EN 13165:2001

(Main)Thermal insulation products for buildings - Factory made rigid polyurethane foam (PUR) products - Specification

Thermal insulation products for buildings - Factory made rigid polyurethane foam (PUR) products - Specification

This European Standard specifies the requirements for factory made products of polyurethane rigid foam, with or without facings or coatings and with or without integral reinforcement, which are used for the thermal insulation of buildings. The products are manufactured in the form of boards. The standard also covers multilayered products and composite insulation products, laminates and cladding panels in which polyurethane rigid foam is the main insulant. The standard describes product characteristics and includes procedures for testing, marking and labelling.

Wärmedämmstoffe für Gebäude - Werkmäßig hergestellte Produkte aus Polyurethan Hartschaum (PUR) - Spezifikation

Diese Europäische Norm nennt die Anforderungen für werkmäßig hergestellte Produkte aus Polyurethan-Hartschaum (PUR) mit oder ohne feste oder flexible Kaschierungen oder Beschichtungen und mit oder ohne integriete Verstärkungen fest, die für die Wärmedämmung von Gebäuden benutzt werden. PUR schließt auch Polyisocyanurat-Hartschaum (PIR) mit ein. Die Produkte werden als Platten hergestellt. Die Norm umfasst euch das Dämmvermögen von Mehrschicht-Verbund-Platten, bei denen Ployurethan-Hartschaum der Haupt-Dämmstoff ist. Diese Norm beschreibt die Stoffeigenschaften und enthält die Prüfverfahren und Festlegungen für die Konformitätsbewertung, die Kennzeichnung und die Etikettierung. In dieser Norm beschriebene Produkte werden auch in vorgefertigten Wärmedämmsystemen und Mehrschicht-Verbundplatten angewendet; die Eigenschaften von Systemen, in die diese Produkte integriet sind, werden nicht behandelt. Diese Norm legt keine Anforderungsniveaus für eine vorgegebene Eigenschaft fest, die ein Produkt erreichen muss, um für einen bestimmten Anwendungsfall tauglich zu sein. Für bestimmte Anwendungen benötigte Anforderungen könnnen Regelwerken oder übereinstimmenden Normen entnommen werden. Diese Norm gilt nicht für Produkte, deren Nennwert des Wärmedurchlasswiderstandes niedriger istals 0,05 m² . K/W oder deren Nennwert der Wärmeleitfähigkeit größer ist als 0,1 W/( m . K) bei 10°C Mitteltemperatur. Diese Norm gilt nicht für in situ-Dämmstoffe und für Produkte, die zur Dämmung von haustechnischen und betriebstechnischen Anlagen bestimmt sind. Diese Norm gilt nicht für Schallschutzaspekte der Trttschall-Übertragung.

Produits isolants thermiques pour le bâtiment - Produits manufacturés en mousse rigide de polyuréthane (PUR) - Spécification

La présente Norme européenne spécifie les exigences auxquelles doivent satisfaire les produits manufacturés en mousse rigide de polyuréthanne (PUR), avec ou sans parements rigides ou souples ou revêtements et avec ou sans renfort incorporé, utilisés pour l'isolation thermique des bâtiments. Le PUR comprend également la mousse de polyisocyanurate (PIR).

Les produits sont fabriqués sous forme de panneaux. Cette norme traite également de la performance thermique des panneaux composites dont la mousse rigide de polyuréthane constitue le principal isolant.

La présente norme décrit les caractéristiques du produit et inclut les procédures d'essai, d'évaluation de la conformité, de marquage et d'étiquetage.

Les produits du domaine d'application de la présente norme sont également utilisés dans des systèmes d'isolation thermique et dans des panneaux composites préfabriqués ; la performance des systèmes dans lesquels entrent ces produits n'est pas définie.

La présente norme ne spécifie pas, pour une propriété donnée, la classe/niveau exigé que doit atteindre un produit pour démontrer son aptitude à l'emploi dans une application particulière. Les classes/niveaux requis pour une application donnée figurent dans les réglementations ou normes non conflictuelles.

Les produits dont la résistance thermique déclarée à une température de 10 °C est inférieure à 0,05 m2.K/W ou dont la conductivité thermique déclarée à une température de 10 °C est supérieure à 0,1 W/(m.K) ne sont pas du domaine d'application de la présente norme.

Les produits mis en ¿uvre in situ et ceux destinés à être utilisés pour l'isolation des équipements du bâtiment et des installations industrielles ne sont pas du domaine d'application de la présente norme. Le phénomène acoustique de transmission des bruits de choc n'est pas traité dans la présente norme.

Toplotnoizolacijski proizvodi za stavbe - Proizvodi iz trde poliuretanske pene (PUR) - Specifikacija

General Information

- Status

- Withdrawn

- Publication Date

- 22-May-2001

- Withdrawal Date

- 25-Nov-2008

- Technical Committee

- CEN/TC 88 - Thermal insulating materials and products

- Drafting Committee

- CEN/TC 88/WG 6 - Rigid cellular polyurethane and polyisocyanurate

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 26-Nov-2008

- Completion Date

- 26-Nov-2008

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 13165:2001 is a standard published by the European Committee for Standardization (CEN). Its full title is "Thermal insulation products for buildings - Factory made rigid polyurethane foam (PUR) products - Specification". This standard covers: This European Standard specifies the requirements for factory made products of polyurethane rigid foam, with or without facings or coatings and with or without integral reinforcement, which are used for the thermal insulation of buildings. The products are manufactured in the form of boards. The standard also covers multilayered products and composite insulation products, laminates and cladding panels in which polyurethane rigid foam is the main insulant. The standard describes product characteristics and includes procedures for testing, marking and labelling.

