CLC/TS 50640:2015

(Main)Clothes washing machines for commercial use - Methods for measuring the performance

Clothes washing machines for commercial use - Methods for measuring the performance

This Technical Specification specifies methods for measuring the performance of clothes washing machines for commercial use utilizing cold and/or hot water supply and without heating or with heating devices for electricity, steam or gas. It also deals with appliances for both washing and drying textiles (washer-dryers) with respect to their washing related functions. This Technical Specification covers top, front and side loaded non household washing machines with horizontal or vertical axis and with one or more wash compartments. NOTE 1 Non household tumble dryer performance is assessed to CLC/TS 50594. NOTE 2 Installation and energy calculations of non-household washing machines heated with gas is assessed in EN ZZZZZ. The object is to state and define the principal performance characteristics of non-household washing machines and to describe the test methods for measuring these characteristics. NOTE 3 This Technical Specification does not apply to continuous batch washing machines (e.g. tunnel washers) or washing machines only possible to operate with automatic loading and unloading. NOTE 4 This Technical Specification does not specify safety requirements for non-household washing machines. Safety requirements are specified in EN 50571 and the EN ISO 10472 series.

Waschmaschinen für den gewerblichen Gebrauch - Verfahren zur Messung der Gebrauchseigenschaften

Die vorliegende Technische Spezifikation spezifiziert Methoden für die Messung der Gebrauchseigen¬schaften von Waschmaschinen für den gewerblichen Gebrauch, welche Kalt- und/oder Warmwasser¬versorgung verwenden und keine Heizung oder Heizgeräte für Elektrizität, Dampf oder Gas aufweisen. Sie behandelt auch Geräte sowohl für Waschen und Trocknen (Waschtrockner) hinsichtlich ihrer auf Waschen bezogenen Funktionen. Die vorliegende Technische Spezifikation deckt von oben, von vorn und seitlich beladene, nicht für den Hausgebrauch vorgesehene Waschmaschinen mit horizontaler oder vertikaler Achse und mit einer oder mehr Waschkammer(n) ab. ANMERKUNG 1 Die Gebrauchseigenschaften von nicht für den Haushaltsgebrauch bestimmten Wäschetrocknern werden in CLC/FprTS 50594 behandelt. ANMERKUNG 2 Aufstellungen und Energieberechnungen von nicht für den Haushaltsgebrauch bestimmten Wasch¬maschinen, welche mit Gas oder Dampf beheizt werden, werden in EN ZZZZZ behandelt. Das Ziel ist die Angabe und Definition der prinzipiellen Gebrauchseigenschaften von nicht für den Haus-haltsgebrauch bestimmten Waschmaschinen, und die Beschreibung der Prüfverfahren für die Messung dieser Eigenschaften. ANMERKUNG 3 Die vorliegende Technische Spezifikation ist nicht anwendbar für Durchlaufwaschmaschinen (z. B. Tunnelwaschmaschinen) oder Waschmaschinen, welche nur mit automatischer Beladung und Entladung betrieben werden können. ANMERKUNG 4 Die vorliegende Technische Spezifikation legt keine Sicherheitsanforderungen für nicht für den Haushaltsgebrauch bestimmte Waschmaschinen fest. Sicherheitsanforderungen sind in EN 50571 und der Normenreihe EN ISO 10472 festgelegt.

Pralni stroji za komercialno uporabo - Metode za merjenje funkcionalnosti

General Information

- Status

- Withdrawn

- Publication Date

- 23-Apr-2015

- Technical Committee

- CLC/TC 59X - Consumer information related to household electrical appliances

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 23-Apr-2021

- Completion Date

- 23-Apr-2021

Relations

- Effective Date

- 24-Jul-2018

- Refers

IEC 60456:2010 - Clothes washing machines for household use - Methods for measuring the performance - Effective Date

- 10-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN 12953-10:2003 - Shell boilers - Part 10 : Requirements for feedwater and boiler water quality - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN ISO/CIE 11664-2:2022 - Colorimetry - Part 2: CIE standard illuminants (ISO/CIE 11664-2:2022) - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 03-Feb-2026

- Effective Date

- 03-Feb-2026

- Effective Date

- 03-Feb-2026

Frequently Asked Questions

CLC/TS 50640:2015 is a technical specification published by CLC. Its full title is "Clothes washing machines for commercial use - Methods for measuring the performance". This standard covers: This Technical Specification specifies methods for measuring the performance of clothes washing machines for commercial use utilizing cold and/or hot water supply and without heating or with heating devices for electricity, steam or gas. It also deals with appliances for both washing and drying textiles (washer-dryers) with respect to their washing related functions. This Technical Specification covers top, front and side loaded non household washing machines with horizontal or vertical axis and with one or more wash compartments. NOTE 1 Non household tumble dryer performance is assessed to CLC/TS 50594. NOTE 2 Installation and energy calculations of non-household washing machines heated with gas is assessed in EN ZZZZZ. The object is to state and define the principal performance characteristics of non-household washing machines and to describe the test methods for measuring these characteristics. NOTE 3 This Technical Specification does not apply to continuous batch washing machines (e.g. tunnel washers) or washing machines only possible to operate with automatic loading and unloading. NOTE 4 This Technical Specification does not specify safety requirements for non-household washing machines. Safety requirements are specified in EN 50571 and the EN ISO 10472 series.

