IEC 60603-7:2008

(Main)Connectors for electronic equipment - Part 7: Detail specification for 8-way, unshielded, free and fixed connectors

Connectors for electronic equipment - Part 7: Detail specification for 8-way, unshielded, free and fixed connectors

IEC 60603-7:2008 covers 8-way unshielded free and fixed connectors and is intended to specify the common dimensions, mechanical, electrical and environmental characteristics and tests for the family of IEC 60603-7-x connectors. These connectors are intermateable and interoperable with other IEC 60603-7 series connectors. This new edition includes the following significant technical changes with respect to the previous edition: updated drawings and test schedules on the basis of IEC 60603-7-4; corrected figure illustrating a connector de-rating curve.

Connecteurs pour équipements électroniques - Partie 7: Spécification particulière pour les fiches et les embases non écrantées à 8 voies

La CEI 60603-7:2008 couvre les fiches et les embases non écrantées à 8 voies; elle est destinée à spécifier les dimensions communes, les caractéristiques mécaniques, électriques et environnementales ainsi que les essais pour la famille des connecteurs CEI 60603-7-x. Ces connecteurs sont accouplables et interopérables avec les autres connecteurs de la série CEI 60603-7. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente: mise à jour des dessins et des programmes d'essai sur la base de la CEI 60603-7-4; correction de la figure illustrant la courbe de taux de réduction.

General Information

- Status

- Published

- Publication Date

- 08-Jul-2008

- Technical Committee

- SC 48B - Electrical connectors

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 09-Oct-2020

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60603-7:2008 is an international standard issued by the International Electrotechnical Commission (IEC) that provides detailed specifications for 8-way, unshielded connectors used in electronic equipment. This standard covers both free (plug) and fixed (socket) connectors, focusing on their common dimensions, mechanical, electrical, and environmental characteristics. It ensures that connectors conforming to this standard are intermateable and interoperable across all IEC 60603-7 series connectors, facilitating global compatibility and ease of integration.

The 2008 edition, including subsequent amendments in 2011 and 2019, introduces updates such as revised drawings, enhanced test schedules aligned with IEC 60603-7-4, and a corrected connector current de-rating curve. These refinements enhance the reliability and performance assessment of these connectors in demanding electronic applications.

Key Topics

- Connector Types: Specifies free (plug) and fixed (socket) 8-way unshielded connectors designed for electronic equipment.

- Dimensions and Mechanical Specs: Standardizes connector sizes, mating features, coupling devices, and insertion force for consistent mechanical operation.

- Electrical Characteristics:

- Creepage and clearance distances to prevent electrical breakdowns.

- Voltage proof and current-temperature derating for reliability under electrical stress.

- Contact resistance and insulation resistance to ensure secure signal transmission.

- Environmental Requirements: Defines climatic categories and environmental tests to assure performance in various operating conditions.

- Testing Protocols: Comprehensive test schedules including contact resistance, vibration, mechanical operation, and preconditioning tests.

- Compatibility and Interoperability: Ensures connectors are intermateable across the IEC 60603-7 family, promoting modular design and backward compatibility.

Applications

IEC 60603-7:2008 connectors are widely used in diverse electronic equipment where reliable, high-quality 8-way connections are required without shielding. Practical applications include:

- Data transmission equipment requiring robust, unshielded 8-pin connectors.

- Consumer electronics where space-efficient, secure connection interfaces are essential.

- Telecommunications devices that employ modular connectors for flexible assembly.

- Industrial control systems benefiting from standardized connectors for maintenance and upgrades.

- Computer networking hardware supporting interoperable cable terminations.

By standardizing these connectors, manufacturers can ensure consistency of interconnectivity, simplifying design processes and reducing compatibility issues in multi-vendor environments.

Related Standards

- IEC 60603-7-x Series: Other parts of this series address variations like shielded connectors and different pin configurations, complementing IEC 60603-7:2008.

- IEC 60603-7-4: Provides updated drawings and test schedules referred to in this standard's latest amendments.

- International Electrotechnical Vocabulary (IEV): Offers terminology definitions pertinent to connector technology, enhancing clear communication.

- ISO/IEC Standards for Electronic Connectors: May provide additional guidelines on interoperability and testing methods.

Practical Value

Adhering to IEC 60603-7:2008 offers numerous benefits:

- Ensures product interoperability with internationally recognized connector designs.

- Facilitates certification and market access through compliance with a globally accepted standard.

- Improves product reliability by following rigorous environmental and electrical testing.

- Simplifies design and manufacturing by using standardized dimensions and connector layouts.

- Supports maintenance and repair via consistent connector interchangeability.

In conclusion, IEC 60603-7:2008 defines essential technical criteria for 8-way unshielded free and fixed connectors, promoting compatibility, performance, and durability across electronic equipment worldwide. Manufacturers, designers, and quality engineers benefit from applying this standard to achieve dependable connector solutions tailored to a variety of industrial and commercial applications.

IEC 60603-7:2008 - Connectors for electronic equipment - Part 7: Detail specification for 8-way, unshielded, free and fixed connectors

IEC 60603-7:2008+AMD1:2011 CSV - Connectors for electronic equipment - Part 7: Detail specification for 8-way, unshielded, free and fixed connectors Released:12/16/2011 Isbn:9782889128310

IEC 60603-7:2008+AMD1:2011+AMD2:2019 CSV - Connectors for electronic equipment - Part 7: Detail specification for 8-way, unshielded, free and fixed connectors Released:1/11/2019 Isbn:9782832264287

Frequently Asked Questions

IEC 60603-7:2008 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Connectors for electronic equipment - Part 7: Detail specification for 8-way, unshielded, free and fixed connectors". This standard covers: IEC 60603-7:2008 covers 8-way unshielded free and fixed connectors and is intended to specify the common dimensions, mechanical, electrical and environmental characteristics and tests for the family of IEC 60603-7-x connectors. These connectors are intermateable and interoperable with other IEC 60603-7 series connectors. This new edition includes the following significant technical changes with respect to the previous edition: updated drawings and test schedules on the basis of IEC 60603-7-4; corrected figure illustrating a connector de-rating curve.

IEC 60603-7:2008 covers 8-way unshielded free and fixed connectors and is intended to specify the common dimensions, mechanical, electrical and environmental characteristics and tests for the family of IEC 60603-7-x connectors. These connectors are intermateable and interoperable with other IEC 60603-7 series connectors. This new edition includes the following significant technical changes with respect to the previous edition: updated drawings and test schedules on the basis of IEC 60603-7-4; corrected figure illustrating a connector de-rating curve.

