EN 1594:2009

(Main)Gas supply systems - Pipelines for maximum operating pressure over 16 bar - Functional requirements

Gas supply systems - Pipelines for maximum operating pressure over 16 bar - Functional requirements

This European Standard is applicable to pipelines with a maximum operating pressure (MOP) over 16 bar for the carriage of processed, non-toxic and non-corrosive natural gas according to EN ISO 13686 in onland gas supply systems, where:

pipeline elements are made of unalloyed or low-alloyed carbon steel;

pipeline elements are joined by welds, flanges or mechanical couplings;

the pipeline is not located within commercial or industrial premises as an integral part of the industrial process on these premises except for any pipelines and facilities supplying such premises;

the design temperature of the system is between -40 °C and 120 °C inclusive;

The standard apply to onshore pipeline systems from the point where the pipeline first crosses what is normally accepted as battery limit between on and offshore, e.g.:

- first isolation valve;

- the base of steep sea shelf;

- above the high water/low water mark onto mainland;

- an island.

The pipeline standard also applies to a pipeline system with a starting point onshore, also when parts of the pipeline system on the mainland subsequently cross fjords, lakes etc.

This European Standard does not apply to existing pipelines, in use prior to the publication of this European Standard, nor to modifications to existing pipelines.

Gas supply systems covered by this European Standard begin after the gas producer's metering station. The functional demarcation of the pipeline system within a plant area will be determined from case to case. Generally speaking, this will be directly after the first isolating valve of the installation.

This standard also describes the mechanical requirements for pipework in stations with a maximum operating pressure greater than 16 bar. Welding requirements are described in a special application standard on welding for gas supply systems EN 12732.

Gasversorgungssysteme - Rohrleitungen für einen maximal zulässigen Betriebsdruck über 16 bar - Funktionale Anforderungen

Diese Europäische Norm gilt für Leitungen mit einem maximal zulässigen Betriebsdruck (MOP) im Bereich von über 16 bar, die für den Transport von aufbereitetem, nicht giftigem und nicht korrosivem Erdgas nachentsprechend

EN ISO 13686 auf dem Festland bestimmt sind und bei denen:

die Leitungsbauteile aus nicht legiertem oder niedrig legiertem Kohlenstoffstahl bestehen;

die Leitungsbauteile durch Schweißnähte, Flansche oder mechanische Rohrverbindungen miteinander verbunden sind;

alle Leitungen und Anlagen, die sich auf Gewerbe- oder Werksgelände befinden, ausschließlich der Versorgung solcher Grundstücke dienen und kein wesentlicher Bestandteil der Anlagen für Betriebsabläufe auf diesem Gelände sind, und

die Auslegungstemperatur zwischen –-40 C und +120 C liegt.

Diese Norm gilt des Weiteren für Leitungssysteme auf dem Festland, und zwar ab der Stelle, an der die Rohrleitung zuerst die üblichernormalerweise als Anlagengrenze (Battery-Limit) zwischen Festland und Meer anerkannte Stelle kreuzt, z. B.:

der ersten Absperrarmatur;

dem Grund eines steilen Festlandsockels;

über der Flut-/Ebbemarke auf dem Festland;

an einer Insel.

Diese Norm gilt auch für auf dem Festland ihren Ausgang nehmende Leitungssysteme sowie für Teile von Leitungssystemen auf dem Festland, die nachfolgend durch Fjorde, Seen usw. verlaufen.

Diese Europäische Norm gilt nicht für Leitungssysteme und deren Änderungen, die vor Veröffentlichung dieser Norm in Betrieb genommen wurden.

Das Gasversorgungssystem, für das diese Norm gilt, beginnt am Ausgang der Messstation des Gasproduzenten. Die Abgrenzung zwischen dem Leitungssystem für den Gastransport und den Stationsleitungen ergibt sich jeweils aus dem Einzelfall. Im Allgemeinen sind die Station und das Leitungssystem durch die Armaturen am Eingang und am Ausgang der Station voneinander abgegrenzt.