This Technical Specification specifies methods for measuring the performance of clothes washing machines for commercial use utilizing cold and/or hot water supply and without heating or with heating devices for electricity, steam or gas. It also deals with appliances for both washing and drying textiles (washer-dryers) with respect to their washing related functions. This Technical Specification covers top, front and side loaded non household washing machines with horizontal or vertical axis and with one or more wash compartments. NOTE 1 Non household tumble dryer performance is assessed to CLC/TS 50594. NOTE 2 Installation and energy calculations of non-household washing machines heated with gas is assessed in EN ZZZZZ. The object is to state and define the principal performance characteristics of non-household washing machines and to describe the test methods for measuring these characteristics. NOTE 3 This Technical Specification does not apply to continuous batch washing machines (e.g. tunnel washers) or washing machines only possible to operate with automatic loading and unloading. NOTE 4 This Technical Specification does not specify safety requirements for non-household washing machines. Safety requirements are specified in EN 50571 and the EN ISO 10472 series.

CLC/TS 50640:2015 is classified under the following ICS (International Classification for Standards) categories: 97.060 - Laundry appliances. The ICS classification helps identify the subject area and facilitates finding related standards.

CLC/TS 50640:2015 has the following relationships with other standards: It is inter standard links to EN 50640:2018, IEC 60456:2010, EN ISO 2061:2015, EN ISO 80000-1:2013, EN 12953-10:2003, EN ISO 2060:1995, EN ISO/CIE 11664-2:2022, EN 12127:1997, EN ISO 3759:2011, EN 50571:2013, EN 60734:2012, R020-001:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

CLC/TS 50640:2015 is associated with the following European legislation: EU Directives/Regulations: 2009/125/EC; Standardization Mandates: M/495. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

CLC/TS 50640:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-junij-2015

Pralni stroji za komercialno uporabo - Metode za merjenje funkcionalnosti

Clothes washing machines for commercial use - Methods for measuring the performance

Waschmaschinen für den gewerblichen Gebrauch - Verfahren zur Messung der

Gebrauchseigenschaften

Ta slovenski standard je istoveten z: CLC/TS 50640:2015

ICS:

97.060 Aparati za nego perila Laundry appliances

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

TECHNICAL SPECIFICATION CLC/TS 50640

SPÉCIFICATION TECHNIQUE

TECHNISCHE SPEZIFIKATION

April 2015

ICS 97.060

English Version

Clothes washing machines for commercial use - Methods for

measuring the performance

Waschmaschinen für den gewerblichen Gebrauch -

Verfahren zur Messung der Gebrauchseigenschaften

This Technical Specification was approved by CENELEC on 2015-01-26.

CENELEC members are required to announce the existence of this TS in the same way as for an EN and to make the TS available promptly

at national level in an appropriate form. It is permissible to keep conflicting national standards in force.

CENELEC members are the national electrotechnical committees of Austria, Belgium, Bulgaria, Croatia, Cyprus, the Czech Republic,

Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia,

Lithuania, Luxembourg, Malta, the Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

European Committee for Electrotechnical Standardization

Comité Européen de Normalisation Electrotechnique

Europäisches Komitee für Elektrotechnische Normung

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2015 CENELEC All rights of exploitation in any form and by any means reserved worldwide for CENELEC Members.

