EN 1127-2:2002+A1:2008

(Main)Explosive atmospheres - Explosion prevention and protection - Part 2: Basic concepts and methodology for mining

Explosive atmospheres - Explosion prevention and protection - Part 2: Basic concepts and methodology for mining

This European Standard gives general guidelines for explosion prevention and protection in mining by outlining the basic concepts and methodology for the design and construction of equipment, protective systems and components.

This European Standard applies to Group I equipment, protective systems and components intended for use in underground parts of mines and those parts of their surface installations at risk from firedamp and/or flammable dust.

NOTE Detailed information on specific equipment, protective systems and components is contained in the relevant individual standards. Safety-relevant data regarding flammable materials and explosive atmospheres are required for the design and construction of the explosion protection measures

This European Standard specifies methods for the identification and assessment of hazardous situations that may lead to explosions and describes the design and construction measures appropriate for the required safety. This is achieved by

- hazard identification;

- risk assessment;

- elimination or minimization of risk;

- information for use.

The safety of equipment, protective systems, and components can be achieved, as described in EN 292-2:1991, by removal of hazards and/or limiting the risk, i.e.

a) by risk reduction by design;

b) by safeguarding;

c) by information for use;

d) by additional precautions.

NOTE Risk reduction by design in accordance with clause 3 of EN 292-2:1991 should not be confused with the concept of "design" as described in 6.5 of this standard.

Measures in accordance with a) (prevention) and b) (protection) against explosions are dealt with in clause 6 of this standard, measures according to c) against explosions are dealt with in clause 7 of this standard. Mea¬sures in accordance with d) are not described in this European Standard. They are dealt with in clause 6 of EN 292 2:1991.

The preventive and protective measures described in this European Standard will not provide the required level of

Explosionsfähige Atmosphären - Explosionsschutz - Teil 2: Grundlagen und Methodik in Bergwerken

Diese Europäische Norm legt allgemeine Leitlinien für den Explosionsschutz im Bergbau fest, indem grundlegende Konzepte und Verfahren für die Konstruktion und den Bau von Geräten, Schutzsystemen und Komponenten dargelegt werden.

Diese Europäische Norm gilt für Geräte, Schutzsysteme und Komponenten der Gruppe I, zur Verwendung in Untertagebetrieben von Bergwerken sowie deren Übertageanlagen, die durch Grubengas und/oder brennbare Stäube gefährdet werden können.

ANMERKUNG 1 Detaillierte Informationen über spezielle Geräte, Schutzsysteme und Komponenten sind in entsprechenden Einzelnormen zusammengefasst. Für Konstruktion und Bau von Explosionsschutzmaßnahmen müssen die sicherheitsrelevanten Daten der brennbaren Stoffe und explosionsfähigen Atmosphären bekannt sein.

Diese Europäische Norm legt Verfahren zum Erkennen und Beurteilen von gefährlichen Situationen, die zu Explosionen führen können fest und beschreibt geeignete Planungs- und Fertigungsmaßnahmen, um die erforderliche Sicherheit zu erreichen. Dies wird erreicht durch

Erkennen von Gefährdungen;

Beurteilen des Risikos;

Beseitigen oder Verringern des Risikos;

Benutzerinformation.

Die Sicherheit von Geräten, Schutzsystemen und Komponenten kann, wie in EN 292-2 beschrieben, durch das Beseitigen von Gefährdungen und/oder die Begrenzung des Risikos erreicht werden durch

a) Risikominderung beim Entwurf;

b) Schutzmaßnahmen;

c) Benutzerinformation;

d) zusätzliche Vorsichtsmaßnahmen.

ANMERKUNG 2 Die Risikominderung beim Entwurf nach EN 292-2:1991, Abschnitt 3, sollte nicht verwechselt werden mit dem Begriff „Entwurf“ nach 6.5 der vorliegenden Norm.

Explosionsschutzmaßnahmen nach a) (Vorbeugung) und b) (Schutz) werden in Abschnitt 6 dieser Norm behandelt, Maßnahmen nach c) in Abschnitt 7. Maßnahmen nach d) sind in dieser Norm nicht beschrieben; letztere werden in EN 292-2:1991, Abschnitt 6, behandelt.

