IEC 60404-10:2016

(Main)Magnetic materials - Part 10: Methods of measurement of magnetic properties of electrical steel strip and sheet at medium frequencies

Magnetic materials - Part 10: Methods of measurement of magnetic properties of electrical steel strip and sheet at medium frequencies

IEC 60404-10:2016(E) is applicable to grain-oriented and non-oriented electrical steel strip and sheet for measurements of a.c. magnetic properties in the frequency range 400 Hz to 10 000 Hz. The object of this document is to define the general principles and the technical details of the measurement of magnetic properties of electrical steel strip and sheet by means of an Epstein frame. This edition includes the following significant technical changes with respect to the previous edition:

a) adaption to modern measurement and evaluation methods, in particular the introduction of the widely spread digital sampling method for the acquisition and evaluation of the measured data;

b) introduction of formal changes which adapt this standard to other standards of the 60404 series;

c) revision of the problem of the air flux compensation taking account of the condition of the higher frequencies;

d) revision of the capacitive coupling of mutual inductor windings together with the consideration of the alternative method of numerical air flux compensation.

The contents of the corrigendum of March 2018 have been included in this copy.

General Information

- Status

- Published

- Publication Date

- 23-Oct-2016

- Technical Committee

- TC 68 - Magnetic alloys and steels

- Drafting Committee

- WG 2 - TC 68/WG 2

- Current Stage

- PPUB - Publication issued

- Start Date

- 24-Oct-2016

- Completion Date

- 31-Dec-2016

Relations

- Effective Date

- 10-Feb-2026

- Effective Date

- 05-Sep-2023

Overview

IEC 60404-10:2016 - Magnetic materials - Part 10 - specifies methods for measuring a.c. magnetic properties of grain‑oriented and non‑oriented electrical steel strip and sheet in the medium frequency range (400 Hz to 10 000 Hz). The standard defines the general principles, apparatus and measurement procedures (notably using an Epstein frame) and incorporates modern evaluation techniques. This is Edition 2.0 (2016) and includes the March 2018 corrigendum.

Key topics and technical requirements

- Scope and frequency range: Applies to electrical steel strip and sheet for a.c. magnetic testing at 400 Hz–10 000 Hz.

- Measurement method: Defines the 25 cm Epstein frame method as the principal test arrangement for comparative and standardized measurements of strip/sheet.

- Quantities measured:

- Specific total loss (core loss) at medium frequencies

- Peak magnetic polarization (J)

- r.m.s. value and peak value of magnetic field strength (H)

- Specific apparent power (S)

- Modern measurement adoption:

- Formal introduction of the digital sampling method for data acquisition and evaluation (Annex B), reflecting contemporary instrumentation and numerical processing.

- Guidance on calibration aspects and requirements for digital sampling systems.

- Air flux compensation:

- Revised treatment of air flux compensation to address issues that arise at higher test frequencies.

- Discussion of capacitive coupling in mutual inductor windings and an alternative numerical air flux compensation technique.

- Apparatus and instruments:

- Epstein frame configuration and jointing details

- Voltage measurement options (average and RMS voltmeters, peak voltmeters)

- Current and power measurement circuits (wattmeter methods, mutual inductors)

- Reference components such as resistors and mutual inductors with capacitive coupling considerations

- Accuracy and reproducibility: The standard explains factors affecting final accuracy and provides reproducibility guidance where agreed by the technical committee.

Practical applications and users

Who uses IEC 60404-10:

- Magnetics and electrical steel manufacturers for product characterization and quality control

- Test laboratories and certification bodies performing standardized core‑loss and magnetic property testing

- Design engineers in power electronics, transformers, motors and inductors who need material data at medium frequencies

- R&D teams developing new electrical steels and magnetic alloys

Practical value:

- Ensures comparable, repeatable measurements across suppliers and labs

- Supports selection of electrical steel for medium‑frequency applications (e.g., high switching‑frequency transformers, EMI components)

- Enables modernization of test setups by adopting digital sampling and numerical compensation techniques

Related standards

- Other parts of the IEC 60404 series (Magnetic materials) - consult the IEC catalogue for related measurement methods and terminology.

- Check for the latest edition, corrigenda and national adoptions to ensure compliance with current requirements.

IEC 60404-10:2016 - Magnetic materials - Part 10: Methods of measurement of magnetic properties of electrical steel strip and sheet at medium frequencies

REDLINE IEC 60404-10:2016 - Magnetic materials - Part 10: Methods of measurement of magnetic properties of electrical steel strip and sheet at medium frequencies Released:10/24/2016 Isbn:9782832237250

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60404-10:2016 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Magnetic materials - Part 10: Methods of measurement of magnetic properties of electrical steel strip and sheet at medium frequencies". This standard covers: IEC 60404-10:2016(E) is applicable to grain-oriented and non-oriented electrical steel strip and sheet for measurements of a.c. magnetic properties in the frequency range 400 Hz to 10 000 Hz. The object of this document is to define the general principles and the technical details of the measurement of magnetic properties of electrical steel strip and sheet by means of an Epstein frame. This edition includes the following significant technical changes with respect to the previous edition: a) adaption to modern measurement and evaluation methods, in particular the introduction of the widely spread digital sampling method for the acquisition and evaluation of the measured data; b) introduction of formal changes which adapt this standard to other standards of the 60404 series; c) revision of the problem of the air flux compensation taking account of the condition of the higher frequencies; d) revision of the capacitive coupling of mutual inductor windings together with the consideration of the alternative method of numerical air flux compensation. The contents of the corrigendum of March 2018 have been included in this copy.

IEC 60404-10:2016(E) is applicable to grain-oriented and non-oriented electrical steel strip and sheet for measurements of a.c. magnetic properties in the frequency range 400 Hz to 10 000 Hz. The object of this document is to define the general principles and the technical details of the measurement of magnetic properties of electrical steel strip and sheet by means of an Epstein frame. This edition includes the following significant technical changes with respect to the previous edition: a) adaption to modern measurement and evaluation methods, in particular the introduction of the widely spread digital sampling method for the acquisition and evaluation of the measured data; b) introduction of formal changes which adapt this standard to other standards of the 60404 series; c) revision of the problem of the air flux compensation taking account of the condition of the higher frequencies; d) revision of the capacitive coupling of mutual inductor windings together with the consideration of the alternative method of numerical air flux compensation. The contents of the corrigendum of March 2018 have been included in this copy.