IEC 60603-7:2008 is classified under the following ICS (International Classification for Standards) categories: 31.220.10 - Plug-and-socket devices. Connectors. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60603-7:2008 has the following relationships with other standards: It is inter standard links to IEC 60603-7:2008/AMD2:2019, IEC 60603-7:2008/AMD1:2011, IEC 60603-7:2020, IEC 60603-7:1996. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60603-7:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60603-7

Edition 3.0 2008-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Connectors for electronic equipment –

Part 7: Detail specification for 8-way, unshielded, free and fixed connectors

Connecteurs pour équipements électroniques –

Partie 7: Spécification particulière pour les fiches et les embases non écrantées

à 8 voies

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60603-7

Edition 3.0 2008-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Connectors for electronic equipment –

Part 7: Detail specification for 8-way, unshielded, free and fixed connectors

Connecteurs pour équipements électroniques –

Partie 7: Spécification particulière pour les fiches et les embases non écrantées

à 8 voies

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

X

CODE PRIX

ICS 31.220.10 ISBN 2-8318-9878-1

– 2 – 60603-7 © IEC:2008

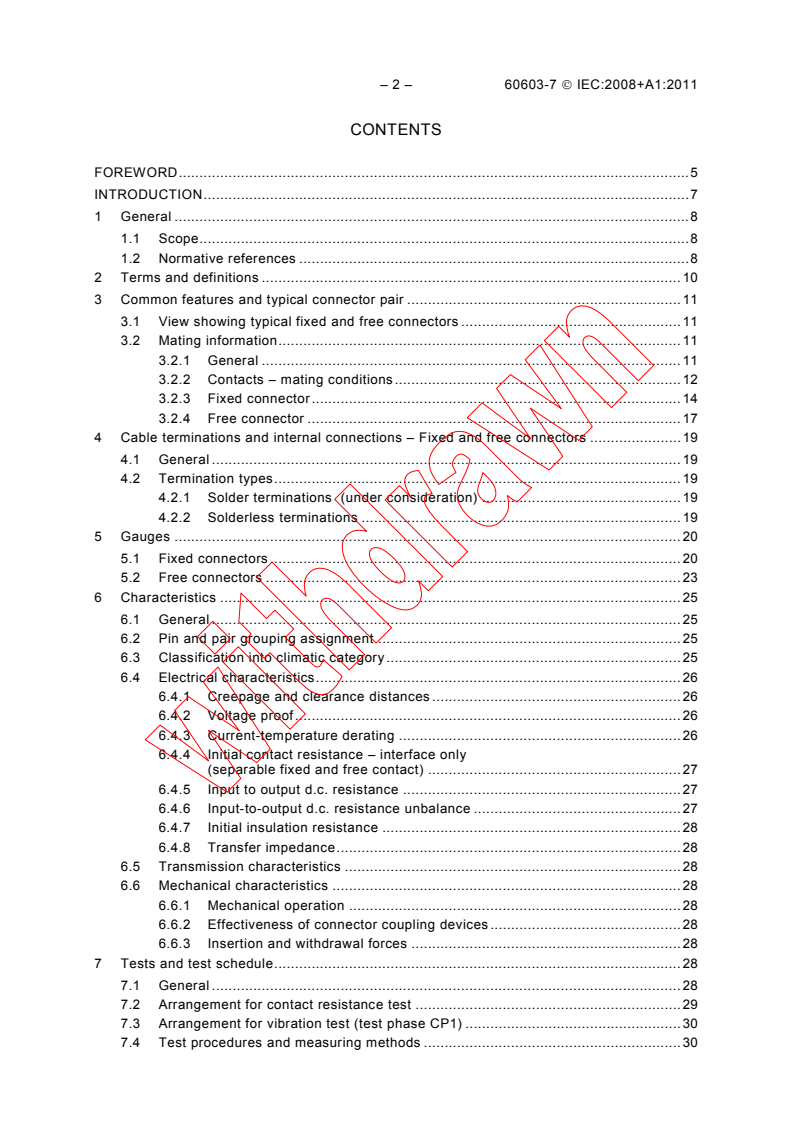

CONTENTS

FOREWORD.5

INTRODUCTION.7

1 General .8

1.1 Scope.8

1.2 Normative references .8

2 Terms and definitions .10

3 Common features and typical connector pair .11

3.1 View showing typical fixed and free connectors .11

3.2 Mating information.11

3.2.1 General .11

3.2.2 Contacts – mating conditions.12

3.2.3 Fixed connector.14

3.2.4 Free connector .17

4 Cable terminations and internal connections – Fixed and free connectors .19

4.1 General .19

4.2 Termination types.19

4.2.1 Solder terminations (under consideration) .19

4.2.2 Solderless terminations .19

5 Gauges .20

5.1 Fixed connectors .20

5.2 Free connectors .23

6 Characteristics .25

6.1 General .25

6.2 Pin and pair grouping assignment .25

6.3 Classification into climatic category.25

6.4 Electrical characteristics.26

6.4.1 Creepage and clearance distances.26

6.4.2 Voltage proof.26

6.4.3 Current-temperature derating .26

6.4.4 Initial contact resistance – interface only (separable fixed and free

contact) .27

6.4.5 Input to output d.c. resistance .27

6.4.6 Input-to-output d.c. resistance unbalance .27

6.4.7 Initial insulation resistance .28

6.4.8 Transfer impedance.28

6.5 Transmission characteristics .28

6.6 Mechanical characteristics .28

6.6.1 Mechanical operation .28

6.6.2 Effectiveness of connector coupling devices.28

6.6.3 Insertion and withdrawal forces .28

7 Tests and test schedule.28

7.1 General .28

7.2 Arrangement for contact resistance test .29

7.3 Arrangement for vibration test (test phase CP1) .30

7.4 Test procedures and measuring methods .30

7.5 Preconditioning .31

60603-7 © IEC:2008 – 3 –

7.6 Wiring and mounting of specimens .31

7.6.1 Wiring.31

7.6.2 Mounting .31

7.7 Test schedules .31

7.7.1 Basic (minimum) test schedule .31

7.7.2 Full test schedule .31

Annex A (normative) Gauging continuity procedure.39

Annex B (normative) Locking-device mechanical operation.43

Annex C (normative) Gauge requirements .44

Annex D (normative) Keystone connector information .45

Bibliography.47

Figure 1 – View showing typical fixed and free connectors.11

Figure 2 – Contact interface dimensions with terminated free connector .12

Figure 3 – Fixed connector details .15

Figure 4 – Free connector view.17

Figure 5 – “Go” gauge.20

Figure 6 – “No-go” gauges .22

Figure 7 – “No-go” gauges .23

Figure 8 – “Go” gauge.24

Figure 9 – Fixed connector pin and pair grouping assignment (front view of connector) .25

Figure 10 – Connector de-rating curve .27

Figure 11 – Arrangement for contact resistance test .29

Figure 12 – Arrangement for vibration test .30

Figure A.1 – Gauge.41

Figure A.2 – Gauge insertion .42

Figure D.1 – Keystone connector .45

Figure D.2 – Panel drawing.46

Table 1 – Dimensions for Figure 2 .13

Table 2 – Dimensions for Figure 3 .16

Table 3 – Dimensions for Figure 4 .18

Table 4 – Dimensions for Figures 5 and 6.22

Table 5 – Dimensions for Figure 7 .23

Table 6 – Dimensions for Figure 8 .24

Table 7 – Climatic categories – selected values.25

Table 8 – Creepage and clearance distances.26

Table 9 – Test group P .32

Table 10 – Test group AP .33

Table 11 – Test group BP .35

Table 12 – Test group CP .36

Table 13 – Test group DP .37

Table 14 – Test group FP .38

Table A.1 – Dimensions for Figure A.1.40

– 4 – 60603-7 © IEC:2008

Table D.1 – Dimensions for Figure D.1 .45

Table D.2 – Dimensions.46

60603-7 © IEC:2008 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

_____________

CONNECTORS FOR ELECTRONIC EQUIPMENT –

Part 7: Detail specification for 8-way, unshielded,

free and fixed connectors

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60603-7 has been prepared by subcommittee 48B: Connectors, of

IEC technical committee 48: Electromechanical components and mechanical structures for

electronic equipment.

