IEC 62276:2025

(Main)Single crystal wafers for surface acoustic wave (SAW) device applications - Specifications and measuring methods

Single crystal wafers for surface acoustic wave (SAW) device applications - Specifications and measuring methods

IEC 62276:2025 applies to the manufacture of synthetic quartz, lithium niobate (LN), lithium tantalate (LT), lithium tetraborate (LBO), and lanthanum gallium silicate (LGS) single crystal wafers intended for use as substrates in the manufacture of surface acoustic wave (SAW) filters and resonators.

This edition includes the following significant technical changes with respect to the previous edition:

a) The terms and definitions, the technical requirements, sampling frequency, test methods and measurement of transmittance, lightness, colour difference for LN and LT have been added in order to meet the needs of industry development;

b) The term “inclusion” (mentioned in 4.13 and 6.10) and its definition have been added because there was no definition for it in Clause 3;

c) The specification of LTV and PLTV, and the corresponding description of sampling frequency for LN and LT have been added, because they are the key performance parameters for the wafers;

d) The tolerance of Curie temperature specification for LN and LT have been added in order to meet the development requirements of the industry;

e) Measurement of thickness, TV5, TTV, LTV and PLTV have been completed, including measurement principle and method of thickness, TV5, TTV, LTV and PLTV.

Tranches monocristallines pour applications utilisant des dispositifs à ondes acoustiques de surface (OAS) - Spécifications et méthodes de mesure

L'IEC 62276:2025 s’applique à la fabrication de tranches monocristallines de quartz synthétique, de niobate de lithium (LN), de tantalate de lithium (LT), de tétraborate de lithium (LBO) et de silicate de gallium et de lanthane (LGS), destinées à être utilisées comme substrats dans la fabrication de résonateurs et de filtres à ondes acoustiques de surface (OAS).

Cette édition inclut les modifications techniques majeures suivantes par rapport à l’édition précédente:

a) les termes et définitions, les exigences techniques, la fréquence d’échantillonnage, les méthodes d'essai et la mesure de la transmission, de la clarté et de la différence de couleur pour le LN et le LT ont été ajoutés, afin de satisfaire aux besoins de développement industriel;

b) le terme « inclusion » mentionné en 4.13 et 6.10 et sa définition ont été ajoutés à l'Article 3, dans la mesure où ils n'était pas suffisamment défini;

c) la spécification de la LTV et du PLTV, et la description correspondante de la fréquence d'échantillonnage pour le LN et le LT ont été ajoutées, dans la mesure où elles correspondent aux paramètres de performances clés pour les tranches;

d) la tolérance de la spécification relative à la température de Curie pour le LN et le LT a été ajoutée afin de satisfaire aux exigences de développement de l'industrie;

e) la mesure de l'épaisseur, de la TV5, de la TTV, de la LTV et du PLTV a été réalisée, y compris le principe et la méthode de mesure de l'épaisseur, de la TV5, de la TTV, de la LTV et du PLTV.

General Information

- Status

- Published

- Publication Date

- 06-Mar-2025

- Technical Committee

- TC 49 - Piezoelectric, dielectric and electrostatic devices and associated materials for frequency control, selection and detection

- Drafting Committee

- WG 5 - TC 49/WG 5

- Current Stage

- PPUB - Publication issued

- Start Date

- 07-Mar-2025

- Completion Date

- 27-Mar-2025

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62276:2025 is the latest international standard specifying single crystal wafers used in surface acoustic wave (SAW) device applications. This standard defines the manufacturing specifications and measurement methods for synthetic quartz, lithium niobate (LN), lithium tantalate (LT), lithium tetraborate (LBO), and lanthanum gallium silicate (LGS) wafers. These wafers serve as critical substrates in fabricating SAW filters and resonators, which are widely used in telecommunications, sensors, and signal processing devices.

The 2025 edition introduces significant technical enhancements across terminology, measurement procedures, and manufacturing tolerances. It aims to align with evolving industrial requirements for higher wafer quality and performance consistency.

Key Topics

- Material Specifications: Detailed requirements for crystal wafers including flatness, thickness, diameter, surface roughness, and surface defects across quartz, LN, LT, LBO, and LGS materials.

- New Definitions & Terms: Inclusion of precise definitions such as “inclusion,” LTV (local total variation), PLTV (peak local total variation), and sampling frequency to standardize quality checks.

- Performance Parameters for LN and LT: Added tolerances for Curie temperature and key parameters like transmittance, lightness, and colour difference to ensure wafers meet stringent industrial criteria.

- Advanced Measurement Methods: Comprehensive procedures for measuring thickness variation (TV5, TTV, LTV, PLTV), orientation by X-ray, bulk resistivity, front/back surface roughness, and visual inspection protocols.

