EN 13802:2004

(Main)Railway applications - Suspension components - Hydraulic dampers

Railway applications - Suspension components - Hydraulic dampers

This standard applies to hydraulic dampers (excluding end mountings) used on rail vehicles. This includes pantograph and dampers that control the dynamic behaviour of vehicle. The dampers covered in this standard include: suspension dampers, yaw dampers, roll dampers, inter-vehicle dampers, pantograph dampers.

Bahnanwendungen - Federungselemente - Hydraulische Dämpfer

Dieses Dokument gilt für hydraulische Dämpfer (ohne Endbefestigungen), die in Schienenfahrzeugen verwendet werden. Die in dieser Norm enthaltenen Dämpfer beinhalten:

- Dämpfer, die das dynamische Verhalten des Fahrzeuges beeinflussen:

- Fahrwerksdämpfer (z. B. Primär-Vertikaldämpfer, Sekundär-Vertikaldämpfer und Sekundär-Horizontaldämpfer),

- Drehdämpfer;

- Wankdämpfer;

- Zwischenwagendämpfer;

- Dämpfer, die das dynamische Verhalten von mechanischen Systemen beeinflussen:

- Stromabnehmerdämpfer;

- usw.

Alle wichtigen Begriffe zum Thema sind in dieser Norm definiert.

Applications ferroviaires - Eléments de suspension - Amortisseurs hydrauliques

Le document s'applique aux amortisseurs hydrauliques (en excluant les articulations) utilisés sur les véhicules ferroviaires. Les amortisseurs couverts par la présente Norme incluent :

- Les amortisseurs qui contrôlent le comportement dynamique du véhicule :

- les amortisseurs de suspension (par ex : amortisseur vertical primaire, amortisseur vertical secondaire, et amortisseur transversal secondaire) ;

- les amortisseurs antilacet ;

- les amortisseurs antiroulis ;

- les amortisseurs intercaisses ;

- Les amortisseurs qui contrôlent le comportement des systèmes mécaniques :

- les amortisseurs de pantographe ;

- etc.

L'ensemble de la terminologie applicable qui est spécifique au sujet est défini dans le présent document.

Železniške naprave – Vzmetenje – Hidravlični blažilniki

General Information

- Status

- Withdrawn

- Publication Date

- 24-Aug-2004

- Withdrawal Date

- 17-Dec-2013

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 2/WG 14 - Steel springs

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 18-Dec-2013

- Completion Date

- 18-Dec-2013

Relations

- Effective Date

- 05-Nov-2011

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish national quality association.

Sponsored listings

Frequently Asked Questions

EN 13802:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Suspension components - Hydraulic dampers". This standard covers: This standard applies to hydraulic dampers (excluding end mountings) used on rail vehicles. This includes pantograph and dampers that control the dynamic behaviour of vehicle. The dampers covered in this standard include: suspension dampers, yaw dampers, roll dampers, inter-vehicle dampers, pantograph dampers.

This standard applies to hydraulic dampers (excluding end mountings) used on rail vehicles. This includes pantograph and dampers that control the dynamic behaviour of vehicle. The dampers covered in this standard include: suspension dampers, yaw dampers, roll dampers, inter-vehicle dampers, pantograph dampers.

EN 13802:2004 is classified under the following ICS (International Classification for Standards) categories: 45.040 - Materials and components for railway engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13802:2004 has the following relationships with other standards: It is inter standard links to EN 13802:2013, EN 14363:2016+A2:2022, EN ISO 2813:2014, EN 3840:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13802:2004 is associated with the following European legislation: EU Directives/Regulations: 93/38/EEC, 96/48/EC; Standardization Mandates: M/024. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13802:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Bahnanwendungen - Federungselemente - Hydraulische DämpferApplications ferroviaires - Eléments de suspension - Amortisseurs hydrauliquesRailway applications - Suspension components - Hydraulic dampers45.040Materiali in deli za železniško tehnikoMaterials and components for railway engineeringICS:Ta slovenski standard je istoveten z:EN 13802:2004SIST EN 13802:2004en01-november-2004SIST EN 13802:2004SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13802August 2004ICS 45.040 English versionRailway applications - Suspension components - HydraulicdampersApplications ferroviaires - Eléments de suspension -Amortisseurs hydrauliquesBahnanwendungen - Federungselemente - HydraulischeDämpferThis European Standard was approved by CEN on 24 June 2004.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13802:2004: ESIST EN 13802:2004

