EN 334:2005

(Main)Gas pressure regulators for inlet pressures up to 100 bar

Gas pressure regulators for inlet pressures up to 100 bar

This document specifies constructional and functional requirements, regulator sizing, testing, documentation and marking of gas pressure regulators used in the pressure regulating stations:

- for inlet pressures up to 100 bar and nominal diameters up to DN 400;

- for an operating temperature range from 20 °C to +60 °C,

which operate with fuel gases of the 1st and 2nd family in accordance with EN 437 in transmission and distribution networks and also in commercial and industrial installations.

"Gas pressure regulators" hereafter will be called "regulators" except in the titles.

The harmonised part of this document deals with standard gas pressure regulators used in pressure regulating stations complying with EN 12186 or EN 12279. For gas pressure regulators integral strength type when used in pressure regulating stations complying with EN 12186 or EN 12279, Annex ZA lists all applicable Essential Requirements except the external resistance to environmental conditions where corrosion occurs.

This document considers the following classes of regulators:

- class 1: operating temperature range from 10 °C to 60 °C;

- class 2: operating temperature range from 20 °C to 60 °C.

This document applies to regulators which use the pipeline gas as a source of control energy unassisted by any external power source.

The regulator may incorporate a creep (venting) relief device, complying with the requirements in Annex F.

The regulators complying with the requirements of this document may be declared as "in compliance with EN 334" and bear the mark "EN 334".

This document does not apply to:

- regulators upstream from/on/in domestic gas consuming appliances which are installed downstream of domestic gas meters;

- regulators in accordance with prEN xxxxxx (WI 00235003 under preparation by CEN/TC 235) that comply with both of the following characteristics:

- volumetric flow rate £ 200 m3/h at normal conditions;

- inlet pressure £ 5 bar;

- regulators for which a specif

Gas-Druckregelgeräte für Eingangsdrücke bis 100 bar

Diese europäische Norm legt Bauanforderungen, Funktionsanforderungen, Dimensionierung, Prüfung, Dokumentation und Kennzeichnung von Gas-Druckregelgeräten, die in den Druckregelanlagen nach EN 12186 und EN 12279 verwendet werden, fest für:

- Eingangsdrücke bis 100 bar und Nennweiten bis DN 400,

- Betriebstemperaturen von -20 °C bis +60 °C,

soweit sie mit Brenngasen der 1. und 2. Familie nach EN 437 (außer Gase der 3. Familie in der Flüssigphase) in Gasversorgungsnetzen wie auch in gewerblichen und industriellen Anlagen betrieben werden.

"Gas-Druckregelgeräte" wird im Weiteren, außer in Überschriften, mit "Regelgeräte" abgekürzt.

Der harmonisierte Teil dieser Europäischen Norm gilt für Gas-Druckregelgeräte mit einheitlichem Festigkeitsbereich, die in den Druckregelanlagen in Übereinstimmung mit den jeweils zutreffenden EN 12186 oder EN 12279 verwendet werden. Die Tabelle ZA.1 des informativen Anhanges ZA schließt alle relevanten grundlegenden Anforderungen nach Anhang 1 der DGR ein, mit Ausnahme der Beständigkeit gegen Umwelteinflüsse im Korrosionsfall.

Diese Europäische Norm behandelt die folgenden Klassen von Regelgeräten:

Temperaturklassen:

- Klasse 1: Betriebstemperaturbereich von -10 °C bis 60 °C,

- Klasse 2: Betriebstemperaturbereich von -20 °C bis 60 °C.

Diese Europäische Norm gilt für Regelgeräte, deren Energie für die Regelung ohne Unterstützung externer Energiequellen dem fortgeleiteten Gas entnommen wird.

Wenn ein Regelgerät mit einer integrierten Abblaseinrichtung für Leckgas ausgerüstet ist, muss es die Anforderungen von Anhang F erfüllen.

Regelgeräte, die den Anforderungen dieser Europäischen Norm entsprechen, dürfen als "in Übereinstimmung mit EN 334" deklariert und mit der Kennzeichnung "EN 334" versehen werden.

Diese Europäische Norm gilt nicht für:

- Regelgeräte vor/an/in Gasgeräten des Haushalts, die hinter Haushaltgaszählern installiert sind,

- Regelgeräte in Übereinstimmung mit prEN xxxxxx (WI 00235003 in Vorbereitung beim CEN/T

Appareils de régulation de pression de gaz (régulateurs) pour des pressions amont jusqu'à 100 bar

Le présent document spécifie les exigences relatives à la construction et au fonctionnement, au dimensionnement, aux essais, à la documentation et au marquage des appareils de régulation de pression de gaz (régulateurs) utilisés avec les postes de détente-régulation de pression :

- pour les pressions amont jusqu'à 100 bar et les diamètres nominaux jusqu'à DN 400 ;

- pour une plage de température ambiante de 20 °C à +60 °C ;

qui sont exploités avec des gaz combustibles de la première et de la deuxième famille conformément à l'EN 437 dans les réseaux de transport et de distribution ainsi que dans les installations commerciales et industrielles.