- Sampling and Testing Plans: Structured guidance on sampling frequency and acceptance criteria during wafer production to maintain quality control.

- Manufacturing Process Insights: Informative annexes describe crystal growth techniques (Czochralski, Bridgman, hydrothermal), mechanical processing steps, and polishing for SAW wafers.

Applications

IEC 62276:2025 is essential for ensuring the quality and reliability of single crystal wafers used in:

- Surface Acoustic Wave Filters and Resonators: Critical components in RF signal processing for mobile communications, aerospace, and consumer electronics.

- Piezoelectric Devices: Enabling precise control in sensors, actuators, and frequency control devices by leveraging well-characterized wafer properties.

- Telecommunication Systems: Ensuring high-performance, low-loss, and stable SAW components for 5G networks and other advanced communication technologies.

- Sensor Technologies: Improving substrate quality for acoustic wave sensors used in environmental monitoring, industrial controls, and medical diagnostics.

Manufacturers, quality assurance teams, and designers of SAW devices rely on this standard to ensure substrate wafers meet exacting geometric, physical, and electrical properties, minimizing defects that degrade device performance.

Related Standards

- IEC 60721 Series – Environmental conditions and testing for electrical equipment relevant to SAW device deployment conditions.

- IEC 60068 Series – Environmental testing protocols to assess wafer and device durability.

- ISO 9001 – Quality management systems applicable to the production and inspection processes of SAW wafers.

- ASTM Standards on Quartz Crystal Measurements – Complementary guidelines for crystal substrate characterization.

Adhering to IEC 62276:2025 enhances global interoperability and quality consistency for SAW wafers. It supports the semiconductor and piezoelectric device industries by providing a unified framework for material specifications, measurement accuracy, and manufacturing excellence.

Keywords: IEC 62276, surface acoustic wave wafers, SAW device substrates, single crystal wafers, lithium niobate specifications, lithium tantalate wafers, synthetic quartz wafer specifications, SAW filter substrates, piezoelectric wafer measurement, wafer manufacturing standards.

Frequently Asked Questions

IEC 62276:2025 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Single crystal wafers for surface acoustic wave (SAW) device applications - Specifications and measuring methods". This standard covers: IEC 62276:2025 applies to the manufacture of synthetic quartz, lithium niobate (LN), lithium tantalate (LT), lithium tetraborate (LBO), and lanthanum gallium silicate (LGS) single crystal wafers intended for use as substrates in the manufacture of surface acoustic wave (SAW) filters and resonators. This edition includes the following significant technical changes with respect to the previous edition: a) The terms and definitions, the technical requirements, sampling frequency, test methods and measurement of transmittance, lightness, colour difference for LN and LT have been added in order to meet the needs of industry development; b) The term “inclusion” (mentioned in 4.13 and 6.10) and its definition have been added because there was no definition for it in Clause 3; c) The specification of LTV and PLTV, and the corresponding description of sampling frequency for LN and LT have been added, because they are the key performance parameters for the wafers; d) The tolerance of Curie temperature specification for LN and LT have been added in order to meet the development requirements of the industry; e) Measurement of thickness, TV5, TTV, LTV and PLTV have been completed, including measurement principle and method of thickness, TV5, TTV, LTV and PLTV.

IEC 62276:2025 applies to the manufacture of synthetic quartz, lithium niobate (LN), lithium tantalate (LT), lithium tetraborate (LBO), and lanthanum gallium silicate (LGS) single crystal wafers intended for use as substrates in the manufacture of surface acoustic wave (SAW) filters and resonators. This edition includes the following significant technical changes with respect to the previous edition: a) The terms and definitions, the technical requirements, sampling frequency, test methods and measurement of transmittance, lightness, colour difference for LN and LT have been added in order to meet the needs of industry development; b) The term “inclusion” (mentioned in 4.13 and 6.10) and its definition have been added because there was no definition for it in Clause 3; c) The specification of LTV and PLTV, and the corresponding description of sampling frequency for LN and LT have been added, because they are the key performance parameters for the wafers; d) The tolerance of Curie temperature specification for LN and LT have been added in order to meet the development requirements of the industry; e) Measurement of thickness, TV5, TTV, LTV and PLTV have been completed, including measurement principle and method of thickness, TV5, TTV, LTV and PLTV.