Atmosphères explosives - Prévention de l'explosion et protection contre l'explosion - Partie 2: Notions fondamentales et méthodologie dans l'exploitation des mines

effets de l’explosion dans l’industrie minière qui précise les notions fondamentales et la méthodologie relatives à la

conception et à la construction des appareils, systèmes de protection et autres composants.

La présente Norme européenne s’applique aux appareils, systèmes de protection et composants du groupe I

destinés aux travaux souterrains des mines et aux parties de leurs installations de surface susceptibles d’être mis

en danger par le grisou et/ou des poussières combustibles.

NOTE Des informations détaillées sur les appareils, les systèmes de protection et les composants spécifiques sont données

dans des normes séparées appropriées. La conception et l’élaboration des mesures de prévention et de protection contre

l’explosion nécessitent la détermination des données adaptées de sécurité des substances inflammables et des atmosphères

explosives.

Cette norme européenne spécifie des méthodes d'identification et d'appréciation des situations dangereuses

pouvant conduire à l'explosion ainsi que les mesures de conception et de construction appropriées pour assurer la

sécurité requise. Ceci est obtenu par :

- l'identification du phénomène dangereux ;

- l'appréciation du risque ;

- la suppression ou la réduction du risque ;

- des informations pour l'utilisation.

La sécurité des appareils, systèmes de protection et composants, peut être atteinte par l'élimination des

phénomènes dangereux et/ou la limitation du risque, tel qu'indiqué dans l'EN 292-2:1991 :

a) par une conception réduisant le risque ;

b) à l'aide de dispositifs de protection ;

c) au moyen d’informations pour l'utilisation ;

d) par des dispositions supplémentaires.

NOTE Il convient de ne pas confondre une conception réduisant le risque au sens de l’article 3 de l’EN 292-2:1991 avec la

«conception» au sens du 6.5 de la présente norme.

Eksplozivne atmosfere - Preprečevanje eksplozije in zaščita pred njo - 2. del: Osnovni pojmi in metodologija za rudarstvo

General Information

- Status

- Withdrawn

- Publication Date

- 15-Apr-2008

- Withdrawal Date

- 20-Jan-2026

- Technical Committee

- CEN/TC 305 - Potentially explosive atmospheres - Explosion prevention and protection

- Drafting Committee

- CEN/TC 305/WG 5 - Equipment and protection systems for mining

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 18-Jun-2014

- Completion Date

- 21-Jan-2026

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 08-Aug-2012

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

Bureau Veritas Chile

Bureau Veritas certification services in Chile.

Bureau Veritas Peru

Bureau Veritas certification services in Peru.

Sponsored listings

Frequently Asked Questions

EN 1127-2:2002+A1:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Explosive atmospheres - Explosion prevention and protection - Part 2: Basic concepts and methodology for mining". This standard covers: This European Standard gives general guidelines for explosion prevention and protection in mining by outlining the basic concepts and methodology for the design and construction of equipment, protective systems and components. This European Standard applies to Group I equipment, protective systems and components intended for use in underground parts of mines and those parts of their surface installations at risk from firedamp and/or flammable dust. NOTE Detailed information on specific equipment, protective systems and components is contained in the relevant individual standards. Safety-relevant data regarding flammable materials and explosive atmospheres are required for the design and construction of the explosion protection measures This European Standard specifies methods for the identification and assessment of hazardous situations that may lead to explosions and describes the design and construction measures appropriate for the required safety. This is achieved by - hazard identification; - risk assessment; - elimination or minimization of risk; - information for use. The safety of equipment, protective systems, and components can be achieved, as described in EN 292-2:1991, by removal of hazards and/or limiting the risk, i.e. a) by risk reduction by design; b) by safeguarding; c) by information for use; d) by additional precautions. NOTE Risk reduction by design in accordance with clause 3 of EN 292-2:1991 should not be confused with the concept of "design" as described in 6.5 of this standard. Measures in accordance with a) (prevention) and b) (protection) against explosions are dealt with in clause 6 of this standard, measures according to c) against explosions are dealt with in clause 7 of this standard. Mea¬sures in accordance with d) are not described in this European Standard. They are dealt with in clause 6 of EN 292 2:1991. The preventive and protective measures described in this European Standard will not provide the required level of

