CLC/TR 50117-8:2013

(Main)Coaxial cables used in cabled distribution networks - Part 8: Repair and substitute of damaged buried cables

Coaxial cables used in cabled distribution networks - Part 8: Repair and substitute of damaged buried cables

This Technical Report describes the procedure to repair damaged CATV cables. The following coaxial cables are considered in this guide: – Coaxial cables with semi air spaced dielectric Outer conductor: copper band, longitudinal welded – Coaxial cables foamed polyethylene or solid polyethylene dielectric Outer conductor: copper band, longitudinal welded – Coaxial cables foamed polyethylene or solid polyethylene dielectric Outer conductor: Overlapped foil of copper or aluminium with braid – Coaxial cables foamed polyethylene or solid polyethylene dielectric Outer conductor: Overlapped foil of copper or aluminium without braid – Coaxial cables foamed polyethylene dielectric Outer conductor: Corrugated copper This guide is a helpful tool for providers and installers to find out the extend and the effects of damaged cables and to achieve and to evaluate appropriate repair operation. For not buried cables, e.g. indoor cables, the application of this guide is analogous. NOTE The kind respectively the material of the cable sheath makes the coaxial cable an "underground" cable. In the underground area the cable jacket determines the long term behaviour of the cable significantly. For this purpose, only plastics with a high long-term stability are used, usually polyethylene (PE). This material provides protection against ingress of water or water-diffusion with good mechanical properties.

Koaxialkabel für Kabelverteilanlagen - Teil 8: Reparatur und Ersatz beschädigter Koaxialkabel

Câbles coaxiaux pour réseaux câblés de distribution - Partie 8: Réparation et remplacement de câbles coaxiaux souterrain

Koaksialni kabli v kabelskih razdelilnih omrežjih - 8. del: Popravilo in zamenjava poškodovanih zasutih kablov

To tehnično poročilo vsebuje opis postopka za popravilo poškodovanih kablov CATV. V navodila so vključeni ti koaksialni kabli:

– koaksialni kabli z medsebojno oddaljenimi dielektiki,

zunanji vodnik: bakreni trak, varjen po dolžini;

– koaksialni kabli z dielektikom iz penastega ali trdega polietilena,

zunanji vodnik: bakreni trak, varjen po dolžini;

– koaksialni kabli z dielektikom iz penastega ali trdega polietilena,

zunanji vodnik: prekrižan oplet folije iz bakra ali aluminija;

– koaksialni kabli z dielektikom iz penastega ali trdega polietilena,

zunanji vodnik: prekrižana folija iz bakra ali aluminija brez opleta;

– koaksialni kabli z dielektikom iz penastega polietilena,

zunanji vodnik: valovita bakrena pločevina.

Ta navodila so ponudnikom in monterjem v pomoč pri ugotavljanju stopnje poškodovanosti kablov in njihovih posledic ter pri ocenjevanju ustreznosti postopka za popravilo in izvedbi popravila. Za kable, ki niso položeni v zemljo, tj. notranje kable, je uporaba teh navodil analogna.

General Information

- Status

- Published

- Publication Date

- 28-Feb-2013

- Technical Committee

- CLC/TC 46X - Communication cables

- Drafting Committee

- CLC/SC 46XA - Coaxial cables

- Current Stage

- 6060 - Document made available - Publishing

- Start Date

- 01-Mar-2013

- Completion Date

- 01-Mar-2013

Overview

CLC/TR 50117-8:2013 - "Coaxial cables used in cabled distribution networks - Part 8: Repair and substitute of damaged buried cables" is a CLC Technical Report that provides guidance for the assessment, repair and replacement of damaged buried coaxial (CATV) cables. It covers common cable constructions (PE foamed/solid dielectric, semi-air dielectric, corrugated copper outer conductor, braided or overlapped foil screens) and explains how cable sheath materials (typically polyethylene) affect long‑term underground performance and water ingress protection.

Key topics and technical requirements

- Cable construction & behaviour

- Inner conductor, dielectric and various outer conductor/screen types; importance of continuous metal tube for optimal shielding.

