EN 12416-1:2024

(Main)Fixed firefighting systems - Powder systems - Part 1: Requirements and test methods for components

Fixed firefighting systems - Powder systems - Part 1: Requirements and test methods for components

This document specifies requirements and test methods for materials, construction and performance of components intended for use in powder firefighting systems complying with EN 12416-2:2001+A1:2007.

The components covered are as follows:

- powder containers;

- expellant gas container assemblies;

- pressure regulators and gauges;

- actuators;

- main isolating valves and selector valves;

- nozzles.

The components are suitable for powder firefighting systems for general use in buildings and other construction works. In areas with a risk of explosion, earthquake zones, extreme environmental conditions, e.g. marine, offshore, mining or aircraft additional considerations apply.

This document covers components for use in powder extinguishing systems complying with EN 12416-2:2001+A1:2007. It does not cover, for example, pipes and fittings which are covered by more general standards for which requirements and recommendations are given in EN 12416-2:2001+A1:2007. Nor does it cover fire detectors or electrical control and indicating equipment.

Ortsfeste Brandbekämpfungsanlagen - Pulverlöschanlagen - Teil 1: Anforderungen und Prüfverfahren für Bauteile

Dieses Dokument legt Anforderungen und Prüfverfahren für Werkstoffe, Konstruktion und Leistungsmerkmale von Bauteilen fest, die für die Anwendung in Pulverlöschanlagen nach EN 12416 2:2001+A1:2007 bestimmt sind.

Folgende Bauteile werden beschrieben:

Pulverbehälter;

Treibgasbehältergruppen;

Druckregler und Druckmessgeräte;

Auslöseeinrichtungen;

Hauptabsperr- und Bereichsventile;

Düsen.

Die Bauteile sind für Pulverlöschanlagen für die allgemeine Verwendung in Gebäuden und sonstigen Bauwerken geeignet. Beim Einsatz in explosionsgefährdeten Bereichen, Erdbebengebieten oder unter extremen Umweltbedingungen, wie in der Seefahrt, auf Bohrinseln, im Bergbau oder in der Luftfahrt, können weitere Anforderungen gelten.

Dieses Dokument behandelt Bauteile für die Anwendung in Pulverlöschanlagen nach EN 12416 2:2001+A1:2007. In dem vorliegenden Dokument werden, z. B. Rohre und Fittings, nicht behandelt, die in anderen allgemeinen Normen beschrieben sind und für die Anforderungen und Empfehlungen in EN 12416 2:2001+A1:2007 gegeben werden. Außerdem werden weder Brandmelder noch Brandmelderzentralen behandelt.

Installations fixes de lutte contre l’incendie - Systèmes d’extinction à poudre - Partie 1 : Exigences et méthodes d’essai des éléments constitutifs

Le présent document spécifie les exigences et les méthodes d’essai s’appliquant aux matériaux, à la construction et aux performances des éléments destinés à un usage au sein d’installations de lutte contre l’incendie utilisant de la poudre conformes à l’EN 12416-2:2001+A1:2007.

Les éléments faisant l’objet de la présente norme sont les suivants :

- réservoirs de poudre ;

- systèmes de réserve du gaz propulseur ;

- régulateurs de pression et manomètres de pression ;

- déclencheurs ;

- vannes d’isolation principales et vannes directionnelles ;

- diffuseurs.

Ces éléments sont adaptés aux installations de lutte contre l’incendie d’usage général utilisant de la poudre, situées dans les immeubles et autres ouvrages de construction. Les surfaces où existent des risques d’explosion, ainsi que les zones de tremblement de terre ou celles dans lesquelles règnent des conditions d’environnement extrêmes, telles que les zones marines, de grand large, minières ou aériennes, peuvent faire l’objet de dispositions complémentaires.

Le présent document s’applique aux éléments destinés à un usage au sein de systèmes d’extinction d’incendie à poudre conformes à l’EN 12416-2:2001+A1:2007. Il ne s’applique pas, par exemple, aux tuyaux et raccords faisant l’objet de normes plus générales, dont les exigences et recommandations sont indiquées dans l’EN 12416-2:2001+A1:2007. Par ailleurs, il ne s’applique pas aux détecteurs ni aux équipements électriques de commande ou d’indication.

Vgrajeni gasilni sistemi - Sistemi s praškom - 1. del: Zahteve in preskusne metode za sestavne dele

Ta evropski standard določa zahteve in preskusne metode za materiale, izdelavo in delovanje sestavnih delov, namenjenih za uporabo v gasilnih sistemih s praškom, ki so v skladu s standardom prEN 12416-2:2000.

Zajeti so naslednji sestavni deli:

– vsebniki za prah;

– sklopi vsebnikov za potisni plin;

– regulatorji in merilniki tlaka;

– sprožila;

– glavni zapirni in preklopni ventili;

– šobe.