Systèmes d'alimentation en gaz - Canalisations pour pression maximale de service supérieure à 16 bar - Prescriptions fonctionnelles

La présente norme s'applique aux canalisations utilisées sous une pression maximale de service (MOP) supérieure

à 16 bar pour le transport de gaz naturel traité non toxique et non corrosif conformément à l'EN ISO 13686 dans

des systèmes d'alimentation en gaz terrestres dont :

- les éléments de canalisations sont en acier non ou faiblement allié ;

- les éléments de canalisations sont réunis par des soudures, des brides ou des assemblages mécaniques ;

- les canalisations ne sont pas situées sur des sites industriels, ou commerciaux en tant que partie intégrante du

procédé industriel, exception faite des canalisations et dispositifs alimentant de tels sites ;-

- la température de conception du réseau est comprise entre - 40 °C et 120 °C inclus.

La présente norme s’applique aux canalisations terrestres depuis le point où la canalisation traverse d’abord ce qui

est normalement accepté comme périmètre des installations entre on shore et off shore, par exemple :

- première vanne de sectionnement ;

- la base de la partie abrupte du plateau continental

- au dessus de la marque marée haute/marée basse sur le continent ;

- une ile.

La présente norme s’applique aussi à un système de canalisations avec un point de départ terrestre, même quand

des parties du système de canalisations sur le continent traverse postérieurement des fjords, des lacs, etc.

La présente Norme européenne ne s’applique pas aux canalisations existantes mises en service avant la

publication de la présente norme, ni aux modifications de ces canalisations existantes.

Les systèmes d’alimentation en gaz couverts par la présente norme commencent après le poste de comptage du

producteur de gaz. La limite fonctionnelle d'un tel système à l'intérieur de la station sera définie cas par cas. D'une

manière générale, elle se situe juste après le premier robinet d’isolement de l'installation.

Sistemi oskrbe s plinom - Cevovodni sistemi za najvišji delovni tlak nad 16 bar - Funkcionalne zahteve

General Information

- Status

- Withdrawn

- Publication Date

- 20-Jan-2009

- Withdrawal Date

- 10-Sep-2013

- Technical Committee

- CEN/TC 234 - Gas infrastructure

- Drafting Committee

- CEN/TC 234/WG 3 - Gas Transportation

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 11-Sep-2013

- Completion Date

- 11-Sep-2013

Relations

- Effective Date

- 28-Jan-2009

- Effective Date

- 18-Sep-2013

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

EN 1594:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Gas supply systems - Pipelines for maximum operating pressure over 16 bar - Functional requirements". This standard covers: This European Standard is applicable to pipelines with a maximum operating pressure (MOP) over 16 bar for the carriage of processed, non-toxic and non-corrosive natural gas according to EN ISO 13686 in onland gas supply systems, where: pipeline elements are made of unalloyed or low-alloyed carbon steel; pipeline elements are joined by welds, flanges or mechanical couplings; the pipeline is not located within commercial or industrial premises as an integral part of the industrial process on these premises except for any pipelines and facilities supplying such premises; the design temperature of the system is between -40 °C and 120 °C inclusive; The standard apply to onshore pipeline systems from the point where the pipeline first crosses what is normally accepted as battery limit between on and offshore, e.g.: - first isolation valve; - the base of steep sea shelf; - above the high water/low water mark onto mainland; - an island. The pipeline standard also applies to a pipeline system with a starting point onshore, also when parts of the pipeline system on the mainland subsequently cross fjords, lakes etc. This European Standard does not apply to existing pipelines, in use prior to the publication of this European Standard, nor to modifications to existing pipelines. Gas supply systems covered by this European Standard begin after the gas producer's metering station. The functional demarcation of the pipeline system within a plant area will be determined from case to case. Generally speaking, this will be directly after the first isolating valve of the installation. This standard also describes the mechanical requirements for pipework in stations with a maximum operating pressure greater than 16 bar. Welding requirements are described in a special application standard on welding for gas supply systems EN 12732.