Ref. No. CLC/TS 50640:2015 E

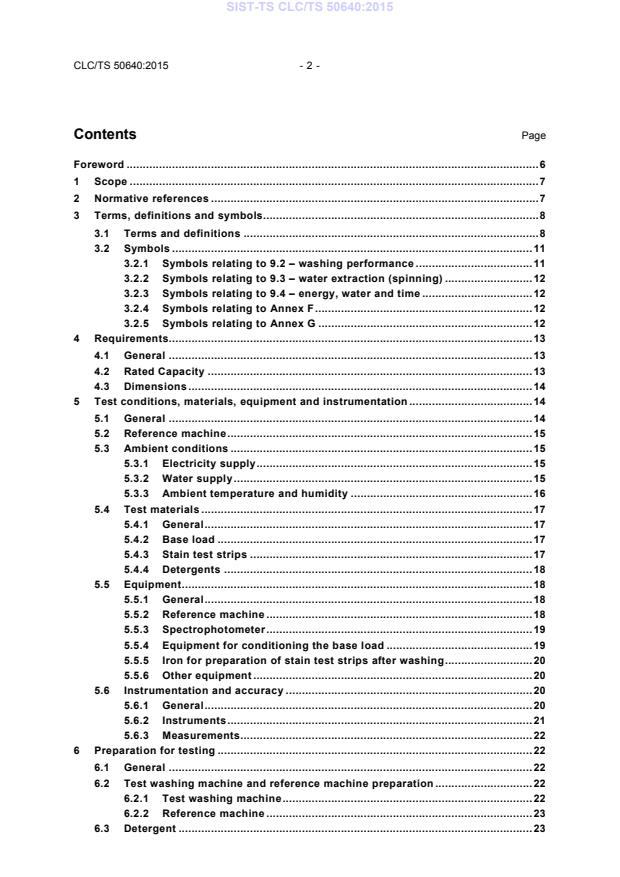

Contents Page

Foreword . 6

1 Scope . 7

2 Normative references . 7

3 Terms, definitions and symbols. 8

3.1 Terms and definitions . 8

3.2 Symbols . 11

3.2.1 Symbols relating to 9.2 – washing performance . 11

3.2.2 Symbols relating to 9.3 – water extraction (spinning) . 12

3.2.3 Symbols relating to 9.4 – energy, water and time . 12

3.2.4 Symbols relating to Annex F . 12

3.2.5 Symbols relating to Annex G . 12

4 Requirements. 13

4.1 General . 13

4.2 Rated Capacity . 13

4.3 Dimensions . 14

5 Test conditions, materials, equipment and instrumentation . 14

5.1 General . 14

5.2 Reference machine . 15

5.3 Ambient conditions . 15

5.3.1 Electricity supply . 15

5.3.2 Water supply . 15

5.3.3 Ambient temperature and humidity . 16

5.4 Test materials . 17

5.4.1 General . 17

5.4.2 Base load . 17

5.4.3 Stain test strips . 17

5.4.4 Detergents . 18

5.5 Equipment . 18

5.5.1 General . 18

5.5.2 Reference machine . 18

5.5.3 Spectrophotometer . 19

5.5.4 Equipment for conditioning the base load . 19

5.5.5 Iron for preparation of stain test strips after washing . 20

5.5.6 Other equipment . 20

5.6 Instrumentation and accuracy . 20

5.6.1 General . 20

5.6.2 Instruments . 21

5.6.3 Measurements. 22

6 Preparation for testing . 22

6.1 General . 22

6.2 Test washing machine and reference machine preparation . 22

6.2.1 Test washing machine . 22

6.2.2 Reference machine . 23

6.3 Detergent . 23

– 3 – CLC/TS 50640:2015

6.3.1 General . 23

6.3.2 Detergent dose . 24

6.3.3 Mixing detergent . 24

6.3.4 Detergent placement . 24

6.3.5 Placing detergent into the drum base . 24

6.4 Test loads . 25

6.4.1 General . 25

6.4.2 Pre-treatment of new base load items prior to use . 26

6.4.3 Requirements regarding the maximum age of base load items . 26

6.4.4 Normalization of base load items before a new test series . 26

6.4.5 Conditioning of base load items before a new test series . 26

6.4.6 Test load composition . 27

6.4.7 Calculation of loads not shown in Table 3 . 29

6.4.8 Addition of stain test strips to the base load . 29

7 Performance measurements – general requirements . 30

8 Tests for performance . 30

8.1 General . 30

8.2 Test procedure for performance tests . 31

8.2.1 Test conditions, materials and preparation for testing . 31

8.2.2 Test load and loading . 31

8.2.3 Programme . 31

8.2.4 Test procedure . 31

8.2.5 Test series . 32

8.3 Measurements to determine washing performance . 32

8.3.1 General . 32

8.3.2 Removal and drying of stain test strips . 33

8.3.3 Assessment of stain test strips . 33

8.4 Measurements to determine maximum spin speed . 34

8.5 Measurements to determine water extraction performance . 34

8.5.1 General . 34

8.5.2 Washing machines . 34

8.5.3 Spin extractors . 34

8.6 Measurement to determine the bath temperature . 34

8.7 Measurements to determine water and energy consumption and

programme time . 35

8.7.1 General . 35

8.7.2 Procedure. 35

8.7.3 Measurement of energy supplied by electricity . 35

8.7.4 Measurement of energy supplied by steam . 35

8.7.5 Measurement of energy supplied by gas . 35

8.7.6 Measurement of energy consumed via compressed air . 35

9 Assessment of performance . 36

9.1 General . 36

9.2 Evaluation of washing performance . 36

9.3 Evaluation of water extraction performance . 38

9.4 Evaluation of water and energy consumption and programme time. 39

9.4.1 General . 39

9.4.2 Water volumes . 39

9.4.3 Bath temperature . 39

9.4.4 Programme time . 39

9.4.5 Energy consumption . 39

10 Data to be reported . 41

Annex A (normative) Specification of stain test strips with standardized soiling . 42