Sestavni deli so primerni za gasilne sisteme s praškom, namenjene za splošno uporabo v stavbah in drugih gradbenih objektih. Na območjih z nevarnostjo eksplozije, potresnih območjih in območjih z izjemnimi okoljskimi pogoji (npr. v marinah, na morju, v rudarstvu ali letalstvu) so potrebni dodatni premisleki.

Ta standard zajema sestavne dele za uporabo v gasilnih sistemih s praškom, ki so v skladu s standardom prEN 12416-2:2000. Ne zajema na primer cevi in fitingov, ki so obravnavani v splošnejših standardih, zahteve in priporočila zanje pa so podani v standardu prEN 12416-2:2000. Prav tako ne zajema javljalnikov požara ali električne nadzorne in indikatorske opreme.

General Information

- Status

- Published

- Publication Date

- 16-Jul-2024

- Technical Committee

- CEN/TC 191 - Fixed firefighting systems

- Drafting Committee

- CEN/TC 191/WG 4 - Powder extinguishing systems

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 17-Jul-2024

- Due Date

- 14-Aug-2024

- Completion Date

- 17-Jul-2024

Relations

- Effective Date

- 03-Jun-2020

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 12416-1:2024 - Fixed firefighting systems - Powder systems - Part 1: Requirements and test methods for components (CEN) specifies material, construction and performance requirements and standardized test methods for components used in powder fire suppression systems. It applies to components intended for use in powder firefighting systems that comply with EN 12416-2:2001+A1:2007 and is aimed at general use in buildings and other construction works. The standard excludes pipes/fittings, fire detectors and electrical control equipment, and notes that special conditions apply for explosion-risk areas, seismic zones and extreme environments (marine, offshore, mining, aircraft).

Key topics and requirements

- Scope and applicability: Components for fixed powder firefighting systems for building protection; not a piping standard.

- Components covered:

- Powder containers

- Expellant gas container assemblies

- Pressure regulators and gauges

- Actuators (solenoid, pneumatic, mechanical, pyrotechnic, manual)

- Main isolating valves and selector valves

- Nozzles (total flooding and local application)

- Design & construction requirements: Material selection, working temperature range, corrosion resistance, pressure resistance and marking/documentation requirements.

- Performance & functional tests: Type testing, factory production control (FPC), opening/closing times, remaining media after discharge, jet velocity, flow rate, and strength tests (see annexes for internal pressure, low/high temperature, salt spray and stress corrosion tests).

- Operational criteria: Vibration resistance, operating force, discharge characteristics and actuator reliability.

- Documentation & marking: Mandatory marking and technical documentation to support installation, maintenance and conformity assessment.

Practical applications

- Ensures consistent safety and performance of powder fire suppression components used in buildings, warehouses, industrial premises and public infrastructure.

- Used by manufacturers to design and certify components to European requirements.

- Guides testing laboratories and conformity assessment bodies performing type tests and factory production control.

- Supports system designers, fire safety engineers and installers in selecting compliant components for fixed powder systems.

- Useful for asset owners and facility managers auditing or procuring powder firefighting systems.

Who should use this standard

- Manufacturers of powder containers, valves, actuators, regulators and nozzles

- Test houses and certification bodies performing EN type tests

- Fire protection system designers and specifiers

- Installers, maintenance contractors and facility safety managers

Related standards

- EN 12416-2:2001+A1:2007 - system requirements and recommendations (components in EN 12416-1 are intended for use with systems complying with Part 2)

- Other general standards for piping and fittings referenced by EN 12416-2 (for system pipework and associated components)

Keywords: EN 12416-1:2024, fixed firefighting systems, powder systems, powder firefighting components, requirements and test methods, CEN, pressure regulators, actuators, nozzles, powder containers.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 12416-1:2024 is a standard published by the European Committee for Standardization (CEN). Its full title is "Fixed firefighting systems - Powder systems - Part 1: Requirements and test methods for components". This standard covers: This document specifies requirements and test methods for materials, construction and performance of components intended for use in powder firefighting systems complying with EN 12416-2:2001+A1:2007. The components covered are as follows: - powder containers; - expellant gas container assemblies; - pressure regulators and gauges; - actuators; - main isolating valves and selector valves; - nozzles. The components are suitable for powder firefighting systems for general use in buildings and other construction works. In areas with a risk of explosion, earthquake zones, extreme environmental conditions, e.g. marine, offshore, mining or aircraft additional considerations apply. This document covers components for use in powder extinguishing systems complying with EN 12416-2:2001+A1:2007. It does not cover, for example, pipes and fittings which are covered by more general standards for which requirements and recommendations are given in EN 12416-2:2001+A1:2007. Nor does it cover fire detectors or electrical control and indicating equipment.