This European Standard is applicable to pipelines with a maximum operating pressure (MOP) over 16 bar for the carriage of processed, non-toxic and non-corrosive natural gas according to EN ISO 13686 in onland gas supply systems, where: pipeline elements are made of unalloyed or low-alloyed carbon steel; pipeline elements are joined by welds, flanges or mechanical couplings; the pipeline is not located within commercial or industrial premises as an integral part of the industrial process on these premises except for any pipelines and facilities supplying such premises; the design temperature of the system is between -40 °C and 120 °C inclusive; The standard apply to onshore pipeline systems from the point where the pipeline first crosses what is normally accepted as battery limit between on and offshore, e.g.: - first isolation valve; - the base of steep sea shelf; - above the high water/low water mark onto mainland; - an island. The pipeline standard also applies to a pipeline system with a starting point onshore, also when parts of the pipeline system on the mainland subsequently cross fjords, lakes etc. This European Standard does not apply to existing pipelines, in use prior to the publication of this European Standard, nor to modifications to existing pipelines. Gas supply systems covered by this European Standard begin after the gas producer's metering station. The functional demarcation of the pipeline system within a plant area will be determined from case to case. Generally speaking, this will be directly after the first isolating valve of the installation. This standard also describes the mechanical requirements for pipework in stations with a maximum operating pressure greater than 16 bar. Welding requirements are described in a special application standard on welding for gas supply systems EN 12732.

EN 1594:2009 is classified under the following ICS (International Classification for Standards) categories: 23.040.01 - Pipeline components and pipelines in general; 75.200 - Petroleum products and natural gas handling equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1594:2009 has the following relationships with other standards: It is inter standard links to EN 1594:2000, EN 1594:2013, EN 12954:2019, EN 10289:2002, EN 10301:2003, EN 12560-4:2001, EN 12560-3:2001, EN 12327:2012, EN ISO 6892-1:2019, EN 12186:2025, EN 10204:2004, EN ISO 3183:2019, EN 14870-2:2004, EN 1515-3:2005, EN 14870-3:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1594:2009 is associated with the following European legislation: Standardization Mandates: M/017. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1594:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sistemi oskrbe s plinom - Cevovodni sistemi za najvišji delovni tlak nad 16 bar - Funkcionalne zahteveGasversorgungssysteme - Rohrleitungen für einen maximal zulässigen Betriebsdruck über 16 bar - Funktionale AnforderungenSystèmes d'alimentation en gaz - Canalisations pour pression maximale de service supérieure à 16 bar - Prescriptions fonctionnellesGas supply systems - Pipelines for maximum operating pressure over 16 bar - Functional requirements91.140.40Sistemi za oskrbo s plinomGas supply systemsICS:Ta slovenski standard je istoveten z:EN 1594:2009SIST EN 1594:2009en,fr,de01-julij-2009SIST EN 1594:2009SLOVENSKI

STANDARDSIST EN 1594:20001DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1594January 2009ICS 23.040.01; 75.200Supersedes EN 1594:2000

English VersionGas supply systems - Pipelines for maximum operating pressureover 16 bar - Functional requirementsSystèmes d'alimentation en gaz - Canalisations pourpression maximale de service supérieure à 16 bar -Prescriptions fonctionnellesGasversorgungssysteme - Rohrleitungen für einen maximalzulässigen Betriebsdruck über 16 bar - FunktionaleAnforderungenThis European Standard was approved by CEN on 8 December 2008.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2009 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1594:2009: ESIST EN 1594:2009