This European Standard gives general guidelines for explosion prevention and protection in mining by outlining the basic concepts and methodology for the design and construction of equipment, protective systems and components. This European Standard applies to Group I equipment, protective systems and components intended for use in underground parts of mines and those parts of their surface installations at risk from firedamp and/or flammable dust. NOTE Detailed information on specific equipment, protective systems and components is contained in the relevant individual standards. Safety-relevant data regarding flammable materials and explosive atmospheres are required for the design and construction of the explosion protection measures This European Standard specifies methods for the identification and assessment of hazardous situations that may lead to explosions and describes the design and construction measures appropriate for the required safety. This is achieved by - hazard identification; - risk assessment; - elimination or minimization of risk; - information for use. The safety of equipment, protective systems, and components can be achieved, as described in EN 292-2:1991, by removal of hazards and/or limiting the risk, i.e. a) by risk reduction by design; b) by safeguarding; c) by information for use; d) by additional precautions. NOTE Risk reduction by design in accordance with clause 3 of EN 292-2:1991 should not be confused with the concept of "design" as described in 6.5 of this standard. Measures in accordance with a) (prevention) and b) (protection) against explosions are dealt with in clause 6 of this standard, measures according to c) against explosions are dealt with in clause 7 of this standard. Mea¬sures in accordance with d) are not described in this European Standard. They are dealt with in clause 6 of EN 292 2:1991. The preventive and protective measures described in this European Standard will not provide the required level of

EN 1127-2:2002+A1:2008 is classified under the following ICS (International Classification for Standards) categories: 13.230 - Explosion protection; 73.100.01 - Mining equipment in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1127-2:2002+A1:2008 has the following relationships with other standards: It is inter standard links to EN 1127-2:2002, EN 1127-2:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1127-2:2002+A1:2008 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 94/9/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1127-2:2002+A1:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Explosionsfähige Atmosphären - Explosionsschutz - Teil 2: Grundlagen und Methodik in BergwerkenAtmosphères explosives - Prévention de l'explosion et protection contre l'explosion - Partie 2: Notions fondamentales et méthodologie dans l'exploitation des minesExplosive atmospheres - Explosion prevention and protection - Part 2: Basic concepts and methodology for mining73.020Rudarstvo in kamnolomsko izkopavanjeMining and quarrying13.230Varstvo pred eksplozijoExplosion protectionICS:Ta slovenski standard je istoveten z:EN 1127-2:2002+A1:2008SIST EN 1127-2:2002+A1:2008en,fr,de01-julij-2008SIST EN 1127-2:2002+A1:2008SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1127-2:2002+A1

April 2008 ICS 13.230; 73.100.01 Supersedes EN 1127-2:2002 English Version

Explosive atmospheres - Explosion prevention and protection - Part 2: Basic concepts and methodology for mining

Atmosphères explosives - Prévention de l'explosion et protection contre l'explosion - Partie 2: Notions fondamentales et méthodologie dans l'exploitation des mines

Explosionsfähige Atmosphären - Explosionsschutz -Teil 2: Grundlagen und Methodik in Bergwerken This European Standard was approved by CEN on 31 August 2001 and includes Amendment 1 approved by CEN on 18 March 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2008 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1127-2:2002+A1:2008: ESIST EN 1127-2:2002+A1:2008

