IEC 62264-2:2004

(Main)Enterprise-control system integration - Part 2: Object model attributes

Enterprise-control system integration - Part 2: Object model attributes

Specifies generic interface content between manufacturing control functions and other enterprise functions. The interfaces considered are the interfaces between Levels 3 and 4 of the hierarchical model defined in IEC 62264-1. The goal is to reduce the risk, cost, and errors associated with implementing these interfaces.

Intégration des systèmes entreprise-contrôle - Partie 2: Attributs pour les modèles d'objets

Spécifie le contenu générique des interfaces entre les fonctions de contrôle de fabrication et les autres fonctions de l'entreprise. Les interfaces considérées sont les interfaces entre les niveaux 3 et 4 du modèle hiérarchique défini dans la CEI 62264-1. Le but est de réduire le risque, le coût et les erreurs associés à la mise en application de ces interfaces.

General Information

- Status

- Published

- Publication Date

- 19-Jul-2004

- Technical Committee

- SC 65E - Devices and integration in enterprise systems

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 27-Jun-2013

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Overview - IEC 62264-2:2004 (Enterprise-control system integration - Part 2)

IEC 62264-2 defines object model attributes used to specify the generic information content exchanged between manufacturing control functions and enterprise functions. It targets the interfaces between Levels 3 and 4 of the hierarchical model (see IEC 62264-1) with the aim to reduce implementation risk, cost and errors when integrating Manufacturing Execution Systems (MES), production control and enterprise IT.

Key topics and technical requirements

- Object model structure and extensibility: standardized class/property structures for consistent mapping and extension of information models.

- Core model domains: attributes and tables for Personnel, Equipment, Material, Process Segment, Production Capability, Process Segment Capability, Product Definition, Production Schedule, and Production Performance.

- Attribute detail: per-domain attribute lists (class, property, instance levels) and example tables for implementation guidance.

- Data modelling guidance: UML notation, examples of logical relationships, and summary object inter-relationships to guide consistent model implementation.

- Implementation aids: annexes on use/examples, database mapping, XML usage and sample data sets (helpful for serialization and system interfaces).

- Compliance: provisions describing how to demonstrate conformance with the standard.

Keywords covered: IEC 62264-2, object model attributes, MES integration, Levels 3 and 4, production capability, process segment, product definition, production performance.

Practical applications and who uses it

- MES and SCADA vendors: to design object models and APIs that interoperate with enterprise resource planning (ERP) systems.

- System integrators and automation engineers: to map equipment, personnel and material data consistently across plant and enterprise systems.

- Enterprise architects and IT/OT teams: to define integration contracts and reduce semantic mismatches between control and business layers.

- Database and XML/schema designers: to implement data persistence and exchange formats using the example database mappings and XML guidance in the annexes.

Typical applications include production scheduling exchange, capability and routing definitions, performance reporting, QA/lot tracking, and maintenance work-order integration.

Related standards

- IEC 62264-1 (hierarchical model and terminology) - foundational for Levels 3/4 interfaces.

- Implementation often aligns with other enterprise-control standards and integration frameworks used in manufacturing IT.

By standardizing object attributes and structure, IEC 62264-2 helps organizations implement consistent, interoperable enterprise-to-manufacturing interfaces that improve data accuracy, reduce integration cost, and speed deployment.

IEC 62264-2:2004 - Enterprise-control system integration - Part 2: Object model attributes Released:7/20/2004 Isbn:2831875757

IEC 62264-2:2004 - Enterprise-control system integration - Part 2: Object model attributes Released:7/20/2004 Isbn:2831881277

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

Sponsored listings

Frequently Asked Questions

IEC 62264-2:2004 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Enterprise-control system integration - Part 2: Object model attributes". This standard covers: Specifies generic interface content between manufacturing control functions and other enterprise functions. The interfaces considered are the interfaces between Levels 3 and 4 of the hierarchical model defined in IEC 62264-1. The goal is to reduce the risk, cost, and errors associated with implementing these interfaces.

Specifies generic interface content between manufacturing control functions and other enterprise functions. The interfaces considered are the interfaces between Levels 3 and 4 of the hierarchical model defined in IEC 62264-1. The goal is to reduce the risk, cost, and errors associated with implementing these interfaces.

IEC 62264-2:2004 is classified under the following ICS (International Classification for Standards) categories: 25.040.40 - Industrial process measurement and control; 35.240.50 - IT applications in industry. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62264-2:2004 has the following relationships with other standards: It is inter standard links to IEC 62264-2:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62264-2:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 62264-2

First edition

2004-07

Enterprise-control system integration –

Part 2:

Object model attributes

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/searchpub) enables you to

search by a variety of criteria including text searches, technical committees

and date of publication. On-line information is also available on recently issued

publications, withdrawn and replaced publications, as well as corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/online_news/ justpub)

is also available by email. Please contact the Customer Service Centre (see

below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD 62264-2

First edition

2004-07

Enterprise-control system integration –

Part 2:

Object model attributes

© IEC 2004

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any

means, electronic or mechanical, including photocopying and microfilm, without permission in writing from the publisher.

