EN 12094-5:2006

(Main)Fixed firefighting systems - Components for gas extinguishing systems - Part 5: Requirements and test methods for high and low pressure selector valves and their actuators

Fixed firefighting systems - Components for gas extinguishing systems - Part 5: Requirements and test methods for high and low pressure selector valves and their actuators

This European Standard specifies requirements and describes test methods for selector valves and their actuators used in CO2 -, Inert Gas- or Halocarbon gas fire extinguishing systems.

Ortsfeste Brandbekämpfungsanlagen - Bauteile für Löschanlagen mit gasförmigen Löschmitteln - Teil 5: Anforderungen und Prüfverfahren für Hoch- und Niederdruck-Bereichsventile und zugehörige Auslöseeinrichtungen

Dieses Dokument legt Anforderungen fest und beschreibt Prüfverfahren für Bereichsventile und deren

Auslöseeinrichtungen, die in CO2-, Inertgas-Feuerlöschanlagen und Feuerlöschanlagen mit halogenierten

Kohlenwasserstoffen eingesetzt werden.

Installations fixes de lutte contre l'incendie - Éléments constitutifs des installations d'extinction à gaz - Partie 5: Exigences et méthodes d'essai pour vannes directionnelles haute et basse pression et leurs déclencheurs

La présente Norme européenne spécifie les exigences et décrit les méthodes d'essais applicables aux vannes directionnelles et à leurs déclencheurs utilisés dans les installations de lutte contre l'incendie au CO2, à gaz inerte ou à gaz inhibiteur.

Vgrajeni gasilni sistemi – Sestavni deli sistemov za gašenje s plinom – 5. del: Zahteve in preskusne metode za visokotlačne in nizkotlačne sortirne ventile in njihova sprožila

General Information

- Status

- Published

- Publication Date

- 25-Apr-2006

- Technical Committee

- CEN/TC 191 - Fixed firefighting systems

- Drafting Committee

- CEN/TC 191/WG 6 - Gas extinguishing Systems and components

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 03-Sep-2024

- Completion Date

- 11-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

CEN/TS 14972:2011 - Fixed firefighting systems - Watermist systems - Design and installation - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 12094-5:2006 is the CEN (European) standard that sets requirements and test methods for high- and low‑pressure selector valves and their actuators used in fixed gas extinguishing systems (CO2, Inert Gas, Halocarbon). It forms part of the EN 12094 series for components of gas extinguishing systems and supports conformity procedures relevant to EU directives (see informative Annex ZA).

Key topics and technical requirements

- Scope: Applies to selector valves and actuators for CO2, Inert Gas and Halocarbon gas fire‑extinguishing installations.

- Materials & construction: Valve bodies and internal parts (except seals) and all mechanical actuator parts must be metallic; moving parts typically stainless steel, copper/copper alloy or corrosion‑protected steel. Materials must be compatible with the extinguishing media.

- Performance limits

- Opening/closing times: Maximum opening time 3 s; CO2 low‑pressure valves also require a maximum closing time of 3 s.

- Working pressure: Manufacturer to specify. Table values include e.g. CO2 high‑pressure selector valves to 140 bar and CO2 low‑pressure to 25 bar (gauge).

- Housing pressure: Shall not exceed working pressure in any operating position.

- Flow data: Manufacturers must provide flow characteristics as equivalent length or flow‑resistance coefficient and specify inlet/outlet pipe diameters. CO2 valves must have free flow cross‑section ≥ 80% of inlet pipe area.

- Actuator types: Pneumatic, gravity, electric - manufacturers must declare supply pressures, mass/drop distance, voltages/currents and duty ratings where relevant.

- Reliability & safety: Design must prevent ejection of parts into discharge pipework; closed position must only be left by activation or manual means; CO2 low‑pressure closed position must not rely on friction alone.

- Test methods covered: Function, resistance to internal pressure and bursting, operational reliability, temperature operation, flow characteristic testing, corrosion and stress‑corrosion resistance, vibration, operating force, plus marking and documentation checks.

- Conformity & traceability: Includes initial type testing, factory production control and CE marking guidance (Annex ZA).