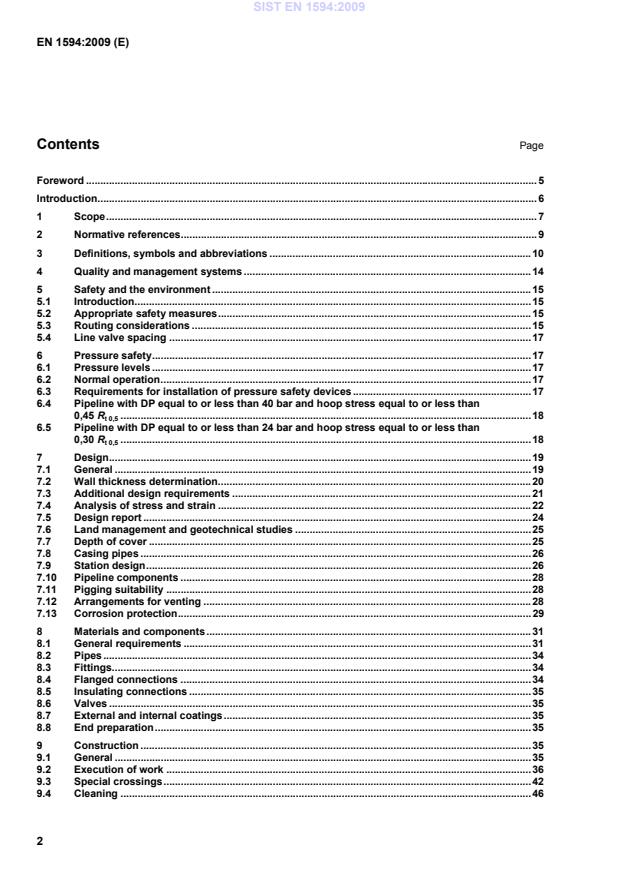

Settlement areas . 55 A.1 General . 55 A.2 Procedure . 55 A.3 Construction settlement . 55 A.4 Strength calculation . 56 A.5 Monitoring . 60 A.6 Action in the event of the allowable/limit values being exceeded . 60 A.7 Literature . 60 Annex B (informative)

Mining subsidence . 61 B.1 General . 61 B.2 Procedure . 61 B.3 Strength calculation . 61 B.4 Action in the event of the allowable/limit values being exceeded . 61 B.5 Monitoring . 62 B.6 Literature . 62 Annex C (informative)

Frost heave . 63 C.1 General . 63 C.2 Procedure . 63 C.3 Strength calculation . 63 C.4 Other possible measures. 63 C.5 Literature . 64 Annex D (informative)

Landslide areas . 65 D.1 General . 65 D.2 Procedure . 65 D.3 Strength calculation . 66 D.4 Possible action to prevent the allowable/limit values being exceeded . 66 D.5 Monitoring . 67 D.6 Literature . 67 Annex E (informative)

Areas with high seismic risk . 68 E.1 General . 68 E.2 Procedure . 68 E.3 Strength calculation . 69 E.4 Literature . 70 Annex F (informative)

Soil mechanics parameters. 72 F.1 Parameters . 72 F.2 Soil engineering study . 73 F.3 Literature . 73 Annex G (informative)

Bored/jacked crossings . 75 G.1 General . 75 G.2 Strength calculation . 75 G.3 Literature . 78 Annex H (informative)

Allowable pulsation and vibration levels . 79 SIST EN 1594:2009

Allowable vibration levels from construction work - blasting . 81 I.1 General . 81 I.2 Procedure . 81 I.3 Strength calculation . 81 I.4 Literature . 82 Bibliography . 83

A list of the relevant functional standards prepared by CEN/TC 234 is included in Clause 2 and the Bibliography of this document.

CEN/TC 234 will continue its work updating this European Standard to the latest developments at regular intervals. In preparing this European Standard a basic understanding of gas supply by the user has been assumed. Gas supply systems are complex and the importance on safety of their construction and use has led to the development of very detailed codes of practice and operating manuals in member countries. These detailed statements embrace recognised standards of gas engineering and specific requirements imposed by legal structures of these member countries. This European Standard has been prepared under mandate M/017 given to CEN by the Commission of the European Communities and the European Free Trade Association. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom. SIST EN 1594:2009

Introduction This European Standard describes the general functional requirements for gas supply through pipe systems and covers the pressure range greater than 16 bar maximum operating pressure (MOP) for steel systems. It gives normative and informative references for safe and secure gas supply systems. It applies to their design, construction, operation and the related aspects of safety, environment and public health, all in order to provide a safe and secure supply of gas. The requirements of this European Standard are based on safe gas engineering practice under conditions normally encountered in the gas industry. Requirements for all unusual conditions cannot be specifically provided for, nor are all engineering and construction details prescribed. Existing industrial safety regulations applying to work areas, safety devices and safe work practices are not intended to be supplanted by this European Standard. Managers with responsibilities for the design, construction and operation of gas supply systems should have regard to the guidance given in this European Standard and to other relevant standards. It is the responsibility of these managers and engineers to apply these functional requirements, supplemented with other proven good practice to the particular circumstances of each gas supply system. The designer, constructor or operator of pipeline systems is cautioned that this European Standard is not a design handbook or code of practice. Additional national or company standards describing the details are needed. These detailed standards should be in line with the basic principles of this European Standard. In preparing this European Standard it was recognized that the suite of relevant European Standards is incomplete. Reference may be made where appropriate to international, national or other standards until relevant European Standards are available. SIST EN 1594:2009