Annex B (normative) Reference detergents — Reference detergent A* . 46

Annex C (normative) Specifications for base load — Cotton/synthetics base

loads . 48

Annex D (normative) Reference machine specification — Specification of the

reference washing machines and method of use . 50

Annex E (normative) Reference machine programme definitions . 53

Annex F (normative) The bone-dry method of conditioning . 56

Annex G (normative) Folding and loading the test load . 58

Annex H (normative) Measuring the bath temperature . 69

Annex I (informative) Performance testing of gas fired washing machines . 71

Annex J (normative) Performance testing of steam heated washing machines . 72

Annex K (normative) Procedure to determine test load size when rated capacity

is not declared . 82

Annex L (informative) Uncertainty of measurements in the present document . 86

Annex M (normative) Test report – Data to be reported . 90

Annex N (informative) Sources of materials and supplies. 96

Bibliography . 97

Figure 1 — Load item preparation prior to a test series . 25

Figure 2 — Attached test strip . 29

Figure 3 – Positions for measuring soiled test pieces . 33

Figure G.1 — Folding medium sheet with a stain test strip attached . 59

Figure G.2 — Folding small sheet . 59

Figure G.3 — Folding medium sheets . 60

Figure G.4 — Folding large sheets . 60

Figure G.5 — Illustration of horizontal axis washing machine . 61

Figure G.6 — Illustration of vertical axis washing machine . 61

Figure G.7 — Horizontal axis washing machine: placement of items in the drum . 62

Figure G.8 — Vertical axis washing machine: placement of items in the drum . 63

Figure G.9 — Schematic view of part loads within a large drum . 66

Figure J.1 — Schematic installation of the measurement equipment for direct

steam heated washing machines . 75

Figure J.2 — Schematic installation of the measurement equipment for indirect

steam heated washing machine (Alternative 1) . 76

Figure J.3 — Schematic installation of the measurement equipment for indirect

steam heated washing machine (Alternative 2) . 77

Figure K.1 — Cross section of drum and lifter . 83

Figure K.2 — Figure showing how the drum diameter d shall be measured for

different kind of drum perforation . 84

Figure K.3 — Definition of volumes V to V . 85

3 6

Figure K.4 — Definition of volume V and V . 85

1 2

– 5 – CLC/TS 50640:2015

Table 1 — Size and mass of the different base load items . 17

Table 2 — Detergent Dose . 24

Table 3 — Number of different load items in the test load for various test load

masses . 28

Table A.1 — Ratios and tolerances of standardized soils: Reference Machine CLS . 45

Table B.1 — Composition of the reference detergent A* . 46

Table C.1 — Specification of the Cotton/synthetics base loads . 48

Table D.1 — Description of the reference washing machine and method of use . 51

Table E.1 — Specification of reference washing programme . 54

Table E.2 — Tolerances given for some procedure parameters . 55

Table G.1 — Orientation of test load items within a part load . 63

Table G.2 — Part load items for a 15 kg test load . 64

Table G.3 — Part load items for a 5 kg test load . 65

Table G.4 — Part load items for a 10 kg test load . 65

Table G.5 — Part load items for a 20 kg test load . 65

Table G.6 — Part load items for a 100 kg test load . 66

Table H.1 — Specification of temperature logger suitable for temperature

measurement for both washing and drying . 69

Table H.2 — Number of temperature loggers for bath temperature measurement . 70

Table M.1 — Data for test washing machine . 90

Table M.2.1 — Data, parameters and results . 91

Table M.2.2 — Performance results of the test washing machine . 94

Table M.3 — Materials . 94

Table M.4 — Equipment . 95

Foreword

This document (CLC/TS 50640:2015) has been prepared by CLC/TC 59X "Performance of household

and similar electrical appliances".

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CENELEC [and/or CEN] shall not be held responsible for identifying any or all such pa-

tent rights.

This document has been prepared under a mandate given to CENELEC by the European Commission

and the European Free Trade Association.

This is a new Technical Specification, but it is based on portions from EN 60456:2011.

