TCN, a real system is said to exhibit conformance if it complies with the

requirements of applicable TCN standard clauses in its communication with a reference

system, i.e. the tester.

A TCN standard is a set of interrelated clauses which, together, define behaviour of TCN

systems in their communication. Conformance of an IUT will, therefore, be expressed at two

levels, conformance to each individual clause, and conformance to the set of clauses.

The following clauses define the conformance requirements and classify them according to

attributes and into feasible groups. Attributes and grouping are defined from the general point

of view with reference to a TCN specification itself and from the IUT point of view. In the

second case, the requirement shall be declared in the appropriate PICS and PIXIT.

2.1.1.2 Conformance requirements

The conformance requirements can be:

a) mandatory requirements: these are to be observed in all cases;

b) conditional requirements: these are to be observed if the conditions, set out in the clause,

apply;

– 12 – 61375-2 © IEC:2007(E)

c) options: these can be selected to suit the implementation, provided that any requirements

applicable to the option are observed.

TCN essential functionality are mandatory requirements; additional functionality can be either

conditional or optional requirements.

Furthermore, conformance requirements in a Part can be stated:

d) positively: they state what shall be done;

e) negatively (prohibitions): they state what shall not be done.

Finally, conformance requirements fall into two groups:

f) static conformance requirements;

g) dynamic conformance requirements;

these are discussed in 2.1.1.3 and 2.1.1.4, respectively.

2.1.1.3 Static conformance requirements

To facilitate interoperability static conformance requirements define the allowed minimum

capabilities of an implementation. These requirements may be at a broad level, such as the

grouping of functional units and options into protocol classes, or at a detailed level, such as a

range of values that have to be supported for specific parameters of timers.

Static conformance requirements and options in TCN parts can be of two varieties:

a) those which determine the capabilities to be included in the implementation of the

particular protocol;

b) those which determine multi-layer dependencies, for example those which place

constraints on the capabilities of the underlying layers of the system in which the protocol

implementation resides. These are likely to be found in upper layer parts (e.g. network

management vs real time protocols).

All capabilities not explicitly stated as static conformance requirements are to be regarded as

optional.

2.1.1.4 Dynamic conformance requirements

Dynamic conformance requirements are all those requirements (and options) which determine

what observable behaviour is permitted by the relevant TCN part in instances of

communication. They form the bulk of each TCN protocol document. They define the set of

allowable behaviours of an implementation or real system. This set defines the maximum

capability that a conforming implementation or real system can have within the terms of the

TCN protocol document.

A system exhibits dynamic conformance in an instance of communication if its behaviour is a

member of the set of all behaviours permitted by the relevant TCN protocol part in a way which

is consistent with the PICS.

2.1.1.4.1 A conforming system

A conforming system or implementation is one which is shown to satisfy both static and

dynamic conformance requirements, consistent with the capabilities stated in the PICS, for

each protocol declared in the system conformance statement.

2.1.1.4.2 Interoperability and conformance

The primary purpose of conformance testing is to increase the probability that different

implementations are able to inter-operate.

61375-2 © IEC:2007(E) – 13 –

Successful interoperability of two or more real open systems is more likely to be achieved if

they all conform to the same subset of a TCN part, or to the same selection of TCN parts, than

if they do not.

To prepare two or more systems to successfully inter-operate, it is recommended that a

comparison is made of the system conformance statements and PICSs of these systems.

If there is more than one version of a relevant TCN part indicated in the PICSs, the differences

between the versions need to be identified and their implications for consideration, including

their use in combination with other parts.

While conformance is a necessary condition, it is not on its own a sufficient condition to

guarantee interoperability capability. Even if two implementations conform to the same TCN

protocol part, they may fail to interoperate because of factors outside the scope of this

standard.

Trial interoperability is recommended to detect these factors. Further information to assist

interoperability between two systems can be obtained by extending the PICS comparison to

other relevant information, including test reports and PIXIT. The comparison can focus on:

a) additional mechanisms claimed to work around known ambiguities or deficiencies not yet

corrected in the TCN standard or in peer real systems, for example solution of multi-layer

problems;

b) selection of free options which are not taken into account in the static conformance

requirements of the TCN parts;

c) the existence of timers not specified in the TCN parts and their associated values.

NOTE The comparison can be made between two individual systems, between two or more types of product, or,

for the PICS comparison only, between two or more specifications for procurement, permissions to connect, etc.

2.1.2 Requirements declaration statements for an IUT

2.1.2.1 Protocol implementation conformance statement (PICS)

To evaluate the conformance of a particular implementation, it is necessary to have a

statement of the capabilities and options which have been implemented, and any features

which have been omitted, so that the implementation can be tested for conformance against

relevant requirements, and against those requirements only. Such a statement is called a

Protocol Implementation Conformance Statement (PICS).

In a PICS there should be a distinction between the following categories of information which it

may contain:

a) information related to the mandatory, optional and conditional static conformance

requirements of the protocol itself;

b) information related to the mandatory, optional and conditional static conformance

requirements for multi-layer dependencies.

If a set of interrelated TCN protocol has been implemented in a system, a PICS is needed for

each protocol. A system conformance statement will also be necessary, summarising all

protocols in the system for each of which a distinct PICS is provided.

2.1.2.2 Protocol implementation extra information for testing (PIXIT)

In order to test a protocol implementation, the test laboratory will require information relating to

the IUT and its testing environment in addition to that provided by the PICS. This "Protocol

– 14 – 61375-2 © IEC:2007(E)

Implementation eXtra Information for Testing" (PIXIT) will be provided by the client submitting

the implementation for testing, as a result of consultation with the test laboratory.