- Long‑term stability of underground cables and role of PE sheaths.

- Laying methods

- Typical installation practices such as sand-bedding, ducts and conduit systems that affect damage risk and repair strategy.

- Types of damage

- Classification of errors: transection/cutting, elongation/strain, deformation, sheath damage, transverse cracks in outer conductor, selective local impacts.

- Failure analysis & repair decision process

- Steps to determine whether to repair or replace, depending on elongation, deformation, sheath and screening condition.

- Joint and connector attenuation

- Guidance on expected effects of repairs on attenuation and screening effectiveness.

- Materials, handling and workmanship

- Recommended use of compatible repair materials and correct processing to restore mechanical and electrical properties.

- Measurement and verification

- Recommended tests to verify repair quality: power level measurement, return loss/reflection measurements, radiated power checks and Bit Error Rate (BER) where applicable.

- Documentation

- Record keeping for repair operations, measurements and asset management.

Practical applications and who uses it

- Cable network operators and service providers - planning and executing field repairs to restore CATV, Internet and VoIP services.

- Field installers and maintenance crews - identifying damage type, choosing repair method, performing jointing and sheath restoration.

- Asset managers and planners - assessing long‑term cable condition, prioritising replacement vs repair and documenting interventions.

- Test and measurement technicians - performing return loss, attenuation and BER verification after repair.

This guide is also applicable, by analogy, to non‑buried (indoor) coaxial cables for troubleshooting and repair.

Related standards

- EN 50117 series (coaxial cables)

- EN 50290 series (communication cables - guide to use)

- IEC 61196 parts (electrical test methods for coaxial cables)

- EN/IEC 60728 series (cable networks for TV and interactive services)

Keywords: coaxial cables, buried cables, CATV cable repair, cable replacement, underground cable sheath, polyethylene (PE), return loss, attenuation, cable laying, cable joint testing.

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

CLC/TR 50117-8:2013 is a technical report published by CLC. Its full title is "Coaxial cables used in cabled distribution networks - Part 8: Repair and substitute of damaged buried cables". This standard covers: This Technical Report describes the procedure to repair damaged CATV cables. The following coaxial cables are considered in this guide: – Coaxial cables with semi air spaced dielectric Outer conductor: copper band, longitudinal welded – Coaxial cables foamed polyethylene or solid polyethylene dielectric Outer conductor: copper band, longitudinal welded – Coaxial cables foamed polyethylene or solid polyethylene dielectric Outer conductor: Overlapped foil of copper or aluminium with braid – Coaxial cables foamed polyethylene or solid polyethylene dielectric Outer conductor: Overlapped foil of copper or aluminium without braid – Coaxial cables foamed polyethylene dielectric Outer conductor: Corrugated copper This guide is a helpful tool for providers and installers to find out the extend and the effects of damaged cables and to achieve and to evaluate appropriate repair operation. For not buried cables, e.g. indoor cables, the application of this guide is analogous. NOTE The kind respectively the material of the cable sheath makes the coaxial cable an "underground" cable. In the underground area the cable jacket determines the long term behaviour of the cable significantly. For this purpose, only plastics with a high long-term stability are used, usually polyethylene (PE). This material provides protection against ingress of water or water-diffusion with good mechanical properties.

This Technical Report describes the procedure to repair damaged CATV cables. The following coaxial cables are considered in this guide: – Coaxial cables with semi air spaced dielectric Outer conductor: copper band, longitudinal welded – Coaxial cables foamed polyethylene or solid polyethylene dielectric Outer conductor: copper band, longitudinal welded – Coaxial cables foamed polyethylene or solid polyethylene dielectric Outer conductor: Overlapped foil of copper or aluminium with braid – Coaxial cables foamed polyethylene or solid polyethylene dielectric Outer conductor: Overlapped foil of copper or aluminium without braid – Coaxial cables foamed polyethylene dielectric Outer conductor: Corrugated copper This guide is a helpful tool for providers and installers to find out the extend and the effects of damaged cables and to achieve and to evaluate appropriate repair operation. For not buried cables, e.g. indoor cables, the application of this guide is analogous. NOTE The kind respectively the material of the cable sheath makes the coaxial cable an "underground" cable. In the underground area the cable jacket determines the long term behaviour of the cable significantly. For this purpose, only plastics with a high long-term stability are used, usually polyethylene (PE). This material provides protection against ingress of water or water-diffusion with good mechanical properties.