This Technical Specification is the main body of a forthcoming European Standard for measuring the

performance of non-household washing machines. The content of this Technical Specification will be

added with the Annex ZZ when the details regarding Ecodesign regulations are defined.

The procedures described in this Technical Specification are modified substantially compared to the

procedures described in EN 60456. Therefore, results of tests according to this Technical

Specification cannot and are bound not to be compared to results of similar procedures of EN 60456.

Significant technical differences from EN 60456 are:

a) test procedures for washing machines of any size on the market;

b) the method includes procedures for measuring steam heated and gas heated washing machines;

c) the introduction of a new type of base load;

d) a new reference programme.

NOTE CLC/TS 50640:2015 is planned to be a European Standard for the energy measurement of gas

heated laundry equipment.

A bilingual version of this publication may be issued at a later date.

– 7 – CLC/TS 50640:2015

1 Scope

This Technical Specification specifies methods for measuring the performance of clothes washing

machines for commercial use utilizing cold and/or hot water supply and without heating or with

heating devices for electricity, steam or gas. It also deals with appliances for both washing and drying

textiles (washer-dryers) with respect to their washing related functions. This Technical Specification

covers top, front and side loaded non household washing machines with horizontal or vertical axis

and with one or more wash compartments.

NOTE 1 Non household tumble dryer performance is assessed to CLC/TS 50594.

The object is to state and define the principal performance characteristics of non-household washing

machines and to describe the test methods for measuring these characteristics.

NOTE 2 This Technical Specification does not apply to continuous batch washing machines (e.g. tunnel

washers) or washing machines only possible to operate with automatic loading and unloading.

NOTE 3 This Technical Specification does not specify safety requirements for non-household washing

machines. Safety requirements are specified in EN 50571 and the EN ISO 10472 series.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

EN 12127, Textiles — Fabrics — Determination of mass per unit area using small samples

EN 12953-10, Shell boilers — Part 10 : Requirements for feedwater and boiler water quality

EN 50571, Household and similar electrical appliances — Safety — Particular requirements for

commercial electric washing machines

EN 60734, Household electrical appliances — Performance — Water for testing (IEC 60734)

EN ISO 2060, Textiles — Yarn from packages — Determination of linear density (mass per unit

length) by the skein method (ISO 2060)

EN ISO 2061, Textiles — Determination of twist in yarns — Direct counting method (ISO 2061)

EN ISO 3759, Textiles — Preparation, marking and measuring of fabric specimens and garments in

tests for determination of dimensional change (ISO 3759)

EN ISO 11664-2, Colorimetry — Part 2: CIE standard illuminants (ISO 11664-2)

EN ISO 80000-1:2013, Quantities and units — Part 1: General (ISO 80000-1:2009 + Cor 1:2011)

IEC 60456, Clothes washing machines for household use — Methods for measuring the performance

DIN 53923, Testing of textiles; determination of water absorption of textile fabrics

1)

CIE 015:2004 , Colorimetry (3rd edition)

———————

1) Address (International Commission on Illumination):

The CIE Central Bureau

Kegelgasse 27, A-1030 Vienna, Austria

Tel: +43 (01) 714 31 87

Fax: +43 (01) 713 0838

E-mail: ciecb@ping.at

http://www.cie.co.at/favicon.ico

IAPWS-IF97, IAPWS Industrial Formulation 1997 for the Thermodynamic Properties of Water and

Steam [International Association for the Properties of Water and Steam]

3 Terms, definitions and symbols

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1.1

washing machine

appliance for cleaning and rinsing of textiles using water which may also have a means of extracting

excess water from the textiles

3.1.2

test washing machine

washing machine that is subjected to part or all of the requirements in this Technical Specification in

order to determine its performance

Note 1 to entry: Test washing machine may include washing machines according to 3.1.6, 3.1.7.

3.1.3

reference machine

specially constructed washing machine of known performance which is used to increase repeatability

and reproducibility of results

Note 1 to entry: It may be used to provide a known performance level within a laboratory against which to

compare selected performance parameters on test washing machines as defined in this Technical Specification

– refer to 5.5.2.

3.1.4

washer-dryer

washing machine which includes both a spin extraction function and also a means for drying the

textiles, usually by heating and tumbling

Note 1 to entry: This Technical Specification only covers the operations which relate to the washing

machine function – see Clause 1.

3.1.5

spin extractor

separate water-extracting appliance in which water is removed from textiles by centrifugal action (spin

extraction)

3.1.6

vertical axis washing machine

washing machine in which the load is placed in a drum which rotates around an axis which is vertical

or close to vertical.