This document specifies requirements and test methods for materials, construction and performance of components intended for use in powder firefighting systems complying with EN 12416-2:2001+A1:2007. The components covered are as follows: - powder containers; - expellant gas container assemblies; - pressure regulators and gauges; - actuators; - main isolating valves and selector valves; - nozzles. The components are suitable for powder firefighting systems for general use in buildings and other construction works. In areas with a risk of explosion, earthquake zones, extreme environmental conditions, e.g. marine, offshore, mining or aircraft additional considerations apply. This document covers components for use in powder extinguishing systems complying with EN 12416-2:2001+A1:2007. It does not cover, for example, pipes and fittings which are covered by more general standards for which requirements and recommendations are given in EN 12416-2:2001+A1:2007. Nor does it cover fire detectors or electrical control and indicating equipment.

EN 12416-1:2024 is classified under the following ICS (International Classification for Standards) categories: 13.220.20 - Fire protection. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12416-1:2024 has the following relationships with other standards: It is inter standard links to EN 12416-1:2001+A2:2007, EN 60529:1991, ISO 3864-1:2011, EN ISO 17871:2020, EN 12094-4:2004, EN 12094-5:2006, EN ISO 4126-2:2019, EN ISO 10297:2024, EN 286-1:1998, EN 12094-13:2001, EN ISO 9809-1:2019, EN 12094-8:2006, EN ISO 4126-1:2013, EN 12416-2:2001+A1:2007, EN 1964-3:2000. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12416-1:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2024

Vgrajeni gasilni sistemi - Sistemi s praškom - 1. del: Zahteve in preskusne metode

za sestavne dele

Fixed firefighting systems - Powder systems - Part 1: Requirements and test methods for

components

Ortsfeste Brandbekämpfungsanlagen - Pulverlöschanlagen - Teil 1: Anforderungen und

Prüfverfahren für Bauteile

Installations fixes de lutte contre l'incendie - Systèmes d'extinction à poudre - Partie 1:

Exigences et méthodes d'essais des éléments constitutifs

Ta slovenski standard je istoveten z: EN 12416-1:2024

ICS:

13.220.10 Gašenje požara Fire-fighting

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12416-1

EUROPEAN STANDARD

NORME EUROPÉENNE

July 2024

EUROPÄISCHE NORM

ICS 13.220.20 Supersedes EN 12416-1:2001+A2:2007

English Version

Fixed firefighting systems - Powder systems - Part 1:

Requirements and test methods for components

Installations fixes de lutte contre l'incendie - Systèmes Ortsfeste Brandbekämpfungsanlagen -

d'extinction à poudre - Partie 1 : Exigences et Pulverlöschanlagen - Teil 1: Anforderungen und

méthodes d'essai des éléments constitutifs Prüfverfahren für Bauteile

This European Standard was approved by CEN on 24 June 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12416-1:2024 E

worldwide for CEN national Members.