Dans la suite du présent document, les "appareils de régulation de pression de gaz" sont désignés par le terme "régulateurs", à l'exception des titres.

La partie harmonisée du présent document traite des appareils de régulation de pression de gaz standard utilisés avec les postes de détente-régulation de pression conformes à l'EN 12186 ou à l'EN 12279. Pour les appareils de régulation de pression de gaz à résistance intégrale utilisés avec les postes de détente régulation de pression conformes à l'EN 12186 ou à l'EN 12279, l'Annexe ZA énumère toutes les exigences essentielles applicables, à l'exception de la résistance externe aux conditions environnementales en cas de corrosion.

Le présent document traite des classes suivantes de régulateurs :

- classe 1 : plage de température de service comprise entre 10 °C et 60 °C ;

- classe 2 : plage de température de service comprise entre 20 °C et 60 °C.

Le présent document s'applique aux régulateurs qui utilisent comme source d'énergie de commande le gaz prélevé dans les canalisations sans l'assistance d'aucune source extérieure d'alimentation que ce soit.

Le régulateur peut comporter une soupape à débit partiel conforme aux prescriptions de l'Annexe F.

Regulatorji tlaka plina za vstopne tlake do 100 bar

General Information

- Status

- Withdrawn

- Publication Date

- 01-Mar-2005

- Withdrawal Date

- 20-Jan-2009

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 21-Jan-2009

- Completion Date

- 21-Jan-2009

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 334:2005 is a standard published by the European Committee for Standardization (CEN). Its full title is "Gas pressure regulators for inlet pressures up to 100 bar". This standard covers: This document specifies constructional and functional requirements, regulator sizing, testing, documentation and marking of gas pressure regulators used in the pressure regulating stations: - for inlet pressures up to 100 bar and nominal diameters up to DN 400; - for an operating temperature range from 20 °C to +60 °C, which operate with fuel gases of the 1st and 2nd family in accordance with EN 437 in transmission and distribution networks and also in commercial and industrial installations. "Gas pressure regulators" hereafter will be called "regulators" except in the titles. The harmonised part of this document deals with standard gas pressure regulators used in pressure regulating stations complying with EN 12186 or EN 12279. For gas pressure regulators integral strength type when used in pressure regulating stations complying with EN 12186 or EN 12279, Annex ZA lists all applicable Essential Requirements except the external resistance to environmental conditions where corrosion occurs. This document considers the following classes of regulators: - class 1: operating temperature range from 10 °C to 60 °C; - class 2: operating temperature range from 20 °C to 60 °C. This document applies to regulators which use the pipeline gas as a source of control energy unassisted by any external power source. The regulator may incorporate a creep (venting) relief device, complying with the requirements in Annex F. The regulators complying with the requirements of this document may be declared as "in compliance with EN 334" and bear the mark "EN 334". This document does not apply to: - regulators upstream from/on/in domestic gas consuming appliances which are installed downstream of domestic gas meters; - regulators in accordance with prEN xxxxxx (WI 00235003 under preparation by CEN/TC 235) that comply with both of the following characteristics: - volumetric flow rate £ 200 m3/h at normal conditions; - inlet pressure £ 5 bar; - regulators for which a specif

This document specifies constructional and functional requirements, regulator sizing, testing, documentation and marking of gas pressure regulators used in the pressure regulating stations: - for inlet pressures up to 100 bar and nominal diameters up to DN 400; - for an operating temperature range from 20 °C to +60 °C, which operate with fuel gases of the 1st and 2nd family in accordance with EN 437 in transmission and distribution networks and also in commercial and industrial installations. "Gas pressure regulators" hereafter will be called "regulators" except in the titles. The harmonised part of this document deals with standard gas pressure regulators used in pressure regulating stations complying with EN 12186 or EN 12279. For gas pressure regulators integral strength type when used in pressure regulating stations complying with EN 12186 or EN 12279, Annex ZA lists all applicable Essential Requirements except the external resistance to environmental conditions where corrosion occurs. This document considers the following classes of regulators: - class 1: operating temperature range from 10 °C to 60 °C; - class 2: operating temperature range from 20 °C to 60 °C. This document applies to regulators which use the pipeline gas as a source of control energy unassisted by any external power source. The regulator may incorporate a creep (venting) relief device, complying with the requirements in Annex F. The regulators complying with the requirements of this document may be declared as "in compliance with EN 334" and bear the mark "EN 334". This document does not apply to: - regulators upstream from/on/in domestic gas consuming appliances which are installed downstream of domestic gas meters; - regulators in accordance with prEN xxxxxx (WI 00235003 under preparation by CEN/TC 235) that comply with both of the following characteristics: - volumetric flow rate £ 200 m3/h at normal conditions; - inlet pressure £ 5 bar; - regulators for which a specif