CLC/TR 50117-8:2013 is classified under the following ICS (International Classification for Standards) categories: 33.120.10 - Coaxial cables. Waveguides. The ICS classification helps identify the subject area and facilitates finding related standards.

CLC/TR 50117-8:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-april-2013

Koaksialni kabli v kabelskih razdelilnih omrežjih - 8. del: Popravilo in zamenjava

poškodovanih zasutih kablov

Coaxial cables used in cabled distribution networks - Part 8 Repair and substitute of

damaged buried cables

Koaxialkabel für Kabelverteilanlagen - Teil 8: Reparatur und Ersatz beschädigter

Koaxialkabel

Câbles coaxiaux pour réseaux câblés de distribution - Partie 8: Réparation et

remplacement de câbles coaxiaux souterrain

Ta slovenski standard je istoveten z: CLC/TR 50117-8:2013

ICS:

33.120.10 Koaksialni kabli. Valovodi Coaxial cables. Waveguides

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

TECHNICAL REPORT

CLC/TR 50117-8

RAPPORT TECHNIQUE

March 2013

TECHNISCHER BERICHT

ICS 33.120.10

English version

Coaxial cables used in cabled distribution networks -

Part 8: Repair and substitute of damaged buried cables

Câbles coaxiaux pour réseaux câblés de Koaxialkabel für Kabelverteilanlagen -

distribution - Teil 8: Reparatur und Ersatz beschädigter

Partie 8: Réparation et remplacement de Koaxialkabel

câbles coaxiaux souterrain

This Technical Report was approved by CENELEC on 2013-02-26.

CENELEC members are the national electrotechnical committees of Austria, Belgium, Bulgaria, Croatia, Cyprus,

the Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany,

Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, the Netherlands, Norway, Poland,

Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom.

CENELEC

European Committee for Electrotechnical Standardization

Comité Européen de Normalisation Electrotechnique

Europäisches Komitee für Elektrotechnische Normung

Management Centre: Avenue Marnix 17, B - 1000 Brussels

© 2013 CENELEC - All rights of exploitation in any form and by any means reserved worldwide for CENELEC members.