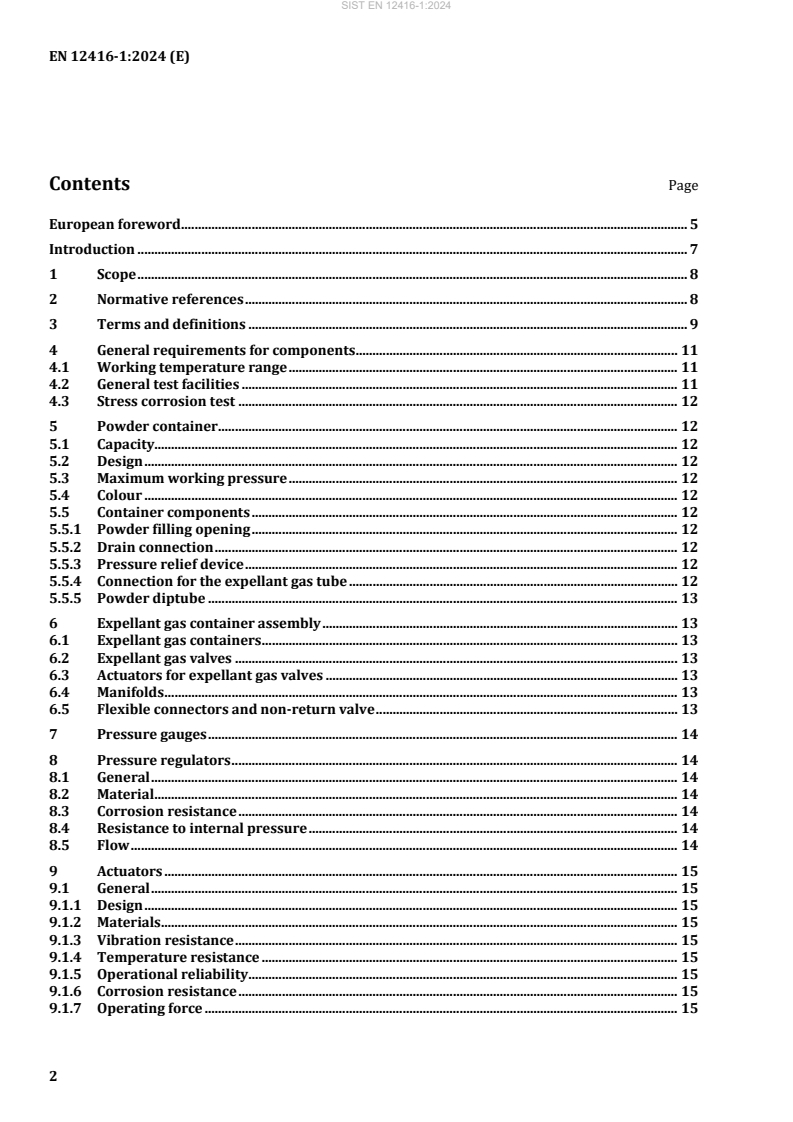

Contents Page

European foreword . 5

Introduction . 7

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 9

4 General requirements for components . 11

4.1 Working temperature range . 11

4.2 General test facilities . 11

4.3 Stress corrosion test . 12

5 Powder container . 12

5.1 Capacity. 12

5.2 Design . 12

5.3 Maximum working pressure . 12

5.4 Colour . 12

5.5 Container components . 12

5.5.1 Powder filling opening . 12

5.5.2 Drain connection . 12

5.5.3 Pressure relief device . 12

5.5.4 Connection for the expellant gas tube . 12

5.5.5 Powder diptube . 13

6 Expellant gas container assembly . 13

6.1 Expellant gas containers . 13

6.2 Expellant gas valves . 13

6.3 Actuators for expellant gas valves . 13

6.4 Manifolds . 13

6.5 Flexible connectors and non-return valve . 13

7 Pressure gauges . 14

8 Pressure regulators . 14

8.1 General . 14

8.2 Material . 14

8.3 Corrosion resistance . 14

8.4 Resistance to internal pressure . 14

8.5 Flow . 14

9 Actuators . 15

9.1 General . 15

9.1.1 Design . 15

9.1.2 Materials . 15

9.1.3 Vibration resistance . 15

9.1.4 Temperature resistance . 15

9.1.5 Operational reliability . 15

9.1.6 Corrosion resistance . 15

9.1.7 Operating force . 15

9.1.8 Electric switch and monitoring equipment . 15

9.2 Solenoid operated type actuators . 15

9.3 Pneumatic powered actuators . 16

9.4 Mechanical operated actuators . 16

9.5 Pyrotechnic actuators . 16

9.6 Manually released actuators . 16

9.7 Use in combination . 17

10 Main isolating valve and selector valve . 17

10.1 General . 17

10.2 Material . 17

10.3 Temperature resistance . 17

10.4 Resistance to pressure . 17

10.5 Flow characteristics . 17

10.6 Corrosion resistance . 17

10.7 Vibration resistance . 17

10.8 Operating force . 17

11 Nozzles . 18

11.1 Material . 18

11.2 Resistance to pressure . 18

11.3 Resistance to heat . 18

11.4 Corrosion resistance . 18

11.5 Orifice diameter . 18

11.6 Connections . 18

11.7 Nozzle covers . 18

11.8 Discharge characteristics . 18

11.8.1 Total flooding nozzle . 18

11.8.2 Local application nozzle . 18

12 Documentation . 18

13 Marking . 19

13.1 General . 19

13.2 Powder containers . 19

13.3 Expellant gas containers and pilot containers . 20

13.4 Actuators . 20

13.5 Expellant gas valves and container valves . 20

13.6 Main isolating valves and selector valves . 20

13.7 Nozzles . 21

14 Type test methods . 21

14.1 Conditions . 21

14.2 Samples and order of tests . 21

15 Evaluation of conformity . 24

15.1 General . 24

15.2 Initial type testing . 24

15.3 Factory production control (FPC) . 24

Annex A (normative) Compliance test . 25

Annex B (normative) Internal pressure test . 26

Annex C (normative) Operating force and function test . 27

C.1 Actuators . 27

C.2 Main isolating valve and selector valve . 28

C.3 Pressure regulators . 28

C.4 Protective cover of nozzles . 29

Annex D (normative) Determination of the remaining media in the container after discharge

............................................................................................................................................................................. 30

Annex E (normative) Opening and closing times . 31

Annex F (normative) Low temperature test for actuators and valves . 32

Annex G (normative) High temperature test for actuators and valves . 33

G.1 Actuators and valves . 33

G.2 Nozzles . 33

Annex H (normative) Salt spray corrosion test . 34

Annex I (normative) Stress corrosion test . 35

Annex J (normative) Strength test for pressure regulators, main isolating valves and selector

valves . 36

Annex K (normative) Jet velocity test . 37

Annex L (normative) Flow rate test . 38

Bibliography . 39

European foreword

This document (EN 12416-1:2024) has been prepared by Technical Committee CEN/TC 191 “Fixed

firefighting systems”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by January 2025, and conflicting national standards shall

be withdrawn at the latest by January 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 12416-1:2001+A2:2007.