IEC Copyright Office Case postale 56 CH-1211 Genève 20 Switzerland

• • •

PRICE CODE

XD

For price, see current catalogue

– 2 – 62264-2 © IEC:2004(E)

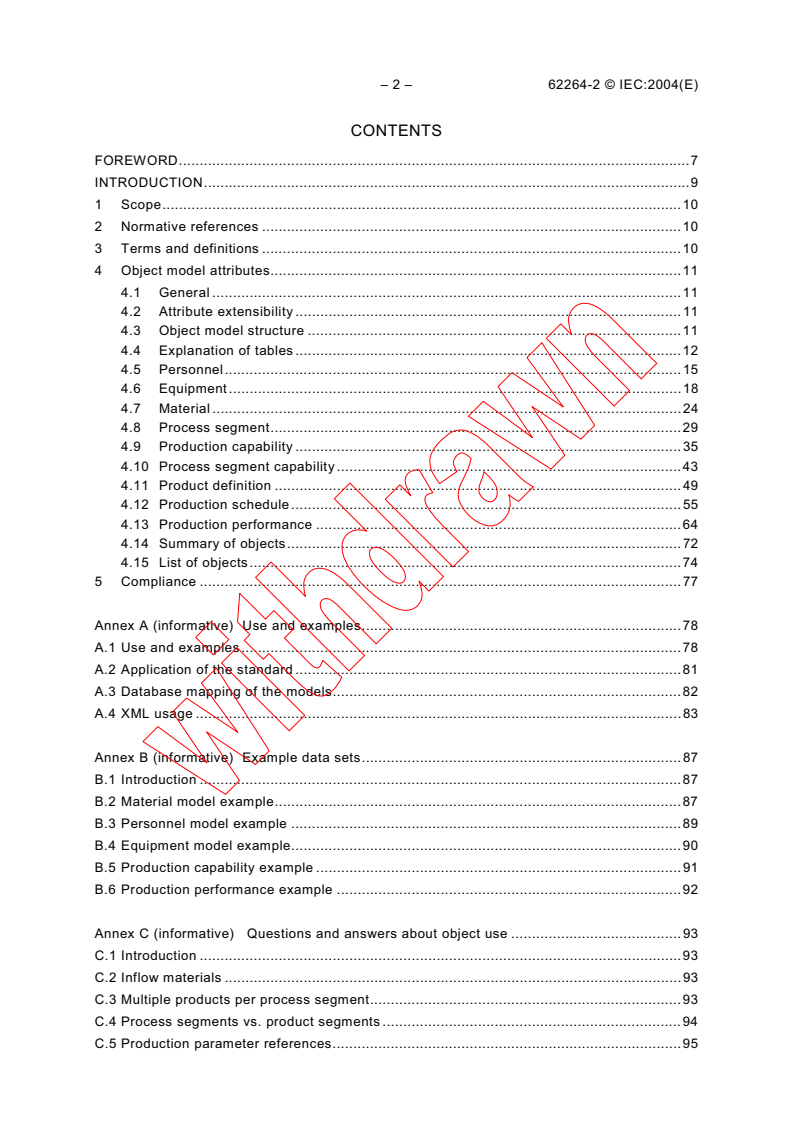

CONTENTS

FOREWORD.7

INTRODUCTION.9

1 Scope.10

2 Normative references .10

3 Terms and definitions .10

4 Object model attributes.11

4.1 General .11

4.2 Attribute extensibility .11

4.3 Object model structure .11

4.4 Explanation of tables .12

4.5 Personnel.15

4.6 Equipment.18

4.7 Material .24

4.8 Process segment.29

4.9 Production capability .35

4.10 Process segment capability .43

4.11 Product definition .49

4.12 Production schedule.55

4.13 Production performance .64

4.14 Summary of objects.72

4.15 List of objects.74

5 Compliance .77

Annex A (informative) Use and examples.78

A.1 Use and examples.78

A.2 Application of the standard .81

A.3 Database mapping of the models.82

A.4 XML usage .83

Annex B (informative) Example data sets.87

B.1 Introduction .87

B.2 Material model example.87

B.3 Personnel model example .89

B.4 Equipment model example.90

B.5 Production capability example .91

B.6 Production performance example .92

Annex C (informative) Questions and answers about object use .93

C.1 Introduction .93

C.2 Inflow materials .93

C.3 Multiple products per process segment.93

C.4 Process segments vs. product segments .94

C.5 Production parameter references.95

62264-2 © IEC:2004(E) – 3 –

C.6 How class name and property names are used to identify elements.96

C.7 Possible capability over-counts.97

C.8 Routing and process capability .98

C.9 Product and process capability dependencies.100

C.10 Representation of dependencies.101

C.11 Representation of material produced and consumed.102

C.12 Material produced and the capability model .102

C.13 How a material transfer is handled.102

C.14 Why the maintenance and QA models are different from the production model .103

Annex D (informative) Logical information flows.104

Figure 1 – Detailed relationship models .14

Figure 2 – Personnel model .15

Figure 3 – Equipment model .18

Figure 4 – Material model .24

Figure 5 – Process segment model .29

Figure 6 – Production capability model .35

Figure 7 – Process segment capability.43

Figure 8 – Product definition model.49

Figure 9 – Production schedule model .55

Figure 10 – Production performance model.64

Figure 11 – Object model inter-relationships .73

Figure A.1 – Personnel model.79

Figure A.2 – Instances of a person class .80

Figure A.3 – UML model for class and class properties .80

Figure A.4 – Class property .80

Figure A.5 – Instances of a person properties .81

Figure A.6 – Instances of person and person properties .81

Figure A.7– XML schema for a person object.84

Figure A.8 – XML schema for person properties.84

Figure A.9 – Example of person and person property.85

Figure A.10 – Example of person class information.85

Figure A.11 – Adaptor to map different property names and values.86

Figure C.1 – Class and property names used to identify elements .96

Figure C.2 – A property defining overlapping subsets of the capability.98

Figure C.3 – Routing for a product .99

Figure C.4 – Routing with co-products and material dependencies.99

Figure C.5 – Product and process capability relationships .100

Figure C.6 – Time-based dependencies .101

Figure C.7 – Maintenance schedule and performance model .103

Figure D.1 – Enterprise to manufacturing system logical information flows .104

Figure D.2 – Logical information flows among multiple systems .105

– 4 – 62264-2 © IEC:2004(E)