IEC 60404-10:2016 is classified under the following ICS (International Classification for Standards) categories: 29.030 - Magnetic materials. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60404-10:2016 has the following relationships with other standards: It is inter standard links to EN 60404-1:2017, IEC 60404-10:2016/COR1:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60404-10:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60404-10 ®

Edition 2.0 2016-10

INTERNATIONAL

STANDARD

Magnetic materials –

Part 10: Methods of measurement of magnetic properties of electrical steel strip

and sheet at medium frequencies

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC 60404-10 ®

Edition 2.0 2016-10

INTERNATIONAL

STANDARD

Magnetic materials –

Part 10: Methods of measurement of magnetic properties of electrical steel strip

and sheet at medium frequencies

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.030 ISBN 978-2-8322-3672-7

– 2 – IEC 60404-10:2016 © IEC 2016

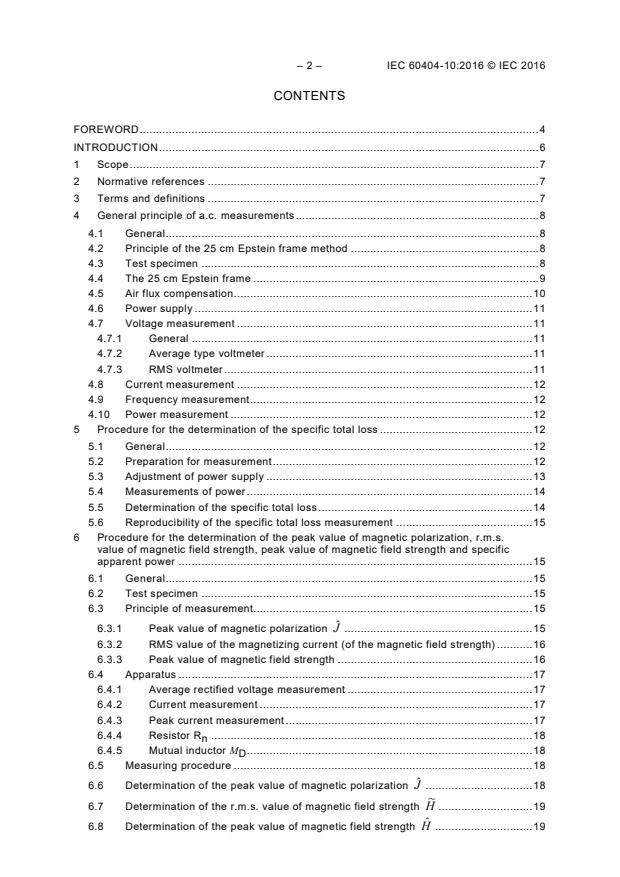

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 General principle of a.c. measurements . 8

4.1 General . 8

4.2 Principle of the 25 cm Epstein frame method . 8

4.3 Test specimen . 8

4.4 The 25 cm Epstein frame . 9

4.5 Air flux compensation . 10

4.6 Power supply . 11

4.7 Voltage measurement . 11

4.7.1 General . 11

4.7.2 Average type voltmeter . 11

4.7.3 RMS voltmeter . 11

4.8 Current measurement . 12

4.9 Frequency measurement . 12

4.10 Power measurement . 12

5 Procedure for the determination of the specific total loss . 12

5.1 General . 12

5.2 Preparation for measurement . 12

5.3 Adjustment of power supply . 13

5.4 Measurements of power . 14

5.5 Determination of the specific total loss . 14

5.6 Reproducibility of the specific total loss measurement . 15

6 Procedure for the determination of the peak value of magnetic polarization, r.m.s.

value of magnetic field strength, peak value of magnetic field strength and specific

apparent power . 15

6.1 General . 15

6.2 Test specimen . 15

6.3 Principle of measurement. 15

ˆ

6.3.1 Peak value of magnetic polarization J . 15

6.3.2 RMS value of the magnetizing current (of the magnetic field strength) . 16

6.3.3 Peak value of magnetic field strength . 16

6.4 Apparatus . 17

6.4.1 Average rectified voltage measurement . 17

6.4.2 Current measurement . 17

6.4.3 Peak current measurement . 17

6.4.4 Resistor R . 18

n

6.4.5 Mutual inductor M . 18

D

6.5 Measuring procedure . 18

ˆ

6.6 Determination of the peak value of magnetic polarization J . 18

~

6.7 Determination of the r.m.s. value of magnetic field strength H . 19

ˆ

6.8 Determination of the peak value of magnetic field strength H . 19

6.9 Determination of the specific apparent power S . 20

s

6.10 Reproducibility . 21

7 Test report . 21

Annex A (informative) Epstein frame for use at medium frequencies . 22

Annex B (informative) Digital sampling method for the determination of the magnetic

properties . 23

B.1 General . 23

B.2 Technical details and requirements . 23

B.3 Calibration aspects . 25

B.4 Numerical air flux compensation . 26

Bibliography . 27

Figure 1 – Double-lapped joints . 8

Figure 2 – The 25 cm Epstein frame . 9

Figure 3 – Circuit for the wattmeter method . 13

Figure 4 – Circuit for measuring r.m.s. value of the magnetizing current . 16

Figure 5 – Circuit for measuring the peak value of magnetic field strength using a peak

voltmeter . 16

Figure 6 – Circuit for measuring the peak value of magnetic field strength using a

mutual inductor M . 17

– 4 – IEC 60404-10:2016 © IEC 2016

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MAGNETIC MATERIALS –

Part 10: Methods of measurement of magnetic properties

of electrical steel strip and sheet at medium frequencies

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60404-10 has been prepared by IEC technical committee 68:

Magnetic alloys and steels.

This second edition cancels and replaces the first edition published in 1988. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) adaption to modern measurement and evaluation methods, in particular the introduction of

the widely spread digital sampling method for the acquisition and evaluation of the

measured data;

b) introduction of formal changes which adapt this standard to other standards of the 60404

series;

c) revision of the problem of the air flux compensation taking account of the condition of the

higher frequencies;

d) revision of the capacitive coupling of mutual inductor windings together with the

consideration of the alternative method of numerical air flux compensation.

The text of this standard is based on the following documents:

CDV Report of voting

68/523/CDV 68/556/RVC

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60404 series, published under the general title Magnetic materials,

can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

The contents of the corrigendum of March 2018 have been included in this copy.

– 6 – IEC 60404-10:2016 © IEC 2016

INTRODUCTION

Besides the fact that the first edition of this part of IEC 60404 is more than 25 years old, the

main purpose of this revision is to adapt it to modern measurement and evaluation methods,

in particular to introduce the widely spread digital sampling method for the acquisition and

evaluation of the measured data.

In addition, the problem of the air flux compensation had to be re-considered under the

condition of the elevated frequencies. Capacitive coupling of mutual inductor windings require

observance of significant phase shift influence and suggest consideration of the alternative

method of numerical air flux compensation. An increase of the frequency range to 20 kHz was

discussed by TC 68 since some manufacturers of electrical steel include this range in their

catalogues. However, TC 68 decided to keep the frequency range to that defined in

IEC 60404-10:1988: 400 Hz to 10 kHz.