This European Standard specifies the requirements for factory made products of polyurethane rigid foam, with or without facings or coatings and with or without integral reinforcement, which are used for the thermal insulation of buildings. The products are manufactured in the form of boards. The standard also covers multilayered products and composite insulation products, laminates and cladding panels in which polyurethane rigid foam is the main insulant. The standard describes product characteristics and includes procedures for testing, marking and labelling.

EN 13165:2001 is classified under the following ICS (International Classification for Standards) categories: 91.100.60 - Thermal and sound insulating materials. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13165:2001 has the following relationships with other standards: It is inter standard links to EN 13165:2008, EN 13165:2001/A2:2004, EN 13165:2001/A1:2004, EN 13165:2001/AC:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13165:2001 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/103. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13165:2001 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Thermal insulation products for buildings - Factory made rigid polyurethane foam (PUR) products - SpecificationToplotnoizolacijski proizvodi za stavbe - Proizvodi iz trde poliuretanske pene (PUR) - SpecifikacijaProduits isolants thermiques pour le bâtiment - Produits manufacturés en mousse rigide de polyuréthane (PUR) - SpécificationWärmedämmstoffe für Gebäude - Werkmäßig hergestellte Produkte aus Polyurethan Hartschaum (PUR) - Spezifikation91.100.60Thermal and sound insulating materialsICS:SIST EN 13165:2002enTa slovenski standard je istoveten z:EN 13165:200101-marec-2002SIST EN 13165:2002SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13165May 2001ICS 91.100.60English versionThermal insulation products for buildings - Factory made rigidpolyurethane foam (PUR) products - SpecificationProduits isolants thermiques pour le bâtiment - Produitsmanufacturés en mousse rigide de polyuréthane (PUR) -SpécificationWärmedämmstoffe für Gebäude - Werkmäßig hergestellteProdukte aus Polyurethan Hartschaum (PUR) -SpezifikationThis European Standard was approved by CEN on 16 April 2001.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2001 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13165:2001 E

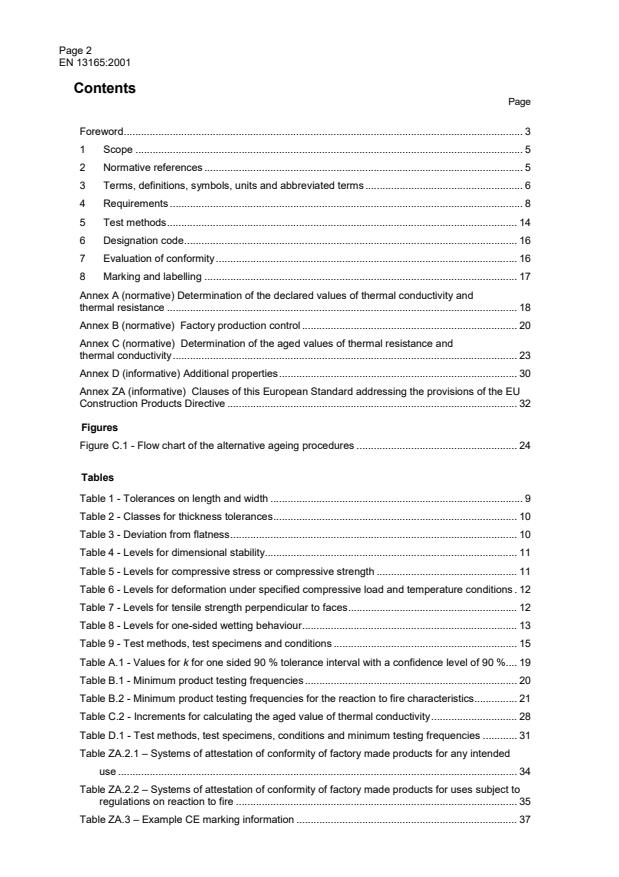

Page 2EN 13165:2001ContentsPageForeword.31 Scope.52 Normative references.53 Terms, definitions, symbols, units and abbreviated terms.64Requirements.85 Test methods.146 Designation code.167 Evaluation of conformity.168 Marking and labelling.17Annex A (normative) Determination of the declared values of thermal conductivity andthermal resistance.18Annex B (normative)

Factory production control.20Annex C (normative)

Determination of the aged values of thermal resistance andthermal conductivity.23Annex D (informative) Additional properties.30Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EUConstruction Products Directive.32FiguresFigure C.1 - Flow chart of the alternative ageing procedures.24TablesTable 1 - Tolerances on length and width.9Table 2 - Classes for thickness tolerances.10Table 3 - Deviation from flatness.10Table 4 - Levels for dimensional stability.11Table 5 - Levels for compressive stress or compressive strength.11Table 6 - Levels for deformation under specified compressive load and temperature conditions.12Table 7 - Levels for tensile strength perpendicular to faces.12Table 8 - Levels for one-sided wetting behaviour.13Table 9 - Test methods, test specimens and conditions.15Table A.1 - Values for k for one sided 90 % tolerance interval with a confidence level of 90 %.19Table B.1 - Minimum product testing frequencies.20Table B.2 - Minimum product testing frequencies for the reaction to fire characteristics.21Table C.2 - Increments for calculating the aged value of thermal conductivity.28Table D.1 - Test methods, test specimens, conditions and minimum testing frequencies.31Table ZA.2.1 – Systems of attestation of conformity of factory made products for any intendeduse.34Table ZA.2.2 – Systems of attestation of conformity of factory made products for uses subject toregulations on reaction to fire.35Table ZA.3 – Example CE marking information.37