EN 334:2005 is classified under the following ICS (International Classification for Standards) categories: 23.060.40 - Pressure regulators. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 334:2005 has the following relationships with other standards: It is inter standard links to EN 334:1999/A1:2000, EN 334:1999, EN 334:2005+A1:2009, EN 746-2:2010, EN 15001-1:2009, EN 14382:2005+A1:2009, EN 334:2005/prA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 334:2005 is associated with the following European legislation: EU Directives/Regulations: 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 334:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Gas pressure regulators for inlet pressures up to 100 barRegulatorji tlaka plina za vstopne tlake do 100 barAppareils de régulation de pression de gaz (régulateurs) pour des pressions amont jusqu'a 100 barGas-Druckregelgeräte für Eingangsdrücke bis 100 barTa slovenski standard je istoveten z:EN 334:2005SIST EN 334:2005en,fr,de23.060.40ICS:SIST EN 334:2000/A1:2003SIST EN 334:20001DGRPHãþDSLOVENSKI

STANDARDSIST EN 334:200501-junij-2005

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 334

March 2005 ICS 23.060.40 Supersedes EN 334:1999 English version

Gas pressure regulators for inlet pressures up to 100 bar

Appareils de régulation de pression de gaz (régulateurs) pour des pressions amont jusqu'à 100 bar

Gas-Druckregelgeräte für Eingangsdrücke bis 100 bar This European Standard was approved by CEN on 23 December 2004.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the Central Secretariat or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2005 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 334:2005: E

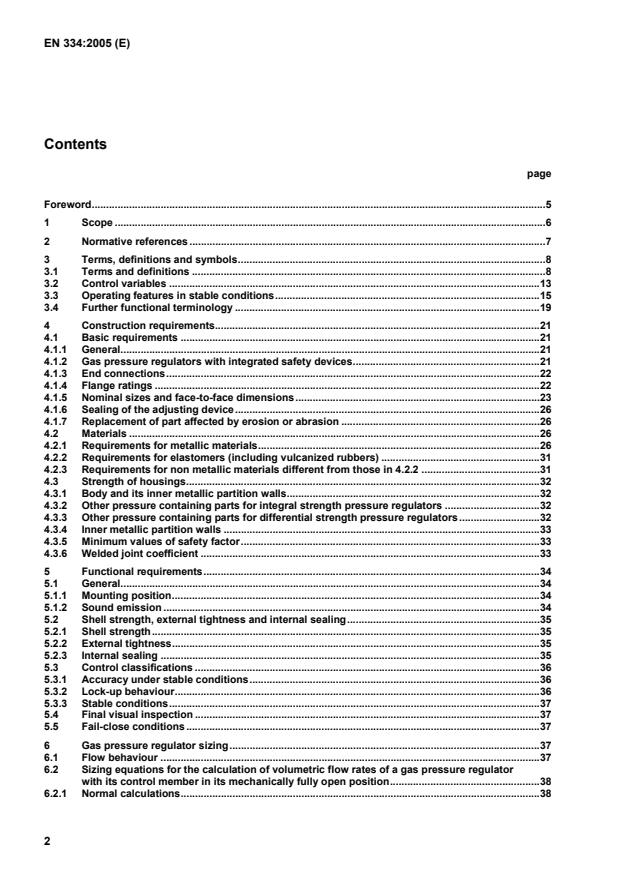

Alternative methods for the determination of the accuracy class, the lock-up pressure class, the maximum accuracy flow rate, the flow coefficients and the verification of the hysteresis band.62 A.1 General.62 A.2 Test methods.62 A.2.1 Direct acting gas pressure regulator.62 A.2.2 Pilot controlled gas pressure regulators.63 A.3 Determination of flow coefficients for larger capacity regulators.64 Annex B (informative)

Inspection certificate.70 Annex C (informative)

Acceptance test.72 Annex D (informative)