MAGNETIC MATERIALS –

Part 10: Methods of measurement of magnetic properties

of electrical steel strip and sheet at medium frequencies

1 Scope

This part of IEC 60404 is applicable to grain-oriented and non-oriented electrical steel strip

and sheet for measurements of a.c. magnetic properties in the frequency range 400 Hz to

10 000 Hz.

The object of this document is to define the general principles and the technical details of the

measurement of magnetic properties of electrical steel strip and sheet by means of an Epstein

frame.

The Epstein frame is applicable to test specimens obtained from electrical steel strips and

sheets of any grade. The AC magnetic characteristics are determined for sinusoidal induced

voltages, for specified peak values of magnetic polarization and for a specified frequency.

The measurements are to be made at an ambient temperature of (23 ± 5)°C on test

specimens which have first been demagnetized.

NOTE Throughout this document the term "magnetic polarization" is used as defined in IEC 60050-221. In some

standards of the IEC 60404 series, the term "magnetic flux density" was used.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60050-121, International Electrotechnical Vocabulary – Part 121: Electromagnetism

IEC 60050-221, International Electrotechnical Vocabulary – Chapter 221: Magnetic materials

and components

IEC 60404-8 (all parts), Magnetic materials – Part 8: Specifications for individual materials

IEC 60404-13, Magnetic materials – Part 13: Methods of measurement of density, resistivity

and stacking factor of electrical steel sheet and strip

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-221 and

IEC 60050-121 apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

– 8 – IEC 60404-10:2016 © IEC 2016

4 General principle of a.c. measurements

4.1 General

Clause 4 specifies the general conditions for the determination of a.c.magnetic properties of

electrical steel strip and sheet by means of the 25 cm Epstein frame.

4.2 Principle of the 25 cm Epstein frame method

The 25 cm Epstein frame, which comprises a primary winding, a secondary winding and the

specimen to be tested as a core, forms an unloaded transformer whose characteristics are

measured by the method described in the following subclauses 4.3 to 4.10.

At the higher end of the frequency range, a specially constructed Epstein frame (see Annex A)

may be required in which the interwinding capacitances are low, so that the capacitive part of

the impedance has a negligible impact on the loss results. The material of the winding formers

supporting the windings has a low dielectric loss.

A separate measuring system (for example a commercially available digital bridge capable of

measuring resistance, capacitance and inductance) is required to determine the inter-winding

capacitance of the Epstein frame.

4.3 Test specimen

The strips to be tested are assembled in a square, having double-overlapped corner joints

(see Figure 1) thus forming four limbs of equal length and equal cross-sectional area.

IEC

Figure 1 – Double-lapped joints

The strips shall be sampled in accordance with the appropriate product standard in the

IEC 60404-8 series.

They shall be cut by a method which will produce substantially burr-free edges and, if so

specified, heat treated in accordance with the corresponding product standard. They shall

have the following dimensions:

– width b = 30 mm ± 0,2 mm;

– length 280 mm ≤ l ≤ 320 mm.

The length of the strips shall be equal within a tolerance of ± 0,5 mm.

When the strips are cut parallel or normal to the direction of rolling, the edge of the parent

sheet shall be taken as the reference direction.

The following tolerances shall apply for the angle between the specified and actual direction

of cutting:

– ± 1° for grain-oriented steel sheet;

– ± 5° for non-oriented steel sheet.

Only flat strips shall be used. Measurements shall be made without additional insulation.

The number of strips comprising the test specimen shall be not less than twelve and shall be

a multiple of four. A force of (1 ± 0,1) N shall be applied to each corner, normal to the plane of

the overlapping strips.

4.4 The 25 cm Epstein frame

The 25 cm Epstein frame (hereinafter referred to as the Epstein frame) shall consist of four

solenoids into which the test specimen strips are inserted in such a manner that a closed

magnetic circuit is formed (see Figure 2).

Dimensions in millimetres

+1

220 0

≥190

l = 940

IEC

Figure 2 – The 25 cm Epstein frame

If measurements are to be made under the conditions specified in 4.5, a mutual inductor for

air flux compensation may be provided.

The winding formers supporting the windings shall be made of hard insulating material of low

dielectric loss, such as polystyrene. They have a rectangular cross-section with 32 mm inner

width. A height of approximately 5 mm is recommended.

The solenoids shall be fixed to an insulating and non-magnetic base in such a way to form a

square (see Figure 2). The length of the sides of the square formed by the internal edges of

+

the strips of the test specimen shall be 220 mm (see Figure 2).

In order to avoid undue wear of the winding formers and especially of their inner surfaces,

winding formers of larger cross-section can be used into which replaceable liners of

appropriate dimensions may be inserted.

Each of the four solenoids shall have two windings:

– 10 – IEC 60404-10:2016 © IEC 2016

– a primary winding, on the outside (magnetizing winding);

– a secondary winding, on the inside (voltage winding).

The windings shall be distributed uniformly over a minimum length of 190 mm, each solenoid

having one quarter of the total number of turns.

The individual primary windings of the four solenoids shall be connected in series, and the

individual secondary windings shall be connected in a similar fashion.

At the higher end of the frequency range, the loss contribution due to the capacitance

between the primary and secondary windings and also the self-capacitance of the secondary

winding could be significant. The windings shall be spaced to minimize this loss.

The capacitance between the windings and the self-capacitance of the secondary winding

shall be measured. If necessary, a correction shall be applied for the loss introduced.

The number of turns of primary and secondary windings shall be chosen to suit the particular

conditions of the power supply, measuring equipment and frequency.

A total number of 200 turns for each of the primary and secondary windings is recommended

and is commonly used for tests in the frequency range 400 Hz to 10 000 Hz.

The impedance of the magnetizing windings shall be sufficiently small to avoid waveform

distortion and minimize internal voltage drops.

The effective magnetic path length, l , of the magnetic circuit shall be conventionally

m

assumed to be equal to 0,94 m.

The active mass, m , i.e. the magnetically active mass of the test specimen, is given by:

a

l

m

m = m (1)

a

4l

where:

m is the magnetically active mass of test specimen, in kilograms;

a

m is the mass of test specimen, in kilograms;

l is the conventional effective magnetic path length, in metres (l = 0,94 m);

m m

l is the length of a test specimen strip, in metres.

4.5 Air flux compensation

A compensation for air flux shall be made for magnetic field strengths greater than or equal to

1 000 A/m. At the lower end of the frequency range (less than or equal to 1 000 Hz) a mutual

inductor may be used to compensate for the air flux.