Ref. No. CLC/TR 50117-8:2013 E

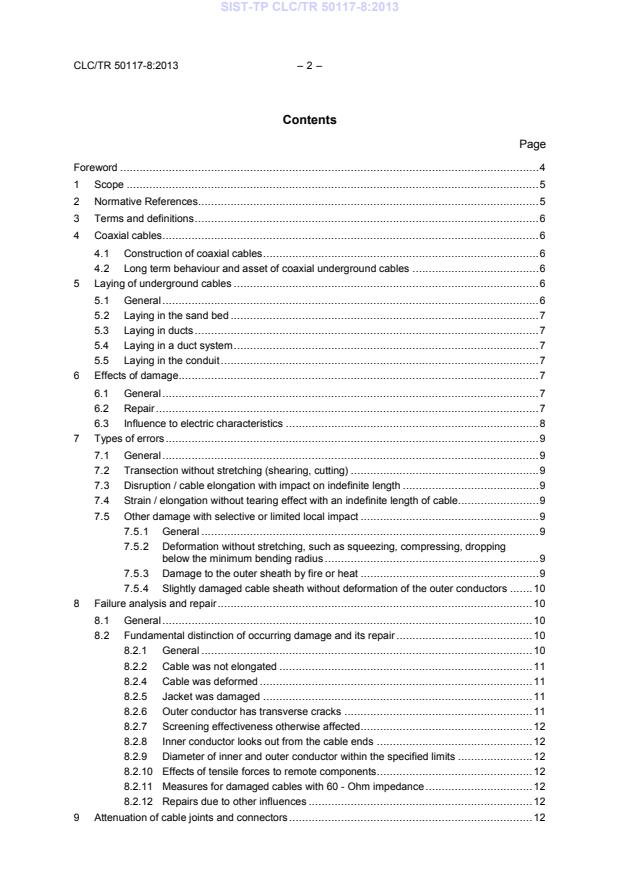

Contents

Page

Foreword . 4

1 Scope . 5

2 Normative References . 5

3 Terms and definitions . 6

4 Coaxial cables . 6

4.1 Construction of coaxial cables . 6

4.2 Long term behaviour and asset of coaxial underground cables . 6

5 Laying of underground cables . 6

5.1 General . 6

5.2 Laying in the sand bed . 7

5.3 Laying in ducts . 7

5.4 Laying in a duct system . 7

5.5 Laying in the conduit . 7

6 Effects of damage . 7

6.1 General . 7

6.2 Repair . 7

6.3 Influence to electric characteristics . 8

7 Types of errors . 9

7.1 General . 9

7.2 Transection without stretching (shearing, cutting) . 9

7.3 Disruption / cable elongation with impact on indefinite length . 9

7.4 Strain / elongation without tearing effect with an indefinite length of cable. 9

7.5 Other damage with selective or limited local impact . 9

7.5.1 General . 9

7.5.2 Deformation without stretching, such as squeezing, compressing, dropping

below the minimum bending radius . 9

7.5.3 Damage to the outer sheath by fire or heat . 9

7.5.4 Slightly damaged cable sheath without deformation of the outer conductors . 10

8 Failure analysis and repair . 10

8.1 General . 10

8.2 Fundamental distinction of occurring damage and its repair . 10

8.2.1 General . 10

8.2.2 Cable was not elongated . 11

8.2.4 Cable was deformed . 11

8.2.5 Jacket was damaged . 11

8.2.6 Outer conductor has transverse cracks . 11

8.2.7 Screening effectiveness otherwise affected . 12

8.2.8 Inner conductor looks out from the cable ends . 12

8.2.9 Diameter of inner and outer conductor within the specified limits . 12

8.2.10 Effects of tensile forces to remote components . 12

8.2.11 Measures for damaged cables with 60 - Ohm impedance . 12

8.2.12 Repairs due to other influences . 12

9 Attenuation of cable joints and connectors . 12

– 3 – CLC/TR 50117-8:2013

10 Use of materials and correct handling . 13

10.1 General . 13

10.2 Proper processing . 13

11 Documentation . 14

12 Measurement evidence . 14

12.1 Measuring of power levels . 14

12.2 Measuring of reflexion . 14

12.3 Measuring of radiated power . 14

12.4 Measuring of Bit Error Rate (BER) . 14

Annex A (informative) Theoretical Background . 15

A.1 Physical background and Characteristics / parameters for coaxial cable . 15

A.2 Reflection coefficient . 16

A.3 Return loss . 16

A.4 Pulse return loss . 17

Annex B (informative) Examples of damage . 19

Bibliography . 23

Figure 1 Construction of a coaxial cable . 6

Figure A.1 Coaxial cables . 15

Figure A.2 Schematic depiction for measuring the return loss . 17

Figure A.3 Composition of the test device for measuring the pulse reflection . 18

Figure B.1 Typical damage by laying new paths across the cable path . 19

Figure B.2 Underground cable repair of a selectively damaged cable without

elongation . 19

Figure B.3 Effect of tensile forces: building entry pulled out of the brickwork, the

basement conduit installation ripped out of wall . 20

Figure B.4 Selectively damaged cable: sheath peeled off . 20

Figure B.5 Cable cut by blade . 20

Figure B.6 Torn underground cables . 21

Figure B.7 Damaged cable by tension forces, inner conductor torned. . 21

Figure B.8 Perforated screening by pulling forces: Screening effectiveness drastically

reduced . 21

Figure B.9 Inside of the perforated screening foil by elongation of the coaxial cable

shielding . 22

Foreword

This document (CLC/TR 50117-8:2013) has been prepared by CLC/SC 46XA "Coaxial cables".