Page 3EN 13165:2001ForewordThis European Standard has been prepared by Technical Committee CEN/TC 88 "Thermal insulating materials andproducts", the secretariat of which is held by DIN.This European Standard shall be given the status of a national standard, either by publication of an identical text or byendorsement, at the latest by November 2001, and conflicting national standards shall be withdrawn at the latest byMarch 2003.This European Standard has been prepared under a mandate given to CEN by the European Commission and theEuropean Free Trade Association, and supports essential requirements of EU Directive(s).For relationship with EU Directive(s), see informative annex ZA, which is an integral part of this standard.This European Standard contains five annexes:Annex A (normative) Determination of the declared values of thermal resistance and thermal conductivity;Annex B (normative) Factory production control;Annex C (normative) Determination of the aged values of thermal resistance and thermal conductivity;Annex D (informative) Additional properties;Annex ZA (informative)Clauses of this European Standard addressing the provisions ofthe EU Construction Products Directive.This European Standard is one of a series of standards for insulating products used in buildings, but thisstandard may be used in other areas where appropriate.In pursuance of Resolution BT 20/1993 Revised, CEN/TC88 has proposed defining the standards listed belowas a package of European standards, setting (21 months after availability) as the date of withdrawal (dow) ofnational standards which conflict with the European Standards of this package.The package of standards comprises the following group of interrelated standards for the specifications offactory made thermal insulation products, all of which come within the scope of CEN/TC88:EN 13162, Thermal insulation products for buildings – Factory made mineral wool (MW) products –Specification.EN 13163, Thermal insulation products for buildings – Factory made products of expanded polystyrene (EPS) –Specification.EN 13164, Thermal insulation products for buildings – Factory made products of extruded polystyrenefoam (XPS) – Specification.EN 13165, Thermal insulation products for buildings – Factory made rigid polyurethane foam (PUR) products –Specification.EN 13166, Thermal insulation products for buildings – Factory made products of phenolic foam (PF) –Specification.EN 13167, Thermal insulation products for buildings – Factory made cellular glass (CG) products – Specification.EN 13168, Thermal insulation products for buildings – Factory made wood wool (WW) products –Specification.EN 13169, Thermal insulation products for buildings – Factory made products of

expanded perlite (EPB) –Specification.

Page 4EN 13165:2001EN 13170, Thermal insulation products for buildings – Factory made products of expanded cork (ICB) –Specification.EN 13171, Thermal insulation products for buildings – Factory made wood fibre (WF) products

– Specification.According to the CEN/CENELEC Internal Regulations, the national standards organizations of the followingcountries are bound to implement this European Standard: Austria, Belgium, Czech Republic, Denmark,Finland, France, Germany, Greece, Iceland, Ireland, Italy, Luxembourg, Netherlands, Norway, Portugal, Spain,Sweden, Switzerland and the United Kingdom.

Page 5EN 13165:20011 ScopeThis European Standard specifies the requirements for factory made rigid polyurethane foam (PUR) products,with or without rigid or flexible facings or coatings and with or without integral reinforcement, which are used forthe thermal insulation of buildings. PUR also includes polyisocyanurate foam (PIR).The products are manufactured in the form of boards. The standard also covers the thermal performance ofcomposite panels in which polyurethane rigid foam is the main insulant.The standard describes product characteristics and includes procedures for testing, evaluation of conformity,marking and labelling.Products covered by this standard are also used in prefabricated thermal insulation systems and compositepanels; the performance of systems incorporating these products is not covered.The standard does not specify the required class/level of a given property to be achieved by a product todemonstrate fitness for purpose in a particular application. The classes/levels required for a given applicationare to be found in regulations or non-conflicting standards.Products with a declared thermal resistance lower than 0,05 m2K/W or a declared thermal conductivity greaterthan 0,1 W/(mK) at 10 oC are not covered by this standard.This standard does not cover in situ insulation products, products intended to be used for the insulation ofbuilding equipment and industrial installations. This standard does not cover the acoustical aspect of impactnoise transmission.2 Normative referencesThis European Standard incorporates by dated or undated reference, provisions from other publications. Thesenormative references are cited at the appropriate places in the text, and the publications are listed hereafter. Fordated references subsequent amendments to or revisions of any of these publications apply to this EuropeanStandard only when incorporated in it by amendment or revision. For undated references the latest edition of thepublication referred to applies (including amendments).EN ISO 354:1993/A1, Acoustics – Measurement of sound absorption in a reverberation room - Amendment 1:Test specimen mountings for sound absorption tests (ISO 354:1985/AMD 1:1997).EN 822, Thermal insulating products for building applications – Determination of length and width.EN 823, Thermal insulating products for building applications – Determination of thickness.EN 824, Thermal insulating products for building applications – Determination of squareness.EN 825, Thermal insulating products for building applications – Determination of flatness.EN 826, Thermal insulating products for building applications – Determination of compression behaviour.prEN ISO 1182, Reaction to fire tests for building products – Non-combustibility test (ISO/DIS 1182:1998).EN 1604, Thermal insulating products for building applications – Determination of dimensional stability under specifiedtemperature and humidity conditions.EN 1605, Thermal insulating products for building applications - Determination of deformation under specifiedcompressive load and temperature conditions.EN 1606, Thermal insulating products for building applications – Determination of compressive creep.EN 1607, Thermal insulating products for building applications - Determination of tensile strength perpendicular tofaces.