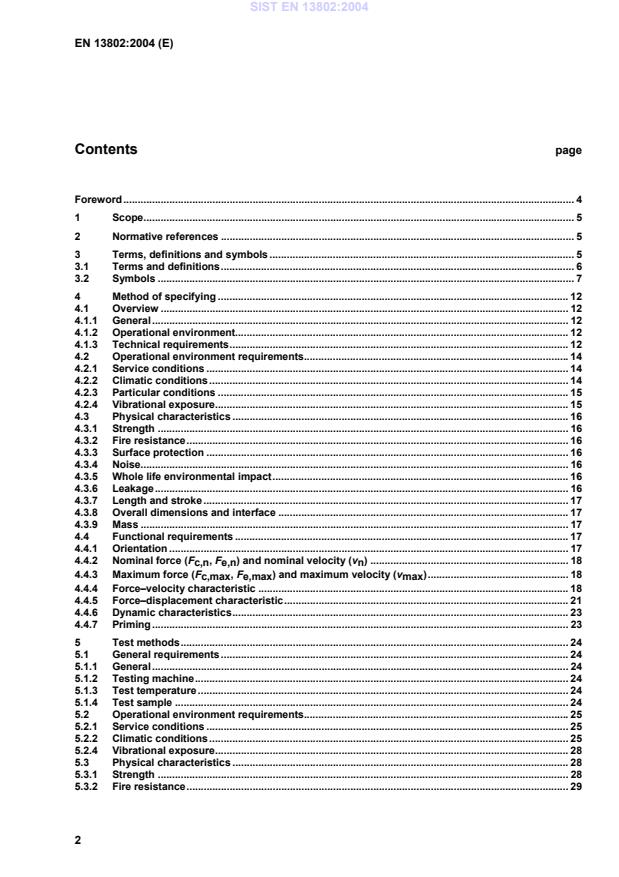

Foreword.4 1 Scope.5 2 Normative references.5 3 Terms, definitions and symbols.5 3.1 Terms and definitions.6 3.2 Symbols.7 4 Method of specifying.12 4.1 Overview.12 4.1.1 General.12 4.1.2 Operational environment.12 4.1.3 Technical requirements.12 4.2 Operational environment requirements.14 4.2.1 Service conditions.14 4.2.2 Climatic conditions.14 4.2.3 Particular conditions.15 4.2.4 Vibrational exposure.15 4.3 Physical characteristics.16 4.3.1 Strength.16 4.3.2 Fire resistance.16 4.3.3 Surface protection.16 4.3.4 Noise.16 4.3.5 Whole life environmental impact.16 4.3.6 Leakage.16 4.3.7 Length and stroke.17 4.3.8 Overall dimensions and interface.17 4.3.9 Mass.17 4.4 Functional requirements.17 4.4.1 Orientation.17 4.4.2 Nominal force (Fc,n, Fe,n) and nominal velocity (vn).18 4.4.3 Maximum force (Fc,max, Fe,max) and maximum velocity (vmax).18 4.4.4 Force–velocity characteristic.18 4.4.5 Force–displacement characteristic.21 4.4.6 Dynamic characteristics.23 4.4.7 Priming.23 5 Test methods.24 5.1 General requirements.24 5.1.1 General.24 5.1.2 Testing machine.24 5.1.3 Test temperature.24 5.1.4 Test sample.24 5.2 Operational environment requirements.25 5.2.1 Service conditions.25 5.2.2 Climatic conditions.25 5.2.4 Vibrational exposure.28 5.3 Physical characteristics.28 5.3.1 Strength.28 5.3.2 Fire resistance.29 SIST EN 13802:2004

Damper performance description.36 Annex B (informative)

Range of damper overall dimensions.39 Annex C (informative)

Nominal velocities.40 Annex D (informative)

Typical force–velocity envelope curves.41 Annex E (informative)