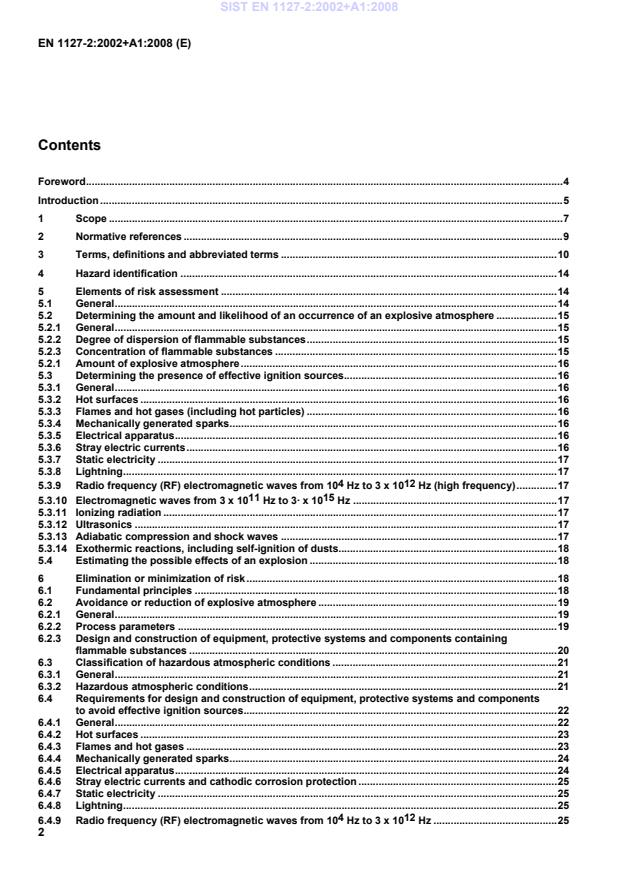

Relation between categories and hazardous atmospheric conditions.32 Annex ZA (informative)

Clauses of this European Standard addressing essential requirements or other provisions of EU Directives.36 Annex ZB (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC.38 Bibliography.39

In mines where flammable minerals/materials are extracted, there can also be a risk of explosions because small particles of the extracted product can be blown into the air to form dust/air mixtures able to support rapid combustion. Flammable dust can either be an explosion risk on its own (when in the form of an explosive dust/air mixture), or it can settle in layers which may be blown from the floor and sides of the roadways by a firedamp explosion. In the latter case, the explosive violence can increase manyfold as more and more fuel in the form of flammable dust is raised by a blast wave and added to the flame as it travels along the roadways. The risk of an explosive atmosphere occurring and its consequences will therefore vary from mine to mine, depending on the type of mine, its layout, the mineral being extracted and the likelihood of firedamp and/or flammable dust occurring. In coal mining, firedamp and coal dust naturally associated with the coal is released by the activity of the miners.

Therefore, the potential explosion risk is greater as a result of explosive air/gas or air/dust mixtures forming that cannot be totally excluded by the preventive measures taken. Firedamp/air mixtures are usually diluted by the ventilation and evacuated to the surface via the mine workings so that the gas content in normal operation is kept far below the lower explosion limit. However, as a result of system malfunction (e.g. fan failure), sudden release of large gas quantities (gas outbursts) or intensified gas release caused by decreasing air pressure or by increased coal production, the permissible gas concentration thresholds may be exceeded. The explosive atmosphere caused in this way, even though limited in space and/or time, may cause a hazard not just at its point of origin but also in the escape roads, waste air paths and other connected mine structures in the mine layout Coal dust/air mixtures are usually neutralized at the dust source by water sprays, dust removal systems on heading machines and/or treating with inert dust in order to reduce the explosive potential.

However, an explosion hazard can exist if explosive dust can become airborne, e.g. at transfer points, in bunkers and other conveying systems. In contrast to surface industries, in gassy mines electrical and non-electrical equipment and mining personnel are in permanent contact with gas and/or dust/air mixtures which, under unfavourable conditions, may constitute explosive atmospheres. Accordingly, particularly stringent safety requirements are in force for explosion protection and escape possibilities in the event of a hazard. Due to the possibly devastating effects of underground gas/dust explosions, underground mining is permitted only well outside the explosion range. As a deviation from EN 1127-1:1997 “Explosive atmospheres – Explosion prevention and protection - Part 1: Basic concepts and methodology", which does not cover mining, the term "area" is not used for the categorization of underground workings exposed to explosion hazards because normally this term stands for a clearly dimensionally specified space around a generally stationary technical installation, e.g. a chemical plant with fixed installations and specified limits around the manufacturing process.