Table 1 – UML notation used .12

Table 2 – Example table .13

Table 3 – Attributes of personnel class .15

Table 4 – Attributes of personnel class property .16

Table 5 – Attributes of person .16

Table 6 – Attributes of person property .17

Table 7 – Attributes of qualification test specification.17

Table 8 – Attributes of qualification test result.18

Table 9 – Attributes of equipment class .19

Table 10 – Attributes of equipment class property.19

Table 11 – Attributes of equipment .20

Table 12 – Attributes of equipment property.20

Table 13 – Attributes of equipment capability test specification.21

Table 14 – Attributes of equipment capability test result .21

Table 15 – Attributes of maintenance request .22

Table 16 – Attributes of maintenance work order .22

Table 17 – Attributes of maintenance response.23

Table 18 – Attributes of material class .24

Table 19 – Attributes of material class property .25

Table 20 – Attributes of material definition .25

Table 21 – Attributes of material definition property .25

Table 22 – Attributes of material lot .26

Table 23 – Attributes of material lot property.26

Table 24 – Attributes of material sublot.27

Table 25 – Attributes of QA test specification.27

Table 26 – Attributes of QA test result .28

Table 27 – Attributes of process segment .30

Table 28 – Attributes of personnel segment specification.30

Table 29 – Attributes of personnel segment specification property .31

Table 30 – Attributes of equipment segment specification .31

Table 31 – Attributes of equipment segment specification property .32

Table 32 – Attributes of material segment specification.32

Table 33 – Attributes of material segment specification property.33

Table 34 – Attributes of process segment parameter .33

Table 35 – Attributes of process segment dependency .34

Tabe 36 – Attributes of production capability .36

Table 37 – Attributes of personnel capability.37

Table 38 – Attributes of personnel capability property.38

Table 39 – Attributes of equipment capability.39

62264-2 © IEC:2004(E) – 5 –

Table 40 – Attributes of equipment capability property .40

Table 41 – Attributes of material capability .41

Table 42 – Attributes of material capability property.42

Table 43 – Attributes of process segment capability.44

Table 44 – Attributes of personnel segment capability .45

Table 45 – Attributes of personnel segment capability property.45

Table 46 – Attributes of equipment segment capability.46

Table 47 – Attributes of equipment segment capability property.46

Table 48 – Attributes of material segment capability .47

Table 49 – Attributes of material segment capability property .48

Table 50 – Attributes of product definition.50

Table 51 – Attributes of manufacturing bill .50

Table 52 – Attributes of product segment.51

Table 53 – Attributes of product parameter .51

Table 54 – Attributes of personnel specification .51

Table 55 – Attributes of personnel specification property .52

Table 56 – Attributes of equipment specification .52

Table 57 – Attributes of equipment specification property .53

Table 58 – Attributes of mmaterial specification .53

Table 59 – Attributes of material specification property .54

Table 60 – Attributes of product segment dependency .54

Table 61 – Attributes of production schedule .56

Table 62 – Attributes of production request.56

Table 63 – Attributes of segment requirement.57

Table 64 – Attributes of production parameter.58

Table 65 – Attributes of personnel requirement.58

Table 66 – Attributes of personnel requirement property .59

Table 67 – Attributes of equipment requirement .59

Table 68 – Attributes of equipment requirement property .60

Table 69 – Attributes of material produced requirement .60

Table 70 – Attributes of material produced requirement property .61

Table 71 – Attributes of material consumed requirement.61

Table 72 – Attributes of material consumed requirement property .62

Table 73 – Attributes of consumable expected .62

Table 74 – Attributes of consumable expected property .63

Table 75 – Attributes of production performance.65

Table 76 – Attributes of production response .65

Table 77 – Attributes of segment response .66

Table 78 – Attributes of production data.67

Table 79 – Attributes of personnel actual .67

Table 80 – Attributes of personnel actual property .68

Table 81 – Attributes of equipment actual .68

Table 82 – Attributes of equipment actual property .69

– 6 – 62264-2 © IEC:2004(E)

Table 83 – Attributes of material produced actual .69

Table 84 – Attributes of material produced actual property.70

Table 85 – Attributes of material consumed actual .70

Table 86 – Attributes of material consumed actual property .71

Table 87 – Attributes of consumable actual.71

Table 88 – Attributes of consumable actual property.72

Table 89 – Personnel model objects .74

Table 90 – Equipment model objects .74

Table 91 – Material model objects .74

Table 92- Process segment model objects .75

Table 93 – Production capability model objects.75

Table 94 – Process segment capability model objects.75

Table 95 – Product definition object models.75

Table 96 – Production schedule model objects .76

Table 97 – Production performance object models .76

Table A.1 – Attributes of person.79

Table A.2 – Database structure for person.82

Table A.3 – Database structure for person property .82

Table A.4 – Database for person with data .82

Table C.1 – Definition of segment types.95

62264-2 © IEC:2004(E) – 7 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ENTERPRISE-CONTROL SYSTEM INTEGRATION –

Part 2: Object model attributes

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62264-2 has been prepared by subcommittee 65A: System

aspects, of IEC technical committee 65: Industrial-process measurement and control, and ISO

SC5, JWG 15, of ISO technical committee 184: Enterprise-control system integration.

It is published as double logo standard.

This standard is based upon ANSI/ISA-95.00.02-2001, Enterprise-Control System Integration,

Part 2: Object Model Attributes. It is used with permission of the copyright holder, the

Instrumentation, Systems and Automation Society (ISA) . ISA encourages the use and

application of its industry standards on a global basis.