Compliance evaluation).73 D.1 General.73 D.2 Introduction.73 D.3 Procedure.73 D.4 Manufacturer’s compliance evaluation.74 D.5 Issue of the certificate of compliance.74 Annex E (informative)

Seat leakage.75 Annex F (normative)

Creep (venting) relief device.76 F.1 General.76

Order specification.78 G.1 General.78 G.2 Minimum specifications.78 G.2.1 Details of construction.78 G.2.2 Dimensions.78 G.2.3 Performance.78 G.3 Optional specifications.79 Annex H (normative)

Materials.80 H.1 Steel materials for pressure containing parts and inner metallic partition walls.80 H.2 Metallic materials different from steel materials for pressure containing parts and inner metallic partition walls.86 H.3 Materials for fixtures, integral process and sensing lines, connectors and fasteners.91 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 97/23/EC.94 Bibliography.95

Key 1 Setting element 6 Sensing line 2 Detector element 7 Regulator body 3 Breather/exhaust line 8 Valve seats 4 Actuator 9 Seat ring 5 Casing of actuator 10 Control member 1 + 2 = Controller Figure 1 — Example of a direct acting regulator 3.1.1.2 pilot controlled gas pressure regulator (indirect acting) regulator in which the net force required to move the control member is supplied by a pilot (see example in Figure 2)

Key 1 Fixture 6 Regulator body 2 Pilot 7 Valve seats 3 Actuator 8 Seat ring 4 Casing of actuator 9 Control member 5 Sensing/process line 10 Motorization chamber Figure 2 — Example of a pilot controlled regulator 3.1.1.3 monitor second regulator normally installed in series with an active regulator which has the task of maintaining the controlled variable within allowable limits in the event of its value exceeds a pre-established value (e.g. in the event of opening of the active regulator due to a failure, etc.) 3.1.1.4 series of regulators regulators with the same design concept but differing only in size 3.1.1.5 fail open regulator regulator whose control member automatically tends to open when the main diaphragm fails or when the energy required to move the control member fails NOTE The definition in this clause is based on typical control failure modes. 3.1.1.6 fail close regulator regulator whose control member automatically tends to close when the main diaphragm fails or when the energy required to move the control member fails NOTE The definition in this clause is based on typical control failure modes. 3.1.1.7 integral strength regulator regulator in which the pressure containing parts have a design pressure equal to the maximum allowable pressure PS

nominal inlet diameter nominal size DN of the inlet connection in accordance with EN ISO 6708 3.1.1.10 nominal outlet diameter nominal size DN of the outlet connection in accordance with EN ISO 6708 3.1.2 main components parts including normally: control member, regulator body, actuator, casing of actuator, controller, pilot (only in pilot controlled regulators) NOTE The regulator might include additional devices such as a shut-off device, a monitor, a relief valve and other fixtures. The Figures 1 and 2 serve as examples. 3.1.2.1 control member movable part of the regulator which is positioned in the flow path to restrict the flow through the regulator NOTE A control member may be a plug, ball, disk, vane, gate, diaphragm, etc. 3.1.2.2 body main pressure containing envelope which provides the fluid flow passageway and the pipe end connections 3.1.2.3 valve seats corresponding sealing surfaces within a regulator which make full contact only when the control member is in the closed position 3.1.2.4 seat ring part assembled in a component of the regulator to provide a replaceable seat 3.1.2.5 actuator device or mechanism which changes the signal from the controller into a corresponding movement controlling the position of the control member 3.1.2.6 casing of actuator housing of the actuator (which may consist of two chambers under pressure) NOTE When the pressure in each chamber is different from atmospheric pressure, the chamber at the higher pressure is termed the "motorization chamber". 3.1.2.7 controller device which normally includes: a setting element, normally a spring, to obtain the set value of the controlled variable;

3.2 Control variables 3.2.1 Reference values 3.2.1.1

pressure all pressures specified in this document are static gauge pressures NOTE Pressure is expressed in bar1). 3.2.1.1.1 inlet pressure pu gas pressure at the inlet of the regulator 3.2.1.1.2 outlet pressure pd gas pressure at the outlet of the regulator 3.2.1.1.3 differential pressure ∆p difference between two values of pressure at two different points 3.2.1.1.4 motorization pressure pm gas pressure in the motorization chamber 3.2.1.1.5 pilot feeding pressure pup gas pressure at the inlet of the pilot 3.2.1.2 Flow conditions 3.2.1.2.1 normal conditions absolute pressure pn of 1,013 bar and temperature Tn of 0 °C (273,15 K) NOTE For calculation purposes a value of 273 K is used in this document. 3.2.1.2.2 gas volume volume of gas at normal conditions NOTE Gas volume is expressed in m3.