The main changes compared with EN 12416-1:2001+A2:2007 are as follows:

— revision of the normative references;

— revision of Clause 6;

— revision of Annexes D, F, G and N;

— deletion of the former Annexes H and I;

— extension of the bibliography.

This European Standard has the general title “Fixed firefighting systems — Powder systems” and consists

of the following two parts:

— Part 1: Requirements and test methods for components;

— Part 2: Design, construction and maintenance.

This document is included in a series of European Standards planned to cover also:

a) gas extinguishing components and systems (the EN 12094 series and the EN 15004 series);

b) sprinkler components and systems (the EN 12259 series and the EN 12845 series);

c) smoke control systems (the EN 12101 series);

d) explosion protection systems;

e) foam systems (the EN 13565 series);

f) hose systems (the EN 671 series);

g) water spray systems (CEN/TS 14816);

h) water mist components and systems (the EN 17450 series and the EN 14972 series).

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

It has been assumed in the preparation of this document that the execution of its provisions is entrusted

to appropriately qualified and experienced people.

1 Scope

This document specifies requirements and test methods for materials, construction and performance of

components intended for use in powder firefighting systems complying with EN 12416-2:2001+A1:2007.

The components covered are as follows:

— powder containers;

— expellant gas container assemblies;

— pressure regulators and gauges;

— actuators;

— main isolating valves and selector valves;

— nozzles.

The components are suitable for powder firefighting systems for general use in buildings and other

construction works. In areas with a risk of explosion, earthquake zones, extreme environmental

conditions, e.g. marine, offshore, mining or aircraft additional considerations apply.

This document covers components for use in powder extinguishing systems complying with

EN 12416-2:2001+A1:2007. It does not cover, for example, pipes and fittings which are covered by more

general standards for which requirements and recommendations are given in

EN 12416-2:2001+A1:2007. Nor does it cover fire detectors or electrical control and indicating

equipment.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 286-1:1998, Simple unfired pressure vessels designed to contain air or nitrogen — Part 1: Pressure

vessels for general purposes

EN 1964-3, Transportable gas cylinders — Specification for the design and construction of refillable

transportable seamless steel gas cylinders of water capacities from 0,5 litre up to and including 150 litres

— Part 3: Cylinders made of seamless stainless steel with an Rm value of less than 1100 MPa

EN 12094-4, Fixed firefighting systems — Components for gas extinguishing systems — Part 4:

Requirements and test methods for container valve assemblies and their actuators

EN 12094-5, Fixed firefighting systems — Components for gas extinguishing systems — Part 5:

Requirements and test methods for high and low pressure selector valves and their actuators

EN 12094-8, Fixed firefighting systems — Components for gas extinguishing systems — Part 8:

Requirements and test methods for connectors

EN 12094-13, Fixed firefighting systems — Components for gas extinguishing systems — Part 13:

Requirements and test methods for check valves and non-return valves

EN 12416-2:2001+A1:2007, Fixed firefighting systems — Powder systems — Part 2: Design, construction

and maintenance

EN 60529, Degrees of protection provided by enclosures (IP Code) (IEC 60529)

EN ISO 4126-1, Safety devices for protection against excessive pressure — Part 1: Safety valves (ISO 4126-

1)

EN ISO 4126-2, Safety devices for protection against excessive pressure — Part 2: Bursting disc safety

devices (ISO 4126-2)

EN ISO 9809-1, Gas cylinders — Design, construction and testing of refillable seamless steel gas cylinders

and tubes — Part 1: Quenched and tempered steel cylinders and tubes with tensile strength less than

1 100 MPa (ISO 9809-1)

EN ISO 9809-2, Gas cylinders — Design, construction and testing of refillable seamless steel gas cylinders

and tubes — Part 2: Quenched and tempered steel cylinders and tubes with tensile strength greater than or

equal to 1 100 MPa (ISO 9809-2)

EN ISO 10297, Gas cylinders — Cylinder valves — Specification and type testing (ISO 10297)

EN ISO 17871, Gas cylinders — Quick-release cylinder valves — Specification and type testing (ISO 17871)