Checks and tests to be performed according to damper category.42 Bibliography.43

1) Official Journal of the European Communities N° L 235 of 17.09.96. 2) Official Journal of the European Communities N° L 199 of 09.08.93. 3) Official Journal of the European Communities N° L 199 of 09.08.93. SIST EN 13802:2004

The dampers covered in this standard include: dampers that control the dynamic behaviour of vehicle: suspension dampers, (e.g. primary vertical dampers, secondary vertical dampers and secondary lateral dampers), yaw dampers, roll dampers, inter-vehicle dampers, dampers that control the dynamic behaviour of mechanical systems: pantograph dampers, etc. All relevant terminology which is specific to the subject is defined in this document. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. prEN 14363, Railway applications — Testing for the acceptance of running characteristics of railway vehicles — Testing of running behaviour and stationary tests. EN 61373, Railway applications — Rolling stock equipment — Shock and vibration tests (IEC 61373:1999). EN ISO 2813, Paints and varnishes - Determination of specular gloss of non-metallic paint films at 20°, 60° and 85° (ISO 2813:1994, including Technical Corrigendum 1:1997). EN ISO 9000, Quality management systems — Fundamentals and vocabulary (ISO 9000:2000). ISO 9227, Corrosion tests in artificial atmospheres — Salt spray tests. 3 Terms, definitions and symbols For the purposes of this document, the following terms, definitions and symbols apply. NOTE 1 Decimal multiple and sub-multiple units defined in this clause may be used. NOTE 2 In this document, the spatial characteristics of the damper are defined with reference to its axis (see Figure 1). Axial characteristics are defined along the x-axis. Extension of the damper is defined as positive and compression is negative. Transverse characteristics are defined in the y–z plane. Rotations are defined as positive in a clockwise direction. SIST EN 13802:2004

π=Φ2tanddkcf This definition is based on a mathematical model with a linear viscous damper of dynamic damping rate cd in series with a linear spring stiffness kd, subjected to a sinusoidal motion with excitation frequency f, displacement amplitude d0 and force amplitude Fo. This is termed the Maxwell model. It does not therefore refer to force amplitude divided by velocity amplitude. cd m compression margin, the part of damper compression travel never reached by the piston during operation in the given mechanical system NOTE 2 =−,minmincudLL ed m extension margin, the part of damper extension travel never reached by the piston during operation in the given mechanical system NOTE 3 −−max,maxeudLL nd m nominal travel, the travel over which the damper meets the operational requirements established by the damper performance description NOTE 4 The nominal travel is indicative of the operating travel of the damper in the given mechanical system. wd m working stroke NOTE 5 =−,max,minwuudLL od m damper displacement amplitude at sinusoidal motion maxD m diameter of an envelope cylinder in which the main body of the damper shall be contained (dust guard included) (see Figures 2 and 3) resD m diameter of damper reservoir envelope (see Figure 3) SIST EN 13802:2004

NOTE 7 Force at nominal velocity. 0F N damper force amplitude at sinusoidal motion resH m height of damper reservoir (to damper centreline) (see Figure 3) dk N/m damper stiffness NOTE 8 =+Φ2001tandFkd(Maxwell model) NOTE 9 Unless otherwise noted, stiffness of the damper structure and fluid. It does not therefore refer to force amplitude divided by displacement amplitude. L m damper length (see Figure 4) delL m damper length at delivery NOTE 10 The length of the damper to permit mounting it on a vehicle at rest on straight, horizontal track (except for particular cases, for example pantograph dampers). iL m length of the damper installed NOTE 11 Length when the damper is mounted on a vehicle at rest on straight, horizontal track. maxL m damper length when the damper is fully extended minL m damper length when the damper is fully compressed nL m nominal damper length NOTE 12 Generally,=niLL. NOTE 13 The reference length used to determine the characteristics of the damper. SIST EN 13802:2004

0v m/s the damper velocity amplitude at sinusoidal motion Φ rad force–displacement phase shift at sinusoidal motion (see the definition for cd and kd) ω rad/s angular velocity of excitation

Figure 1 — Spatial definition

DMAX

Figure 2 — Diameter Dmax of the damper space envelope SIST EN 13802:2004

DmaxDresHres

Figure 3 — Cross sectional dimensions of damper (Dmax, Dres, Hres)

NOTE 18 The damper length definition will vary according to attachment details which are defined in the damper performance description. The length for the stern end attachment point is referenced from the support base of end mountings. The loop end attachment type is referenced from the centre of the loop.