IEC 62276:2025 is classified under the following ICS (International Classification for Standards) categories: 31.140 - Piezoelectric devices. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62276:2025 has the following relationships with other standards: It is inter standard links to IEC 62276:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62276:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62276 ®

Edition 4.0 2025-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Single crystal wafers for surface acoustic wave (SAW) device applications –

Specifications and measuring methods

Tranches monocristallines pour applications utilisant des dispositifs à ondes

acoustiques de surface (OAS) – Spécifications et méthodes de mesure

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews, graphical symbols and the glossary.

committee, …). It also gives information on projects, replaced With a subscription you will always have access to up to date

and withdrawn publications. content tailored to your needs.

IEC Just Published - webstore.iec.ch/justpublished

Electropedia - www.electropedia.org

Stay up to date on all new IEC publications. Just Published

The world's leading online dictionary on electrotechnology,

details all new publications released. Available online and once

containing more than 22 500 terminological entries in English

a month by email.

and French, with equivalent terms in 25 additional languages.

Also known as the International Electrotechnical Vocabulary

IEC Customer Service Centre - webstore.iec.ch/csc

(IEV) online.

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications, symboles

en utilisant différents critères (numéro de référence, texte, graphiques et le glossaire. Avec un abonnement, vous aurez

comité d’études, …). Elle donne aussi des informations sur les toujours accès à un contenu à jour adapté à vos besoins.

projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au monde,

Restez informé sur les nouvelles publications IEC. Just

avec plus de 22 500 articles terminologiques en anglais et en

Published détaille les nouvelles publications parues.

français, ainsi que les termes équivalents dans 25 langues

Disponible en ligne et une fois par mois par email.

additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 62276 ®

Edition 4.0 2025-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Single crystal wafers for surface acoustic wave (SAW) device applications –