1 Scope This European Standard is applicable to pipelines with a maximum operating pressure (MOP) over 16 bar for the carriage of processed, non-toxic and non-corrosive natural gas according to EN ISO 13686 in onland gas supply systems, where: pipeline elements are made of unalloyed or low-alloyed carbon steel; pipeline elements are joined by welds, flanges or mechanical couplings; the pipeline is not located within commercial or industrial premises as an integral part of the industrial process on these premises except for any pipelines and facilities supplying such premises; the design temperature of the system is between -40 ûC and 120 ûC inclusive. The standard applies to onshore pipeline systems from the point where the pipeline first crosses what is normally accepted as battery limit between on and offshore, e.g.: first isolation valve; the base of steep sea shelf; above the high water/low water mark onto mainland; an island.

The pipeline standard also applies to a pipeline system with a starting point onshore, also when parts of the pipeline system on the mainland subsequently cross fjords, lakes etc. This European Standard does not apply to existing pipelines, in use prior to the publication of this European Standard, nor to modifications to existing pipelines. Gas supply systems covered by this European Standard begin after the gas producer's metering station. The functional demarcation of the pipeline system within a plant area will be determined from case to case. Generally speaking, this will be directly after the first isolating valve of the installation. This standard also describes the mechanical requirements for pipework in stations with a maximum operating pressure greater than 16 bar. Welding requirements are described in a special application standard on welding for gas supply systems EN 12732. Functional requirements for stations are given in: EN 1776, Gas supply systems - Natural gas measuring stations - Functional requirements EN 1918-5, Gas supply systems - Underground gas storage - Part 5: Functional recommendations for surface facilities EN 12186, Gas supply systems - Gas pressure regulating stations for transmission and distribution - Functional requirements EN 12583, Gas supply systems - Compressor stations - Functional requirements This European Standard specifies common basic principles for gas supply systems. Users of this European Standard should be aware that there may exist more detailed national standards and codes of practice in the CEN member countries. This European Standard is intended to be applied in association with these national standards and/or codes of practice setting out the above mentioned principles. In the event of conflicts in terms of more restrictive requirements in the national legislation/regulation with the requirements of this European Standard, the national legislation/regulation shall take precedence.

Reference is made in this European Standard to relevant European and other recognized standards for products used to construct and operate gas supply systems. A schematic representation of pipelines for gas transmission is given in Figure 1.SIST EN 1594:2009

KEY Figure 1 — Schematic representation of pipelines for gas supply over 16 bar

PIPELINES COVERED BY THIS STANDARD STATIONS 1 2 3 P - WELL, PRODUCTION

T - TREATMENT

D – ODORIZATION 4 S 1 -GAS RECEIVING 5 S 2 -VALVE STATION 6 S 3 -DELIVERY STATION 7 S 4 -COMPRESSOR STATION 8 S 5 -OTHER SUPPLY (E.G. FOR BLENDING) 9 S 6 -EXPORT OR IMPORT 10 S 7 -PRESSURE REGULATING 11 S 8 -DOMESTIC DISTRIBUTION 12 S 9 -INDUSTRIAL DISTRIBUTION 13 S10 –STORAGE