LLLL

Figure 4 — Definition of damper length L SIST EN 13802:2004

4 Method of specifying 4.1 Overview 4.1.1 General The customer requirements shall be defined by means of a damper performance description. An example of a form which may be used for this purpose is given in Annex A. This form allows the values proposed by the customer and the corresponding values offered by the supplier to be recorded. 4.1.2 Operational environment The customer shall supply the details on the operational environment listed below, to enable the supplier to provide a safe and effective product: service conditions: (see 4.2.1); climatic conditions: (see 4.2.2); particular conditions: (see 4.2.3); mounting conditions (if required). 4.1.3 Technical requirements The customer shall specify the characteristics for defining the damper according to its usage. These characteristics shall be selected from those specified in Table 1. The damper requirements and tolerances shall be agreed between the customer and supplier using a damper performance description of a form similar to that in Annex A. The variation criteria (tolerance) of the force-velocity characteristic shall be defined by the customer and specified in accordance with 4.4.4. Unless otherwise defined, the characteristics of the damper are defined under the range of temperatures from 17 °C to 23 °C. SIST EN 13802:2004

Table 1 — Items to be considered for inclusion in the damper performance description Item Defined Testing Operational environment requirements 4.2 5.2

Service conditions 4.2.1 5.2.1

Service interval 4.2.1.1 5.2.1.1

Climatic conditions 4.2.2 5.2.2

Operating temperature Range 4.2.2.1 5.2.2.1

Temperature extremes 4.2.2.2 5.2.2.2

Storage temperatures 4.2.2.3 5.2.2.3

Specific climatic conditions 4.2.2.4 5.2.2.4

Other conditions 4.2.3 5.2.3

Vibrational exposure 4.2.4 5.2.3.1 Physical characteristics 4.3 5.3

Strength a 4.3.1 5.3.1

Fire resistance 4.3.2 5.3.2

Surface protection

a 4.3.3 5.3.3

Noise 4.3.4 5.3.4

Whole life environmental impact 4.3.5 5.3.5

Leakage 4.3.6 5.3.6

Length and stroke a 4.3.7 5.3.7

Overall dimensions and interface a 4.3.8 5.3.8

Mass 4.3.9 5.3.9 Functional requirements 4.4

5.4

Orientation a 4.4.1 5.4.1

Nominal force and nominal velocity a 4.4.2 5.4.2

Maximum force and maximum velocity a 4.4.3 5.4.3

Force-velocity characteristic a 4.4.4 5.4.4

Target values a 4.4.4.2 5.4.4.2

Force-displacement characteristic 4.4.5 5.4.5

Dynamic characteristic 4.4.6

Dynamic damping characteristics

5.4.6.2

Dynamic stiffness characteristic

5.4.6.3

Priming 4.4.7 5.4.7 a These items are mandatory. SIST EN 13802:2004

to Tao,max] The range of ambient operating temperature shall be included in the damper performance description.

— ,minaoT — ,maxaoT When exposed to the minimum and maximum operating temperatures, the damper shall conform to the characteristics specified for these temperatures. After exposure to the operating temperature range and return to the ambient temperature, the damper shall conform to the specified damper characteristics. NOTE If not known, the following limits are taken into consideration: — ,minaoT= -10 °C; — ,maxaoT= +40 °C.

4.2.2.2 Temperature extremes [Tae,min to Tae,max] Temperature extremes shall be included in the damper performance description. SIST EN 13802:2004

(e.g. wheelsets and bogie frame) the worse case vibrational environment shall be used in assessing the damper. SIST EN 13802:2004

FV1

Figure 5 — Variation of force as a function of velocity for a symmetrical damper

FV12 Figure 6 — Variation of force as a function of velocity for an asymmetrical damper SIST EN 13802:2004

4.4.4.2 Target values The force–velocity characteristics for damper extension and compression shall be within the tolerances specified in the damper performance description. The tolerances shall be defined: a) by max./min. envelope curves established for different ranges of velocities (see Figure 7); or b) by max./min. force values established for specified velocities (see Figure 8).