Note 1 to entry: For the purposes of this Technical Specification, vertical axis is where the angle of the

axis of rotation is more than 45 ° to horizontal. Where the drum does not rotate, the washing machine will be

classified as a vertical axis washing machine.

Note 2 to entry: The classification of vertical axis or horizontal axis in this Technical Specification is only

used to define the placement of the load into the drum.

3.1.7

horizontal axis washing machine

washing machine in which the load is placed in a drum which rotates around an axis which is

horizontal or close to horizontal

– 9 – CLC/TS 50640:2015

Note 1 to entry: For the purposes of this Technical Specification, horizontal axis is where the angle of the

axis is less than or equal to 45° to horizontal.

Note 2 to entry: The classification of vertical axis or horizontal axis in this Technical Specification is only

used to define the placement of the load into the drum.

3.1.8

automatic machine

washing machine where the load is fully treated by the machine without the need for user

intervention at any point during the programme prior to its completion

3.1.9

top loaded machine

washing machine where the load is placed in the wash compartment from the top, and which may be

of a horizontal or vertical axis type

3.1.10

side loaded machine

washing machine where the load is placed in the wash compartment from the side, and which is of a

horizontal axis type

3.1.11

pullman machine

washing machine where the wash compartment is divided in two compartments

3.1.12

Y-pocket machine

washing machine where the wash compartment is divided in three compartments

3.1.13

test run

single performance assessment as specified in Clause 8 of this Technical Specification

3.1.14

test series

group of test runs on a test washing machine which, collectively, are used to assess the

performance of a washing machine

3.1.15

operation

each performance of a function that occurs during the washing machine programme such as pre-

wash, washing, rinsing, draining or spinning

3.1.16

programme

series of operations which are pre-defined within the washing machine and which are declared by

the manufacturer as suitable for washing certain textile types

3.1.17

cycle

complete washing process, as defined by the programme selected, consisting of a series of

operations (wash, rinse, spin, etc.) and including any operations that occur after the completion of

the programme

Note 1 to entry: Examples of operations that may occur after the completion of the programme are

pumping, monitoring and anti-creasing (where applicable).

3.1.18

spin extraction

water-extracting function by which water is removed from textiles by centrifugal action, which is

included as a function (built in operation) of an automatic washing machine but may also be

performed in a spin extractor

3.1.19

spin speed

rotational frequency of a drum during spin extraction

Note 1 to entry: A method for determination of spin speed is not defined in this Technical Specification.

3.1.20

base load

unsoiled textiles used for testing

3.1.21

test load

base load used for testing plus stain test strips

3.1.22

test load mass

actual mass of the base load including stain test strips

3.1.23

nominal test load mass

mass of dry textiles of a particular type for which the performance of the test washing machine shall

be tested (rated capacity or part load)

Note 1 to entry: Target value for the conditioned test load mass.

3.1.24

rated capacity

maximum mass in kilograms of dry textiles of a particular type which the manufacturer declares can be

treated in the washing machine on the selected programme

3.1.25

programme time

time from the initiation of the programme (excluding any user programmed delay) until the completion

of the programme. If the end of programme is not indicated, the programme time is equal to the

cycle time

3.1.26

end of programme

completion of the programme, i.e. when the washing machine indicates the end of the programme

and the load is accessible to the user

Note 1 to entry: Where there is no end of programme indicator and the door is locked during operation,

the programme is complete when the load is accessible to the user. Where there is no end of programme

indicator and the door is not locked during operation, the programme is complete when the power consumption

of the appliance drops to some steady state condition and is not performing any function.

– 11 – CLC/TS 50640:2015

Note 2 to entry: An indication of the end of the programme may be in the form of a light (on or off), a

sound, an indicator shown on a display or the release of a door or latch. In some washing machines there may

be a short delay from an end of programme indicator until the load is accessible by the user.

3.1.27

cycle time

time from the initiation of the programme (excluding any user programmed delay) until all activity

ceases, which is considered to be the case when the power consumption reverts to a steady state

condition that persists indefinitely without user intervention

Note 1 to entry: If there is no activity after the end of the programme, the cycle time is equal to the

programme time.

Note 2 to entry: Cycle time includes any activity that may occur after the programme is completed. This

could include any electronic activity or any additional mechanical activity that occurs for a limited period after any

end of programme indicator. Any cyclic event that occurs indefinitely is considered to be steady-state.

3.1.28

main wash duration

time from the commencement of the initial water intake for the main wash until the commencement of

the initial water intake for the first rinse

Note 1 to entry: Variations in the laboratory water supply pressure may affect the main wash duration.

This definition is only applicable to test washing machines. The reference machine wash time used for

calibration of the reference machine is defined differently. Refer to Table E.1.