The primary winding of the mutual inductor shall be connected in series with the primary

winding of the Epstein frame, and the secondary winding of the mutual inductor shall be

connected to the secondary winding of the Epstein frame in series opposition (see Figure 3).

An adjustment of the value of the mutual inductance shall be made so that, when passing an

alternating current through the combined primary windings in the absence of the specimen in

the apparatus, the voltage measured between the non-common terminals of the combined

secondary windings shall be no more than 0,1 % of the voltage appearing across the

secondary winding of the test apparatus alone.

Thus the average rectified value of the voltage induced in the combined secondary windings

is proportional to the peak value of the magnetic polarization in the test specimen.

At the higher end of the frequency range, coupling through interwinding capacitances of the

mutual inductor can lead to a significant phase shift of the secondary induced voltage

followed by a relevant error in the measurement of the magnetic loss value. It has to be

ensured that the mutual inductance does not lead to a significant phase shift of the secondary

induced voltage. Appropriate design of the secondary winding of the mutual inductor, i.e.

larger distances between the windings, can avoid the phase shift. If, at the higher end of the

frequency range, a relevant phase shift cannot be avoided in this way, the mutual inductor

shall be removed from the measurement circuit and numerical air flux compensation shall be

applied (see Clause B.4).

4.6 Power supply

The power supply shall have a low internal impedance and a high stability of voltage and

frequency. During the measurement, the voltage and frequency variations shall not exceed

± 0,2 % of the required value.

For the determination of the specific total loss, the specific apparent power and r.m.s. value of

the magnetic field strength, the form factor of the secondary induced voltage shall be

1,111 within ± 1 %.

NOTE This is possible in several ways; for example by using an electrically controlled power supply or a negative

feedback power amplifier.

The form factor of the secondary induced voltage is the ratio of its r.m.s. value to its average

rectified value. Two voltmeters, one responsive to r.m.s. values and the other responsive to

average rectified values shall be used to determine the form factor.

When a negative feedback amplifier is used for the supply, it may be necessary to observe

the waveform of the secondary induced voltage on an oscilloscope to ensure that the correct

waveform of the fundamental frequency is being produced.

4.7 Voltage measurement

4.7.1 General

The secondary induced voltage shall be measured by means of appropriate voltmeters having

an input impedance greater than or equal to 1 000 Ω/V.

NOTE For the application of digital sampling methods, see Annex B.

4.7.2 Average type voltmeter

A voltmeter responsive to average rectified values having an accuracy of ± 0,5 % or better

shall be used.

NOTE 1 Instruments of this type are usually graduated in average rectified value multiplied by 1,111.

The load on the secondary circuit of the network shall be as small as possible. Consequently,

the internal resistance of the average type voltmeter shall be at least 1 000 Ω/V.

NOTE 2 The preferred instrument is a digital voltmeter.

4.7.3 RMS voltmeter

A voltmeter responsive to r.m.s. values having an accuracy of ± 0,5 % or better shall be used.

NOTE The preferred instrument is a digital voltmeter.

– 12 – IEC 60404-10:2016 © IEC 2016

4.8 Current measurement

The magnetizing current shall be measured by either:

– an ammeter having an accuracy ± 0,5 % or better of low impedance;

or

– measuring the voltage drop across a non-inductive precision resistor connected in series

with the primary winding. The combined uncertainties of the resistor and the voltmeter

shall not exceed 1 %.

The current measuring device shall be short-circuited when the secondary induced voltage

has been adjusted and the loss is being measured.

NOTE 1 The preferred instrument is a digital ammeter or a digital voltmeter.

NOTE 2 For the application of digital sampling methods, see Annex B.

4.9 Frequency measurement

A frequency meter having an accuracy ± 0,1 % or better shall be used.

NOTE For the application of digital sampling methods, see Annex B.

4.10 Power measurement

The power shall be measured by a wattmeter having an accuracy of ± 0,5 % or better at the

frequency, power factor, and crest factor to be used. Readings in the first quarter of the scale

shall be avoided as far as possible.

NOTE For the application of digital sampling methods, see Annex B.

The resistance of the voltage circuit of the wattmeter shall be at least 100 Ω/V for all ranges.

If necessary the losses in the secondary circuit shall be subtracted from the indicated loss

value.

Moreover, the ohmic resistance of the voltage circuit of the wattmeter shall be at least 5 000

times its reactance, unless the wattmeter is compensated for its reactance, to avoid

necessary corrections of phase angle.

5 Procedure for the determination of the specific total loss

5.1 General

Clause 5 describes the wattmeter method for the determination of the specific total loss of

electrical steel strip and sheet at frequencies in the range 400 Hz to 10 000 Hz.

The specific total loss is determined, according to this method, for specified peak values of

magnetic polarization and for a spe

...