___________

For information on ISA standards, contact ISA at: ISA – The Instrumentation, Systems and Automation Society,

PO Box 12277, Research Triangle Park, NC 27709, USA, Tel. 1+919.549.8411, URL: standards.isa.org.

– 8 – 62264-2 © IEC:2004(E)

This standard was submitted to the National Committees for voting under the Fast Track

Procedure as the following documents:

FDIS Report on voting

65A/408/FDIS 65A/416/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table. In ISO, the standard has been approved by 10 P members

out of 11 having cast a vote.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

IEC 62264 consists of the following parts under the general title Enterprise-control system

integration:

Part 1: Models and terminology

Part 2: Object model attributes

Part 3: Models of manufacturing operations

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

A bilingual version may be issued at a later date.

62264-2 © IEC:2004(E) – 9 –

INTRODUCTION

IEC 62264 is a multi-part standard that defines the interface content between enterprise

activities and control activities. This part of IEC 62264 provides the definitions of the

attributes of the object models in IEC 62264-1.

IEC 62264 defines object models of exchanged information between enterprise systems and

control systems. This part of IEC 62264 adds details to the object models through the

definition of attributes, so that implement able interfaces may be constructed. IEC 62264

does not define models of enterprise objects or control objects.

The area of concern of this standard is strongly related to the ISO TC 184 (Industrial

automation systems and integration) scope. Nevertheless the objectives and approaches are

completely different and complementary. Relevant TC184 standards or work in progress

address the modeling of enterprise and/or the modeling of enterprise objects whereas this

standard specifies the content of interfaces between control functions and enterprise

functions. The functions may be precisely modeled with TC184 standards. See

ISO/IEC 62264-1 Annex A for further details.

– 10 – 62264-2 © IEC:2004(E)

ENTERPRISE-CONTROL SYSTEM INTEGRATION –

Part 2: Object model attributes

1 Scope

This part of IEC 62264, in conjunction with IEC 62264-1, specifies generic interface content

between manufacturing control functions and other enterprise functions. The interfaces

considered are the interfaces between Levels 3 and 4 of the hierarchical model defined in

IEC 62264-1. The goal is to reduce the risk, cost, and errors associated with implementing

these interfaces.

Since IEC 62264 covers many domains, and there are many different standards in those

domains, the semantics of this Standard are described at a level intended to enable the other

standards to be mapped to these semantics. To this end, this Standard defines a set of

generic interfaces content elements, together with a mechanism for extending those elements

for implementations.

The scope of this part of IEC 62264 is limited to the definition of attributes of the IEC 62264-1

object models.

This part of IEC 62264 does not define attributes to represent the object relationships defined

in IEC 62264-1.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 62264-1, Enterprise-Control System Integration – Part 1: Models and terminology

ISO 10303-1:1994, Industrial automation systems and integration – Product data representa-

tion and exchange – Part 1: Overview and fundamental principles

ISO 15704:2000, Industrial automation systems – Requirements for enterprise–reference

architectures and methodologies

3 Terms and definitions

For the purpose of this document, the terms and definitions given in IEC 62264-1 as well as

the following apply.

3.1

event

representation of a solicited or unsolicited fact indicating a state change in the enterprise

62264-2 © IEC:2004(E) – 11 –

3.2

product

the desired output or by-product of the processes of an enterprise

NOTE 1 A product may be an intermediate product or end product from a business perspective.

NOTE 2 Also defined in ISO 10303-1 as: ‘a substance produced by a natural or artificial process’.

3.3

property

object denoting an implementation specific characteristic of an entity

4 Object model attributes

4.1 General

This clause describes the attributes associated with the objects listed in IEC 62264-1.

Tables 3 to 88 in Clause 4 define the attributes of objects defined in IEC 62264-1, Clause 7.

The attributes are an extension to the object information model presented in IEC 62264-1 and

are thus a part of the definition of terms. The attributes of this part of IEC 62264 and the

object models of IEC 62264-1 define interface content for integration of Level 3 and Level 4

enterprise-control systems. See also IEC 62264-1, Clause 7.4.

In this part of IEC 62264, the word “Class” used as part of an object definition name is to be

considered as a category, not as a “Class” in the object-oriented sense.

EXAMPLE “Personnel class” is to be considered a “personnel category”, in the sense of distinguishing between the

kinds of personnel in the real world.

A minimum set of industry-independent information has been defined, in this part of

IEC 62264, as attributes. However, values for all attributes may not be required depending on

the actual usage of the models. If additional information, including industry- and application-

specific information, is needed, it shall be represented as property objects. This mechanism is

the extension capability referenced in Clause 1. This solution increases the usability through

the use of standard attributes, and allows flexibility and extensibility through the use of

properties. This was done to make the standard as widely applicable as possible.

4.2 Attribute extensibility

For particular applications, the objects defined in the object models will need to be extended

through the addition of attributes to object class definitions. Accordingly, this part of

IEC 62264 provides for attributes that are application or industry specific, to be modeled in

terms of properties and represented in property classes in the model. For example, the

personnel class property would be used to define application or industry specific attributes for

personnel classes, and person property would be used to contain instance values for the

properties.

4.3 Object model structure

The object models are depicted using the Unified Modelling Language (UML) notational

methodology.

Table 1 defines the UML notations used in the object diagrams.

– 12 – 62264-2 © IEC:2004(E)

Table 1 – UML notation used

Symbol Definition

Defines a package, a collection of object models, state models, use

classes, and other UML models. In this document a package is used to

specify an external model, such as a production rule model, or a reference

Package

to another part of the model.