1) 1 bar = 1 000 mbar = 105 N/m2 = 105 Pa = 10-1 MPa.

Key 1 Max hysteresis band 2 Hysteresis band

Start setting

Measured values Figure 3 — Performance curve (pds constant, pu constant)

Figure 4 — Family of performance curves (pds constant) 3.3.4 family of performance curves set of the performance curves for each value of inlet pressure determined for a given set point (see Figure 4)

3.3.5 Features pertinent to accuracy 3.3.5.1 accuracy average, expressed as a percentage of the set point, of the absolute maximum values of the positive and negative control deviation within the operating range 3.3.5.2 accuracy class AC maximum permissible value of the accuracy 3.3.5.3 inlet pressure range bpu range of the inlet pressure for which the regulator ensures a given accuracy class NOTE The inlet pressure range is characterized by its limit values pumax and pumin. 3.3.5.4 maximum accuracy flow rate lowest value of the maximum volumetric flow rate up to which, for a given set point and within the ambient temperature range specified, a given accuracy class is ensured: at the lowest inlet pressure (see Figure 5) Qmax,pumin; at the highest inlet pressure (see Figure 5) Qmax,pumax; at an intermediate inlet pressure between pumax and pumin (see Figure 5) Qmax,pu 3.3.6 Features pertinent to lock-up behaviour 3.3.6.1 lock-up time tf time taken for the control member to move from an open position to the closed position

= Qmax with the control member at the limit imposed by the mechanical stop Figure 5 — Family of performance curves indicating maximum accuracy flow rates and minimum flow rates (pds constant, stable conditions) 3.3.6.2 lock-up pressure pf pressure that occurs at the measuring point of the controlled variable when the control member is in the closed position NOTE The lock-up pressure corresponds to the outlet pressure at the volumetric flow rate Q = 0 in the performance curve (see Figure 3). It results when the time taken for a change in volumetric flow rate from Q to zero is greater than the lock- up time of the regulator. 3.3.6.3 lock-up pressure class SG maximum permissible positive difference between the actual lock-up pressure and the set point expressed as a percentage of the set point e.g. 100

-

=SG dsdsf×PPP (1) 3.3.6.4 minimum flow rate largest value of the minimum volumetric flow rate down to which, for a given set point and within the ambient temperature range specified, stable conditions as per 5.3.3 are obtained: at the lowest inlet pressure (see Figure 5) Qmin,pumin; at the highest inlet pressure (see Figure 5) Qmin,pumax; at an intermediate inlet pressure between pumax and pumin (see Figure 5) Qmin,pu

= SZpumax,pumin,×QQ (2)

Key 1 Lock-up pressure zone Figure 6 — Performance curve indicating lock-up pressure zone (stable condition) 3.4 Further functional terminology 3.4.1 Pressures pertinent to design of gas pressure regulator 3.4.1.1 component operating pressure p gas pressure occurring in any part of a regulator during operation

3.4.1.2 maximum component operating pressure pmax highest operating pressure at which a component of a regulator will continuously operate within specified conditions 3.4.1.3 maximum allowable pressure PS maximum pressure for which the body and its inner metallic partition walls are designed in accordance with the strength requirements in this document 3.4.1.4 test pressure pressure applied to a section of the regulator for a limited period of time in order to prove certain characteristics 3.4.1.5 limit pressure pl pressure at which yielding becomes apparent in any component of the regulator or its fixtures 3.4.1.6 safety factor ratio of the limit pressure pl to the maximum allowable pressure PS applied to: the regulator body: Sb; the other pressure containing parts of the regulator: S 3.4.1.7 maximum inlet pressure pumax highest inlet pressure at which the regulator can continuously operate within specified conditions 3.4.1.8 permissible outlet pressure pdmax highest outlet pressure at which the regulator can continuously operate within specified conditions 3.4.1.9 minimum operating differential pressure ∆pmin minimum operating differential pressure between the inlet and outlet pressures below which the regulator will no longer function correctly within specified conditions 3.4.2 nominal pressure numerical designation relating to pressure, which is a convenient round number for reference purposes in accordance with the relevant parts of ISO 7005 (some parts of these documents can be replaced by the equivalent documents when they are available. At the time of writing, this subject is dealt with in EN 1092-1, EN 1092-2, EN 1092-3, EN 1092-4, EN 1759-3, EN 1759-4 and EN 1759-1) NOTE 1 For the specific purpose of this document this term applies to flanges.

o-rings, gaskets, etc.). Jointing

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...