ISO 3864-1, Graphical symbols — Safety colours and safety signs — Part 1: Design principles for safety signs

and safety markings

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

• ISO Online browsing platform: available at https://www.iso.org/obp

• IEC Electropedia: available at https://www.electropedia.org/

3.1

actuator

component which when receiving a signal operates another component

3.2

bursting disc

diaphragm designed to burst at a predetermined pressure difference

3.3

calculation zone

zone for which the design quantity of the extinguishing media required is calculated separately

3.4

diptube

tube through which powder from the lower part of the container is transported into the piping

3.5

equipment fire

fire of three dimensional objects, also subject to leakage, dripping or splashing

3.6

expellant gas container

high pressure container to store the expellant gas

3.7

expellant gas container valve

valve which retains the expellant gas in the expellant gas container, and which releases it when actuated

3.8

fill ratio

mass of an expellant gas relative to the net capacity of the expellant gas container, expressed in kilograms

per litre (kg/l)

3.9

flooding zone

zone comprising all calculation zones to be flooded simultaneously with the extinguishing media via one

selector valve

3.10

local application system

system to protect separate objects

3.11

maximum working pressure

pressure (at a temperature of 50 °C) at which the system or the component can still work and may be

operated

3.12

minimum release energy

energy which is needed for the operation of a component

3.13

minimum working pressure

pressure (at a temperature of –20 °C) at which the system or the component can still be operated

3.14

non-return valve

component permitting flow only in one direction

3.15

nozzle

component to achieve determined performance characteristics and a uniform distribution into or at a

protected zone

3.16

pilot container

power source for a pneumatic alarm device and for actuation of the expellant gas container

3.17

(extinguishing) powder

extinguishing medium composed of finely divided solid chemical products consisting of one or more

principle components, which are combined with additives to improve its characteristics

EXAMPLE BC powder is designed to extinguish class B (liquids or liquefied solids) and class C (gases) fires;

ABC powder is designed to extinguish class A (solids which form glowing members), class B and class C fires.

Note 1 to entry: In North America and some other countries, the term “dry powder” is used to denote special metal

fire extinguishing agents and the term “dry chemical extinguishing agent” is used to denote the extinguishing

medium specified in this European Standard.

Note 2 to entry: When it is useful to indicate the class of fire for which a powder is designed, capital letters may be

added before the term. The letters used in this European Standard are those specified in EN 2.

[SOURCE: EN 615:2009, 3.1]

3.18

protected zone

entire number of flooding zones protected by one system

3.19

selector valve

component which opens or prevents the flow of extinguishing media into a flooding zone

3.20

surface fire

fire spreading across horizontal surfaces. A surface fire may be a fire involving flammable liquids, gases

or solids, not subjected to smouldering

3.21

total flooding system

system to protect the entire contents of an enclosed space

3.22

working pressure

pressure at which the component is used in the system

3.23

working temperature range

temperature range at which the system or the component can still work and may be operated

4 General requirements for components

4.1 Working temperature range

The components shall have a working temperature range of –20 °C to +50 °C.

If CO pilot containers or CO expellant gas containers are used the working temperature range shall be

2 2

0 °C to 40 °C.

4.2 General test facilities

It shall be ensured that the function of all actuators can be tested without discharging the expellant gas.

Depending on the type of the system test connectors for an external test cylinder shall be available.

4.3 Stress corrosion test

If copper alloy parts are used they shall be subjected to the stress corrosion test in Annex I.

5 Powder container

5.1 Capacity

The volume shall be not more than 4000 l.

5.2 Design

The powder container shall be designed in accordance with EN 286-1 and shall be made of steel.

5.3 Maximum working pressure

The maximum working pressure shall not exceed 25 bar.

5.4 Colour

The powder containers shall be coloured red in accordance with ISO 3864-1.

5.5 Container components

5.5.1 Powder filling opening

The powder filling opening of the container shall be not less than DN 100.

Sight-holes, handholes, headholes and manholes may be used for filling in accordance with EN 286-1, if

they are located on the top of the powder container.

5.5.2 Drain connection

For inspection of the interior of the container and testing of the powder, a drain connection to empty the

powder container should be provided.

Drain connections, if provided, shall be not less than:

— for V up to 1000 l: R 1/2 or R 1/2 or G 1/2;

p

— for V above 1000 l : R 1 or R 1 or G 1.

p

5.5.3 Pressure relief device

The powder container shall be fitted with a pressure relief device. The set pressure of the pressure relief

device is never greater than the maximum working pressure, but after pressure relief has commenced

the pressure can exceed the maximum working pressure by 10 % maximum. The gas flow rate through

the pressure relief device shall be greater than the maximum rate of expellant gas entering into the

powder container.