Defines a class of objects, each with the same types of attributes. Each

object is uniquely identifiable or enumerable. No operations or methods are

Class

listed for the classes. Attributes with a “ – ” before their name indicate

attributes that are generally optional in any use of the class.

An association between elements of a class and elements of another or the

same class. Each association is identified. May have the expected number

Role 1.1 or range of members of the subclass, when ‘n’ indicates an indeterminate

number. For example, 0,n means that zero or more members of the

Association name

0.n Role

subclass may exist.

Generalization (arrow points to the super class) shows that an element of

the class is a specialized type of the super class.

Is a type of

Dependence is a weak association that shows that a modelling element

depends on another modelling element. The item at the tail depends on the

Depends on

item at the head of the relationship.

Aggregation (made up of) shows that an element of the class is made up of

elements of other classes.

Is an aggregation of

Composite shows a strong form of aggregation, which requires that a part

instance be included in at most one composite at a time and that the

Is a composite of

composite object has sole responsibility for disposition of its parts.

4.4 Explanation of tables

4.4.1 Tables of attributes

This subclause gives the meaning of the attribute tables. This includes a listing of the object

identification, data types, and presentation of the examples in the tables.

4.4.2 Object identification

Many objects in the information model require unique identifications (IDs). These IDs shall be

unique within the scope of the exchanged information. This may require translations:

– from the internal ID of the source system to the interface content ID;

– from the interface content ID to the internal ID of the target system.

EXAMPLE A unit may be identified as “X6777” in the interface content, as resource “R100011” in the business

system, and as “East Side Reactor” in the control system.

A unique identification set shall be agreed to in order to exchange information.

The object IDs are used only to identify objects within related exchanged information sets.

The object ID attributes are not global object IDs or database index attributes.

62264-2 © IEC:2004(E) – 13 –

Generally, objects that are elements of aggregations, and are not referenced elsewhere in the

model, do not require unique IDs.

4.4.3 Data types

The attributes presented are abstract representations, without any specific data type

specified. A specific implementation will show how the information is represented.

Example 1 An attribute may be represented as a string in one implementation and as a

numeric value in another implementation.

Example 2 A date/time value may be represented in ISO standard format in one

implementation and in Julian calendar format in another.

Example 3 A relationship may be represented by two fields (type and key) in database

tables or by a specific tag in XML.

4.4.4 Presentation of examples

Examples are included with each attribute given. Where multiple examples are used, there

are multiple rows in the right hand column. See Table Table 2 below for how the example

rows and columns are used.

Table 2 – Example table

Attribute name Description Examples

Name of first attribute Description of first attribute Example #1 for first attribute

Example #2 for first attribute

Example #3 for first attribute

Name of second attribute Description of second attribute Example #1 for second attribute

Example #2 for second attribute

Example #3 for second attribute

Name of third attribute Description of third attribute Example #1 for third attribute

Example #2 for third attribute

Example #3 for third attribute

When an example value is a set of values, or a member of a set of values, the set of values is

given within a set of braces, {}.

The examples are purely fictional. They are provided to further describe attributes in the

model. No attempt was made to make the examples complete or representative of any

manufacturing enterprise.

4.4.5 Data relationships

The models used to document a reference to a resource, in another package, using the class

or instance, with additional optional specification using properties, are not fully illustrated in

the IEC 62264-1 object model figures. This relationship does not conform to the Unified

Modeling Language (UML) modeling methodology, but was done to keep the diagrams

simpler. Figure 1 illustrates how it is currently presented, on the left side, and how it could be

more accurately modeled in UML on the right side. UML was used in this standard as a

visualization method and not meant to describe implementations. The simplified relationship

diagram method is used for the following objects and their relationship to another package:

– 14 – 62264-2 © IEC:2004(E)

Personnel capability Equipment capability

Material capability Personnel segment capability

Equipment segment capability Material segment capability

Personnel segment specification Equipment segment specification

Material segment specification Personnel specification

Equipment specification Material specification

Personnel requirement Equipment requirement

Material produced requirement Material consumed requirement

Consumable expected Personnel actual

Equipment actual Material produced actual

Material consumed actual Consumable actual

ReRessoouurrcece

Ccaappaabbilitilityy

0.n

ReRessoouurrcece

ReRessoouurrcece

Note: The

Ccaappaabbilitilityy

Ccaappaabbilitilityy

correspondence

Pprropopererttyy

relationship is

defined through one

0.n 0.n

and only one of four

0.n

relationships A, A and

ReRessoouurrcece

B, C, or C and D.

Ccaappaabbilitilityy

A C

Pprropopererttyy

B D

0.1

0.n Corresponds

to element in 0.n

0.1

ResoResoururccee 0.n ResoResoururccee

Catcateegogory ry Definitidefinitioonn Definitidefinitioonn

Defined

1.1

by

ReRessoouurrcece

Modmodelel

0.n

0.n

1.1

ResoResoururccee 1.1

Simplified relationship ResoResoururccee

Catcateegogoryry

Pprropopererttyy

Maps to

Pprropopererttyy

model

Detailed relationship

model

IEC 953/04

Figure 1 – Detailed relationship models

The correspondence relationship is determined through one and only one of four possible

relationships: to the resource catagory definition; to the resource catagory definition and

resource catagory property; to the resource definition; or to the resource definition and

resource property.

In the model above, the term resource catagory indicates: personnel class, equipment class,

material class, and material definitions. The term resource indicates: person, equipment,

material lot, and material sublot. The term resource capability indicates the use in the

capability model, the process segment capability model, the process segment model, the

product definition model, the production schedule model, and the production performance

model.