Applications and users

- Who uses it: Manufacturers of selector valves and actuators, system designers, installers, testing laboratories, certification bodies, maintenance organizations and procurement/specification engineers for fixed gas extinguishing systems.

- Practical use: Ensures components meet performance, safety and compatibility requirements for CO2, Inert Gas and Halocarbon flooding systems in industrial, marine, data centre and high‑risk enclosures.

Related standards

- EN 12094 series (other component parts), EN ISO 9001 (quality management), environmental test standards (e.g., EN 60068‑2‑6 for vibration) and national implementations of the EN 12094 family.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 12094-5:2006 is a standard published by the European Committee for Standardization (CEN). Its full title is "Fixed firefighting systems - Components for gas extinguishing systems - Part 5: Requirements and test methods for high and low pressure selector valves and their actuators". This standard covers: This European Standard specifies requirements and describes test methods for selector valves and their actuators used in CO2 -, Inert Gas- or Halocarbon gas fire extinguishing systems.

This European Standard specifies requirements and describes test methods for selector valves and their actuators used in CO2 -, Inert Gas- or Halocarbon gas fire extinguishing systems.

EN 12094-5:2006 is classified under the following ICS (International Classification for Standards) categories: 13.220.20 - Fire protection. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12094-5:2006 has the following relationships with other standards: It is inter standard links to EN 12094-5:2000, EN ISO 9001:2000, EN 15004-1:2019, EN 15004-1:2024, EN 12094-6:2006, EN 12416-1:2001+A2:2007, CEN/TS 14816:2008, CEN/TS 14972:2011, EN 17966:2024, EN 15004-1:2008, EN 12416-1:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12094-5:2006 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/109. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12094-5:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Ortsfeste Brandbekämpfungsanlagen - Bauteile für Löschanlagen mit gasförmigen Löschmitteln - Teil 5: Anforderungen und Prüfverfahren für Hoch- und Niederdruck-Bereichsventile und zugehörige AuslöseeinrichtungenInstallations fixes de lutte contre l'incendie - Éléments constitutifs des installations d'extinction a gaz - Partie 5: Exigences et méthodes d'essai pour vannes directionnelles haute et basse pression et leurs déclencheursFixed firefighting systems - Components for gas extinguishing systems - Part 5: Requirements and test methods for high and low pressure selector valves and their actuators13.220.10Gašenje požaraFire-fightingICS:Ta slovenski standard je istoveten z:EN 12094-5:2006SIST EN 12094-5:2006en01-julij-2006SIST EN 12094-5:2006SLOVENSKI

STANDARDSIST EN 12094-5:20011DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12094-5April 2006ICS 13.220.20Supersedes EN 12094-5:2000

English VersionFixed firefighting systems - Components for gas extinguishingsystems - Part 5: Requirements and test methods for high andlow pressure selector valves and their actuatorsInstallations fixes de lutte contre l'incendie - Élémentsconstitutifs des installations d'extinction à gaz - Partie 5:Exigences et méthodes d'essai pour vannes directionnelleshaute et basse pression et leurs déclencheursOrtsfeste Brandbekämpfungsanlagen - Bauteile fürLöschanlagen mit gasförmigen Löschmitteln - Teil 5:Anforderungen und Prüfverfahren für Hoch- undNiederdruck-Bereichsventile und zugehörigeAuslöseeinrichtungenThis European Standard was approved by CEN on 9 March 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2006 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12094-5:2006: ESIST EN 12094-5:2006