Therefore, Directive 94/9/EEC deals with the mining and non-mining industries separately by having equipment category I for mining and equipment category II for non-mining industry. In gassy mines, the decision as to whether or not mine workers can operate in a particular workplace depends upon the atmospheric conditions prevailing at the time. Traditionally, a factor of safety is also introduced so that it is common practice throughout the European member states for equipment to be de-energized or made safe and for miners to be withdrawn from their workplace if the atmospheric conditions attain a specific percentage of the lower explosion limit (LEL) of methane (firedamp) in air as defined by the relevant national legislation of the member states NOTE The current limit values for disconnecting equipment and withdrawing personnel are different in each member state. SIST EN 1127-2:2002+A1:2008

range between 0 % and below LEL or above UEL up to 100 % of firedamp in air

- hazardous condition 1 ( explosive atmosphere)

range between LEL and UEL of firedamp in air In mine workings with hazardous condition 1, only M 1 equipment is allowed to be used as it has a high degree of intrinsic safety.

M 1 equipment, e.g. telephones or gas measuring equipment, may continue to be operated even in the event of rare equipment faults in explosive atmospheres. This is ensured by the existence of two independent protective measures or double fail-safe systems.

In mine workings with hazardous condition 2, both M 1 and M 2 equipment may be used. M 2 equipment may be used as it has a high degree of safety and is suitable for the severe conditions in mining. In an explosive atmosphere, M 2 equipment shall be capable of being disconnected or made safe NOTE Under special conditions, it may be necessary to operate M 2 equipment in an explosive atmosphere for a short time, e.g. when personnel are escaping from mine workings with high firedamp readings with their M 2 caplights switched on, when personnel are being recovered by the mine rescue service or the firedamp extraction system has been started up

M 1 and M 2 equipment can only be operated with the characteristics specified by the manufacturer as only then do they ensure the relevant level of safety. The manufacturer specifies the operating characteristics for the equipment.

In practice, national regulations require that gas measurements be taken at certain points and at specific intervals and suitable measures are taken to de-energize the equipment either manually or automatically if the firedamp concentration reaches a certain value. A subdivision into hazards caused by an explosive gas atmosphere and those caused by an explosive dust atmosphere is, in contrast to EN 1127-1:1997, not advisable in underground mining as the hazard to the mine workings can be caused simultaneously by firedamp and by clouds of flammable dust. Therefore, the explosion protection measures shall always cover both, i.e. the hazard caused by firedamp and the one caused by flammable dust. Directive 94/9/EEC extends the definition of potentially explosive atmosphere to include flammable dust as well as firedamp. Extensive research [2] has shown that the minimum ignition energy (MIE) of coal dust/air mixtures is several hundred times that of firedamp/air mixtures and that the maximum experimental safe gap (MESG) of coal dust particles is more than double that for firedamp. It is therefore reasonable to assume that the equipment, protective systems and components which are designed and constructed for use in firedamp/air mixtures are also suitable for use in coal dust/air mixtures. The comparison of firedamp and coal dust experimental data relates only to atmospheres. Additional precautions are required when considering coal dust deposits as, in this case, the maximum surface temperature of the equipment (limited to 150 °C for Group I equipment) on which the deposits can form can be limited to values below the minimum ignition temperature. It shall be borne in mind that in coal mines and non-coal mines there can be areas where firedamp does not occur but where there is a risk of explosion because of flammable dust. A list of standards under preparation by CEN/TC 305 is given in annex C. 1 Scope This European Standard gives general guidelines for explosion prevention and protection in mining by outlining the basic concepts and methodology for the design and construction of equipment, protective systems and components. This European Standard applies to Group I equipment, protective systems and components intended for use in underground parts of mines and those parts of their surface installations at risk from firedamp and/or flammable dust. SIST EN 1127-2:2002+A1:2008

Safety-relevant data regarding flammable materials and explosive atmospheres are required for the design and construction of the explosion protection measures This European Standard specifies methods for the identification and assessment of hazardous situations that may lead to explosions and describes the design and construction measures appropriate for the required safety. This is achieved by - hazard identification; - risk assessment; - elimination or minimization of risk; - information for use. The safety of equipment, protective systems, and components can be achieved, as described in EN 292-2:1991, by removal of hazards and/or limiting the risk, i.e. a) by risk reduction by design; b) by safeguarding; c) by information for use; d) by additional precautions. NOTE