Corresponds

to element in

Corresponds

to element in

Corresponds

to element in

Corresponds

to element in

62264-2 © IEC:2004(E) – 15 –

4.5 Personnel

4.5.1 Personnel model

The personnel model contains the information about specific personnel, classes of personnel,

and qualifications of personnel. Figure 2 is a modified copy of Figure 14 in Part 1. This

corresponds to a resource model for personnel, as given in ISO 15704.

0.n

Personnel

Person

class 0.n

Defined by

0.n

0.n

Maps to

Personnel Person

class property property

1.n 0.n

< Records the

Qualification

testing of

test

Qualification

0.n 0.n

result

test

< Defines a procedure

Is used to test >

specification

for how to test

IEC 954/04

Figure 2 – Personnel model

4.5.2 Personnel class

Table 3 lists the attributes of personnel class.

Table 3 – Attributes of personnel class

Attribute

...

IEC 62264-2

Edition 1.0 2004-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Enterprise-control system integration –

Part 2: Object model attributes

Intégration des systèmes entreprise-contrôle –

Partie 2: Attributs pour les modèles d’objets

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 62264-2

Edition 1.0 2004-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Enterprise-control system integration –

Part 2: Object model attributes

Intégration des systèmes entreprise-contrôle –

Partie 2: Attributs pour les modèles d’objets

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

XE

CODE PRIX

ICS 25.040.40; 35.240.50 ISBN 2-8318-8127-7

– 2 – 62264-2 © CEI:2004

SOMMAIRE

AVANT-PROPOS.14

INTRODUCTION.18

1 Domaine d’application .20

2 Références normatives.20

3 Termes et définitions .20

4 Attributs des modèles d’objets.22

4.1 Généralités.22

4.2 Extensibilité des attributs .22

4.3 Structure des modèles d’objets .22

4.4 Explication des Tableaux.24

4.4.1 Tableaux des attributs .24

4.4.2 Identification des objets.24

4.4.3 Types de données .26

4.4.4 Présentation des exemples.26

4.4.5 Relation entre les données .26

4.5 Personnel.30

4.5.1 Modèles de personnel .30

4.5.2 Classe de personnel.30

4.5.3 Propriété de classe de personnel.32

4.5.4 Personne.32

4.5.5 Propriétés de personne .34

4.5.6 Spécification de test de qualification.34

4.5.7 Résultat de test de qualification.36

4.6 Equipement .36

4.6.1 Modèle d’équipement .36

4.6.2 Classe d’équipement .38

4.6.3 Propriété de classe d’équipement.38

4.6.4 Equipement .40

4.6.5 Propriété d’équipement.40

4.6.6 Spécification de test de capacité d’équipement.42

4.6.7 Résultat de test de capacité d’équipement.42

4.6.8 Demande de maintenance .44

4.6.9 Ordre de travail de maintenance.44

4.6.10 Réponse de maintenance .46

4.7 Matière.48

4.7.1 Modèle matière.48

4.7.2 Classe matière .48

4.7.3 Propriété de la classe matière .50

4.7.4 Définition matière .50

4.7.5 Propriété de définition matière.50

4.7.6 Lot matière .52

4.7.7 Propriété de lot matière .52

4.7.8 Sous-lot matière .54

4.7.9 Spécification de test AQ .54

4.7.10 Résultats de test AQ.56

62264-2 © IEC:2004 – 3 –

CONTENTS

FOREWORD.15

INTRODUCTION.19

1 Scope.21

2 Normative references .21

3 Terms and definitions .21

4 Object model attributes.23

4.1 General .23

4.2 Attribute extensibility .23

4.3 Object model structure .23

4.4 Explanation of tables .25

4.4.1 Tables of attributes.25

4.4.2 Object identification.25

4.4.3 Data types .27

4.4.4 Presentation of examples .27

4.4.5 Data relationships.27

4.5 Personnel.31

4.5.1 Personnel model.31

4.5.2 Personnel class .31

4.5.3 Personnel class property .33

4.5.4 Person.33

4.5.5 Person property.35

4.5.6 Qualification test specification .35

4.5.7 Qualification test result .37

4.6 Equipment.37

4.6.1 Equipment model.37

4.6.2 Equipment class .39

4.6.3 Equipment class property .39

4.6.4 Equipment .41

4.6.5 Equipment property .41

4.6.6 Equipment capability test specification .43

4.6.7 Equipment capability test result .43

4.6.8 Maintenance request .45

4.6.9 Maintenance work order .45

4.6.10 Maintenance response.47

4.7 Material .49

4.7.1 Material model.49

4.7.2 Material class .49

4.7.3 Material class property .51

4.7.4 Material definition .51

4.7.5 Material definition property .51

4.7.6 Material lot .53

4.7.7 Material lot property.53

4.7.8 Material sublot.55

4.7.9 QA test specification.55

4.7.10 QA test result .57

– 4 – 62264-2 © CEI:2004

4.8 Segment processus.58

4.8.1 Modèle de segment processus .58

4.8.2 Segment processus .58

4.8.3 Spécification du segment personnel .60

4.8.4 Propriété de la spécification du segment personnel .62

4.8.5 Spécification de segment d’équipement.62

4.8.6 Propriété de la spécification de segment d’équipement.64

4.8.7 Spécification de segment matière .64

4.8.8 Propriété de spécification de segment matière.66