IEC 60404-10 ®

Edition 2.0 2016-10

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Magnetic materials –

Part 10: Methods of measurement of magnetic properties of magnetic electrical

steel strip and sheet at medium frequencies

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC 60404-10 ®

Edition 2.0 2016-10

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Magnetic materials –

Part 10: Methods of measurement of magnetic properties of magnetic electrical

steel strip and sheet at medium frequencies

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.030 ISBN 978-2-8322-3725-0

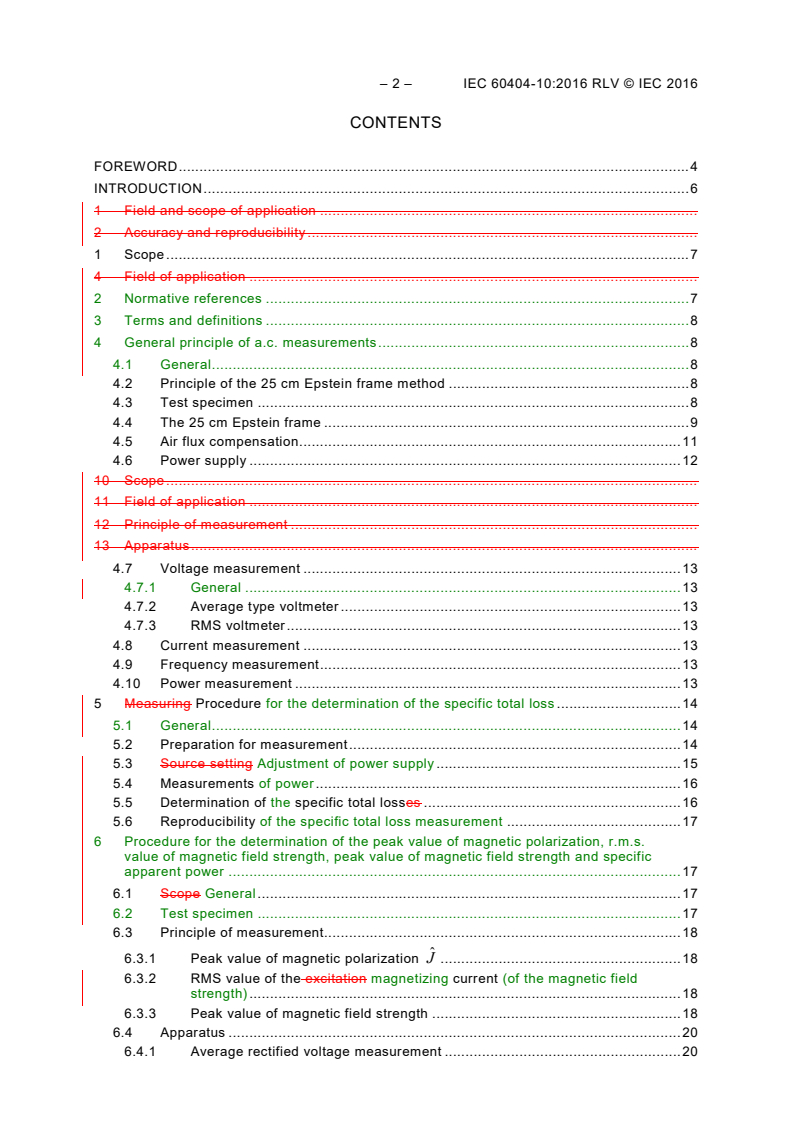

– 2 – IEC 60404-10:2016 RLV © IEC 2016

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Field and scope of application .

2 Accuracy and reproducibility .

1 Scope . 7

4 Field of application .

2 Normative references . 7

3 Terms and definitions . 8

4 General principle of a.c. measurements . 8

4.1 General . 8

4.2 Principle of the 25 cm Epstein frame method . 8

4.3 Test specimen . 8

4.4 The 25 cm Epstein frame . 9

4.5 Air flux compensation . 11

4.6 Power supply . 12

10 Scope .

11 Field of application .

12 Principle of measurement .

13 Apparatus .

4.7 Voltage measurement . 13

4.7.1 General . 13

4.7.2 Average type voltmeter . 13

4.7.3 RMS voltmeter . 13

4.8 Current measurement . 13

4.9 Frequency measurement . 13

4.10 Power measurement . 13

5 Measuring Procedure for the determination of the specific total loss . 14

5.1 General . 14

5.2 Preparation for measurement . 14

5.3 Source setting Adjustment of power supply . 15

5.4 Measurements of power . 16

5.5 Determination of the specific total losses . 16

5.6 Reproducibility of the specific total loss measurement . 17

6 Procedure for the determination of the peak value of magnetic polarization, r.m.s.

value of magnetic field strength, peak value of magnetic field strength and specific

apparent power . 17

6.1 Scope General . 17

6.2 Test specimen . 17

6.3 Principle of measurement. 18

ˆ

6.3.1 Peak value of magnetic polarization J . 18

6.3.2 RMS value of the excitation magnetizing current (of the magnetic field

strength) . 18

6.3.3 Peak value of magnetic field strength . 18

6.4 Apparatus . 20

6.4.1 Average rectified voltage measurement . 20

6.4.2 Current measurement . 20

6.4.3 Peak current measurement . 20

6.4.4 Resistor R . 20

n

6.4.5 Mutual inductor M . 20

D

6.5 Measuring procedure . 20

21 Determination of characteristics .

ˆ

6.6 Determination of the peak value of magnetic polarization J . 21

~

6.7 Determination of the r.m.s. value of magnetic field strength H . 22

ˆ

6.8 Determination of the peak value of magnetic field strength H . 22

6.9 Determination of the specific apparent power S . 23

s

6.10 Reproducibility . 24

7 Test report . 24

Annex A (informative) Epstein frame for use at medium frequencies . 25

Annex B (informative) Digital sampling method for the determination of the magnetic

properties . 26

B.1 General . 26

B.2 Technical details and requirements . 26

B.3 Calibration aspects . 28

B.4 Numerical air flux compensation . 29

Bibliography . 30

Figure 1 – Double-lapped joints . 8

Figure 2 – The 25 cm Epstein frame . 10

Figure 3 – Circuit for the wattmeter method . 15

Figure 4 – Circuit for measuring r.m.s. value of the excitation magnetizing current . 18

Figure 5 – Circuit for measuring the peak value of magnetic field strength using a peak

voltmeter . 19

Figure 6 – Circuit for measuring the peak value of magnetic field strength using a

mutual inductor M . 19

– 4 – IEC 60404-10:2016 RLV © IEC 2016

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MAGNETIC MATERIALS –

Part 10: Methods of measurement of magnetic properties

of magnetic electrical steel strip and sheet at medium frequencies

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 60404-10 has been prepared by IEC technical committee 68:

Magnetic alloys and steels.

This second edition cancels and replaces the first edition published in 1988. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) adaption to modern measurement and evaluation methods, in particular the introduction of

the widely spread digital sampling method for the acquisition and evaluation of the

measured data;

b) introduction of formal changes which adapt this standard to other standards of the 60404

series;

c) revision of the problem of the air flux compensation taking account of the condition of the

higher frequencies;

d) revision of the capacitive coupling of mutual inductor windings together with the

consideration of the alternative method of numerical air flux compensation.

The text of this standard is based on the following documents:

CDV Report of voting

68/523/CDV 68/556/RVC

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60404 series, published under the general title Magnetic materials,

can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

The contents of the corrigendum of March 2018 have been included in this copy.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

– 6 – IEC 60404-10:2016 RLV © IEC 2016

INTRODUCTION

1 Field and scope of application

This standard is applicable to magnetic steel sheet and strip for the construction of magnetic

circuits for use in the frequency range 400 Hz to 10 000 Hz.

Its object is to define the terminology and to specify the methods for the measurement of

magnetic properties of magnetic steel sheet and strip.

2 Accuracy and reproducibility

The final accuracy of the test apparatus is a complex function dependent on the measuring

instruments and other features of the measuring environment and equipment components;

therefore it is not always possible to state the absolute accuracy which can be attained.

Moreover, experience in the use of a given method indicates the reproducibility which can be

expected. Whenever the drafting Technical Committee has agreed upon reproducibility values,

these have been given in this standard.

Besides the fact that the first edition of this part of IEC 60404 is more than 25 years old, the

main purpose of this revision is to adapt it to modern measurement and evaluation methods,

in particular to introduce the widely spread digital sampling method for the acquisition and

evaluation of the measured data.