This third edition cancels and replaces the second edition published in 1996 and constitutes a

technical revision. This edition includes the following significant technical change with respect

to the previous edition:

– Drawings and test schedules were updated based on the work done developing

IEC 60603-7-4.

– A corrected figure (Figure 10) illustrating a connector de-rating curve has been

prepared and inserted in the text.

– Annex D contains the dimensions that define the panel mounting features on the

connector and panel that were referenced as the Type A, variant 03 connector in the

previous edition.

– 6 – 60603-7 © IEC:2008

The text of this standard is based on the following documents:

FDIS Report on voting

48B/1883A/FDIS 48B/1917/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of IEC 60603-7 series, under the general title: Connectors for electronic

equipment, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

60603-7 © IEC:2008 – 7 –

INTRODUCTION

IEC 60603-7 is the base specification of the whole series. Subsequent specifications do not

duplicate information given in the base document, but list only additional requirements. For

complete specification regarding a component of a higher number document all lower

numbered documents must be considered as well. The following diagram shows the

interrelation of the documents:

Unshielded Shielded

3 MHz

IEC 60603-7 IEC 60603-7-1

100 MHz

IEC 60603-7-2 IEC 60603-7-3

250 MHz

IEC 60603-7-4 IEC 60603-7-5

500 MHz IEC 60603-7-41 IEC 60603-7-51

600 MHz

Indicates reference for IEC 60603-7-7

dimensions, mechanical and

electrical characteristics, tests

and test schedules.

1 000 MHz

IEC 60603-7-71

Indicates reference for

transmission performance

(backward compatibility).

It should be noted that during the preparation of the third edition of IEC 60603-7, the

subcommittee 48B Cat 6&7 project team members determined the current de-rating curve in

the standard was not correct. Several experts researched the current rating-temperature rise

measurements for 60603-7 style connectors and verified that the de-rating curve in the

published standard has been incorrect for many years. A corrected figure (Figure 10) has

been prepared and inserted in this edition.

– 8 – 60603-7 © IEC:2008

CONNECTORS FOR ELECTRONIC EQUIPMENT –

Part 7: Detail specification for 8-way, unshielded,

free and fixed connectors

1 General

1.1 Scope

This part of IEC 60603-7 covers 8-way unshielded free and fixed connectors, it is intended to

specify the common dimensions, mechanical, electrical and environmental characteristics and

tests for the family of IEC 60603-7-x connectors.

These connectors are intermateable (according to IEC 61076-1 level 2) and interoperable with

other IEC 60603-7 series connectors.

1.2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60050-581, International Electrotechnical Vocabulary (IEV) – Chapter 581:

Electromechanical components for electronic equipment

IEC 60068-1, Environmental testing – Part 1: General and guidance

IEC 60068-2-14, Basic environmental testing procedures – Part 2-14: Tests − Test N: Change

of temperature

IEC 60068-2-38, Basic environmental testing procedures – Part 2-38: Tests − Test Z/AD:

Composite temperature/ humidity cyclic test

IEC 60352-2, Solderless connections – Part 2: Crimped connections − General requirements,

test methods and practical guidance

IEC 60352-3, Solderless connections – Part 3: Solderless accessible insulation displacement

connections − General requirements, test methods and practical guidance

IEC 60352-4, Solderless connections – Part 4: Solderless non-accessible insulation displace-

ment connections − General requirements, test methods and practical guidance

IEC 60352-5, Solderless connections – Part 5: Press-in connections − General requirements,

test methods and practical guidance

IEC 60352-6, Solderless connections – Part 6: Insulation piercing connections – General

requirements, test methods and practical guidance

IEC 60352-7, Solderless connections – Part 7: Spring clamp connections − General

requirements, test methods and practical guidance

IEC 60512 (all parts), Connectors for electronic equipment – Tests and measurements

60603-7 © IEC:2008 – 9 –

IEC 60512-1-100, Connectors for electronic equipment – Tests and measurements – Part 1-

100: General – Applicable publications

IEC 60603-7 (all parts), Connectors for electronic equipment

IEC 60664-1, Insulation coordination for equipment within low-voltage systems – Part 1:

Principles, requirements and tests

IEC 61076-1:2006, Connectors for electronic equipment – Product Requirements – Part 1:

Generic specification

IEC 61156 (all parts), Multicore and symmetrical pair/quad cables for digital communications

IEC 61156-1, Multicore and symmetrical pair/quad cables for digital communications – Part 1:

Generic specification

IEC 61156-2, Multicore and symmetrical pair/quad cables for digital communications – Part 2:

Horizontal floor wiring – Sectional specification

IEC 61156-3, Multicore and symmetrical pair/quad cables for digital communications – Part 3:

Work area wiring – Sectional specification

IEC 61156-4, Multicore and symmetrical pair/quad cables for digital communications – Part 4:

Riser cables – Sectional specification

IEC 61156-5, Multicore and symmetrical pair/quad cables for digital communications – Part 5:

Symmetrical pair/quad cables with transmission characteristics up to 600 MHz – Horizontal

floor wiring – Sectional specification

IEC 61156-6, Multicore and symmetrical pair/quad cables for digital communications – Part 6:

Symmetrical pair/quad cables with transmission characteristics up to 1 000 MHz – Work area

wiring – Sectional specification

IEC 61156-7, Multicore and symmetrical pair/quad cables for digital communications – Part 7:

Symmetrical pair cables with transmission characteristics up to 1 200 MHz – Sectional

specification for digital and analog communication cables

ISO/IEC 11801, Information technology – Generic cabling for customer premises

ISO 1302, Geometrical Product Specifications (GPS) – Indication of surface texture in

technical product documentation

ITU-T Recommendation K.20:2000 , Resistibility of telecommunication equipment installed in

a telecommunications centre to overvoltages and overcurrents

ITU-T Recommendation K.44:2000 , Resistibility tests for telecommunication equipment

exposed to overvoltages and overcurrents – Basic Recommendation

———————

This document has been replaced by a new edition (2003), but for the purposes of this standard, the 2000

edition is cited.

This document has been replaced by a new edition (2003), but for the purposes of this standard, the 2000

edition is cited.

– 10 – 60603-7 © IEC:2008

2 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-581,

IEC 61076-1, IEC 60512-1, and the following apply.

2.1

intermateability

intermateability (level 2 of IEC 61076-1:2006 (Ed 2.0)) is ensured by application of the “Go”

and “No-Go” gauge requirements in the standards that may be referenced, and adherence to

the dimensional requirements within

2.2

interoperability

interoperability of different IEC 60603-7 connectors is assured by compliance with the

specified interface dimensions

2.3

category

relevant level of transmission performance as given in ISO/IEC 11801

2.4

Keystone connector

a Keystone connector is defined by it’s mounting features. The dimensional requirements for

the connector and it’s corresponding mounting panel are defined in Annex D

60603-7 © IEC:2008 – 11 –

3 Common features and typical connector pair

3.1 View showing typical fixed and free connectors

IEC 086/05

Figure 1 – View showing typical fixed and free connectors

3.2 Mating information

3.2.1 General

Dimensions are given in millimetres. Drawings are shown in third-angle projection. The shape

of connectors may deviate from those given in Figures 1 to 4 as long as the dimensions

specified are not changed.

