prEN 17149

(Main)Railway Applications - Fatigue strength assessment of railway vehicle structures based on cumulative damage

Railway Applications - Fatigue strength assessment of railway vehicle structures based on cumulative damage

The purpose of this European standard is to specify the procedure for fatigue strength assessment of railway vehicle structures based on cumulative damage.

This document is applicable to all rail vehicle structures, which are covered by EN 12663 series (car body) and EN 13749 (bogie frame).

It considers materials used for design of car bodies and bogie frames (steel, aluminum, castings and forgings) and the manufacturing according to the standards valid for railway applications.

Note As a manufacturing standard, EN 15085 series covers the welding of rail vehicle structures.

It is applicable for variable amplitude load data with total number of cycles higher than 10000 cycles.

This document is not applicable for:

- Corrosive conditions or

- Elevated temperature operation in the creep range.

A static strength assessment is outside the scope of this European Standard.

Bahnanwendungen - Betriebsfestigkeitsnachweis von Schienenfahrzeugstrukturen

Der Zweck dieser Europäischen Norm ist, ein Verfahren zum Nachweis der Ermüdungsfestigkeitsnachweis als Betriebsfestigkeitsnachweis für Schienenfahrzeug-Strukturen festzulegen.

Dieses Dokument ist für alle Schienenfahrzeug-Strukturen anwendbar, die durch die Reihe EN 12663 (Wagenkasten) und EN 13749 (Drehgestellrahmen) abgedeckt sind.

Es berücksichtigt Werkstoffe für die Konstruktion der Wagenkästen und Drehgestellrahmen (Stahl, Aluminium, Guss- und Schmiedeteile) sowie die Fertigung nach für Schienenfahrzeuganwendungen gültigen Normen.

ANMERKUNG Als Fertigungsnorm deckt die Reihe EN 15085 das Schweißen von Schienenfahrzeug-Strukturen ab.

Sie ist für Daten variabler Belastungsamplituden mit einer Gesamtzahl von mehr als 10 000 Spannungszyklen anwendbar.

Dieses Dokument ist nicht anwendbar für:

Korrosive Bedingungen oder

Betrieb bei erhöhten Temperaturen im Kriechbereich.

Ein statischer Festigkeitsnachweis liegt außerhalb des Anwendungsbereichs dieser Europäischen Norm.

Applications ferroviaires - Évaluation de la résistance à la fatigue des structures de véhicule ferroviaire basée sur la méthode des dommages cumulés

La présente Norme européenne vise à spécifier le mode opératoire à appliquer pour la détermination de la limite de fatigue des structures de véhicules ferroviaires sur la base des dommages cumulés.

Le présent document s'applique à toutes les structures de véhicules ferroviaires couvertes par la série EN 12663 (structures de véhicules) et l'EN 13749 (châssis de bogie).

Il traite des matériaux utilisés lors de la conception des structures de véhicules et des châssis de bogie (acier, aluminium, pièces moulées et forgées) et de la fabrication selon les normes en vigueur pour les applications ferroviaires.

NOTE La série EN 15085, qui traite du soudage des structures de véhicules ferroviaires, est un exemple de norme de fabrication.

Le présent document est applicable pour des données de charge à amplitude variable avec un nombre total de cycles supérieur à 10 000 cycles.

Le présent document n'est pas applicable dans les cas suivants :

conditions corrosives ; ou

exploitation à une température élevée dans la plage de fluage.

L'évaluation de la résistance statique ne relève pas du domaine d'application de la présente Norme européenne.

Železniške naprave - Ocenjevanje odpornosti proti utrujenosti konstrukcije železniških vozil na podlagi kumulativnega poškodovanja

General Information

- Status

- Not Published

- Publication Date

- 10-Apr-2019

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/WG 2 - Structural requirements

- Current Stage

- 4098 - Decision to abandon - Enquiry

- Start Date

- 03-Apr-2019

- Completion Date

- 09-Feb-2026

Overview

The CEN draft standard prEN 17149:2017 addresses the fatigue strength assessment of railway vehicle structures based on cumulative damage. It specifies procedures essential for evaluating the durability of key rail vehicle components subjected to variable amplitude loading over time. This standard applies to rail vehicle structures covered by existing EN 12663 series for car bodies and EN 13749 for bogie frames. Materials within scope include steel, aluminum, castings, and forgings designed and manufactured according to recognized railway standards.

This standard complements manufacturing requirements such as those in the EN 15085 series-focusing on welding processes-and is tailored for scenarios involving more than 10,000 fatigue cycles under variable amplitude loads. It explicitly excludes conditions involving corrosive environments or elevated temperatures leading to creep. Notably, prEN 17149 does not cover static strength assessments.