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CENELEC [and/or CEN] shall not be held responsible for identifying any or all such

patent rights.

EN 50117 is divided into the following parts:

− EN 50117-1, Coaxial cables Part 1: Generic specification

− EN 50117-2-1, Coaxial cables Part 2-1: Sectional specification for cables used in cabled

distribution networks Indoor drop cables for systems operating at 5 MHz - 1 000 MHz

− EN 50117-2-2, Coaxial cables Part 2-2: Sectional specification for cables used in cabled

distribution networks Outdoor drop cables for systems operating at 5 MHz - 1 000 MHz

− EN 50117-2-3, Coaxial cables Part 2-3: Sectional specification for cables used in cabled

distribution networks Distribution and trunk cables for systems operating at 5 MHz - 1 000 MHz

− EN 50117-2-4, Coaxial cables Part 2-4: Sectional specification for cables used in cabled

distribution networks Indoor drop cables for systems operating at 5 MHz - 3 000 MHz

− EN 50117-2-5, Coaxial cables Part 2-5: Sectional specification for cables used in cabled

distribution networks Outdoor drop cables for systems operating at 5 MHz - 3 000 MHz

− EN 50117-3-1, Coaxial cables Part 3-1: Sectional specifications for cables used in Telecom

applications Miniaturized cables used in digital communication systems

− EN 50117-4-1, Coaxial cables Part 4-1: Sectional specification for cables for BCT cabling in

accordance with EN 50173 Indoor drop cables for systems operating at 5 MHz - 3 000 MHz

− EN 50117-5, Coaxial cables used in cabled distribution networks Part 5: Sectional specification

for indoor drop cables for use in networks operating at frequencies between 5 MHz and 2150

MHz

− EN 50117-6, Coaxial cables used in cabled distribution networks Part 6: Sectional specification

for outdoor drop cables for use in networks operating at frequencies between 5 MHz and 2150

MHz

− CLC/TR 50117-8, Coaxial cables used in cabled distribution networks Part 8 Repair and

substitute of damaged buried cables

– 5 – CLC/TR 50117-8:2013

1 Scope

This Technical Report describes the procedure to repair damaged CATV cables.

The following coaxial cables are considered in this guide:

– Coaxial cables with semi air spaced dielectric

Outer conductor: copper band, longitudinal welded

– Coaxial cables foamed polyethylene or solid polyethylene dielectric

Outer conductor: copper band, longitudinal welded

– Coaxial cables foamed polyethylene or solid polyethylene dielectric

Outer conductor: Overlapped foil of copper or aluminium with braid

– Coaxial cables foamed polyethylene or solid polyethylene dielectric

Outer conductor: Overlapped foil of copper or aluminium without braid

– Coaxial cables foamed polyethylene dielectric

Outer conductor: Corrugated copper

This guide is a helpful tool for providers and installers to find out the extend and the effects of

damaged cables and to achieve and to evaluate appropriate repair operation.

For not buried cables, e.g. indoor cables, the application of this guide is analogous.

NOTE The kind respectively the material of the cable sheath makes the coaxial cable an "underground" cable. In the

underground area the cable jacket determines the long term behaviour of the cable significantly. For this purpose, only plastics

with a high long-term stability are used, usually polyethylene (PE). This material provides protection against ingress of water or

water-diffusion with good mechanical properties.