In addition, the problem of the air flux compensation had to be re-considered under the

condition of the elevated frequencies. Capacitive coupling of mutual inductor windings require

observance of significant phase shift influence and suggest consideration of the alternative

method of numerical air flux compensation. An increase of the frequency range to 20 kHz was

discussed by TC 68 since some manufacturers of electrical steel include this range in their

catalogues. However, TC 68 decided to keep the frequency range to that defined in

IEC 60404-10:1988: 400 Hz to 10 kHz.

MAGNETIC MATERIALS –

Part 10: Methods of measurement of magnetic properties

of magnetic electrical steel strip and sheet at medium frequencies

CHAPTER I: GENERAL CONDITIONS FOR A.C. MEASUREMENTS

MADE WITH THE 25 CM EPSTEIN FRAME

1 Scope

This chapter specifies the general conditions for the determination of a.c. magnetic properties

of magnetic steel sheet and strip by means of the 25 cm Epstein frame.

This part of IEC 60404 is applicable to grain-oriented and non-oriented electrical steel strip

and sheet for measurements of a.c. magnetic properties in the frequency range 400 Hz to

10 000 Hz.

The object of this document is to define the general principles and the technical details of the

measurement of magnetic properties of electrical steel strip and sheet by means of an Epstein

frame.

4 Field of application

The use of the 25 cm Epstein frame is applicable to flat strip test specimens obtained from

magnetic electrical steel strips and sheets of any quality grade. The AC magnetic properties

characteristics are determined for a sinusoidal induced voltages, for specified peak values of

magnetic polarization and for a specified frequency.

The measurements are to be made at an ambient temperature of (23 ± 5)°C on test

specimens which have first been demagnetized.

NOTE Throughout this document the term "magnetic polarization" is used as defined in IEC 60050-221. In some

standards of the IEC 60404 series, the term "magnetic flux density" was used.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60050-121, International Electrotechnical Vocabulary – Part 121: Electromagnetism

IEC 60050-221, International Electrotechnical Vocabulary – Chapter 221: Magnetic materials

and components

IEC 60404-8 (all parts), Magnetic materials – Part 8: Specifications for individual materials

IEC 60404-13, Magnetic materials – Part 13: Methods of measurement of density, resistivity

and stacking factor of electrical steel sheet and strip

– 8 – IEC 60404-10:2016 RLV © IEC 2016

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-221 and

IEC 60050-121 apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

4 General principle of a.c. measurements

4.1 General

Clause 4 specifies the general conditions for the determination of a.c.magnetic properties of

electrical steel strip and sheet by means of the 25 cm Epstein frame.

4.2 Principle of the 25 cm Epstein frame method

The 25 cm Epstein frame, which comprises a primary winding, a secondary winding and the

specimen to be tested as a core, forms an unloaded transformer whose properties

characteristics are measured by the method described in the following subclauses 4.3 to 4.10.

At the higher end of the frequency range, a specially constructed Epstein frame (see Annex A)

may be required in which the interwinding capacitances are low, so that the capacitive part of

the impedance has a negligible impact on the loss results. The material of the winding formers

supporting the solenoids windings has a low dielectric loss.

A separate measuring system (for example a commercially available universal digital bridge

capable of measuring resistance, capacitance and inductance) is required to determine the

inter-winding capacitance of the Epstein frame.

4.3 Test specimen

The magnetic circuit shall be made up of a core constructed with the strips to be tested,

assembled in a square having double-lapped joints (see Figure 1) to form four branches The

strips to be tested are assembled in a square, having double-overlapped corner joints (see

Figure 1) thus forming four limbs of equal length and equal cross-sectional area.

IEC

Figure 1 – Double-lapped joints

The strips shall be sampled in accordance with the appropriate product standard in the

IEC 60404-8 series.

They shall be cut by a method which will produce clean substantially burr-free edges and, if

so specified, heat treated in accordance with the corresponding product standard. They shall

have the following dimensions:

– width b = 30 mm ± 0,2 mm;

– length 280 mm ≤ l ≤ 500 320 mm

The strips being of the same length of the strips shall be equal within a tolerance of

± 0,5 mm.

For strips of length greater than 305 mm, care shall be taken to avoid bending the strips

during the test.

When the strips are cut parallel or normal to the direction of rolling, the edge of the parent

sheet shall be taken as the reference direction.

The following tolerances shall be allowed apply for the angle between the specified and actual

direction of rolling and that of cutting:

– ± 1° for grain-oriented steel sheet;

– ± 5° for non-oriented steel sheet.

Only flat strips shall be used. Measurements shall be made without additional insulation.

The number of strips forming a comprising the test specimen shall be not less than twelve and

shall be a multiple of four. A force of (1 ± 0,1) N shall be applied to each corner, normal to the

plane of the overlapping strips.

4.4 The 25 cm Epstein frame

The 25 cm Epstein frame (hereinafter referred to as the Epstein frame) shall consist of four

solenoids into which the test specimen strips are introduced inserted in such a manner that a

closed magnetic circuit is formed (see Figure 2).

– 10 – IEC 60404-10:2016 RLV © IEC 2016

Dimensions in millimetres

+1

220 0

≥190

l = 940

IEC

Figure 2 – The 25 cm Epstein frame

If measurements are to be made under the conditions specified in 4.5, a mutual inductor for

air flux compensation shall may be provided.

The winding formers supporting the solenoids windings shall be made of hard insulating

material of low dielectric loss, such as polystyrene. They have a rectangular cross-section

with 32 mm inner width. A height of about approximately 5 mm will be sufficient and is

recommended.

The solenoids shall be mounted on a non-conducting fixed to an insulating and non-magnetic

base plate in a square arrangement in such a way to form a square (see Figure 2). Each side

of the inner square formed by the test specimen strip shall have a length of The length of the

sides of the square formed by the internal edges of the strips of the test specimen shall be

+

220 mm (see Figure 2).

In order to avoid undue wear of the winding formers and especially of their inner surfaces,

winding formers of larger cross-section can be used into which replaceable liners of

appropriate dimensions may be inserted.

Each of the four solenoids comprises shall have two windings:

– a primary winding, on the outside (magnetizing winding);

– a secondary winding, on the inside (voltage winding).

The windings on each solenoid shall be evenly distributed uniformly over a minimum length of

190 mm, each solenoid carrying one-fourth having one quarter of the total number of turns.

The individual primary windings of the four solenoids shall be connected in series, and the

individual secondary windings shall be connected in a similar fashion.

At high frequencies the higher end of the frequency range, the loss contribution due to the

capacitance between the primary and secondary windings and also the self-capacitance of the

secondary winding could be significant. The windings shall be spaced to minimize this loss.

The capacitance between the windings and the self-capacitance of the secondary winding

shall be measured. If necessary, a correction shall be applied for the loss introduced.

The number of turns of primary and secondary windings shall be chosen to suit the particular

conditions of the power supply, instrumentation and measuring equipment and frequency.