4.8.9 Paramètre de spécification de segment processus .66

4.8.10 Dépendance de segment processus .66

4.9 Capacité de production.70

4.9.1 Modèle de capacité de production .70

4.9.2 Capacité de production.72

4.9.3 Capacité de personnel.74

4.9.4 Propriété de capacité de personnel .76

4.9.5 Capacité d’équipement .78

4.9.6 Propriété de capacité d’équipement.80

4.9.7 Capacité de matière .82

4.9.8 Propriété de capacité de matière .84

4.10 Capacité de segment de processus .86

4.10.1 Modèle de capacité de segment de processus.86

4.10.2 Capacité de segment processus .88

4.10.3 Capacité de segment personnel.90

4.10.4 Propriété de capacité de segment de personnel .90

4.10.5 Capacité de segment équipement.92

4.10.6 Propriété de capacité de segment équipement .94

4.10.7 Capacité de segment matière .94

4.10.8 Propriété de capacité de segment matière.98

4.11 Définition du produit .100

4.11.1 Modèle de définition du produit.100

4.11.2 Définition du produit .102

4.11.3 Nomenclature de fabrication .102

4.11.4 Segment produit .104

4.11.5 Paramètre produit.104

4.11.6 Spécification de personnel.106

4.11.7 Propriété de spécification de personnel .106

4.11.8 Spécification d'équipement .108

4.11.9 Propriété de spécification d'équipement.108

4.11.10 Spécification de matière .110

4.11.11 Propriété de spécification de matière.110

4.11.12 Dépendance de segment produit .112

4.12 Plan de production .114

4.12.1 Modèle de Plan de production .114

4.12.2 Plan de production .116

4.12.3 Demande de production.116

4.12.4 Besoin de segment .118

4.12.5 Paramètre de production .120

4.12.6 Besoin en personnel.120

62264-2 © IEC:2004 – 5 –

4.8 Process segment.59

4.8.1 Process segment model .59

4.8.2 Process segment.59

4.8.3 Personnel segment specification .61

4.8.4 Personnel segment specification property.63

4.8.5 Equipment segment specification .63

4.8.6 Equipment segment specification property.65

4.8.7 Material segment specification.65

4.8.8 Material segment specification property.67

4.8.9 Process segment parameter .67

4.8.10 Process segment dependency .67

4.9 Production capability .71

4.9.1 Production capability model.71

4.9.2 Production capability .73

4.9.3 Personnel capability .75

4.9.4 Personnel capability property .77

4.9.5 Equipment capability .79

4.9.6 Equipment capability property.81

4.9.7 Material capability .83

4.9.8 Material capability property.85

4.10 Process segment capability .87

4.10.1 Process segment capability model.87

4.10.2 Process segment capability .89

4.10.3 Personnel segment capability .91

4.10.4 Personnel segment capability property .91

4.10.5 Equipment segment capability .93

4.10.6 Equipment segment capability property .95

4.10.7 Material segment capability .95

4.10.8 Material segment capability property .99

4.11 Product definition .101

4.11.1 Product definition model .101

4.11.2 Product definition .103

4.11.3 Manufacturing bill .103

4.11.4 Product segment .105

4.11.5 Product parameter.105

4.11.6 Personnel specification.107

4.11.7 Personnel specification property.107

4.11.8 Equipment specification.109

4.11.9 Equipment specification property.109

4.11.10 Material specification.111

4.11.11 Material specification property .111

4.11.12 Product segment dependency.113

4.12 Production schedule.115

4.12.1 Production schedule model.115

4.12.2 Production schedule .117

4.12.3 Production request .117

4.12.4 Segment requirement .119

4.12.5 Production parameter .121

4.12.6 Personnel requirement .121

– 6 – 62264-2 © CEI:2004

4.12.7 Propriété de besoin en personnel .122

4.12.8 Besoin en équipement .122

4.12.9 Propriété de besoin en équipement .124

4.12.10 Besoin en matière produite .124

4.12.11 Propriété de besoin en matière produite .126

4.12.12 Besoin en matière consommée.126

4.12.13 Propriété de besoin en matière consommée .128

4.12.14 Consommable attendu.128

4.12.15 Propriété de consommable attendu.130

4.12.16 Réponse de segment demandée.130

4.13 Rapport de production .132

4.13.1 Modèle de rapport de production .132

4.13.2 Rapport de production .134

4.13.3 Réponse de production.134

4.13.4 Réponse de segment.136

4.13.5 Données de production.138

4.13.6 Réel personnel .138

4.13.7 Propriété de réel personnel .140

4.13.8 Réel équipement .140

4.13.9 Propriété de réel équipement.142

4.13.10 Réel matière produite .142

4.13.11 Propriété de réel matière produite .144

4.13.12 Réel matière consommée .144

4.13.13 Propriété de réel matière consommée .146

4.13.14 Réel consommable .146

4.13.15 Propriété de réel consommable .148

4.14 Résumé des objets.148

4.15 Liste des objets .152

5 Conformité .158

Annex A (informative) Utilisation et exemples .160

Annex B (informative) Exemple d’ensemble de données .178

Annex C (informative) Questions et réponses concernant l’utilisation des objets.190