– 12 – 60603-7 © IEC:2008

3.2.2 Contacts – mating conditions

P1

B2

-D-

F2

K2

N2

0,15 mm D R2

A2

P3

C2

B2

-D-

N2

0,15 mm D

IEC 1011/08

H2 2

J2

G2

M2

D2

E2

IEC 087/05

Key

1 Female contact of fixed connector The mating information shown can only be achieved with a free

connector with a cable attached.

2 Burrs shall not project above the top of the contact in this area, since it may be a contact area.

3 Optional angle.

4 Preferred contact interface detail.

5 Minimum preferred contact configuration.

6 Configuration with round contact profile.

7 Configuration with rectangular contact profile.

Figure 2 – Contact interface dimensions with terminated free connector

60603-7 © IEC:2008 – 13 –

Table 1 – Dimensions for Figure 2

Letter Maximum Minimum

mm

mm

A2 1,45 0,89

B2 0,61 0,51

C2 0,46 0,03

D2 2,79

E2 4,11

F2 6,22

H2 0,38

J2 0,64 0,38

K2 6,15 5,89

M2 0,30

N2 0,28

P1 0,50 0,45

P3 0,50 0,36

R2 4,83

Letter Maximum

G2 10°

Care shall be taken that the fixed connector contacts avoid interference with the plastic of the free connector.

– 14 – 60603-7 © IEC:2008

3.2.3 Fixed connector

-X-

B1

0,05 mm X

AD1 A

0,05 mm

C

(7×) AH1

AH1

AM1

AD1

K1

-B-

AB1

AB1

AM1

A

T1

0,25 mm C

W1

0,25 mm C

S1

-C-

IEC 1012/08

Key

1 Contact zone. Contacts shall be completely within their individual contact zone in the area indicated.

2 0°15’ maximum taper.

3 Section A-A: see Figure 3b).

4 Relief outside of the area defined by dimension AM1 on both sides of the spring contacts in the fixed

connector is permitted.

Figure 3a) – View of contact zone

60603-7 © IEC:2008 – 15 –

AN1

AT1

AS1

1 2

AT1

-B-

AC1

Z1

AK1

AA1

AP1

AJ1

AL1

SE1

X1

A1

Y1

-A-

IEC 1013/08

View of contact zone section A-A

Key

1 Optional contact rest.

2 Preferred free connector stop.

3 Contacts shown at rest. Contacts shall always be contained inside guide slots. Contacts shall move

freely within their guide slots.

4 This surface need not be planar or coincident with the surface below the locking device as long as

insertion, latching and unlatching of free connectors is not inhibited.

5 Maximum forward extension of contacts below surface AC1 to avoid contact with shields of free

connectors. Applies in the mated state.

6 Projections beyond AL1 dimension shall not prevent finger access to the free connector locking device.

7 All internal corners in the connector cavity shall be 0,38 mm radius maximum unless otherwise

specified.

Figure 3b) – Section A-A

Figure 3 – Fixed connector details

– 16 – 60603-7 © IEC:2008

Table 2 – Dimensions for Figure 3

Letter Maximum Minimum Nominal (ref.)

mm mm mm

A1 1,47

B1 0,71

K1 5,84

S1 12,04 11,84 11,94

T1 4,19 3,94

W1 6,38 6,22

X1 6,86 6,68

Y1 2,40

Z1 2,08

AA1 1,24

AB1 0,38

AC1 6,96 6,76 6,86

AD1 0,13

AH1 1,02

a

TP

AK1 8,66 8,38

AL1 1,40

AM1 1,52

AP1 1,27

AS1 0,08

AT1 0,76

SE1 5,80

a

TP indicates true position.

Letter Maximum Suggested minimum

AJ1 15°

AN1 3°30’

60603-7 © IEC:2008 – 17 –

3.2.4 Free connector

-A-

BE2

BF2

2 AH2

(7×) AH2

0,15 mm C

BG2

S2

-C-

B2

BD2

BH2

BC2

BJ2 BN2

AD2

AW2 3

BL2

Z2

AZ2

AC2

-B-

AA2

AX2

BB2

AY2

BB2

BK2

X2

AB2

BA2

T2

BM2

0,15 mm C

Y2

W2

0,15 mm C

A2

-A-

IEC 1014/08

Key

1 Full radius permitted on all slots.

2 These dimensions apply to the locations of the contact slots.

3 Applies with locking device depressed.

Figure 4 – Free connector view

– 18 – 60603-7 © IEC:2008

Table 3 – Dimensions for Figure 4

Letter Maximum Minimum Nominal (ref.)

mm mm mm

a a

a

A2 1,17

a a

a

B2 0,56

S2 11,79 11,58 11,68

T2 3,38 3,12

W2 6,17 6,02

X2 6,02 5,77

Y2 2,34

Z2 2,06

AA2 1,24

AB2 0,64 0,38

AC2 6,71 6,50 6,60

AD2 0,64 0,13

AH2 1,02

AW2 0,51

AX2 1,32

AY2 2,87 2,67

AZ2 0,64

BA2 12,32

BB2 1,14 0,38

BC2 1,02 0,51

BD2 0,51

BE2 1,09

BF2 0,64

BG2 0,64 0,38

BH2 0,13

BL2 8,36

BM2 15,88 14,61

BN2 8,00

a

See Table 1.

Letter Maximum Nominal (ref.)

BJ2 Full radius

BK2 3°30'

60603-7 © IEC:2008 – 19 –

4 Cable terminations and internal connections – Fixed and free connectors

4.1 General

A connector may include multiple terminations between the cable termination and the

separable contact interface. These may include press-in connections of fixed connector

contacts into PCBs for example. All terminations shall meet the relevant termination

requirements.

Free connectors are intended to be terminated to cable to provide connector and cable

assemblies. The connector manufacturer shall provide basic information concerning the type

of conductor (stranded, solid) to which the connector may be applied, and the type of

connection used (solder, insulation displacement, etc.). Specific details concerning wire

gauge size, type and thickness of conductor insulation, size and shape of cordage or cable

sheath, etc. are not intended to be part of this detail specification. Minor variations in a free

connector’s interior details to accommodate differing wire gauge sizes, outer sheaths, etc. do

not require the generation of new free-connector specifications.

4.2 Termination types

4.2.1 Solder terminations

(under consideration)

4.2.2 Solderless terminations

4.2.2.1 Insulation displacement terminations

Insulation displacement terminations shall conform to IEC 60352-3 or IEC 60352-4.

4.2.2.2 Crimp terminations

Crimp terminations shall conform to IEC 60352-2.

4.2.2.3 Insulation piercing terminations

Insulation piercing terminations shall conform to IEC 60352-6.