Specifications and measuring methods

Tranches monocristallines pour applications utilisant des dispositifs à ondes

acoustiques de surface (OAS) – Spécifications et méthodes de mesure

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.140 ISBN 978-2-8327-0246-8

– 2 – IEC 62276:2025 © IEC 2025

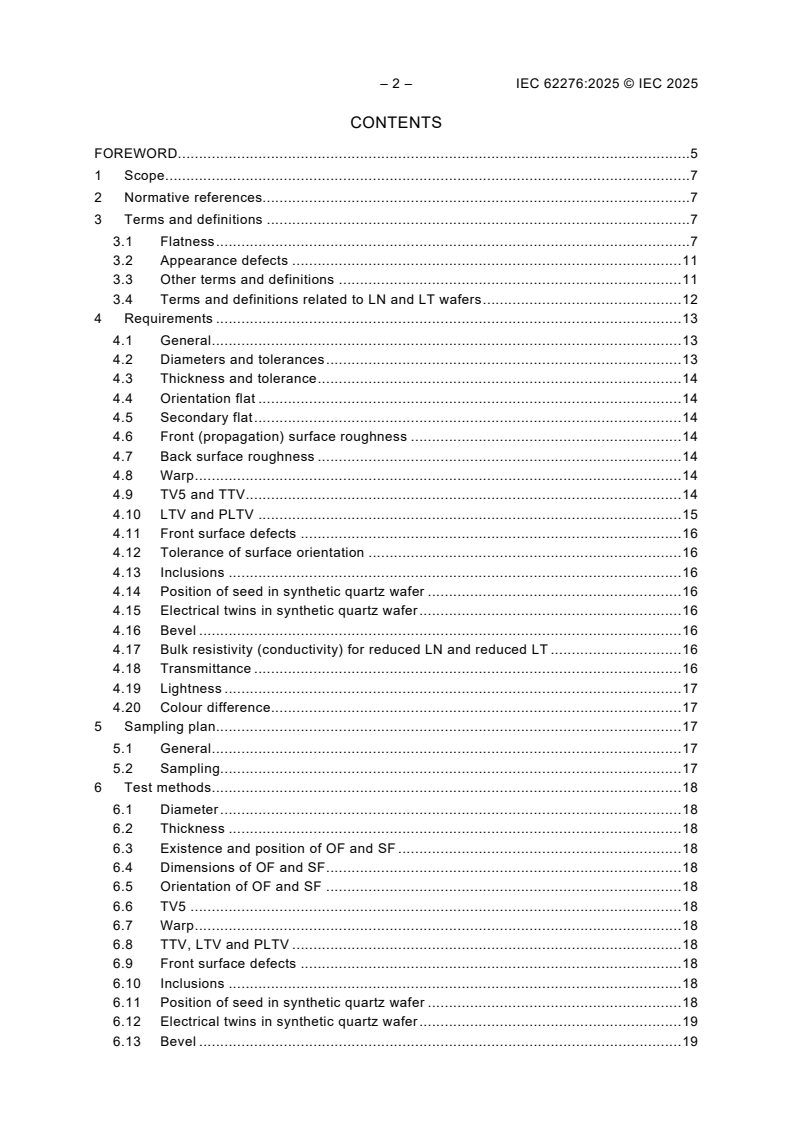

CONTENTS

FOREWORD . 5

1 Scope . 7

2 Normative references. 7

3 Terms and definitions . 7

3.1 Flatness . 7

3.2 Appearance defects . 11

3.3 Other terms and definitions . 11

3.4 Terms and definitions related to LN and LT wafers . 12

4 Requirements . 13

4.1 General . 13

4.2 Diameters and tolerances . 13

4.3 Thickness and tolerance . 14

4.4 Orientation flat . 14

4.5 Secondary flat . 14

4.6 Front (propagation) surface roughness . 14

4.7 Back surface roughness . 14

4.8 Warp . 14

4.9 TV5 and TTV . 14

4.10 LTV and PLTV . 15

4.11 Front surface defects . 16

4.12 Tolerance of surface orientation . 16

4.13 Inclusions . 16

4.14 Position of seed in synthetic quartz wafer . 16

4.15 Electrical twins in synthetic quartz wafer . 16

4.16 Bevel . 16

4.17 Bulk resistivity (conductivity) for reduced LN and reduced LT . 16

4.18 Transmittance . 16

4.19 Lightness . 17

4.20 Colour difference . 17

5 Sampling plan . 17

5.1 General . 17

5.2 Sampling. 17

6 Test methods . 18

6.1 Diameter . 18

6.2 Thickness . 18

6.3 Existence and position of OF and SF . 18

6.4 Dimensions of OF and SF . 18

6.5 Orientation of OF and SF . 18

6.6 TV5 . 18

6.7 Warp . 18

6.8 TTV, LTV and PLTV . 18

6.9 Front surface defects . 18

6.10 Inclusions . 18

6.11 Position of seed in synthetic quartz wafer . 18

6.12 Electrical twins in synthetic quartz wafer . 19

6.13 Bevel . 19

6.14 Front surface and back surface roughness . 19

6.15 Orientation . 19

6.16 Bulk resistivity . 19

6.17 Transmittance . 19

6.18 Lightness . 19

6.19 Colour difference . 19

7 Identification, labelling, packaging, delivery condition . 19

7.1 Packaging . 19

7.2 Labelling and identification . 20

7.3 Delivery condition . 20

8 Measurements of orientation by X-ray . 20

8.1 Measurement principle . 20

8.2 Measurement method . 21

8.3 Measuring surface orientation . 21

8.4 Measuring OF flat orientation . 21

8.5 Typical wafer orientations and reference planes . 21

9 Measurement of bulk resistivity . 22

9.1 Resistance measurement . 22

9.2 Electrode . 23

9.3 Bulk resistivity . 23

10 Visual inspections – Front surface defects and inclusions inspection method . 24

11 Measurement of thickness and thickness variation. 25

11.1 Measurement principle . 25

11.1.1 Contact measurement . 25

11.1.2 Contactless measurement . 25

11.2 Sample . 25

11.3 Measurement method . 25

11.3.1 Contact measurement . 25

11.3.2 Contactless measurement . 25

12 Measurement of transmittance . 26

12.1 Measurement principle . 26

12.2 Sample . 26

12.3 Measurement method . 26

13 Measurement of lightness and colour difference . 26

13.1 Measurement principle . 26

13.2 Sample . 26

13.3 Measurement method . 27

Annex A (normative) Expression using Euler angle description for piezoelectric single

crystals . 29

Annex B (informative) Manufacturing process for SAW wafers . 32

B.1 Crystal growth methods . 32

B.1.1 Czochralski growth method . 32

B.1.2 Vertical Bridgman method . 35

B.1.3 Hydrothermal temperature gradient method . 36

B.2 Standard mechanical wafer manufacturing . 36

B.2.1 Process flow-chart . 36

B.2.2 Cutting both ends and cylindrical grinding . 37

B.2.3 Marking orientation . 37

– 4 – IEC 62276:2025 © IEC 2025

B.2.4 Slicing . 38

B.2.5 Double-sided lapping . 38

B.2.6 Bevelling (edge rounding) . 38

B.2.7 Polishing . 38

Annex C (informative) Measurement principle of lightness and colour difference . 39

Bibliography . 40

Figure 1 – Wafer sketch and measurement points . 8

Figure 2 – Schematic diagram of a TTV . 8

Figure 3 – Schematic diagram of a warp . 9

Figure 4 – Schematic diagram of a sori . 9

Figure 5 – Example of the distribution of sites for measurement of the LTV . 10

Figure 6 – LTV defined within each site on the wafer surface . 10

Figure 7 – Measurement method by X-ray . 20

Figure 8 – Relationship between cut angle and lattice planes . 21

Figure 9 – Measuring circuit . 22

Figure 10 – Resistance measuring equipment. 22

Figure 11 – Shape of electrode . 23

Figure 12 – Measurement points for lightness and colour difference determination . 27