Page 6EN 13165:2001prEN ISO 1716, Reaction to fire tests for building products – Determination of calorific value (ISO/DIS 1716:1998).prEN ISO 9229, Thermal insulation – Definitions of terms (ISO/DIS 9229:1997).EN ISO 11654, Acoustics – Sound absorbers for use in buildings – Rating of sound absorption (ISO 11654:1997).prEN ISO 11925-2, Reaction to fire tests for building products – Part 2: Ignitability when subjected to directimpingement of flame (ISO/DIS 11925-2:1998).EN 12086:1997, Thermal insulating products for building applications – Determination

of

water vapourtransmission properties.EN 12087, Thermal insulating products for building applications – Determination of long term water absorption byimmersion.prEN 12667:2000, Thermal performance of building materials and products – Determination of thermal resistanceby means of guarded hot plate and heat flow meter method - Products of high and medium thermal resistance.EN 12939, Thermal performance of building materials and products – Determination of thermal resistanceby means of guarded hot plate and heat flow meter methods – Thick products of high and medium thermalresistance.EN 13172:2001, Thermal insulating products – Evaluation of conformity.prEN 13501-1, Fire classification of construction products and building elements – Part 1: Classificationusing test data from reaction to fire test.prEN 13820, Thermal insulating products for building applications – Determination of organic content.prEN 13823, Reaction to fire tests for building products – Building products excluding floorings exposed to thethermal attack by a single burning item.ISO 4590, Cellular plastics - Determination of volume percentage of open and closed cells of rigid materials.ISO 12491, Statistical methods for quality control of building materials and components.3 Terms, definitions, symbols, units and abbreviated terms3.1 Terms and definitionsFor the purposes of this standard, the following terms and definitions apply.3.1.1 Terms and definitions as given in prEN ISO 92293.1.1.1board; slabrigid or semi-rigid (insulation) product of rectangular shape and cross section in which the thickness is uniformand substantially smaller than the other dimensionsNOTEBoards are usually thinner than slabs. They may also be supplied in tapered form.3.1.1.2composite insulationcombination of layers of at least two different insulation materials. The insulation property of the composite isderived from the insulation properties of the individual materials3.1.1.3composite panelpanel made from two or more different materials deriving its performance from a combination of the propertiesof the individual materials, e.g. metal, plywood, particle board and insulation material

Page 7EN 13165:20013.1.1.4facingfunctional or decorative surface material, e.g. paper, plastic film, fabric or metal foil3.1.1.5rigid polyurethane foamrigid or semi-rigid cellular plastics insulation material or product with a substantially closed cell structure basedon polyurethane3.1.2 Additional terms and definitions3.1.2.1levelthe given value, which is the upper or lower limit of a requirement. The level is given by the declared value ofthe characteristic concerned3.1.2.2classa combination of two levels of the same property between which the performance shall fall3.1.2.3integral reinforcementa non-polyurethane product introduced into the polyurethane foam to improve some properties3.1.2.4polyisocyanurate foamrigid cellular plastics insulation material with a substantially closed cell structure based on polymers mainly ofthe isocyanurate typeNOTE

Regarding the properties described in this standard it is not distinguished between rigid polyurethane foam (PUR)and polyisocyanurate foam (PIR). The abbreviation PUR used in this standard includes PIR products.3.2Symbols, units and abbreviated termsSymbols and units used in this standard:pis the practical sound absorption coefficient

-wis the weighted sound absorption coefficient-bis the widthmmdis the thicknessmmdNis the nominal thickness of the productmmdSis the thickness of the test specimenmmbis the relative change in width%dis the relative change in thickness%lis the relative change in length%ct is the compressive creep%t is the total thickness reduction%kis a factor related to the number of test results-kais a factor related to the number of aged test results-kiis a factor related to the number of initial test results-lis the lengthmm90/90is the 90 % fractile with a confidence level of 90 % for the thermal conductivityW/(mK)Dis the declared thermal conductivityW/(mK)iis one test result of thermal conductivityW/(mK)meanis the mean thermal conductivityW/(mK)mean,ais the mean thermal conductivity of aged valuesW/(mK)mean,i

is the mean thermal conductivity of initial valuesW/(mK)ais the ageing increment from measured aged values of thermal conductivityW/(mK)fis the fixed ageing incrementW/(mK)is the water vapour diffusion resistance factor-

Page 8EN 13165:2001nis the number of test results-R90/90is the 90 % fractile with a confidence level of 90 % for the thermal resistancem2K/WRDis the declared thermal resistancem2K/WRiis one test result of thermal resistancem2K/WRmeanis the mean thermal resistancem2K/WSbis the deviation from squareness on length and widthmm/mSmaxis the deviation from flatnessmmsRis the estimate of the standard deviation of the thermal resistancem2K/Wsis the estimate of the standard deviation of the thermal conductivityW/(mK)s,ais the estimate of the standard deviation of the aged values of the thermalconductivityW/(mK)s,iis the estimate of the standard deviation of the initial values of the thermalconductivityW/(mK)cis the declared compressive stresskPa10is the compressive stress at 10 % deformationkPamis the compressive strengthkPamtis the tensile strength perpendicular to faceskPaWltis the long-term water uptake by total immersion%Zis the water vapour resistancem2hPa/mgAP is the symbol of the declared level of practical sound absorption coefficientAWis the symbol of the declared level of weighted sound absorption coefficientCC(i1/i2/y)cis the symbol of the declared level for compressive creepCS(10\Y)is the symbol of the declared level for compressive stress or strengthDLT(i)5is the symbol of the declared level for deformation under load and temperature at conditions setwith a maximum of 5 % deformationDS(TH)is the symbol of the declared level for dimensional stability under specified temperature andhumidityMUis the symbol of the declared level for the water vapour diffusion resistance factorFWis the symbol of the declared level for change in deviation from flatness after one-sided wettingTis the symbol of the declared class for thickness tolerancesTRis the symbol of the declared level for tensile strength perpendicular to facesWL (T)is the symbol of the declared level for long term water absorption by total immersionZis the symbol of the declared level for water vapour resistanceAbbreviated terms used in this standard:PURis Rigid PolyUrethane foamITTis Initial Type Test4Requirements4.1GeneralProduct properties shall be assessed in accordance with clause 5. To comply with this standard, products shallmeet the requirements of 4.2, and the requirements of 4.3 as appropriate.NOTEInformation on additional properties is given in annex D.One test result for a product property is the average of the measured values on the number of test specimensgiven in Table 9.4.2 For all applications4.2.1 Thermal resistance and thermal conductivityThermal resistance and thermal conductivity shall be based upon measurements carried out in accordance withprEN 12667 or EN 12939 for thick products.The thermal resistance and thermal conductivity shall be determined in accordance with annex A and annex C