Risk reduction by design in accordance with clause 3 of EN 292-2:1991 should not be confused with the concept of "design" as described in 6.5 of this standard. Measures in accordance with a) (prevention) and b) (protection) against explosions are dealt with in clause 6 of this standard, measures according to c) against explosions are dealt with in clause 7 of this standard. Measures in accordance with d) are not described in this European Standard. They are dealt with in clause 6 of EN 292-2:1991. The preventive and protective measures described in this European Standard will not provide the required level of safety unless the equipment, protective systems and components are operated in line with their intended use and are installed and maintained according to the relevant codes of practice or requirements. This standard is applicable to any equipment, protective systems and components intended to be used in potentially explosive atmospheres. These atmospheres can arise from flammable materials processed, used or released by the equipment, protective systems and components or from materials in the vicinity of the equipment, protective systems and components and/or from the materials of construction of the equipment, protective systems and components. As shot firing can release potentially explosive atmospheres, this standard is also applicable to the equipment used for shot firing, apart from the explosives and detonators. This standard is applicable to equipment, protective systems and components at all stages of use. This standard is not applicable to: - medical devices intended for use in a medical environment; - equipment, protective systems and components where the explosion hazard results exclusively from the presence of explosives or unstable chemical substances; - equipment, protective systems and components where the explosion can result from reaction of substances with oxidizing agents other than atmospheric oxygen or by other hazardous reactions or conditions other than atmospheric conditions; SIST EN 1127-2:2002+A1:2008

electrical/electronic/programmable

electronic safety-related systems. EN 61779-1, Electrical apparatus for the detection and measurement of flammable gases - Part 1: General requirements and test methods. EN 61779-2, Electrical apparatus for the detection and measurement of flammable gases - Part 2: Performance

requirements for group I apparatus

indicating a volume fraction up to 5 %

methane in air (IEC 61779-2:1998,

modified). EN 61779-3, Electrical apparatus for the detection and measurement of flammable gases - Part 3: Performance

requirements for group I apparatus

indicating a volume fraction up to 100

% methane in air (IEC 61779-3:1998,

modified). EN 61779-4, Electrical apparatus for the detection and measurement of flammable gases - Part 4: Performance

requirements for group II apparatus

indicating a volume fraction up to 100

% lower explosive limit

(IEC

61779-4:1998, modified). EN 61779-5, Electrical apparatus for the detection and measurement of flammable gases - Part 5: Performance

requirements for group II apparatus

indicating a volume fraction up to 100

% gas (IEC 61779-5:1998, modified). CLC/R 044-001, Safety of machinery – Guidance and recommendations for the avoidance of hazards due to static electricity. 3 Terms, definitions and abbreviated terms For the purposes of this European Standard, the following terms and definitions as well as abbreviated terms apply in addition to the terms and definitions of prEN 13237-1. 3.1 firedamp any potentially explosive mixture of gases or any flammable gas naturally occurring in a mine NOTE As firedamp consists mainly of methane, the terms firedamp and methane are used frequently in mining practice as synonyms. 3.2 protection against firedamp explosions explosion prevention and protection in underground parts of mines and those parts of surface installations of such mines liable to be endangered by firedamp and or flammable dust 3.3 flammable substance substance in the form of gas, vapour, liquid, solid, or mixtures of these, able to undergo an exothermic reaction with air when ignited [EN 1127-1:1997] 3.4 component "component" means any item essential to the safe functioning of equipment and protective systems but with no autonomous function [Directive 94/9/EC, Chapter I, Article 1] 3.5 deflagration explosion propagating at subsonic velocity [ISO 8421-1, 1987-03-01, 1.11] 3.6 detonation explosion propagating at supersonic velocity and characterized by a shock wave [ISO 8421-1, 1987-03-01, 1.12] SIST EN 1127-2:2002+A1:2008

different physical states NOTE Examples of hybrid mixtures are mixtures of methane, coal dust and air or mixtures of gasoline vapour and gasoline droplets with air [EN 1127-1:1997] 3.23 inerting addition of inert substances to prevent explosive atmospheres [EN 1127-1:1997] 3.24 intended use use of equipment, protective systems and devices in accordance with the equipment group and category as specified in Directive 94/9/EC, Annex I, and