A total number of 200 turns for each of the primary and secondary windings is recommended

and is commonly used for tests in the frequency range 400 Hz to 10 000 Hz.

The impedance of the magnetizing windings shall be sufficiently small to avoid waveform

distortion and minimize internal voltage drops.

The effective magnetic path length, l , of the magnetic path circuit in this test equipment is

m

shall be conventionally taken as assumed to be equal to 0,94 m. This value shall be used.

Consequently, The effective active mass, m , i.e. the magnetically active mass of the test

a

specimen, is given by:

l

m

m = m (1)

a

4l

where:

m is the effective magnetically active mass of test specimen, in kilograms;

a

m is the mass of test specimen, in kilograms;

l is the conventional effective magnetic path length, in metres (l = 0,94 m);

m m

l is the length of a test specimen strip, in metres.

4.5 Air flux compensation

A correction compensation for air flux shall be made for magnetic field strengths greater than

or equal to 1 000 A/m. For low frequencies At the lower end of the frequency range (less than

or equal to 1 000 Hz) a mutual inductor may be used to compensate for the air flux.

The mutual inductance of the compensator shall be adjusted to be the same as that of the

windings of the empty Epstein frame. Thus when the windings are properly connected, the

voltage induced in the secondary winding of the mutual inductor by the primary current

compensates for the voltage induced in the secondary winding of the empty Epstein frame by

the flux attributed to the primary current.

The primary winding of the mutual inductor shall be connected in series with the primary

winding of the Epstein frame, and the secondary winding of the mutual inductor shall be

connected to the secondary winding of the Epstein frame in series opposition (see Figure 3).

An adjustment of the value of the mutual inductance shall be made so that, when passing an

alternating current through the combined primary windings in the absence of the specimen in

the apparatus, the voltage measured between the non-common terminals of the combined

secondary windings shall be no more than 0,1 % of the voltage appearing across the

secondary winding of the test apparatus alone.

Thus the average rectified value of the voltage induced in the combined secondary windings

is proportional to the peak value of the magnetic polarization in the test specimen.

At the higher end of the frequency range, coupling through interwinding capacitances of the

mutual inductor can lead to a significant phase shift of the secondary induced voltage

followed by a relevant error in the measurement of the magnetic loss value. It has to be

ensured that the mutual inductance does not lead to a significant phase shift of the secondary

– 12 – IEC 60404-10:2016 RLV © IEC 2016

induced voltage. Appropriate design of the secondary winding of the mutual inductor, i.e.

larger distances between the windings, can avoid the phase shift. If, at the higher end of the

frequency range, a relevant phase shift cannot be avoided in this way, the mutual inductor

shall be removed from the measurement circuit and numerical air flux compensation shall be

applied (see Clause B.4).

4.6 Power supply

The source power supply shall be of have a low internal impedance and shall be highly stable

a high stability of voltage and frequency. During the measurement, the voltage and frequency

variations shall not exceed ± 0,2 % of the specified required value.

For the determination of the specific total loss, the specific apparent power and r.m.s. value of

the magnetic field strength, the form factor of the secondary induced voltage shall be

maintained 1,111 within ± 1 % (this can be achieved by various means, e.g. electronic

feedback amplifiers).

NOTE This is possible in several ways; for example by using an electrically controlled power supply or a negative

feedback power amplifier.

The form factor of the secondary induced voltage is the quotient ratio of the its r.m.s. value

and the to its average rectified value. The former is measured by an r.m.s. voltmeter, such as

a moving iron instrument, and the latter by an average type voltmeter, such as a rectifier-type

instrument. Two voltmeters, one responsive to r.m.s. values and the other responsive to

average rectified values shall be used to determine the form factor.

NOTE When a negative feedback amplifier is used for the supply, it may be necessary to

observe the waveform of the secondary induced voltage on an oscilloscope to ensure that the

correct waveform of the fundamental frequency is being produced.

CHAPTER II: DETERMINATION OF SPECIFIC TOTAL LOSSES

BY THE WATTMETER METHOD

10 Scope

This chapter describes the wattmeter method for the determination of the specific total losses

of magnetic steel sheet and strip at frequencies in the range 400 Hz to 10 000 Hz.

11 Field of application

The specific total losses are determined, according to this method, for specified peak values

of magnetic polarization and for a specified frequency.

In order to obtain comparable results, test values shall be referred to magnetic polarization of

sinusoidal waveform.

NOTE Throughout this publication the term "magnetic polarization" is used as defined in Chapter 901 of the

International Electrotechnical Vocabulary (IEV) [IEC Publication 50(901)]. In some publications of the IEC 404

series, the term "magnetic flux density" has been used.

12 Principle of measurement

The 25 cm Epstein frame with the test specimen represents an unloaded transformer whose

total losses are measured by the wattmeter method in the circuit shown in Figure 3 which

illustrates the principle.

13 Apparatus

4.7 Voltage measurement

4.7.1 General

The secondary induced voltage shall be measured by means of appropriate voltmeters having

an input impedance greater than or equal to 1 000 Ω/V.

NOTE For the application of digital sampling methods, see Annex B.

4.7.2 Average type voltmeter

The average value of the secondary rectified voltage of the Epstein frame shall be measured

with an average type voltmeter of accuracy 0.5% or better, e.g. a rectifier type digital

voltmeter. A voltmeter responsive to average rectified values having an accuracy of ± 0,5 %

or better shall be used.

NOTE 1 Instruments of this type are usually graduated in average rectified value multiplied by 1,111.

The load on the secondary circuit of the network shall be as small as possible. Consequently,

the internal resistance of the average type voltmeter shall be at least 1 000 Ω/V.

NOTE 2 The preferred instrument is a digital voltmeter.

4.7.3 RMS voltmeter

A voltmeter responsive to r.m.s. values having an accuracy of ± 0,5 % or better shall be used.

NOTE e.g. a r.m.s. sensing The preferred instrument is a digital voltmeter.

4.8 Current measurement

The primary magnetizing current may shall be measured by either:

– an class 1 ammeter having an accuracy ± 0,5 % or better of low impedance;

or

– measuring the voltage drop across a non-inductive precision resistor connected in series

with the primary winding. The combined uncertainties of the resistor and the voltmeter shall

not exceed 1 %.

The ammeter and the precision resistor, respectively, current measuring device shall be short-

circuited when the secondary induced voltage is has been adjusted and the losses are is

being measured.

NOTE 1 The preferred instrument is a digital ammeter or a digital voltmeter.

NOTE 2 For the application of digital sampling methods, see Annex B.

4.9 Frequency measurement

A frequency meter having an accuracy 0.2 ± 0,1 % or better shall be used.

NOTE For the application of digital sampling methods, see Annex B.