Page 9EN 13165:2001and declared by the manufacturer according to the following:– the reference mean temperature shall be 10 oC;– the measured values shall be expressed with three significant figures;– the thermal resistance, RD, shall always be declared. The thermal conductivity, D, shall be declared wherepossible;– the declared thermal resistance, RD, and thermal conductivity, D, shall be given as limit values representingat least 90 % of the production, determined with a confidence level of 90 %;– the value of thermal conductivity, 90/90, shall be rounded upwards to the nearest 0,001 W/(mK) anddeclared as D in levels with steps of 0,001 W/(mK);– the declared thermal resistance, RD, shall be calculated from the nominal thickness, dN, and the corre-sponding thermal conductivity 90/90;– the value of thermal resistance, R90/90, when calculated from the nominal thickness, dN, and thecorresponding thermal conductivity, 90/90, shall be rounded downwards to the nearest 0,05 m2K/W, anddeclared as RD in levels with steps of 0,05 m2K/W;– the value of R90/90, for those products for which only the thermal resistance is measured directly, shall berounded downwards to the nearest 0,05 m2K/W and declared as RD in levels with steps of 0,05 m2K/W.4.2.2Length and widthLength, l, and width, b, shall be determined in accordance with EN 822. No test result shall deviate from thenominal values by more than the tolerances given in Table 1.Table 1 - Tolerances on length and widthDimensionsmmTolerancesmm< 10001000 to 20002001 to 4000> 4000± 5± 7,5± 10± 154.2.3ThicknessThickness, d, shall be determined in accordance with EN 823. No test result shall deviate from the nominalthickness, dN , by more than the tolerances given in Table 2 for the declared class.

Page 10EN 13165:2001Table 2 - Classes for thickness tolerancesClassNominal thicknessmm< 5050 to 75> 75TolerancemmT1± 3± 4+ 6,- 3T2± 2± 3+ 5,- 2T3± 1,5± 1,5± 1,54.2.4 SquarenessSquareness shall be determined in accordance with EN 824. The deviation from squareness on length andwidth, Sb, shall not exceed 6 mm/m.4.2.5 FlatnessFlatness shall be determined in accordance with EN 825. The deviation from flatness, Smax, shall not exceed thevalues given in Table 3.Table 3 - Deviation from flatnessFull-size productDeviation fromflatnessLengthmAream2mm

2,50 0,75 5> 0,75 104.2.6 Dimensional stability under specified temperature and humidity conditionsDimensional stability under specified temperature and humidity conditions shall be determined in accordancewith EN 1604. The tests, each on different sets of specimens, shall be carried out under the following testconditions:1)(48 ± 1) h at (70 ± 2) °C and a relative humidity of (90 ± 5) %;2)(48 ± 1) h at (-20 ± 3) °C.The relative changes in length, l, width, b and thickness, d , shall not exceed the values given in Table 4for the declared level.

Page 11EN 13165:2001Table 4 - Levels for dimensional stabilityTestcondi-tionsRelativechangesLevel DS(TH)1 234567891011121l,b%555333222111d%1010108886664442l,b%a10,5a10,5a10,5a10,5d%a22a22a22a22a No requirement4.2.7 Compressive stress or compressive strengthCompressive stress at 10 % deformation, 10, or the compressive strength, m, shall be determined inaccordance with EN 826. No test result for either the compressive stress at 10 % deformation or thecompressive strength, whichever is the smaller, shall be lower than the value, given in Table 5, for the declaredlevel.Table 5 - Levels for compressive stress or compressive strengthLevelRequirementkPaCS(10\Y)25 25CS(10\Y)50 50CS(10\Y)100 100CS(10\Y)120 120CS(10\Y)130 130CS(10\Y)140 140CS(10\Y)150 150CS(10\Y)175 175CS(10\Y)200 200CS(10\Y)225 225CS(10\Y)250 250CS(10\Y)350 350CS(10\Y)400 400CS(10\Y)800 800For handling purposes products shall have a minimum compressive stress or compressive strength of 25 kPa.

Page 12EN 13165:20014.2.8 Reaction to fireReaction to fire classification (Euroclasses) shall be determined in accordance with prEN 13501-1.4.3 For specific applications4.3.1 GeneralIf there is no requirement for a property described in 4.3 for a product in use, then the property does not need tobe determined and declared by the manufacturer.4.3.2 Deformation under specified compressive load and temperature conditionsDeformation under specified compressive load and temperature conditions shall be determined in accordancewith EN 1605. The relative change in thickness, d, shall not exceed the values, given in Table 6, for thedeclared level.Table 6 - Levels for deformation under specified compressive load and temperature conditionsLevelTest conditionsRequirement%DLT(1)5load: 20 kPatemperature: (80 ± 1) °C time: (48 ± 1) hDLT(2)5load: 40 kPatemperature: (70 ± 1) °C time: (168 ± 1) h 5DLT(3)5load: 80 kPatemperature: (60 ± 1) °C time: (168 ± 1) h4.3.3Tensile strength perpendicular to facesTensile strength perpendicular to faces, mt , shall be determined in accordance with EN 1607. No test resultshall be less than the value, given in Table 7, for the declared level.Table 7 - Levels for tensile strength perpendicular to facesLevelRequirementkPaTR40 40TR50 50TR60 60TR70 70TR80 80TR90 90TR100 100TR150 1504.3.4 Point loadThe effects of foot traffic shall be assessed by means of determination of the compressive stress orcompressive strength in accordance with EN 826, see 4.2.7.