5.5.4 Connection for the expellant gas tube

The expellant gas tube shall be fitted to the powder container discharging the gas below the powder

surface. The system shall be designed to prevent powder entering the expellant gas system.

5.5.5 Powder diptube

The powder container shall be fitted with a powder diptube.

The diptube shall be fixed with sufficient strength to resist damage during operation (filling, emptying of

the container or during the discharge of powder).

The length and configuration of the diptube shall be such that the volume of powder remaining in the

container at the end of the discharge is less than 5 % of the internal volume of the container.

The function of the container including the diptube shall be demonstrated by test as specified in Annex D.

The powder filling opening of the container shall be not less than DN 100.

Sight-holes, handholes, headholes and manholes may be used for filling in accordance with EN 286-1, if

they are located on the top of the powder container.

6 Expellant gas container assembly

6.1 Expellant gas containers

Expellant gas containers shall be constructed in accordance with EN ISO 9809-1, EN ISO 9809-2 and

EN 1964-3.

To check the contents of the expellant gas container at any time, all individual containers shall be fitted

with

a) a weighing device in case of pressure liquefied gases to weigh the contents;

b) in other cases with a working pressure gauge in accordance with Table 1 to indicate the internal

pressure of the container.

6.2 Expellant gas valves

If the system has an automatic and a manual release, the expellant gas valve shall be in accordance with

EN 12094-4 but without a diptube. If the system has a manual release only, an expellant gas container

valve in accordance with EN ISO 10297 may be used, in this case CO as expellant gas is not permitted

and there is no need for any safety precautions, such as delay devices.

6.3 Actuators for expellant gas valves

Actuators for expellant gas valves shall comply with requirements for actuators in EN 12094-4.

6.4 Manifolds

Manifolds shall withstand a pressure of 1,5 times the maximum pressure of the gas used at a temperature

of 50 °C when tested in accordance with Annex B.

Manifolds shall be designed in accordance with the relevant requirements for the pipework design as

specified in EN 12416-2.

6.5 Flexible connectors and non-return valve

Expellant gas containers shall be fitted to the pipework or the manifold by flexible connectors in

accordance with EN 12094-8.

When more than one container is used, each flexible connection to a manifold shall be fitted with a non-

return valve in accordance with EN 12094-13.

7 Pressure gauges

Pressure gauges shall be in accordance with Table 1.

Table 1 — Pressure gauges

Expellant gas

Parameter Pressure regulators

container

A B

downstream upstream

Scale 0 to 1,5 times of the working pressure

Graduation 1 bar 5 bar 10 bar

Accuracy > 1,6 % > 2 % ±5 %

Diameter > 38 mm

8 Pressure regulators

8.1 General

Powder containers with a capacity of more than 100 kg shall be fitted with a pressure regulator. A

pressure regulator shall be fitted to build-up the necessary expellant gas pressure in the powder

container and to maintain the working pressure of the powder system. The minimum setting of the

pressure regulator shall be 10 % lower than the maximum working pressure. The pressure gauge of Type

A shall be installed before and the pressure gauge of Type B behind the pressure regulator. The pressure

gauges shall be in accordance with Table 1.

8.2 Material

All mechanical parts of the pressure regulator for the powder discharge valves and powder selector

valves shall be made of metal or other materials which have at least the same performance

characteristics.

Non-metallic materials and elastomers used in the pressure regulator shall not alter so that the operation

is impaired before or after any of the tests. All materials shall be resistant to the media with which they

come into contact.

If copper alloy is used the component shall be tested in accordance with Annex K.

8.3 Corrosion resistance

The pressure regulator shall be tested in accordance with Annex J.

8.4 Resistance to internal pressure

The pressure regulator shall be tested in accordance with Annex B.

8.5 Flow

The pressure regulator shall be designed so that the expellant gas flow ensures the required powder

discharge in at least the minimum discharge time.

9 Actuators

9.1 General

9.1.1 Design

Actuators should be designed in accordance with EN 12094-4.

The requirements of this clause shall be met as minimum requirements.

9.1.2 Materials

All mechanical parts of the actuator for the powder discharge valves and powder selector valves shall be

made of metal or other materials which have at least the same performance characteristics.

Non-metallic materials and elastomers used in the actuator shall not alter so that the operation is

impaired before or after any of the tests. All materials shall be resistant to the media with which they

come into contact.

If copper alloy is used the component shall be tested in accordance with Annex K.

9.1.3 Vibration resistance

The valve assembly including accessories and actuator shall not operate or be damaged when tested in

accordance with EN ISO 10297 or EN ISO 17871.

9.1.4 Temperature resistance

The actuator shall be tested in accordance with Annex F and G.

9.1.5 Operational reliability

Actuators shall operate together with the associated valve and shall be tested in accordance with

EN ISO 10297 or EN ISO 17871.