taking into account all the information supplied by the manufacturer which is required for the safe functioning of equipment, protective systems and devices (see also Directive 94/9/EEC, Chapter I, Article 1) 3.25 limiting oxygen concentration (LOC) maximum oxygen concentration in a mixture of a flammable substance and air and an inert gas, in which an explosion will not occur, determined under specified test conditions [EN 1127-1:1997] 3.26 machinery assembly of linked parts or components, at least one of which moves, with the appropriate actuators, control and power circuits, etc., joined together for a specific application, in particular for the processing, treatment, moving or packaging of a material (material is equivalent to substance or product) term "machinery" also covers an assembly of machines which, in order to achieve the same end, are arranged and controlled so that they function as an integral whole [Directive 98/37, article 1.2] 3.27 malfunction equipment, protective systems and components do not perform the intended function (see also 5.2.2.b of

EN 292-1:1991) NOTE For the purposes of this standard this can happen due to a variety of reasons, including - variation of a property or of a dimension of the processed material or of the workpiece; - failure of one (or more) of

component parts of the equipment, protective systems or components; - external disturbances (e.g. shocks, vibration, electromagnetic fields); - design error or deficiency (e.g. software errors); SIST EN 1127-2:2002+A1:2008

the power supply or other services; - loss of control by the operator (especially for hand-held machines). [EN 1127-1:1997] 3.28 maximum experimental safe gap (MESG) maximum gap of the joint between the two parts of the interior chamber of a test apparatus which, when the internal gas mixture is ignited and under specified conditions, prevents ignition of the external gas mixture through a 25 mm long joint, for all concentrations of the tested gas or vapour in air. The MESG is a property of the respective gas mixture (see also IEC 60050-426, 1990-10) [EN 1127-1:1997] 3.29 maximum explosion pressure (pmax) maximum pressure occurring in a closed vessel during the explosion of an explosive atmosphere determined under specified test conditions [EN 1127-1:1997] 3.30 maximum rate of explosion pressure rise ((dp/dt)max) maximum value of the pressure rise per unit time during explosions of all explosive atmospheres in the explosive range of a combustible substance in a closed vessel under specified test conditions [EN 1127-1:1997] 3.31 minimum ignition energy (MIE) lowest electrical energy stored in a capacitor which upon discharge is sufficient to effect ignition of the most ignitable atmosphere under specified test conditions [EN 1127-1:1997] 3.32 minimum ignition temperature of an explosive atmosphere ignition temperature of a combustible gas or of a vapour of a combustible liquid or the minimum ignition temperature of a dust cloud under specified test conditions [EN 1127-1:1997] 3.33 ignition temperature (of a combustible gas or of a combustible liquid) lowest temperature of a hot surface as determined under specified test conditions, at which the ignition of a combustible substance in the form of gas or vapour mixture with air will occur [EN 1127-1:1997] 3.34 minimum ignition temperature of a dust cloud lowest temperature of a hot surface on which the most ignitable mixture of the dust with air is ignited under specified test conditions [EN 1127-1:1997] 3.35 minimum ignition temperature of a dust layer lowest temperature of a hot surface at which ignition occurs in a dust layer under specified test conditions

[EN 1127-1:1997] 3.36 normal operation situation when the equipment, protective systems and

components perform their intended function within their design parameters (see also 5.2.2.a of EN 292-1:1991) minor releases of flammable material may be part of normal operation. For example, releases of substances from seals which rely on wetting by the fluid which is being pumped are considered to be minor releases failures (such as a breakdown of pump seals, flange gaskets or releases of substances caused by accidents) which involve repair or shut-down are not considered to be part of normal operation [EN 1127-1:1997] 3.37 potentially explosive atmosphere atmosphere which could become explosive due to local and operational conditions [Directive 94/9/EC, Chapter I, Article 1]

This risk assessment shall always be carried out for each individual situation in accordance with EN 1050. Risk assessment includes the following elements for which the standard gives guidance: a) hazard identification. The safety data in accordance with clause 4 assist in the identification of hazards by demonstrating whether substances are flammable and indicate their ease of ignition; b) determine whether an explosive atmosphere is likely to occur and the amount involved (in accordance with 5.2); c) determine the presence and likelihood of ignition sources that are capable of igniting the explosive atmosphere (in accordance with 5.3); d) determine the possible effects of an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...