EN 13020:2004+A1:2010

(Main + Amendment)Road surface treatment machines - Safety requirements

Road surface treatment machines - Safety requirements

This document applies to road surface treatment machines, which are in particular:

- binder sprayers [or sprayers];

- chipping spreaders [or spreaders];

- machines for surface repairs (binder sprayer chipping spreader [or sprayer spreader]);

- mastics asphalt mixers;

- joint sealer;

- micro-surfacing machines/slurry machines;

- cold asphalt laying / micro-asphalt-paving machines;

(see also Clause 3).

Road surface treatment machines can be mounted on a carrier vehicle, trailer or articulated truck, combining to form an integral unit. It is also possible to mount a road surface treatment machine on its own chassis construction and propulsion system (self-propelled or pedestrian-controlled). In all cases the machine and chassis form an integral unit.

Directives and standards for the vehicular truck chassis aspects, termed 'carrier vehicle' in this document, would be those relative to that equipment, even where specific modifications have been made to realize the road surface treatment application. The use in public road traffic is governed by the national regulations.

This document deals with all significant hazards identified through a risk assessment relevant to road surface treatment machines when they are used as intended and under the conditions foreseen by the manufacturer (see Clause 4). This document does not deal with significant hazards associated with pressurized tanks, noise and EMC. This document specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards associated with machine operation, setting and adjustments, load discharge and routine maintenance.

This document does not include requirements for the carrier vehicles or special constructions. These are covered in directives related to the construction of vehicles. Demountable bodywork systems (e.g. demountable containers) are specified in other standards.

Maschinen für die Straßenoberflächenbehandlung - Sicherheitsanforderungen

Dieses Dokument bezieht sich auf Maschinen zur Straßenoberflächenbehandlung, als da sind im Einzelnen:

Bindemittel-Spritzmaschinen [oder Spritzmaschinen];

Splitt-Spritzstreuer [oder Splittstreuer];

Oberflächenreparaturmaschinen (Bindemittel-Splitt-Spritzstreuer [oder Spritzstreuer]);

Gussasphaltkocher;

Fugenfüller;

Mikrooberflächenmaschinen/Schlämmemaschinen;

(siehe hierzu auch Abschnitt 3).

Eine Maschine zur Straßenoberflächenbehandlung kann auf ein Trägerfahrzeug, einen Anhänger oder ein Spezialfahrzeug aufgebaut sein. Ebenfalls möglich ist der Aufbau einer Maschine zur Straßenoberflächen-behandlung auf einem speziell konstruierten Fahrgestell- und Antriebssystem (selbstfahrend oder mitgänger-geführt). In jedem Fall bilden Aufbau und Fahrgestell eine Einheit.

Richtlinien und Normen des Fahrzeugbaues sind bindend, auch wenn spezielle Anpassungen zum Aufbau einer Maschine zur Straßenoberflächenbehandlung erforderlich sind. Für die Teilnahme am öffentlichen Straßenverkehr gelten die nationalen Vorschriften.

Dieses Dokument behandelt alle anhand einer Risikobeurteilung festgestellten signifikanten Gefährdungen, die von Maschinen für die Straßenoberflächenbehandlung ausgehen, wenn sie bestimmungsgemäß und entsprechend den Empfehlungen des Herstellers verwendet werden (siehe Abschnitt 4). Dieses Dokument behandelt nicht signifikante Gefährdungen bezüglich druckbeaufschlagter Tanks, Lärm und elektromagne-tischer Verträglichkeit (EMV). Dieses Dokument spezifiziert die entsprechenden technischen Maßnahmen zur Beseitigung oder Verminderung der Risiken, die von den signifikanten Gefährdungen beim Einsatz, der Einstellung, der Be- und Entladung und der Wartung der Maschine ausgehen.

(...)

Machines pour le traitement des surfaces routières - Prescriptions de sécurité

Le présent document s’applique aux machines pour le traitement des surfaces routières. Elles comprennent

en particulier :

- les répandeuses ;

- les gravillonneurs ;

- les machines pour réparation de surfaces de chaussée !(unités point-à-temps, répandeuses gravillonneurs)";

- les malaxeurs-fondoirs à bitume ;

- !les jointeuses ;"

- !les machines à enrobés coulés à froid/machines à coulis."

!texte supprimé"

(voir également l’Article 3).

Les machines pour le traitement des surfaces routières peuvent être montées sur un véhicule porteur, une remorque

ou une semi-remorque, qui combinés forment un tout. Il est également possible de monter une machine pour le

traitement des surfaces routières sur son propre châssis doté d’un système de propulsion intégré (automoteur ou

à conducteur à pied). Dans tous les cas, la machine et le châssis forment un tout.