2 Normative References

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

EN 50117 (series), Coaxial cables

EN 50117-1:2002, Coaxial cables Part 1: Generic specification

EN 50290-1-2:2004, Communication cables Part 1-2: Definitions

EN 50290-4-2, Communication cables Part 4-2: General considerations for the use of cables

Guide to use

EN 60728-1, Cable networks for television signals, sound signals and interactive services Part 1:

System performance of forward paths (IEC 60728-1)

EN 60728-1-1, Cable networks for television signals, sound signals and interactive services Part 1-

1: RF cabling for two way home networks (IEC 60728-1-1)

IEC 61196-1-108, Coaxial communication cables Part 1-108: Electrical test methods Test for

characteristic impedance, phase and group delay, electrical length and propagation velocity

IEC 61196-1-112, Coaxial communication cables Part 1-112: Electrical test methods Test for

return loss (uniformity of impedance)

IEC 61196-1-115, Coaxial communication cables Part 1-115: Electrical test methods Test for

regularity of impedance (pulse/step function return loss)

3 Terms and definitions

For the purposes of this document the terms and definitions given in EN 50117-1:2002 and in

EN 50290-1-2:2004 apply.

4 Coaxial cables

4.1 Construction of coaxial cables

Outer conductor D+d

G

Inner

condutor d

Insulation D Outer sheeth OD

Figure 1 Construction of a coaxial cable

Coaxial cables (Figure 1) consist of an inner conductor, the dielectric and an overlying outer

conductor. The structure is protected by a plastic sheath. The outer conductor also acts as a shield

against radiation and electromagnetic fields.

The outer conductor respectively the screen may consist of a single braid, or a combination of metal

bonded sheets and braids. The shielding characteristics are determined by the construction of the

screen and the optical coverage. Optimal shielding effect is achieved by cables with a continuously

closed metal tube, which for example, is often used in case of buried cables for cabled TV distribution.

Coaxial cable for direct burial can also be provided with other elements, such as intermediate sheaths

or moisture barriers.

4.2 Long term behaviour and asset of coaxial underground cables

High-quality underground cables are of good long-term stability. They are most durable and without

loss of quality. Good example for the high durability are the CATV cable types ikx, nkx, qkx and skx.

These cables have a cable sheath of PE and fulfil to date the demands on the transmission

characteristics according to the applicable standards for the transmission characteristics, even after 25

years and more of use.

Today, these cables are also used for the transfer of the so-called "Triple Play" services; that means,

additional to the digital transmission of radio and television signals the transmission of signals for

Internet access services and telephony services using Voice over IP. By means of digital transmission

methods, conventional coaxial cables offer transmission bit rate of the high Gigabit range. Only fibre

optic cable offers a higher transmission power.

The laid underground cables are thus a valuable and lasting transmission resource, one of the

business basics of cable operators. This applies regardless of the age of cable laid, as the

transmission performance does not deteriorate, except in case of damage of the cable.

5 Laying of underground cables

5.1 General

For general hints for laying, see EN 50290-4-2.

– 7 – CLC/TR 50117-8:2013

5.2 Laying in the sand bed

Typically, the cables are laid in the sand bed in a cable trench. The sand bed provides protection

against damage by stones and dissipates the weight of the overlying ground, under the best possible

protection of the cable. The so-called Warning tape marked "Caution Cable”, or “Cable Television"

above the laid cable in the sand bed is supposed to draw attention to possible earthworks on the

underground cables underneath.

5.3 Laying in ducts

Basically it is the same installation technology as in the laying of cables in the sand bed. However,

instead of a cable, a conduit is laid, through which the cable is pulled or blown after laying the conduit.

Laying in ducts is also possible, with the so-called "Press to move procedure" (Pressverfahren),

whereby a drive head, driven by compressed air produces an underground channel. In this channel, a

conduit is pushed where finally the cable is blown or pulled.

There are other procedures in which the conduit is injected or otherwise introduced into the earth.

Since at the latter procedure not a cable trench is made, there is no Warning Tape. Nevertheless,

such laid cables can be located with appropriate cable fault location systems.

5.4 Laying in a duct system

Duct systems consist of bundles of pipes of installed cables or cable ducts with “cable stones”

(Kabelsteine) in certain intervals. The cables are placed in the respective tube.

5.5 Laying in the conduit

Laying in the conduit is done by install conduits, or cable trays etc. In the event of damage procedures

described in this guide apply accordingly.