V123F

1 Figure 7 — Typical force/velocity envelope

FVV11122231V2V2 Figure 8 — Typical max/min force limits SIST EN 13802:2004

Annex D gives examples of typical envelope curves for the following two cases: linear damper characteristic; friction type characteristic damper. 4.4.5 Force–displacement characteristic A force–displacement characteristic may be included in the damper performance description. The force–displacement characteristic is the variation in damper force F as a function of damper displacement nd. It shall be established for a given damper displacement and length. If these are not specified, a default damper displacement of ± 25 mm shall be used and the length assumed to be the nominal length (Ln). A force–displacement diagram shows the damper force F versus displacement at a given harmonic motion: for nominal travel dn; over the nominal length Ln; at defined velocity ω=0sinvvt The force–displacement diagram shall be constructed from the following parameters: displacement (setpoint) versus time; force (response) versus time. The evaluation of the force–displacement diagram allows the diagnosis of the functioning of the damper. Consequently, the record of this diagram shall be made at a scale to ensure correct analysis. When the damper is excited by a sinusoidal input, the shape of the theoretical force–displacement is the one shown: in Figure 9 for a symmetrical linear characteristic damper; in Figure 10 for a symmetrical friction type characteristic damper.

FAOBF21CFC Figure 9 — Example of theoretical force–displacement diagram for symmetrical linear characteristic dampers

ABF1FeFe

Figure 10 — Example of theoretical force–displacement diagram for symmetrical friction type characteristic dampers SIST EN 13802:2004

The force–displacement diagram shall be regular and shall not have any default indicative of malfunctioning of the damper (for example vibrational phenomena, jumping, loss of force, sudden change in the shape of the diagram; however, at points A and B in Figures 9 and 10 since the force is zero some rapid changes are to be expected) customer and supplier may agree the detail of an acceptable diagram. The value of forces ,maxeFand ,maxcFwhich shall be taken into account to establish the force–velocity characteristic (see 4.4.4) are those produced by the damper at the instantaneous test velocity v defined. The values of the forces ,maxeFand ,maxcFare generally taken at mid-travel on the diagram, but may be displaced away from the zero displacement point. The variation in characteristic at ,minaoTand ,maxaoTfor all specified velocities shall be defined in the damper performance description. The variation of the characteristic with frequency shall be agreed between the supplier and customer and defined in the damper performance description. 4.4.6 Dynamic characteristics The test and analysis methods to be used to evaluate the dynamic characteristics of the damper are to be agreed between the customer and supplier, these are to be based upon the Maxwell model (see 3.2). For dampers of small operating damper displacement, where the dynamic damping characteristic forms part of the damper performance description, all measured values of the dynamic damping rate at the test temperature and within the stated frequency and amplitude range shall be equal to or exceed the minimum dynamic damping rate stated in the damper performance description. Unless defined differently in the damper performance description, the specified value tolerance shall be: 0 % and + 30 %. 4.4.7 Priming The customer shall define the requirements with regard to loss of priming during service, transport or storage. Dampers shall not lose priming during service or after storage or transport when maintained within the extreme temperature range (,minaeT to ,maxaeT). If the damper becomes unprimed information on how to treat the damper to reach a primed condition shall be provided by the supplier. Details of the priming operation shall be agreed by the customer. The damper shall then remain in an operational (primed) condition following this treatment for the duration of its service interval. SIST EN 13802:2004

+/- 250 N; displacements: +/- 1 mm; frequency:

+/- 0,01 Hz; velocity:

+/- 0,050v. 5.1.3 Test temperature Unless otherwise stated, the test temperature shall be within the range 17 °C to 23 °C. The damper shall be left in a location at the test temperature in its service assembly position for at least 24 h before the test. 5.1.4 Test sample Unless otherwise specified, the test sample shall be the production damper, without its end mountings. SIST EN 13802:2004

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...