Annex D (informative) Flux d’informations logiques.212

Figure 1 – Modèles de relation détaillée.28

Figure 2 – Modèle de personnel.30

Figure 3 – Modèle d’équipement .36

Figure 4 – Modèle matière .48

Figure 5 – Modèle de segment processus .58

Figure 6 – Modèle de capacité de production .70

Figure 7 – Capacité de segment de processus.86

Figure 8 – Modèle de définition du produit .100

Figure 9 – Modèle de Plan de production .114

Figure 10 – Modèle de rapport de production.132

Figure 11 – Inter-relation du modèle objet.150

62264-2 © IEC:2004 – 7 –

4.12.7 Personnel requirement property.123

4.12.8 Equipment requirement.123

4.12.9 Equipment requirement property.125

4.12.10 Material produced requirement .125

4.12.11 Material produced requirement property .127

4.12.12 Material consumed requirement.127

4.12.13 Material consumed requirement property .129

4.12.14 Consumable expected .129

4.12.15 Consumable expected property .131

4.12.16 Requested segment response .131

4.13 Production performance .133

4.13.1 Production performance model .133

4.13.2 Production performance .135

4.13.3 Production response.135

4.13.4 Segment response.137

4.13.5 Production data .139

4.13.6 Personnel actual.139

4.13.7 Personnel actual property.141

4.13.8 Equipment actual.141

4.13.9 Equipment actual property.143

4.13.10 Material produced actual .143

4.13.11 Material produced actual property.145

4.13.12 Material consumed actual .145

4.13.13 Material consumed actual property .147

4.13.14 Consumable actual .147

4.13.15 Consumable actual property .149

4.14 Summary of objects.149

4.15 List of objects.153

5 Compliance .159

Annex A (informative) Use and examples.161

Annex B (informative) Example data sets.179

Annex C (informative) Questions and answers about object use .191

Annex D (informative) Logical information flows.213

Figure 1 – Detailed relationship models .29

Figure 2 – Personnel model .31

Figure 3 – Equipment model .37

Figure 4 – Material model .49

Figure 5 – Process segment model .59

Figure 6 – Production capability model .71

Figure 7 – Process segment capability.87

Figure 8 – Product definition model.101

Figure 9 – Production schedule model .115

Figure 10 – Production performance model.133

Figure 11 – Object model inter-relationships .151

– 8 – 62264-2 © CEI:2004

Figure A.1 – Modèle de personnel .162

Figure A.2 – Instances d'une classe de personne .164

Figure A.3 – Modèle UML applicable à la classe et aux propriétés de classe .164

Figure A.4 – Propriété de classe .166

Figure A.5 – Instances relatives aux propriétés d'une personne.166

Figure A.6 – Instances de personne et de propriétés de personne .166

Figure A.7– Schéma XML de l’objet d’une personne .172

Figure A.8 – Schéma XML des propriétés d’une personne .174

Figure A.9 – Exemple d’attributs relatifs à une personne et à la propriété de personne.174

Figure A.10 – Exemple d’information concernant la classe de personne .176

Figure A.11 – Adaptateur de correspondance entre différents noms et valeurs de

propriété .176

Figure C.1 – Noms de classe et de propriété pour identifier des éléments .196

Figure C.2 – Propriété définissant les sous-ensembles de recouvrement de la capacité .200

Figure C.3 – Routage d'un produit .202

Figure C.4 – Routage avec les dépendances de co-produits et de matières.202

Figure C.5 – Relations entre les capacités de produit et de processus.204

Figure C.6 – Dépendances temporelles .206

Figure C.7 – Modèle de plan et de rapport de maintenance .210

Figure D.1 – Flux d'information logique entre les systèmes d'entreprise et les

systèmes de fabrication .212

Figure D.2 – Flux d'information logique entre plusieurs systèmes .214

Tableau 1 – Notation ULM utilisée .24

Tableau 2 – Exemple de Tableau.26

Tableau 3 – Attributs relatifs à la classe de personnel .30

Tableau 4 – Attributs relatifs à la propriété de classe de personnel.32

Tableau 5 – Attributs relatifs à la personne .32

Tableau 6 – Attributs relatifs à la propriété de personne .34

Tableau 7 – Attributs relatifs à la spécification de test de qualification .34

Tableau 8 – Attributs relatifs au résultat de test de qualification.36

Tableau 9 – Attributs relatifs à la classe d’équipement.38

Tableau 10 – Attributs relatifs à la propriété de classe d’équipement .38

Tableau 11 – Attributs relatifs aux équipements.40

Tableau 12 – Attributs relatifs à la propriété d’équipement.40

Tableau 13 – Attributs relatifs à la spécification de test de capacité d’équipement .42

Tableau 14 – Attributs relatifs au résultat de test de capacité d’équipement.42

Tableau 15 – Attributs relatifs à la demande de maintenance.44

Tableau 16 – Attributs relatifs à l’ordre de travail de maintenance .44

Tableau 17 – Attributs relatifs à la réponse de maintenance .46

Tableau 18 – Attributs relatifs à la classe matière .48

Tableau 19 – Attributs relatifs à la propriété de la classe matière.50

Tableau 20 – Attributs relatifs à la définition matière.50

Tableau 21 – Attributs relatifs à la propriété de définition matière .50

62264-2 © IEC:2004 – 9 –

Figure A.1 – Personnel model.163

Figure A.2 – Instances of a person class .165

Figure A.3 – UML model for class and class properties.165

Figure A.4 – Class property .167

Figure A.5 – Instances of a person properties.167

Figure A.6 – Instances of person and person properties .167

Figure A.7– XML schema for a person object.173

Figure A.8 – XML schema for person properties.175

Figure A.9 – Example of person and person property.175

Figure A.10 – Example of person class information.177

Figure A.11 – Adaptor to map different property names and values.177

Figure C.1 – Class and property names used to identify elements .197

Figure C.2 – A property defining overlapping subsets of the capability.201

Figure C.3 – Routing for a product .203

Figure C.4 – Routing with co-products and material dependencies.203

Figure C.5 – Product and process capability relationships .205

Figure C.6 – Time-based dependencies .207

Figure C.7 – Maintenance schedule and performance model .211

Figure D.1 – Enterprise to manufacturing system logical information flows.213

Figure D.2 – Logical information flows among multiple systems .215

Table 1 – UML notation used .25

Table 2 – Example table .27

Table 3 – Attributes of personnel class .31

Table 4 – Attributes of personnel class property .33

Table 5 – Attributes of person .33

Table 6 – Attributes of person property .35

Table 7 – Attributes of qualification test specification.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...