Key Topics

Fatigue Strength Assessment

Emphasizes evaluation using a cumulative damage approach, accounting for varying stress amplitudes and cycle counts rather than relying solely on peak stress endurance limits. This approach helps capture realistic usage patterns in rail vehicle operations.Stress Determination Methods

Covers nominal, structural, and notch stress assessments, including specialized guidelines for welded and non-welded structures. It identifies specific locations and methods for measuring fatigue-relevant stresses on vehicle components.Material Considerations

Details fatigue properties related to steel and aluminum alloys, including castings and forgings. It integrates material mechanical characteristics, surface quality factors, and fatigue resistance curves (S-N curves) into the assessment process.Load Spectra and Damage Calculation

Provides methodologies for processing variable amplitude load data, stress cycle counting, mean stress corrections, and cumulative damage summation. Partial safety factors are introduced to cover uncertainties in load spectra, fatigue strength, inspection regimes, and validation.Fatigue Strength Factors and Enhancements

Addresses factors affecting fatigue strength like thickness effects, bending influences, and improvements from post-weld treatments or non-destructive testing (NDT) during manufacturing.Assessment Procedure

A stepwise process is defined-from stress analysis and data conditioning to damage summation and fatigue strength evaluation-aligned with European railway regulatory frameworks.

Applications

Rail Vehicle Design and Certification

Enables engineers and manufacturers to verify that car body and bogie frame structures meet fatigue durability targets, ensuring safety and reliability over operational lifetimes.Maintenance and Inspection Planning

Fatigue assessment results inform maintenance schedules, inspection intervals, and preventive repairs, optimizing lifecycle management of rolling stock.Material Selection and Welding Process Optimization

Assists in selecting materials and welding techniques that improve fatigue resistance, supporting compliance with manufacturing standards like EN 15085.Risk Management under Variable Loads

Supports comprehensive railway fatigue management by evaluating complex load histories rather than simplistic peak load checks, leading to more accurate fatigue life predictions.

Related Standards

- EN 12663 Series – Structural requirements for railway vehicle bodies

- EN 13749 – Design of bogie frames

- EN 15085 Series – Welding of railway vehicles and components

- BS 7608:2014+A1:2015 – Guidelines for fatigue design and assessment of steel products

- EN 1706:2010 – Aluminium and aluminium alloys castings

These standards provide essential context and complementary technical rules for the design, manufacturing, and fatigue analysis processes related to railway vehicle structural components.

Keywords: fatigue strength assessment, railway vehicle structures, cumulative damage, variable amplitude loading, car body fatigue, bogie frame fatigue, steel and aluminum fatigue, S-N curves, welding fatigue, EN 17149, prEN 17149, railway rolling stock durability, fatigue load spectra, structural fatigue evaluation.

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

prEN 17149 is a draft published by the European Committee for Standardization (CEN). Its full title is "Railway Applications - Fatigue strength assessment of railway vehicle structures based on cumulative damage". This standard covers: The purpose of this European standard is to specify the procedure for fatigue strength assessment of railway vehicle structures based on cumulative damage. This document is applicable to all rail vehicle structures, which are covered by EN 12663 series (car body) and EN 13749 (bogie frame). It considers materials used for design of car bodies and bogie frames (steel, aluminum, castings and forgings) and the manufacturing according to the standards valid for railway applications. Note As a manufacturing standard, EN 15085 series covers the welding of rail vehicle structures. It is applicable for variable amplitude load data with total number of cycles higher than 10000 cycles. This document is not applicable for: - Corrosive conditions or - Elevated temperature operation in the creep range. A static strength assessment is outside the scope of this European Standard.

The purpose of this European standard is to specify the procedure for fatigue strength assessment of railway vehicle structures based on cumulative damage. This document is applicable to all rail vehicle structures, which are covered by EN 12663 series (car body) and EN 13749 (bogie frame). It considers materials used for design of car bodies and bogie frames (steel, aluminum, castings and forgings) and the manufacturing according to the standards valid for railway applications. Note As a manufacturing standard, EN 15085 series covers the welding of rail vehicle structures. It is applicable for variable amplitude load data with total number of cycles higher than 10000 cycles. This document is not applicable for: - Corrosive conditions or - Elevated temperature operation in the creep range. A static strength assessment is outside the scope of this European Standard.

prEN 17149 is classified under the following ICS (International Classification for Standards) categories: 45.060.20 - Trailing stock. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 17149 is associated with the following European legislation: EU Directives/Regulations: 2008/57/EC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

prEN 17149 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2017

Železniške naprave - Ocenjevanje odpornosti proti utrujenosti konstrukcije

železniških vozil na podlagi kumulativnega poškodovanja

Railway Applications - Fatigue strength assessment of railway vehicle structures based

on cumulative damage

Bahnanwendungen - Betriebsfestigkeitsnachweis von Schienenfahrzeugstrukturen

Applications ferroviaires - Évaluation de la résistance à la fatigue des structures de

véhicule ferroviaire basée sur la méthode des dommages cumulés

Ta slovenski standard je istoveten z: prEN 17149

ICS:

45.060.01 Železniška vozila na splošno Railway rolling stock in

general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

September 2017

ICS 45.060.20

English Version

Railway Applications - Fatigue strength assessment of

railway vehicle structures based on cumulative damage

Applications ferroviaires - Évaluation de la résistance à Bahnanwendungen - Betriebsfestigkeitsnachweis von

la fatigue des structures de véhicule ferroviaire basée Schienenfahrzeugstrukturen

sur la méthode des dommages cumulés

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 256.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2017 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 17149:2017 E

worldwide for CEN national Members.