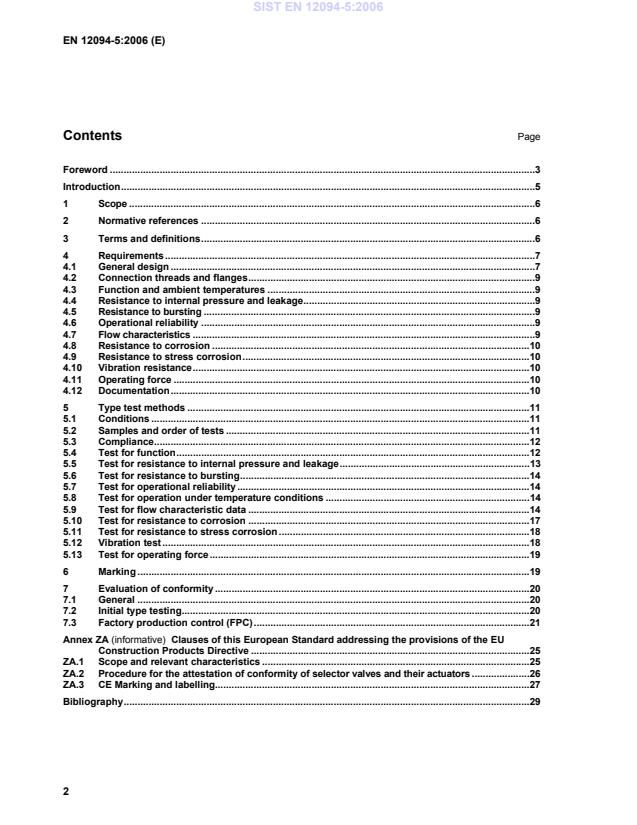

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive.25 ZA.1 Scope and relevant characteristics.25 ZA.2 Procedure for the attestation of conformity of selector valves and their actuators.26 ZA.3 CE Marking and labelling.27 Bibliography.29

NOTE 1 Actuators may have a different working pressure than selector valves. NOTE 2 Guidelines for planning and installation may require that a manual emergency operating device, if applicable, at the selector valve does not override pre-warning and time delay. 4.1.6 The pressure of the housing of the selector valve shall not exceed the working pressure in any operat-ing position. NOTE Cold liquid CO2 locked in a closed CO2-low pressure selector valve after flooding may cause pressures ex-ceeding the working pressure when the temperature of the CO2 and the valve goes up again. 4.1.7 The test samples shall comply with the technical description as specified in 4.12 (drawings, parts lists, description of functions, operating and installation instructions) when checked in accordance with 5.3. 4.1.8 Selector valves and actuators shall be designed so that during operation no part of the valve or its components shall be ejected outside the confines of the valve or into the discharge pipework. 4.1.9 The flow characteristics of the valve shall be specified by the manufacturer either as an equivalent length or as a flow-resistance coefficient. 4.1.10 The nominal and the internal diameter of the pipes at the inlet and the outlet of the valve shall be specified by the manufacturer. 4.1.11 The free flow cross sectional area of CO2 selector valves shall be not less than 80 % of the area given by the inlet pipe internal diameter. 4.1.12 Where the component incorporates a pneumatic actuator, the manufacturer shall specify nominal, maximum and minimum figures for the pressure supply. 4.1.13 Where the component incorporates a gravity powered actuator, the manufacturer shall specify the mass and the drop distance. 4.1.14 Where the component incorporates an electric powered actuator, the manufacturer shall specify nominal, maximum and minimum figures for voltage and current and the electrical data giving 50 % of the force achieved for nominal electrical conditions (voltage and current). Electric powered actuators shall be specified for continuous duty. 4.1.15 The component shall be specified by the manufacturer either for installation on walls only or for instal-lation on both walls and machinery. 4.1.16 For Inert gas and Halocarbon gas selector valves not specified for use in systems with reduced and controlled pressure only the manufacturer shall specify the maximum developed pressure in the container at 20 °C with the highest fill ratio/superpressurization, as applicable. SIST EN 12094-5:2006

impossible. This documentation shall include drawings, parts lists, block diagrams (if applicable), circuit

5.8.1 Low temperature test (including leakage test) 6 6 a 6 a 5.8.2 High temperature test (including leakage test) 5 5 a 5 a 5.9 Test for flow characteristic data 4 a 4 a 4 5.10 Test for resistance to corrosion 13 5.11 Test for resistance to stress corrosion 8 5.12 Vibration test 8 5.13 Test for operating force 7 7 a 7 a A = largest cross section B = medium cross section C = smallest cross section ------------ a The need for these tests depends on design, e.g. seal materials, flow way design.