Les Directives et les normes relatives aux aspects du châssis des camions appelés «véhicules porteurs» dans le

présent document seront celles relatives à cet équipement, même lorsque des modifications particulières ont été

effectuées pour réaliser l’exécution du traitement des surfaces routières. L’utilisation sur routes publiques est régie

par des réglementations nationales.

Le présent document traite de l’ensemble des phénomènes dangereux significatifs, identifiés par une estimation du

risque, relatifs aux machines pour le traitement des surfaces routières lorsqu'elles sont utilisées normalement et dans

les conditions prévues par le fabricant (voir Article 4). Le présent document ne traite pas des phénomènes dangereux

significatifs associés aux réservoirs sous pression, au bruit et à la compatibilité électromagnétique. Le présent

document spécifie les mesures techniques appropriées pour éliminer ou réduire les risques dus aux phénomènes

dangereux significatifs associés au fonctionnement de la machine, sa mise en service et ses réglages, à l'épandage

et à la maintenance de routine.

Stroji za obdelovanje cestišč - Varnostne zahteve

Ta dokument velja za stroje za obdelovanje cestišč, ki so zlasti: - škropilnice veziv [ali škropilnice]; - trosilniki odlomkov [ali trosilniki]; - stroji za popravilo površine (škropilnica veziv trosilnik odlomkov [ali škropilnica trosilnik]); - mešalniki asfaltnih mas; - stroj za tesnjenje fug; - mikropovršinski stroji/stroji za tekoče zmesi. Stroji za obdelovanje cestišč se lahko namestijo na nosilno vozilo, prikolico ali zglobni tovornjak in skupaj tvorijo celoto. Stroj za obdelovanje cestišč se lahko namesti tudi na svojo šasijo in pogonski sistem (samognani stroj ali stroj, ki ga krmili pešec). V vsakem primeru stroj in šasija tvorita celoto. Direktive in standardi za vidike kamionskega podvozja, v tem dokumentu imenovano 'nosilno vozilo', so tisti, ki so povezani s to opremo, tudi če če pri obdelovanju cestišč pride do posameznih sprememb. Za uporabo v javnem cestnem prometu veljajo nacionalna pravila. Ta standard obravnava vse bistvene nevarnosti, ugotovljene z ocenjevanjem tveganja v zvezi s stroji za obdelovanje cestišč, ko se uporabljajo kot predvideno in pod pogoji napačne uporabe, ki jo predvidi proizvajalec. Ta dokument ne obravnava pomembnih nevarnosti, povezanih z rezervoarji pod pritiskom, hrupom in EMC. Ta standard določa ustrezne tehnične ukrepe za preprečevanje in zmanjševanje tveganj, ki izhajajo iz bistvenih nevarnosti, povezanih z delovanjem stroja, nastavitvijo in prilagajanjem, raztovarjanjem in rutinskim vzdrževanjem. Ta dokument ne vključuje zahtev za nosilno vozilo ali posebne konstrukcije. Te zajemajo direktive, povezane s konstrukcijo vozil. Snemljive karoserijske sisteme (npr. snemljive vsebnike) določajo drugi standardi. Ta standard ne obravnava vibracij, saj za vse stroje v tej družini vibracije zaradi nizke delovne hitrosti in posebnih delovnih pogojev (npr. ravnih površin) ne predstavljajo pomembne nevarnosti. Ta dokument ne obravnava tveganj, povezanih z delovanjem strojev v potencialno eksplozivnih atmosferah. Ta dokument ne vključuje zahtev Direktive 94/55/ES v zvezi s prevozom nevarnih snovi po cesti, vendar vsebuje dodatne specifikacije v zvezi s temi obstoječimi zahtevami. Ta dokument velja za stroje, ki so izdelani po datumu, ko je ta standard odobril CEN.

General Information

- Status

- Withdrawn

- Publication Date

- 06-Apr-2010

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 151 - Construction equipment and building material machines - Safety