3.1.29

remaining moisture content

measure of the additional amount of moisture that is contained in the base load in relation to the

equilibrium condition for base load items which have been conditioned in a controlled space (refer to

6.4.5.2)

Note 1 to entry: This equilibrium condition is defined as 0 % remaining moisture content in this

Technical Specification. Hence it is possible for a base load or load items to have a negative remaining

moisture content when treated with a tumble drier. Refer also to Annex F.

3.1.30

rated voltage

voltage assigned to the appliance by the manufacturer

3.1.31

programme energy

energy consumed during the programme time in one test run

3.2 Symbols

3.2.1 Symbols relating to 9.2 – washing performance

C the sum of the average reflectance values (Y-values) for each test run

k

the average sum of the reflectance values (Y-values) for each of the five types of soils, for all

C

valid test runs

the sum of the reflectance values in each test run of the test washing machine

C

k

test

the average sum of the reflectance values of the test washing machine

C test

the average sum of the reflectance values in each test run of the reference machine

Cref

m the number of soil types per stain test strip

n the number of stain test strips in each test run

p confidence interval for q

q

ratio between the test washing machine, , and the reference machine,

C test Cref

standard deviation of the ratio q

s

q

the standard deviation of C

k

s

C

s the standard deviation of the reflectance values for each soil type within a given test run

i

t the “Student T” factor for (w-1) degrees of freedom for a confidence of 95 % (i.e. 2,776 for

w-1, 0,05

five test runs equals four degrees of freedom, two sided test)

w the number of test runs in the test series

the average reflectance values for each soil type

x

i

the average reflectance value of the 4 individual readings for each of the 5 soil types on a

x

ij

stain test strip

3.2.2 Symbols relating to 9.3 – water extraction (spinning)

RMC remaining moisture content

M the mass of the conditioned base load (g)

M the mass of base load at the end of the test run (g)

r

3.2.3 Symbols relating to 9.4 – energy, water and time

T the measured average cold water inlet temperature (°C)

c

T the measured average hot water inlet temperature (°C)

h

V the volume of the cold water used during an operation (l)

c

V the volume of external hot water used during operation (l)

h

W the cold water energy correction for the operation (kWh)

c

W the total cold water energy correction determined during the test (kWh)

ct

W the total electrical energy metered during the test (kWh)

et

W the total gas energy metered during the operation (kWh)

gt

W the calculated hot water energy for the operation (kWh)

h

W the calculated total hot water energy determined during the test (kWh)

ht

W the total steam energy metered during the operation (kWh)

st

W total energy (kWh)

total

3.2.4 Symbols relating to Annex F

M the mass of base load at the end of the bone dry run (g)

bd

3.2.5 Symbols relating to Annex G

M the desired total load mass (kg)

T

M the mass of a small sheet

S

M the mass of a medium sheet

M

M the mass of a large sheet

L

M the mass of a stain test strip .

ST

– 13 – CLC/TS 50640:2015

M the mass of a medium sheet with a stain test strip attached

M+ST

X the number of small sheets

S

X the number of medium sheets

M

X the number of large sheets

L

X the number of medium sheets with stain test strips attached

M+ST

4 Requirements

4.1 General

This Technical Specification describes test methods for the measurement of the following performance

parameters:

— washing performance;

— rinsing performance (under consideration);

— water extraction performance;

— water consumption;

— energy consumption;

— wash bath temperature;

— cycle time.

Any claims of performance referring to this Technical Specification for these parameters shall be

measured in accordance with the requirements of this Technical Specification (refer to Clause 8 for

details).

This Technical Specification does not specify minimum performance requirements for clothes

washing machines.

4.2 Rated Capacity

Either the manufacturer or supplier shall declare the rated capacity at 0,5 kg intervals for each

relevant textile type. For washing machines with a capacity above 10 kg the rated capacity shall be

declared at 1 kg intervals. Relevant textile types are cotton and synthetic/blends.

NOTE For different textile types the rated capacity of a washing machine is usually different.

The rated capacity shall not exceed the maximum mass of dry laundry, in kilograms, to be used in the

test washing machine in accordance with EN 50571.

When the manufacturer or supplier gives a range of values for the rated capacity for a particular

textile type, the highest value shall be used.

Where information on the rated capacity is not available, the test load mass shall be determined

according to Annex K.

If the rated capacity for a synthetics/blends programme is not specified by the manufacturer or

supplier, the test load shall be 40 % of that for a cotton programme.

4.3 Dimensions

Where a manufacturer declares dimensions, these shall be in accordance with the following

requirements, as applicable. The dimensions shall be given in mm and shall be rounded up to the

nearest whole mm.