4.2.2.4 Press-in terminations

The compliant pin shall conform to IEC 60352-5.

4.2.2.5 Spring clamp terminations

Spring clamp terminations shall conform to IEC 60352-7.

4.2.2.6 Other types

In the case where a type of solderless termination is used which is not covered by any IEC

standard and the supplier cannot demonstrate a similar level of performance or there is no

applicable IEC 60352 standard to be used as a reference, the supplier shall show

conformance with the full test schedule in 7.7 for all possible variations of termination, for

example each cable construction type (screen construction types, wire construction (solid,

flexible)) the connector is intended to be used for.

– 20 – 60603-7 © IEC:2008

5 Gauges

5.1 Fixed connectors

Gauges shall be made according to the following requirements:

Material: hardened and tempered steel, all sharp edges removed, hardness 650 HV 20

minimum.

= Surface roughness, according to ISO 1302.

Ra = 0,25 μm maximum.

A 0,01 mm wear tolerance shall be applied.

Clearance shall be provided for connector contacts.

BC1

X3

-C-

S3

BC1

AB3

AC3

AK3

C

W3 0,05 mm

IEC 091/05

Key

1 Four places.

2 Six places.

3 All around.

Figure 5 – “Go” gauge

60603-7 © IEC:2008 – 21 –

BC1

X3

-C-

S5

BC1

AB3

AC5

AK5

W5

0,05 mm C

IEC 092/05

Key

1 Four places.

2 Six places.

3 All around.

Figure 6a) – “No-go” gauge width

– 22 – 60603-7 © IEC:2008

BC1

X3

-C-

S7

BC1

AB3

AC7

AK7

W7 0,05 mm C

IEC 093/05

Key

1 Four places.

2 Six places.

3 All around.

Figure 6b) – “No-go” gauge height

Figure 6 – “No-go” gauges

Table 4 – Dimensions for Figures 5 and 6

Letter Maximum Minimum Nominal (ref)

mm mm mm

S3 11,796 11,786

S5 12,050 12,040

S7 11,68 11,58

X3 10,16

AB3 0,51 0,389 0,450

AC3 6,716 6,706

AC5 6,45 6,35

AC7 6,970 6,96

BC1 0,89 0,64 0,76

W3 6,12 6,109

W5 6,38 6,365

W7 5,97 5,89

AK3 8,357 8,346

AK5 8,13 8,05

AK7 8,672 8,66

60603-7 © IEC:2008 – 23 –

5.2 Free connectors

Material: hardened and tempered steel, all sharp edges removed, hardness 650 HV

20 minimum.

= Surface roughness, according to ISO 1302.

Ra = 0,25 μm maximum.

A 0,01 mm wear tolerance shall be applied.

B

A

AX2

AX2

1 1

AT2

B

AT2

A

AD4

AD4

AD4

AK4 AK4

AC6

AC4

AB4

W6

0,1 mm C

AB4

AB4

0,1 mm

C W4

S6

S4 -C-

-C-

View A-A

View B-B

IEC 1015/08

Key

1 All around.

2 Width gauge.

3 Height gauge.

Figure 7 – “No-go” gauges

Table 5 – Dimensions for Figure 7

Letter Maximum Minimum

mm mm

S4 11,593 11,582

S6 11,989 11,887

W4 6,02 6,010

W6 6,40 6,30

AB4 0,38 0,0

AC4 6,91 6,81

AC6 6,512 6,502

AD4 0,127 0,0

AK4 9,42 9,32

AT2 15,29 15,19

AX2 0,635 0,38

– 24 – 60603-7 © IEC:2008

AD6

A4

A

AD6

AX2 1

AW2

-B-

AC8

AB6

AK8

AA4 Z4

AC6

X4

A

AJ2

Y4 T4

0,05 mm C

W6

AZ2

C

0,05 mm

-C-

S8

-A-

Section A-A

IEC 1016/08

Key

1 All around.

Figure 8 – “Go” gauge

Table 6 – Dimensions for Figure 8

Maximum Minimum

Letter

mm mm

A4 1,448 1,438

S8 11,847 11,836

T4 4,115 4,013

W6 6,198 6,187

X4 6,604 6,594

Y4 2,39 2,34

Z4 2,39 2,29

AA4 1,255 1,245

AB6 0,38 0,0

AC8 6,767 6,756

AD6 0,13 0,0

AK8 8,357 8,346

AW2 9,725 9,615

AX2 0,64 0,38

AZ2 11,91 11,81

Letter Maximum Minimum

AJ2 16° 14°

60603-7 © IEC:2008 – 25 –

6 Characteristics

6.1 General

Compliance to the test schedules is intended to ensure the reliability of all performance

parameters, including transmission parameters, over the range of operating climatic

conditions. Stable and compliant contact resistance is a good indication of the stability of

transmission performance.

6.2 Pin and pair grouping assignment

For those specifications where pin and pair groupings are relevant, the pin and pair grouping

assignments shall be as shown in Figure 9 unless otherwise specified.

IEC 096/05

Figure 9 – Fixed connector pin and pair grouping assignment

(front view of connector)

6.3 Classification into climatic category

The lowest and highest temperatures and the duration of the damp-heat steady-state test

should be selected from the preferred values stated in 2.3 of IEC 61076-1:2006. The

connectors are classified into climatic categories in accordance with the general rules given in

IEC 60068-1. The temperature range and severity of the damp heat, steady state test given in

Table 7 are compatible with ISO/IEC 11801 classification of an office environment.

Table 7 – Climatic categories – selected values

Lower temperature Upper temperature Damp heat, steady state

Climatic category

days

°C °C

40/070/21 –40 70 21

– 26 – 60603-7 © IEC:2008

6.4 Electrical characteristics

6.4.1 Creepage and clearance distances

The permissible operating voltages depends on the application and also on the specified

safety requirements.

Insulation coordination is not required for this connector; therefore, the creepage and

clearance distances in IEC 60664-1 are reduced and covered by overall performance

requirements.

The creepage and clearance distances are given as operating characteristics of mated

connectors.

In practice, reductions in creepage or clearance distances may occur due to the conductive

pattern of the printed board or the wiring used, and shall duly be taken into account.

Table 8 – Creepage and clearance distances

Minimum distance between contacts and chassis Minimum distance between adjacent contacts

Creepage Clearance Creepage Clearance

mm mm mm mm

1,40 0,51 0,36 0,36

6.4.2 Voltage proof

Conditions: IEC 60512, Test 4a, Method A

Standard atmospheric conditions

Mated connectors

All variants: 1 000 V d.c. or a.c. peak; one contact to all other contacts

connected together.

1 500 V d.c. or a.c. peak; all contacts connected together to

shield, (housing/mounting plate) if present.

6.4.3 Current-temperature derating

Conditions: IEC 60512, Test 5b

All contacts, connected in series

The current-carrying capacity of connectors in accordance with the requirements of 2.5 of

IEC 61076-1:2006 shall comply with the de-rating curve given in Figure 10.