- Drafting Committee

- CEN/TC 151/WG 5 - Road construction machines - Safety

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 18-Nov-2015

- Completion Date

- 11-Feb-2026

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 30-Jan-2010

- Effective Date

- 25-Nov-2015

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 500-1:2006+A1:2009 - Mobile road construction machinery - Safety - Part 1: Common requirements - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN ISO 3457:2008 - Earth-moving machinery - Guards - Definitions and requirements (ISO 3457:2003) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN ISO 2867:2008 - Earth-moving machinery - Access systems (ISO 2867:2006, including Cor 1:2008) - Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 13020:2004+A1:2010 is a standard published by the European Committee for Standardization (CEN). Its full title is "Road surface treatment machines - Safety requirements". This standard covers: This document applies to road surface treatment machines, which are in particular: - binder sprayers [or sprayers]; - chipping spreaders [or spreaders]; - machines for surface repairs (binder sprayer chipping spreader [or sprayer spreader]); - mastics asphalt mixers; - joint sealer; - micro-surfacing machines/slurry machines; - cold asphalt laying / micro-asphalt-paving machines; (see also Clause 3). Road surface treatment machines can be mounted on a carrier vehicle, trailer or articulated truck, combining to form an integral unit. It is also possible to mount a road surface treatment machine on its own chassis construction and propulsion system (self-propelled or pedestrian-controlled). In all cases the machine and chassis form an integral unit. Directives and standards for the vehicular truck chassis aspects, termed 'carrier vehicle' in this document, would be those relative to that equipment, even where specific modifications have been made to realize the road surface treatment application. The use in public road traffic is governed by the national regulations. This document deals with all significant hazards identified through a risk assessment relevant to road surface treatment machines when they are used as intended and under the conditions foreseen by the manufacturer (see Clause 4). This document does not deal with significant hazards associated with pressurized tanks, noise and EMC. This document specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards associated with machine operation, setting and adjustments, load discharge and routine maintenance. This document does not include requirements for the carrier vehicles or special constructions. These are covered in directives related to the construction of vehicles. Demountable bodywork systems (e.g. demountable containers) are specified in other standards.

This document applies to road surface treatment machines, which are in particular: - binder sprayers [or sprayers]; - chipping spreaders [or spreaders]; - machines for surface repairs (binder sprayer chipping spreader [or sprayer spreader]); - mastics asphalt mixers; - joint sealer; - micro-surfacing machines/slurry machines; - cold asphalt laying / micro-asphalt-paving machines; (see also Clause 3). Road surface treatment machines can be mounted on a carrier vehicle, trailer or articulated truck, combining to form an integral unit. It is also possible to mount a road surface treatment machine on its own chassis construction and propulsion system (self-propelled or pedestrian-controlled). In all cases the machine and chassis form an integral unit. Directives and standards for the vehicular truck chassis aspects, termed 'carrier vehicle' in this document, would be those relative to that equipment, even where specific modifications have been made to realize the road surface treatment application. The use in public road traffic is governed by the national regulations. This document deals with all significant hazards identified through a risk assessment relevant to road surface treatment machines when they are used as intended and under the conditions foreseen by the manufacturer (see Clause 4). This document does not deal with significant hazards associated with pressurized tanks, noise and EMC. This document specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards associated with machine operation, setting and adjustments, load discharge and routine maintenance. This document does not include requirements for the carrier vehicles or special constructions. These are covered in directives related to the construction of vehicles. Demountable bodywork systems (e.g. demountable containers) are specified in other standards.

EN 13020:2004+A1:2010 is classified under the following ICS (International Classification for Standards) categories: 93.080.10 - Road construction. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13020:2004+A1:2010 has the following relationships with other standards: It is inter standard links to EN 13020:2004, EN 13020:2004/FprA1, EN 13020:2015, EN 811:1996, EN ISO 14119:2025, EN 982:1996, CEN/TR 15855:2009, EN ISO 13732-1:2008, EN 12999:2002, EN 500-1:2006+A1:2009, EN ISO 12100-2:2003, EN ISO 3457:2008, EN ISO 2860:2008, EN ISO 12100-1:2003, EN ISO 2867:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13020:2004+A1:2010 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13020:2004+A1:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Maschinen für die Straßenoberflächenbehandlung - SicherheitsanforderungenMachines pour le traitement des surfaces routières - Prescriptions de sécuritéRoad surface treatment machines - Safety requirements93.080.10Gradnja cestRoad constructionICS:Ta slovenski standard je istoveten z:EN 13020:2004+A1:2010SIST EN 13020:2005+A1:2010en,fr01-junij-2010SIST EN 13020:2005+A1:2010SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13020:2004+A1

April 2010 ICS 93.080.10 Supersedes EN 13020:2004English Version

Road surface treatment machines - Safety requirements

Machines pour le traitement des surfaces routières - Prescriptions de sécurité

Maschinen für die Straßenoberflächenbehandlung - Sicherheitsanforderungen This European Standard was approved by CEN on 10 September 2004 and includes Amendment 1 approved by CEN on 21 February 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13020:2004+A1:2010: ESIST EN 13020:2005+A1:2010