Figure A.1 – Definition of Euler angles to rotate coordinate system (X, Y, Z) onto

(𝔁𝔁 , 𝔁𝔁 , 𝔁𝔁 ) . 29

1 2 3

Figure A.2 – SAW wafer coordinate system . 30

Figure A.3 – Relationship between the crystal axes, Euler angles, and SAW

orientation for some wafer orientations . 31

Figure B.1 – Czochralski crystal growth method . 33

Figure B.2 – Example of non-uniformity in crystals grown from different starting melt

compositions . 35

Figure B.3 – Schematic of a Vertical Bridgman furnace and example of temperature

distribution. 36

Figure B.4 – Process flow-chart . 37

Figure C.1 – Sketch for CIE LAB colour space . 39

Table 1 – Roughness, warp, TV5 and TTV specification limits . 15

Table 2 – LTV and PLTV specification for LN and LT . 15

Table 3 – Sampling plan . 17

Table 4 – Crystal planes to determine surface and OF orientations . 21

Table 5 – Electrode size . 23

Table A.1 – Selected SAW substrate orientations and corresponding Euler angles . 30

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SINGLE CRYSTAL WAFERS FOR SURFACE ACOUSTIC WAVE (SAW)

DEVICE APPLICATIONS – SPECIFICATIONS AND MEASURING METHODS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

IEC 62276 has been prepared by IEC technical committee 49: Piezoelectric, dielectric and

electrostatic devices and associated materials for frequency control, selection and detection. It

is an International Standard.

This fourth edition cancels and replaces the third edition published in 2016. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) The terms and definitions, the technical requirements, sampling frequency, test methods

and measurement of transmittance, lightness, colour difference for LN and LT have been

added in order to meet the needs of industry development;

b) The term “inclusion” (mentioned in 4.13 and 6.10) and its definition have been added

because there was no definition for it in Clause 3;

– 6 – IEC 62276:2025 © IEC 2025

c) The specification of LTV and PLTV, and the corresponding description of sampling

frequency for LN and LT have been added, because they are the key performance

parameters for the wafers;

d) The tolerance of Curie temperature specification for LN and LT have been added in order

to meet the development requirements of the industry;

e) Measurement of thickness, TV5, TTV, LTV and PLTV have been completed, including

measurement principle and method of thickness, TV5, TTV, LTV and PLTV.

The text of this International Standard is based on the following documents:

Draft Report on voting

49/1454/CDV 49/1460/RVC

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn, or

• revised.

SINGLE CRYSTAL WAFERS FOR SURFACE ACOUSTIC WAVE (SAW)

DEVICE APPLICATIONS – SPECIFICATIONS AND MEASURING METHODS

1 Scope

This document applies to the manufacture of synthetic quartz, lithium niobate (LN), lithium

tantalate (LT), lithium tetraborate (LBO), and lanthanum gallium silicate (LGS) single crystal

wafers intended for use as substrates in the manufacture of surface acoustic wave (SAW) filters

and resonators.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60758:2016, Synthetic quartz crystal – Specifications and guidelines for use

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1 Flatness

3.1.1

fixed quality area

FQA

central area of a wafer surface, defined by a nominal edge exclusion, X, over which the specified

values of a parameter apply

Note 1 to entry: The boundary of the FQA is at all points (e.g. along wafer flats) the distance X away from the

perimeter of the wafer of nominal dimensions as shown in Figure 1.

3.1.2

reference plane

plane used as a reference for flatness measurements

Note 1 to entry: The reference plane can be one of the following types:

a) for measurements in which the wafer is clamped, the reference plane is the flat chuck surface that is identical

with the back surface of the wafer;

b) for measurements in which the wafer is not clamped, the reference plane is defined by the surface height at three

points on the front surface of the wafer within the FQA;

c) for measurements in which the wafer is not clamped, the reference plane is defined by the least-squares fit to

the front surface of the wafer using the surface height at all measured points within the FQA.

– 8 – IEC 62276:2025 © IEC 2025

3.1.3

site

square area on the front surface of the wafer with one side parallel to the OF

Note 1 to entry: Flatness parameters are assessed either globally for the FQA, or for each site individually.