Page 13EN 13165:20014.3.5 Compressive creepCompressive creep, ct, and total thickness reduction, t, shall be determined after at least one hundred twentytwo days of testing at a declared compressive stress, c, given in steps of at least 1 kPa, and the resultsextrapolated thirty times, corresponding to ten years, to obtain the declared levels in accordance with EN 1606.Compressive creep shall be declared in levels, i2, and the total thickness reduction shall be declared in levels i1,with steps of 0,5 %, at the declared stress. No test result shall exceed the declared levels at the declared stress.NOTE 1

Examples for declaration of levels for compressive creepLevelTest timedaysExtrapolation timeyearsDeclared stresskPaRequirement%CC(i1/i2/10) c12210ci1,

i2CC(i1/i2/25) c30425ci1,

i2CC(i1/i2/50) c60850ci1,

i2NOTE 2

Referring to the designation code CC(i1/i2/y)c, according to clause 6, a declared level CC(3/2/25)40, as forexample, indicates a value not exceeding 2 % for compressive creep and 3 % for total thickness reduction after extrapolationat 25 years (i.e. 30 times three hundred and four days of testing) under a declared stress of 40 kPa.4.3.6 Water absorptionLong term water absorption by total immersion, Wlt, shall be determined in accordance with EN 12087. No testresult shall exceed the declared value.4.3.7 Flatness after one-sided wettingChange in deviation from flatness after one-sided wetting shall be determined from measurements of flatnessmade in accordance with EN 825 before and after conditioning the product in accordance with 5.3.3. Both sidesof the product shall be tested. The change in deviation from flatness for each side shall not exceed the value,given in Table 8, for the declared level.Table 8 - Levels for one-sided wetting behaviourLevelChange in deviationmmFW1 20FW2 104.3.8Water vapour transmissionWater vapour transmission properties of the foam including facings or coatings shall be determined inaccordance with EN 12086 and declared as the water vapour diffusion resistance factor, , for homogeneousproducts and as the water vapour resistance, Z, for faced or non-homogeneous products. No test result shall beless than the declared value.4.3.9Sound absorptionSound absorption coefficient shall be determined in accordance with EN ISO 354:1993/A1. The soundabsorption characteristics shall be calculated in accordance with EN ISO 11654 using the values for thepractical sound absorption coefficient, p, at the frequencies: 125 Hz, 250 Hz, 500 Hz, 1000 Hz, 2000 Hz and4000 Hz and the single number value for the weighted sound absorption coefficient, w.p and w shall be rounded to the nearest 0,05 (p larger than 1 shall be expressed as p= 1) and declared inlevels with steps of 0,05. No result of p and w shall be lower than the declared level.

Page 14EN 13165:20014.3.10 Release of dangerous substancesNOTE

See annex ZA.5 Test methods5.1 SamplingTest specimens shall be taken from the same sample.5.2 ConditioningConditioning of the test specimens shall be at least 6 h at (23 ± 5) °C unless otherwise specified in the teststandard. In case of dispute, the test specimens shall be stored at (23 ± 2) °C and (50 ± 5) % relative humidityfor 7 days prior to testing.5.3 Testing5.3.1 GeneralTable 9 gives the dimensions of the test specimens, the minimum number of measurements required to get onetest result and any specific conditions which are necessary.5.3.2 Thermal resistance and thermal conductivityThermal resistance and thermal conductivity shall be determined in accordance with prEN 12667 or EN 12939for thick products and under the following conditions:-

at a mean temperature of (10

0,3) °C;-after conditioning in accordance with 5.2;-taking into account the effect of ageing according to annex C.NOTE

Thermal resistance and thermal conductivity may also be measured at mean temperatures other than 10 °C,providing that the accuracy of the relationship between temperature and thermal properties is well documented.Thermal resistance and thermal conductivity shall be determined directly at measured thickness. In the eventthat this is not possible, they shall be determined by measurements on other thicknesses of the productproviding that:-the product is of similar chemical and physical characteristics and is produced on the same productionline;-and it can be demonstrated in accordance with EN 12939 that the thermal conductivity does not varymore than 2 % over the range of thicknesses where the calculation is applied.5.3.3 Flatness after one-sided wetting - Conditioning procedureThe conditioning procedure referred to in 4.3.7 is as follows:-place the test specimen in a water tank, in such a way that partial immersion is 5 mm;-dispose a load on the test specimen to avoid floatation;-remove the test specimen after 15 min and turn it upside down on a dry support, therefore leaving thewetted side upwards;-allow to dry the test specimen for 30 min at (23 ± 5) °C;

Page 15EN 13165:2001-measure the deviation from flatness in accordance with EN 825.Table 9 - Test methods, test specimens and conditionsDimensions in millimetresClauseNoTitleTestmethodTest specimenlength and width a Minimumnumber ofmeasurementsto get one testresultSpecificconditions4.2.1Thermal resistanceand thermalconductivityprEN 12667 orEN 12939See annex C1See annex C4.2.2Length and widthEN 822Full-size1-4.2.3ThicknessEN 823Full-size1Load =50 Pa4.2.4SquarenessEN 824Full-size1-4.2.5FlatnessEN 825Full-size1-4.2.6Dimensional stabilityunder specifiedtemperature andhumidity conditionsEN 1604200 x 2003-4.2.7Compressive stress orcompressive strengthEN 826d=50: 50 x 50d>50: 100 x 1003-4.2.8Reaction to fireSee prEN 13501-1-4.3.2Deformation underspecified compressiveload and temperatureconditionsEN 1605d

50:

50 x 50d >50:

100 x 1003-4.3.3Tensile strengthperpendicular to facesEN 160750 x 503-4.3.5Compressive creepEN 1606Same as 4.2.72-4.3.6Long term waterabsorptionEN 12087200 x 2002Method 2A4.3.7Flatness after one-sided wettingEN 825Full-size product or1200 x 6001 per sideConditioningas in 5.3.34.3.8Water vapourtransmissionEN 12086See 6.1 in EN 12086:19973-4.3.9Sound absorptionEN ISO 354Minimum 10 m21To be reported4.3.10Release of dangeroussubstancesb---C.5.1Closed cell contentISO 4590100 x 30 x 303Method 2, withcorrectiona Full-size product thickness, except for 4.2.8.b Not yet available.