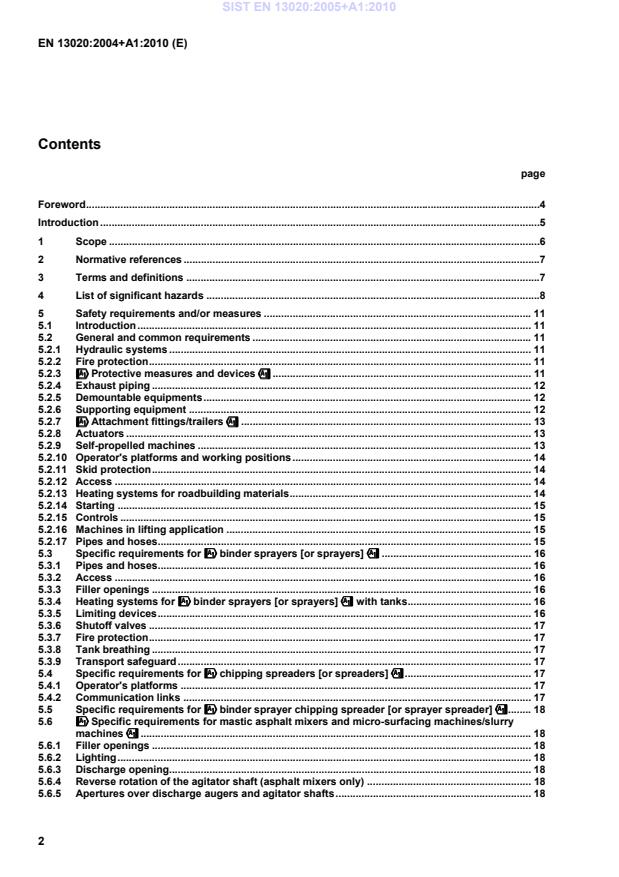

Truck attachment plate. 22Annex B (informative)

!!!!Terminology"""" . 23Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC . 26Annex ZB (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC"""" . 27Bibliography . 28 SIST EN 13020:2005+A1:2010

NOTE 2 Bitumen emulsion is a product with a temperature below 100 °C and out of the scope of TDG (94/55/EC -Transport of dangerous goods) regulation." 3.2 !!!!chipping spreader [or spreader] machine used to spread a layer of chippings on the pavement at a predetermined rate (see informative annex) Some of these machines can be equipped with a loading device (e.g. bucket, stick, boom). NOTE Several types of chippings spreaders may be identified e.g. mounted on a carrier vehicle (truck) or self- propelled." 3.3 !!!!binder sprayer chipping spreader [or sprayer spreader] machine used for coating roads with binder (bitumen/emulsion) and with aggregates in a single operation NOTE 1 Bitumen is a dangerous good in regard to TDG (94/55/EC -Transport of dangerous goods) regulation.

NOTE 2 Bitumen emulsion is a product with a temperature below 100 °C and out of the scope of TDG (94/55/EC -Transport of dangerous goods) regulation." 3.4 mastic asphalt mixer machine consisting of a tank with horizontal or vertical mixer (agitating shaft and stirrer arms) for preparing !transporting, heating (over 100 °C), mixing and discharging mastic asphalt. This machine can be mounted on a carrier-vehicle, semi-trailer, trailer or can be self-propelled" !deleted text" 3.5 !!!!joint sealer machine consisting of a tank with horizontal or vertical mixer and designed for melting and preparing mastics (over 100 °C) that are used in treating roadway joints and cracks" 3.6 !!!!micro-surfacing machines/slurry machines machine usually mounted on a truck (or a semi-trailer) designed for

the production of slurries and micro-surfacing which contains all necessary components (e.g. emulsion, water, cement, additives) in separated tanks" 3.7 demountable equipment equipment that intended to be demounted from and remounted to the carrier vehicle !, e.g. chipping spreader or binder sprayer [or sprayer]" 4 List of significant hazards This clause contains all hazards and hazardous situations, as far as they are dealt with in this document, identified by risk assessments as significant for this type of machinery and which require action to eliminate or reduce the risk. SIST EN 13020:2005+A1:2010

Binder sprayer [or sprayer]Chipping spreader [or spreader]Binder sprayer chipping spreader [or sprayer spreader] Mastic asphalt mixer and join sealer Micro-surfacing machines/Slurry machines

""""