3.1.4

TV5

thickness variation for five points

difference between the maximum thickness and the minimum thickness at the centre and four

peripheral points of the wafer as shown in Figure 1

Dimensions in millimetres

Figure 1 – Wafer sketch and measurement points

3.1.5

TTV

total thickness variation

difference between the maximum thickness d and the minimum thickness d of a wafer as

1 2

shown in Figure 2

Figure 2 – Schematic diagram of a TTV

Note 1 to entry: Measurement of TTV is performed on a clamped wafer with the reference plane as defined in

3.1.2 a).

3.1.6

warp

maximum distance between the highest point and the lowest point on the front surface of an

unclamped wafer from the reference plane, where the three-point reference plane is used

Figure 3 – Schematic diagram of a warp

Note 1 to entry: The warp describes the deformation of a wafer that is not clamped, as shown in Figure 3.

Note 2 to entry: The reference plane is defined by the surface height at three points on the front surface of the

wafer as described in 3.1.2 b).

3.1.7

sori

maximum distance between the highest point and the lowest point on the front surface of an

unclamped wafer from the reference plane, where the least-squares fit reference plane is used

Figure 4 – Schematic diagram of a sori

Note 1 to entry: The sori describes the deformation of a wafer that is not clamped, as shown in Figure 4.

Note 2 to entry: The reference plane is defined by the least-squares fit to the front surface of the wafer as described

in 3.1.2 c).

3.1.8

LTV

local thickness variation

difference between the maximum value and the minimum value of a wafer thickness at each

site of the wafer surface

– 10 – IEC 62276:2025 © IEC 2025

Note 1 to entry: All sites existing within the fixed quality area (FQA) on the wafer surface possess their own LTV

value.

Figure 5 – Example of the distribution of sites for measurement of the LTV

Figure 6 – LTV defined within each site on the wafer surface

Note 2 to entry: Measurement is performed on a clamped wafer with the reference plane as defined in 3.1.2 a). An

example of the distribution of sites for measurement of the LTV is shown in Figure 5. The LTV is defined within each

site, as illustrated in Figure 6.

3.1.9

PLTV

percent local thickness variation

percentage of sites whose local thickness variation values fall within the specified value

Note 1 to entry: As with the LTV, measurement is performed on a clamped wafer with the reference plane defined

in 3.1.2 a).

3.1.10

FPD

focal plane deviation

maximum distance between a point on the wafer surface within the fixed quality area and the

three-point reference plane

Note 1 to entry: The three-point reference plane is defined in 3.1.2 b).

Note 2 to entry: If the point on the wafer surface is above the three-point reference plane, the FPD is positive. If

that point is below the three-point reference plane, the FPD is negative.

3.2 Appearance defects

3.2.1

contamination

foreign matter on a surface of wafer which cannot be removed after cleaning

3.2.2

crack

fracture that extends to the surface of the wafer and that can or cannot penetrate the entire

thickness

3.2.3

scratch

shallow groove or cut below the established plane of the surface, with a length to width ratio

greater than 5:1

3.2.4

chip

region where material has been removed from the surface or edge of the wafer

Note 1 to entry: The size of a chip can be expressed by its maximum radial depth and peripheral chord length.

3.2.5

dimple

smooth surface depression larger than 3 mm diameter

3.2.6

pit

non-removable surface anomaly

EXAMPLE A hollow, typically resulting from a bulk defect or faulty manufacturing process.

3.2.7

orange peel

pear skin

large-featured, roughened surface visible to the unaided eye under diffuse illumination

3.3 Other terms and definitions

3.3.1

manufacturing lot

lot established by agreement between the customer and the supplier

3.3.2

orientation flat

OF

flat portion of a wafer perimeter indicating the crystal orientation

Note 1 to entry: Generally, the OF corresponds to the SAW propagation direction (see Figure 1).

3.3.3

secondary flat

SF

flat portion of a wafer perimeter shorter than the orientation flat

Note 1 to entry: When present, the SF indicates wafer polarity and can serve to distinguish different wafer cuts (see

Figure 1).

– 12 – IEC 62276:2025 © IEC 2025

3.3.4

back surface roughness

roughness that scatters and suppresses spurious bulk waves at the back surface of a wafer

3.3.5

surface orientation

crystallographic orientation of the axis perpendicular to the polished surface of the wafer

3.3.6

description of orientation and SAW propagation

indication of the surface orientation and the SAW propagation direction, separated by the

symbol "-"

Note 1 to entry: Specification of a 0° orientation is normally omitted.

Note 2 to entry: Description of wafer orientation rule is shown in Annex A.

3.3.7

tolerance of surface orientation

maximum permissible angular deviation of the surface orientation measured by X-ray diffraction

from the specified surface orientation

3.3.8

bevel

slope of the perimeter edge of a wafer

Note 1 to entry: The process of forming a slope is called "bevelling".