PIPELINES NOT COVERED BY THIS STANDARD

PRESSURE REGULATION

PRESSURE SAFETY SYSTEM

METERING SYSTEM

COMPRESSION

VALVE

ISOLATION DEVICE

2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 1515-3, Flanges and their joints - Bolting - Part 3: Classification of bolt materials for steel flanges, class designated EN 1759-1, Flanges and their joint - Circular flanges for pipes, valves, fittings and accessories, Class designated - Part 1: Steel flanges, NPS 1/2 to 24 EN 10002-1, Metallic materials - Tensile testing - Part 1: Method of test at ambient temperature EN 10204:2004, Metallic products - Types of inspection documents EN 10208-2, Steel pipes for pipelines for combustible fluids - Technical delivery conditions - Part 2: Pipes of requirement class B EN 10288, Steel tubes and fittings for onshore and offshore pipelines - External two layer extruded polyethylene based coatings EN 10289, Steel tubes and fittings for onshore and offshore pipelines - External liquid applied epoxy and epoxy-modified coatings EN 10290, Steel tubes and fittings for onshore and offshore pipelines - External liquid applied polyurethane and polyurethane-modified coatings EN 10301, Steel tubes and fittings for on and offshore pipelines - Internal coating for the reduction of friction for conveyance of non corrosive gas EN 12068, Cathodic protection - External organic coatings for the corrosion protection of buried or immersed steel pipelines used in conjunction with cathodic protection - Tapes and shrinkable materials EN 12186, Gas supply systems - Gas pressure regulating stations for transmission and distribution - Functional requirements EN 12327, Gas supply systems - Pressure testing, commissioning and decommissioning procedures – Functional requirements EN 12560-1, Flanges and their joints - Gaskets for Class-designated flanges - Part 1: Non-metallic flat gaskets with or without inserts EN 12560-2, Flanges and their joints - Gaskets for Class-designated flanges - Part 2: Spiral wound gaskets for use with steel flanges EN 12560-3, Flanges and their joints - Gaskets for Class-designated flanges - Part 3: Non-metallic PTFE envelope gaskets EN 12560-4, Flanges and their joints - Gaskets for Class-designated flanges - Part 4: Corrugated, flat or grooved metallic and filled metallic gaskets for use with steel flanges EN 12583, Gas supply systems - Compressor stations - Functional requirements EN 12732, Gas supply systems - Welding steel pipework - Functional requirements SIST EN 1594:2009

EN 14141, Valves for natural gas transportation in pipelines - Performance requirements and tests

EN 14870-1:2004, Petroleum and natural gas industries - Induction bends, fittings and flanges for pipeline transportation systems - Part 1: Induction bends (ISO 15590-1:200,1 modified) EN 14870-2:2004, Petroleum and natural gas industries - Induction bends, fittings and flanges for pipeline transportation systems - Part 2: Fittings (ISO 15590-2:2003, modified) EN 14870-3:2006, Petroleum and natural gas industries - Induction bends, fittings and flanges for pipeline transportation systems - Part 3: Flanges (ISO 15590-3:2004, modified) 3 Definitions, symbols and abbreviations For the purposes of this document, the following definitions apply. Symbols used in formulae are defined where they occur. 3.1 casing protection by means of a construction around the pipeline in order to prevent external loads, or third party interference 3.2 commissioning activities required to pressurize pipework, stations, equipment and assemblies with gas and to put them into operation 3.3 control zone strip of land over which the pipeline operator has a right to control activities 3.4 decommissioning activities required to take out of service any pipework, station, equipment or assemblies filled with gas and to disconnect them from the system 3.5 design factor

fo factor applied when calculating the wall thickness or pressure 3.6 design pressure

DP

pressure on which design calculations are based 3.7 design temperature temperature on which design calculations are based 3.8 emergency SIST EN 1594:2009

pressure which occurs incidentally within a system at which a safety device becomes operative 3.17 inspection process of measuring, examining, testing, gauging or otherwise determining the status of items of the pipeline system, or installation and comparing it with the applicable requirements 3.18 installation equipment and facilities for the extraction, production, chemical treatment, measurement, control, storage, or off-take of the transported gas 3.19 installation temperature temperature arising from ambient or installation conditions during laying or during construction 3.20 maintenance SIST EN 1594:2009