9.1.6 Corrosion resistance

Actuators shall operate together with the associated valve and shall be tested in accordance with Annex J.

9.1.7 Operating force

Corresponding to an opening time of maximum 1 s the effective force of the actuator shall be at least two

times and in the case of pyrotechnic actuators at least three times the force necessary to open the valve

under the most severe conditions, when the component is tested as specified in Annex C.

9.1.8 Electric switch and monitoring equipment

The degree of protection for enclosures of the switch and monitoring equipment as well as solenoid coils

shall comply with class IP 54 according to EN 60529.

9.2 Solenoid operated type actuators

9.2.1 The degree of protection for enclosures shall conform to a minimum classification of IP 54 in

accordance with EN 60529.

9.2.2 The solenoid operated type actuators shall be tested in accordance with Annexes C, D, E, F, G, H

and I.

9.3 Pneumatic powered actuators

Pneumatic actuators of expellant gas containers shall comply with the requirements of EN 12094-4.

Pneumatic actuators of powder container main isolating valves and selector valves shall comply with the

requirements of EN 12094-5, but shall operate in a maximum actuating time of 5 s. Pneumatic powered

actuators shall be tested in accordance with Annexes C, D, E, F, G, H and I.

9.4 Mechanical operated actuators

The drop distance shall be at least 75 mm greater than the distance required to open the valve.

Springs acting as the prime mover in the release device shall be free to complete their full travel without

impedance.

9.5 Pyrotechnic actuators

The actuator shall be tested in accordance with Annex C, D, E, F, G, H and I.

The manufacturer shall specify:

— minimum all-fire current and its minimum duration and the form of the signal; and

— maximum monitoring current; and

— range of voltage; and

— maximum storage time under specified storage conditions; and

— maximum life time under stand-by conditions (50 °C and 70 % relative humidity).

In addition, data shall be provided by the manufacturer to show that:

a) the failure rate of the device in the energy transfer path does not exceed 1 in 100 000 at the

recommended firing current; and

b) actuators will achieve the required power output after being subjected to a 90-day ageing test at a

test temperature of (90 ± 2) °C; and

c) the power output of the actuator at the end of its service life as recommended by the manufacturer

will be not less than three times that required to operate the valve at the most disadvantageous

operating conditions.

9.6 Manually released actuators

The manually released actuators shall be protected against unintentional use.

The force required to operate a manually released actuator shall not exceed:

a) 150 N for hand operated controls; or

b) 50 N for finger pull operated controls; or

c) 10 N for finger push operated controls;

The movement of the release shall not exceed 300 mm to achieve actuation. The manual remote release

shall be tested together with the actuator in accordance with C.1.5.

9.7 Use in combination

Actuators for use in combination shall comply with the individual requirements of the appropriate

clauses when tested as a combined assembly.

10 Main isolating valve and selector valve

10.1 General

The main isolating valves and the selector valve shall have a mechanical indicator to show the open and

closed position.

Only ball valves or cavity free valves shall be used.

10.2 Material

All mechanical parts of main isolating valves and selector valves shall be made of metal or other materials

which have at least the same performance characteristics.

Non-metallic materials and elastomers used in the main isolating valve and selector valve shall not alter

so that the operation is impaired before or after any of the tests. All materials shall be resistant to the

media with which they come into contact.

If copper alloy is used the component shall be tested in accordance with Annex K.

10.3 Temperature resistance

Main isolating valves and selector valves shall be tested in accordance with Annex F and G.

10.4 Resistance to pressure

The valve with actuator shall be tested in accordance with Annex B.

10.5 Flow characteristics

The free flow cross section of the valve shall be not less than 95 % of the area given by the inlet pipe

nominal diameter.

The flow characteristic of the valve shall be stated by the manufacturer, either as an equivalent length of

pipe, equal to the inlet pipe nominal diameter or as a flow resistance coefficient.

The valves shall be designed so that during operation no part of the valve or its components shall be

ejected outside of the confines of the valve or into the discharge pipework.

10.6 Corrosion resistance

The main isolating valves and selector valves shall be tested in accordance with Annex J.

10.7 Vibration resistance

The valve assembly including accessories and actuator shall not operate or be damaged when tested in

accordance with EN ISO 10297 or EN ISO 17871.

10.8 Operating force

The effective force of the actuator shall - under the most unfavourable conditions - be at least twice the

force required to operate the valve.

The valves shall be tested in accordance with Annex C.

11 Nozzles

11.1 Material

The nozzle and internal parts shall be made of metal or material with equivalent properties.

The nozzle protective covers may be made of other materials.

11.2 Resistance to pressure

The nozzle shall be tested in accordance with Annex B.

11.3 Resistance to heat

The nozzle shall be tested in accordance with G.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...