Note 2 to entry: Machining of the perimeter edge of a wafer can be performed through bevelling or edge rounding.

Whereas bevelling produces a flat slope, edge rounding (as the term implies) produces a rounded edge.

Note 3 to entry: Both bevelling and edge rounding, and their tolerances, are subject to agreement between the user

and the supplier.

3.3.9

diameter of wafer

diameter of circular portion of wafer excluding the OF and SF regions

3.3.10

wafer thickness

thickness measured at the centre of the wafer

3.3.11

inclusion

foreign material (solid, liquid or vapor) within a piezoelectric crystal, detectable by examination

of scattered light

3.3.12

electrical twins in synthetic quartz wafer

synthetic quartz wafer in which regions with the common Z-axis exist showing a polarity reversal

of the electrical X-axis

Note 1 to entry: Electrical twins can result from extreme conditions (temperature and pressure, for example) during

processing.

3.4 Terms and definitions related to LN and LT wafers

3.4.1

colour difference

*

∆E

ab

difference in colour at different parts of the object surface

*

Note 1 to entry: In the CIE LAB colour space, ∆E is the value representing the colour difference of different parts

ab

of the object surface.

3.4.2

lightness

L*

relative light-dark properties of the object surface

Note 1 to entry: In the CIE LAB colour space, L* is the coordinates representing the lightness of the colour of the

object.

3.4.3

reduced LN

LN treated with a reduction process

Note 1 to entry: Reduced LN is sometimes referred to as "black LN".

3.4.4

reduced LT

LT treated with a reduction process

Note 1 to entry: Reduced LT is sometimes referred to as "black LT".

3.4.5

reduction process

process comprising a reduction-oxidation (REDOX) reaction to increase conductivity to reduce

the harmful effects of pyroelectricity

3.4.6

transmittance

𝝉𝝉

ratio of transmitted power through the sample to incident power on the sample, expressed in

percent

4 Requirements

4.1 General

The specifications listed in Clause 4 apply in the absence of superseding agreements between

user and supplier. Manufacturing process for SAW wafers are shown in Annex B, these

specifications are expected to evolve and change as existing processes are refined and new

ones are developed. For wafers that are typically used in conjunction with a photolithographic

stepper equipment, LTV is typically specified as one of the flatness criteria. When using

projection lithography for full wafer exposure, FPD is often more relevant than TTV, as the

system will perform a tilt correction referenced off the front surface. Sori is often more

meaningful than warp since the least-squares derived reference plane used in that

measurement typically provides a more accurate representation of the wafer surface.

4.2 Diameters and tolerances

– 76,2 mm ± 0,25 mm (henceforth referred to as 76,2 mm wafer, commonly referred to as a

"3 inch" wafer);

– 100,0 mm ± 0,5 mm (henceforth referred to as 100 mm wafer, commonly referred to as a

"4 inch" wafer);

– 125,0 mm ± 0,5 mm (henceforth referred to as 125 mm wafer, commonly referred to as a

"5 inch" wafer);

– 150,0 mm ± 0,5 mm (henceforth referred to as 150 mm wafer, commonly referred to as a

"6 inch" wafer).

– 14 – IEC 62276:2025 © IEC 2025

4.3 Thickness and tolerance

Thickness is 0,18 mm to 0,80 mm. Tolerance for diameter of up to 100 mm is ±0,03 mm. For

diameter greater than 100 mm, thickness tolerance is to be agreed between the buyer and the

manufacturer.

4.4 Orientation flat

a) Dimensions of OF and tolerances

– 22,0 mm ± 3,0 mm unless otherwise agreed upon (for a 76,2 mm wafer);

– 32,5 mm ± 3,0 mm unless otherwise agreed upon (for a 100 mm wafer);

– 42,5 mm ± 3,0 mm unless otherwise agreed upon (for a 125 mm wafer);

– 47,5 mm ± 3,0 mm unless otherwise agreed upon (for a 150 mm wafer).

b) Orientation tolerance

Orientation tolerance: ±30′

Orientation of the OF shall be perpendicular to SAW propagation unless otherwise agreed

upon by the user and the supplier. Orientation of the OF for synthetic quartz wafers is in the

lesser X (-X) direction [1 1 –2 0].

4.5 Secondary flat

a) Dimensions of SF and tolerances

Dimensions and these tolerances of the SF are specified as reference values.