The PIXIT may contain the following information:

a) information needed by the test laboratory in order to be able to run the appropriate test

suite on the specific system (e.g. information related to the test method to be used to run

the test cases, addressing information);

b) information already mentioned in the PICS and which needs to be made precise (e.g. a

timer value range which is declared as a parameter in the PICS should be specified in the

PIXIT);

c) information to help determine which capabilities stated in the PICS as being supported are

testable and which are untestable;

d) other administrative matters (e.g. the IUT identifier, reference to the related PICS).

The PIXIT should not conflict with the appropriate PICS.

The abstract test suite specifier, test implementor and test laboratory will all contribute to the

development of the PIXIT pro-forma.

2.2 Boundaries

2.2.1 General

Conformance testing as discussed in this standard is focused on testing for conformance to

TCN clauses as they are specified in IEC 61375-1 (second edition).

In principle, the objective of conformance testing is to establish whether the implementation

being tested conforms to the specification in the relevant clause. Practical limitations make it

impossible to be exhaustive, and economic considerations may restrict testing still further.

Therefore, this standard distinguishes four types of testing, according to the extent to which

they provide an indication of conformance:

a) basic interconnection tests, which provide prima facie evidence that an IUT conforms;

b) capability tests, which check that the observable capabilities of the IUT are in accordance

with the static conformance requirements and the capabilities claimed in the PICS;

c) behaviour tests, which endeavour to provide testing which is as comprehensive as possible

over the full range of dynamic conformance requirements within the capabilities of the IUT;

d) conformance resolution tests, which probe in depth the conformance of an IUT to particular

requirements, to provide a definite yes/no answer and diagnostic information in relation to

specific conformance issues; such tests are not covered by this standard.

Tests a), b), c) and d) are foreseen in A.6.3 of IEC 61375-1, and are described in detail by the

following subclauses.

Relations to interoperability and performance are hereinafter considered and defined to clarify

their boundaries.

2.2.2 Basic interconnection tests

Basic interconnection tests provide limited testing of an IUT to establish that there is sufficient

conformance for interconnection to be possible, without trying to perform thorough testing.

2.2.2.1 Applicability of basic interconnection tests

Basic interconnection tests are appropriate:

61375-2 © IEC:2007(E) – 15 –

a) for detecting severe cases of non-conformance;

b) as a preliminary filter before undertaking more costly tests;

c) to give a prima facie indication that an implementation which has passed full conformance

tests in one environment still conforms in a new environment (e.g. before testing an (N)-

implementation, to check that a tested (N – 1)-implementation has not undergone any

severe change due to being linked to the (N)-implementation);

d) for use by users of implementations, to determine whether the implementations appear to

be usable for communication with other conforming implementations, for example as a

preliminary to data interchange.

Basic interconnection tests are inappropriate:

e) as a basis for claims of conformance by the supplier of an implementation;

f) as a means of arbitration to determine causes for communications failure.

Basic interconnection tests are standardised a subset of a conformance test suite (including

capability and behaviour tests). They can be used on their own or together with a conformance

test suite. The existence and execution of basic interconnection tests are optional.

2.2.3 Capability tests

Capability tests provide limited testing of each of the static conformance requirements in a

Part, to ascertain what capabilities of the IUT can be observed and to check that those

observable capabilities are valid with respect to the static conformance requirements and the

PICS.

2.2.3.1 Applicability of capability tests

Capability tests are appropriate:

a) to check as far as possible the consistency of the PICS with the IUT;

b) as a preliminary filter before undertaking more in-depth and costly testing;

c) to check that the capabilities of the IUT are consistent with the static conformance

requirements;

d) to enable efficient selection of behaviour tests to be made for a particular IUT;

e) when taken together with behaviour tests, as a basis for claims of conformance.

Capability tests are inappropriate:

f) on their own, as a basis for claims of conformance by the supplier of an implementation;

g) for testing in detail the behaviour associated with each capability which has been

implemented or not implemented;

h) for resolution of problems experienced during live usage or where other tests indicate

possible non-conformance even though the capability tests have been satisfied.

Capability tests are standardised within a conformance test suite. They can either be

separated into their own test group(s) or merged with the behaviour tests.

2.2.4 Behaviour tests

Behaviour tests test an implementation as thoroughly as is practical, over the full range of

dynamic conformance requirements specified in a Part. Since the number of possible

combinations of events and timing of events is infinite, such testing cannot be exhaustive.

There is a further limitation, namely that these tests are designed to be run collectively in a

single test environment, so that any faults which are difficult or impossible to detect in that

environment are likely to be missed. Therefore, it is possible that a non-conforming

implementation passes the conformance test suite; one aim of the test suite design is to

minimise the number of times that this occurs.

– 16 – 61375-2 © IEC:2007(E)

Behaviour tests with capability tests are the basis for the conformance assessment process.

Behaviour tests are inappropriate:

a) for resolution of problems experienced during live usage or where other tests indicate

possible non-conformance even though the behaviour tests have been satisfied.

Behaviour tests are standardised as the bulk of a conformance test suite.

NOTE Behaviour tests include tests for valid behaviour by the IUT in response to valid, inopportune and

syntactically invalid protocol behaviour by the real tester. This includes testing the rejection by the IUT of attempts

to use features (capabilities) which are stated in the PICS as being not implemented. Thus, capability tests do not

need to include tests for capabilities omitted from the PICS.

2.2.5 Conformance resolution tests

Conformance resolution tests provide diagnostic answers, as near to definitive as possible, to

the resolution of whether an implementation satisfi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...