Height a a = vertical dimension measured from the floor to a horizontal plane at the maximum

1/ 2

height of the washing machine, with the door/lid closed. If adjustable levelling

feet are provided, they shall be moved up and down to determine minimum (a

1)

and maximum (a possible heights.

)

Height a a = maximum vertical dimension measured from the floor to a horizontal plane at the

3/ 4

maximum height of the washing machine with the door/lid open (generally when

at right angles to the machine top). If adjustable levelling feet are provided, they

shall be moved up and down to determine minimum (a and maximum (a

3 4

) )

possible heights.

Width b = horizontal dimension, between the sides, as measured between two parallel

vertical planes against the sides of the washing machine including all

projections.

Width b = horizontal dimension, between the sides, as measured between two parallel

vertical planes against the sides of the washing machine including all

projections including an open side mounted door/lid .

Depth c = horizontal dimension as measured from a vertical rear plane against the back of

the washing machine and the most prominent part of the front fascia, with the

door/lid closed. For this measurement, the door thickness, knobs and handles

are generally not included in the measurement.

Depth c = horizontal dimension as measured from a vertical rear plane against the washing

machine and the most prominent part of the front, knobs and handles also being

taken into account, with the door/lid open (generally when at right angles to the

machine front).

Drum volume = the volume of a washing machine, where required, shall be determined in

accordance with Annex K.

NOTE 1 Dimension a a is generally only applicable to top loaded washing machines while dimension c is

3 4 2

/

generally only applicable to front loaded washing machines.

NOTE 2 Width b2 is referring to washing machines with a loading door at the side of the machine.

NOTE 3 Dimension c is intended to provide an indication of the required depth for the washing machine

where the fascia is intended to be flush with adjacent furniture or appliances.

5 Test conditions, materials, equipment and instrumentation

5.1 General

The tolerances specified for parameters within this Technical Specification, using the symbol “±”,

indicate the allowable limits of variation from the specified parameter outside which the test or results

shall be invalid. The statement of tolerance does not permit the deliberate variation of these specified

parameters.

Rounding shall only be applied to reported values in Annex M. If numbers have to be rounded, they

shall be rounded to the nearest number according to EN ISO 80000-1:2013, B.3, Rule B. If the

rounding takes place to the right of the comma, the omitted places shall not be filled with zeros. If a

value to be reported is an intermediate required for use in the calculation of other values then rounding

shall only apply to the format of the intermediate in the report; the rounding shall not apply prior to its

use in subsequent calculations.

– 15 – CLC/TS 50640:2015

5.2 Reference machine

Unless otherwise specified, the reference machine shall be considered a test washing machine with

respect to conditions, materials and equipment specified.

5.3 Ambient conditions

5.3.1 Electricity supply

The supply voltage to each test washing machine shall be maintained throughout the test at

230 V ± 2 % or at 400 V ± 2 % as defined by the manufacturer’s installation guide. If more than one

option for installation is available and no clear indication for testing is given, the supply voltage shall

be 400 V ± 2 %. The supply voltage measured during the tests shall be recorded. For washing

machines with a drum volume equal or larger than 400 l the voltage tolerance can be increased

to ± 3 %.

In the case of a fixed cable, the plug (or the end of the cable) is the reference point at which the supply

voltage shall be maintained.

The supply frequency to each test washing machine shall be maintained at 50 Hz ± 1 % throughout

the test.

Voltage stabilizers should be designed such that the normal operation of the test washing machine

does not cause undue distortion of the voltage waveform.

5.3.2 Water supply

5.3.2.1 General

The measured total water hardness, water temperature and water pressure of water supplied to test

washing machines shall comply with the following requirements and shall be reported. This water is

generally referred to as laboratory supply water in this Technical Specification.

5.3.2.2 Water hardness

For all treatments of the base load prior to a test series and all washing machine test runs in

accordance with this Technical Specification soft water shall be used. The soft water shall have a total

water hardness of (0,5 ± 0,2) mmol/l.

Normalization of a base load prior to use in a test series (refer to 6.4.2) shall always be done using

laboratory supply water with the same total water hardness as that used for the subsequent test

series.

Total water hardness is determined and expressed in mmol/l of CaCO equivalent.

If total water hardness needs to be adjusted, it shall be prepared according to EN 60734.

Measurements of total water hardness shall be undertaken on water that is representative of the

laboratory supply water used for tests.

5.3.2.3 Water temperature

The temperature of the laboratory supply water to each test washing machine shall be measured

and recorded to the nearest 0,1°C. It shall be:

– for cold water (15 ± 2)°C;

– for hot water the temperature indicated by the manufacturer ± 2 K, or (60 ± 2)°C, if no value is

given.

For washing machines with a drum volume equal or larger than 400 l the cold and hot water

tem

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...