operating pressure OP pressure which occurs within a system under normal operating conditions 3.26 operating temperature OT temperature which occurs within a system under normal operating conditions 3.27 pig device which is driven through a pipeline by the flow of fluid, for performing various internal activities (depending on pig type), such as separating fluids, cleaning or inspecting the pipeline 3.28 pipeline system of pipework with all associated equipment and stations up to the point of delivery. NOTE This pipework is mainly below ground but also includes above ground parts. 3.29 pipeline components elements from which the pipeline is constructed a) specially

designed and manufactured elements: 1)

pipe including cold-formed bends; 2)

fittings; EXAMPLE 1 Reducers, tees, factory-made elbows, flanges, caps, welding stubs, mechanical joints. 3) factory made bends; 4) fabrications, manufactured from the elements referred to above; EXAMPLE 2 Manifolds, slug catchers, pig launching/receiving stations, metering and control runs 5) equipment; SIST EN 1594:2009

Valves, expansion joints, insulation joints, compressors 6) pressure vessels b) standard pressure equipment: 1) pressure equipment at pipelines, pressure reduction stations or compression stations not

specially

designed and manufactured for the pipeline EXAMPLE 4 Measuring devices, valves, pressure regulators, safety valves, filters, heat exchangers, vessels. 3.30 pipeline operator private or public organization authorized to design, construct and/or operate and maintain the gas supply system NOTE Synonyms are: network operator, grid operator 3.31 pipework assembly of pipes and fittings 3.32 point of delivery point where the gas is transferred to the user

NOTE This can be at a means of isolation or at a meter connection 3.33 precommissioning activities, including cleaning and possible drying, executed prior to pipeline commissioning 3.34 pressure gauge pressure of the fluid inside the system, measured in static conditions 3.35 pressure control system combined system including pressure regulating, pressure safety and eventually pressure recording and alarm systems 3.36 pressure regulating system system which ensures that a pressure is maintained at the outlet system within required limits 3.37 pressure safety system system which, independent of the pressure regulating system, ensures that the outlet pressure of the regulator does not exceed the preset value 3.38 Raise boring (back reaming)

method of vertical drilling in solid rock where a reamer head is pulled back upwards through the small pilot hole 3.39 recommissioning activities required to put a decommissioned pipeline, associated stations and equipment into service again 3.40 SIST EN 1594:2009

The life of a pipeline for transmission of gas can be divided into three phases: 1) design; 2) construction and testing; 3) operation and maintenance. Quality and safety management systems should be applied to these three phases in accordance with this European Standard. SIST EN 1594:2009

5.1 General Various safety measures are required to ensure a safe pipeline. Measures that are appropriate to the specific circumstances shall be adopted. 5.2 Appropriate safety measures Possible measures to ensure safety in design, construction and operation are listed below. The list is not intended to be exhaustive nor will it be necessary to incorporate all the measures on each occasion. When selecting measures, consideration shall be given to the safety and environmental conditions existing at the time of construction for which firm details are known: a) a control zone shall be established to control all third-party activities in order to safeguard the pipeline against interference; b) if a system of area classification is used, design factors shall be chosen relevant to the classification levels; c) this design factor may be increased if additional measures are taken against third-party interference (for limitation on the design factor reference is made to 7.2); d) the route of the pipeline shall be at an appropriate distance from buildings. The distance should be determined by the particular parameters and/or national requirements; e) for high-strength pipe steels, appropriate toughness properties for fracture-arrest capability should be selected; f) the minimum depth for the pipeline shall be greater than that of normal agricultural/horticultural activities expected in the area. The probability of third-party interference to the pipeline will decrease if a depth greater than the minimum specified in 7.7 is adopted; g) additional forms of mechanical protection can reduce interference by third-party activity. Designers shall carefully select the forms of the additional protection to minimize any adverse effects on the efficiency of the cathodic protection; h) the route of the pipeline should be identified by a locating system such as markers. Pipeline safety can further be increased by ensuring an adequate frequency of surveillance. 5.3 Routing considerations 5.3.1 General Safety, environmental and technical considerations are the primary factors governing the pipeline route.

The shortest route needs not to be the most suitable. Physical and environmental obstacles, high voltage cables and installations and other factors shall be considered. SIST EN 1594:2009

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...