5.3 Compliance NOTE This test relates to the requirements of 4.1.7. A visual and measurement check shall be made to determine whether the test samples correspond to the description in the technical literature (drawings, parts lists, description of functions, operating and installation instructions). 5.4 Test for function NOTE This test relates to the requirements of 4.3, 4.8 and 4.10. 5.4.1 The test pressure is for CO2-low-pressure selector valves (20 ± 3) bar; for CO2-high-pressure selector valves (60 ± 5) bar; for other than CO2 selector valves not specified for use in systems with reduced and controlled pressure only the pressure developed in the container at 20 °C; for other than CO2 selector valves specified for use in systems with reduced and controlled pressure only the specified working pressure. SIST EN 12094-5:2006

actuator. Check the correct function of the sample and measure the closing time. In the case of other

selector valves, after (10 ± 5) s depressurise the sample to a value below 5 bar and close it manually. d) Allow the test facility and the test sample to cool to the normal test temperature. During each test cycle the supply pressure to the valve shall not drop below: 15 bar for CO2-low-pressure selector valves, 50 bar for CO2-high-pressure selector valves, and 80 % of the test pressure for other selector valves. 5.4.3 Fit replacement parts at the end of each cycle on test samples in which parts are designed to be

destroyed on normal operation of the valve. 5.4.4 The relevant characteristics of the test facility shall be as follows: a) pipework between control valve of the test rig and the test sample shall be as specified and provided by the manufacturer. If there are no data provided, the test pipe shall have the following dimensions: nominal size DN 50; length (2 ± 0,1) m; b) control valve quick opening valve upstream of the test pipe to achieve the test pressure at the test sample within 1 s. 5.5 Test for resistance to internal pressure and leakage NOTE This test relates to the requirements of 4.3, 4.4, 4.6, 4.8 and 4.10. 5.5.1 The valve in its closed position shall be connected via the inlet to a suitable hydraulic pressure supply. Provision for venting shall be available. The system shall be vented of air and the pressure shall be increased at (2 ± 1) bar/s up to the test

pressure (50+) %. This pressure shall be maintained for a period of (105+) min. At the end of this period the hydraulic pressure shall be released. SIST EN 12094-5:2006

maintained at the required test temperature, the leakage shall be measured using a water bath. 5.6 Test for resistance to bursting NOTE This test relates to the requirements of 4.5. The valve in its open position with blocked outlet shall be connected via the inlet to a suitable hydraulic pressure supply. Provision for venting shall be available. The system of air shall be vented and the pressure shall be increased at (2 ± 1) bar/s up to the test pressure (50+) %. This pressure shall be maintained for a period of (105+) min. At the end of this period the hydraulic pressure shall be released. 5.7 Test for operational reliability NOTE This test relates to the requirements of 4.6. The test cycle described in 5.4 shall be carried out 100 times, but without measuring the opening/closing time. 5.8 Test for operation under temperature conditions NOTE This test relates to the requirements of 4.3. 5.8.1 Low temperature The test assembly shall be cooled to (0220−−) °C, in the case of CO2-low pressure valves to (0230−−) °C, and shall be maintained at this temperature for (2 ± 0,5) h. It shall be ensured that no water is in the test sample. The valve shall be closed carefully before cooling. The test procedure described in 5.4.1 to 5.4.3 (excluding the requirements of 5.4.4) shall be carried out five times. Subsequently a leakage test shall be carried out in accordance with 5.5.2 with the test sample at test temperature. 5.8.2 High temperature The test assembly shall be heated to (2050+) °C and shall be maintained at this temperature for (2 ± 0,5) h. The test procedure described in 5.4.1 to 5.4.3 (excluding the requirements of 5.4.4) shall be carried out five times. Subsequently a leakage test shall be carried out in accordance with 5.5.2 with the test sample at test temperature. 5.9 Test for flow characteristic data NOTE This test relates to the requirements of 4.7. 5.9.1 Except as stated in 5.9.2, the test shall be done using: SIST EN 12094-5:2006

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...