6 Effects of damage

6.1 General

Coaxial cables are sensitive and should be laid with great care. The manufacturer’s instructions

specify characteristics like minimum bending radius and maximum pulling force. Even small changes

in dimensions affect the characteristics of the various parameters of the coaxial cables.

6.2 Repair

Repairs of coaxial cables require special care. Coaxial cables are components that can serve its

purpose only if the continuous construction is not altered in their mechanical dimensions. Even small

changes in the dimensions of the cable structure cause reflections that affect the transmission

characteristics.

In analogy, the coaxial cables can be considered as a water pipe, in which changes of the cross-

section influences the flow of water, (holes in the pipe leads to the leakage of liquid-ness).

By external influences coaxial cables may be damaged, with all the negative impact performance

which are described below.

Frequent causes of damage are dredging. In this case, the cable is cut in the ground, stretched, torn,

bruised or otherwise damaged. A proper repair is essential to ensure the full transmission capacity of

the affected cable. Repair of the cable shall guarantee the intended long-term continued operation.

Even minor damage to the sheath affect the transfer properties and durability of the cable sustainable.

Even the smallest damage to the cable sheath causes far-reaching implications due to moisture

penetration. Mechanical deformation of the cable causes a deterioration of the transmission

characteristics. The affected cable cannot fulfil its purpose extensively and loses its lasting value.

Only repair measures, which are suitable to restore the original transfer properties, are necessary for

the operation of cable networks. Doubtful solutions that may cause damage to an unspecified date,

are hereby rejected.

The range of appropriate repair measures ranges from the replacement of sleeves and the partial

replacement of cables, to the replacement of complete cable lengths between the respective ends or

points of connection.

In consequence damages cause changes in the design of the damaged cable. This may affect the

cable only selective but at worst on the entire cable length. The following parameters, characteristics

or construction details of the cable are affected by an accident:

– diameter of the inner conductor,

– shape of dielectric,

– diameter of the outer conductors,

– outer diameter of cable sheath,

– impermeability to water,

– long-time behaviour.

6.3 Influence to electric characteristics

The effects listed under 6.1 on the mechanical design of the affected cables are coupled in sequence

with a deterioration of electrical characteristics. This in turn determines the transmission performance

of the cable for the distribution of analogue and digital radio and television programs. Furthermore,

digital transmission methods of telecommunication services such as internet telephony or internet

account with Voice over IP, etc. are affected.

Cable damage changes the transmission behaviour for the worse. Faults or damage and/or failures of

telecommunications services are the result. Besides the physical damage with the possible effects on

the long life performance, the following radio frequency and electrical characteristics are deteriorated:

– characteristic impedance,

– attenuation,

– return loss,

– screening attenuation,

– transfer impedance,

– conductor loop resistance,

– current carrying capacity.

The above parameters for coaxial cables are specified in EN 50117-1 and are used for planning and

construction of telecommunications networks, such as cable-TV networks. A deterioration of the

transmission characteristics of coaxial cables leads naturally to the deterioration of signal quality,

which is described for example in EN 60728-1 and EN 60728-1-1 (see also Clause 8).

Basically, a change of the relevant parameters has following impacts:

– A change in the characteristic impedance leads to reflections and causes a deterioration of the

attenuation and return loss. A direct impact of the signal transmission, in particular of digital

signals is the result.

– 9 – CLC/TR 50117-8:2013

– Deterioration of screening attenuation and transfer impedance increase the radiation of disturbing

power (exceeding the allowable limits) and reduce the noise immunity of the system. The

resulting so-called "Ingress" disturbs the back-channel operation and may impact two-way

services such as Internet access and Voice over IP substantially or make its transmission even

impossible.

– An increase in the loop resistance affects the current carrying capacity, which has an adverse

impact on the cables to the remote power feeding over the coaxial cables and affects the power

supply of the active components supplied thereon.

7 Types of errors

7.1 General

When cables are stretched or ruptured through external influence (e.g. by dredging), this basically

leads to a permanent elongation of the af

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...