4.10 Power measurement

The power shall be measured by a wattmeter having an accuracy of ± 0,5 % or better at the

frequency, power factor, and crest factor to be used. Readings in the first quarter of the scale

shall be avoided as far as possible.

– 14 – IEC 60404-10:2016 RLV © IEC 2016

NOTE For the application of digital sampling methods, see Annex B.

The resistance of the voltage circuit of the wattmeter shall be greater than or equal to at least

100 Ω/V for all ranges. If necessary the losses in the secondary circuit shall be subtracted

from the indicated loss value.

Moreover, the ohmic resistance of the voltage circuit of the wattmeter shall be at least 5 000

times the its reactance, unless the wattmeter is compensated for its reactance, to avoid

necessary corrections of phase angle.

5 Measuring Procedure for the determination of the specific total loss

5.1 General

Clause 5 describes the wattmeter method for the determination of the specific total loss of

electrical steel strip and sheet at frequencies in the range 400 Hz to 10 000 Hz.

The specific total loss is determined, according to this method, for specified peak values of

magnetic polarization and for a specified frequency.

In order to obtain comparable results, test values shall be referred to magnetic polarization of

sinusoidal waveform.

5.2 Preparation for measurement

The Epstein frame and measuring equipment shall be connected as shown in Figure 3.

A1

S1

V1 V2

E

F1

M

W1

IEC

Components

V1 mesures average rectified voltage type voltmeter

V2 mesures r.m.s. voltage voltmeter

A1 current measuring device

F1 frequency meter

W1 wattmeter

M mutual inductor

c

E Epstein frame

S1 switch

NOTE The circuit diagram of Figure 3 illustrates the principle of the wattmeter method. It also sets out the

fundamentals of the digital Wattmeter method where the instrumental functions are realized partly through the

evaluating software.

Figure 3 – Circuit for the wattmeter method

The test specimen shall be weighed and its mass determined within ± 0,1 %. After weighing,

the strips shall be loaded into the solenoids of the Epstein frame with forming double-

overlapping corner joints. In the case of strips which are cut half in the direction of rolling and

half normal to that direction, care shall be taken that all the strips cut in the direction of rolling

are placed in two opposite arms solenoids of the frame and that those cut normal to that

direction are placed in the two other opposite arms solenoids. The joints shall form a minimum

gap between the strips. The strips shall be positioned so as to conform with the requirements

of 4.4. The number of strips shall be the same in each solenoid.

Before measurement, the test specimen shall be demagnetized by a decreasing alternating

magnetic field of an initial level higher than used in previous measurements.

5.3 Source setting Adjustment of power supply

ˆ

In order to achieve the specified peak value of the polarisation, J , the source power supply

output shall be adjusted so that the average rectified value of the secondary induced voltage

is:

R

i ˆ

U = 4 fN AJ (2)

2 2

R +R

i t

where:

U is the average rectified value of the voltage induced in the combined secondary rectified

voltage windings, in volts;

– 16 – IEC 60404-10:2016 RLV © IEC 2016

f is the frequency, in hertz;

R is the combined equivalent resistance of instruments in the secondary circuit, in ohms;

i

R is the series resistance of the combined secondary windings of Epstein frame and

t

mutual inductor, in ohms;

N is the number of turns of the secondary winding of the Epstein frame;

A is the cross-sectional area of the test specimen, in square metres;

ˆ

J is the peak value of magnetic polarization, in teslas.

The cross-sectional area of the test specimen, A, is obtained by the formula:

m

A = (3)

4lρ

m

where:

m is the total mass of test specimen, in kilograms;

l is the length of a test specimen strip, in metres;

ρ is the conventional density, or the value determined in accordance with IEC 60404-13,

m

of the test material, in kilograms per cubic metre.

5.4 Measurements of power

The ammeter in the primary circuit shall be observed to ensure that the current circuit of the

wattmeter is not overloaded. Then the ammeter shall be short-circuited and the secondary

induced voltage readjusted. After checking the waveform of the secondary induced voltage in

compliance with 4.6, the wattmeter shall be read.

NOTE In order to avoid undue heating of the test specimen and to facilitate reproducibility,

measurements should be made as quickly as possible after energizing the Epstein frame. The

specimen should be allowed to cool between readings.

NOTE For the application of digital sampling methods, see Annex B.

5.5 Determination of the specific total losses

The power, P , measured by the wattmeter includes the power consumed by the instruments

m

in the secondary circuit, which to a first approximation is equal to (1,111⋅ U ) / R since the

2 i

secondary induced voltage is essentially sinusoidal.

NOTE For the application of digital sampling methods, see Annex B.

Thus, the total losses, P of the test specimen shall be calculated from the formula:

c

1,111⋅ U

N

P = ⋅ P – (4)

c m

N R

2 i

where:

P is the calculated total losses of test specimen, in watts;

c

P is the power measured by the wattmeter, in watts;

m

N is the number of turns of the primary winding;

N is the number of turns of the secondary winding;

R is the combined equivalent resistance of the instruments in the secondary circuit, in

i

ohms;

U is the average rectified value of the voltage induced in the combined secondary rectified

voltage winding, in volts.

The specific total losses, P shall be obtained by dividing P by the effective magnetically

s c

active mass of the test specimen (see 4.4).

P P ⋅ 4l

c c

P = = (5)

s

m m ⋅ l

a m

where:

P is the specific total losses of test specimen, in watts per kilogram (corrected if

s

necessary for flux waveform distortion according to 4.4);

m is the total mass of test specimen, in kilograms;

m is the effective magnetically active mass of test specimen, in kilograms;

a

l is the length of a test specimen, in metres;

l is the conventional effective magnetic path length, in metres (l = 0,94 m).

m m

5.6 Reproducibility of the specific total loss measurement

The reproducibility of the results obtained from this method is characterized by a relative

standard deviation in the range between 2% and 5%, the value of this standard deviation

depending on the frequency and the magnetic polarization which are used.

CHAPTER III: DETERMINATION OF MAGNETIC FIELD STRENGTH,

EXCITATION CURRENT AND SPECIFIC APPARENT POWER

6 Procedure for the determination of the peak value of magnetic polarization,

r.m.s. value of magnetic field strength, peak value of magnetic field strength

and specific apparent power

6.1 Scope General

Clause 6 describes measuring methods for the determination of the following quantities:

~

– r.m.s. value of the excitation current I ;

ˆ

– peak value of magnetic polarization J ;

~

– r.m.s. value of magnetic field strength H ;

ˆ

– peak value of magnetic field strength H ;

– specific apparent power S .

s

The quantities are determined, according to these methods, for specified peak values of

magnetic polarization and for a specified frequency.

6.2 Test specimen

The test specimen shall comply with 4.3.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...