60603-7 © IEC:2008 – 27 –

Current de-rating diagram

2,0

1,8

1,6

1,4

1,2

1,0

0,8

0,6

0,4

0,2

0,0

0 10 20 30 40 50 60 70 80 90 100

Ambient temperature (°C)

IEC 1017/08

0,5

t

⎛ ⎞

NOTE 1 The maximum permissible current for a given ambient temperature (t) is:

I =1,76 ⋅ 1−

⎜ ⎟

(t)

⎝ ⎠

NOTE 2 For ambient temperatures lower than 0 °C, the maximum permissible current per conductor is 1,76 A.

NOTE 3 For further information, see Introduction.

Figure 10 – Connector de-rating curve

6.4.4 Initial contact resistance – interface only (separable fixed and free contact)

Conditions: IEC 60512, Test 2a

Arrange according to 7.2

Mated connectors

Connection points: as specified in Figure 11

All types: 20 mΩ maximum

6.4.5 Input to output d.c. resistance

Conditions: IEC 60512, Test 2a

Mated connectors

Connection points: Cable termination to cable termination

All types: 200 mΩ maximum

6.4.6 Input-to-output d.c. resistance unbalance

Conditions: IEC 60512, Test 2a

Mated connectors

Connection points: Cable termination to cable termination

Among all signal conductors, maximum difference between maximum and

minimum

All types: 50 mΩ maximum

Current (A)

– 28 – 60603-7 © IEC:2008

6.4.7 Initial insulation resistance

Conditions: IEC 60512, Test 3a

Method A

Mated connectors

Test voltage: 100 V d.c.

All types: 500 MΩ minimum

6.4.8 Transfer impedance

Not applicable

6.5 Transmission characteristics

Transmission characteristics are defined in the applicable IEC 60603-7-x specification.

6.6 Mechanical characteristics

6.6.1 Mechanical operation

Conditions: IEC 60512, Test 9a

Speed: 10 mm/s maximum

Rest: 1 s minimum (mated and unmated)

PL 1: 750 operations

PL 2: 2 500 operations

NOTE PL defines the performance level. This standard specifies two of them.

6.6.2 Effectiveness of connector coupling devices

Conditions: IEC 60512, Test 15f

All types: 50 N for 60 s ± 5 s

6.6.3 Insertion and withdrawal forces

Conditions: IEC 60512, Test 13b

Speed: 10 mm/s maximum

All types, insertion and withdrawal: 20 N maximum

7 Tests and test schedule

7.1 General

See Clause 5 of IEC 61076-1:2006.

This document states the test sequence (in accordance with this standard) and the number of

specimens for each test sequence.

Individual variants may be submitted to type tests for approval of those particular variants.

It is permissible to limit the number of variants tested to a selection representative of the

whole range for which approval is required (which may be less than the range covered by the

60603-7 © IEC:2008 – 29 –

detail specification), but each feature and characteristic shall be validated against the

dimensional requirements and test sequences s

...

IEC 60603-7 ®

Edition 3.1 2011-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Connectors for electronic equipment –

Part 7: Detail specification for 8-way, unshielded, free and fixed connectors

Connecteurs pour équipements électroniques –

Partie 7: Spécification particulière pour les fiches et les embases non écrantées

à 8 voies

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60603-7 ®

Edition 3.1 2011-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Connectors for electronic equipment –

Part 7: Detail specification for 8-way, unshielded, free and fixed connectors

Connecteurs pour équipements électroniques –

Partie 7: Spécification particulière pour les fiches et les embases non écrantées

à 8 voies

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX CN

ICS 31.220.01 ISBN 978-2-88912-831-0

– 2 – 60603-7 IEC:2008+A1:2011

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 General . 8

1.1 Scope . 8

1.2 Normative references . 8

2 Terms and definitions . 10

3 Common features and typical connector pair . 11

3.1 View showing typical fixed and free connectors . 11

3.2 Mating information . 11

3.2.1 General . 11

3.2.2 Contacts – mating conditions . 12

3.2.3 Fixed connector . 14

3.2.4 Free connector . 17

4 Cable terminations and internal connections – Fixed and free connectors . 19

4.1 General . 19

4.2 Termination types . 19

4.2.1 Solder terminations (under consideration) . 19

4.2.2 Solderless terminations . 19

5 Gauges . 20

5.1 Fixed connectors . 20

5.2 Free connectors . 23

6 Characteristics . 25

6.1 General . 25

6.2 Pin and pair grouping assignment . 25

6.3 Classification into climatic category . 25

6.4 Electrical characteristics . 26

6.4.1 Creepage and clearance distances . 26

6.4.2 Voltage proof . 26

6.4.3 Current-temperature derating . 26

6.4.4 Initial contact resistance – interface only

(separable fixed and free contact) . 27

6.4.5 Input to output d.c. resistance . 27

6.4.6 Input-to-output d.c. resistance unbalance . 27

6.4.7 Initial insulation resistance . 28

6.4.8 Transfer impedance . 28

6.5 Transmission characteristics . 28

6.6 Mechanical characteristics . 28

6.6.1 Mechanical operation . 28

6.6.2 Effectiveness of connector coupling devices . 28

6.6.3 Insertion and withdrawal forces . 28

7 Tests and test schedule . 28

7.1 General . 28

7.2 Arrangement for contact resistance test . 29

7.3 Arrangement for vibration test (test phase CP1) . 30

7.4 Test procedures and measuring methods . 30

60603-7 IEC:2008+A1:2011 – 3 –

7.5 Preconditioning . 31

7.6 Wiring and mounting of specimens . 31

7.6.1 Wiring . 31

7.6.2 Mounting . 31

7.7 Test schedules . 31

7.7.1 Basic (minimum) test schedule . 31

7.7.2 Full test schedule . 31

Annex A (normative) Gauging continuity procedure . 40

Annex B (normative) Locking-device mechanical operation . 44

Annex C (normative) Gauge requirements . 45

Annex D (normative) Keystone connector information . 46

Bibliography . 48

Figure 1 – View showing typical fixed and free connectors . 11

Figure 2 – Contact interface dimensions with terminated free connector . 12

Figure 3 – Fixed connector details . 15

Figure 4 – Free connector view . 17

Figure 5 – “Go” gauge . 20

Figure 6 – “No-go” gauges . 22

Figure 7 – “No-go” gauges . 23

Figure 8 – “Go” gauge . 24

Figure 9 – Fixed connector pin and pair grouping assignment (front view of connector) . 25

Figure 10 – Connector de-rating curve . 27

Figure 11 – Arrangement for contact resistance test . 29

Figure 12 – Arrangement for vibration test . 30

Figure A.1 – Gauge. 42

Figure A.2 – Gauge insertion . 43

Figure D.1 – Keystone connector . 46

Figure D.2 – Panel drawing . 47

Table 1 – Dimensions for Figure 2 . 13

Table 2 – Dimensions for Figure 3 . 16

Table 3 – Dimensions for Figure 4 . 18

Table 4 – Dimensions for Figures 5 and 6 . 22

Table 5 – Dimensions for Figure 7 . 23

Table 6 – Dimensions for Figure 8 . 24

Table 7 – Climatic categories – selected values . 25

Table 8 – Creepage and clearance distances . 26

Table 9 – Test group P . 32

Table 10 – Test group AP . 33

Table 11 – Test group BP . 35

Table 12 – Test group CP . 36

Table 13 – Test group DP . 37

– 4 – 60603-7 IEC:2008+A1:2011

Table 14 – Test group EP . 38

Table 14 15 – Test group FP. 39

Table A.1 – Dimensions for Figure A.1 . 41

Table D.1 – Dimensions for Figure D.1 . 46

Table D.2 – Dimensions . 47

60603-7 IEC:2008+A1:2011 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

_____________

CONNECTORS FOR ELECTRONIC EQUIPMENT –

Part 7: Detail specification for 8-way, unshielded,

free and fixed connectors

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of IEC 60603-7 consists of the third edition (2008)

[documents 48B/1883A/FDIS and 48B/1917/RVD] and its amendment 1 (2011)

[documents 48B/2145/CDV and 48B/2205/RVC]. It bears the edition number 3.1.