1.1 Crushing hazard 5.2.6 5.2.7 5.2.6 5.2.7 5.4.2 5.2.6 5.2.7 5.2.6 5.2.7 5.2.6 5.2.7 1.2 Entanglement hazard 5.2.14.2 5.2.14.2 5.2.14.2 5.2.14.2 5.6.4 5.6.5 5.2.14.2 5.7.1 5.7.2 1.3 High pressure fluid ejection hazard 5.2.1 5.3.1 5.3.5 5.3.6 7.4 5.2.1 5.2.1 5.3.1 5.3.5 5.2.1 5.2.1 1.4 Loss of stability (of machinery and machine parts) 5.2.5 5.2.6 5.2.5 5.2.6

5.2.5 5.2.6 5.2.5 5.2.6 1.5 Slip, trip and fall hazards in relationship with machinery (because of their mechanical nature) 5.2.10 5.2.11 5.2.12 5.3.2 5.3.3 5.2.10 5.2.11 5.2.12 5.4.1 5.2.10 5.2.11 5.2.12 5.3.2 5.3.3 5.4.1 5.2.10 5.2.11 5.2.12 5.6.1 5.2.10 5.2.11 5.2.12 5.7.3

2.1 Burns and scalds, by a possible contact of persons, by flames or explosions and also by the radiation of heat sources 5.2.2 5.2.3 5.2.13 5.3.1 5.3.4 5.3.5 5.3.9 7.3 5.2.2 5.2.3

5.2.2 5.2.3 5.2.13 5.3.4 5.3.9 7.3 5.2.2 5.2.3 5.2.13 5.6.1 5.6.6 5.2.2 5.2.3

3.1 Hazards resulting from contact with or inhalation of harmful fluids, gases, mists, fumes and dusts. 5.2.4 7.3 5.2.4 5.2.4 7.3 5.2.4 5.2.4 3.2 Fire or explosion hazard 5.2.13.1 5.3.4 5.3.7 5.3.8

5.2.13.1 5.3.4 5.3.7 5.3.8 5.2.13.1 5.6.1

""""

4.1 Unhealthy postures or excessive efforts

5.3.1 5.3.1

4.2 Inadequate consideration of human hand-arm or foot-leg anatomy 5.2.8 5.2.9 5.2.14 5.2.8 5.2.9 5.2.14 5.4.3 5.2.8 5.2.9 5.2.14 5.4.3 5.2.8 5.2.9 5.2.14 5.2.8 5.2.9 5.2.14 5.7.1 4.3 Neglected use of personal protection equipment 7.2 7.2 7.2 7.2 7.2 4.4 Inadequate area lighting

5.6.2

4.5 Human errors 7.2 7.2 7.2 7.2 7.2 5 Hazards combinations 7.2 7.2 7.2 7.2 7.2

6.1 Unexpected ejection of machine parts or fluids 5.3.7 7.3

5.3.7 7.3

6.2 Failure, malfunction of control systems (unexpected start-up, unexpected overrun) 5.2.14 5.2.14 5.2.14 5.2.14 5.6.3 5.6.4 5.2.14 5.7.1 6.3 Errors of fitting 5.2.7 5.2.7 5.2.7 5.2.7 5.2.7

7.1 All kinds of guard

5.6.6

7.2 All kinds of safety related (protection) devices

5.6.5 5.6.6 5.7.1 5.7.2 7.3 Safety signs and signals 5.2.6 5.2.8 5.2.6 5.2.8 5.2.6 5.2.8 5.2.6 5.2.8 5.2.6 5.2.8 7.4 Essential equipment and accessories for safe adjusting and/or maintaining 7.2 7.2 7.2 7.2 7.2 7.5 Equipment for evacuating gases etc. 5.2.4 5.2.4 5.2.4 5.2.4 5.2.4 8 Hazards resulting from the machine mobility 5.2.9 5.2.9 5.2.9 5.2.9 5.2.9

Temperatures of surfaces of machinery with which the operator may come into contact shall conform to !EN ISO 13732-1". !Where necessary" this shall be achieved by the use of guards !deleted text". Where guarding is impractical, e.g. !spray bar," engine radiator caps, adequate warning signs shall be employed advising on the nature of the risk and avoidance measures described in information for use. Temperatures of !the contact surface, e.g. handle, grip of" hot operating devices e.g. hand spray lances to be carried by operator shall conform to !EN ISO 13732-1". !!!! 5.2.3.2 Moving parts All moving parts which create a hazard shall be designed, constructed, positioned or provided with protection devices to minimise the risk of crushing, shearing and cutting. The mobile parts shall be protected by protective devices or guards in accordance with EN ISO 13857. Where guarding is impractical, e.g. spray bar, chips distributor extension, adequate warning signs shall be employed advising on the nature of the risk and avoidance measures described in information for use. SIST EN 13020:2005+A1:2010

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...