Page 16EN 13165:20016 Designation codeA designation code for the product shall be given by the manufacturer. The following shall be included exceptwhen there is no requirement for a property described in 4.3:-The rigid polyurethane foam abbreviated termPUR-This European Standard numberEN 13165-Thickness tolerancesTi-Dimensional stability under specified temperature and humidity conditionsDS(TH)i-Behaviour under load and temperatureDLT(i)5-Compressive stress or strengthCS(10\Y)i-Compressive creepCC(i1/i2/y)c-Tensile strength perpendicular to facesTRi-Flatness after one-sided wettingFWi-Long term water absorptionWL(T)i-Water vapour transmissionMUi or Zi-Practical sound absorption coefficientAPi-Weighted sound absorption coefficientAWiwhere "i" shall be used to indicate the relevant class or level, “c” shall be used to indicate the compressive stressand “y” to indicate the number of years.The designation code for a rigid polyurethane foam product is illustrated by the following example:PUR - EN 13165 – T2 –DS(TH)9 –DLT(2)5 – CS(10)100 – CC(3/2/25)40 – TR1 – FW1 – WL(T)2 – MU607 Evaluation of conformityThe manufacturer or his authorised representative shall be responsible for the conformity of his product with therequirements of this European Standard. The evaluation of conformity shall be carried out in accordance with EN13172 and shall be based on factory production control and tests on samples taken at the factory.If a manufacturer decides to group his products it shall be done in accordance with EN 13172.The minimum frequencies of tests in the factory production control shall be in accordance with annex B of thisstandard. When indirect testing is used, the correlation to direct testing shall be established in accordance withEN 13172.NOTE 1

The system of attestation of conformity for the CE marking of the product is chosen in accordance with annex ZAof this standard (see ZA.2.2). For rigid polyurethane foam (PUR) products the footnote * of Table ZA.2.2 applies except whenit can be demonstrated to the notified body for a particular product that no stage in the production process will result in animprovement of the reaction to fire classification (see Table ZA.2.2, footnote **).The manufacturer or his authorised representative shall make available, in response to a request, a certificate ordeclaration of conformity as appropriate.NOTE 2

For the EC certificate and declaration of conformity, as appropriate, see ZA.2.3.

Page 17EN 13165:20018 Marking and labellingProducts conforming with this standard shall be clearly marked, either on the product or on the label or on thepackaging, with the following information:-product name or other identifying characteristic;-name or identifying mark and address of the manufacturer or his authorised representative;-year of manufacture (the last two digits);-shift or time of production and manufacturing plant or traceability code;-reaction to fire class;-declared thermal resistance;-declared thermal conductivity;-nominal thickness;-designation code as given in clause 6;-type of facing, if any;-nominal length, nominal width;-number of pieces and area in the package, as appropriate.NOTE

For CE marking and labelling see ZA.3.

Page 18EN 13165:2001Annex A(normative)Determination of the declared values of thermal conductivity and thermalresistanceA.1IntroductionIt is the responsibility of the manufacturer to determine the declared values of thermal resistance and thermalconductivity. He will have to demonstrate conformity of the product to its declared values. The declared valuesof thermal resistance and thermal conductivity of a product are the expected values of these properties duringan economically reasonable working life under normal conditions, assessed through measured data atreference conditions.A.2 Input dataThe manufacturer shall have at least ten test results for thermal resistance or thermal conductivity, obtainedfrom internal or external direct measurements in order to calculate the declared values. The direct thermalresistance or thermal conductivity measurements shall be carried out at regular intervals spread over a period ofthe last twelve months. If less than ten test results are available that period may be extended until ten testresults are obtained, but with a maximum period of three years, within which the product and productionconditions have not changed significantly.For new products the ten thermal resistance or thermal conductivity tests shall be carried out spread over aminimum period of ten days.The declared value shall be calculated according to the method given in A.3 and shall be recalculated atintervals not exceeding three months of production.A.3 Declared valuesThe derivation of the declared values, RD and D, from the calculated values, R90/90 and 90/90, shall use the rulesgiven in 4.2.1, which include the rounding conditions.A.3.1 Case where thermal resistance and thermal conductivity are declaredThe declared values, RD and D, shall be derived from the calculated values, R90/90 and 90/90, which aredetermined using equations A.1, A.2 and A.3.90/90 = mean + k

s(A.1)sniin()mean211(A.2)R90/90 = dN / 90/90(A.3)A.3.2 Case where thermal resistance alone is declaredThe declared value, RD, shall be derived from the calculated value, R90/90, which is determined using theequations A.4 and A.5.R90/90 = Rmean - k

sR(A.4)

Page 19EN 13165:2001SRRnRiin()mean211(A.5)Table A.1 - Values for k for one sided 90 % tolerance interval with a confidence level of 90 %Number of test resultsk102,07112,01121,97131,93141,90151,87161,84171,82181,80191,78201,77221,74241,71251,70301,66351,62401,60451,58501,561001,473001,395001,3620001,32For other numbers of test results use ISO 12491 or linearinterpolation