The technical content is therefore identical to the base edition and its amendment and

has been prepared for user convenience. A vertical line in the margin shows where the

base publication has been modified by amendment 1. Additions and deletions are

displayed in red, with deletions being struck through.

– 6 – 60603-7 IEC:2008+A1:2011

International Standard IEC 60603-7 has been prepared by subcommittee 48B: Connectors, of

IEC technical committee 48: Electromechanical components and mechanical structures for

electronic equipment.

This third edition cancels and replaces the second edition published in 1996 and constitutes a

technical revision. This edition includes the following significant technical change with respect

to the previous edition:

– Drawings and test schedules were updated based on the work done developing

IEC 60603-7-4.

– A corrected figure (Figure 10) illustrating a connector de-rating curve has been prepared

and inserted in the text.

– Annex D contains the dimensions that define the panel mounting features on the

connector and panel that were referenced as the Type A, variant 03 connector in the

previous edition.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of IEC 60603-7 series, under the general title: Connectors for electronic

equipment, can be found on the IEC website.

The committee has decided that the contents of the base publication and its amendments will

remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date, the

publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

60603-7 IEC:2008+A1:2011 – 7 –

INTRODUCTION

IEC 60603-7 is the base specification of the whole series. Subsequent specifications do not

duplicate information given in the base document, but list only additional requirements. For

complete specification regarding a component of a higher number document all lower

numbered documents must be considered as well. The following diagram shows the

interrelation of the documents:

Unshielded Shielded

3 MHz

IEC 60603-7 IEC 60603-7-1

100 MHz

IEC 60603-7-2 IEC 60603-7-3

250 MHz

IEC 60603-7-4 IEC 60603-7-5

500 MHz IEC 60603-7-41 IEC 60603-7-51

600 MHz

Indicates reference for IEC 60603-7-7

dimensions, mechanical and

electrical characteristics, tests

and test schedules.

1 000 MHz

IEC 60603-7-71

Indicates reference for

transmission performance

(backward compatibility).

It should be noted that during the preparation of the third edition of IEC 60603-7, the

subcommittee 48B Cat 6&7 project team members determined the current de-rating curve in

the standard was not correct. Several experts researched the current rating-temperature rise

measurements for 60603-7 style connectors and verified that the de-rating curve in the

published standard has been incorrect for many years. A corrected figure (Figure 10) has

been prepared and inserted in this edition.

– 8 – 60603-7 IEC:2008+A1:2011

CONNECTORS FOR ELECTRONIC EQUIPMENT –

Part 7: Detail specification for 8-way, unshielded,

free and fixed connectors

1 General

1.1 Scope

This part of IEC 60603-7 covers 8-way unshielded free and fixed connectors, it is intended to

specify the common dimensions, mechanical, electrical and environmental characteristics and

tests for the family of IEC 60603-7-x connectors.

These connectors are intermateable (according to IEC 61076-1 level 2) and interoperable with

other IEC 60603-7 series connectors.

1.2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60050-581, International Electrotechnical Vocabulary (IEV) – Chapter 581:

Electromechanical components for electronic equipment

IEC 60068-1, Environmental testing – Part 1: General and guidance

IEC 60068-2-14, Basic environmental testing procedures – Part 2-14: Tests − Test N: Change

of temperature

IEC 60068-2-38, Basic environmental testing procedures – Part 2-38: Tests − Test Z/AD:

Composite temperature/ humidity cyclic test

IEC 60352-2, Solderless connections – Part 2: Crimped connections − General requirements,

test methods and practical guidance

IEC 60352-3, Solderless connections – Part 3: Solderless accessible insulation displacement

connections − General requirements, test methods and practical guidance

IEC 60352-4, Solderless connections – Part 4: Solderless non-accessible insulation displace-

ment connections − General requirements, test methods and practical guidance

IEC 60352-5, Solderless connections – Part 5: Press-in connections − General requirements,

test methods and practical guidance

IEC 60352-6, Solderless connections – Part 6: Insulation piercing connections – General

requirements, test methods and practical guidance

IEC 60352-7, Solderless connections – Part 7: Spring clamp connections − General

requirements, test methods and practical guidance

IEC 60512 (all parts), Connectors for electronic equipment – Tests and measurements

60603-7 IEC:2008+A1:2011 – 9 –

IEC 60512-1-100, Connectors for electronic equipment – Tests and measurements – Part 1-

100: General – Applicable publications

IEC 60603-7 (all parts), Connectors for electronic equipment

IEC 60664-1, Insulation coordination for equipment within low-voltage systems – Part 1:

Principles, requirements and tests

IEC 61076-1:2006, Connectors for electronic equipment – Product Requirements – Part 1:

Generic specification

IEC 61156 (all parts), Multicore and symmetrical pair/quad cables for digital communications

IEC 61156-1, Multicore and symmetrical pair/quad cables for digital communications – Part 1:

Generic specification

IEC 61156-2, Multicore and symmetrical pair/quad cables for digital communications – Part 2:

Horizontal floor wiring – Sectional specification

IEC 61156-3, Multicore and symmetrical pair/quad cables for digital communications – Part 3:

Work area wiring – Sectional specification

IEC 61156-4, Multicore and symmetrical pair/quad cables for digital communications – Part 4:

Riser cables – Sectional specification

IEC 61156-5, Multicore and symmetrical pair/quad cables for digital communications – Part 5:

Symmetrical pair/quad cables with transmission characteristics up to 600 MHz – Horizontal

floor wiring – Sectional specification

IEC 61156-6, Multicore and symmetrical pair/quad cables for digital communications – Part 6:

Symmetrical pair/quad cables with transmission characteristics up to 1 000 MHz – Work area

wiring – Sectional specification

IEC 61156-7, Multicore and symmetrical pair/quad cables for digital communications – Part 7:

Symmetrical pair cables with transmission characteristics up to 1 200 MHz – Sectional

specification for digital and analog communication cables

ISO/IEC 11801, Information technology – Generic cabling for customer premises

ISO 1302, Geometrical Product Specifications (GPS) – Indication of surface texture in

technical product documentation

ITU-T Recommendation K.20:2000 , Resistibility of telecommunication equipment installed in

a telecommunications centre to overvoltages and overcurrents

ITU-T Recommendation K.44:2000 , Resistibility tests for telecommunication equipment

exposed to overvoltages and overcurrents – Basic Recommendation

———————

This document has been replaced by a new edition (2003), but for the purposes of this standard, the 2000

edition is cited.