– 11,2 mm ± 4 mm unless otherwise agreed upon (for 76,2 mm wafer);

– 18,0 mm ± 4 mm unless otherwise agreed upon (for 100 mm wafer);

– 27,5 mm ± 4 mm unless otherwise agreed upon (for 125 mm wafer);

– 37,5 mm ± 4,5 mm unless otherwise agreed upon (for 150 mm wafer).

b) Orientation tolerance of SF

Orientation tolerances of the SF are measured with respect to the OF and are agreed on by

the user and the supplier with a typical value being ±1,0°.

Laser marking can be used as an alternative method to indicate the front surface.

4.6 Front (propagation) surface roughness

The front surface shall be polished. Surface roughness details are subject to agreement

between the user and the supplier.

4.7 Back surface roughness

As agreed upon by the user and the supplier (see Table 1).

4.8 Warp

As specified in Table 1.

4.9 TV5 and TTV

As specified in Table 1.

Table 1 – Roughness, warp, TV5 and TTV specification limits

W arp TV5 TTV

Diameter of Roughness of back

Material specified specified specified

wafer surface

value value value

(R )

μm μm μm

a

0,5 μm or greater 30 10 10

76,2 mm

(3 inch)

Less than 0,5 μm 20 10 10

Synthetic

quartz

0,5 μm or greater 40 10 10

100 mm

(4 inch)

Less than 0,5 μm 30 10 10

2,0 μm or greater 50 15 15

76,2 mm

LN, LT 2,0 μm to 0,5 μm 40 15 15

(3 inch)

Less than 0,5 μm 40 10 10

2,0 μm or greater 50 20 20

100 mm

2,0 μm to 0,5 μm 40 15 15

(4 inch)

Less than 0,5 μm 40 10 10

2,0 μm or greater 60 20 20

125 mm

LN, LT 2,0 μm to 0,5 μm 50 15 15

(5 inch)

Less than 0,5 μm 40 10 10

2,0 μm or greater 60 20 20

150 mm

2,0 μm to 0,5 μm 50 15 15

(6 inch)

Less than 0,5 μm 40 10 10

0,5 μm or greater 40 15 15

76,2 mm

(3 inch)

Less than 0,5 μm 40 10 15

LBO

0,5 μm or greater 40 10 10

100 mm

(4 inch)

Less than 0,5 μm 40 10 10

0,5 μm or greater 40 15 15

76,2 mm

(3 inch)

Less than 0,5 μm 40 10 10

LGS

0,5 μm or greater 40 20 20

100 mm

(4 inch)

Less than 0,5 μm 40 10 10

4.10 LTV and PLTV

When required, LTV and PLTV for LN and LT are specified in Table 2.

Table 2 – LTV and PLTV specification for LN and LT

Maximum LTV PLTV

Grade

(5 mm × 5 mm site) (3 mm from edge excluded)

I 0,5 μm ≥ 95 %

II 1 μm ≥ 95 %

III 2 μm ≥ 95 %

– 16 – IEC 62276:2025 © IEC 2025

4.11 Front surface defects

a) Scratches

No scratches on visual inspection.

b) Chips

1) Edge chips:

– Radial depth: less than 0,5 mm;

– Peripheral chord length: less than 1,0 mm.

2) Surface:

No chips on visual inspection.

c) Cracks

No cracks on visual inspection.

d) Contamination

No contamination on visual inspection.

e) Others

Other defects such as dimples, pits, and orange peel: no such defects on visual inspection.

4.12 Tolerance of surface orientation

– Synthetic quartz: ±10′;

– LN, LT, LBO: ±20′;

– LGS: ±10′.

4.13 Inclusions

LN/LT/LBO/LGS: No visible inclusions on naked eye inspection.

Synthetic quartz: material satisfies the specification Grade II of IEC 60758:2016, 4.1.3.

4.14 Position of seed in synthetic quartz wafer

The seed shall be included within ±3,5 mm centre width of the Z′ direction and parallel to the

X-direction of the centre of the wafer.

4.15 Electrical twins in synthetic quartz wafer

No electrical twins in synthetic quartz wafer.

4.16 Bevel

The bevel shall be as agreed upon by the user and the supplier.

4.17 Bulk resistivity (conductivity) for reduced LN and reduced LT

8 12 -12 -8

LN: 1,0 × 10 Ω·cm < BR < 1,0 × 10 Ω·cm (1,0 × 10 Ω/cm < BC < 1,0 × 10 Ω/cm).

10 13 -13 -10

LT: 1,0 × 10 Ω·cm < BR < 1,0 × 10 Ω·cm (1,0 × 10 Ω/cm < BC < 1,0 × 10 Ω/cm).

4.18 Transmittance

The requirement of transmittance is as agreed upon by the user and the supplier, according to

the product specifications.

4.19 Lightness

The requirement of lightness is as agreed upo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...