Page 20EN 13165:2001Annex B(normative)Factory production controlTable B.1 - Minimum product testing frequenciesClauseMinimum testing frequency aNoTitle4.2.1Thermal resistance

and thermal conductivity1 per 24 h b4.2.2Length and width1 per 2 h4.2.3Thickness1 per 2 h4.2.4Squareness1 per 8 h4.2.5Flatness1 per 8 h4.2.6Dimensional stability under specified tempera-ture and humidity conditionsITTc4.2.7Compressive stress or compressive strength1 per 24 h4.2.8Reaction to fireSee Table B.24.3.2Deformation under specified compressive loadand temperature conditionsITTc4.3.3Tensile strength perpendicular to facesITTc4.3.5Compressive creepITTc4.3.6Long term water absorptionITTc4.3.7Flatness after one-sided wettingITTc4.3.8Water vapour transmissionITTc4.3.9Sound absorptionITTc4.3.10Release of dangerous substances dAccelerated aged value of thermal conductivity inaccordance with C.4.2Acceleration test in accordance with

C.4.41 per 2 yearsDiffusion tightness of facing

in accordance withC.5.1ITTcClosed cell content in accordance with C.5.1 eAnnex CNormality test acc. in accordance with C.5.21 per 2 yearsaThe minimum testing frequencies, expressed in test results, shall be understood as the minimum foreach production line under stable conditions. In addition to the testing frequencies given above,testing of relevant properties of the product shall be repeated when changes or modifications aremade that are likely to affect the conformity of the product.For mechanical properties, the testing frequencies given are independent of the change of product.In addition the manufacturer shall establish internal rules for process adjustments related to theseproperties when changing the product.bInitial values only.cITT, see EN 13172.dFrequencies are not given, as test methods are not yet available.eOnly for CO2 blown products and if the "fixed increment procedure" is applied.

Page 21EN 13165:2001Table B.2 - Minimum product testing frequencies for the reaction to fire characteristicsClauseMinimum testing frequency aNoTitleDirect testing bIndirect testing c,d4.2.8Reaction tofire classProductComponents fPUR rigid foamFacingsTest methodFrequencyTest methodFrequencyTest methodFrequencyTest methodFrequencyA1 withouttesting eprEN 138201 per 3 months g or------1 per 2 years andindirect testing--check of rawmaterial formulationand density1 per daymanufacturer’s method1 per weekA1prEN ISO 1182andprEN ISO 1716(and prEN13823)1 per 2 years andindirect testing--check of rawmaterial formulationand density1 per daymanufacturer’s method1 per weekA2prEN ISO 1182orprEN ISO 1716and prEN138231 per 2 years andindirect testing--check of rawmaterial formulationand density1 per daymanufacturer’s method1 per weekBCprEN 138231 per 2 years andindirect testingSpecificcharacteristic fromprEN ISO 11925-21 per weekcheck of rawmaterial formulationand density1 per daymanufacturer’s method1 per weekDandprEN ISO11925-21 per week or 1 per 2years and indirecttesting--check of rawmaterial formulationand density1 per daymanufacturer’s method1 per weekEprEN ISO11925-21 per week or 1 per 2years and indirecttesting--check of rawmaterial formulationand density1 per daymanufacturer’s method1 per weekF--------

Page 22EN 13165:2001Table B.2 (continued) – Minimum product testing frequencies for the reaction to fire characteristicsaThe minimum testing frequencies, expressed in test results, shall be understood as the minimum for a product or product group for each production line under stableconditions. In addition to the testing frequencies given above, testing of relevant properties of the product shall be repeated when changes or modifications are made that arelikely to affect the conformity of the product.bDirect testing may be conducted either by third party or by the manufacturer.cIndirect testing may be either on the product or on its components.dIndirect testing is only possible in the case of products falling within the system 1 for attestation of conformity of reaction to fire or by having a notified body verifying thecorrelation to the direct testing.eEuropean Decision 96/603EC: Materials to be considered as reaction to fire class A provided for in Decision 94/611/EC without the need for testing (of reaction to firecharacteristics).fIn case of certified components no testing is required.gOnly for unfaced products.NOTE

Not all Euroclasses may apply for the products conforming to this standard

Page 23EN 13165:2001Annex C(normative)Determination of the aged values of thermal resistance and thermalconductivityC.1GeneralThis annex describes methods which are used to take account of the ageing effect, which when it occurs is dueto changes in the cell gas composition with time. These methods give a prediction of the ‘time averaged’ aged valueover 25 years.The determination of the aged value shall be made either by the direct measurement method (acceleratedageing procedure, C.4) or by a combination of the normality test and the calculation method (fixed incrementprocedure, C.5). For both methods the sampling and test specimen preparation procedure shall be as describedin C.2.NOTE

See Figure C.1 for a flow chart of the alternative ageing procedures.The ageing methods are valid for closed cell PUR products produced by using high molecular weight blowingagents such as hydro chlorofluorocarbons (e.g. HCFC 141b), hydro fluorocarbons(e.g. HFC 134a) and hydrocarbons (e.g. pentanes), which substantially stay in the products for time periods wellin excess of those required for an economically reasonable life. These blowing agents are therefore called‘permanent‘. They can be used mixed together with carbon dioxide (CO2). CO2 is a ‘non-permanent‘ blowingagent, which may readily diffuse out of the product. Ageing of the thermal properties of PUR products istherefore predominantly caused by the inward diffusion of air into the product and outward diffusion of CO2, ifdiffusion tight facings do not prevent both.PUR products blown only with CO2 are also covered by these ageing methods.If new blowing agents are shown to be ‘permanent types‘ (meaning having diffusion coefficients similar to theestablished values for pentane, hydro chlorofluorocarbons and hydro fluorocar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...