This document has been replaced by a new edition (2003), but for the purposes of this standard, the 2000

edition is cited.

– 10 – 60603-7 IEC:2008+A1:2011

2 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-581,

IEC 61076-1, IEC 60512-1, and the following apply.

2.1

intermateability

intermateability (level 2 of IEC 61076-1:2006 (Ed 2.0)) is ensured by application of the “Go”

and “No-Go” gauge requirements in the standards that may be referenced, and adherence to

the dimensional requirements within

2.2

interoperability

interoperability of different IEC 60603-7 connectors is assured by compliance with the

specified interface dimensions

2.3

category

relevant level of transmission performance as given in ISO/IEC 11801

2.4

Keystone connector

a Keystone connector is defined by it’s mounting features. The dimensional requirements for

the connector and it’s corresponding mounting panel are defined in Annex D

60603-7 IEC:2008+A1:2011 – 11 –

3 Common features and typical connector pair

3.1 View showing typical fixed and free connectors

IEC 086/05

Figure 1 – View showing typical fixed and free connectors

3.2 Mating information

3.2.1 General

Dimensions are given in millimetres. Drawings are shown in third-angle projection. The shape

of connectors may deviate from those given in Figures 1 to 4 as long as the dimensions

specified are not changed.

– 12 – 60603-7 IEC:2008+A1:2011

3.2.2 Contacts – mating conditions

P1

B2

-D-

F2

K2

N2

D R2

0,15 mm

A2

P3

C2

B2

-D-

N2

0,15 mm D

IEC 1011/08

H2

J2

G2

M2

D2

E2

IEC 087/05

Key

1 Female contact of fixed connector The mating information shown can only be achieved with a free

connector with a cable attached.

2 Burrs shall not project above the top of the contact in this area, since it may be a contact area.

3 Optional angle.

4 Preferred contact interface detail.

5 Minimum preferred contact configuration.

6 Configuration with round contact profile.

7 Configuration with rectangular contact profile.

Figure 2 – Contact interface dimensions with terminated free connector

60603-7 IEC:2008+A1:2011 – 13 –

Table 1 – Dimensions for Figure 2

Letter Maximum Minimum

mm

mm

A2 1,45 0,89

B2 0,61 0,51

C2 0,46 0,03

D2 2,79

E2 4,11

F2 6,22

H2 0,38

J2 0,64 0,38

K2 6,15 5,89

M2 0,30

N2 0,28

P1 0,50 0,45

P3 0,50 0,36

R2 4,83

Letter Maximum

G2 10°

Care shall be taken that the fixed connector contacts avoid interference with the plastic of the free connector.

– 14 – 60603-7 IEC:2008+A1:2011

3.2.3 Fixed connector

-X-

B1

0,05 mm X

AD1

A 3

0,05 mm C

(7×) AH1

AH1

AM1 4

AD1

K1

-B-

AB1

AB1

AM1

A

T1

0,25 mm C

W1

C

0,25 mm

S1

-C-

IEC 1012/08

Key

1 Contact zone. Contacts shall be completely within their individual contact zone in the area indicated.

2 0°15’ maximum taper.

3 Section A-A: see Figure 3b).

4 Relief outside of the area defined by dimension AM1 on both sides of the spring contacts in the fixed

connector is permitted.

Figure 3a) – View of contact zone

60603-7 IEC:2008+A1:2011 – 15 –

AN1

AT1

AS1

1 2

AT1

-B-

AC1

Z1

AK1

AA1

AP1

AJ1

AL1

SE1

X1

A1

Y1

-A-

IEC 1013/08

View of contact zone section A-A

Key

1 Optional contact rest.

2 Preferred free connector stop.

3 Contacts shown at rest. Contacts shall always be contained inside guide slots. Contacts shall move

freely within their guide slots.

4 This surface need not be planar or coincident with the surface below the locking device as long as

insertion, latching and unlatching of free connectors is not inhibited.

5 Maximum forward extension of contacts below surface AC1 to avoid contact with shields of free

connectors. Applies in the mated state.

6 Projections beyond AL1 dimension shall not prevent finger access to the free connector locking device.

7 All internal corners in the connector cavity shall be 0,38 mm radius maximum unless otherwise

specified.

Figure 3b) – Section A-A

Figure 3 – Fixed connector details

– 16 – 60603-7 IEC:2008+A1:2011

Table 2 – Dimensions for Figure 3

Letter Maximum Minimum Nominal (ref.)

mm mm mm

A1 1,47

B1 0,71

K1 5,84

S1 12,04 11,84 11,94

T1 4,19 3,94

W1 6,38 6,22

X1 6,86 6,68

Y1 2,40

Z1 2,08

AA1 1,24

AB1 0,38

AC1 6,96 6,76 6,86

AD1 0,13

AH1 1,02

a

TP

AK1 8,66 8,38

AL1 1,40

AM1 1,52

AP1 1,27

AS1 0,08

AT1 0,76

SE1 5,80

a

TP indicates true position.

Letter Maximum Suggested minimum

AJ1 15°

AN1 3°30’

60603-7 IEC:2008+A1:2011 – 17 –

3.2.4 Free connector

-A-

BE2

BF2

AH2

(7×) AH2

0,15 mm C

BG2

S2

-C-

B2

BD2

BH2

BC2

BJ2

BN2

AD2

AW2

BL2

Z2

AZ2

AC2

-B-

AA2

AX2

BB2

AY2

BB2

BK2

X2

AB2

BA2

T2

BM2

0,15 mm

C

Y2

W2

0,15 mm C

A2

-A-

IEC 1014/08

Key

1 Full radius permitted on all slots.

2 These dimensions apply to the locations of the contact slots.

3 Applies with locking device depressed.

Figure 4 – Free connector view

– 18 – 60603-7 IEC:2008+A1:2011

Table 3 – Dimensions for Figure 4

Letter Maximum Minimum Nominal (ref.)

mm mm mm

a a

a

A2 1,17

a a

a

B2 0,56

S2 11,79 11,58 11,68

T2 3,38 3,12

W2 6,17 6,02

X2 6,02 5,77

Y2 2,34

Z2 2,06

AA2 1,24

AB2 0,64 0,38

AC2 6,71 6,50 6,60

AD2 0,64 0,13

AH2 1,02

AW2 0,51

AX2 1,32

AY2 2,87 2,67

AZ2 0,64

BA2 12,32

BB2 1,14 0,38

BC2 1,02 0,51

BD2 0,51

BE2 1,09

BF2 0,64

BG2 0,64 0,38

BH2 0,13

BL2 8,36

BM2 15,88 14,61

BN2 8,00

a

See Table 1.

Letter Maximum Nominal (ref.)

BJ2 Full radius

BK2 3°30'

60603-7 IEC:2008+A1:2011 – 19 –

4 Cable terminations and internal connections – Fixed and free connectors

4.1 General

A connector may include multiple terminations between the cable termination and the

separable contact interface. These may include press-in connections of fixed connector

contacts into PCBs for example. All terminations shall meet the relevant termination

requirements.

Free connectors are intended to be terminated to cable to provide connector and cable

assemblies. The connector manufacturer shall provide basic information concerning the type

of conductor (stranded, solid) to which the connector may be applied, and the type of