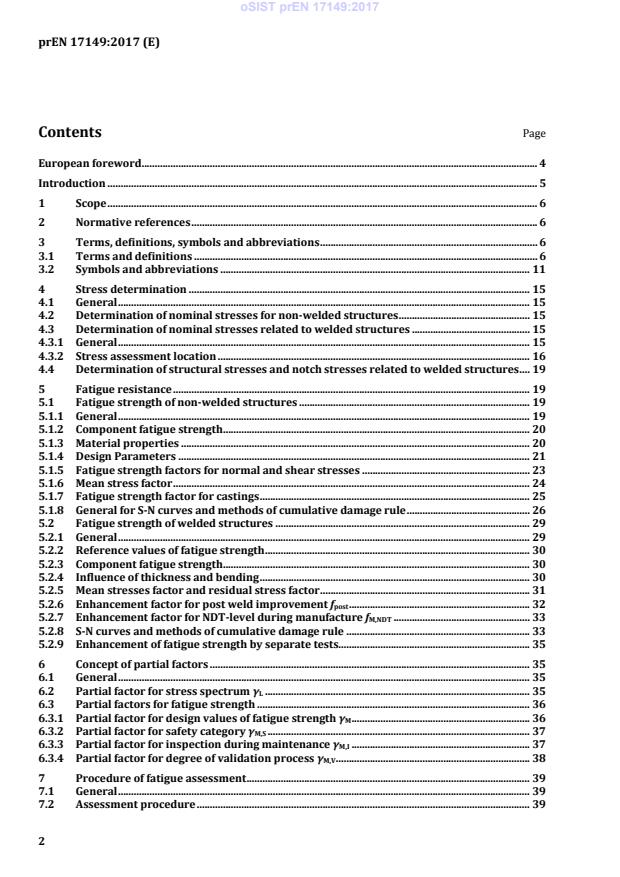

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms, definitions, symbols and abbreviations . 6

3.1 Terms and definitions . 6

3.2 Symbols and abbreviations . 11

4 Stress determination . 15

4.1 General . 15

4.2 Determination of nominal stresses for non-welded structures . 15

4.3 Determination of nominal stresses related to welded structures . 15

4.3.1 General . 15

4.3.2 Stress assessment location . 16

4.4 Determination of structural stresses and notch stresses related to welded structures . 19

5 Fatigue resistance . 19

5.1 Fatigue strength of non-welded structures . 19

5.1.1 General . 19

5.1.2 Component fatigue strength . 20

5.1.3 Material properties . 20

5.1.4 Design Parameters . 21

5.1.5 Fatigue strength factors for normal and shear stresses . 23

5.1.6 Mean stress factor . 24

5.1.7 Fatigue strength factor for castings . 25

5.1.8 General for S-N curves and methods of cumulative damage rule . 26

5.2 Fatigue strength of welded structures . 29

5.2.1 General . 29

5.2.2 Reference values of fatigue strength . 30

5.2.3 Component fatigue strength . 30

5.2.4 Influence of thickness and bending . 30

5.2.5 Mean stresses factor and residual stress factor . 31

5.2.6 Enhancement factor for post weld improvement f . 32

post

5.2.7 Enhancement factor for NDT-level during manufacture f . 33

M,NDT

5.2.8 S-N curves and methods of cumulative damage rule . 33

5.2.9 Enhancement of fatigue strength by separate tests. 35

6 Concept of partial factors . 35

6.1 General . 35

6.2 Partial factor for stress spectrum γ . 35

L

6.3 Partial factors for fatigue strength . 36

6.3.1 Partial factor for design values of fatigue strength γ . 36

M

6.3.2 Partial factor for safety category γ . 37

M,S

6.3.3 Partial factor for inspection during maintenance γ . 37

M,I

6.3.4 Partial factor for degree of validation process γ . 38

M,V

7 Procedure of fatigue assessment . 39

7.1 General . 39

7.2 Assessment procedure . 39

7.3 Stress determination . 40

7.4 Data pre-processing . 40

7.4.1 Conditioning . 40

7.4.2 Application of partial factor for stress spectrum γ . 40

L

7.4.3 Counting . 40

7.4.4 Mean stress adjustment . 40

7.4.5 Omission . 41

7.5 Damage calculation for each single stress component . 41

7.5.1 General . 41

7.5.2 Determination of stress spectrum shape factor . 41

7.5.3 Determination of admissible damage sum . 42

7.5.4 Determination of cumulative damage sum and scaling factor to reach admissible

damage sum . 42

7.6 Assessment of fatigue strength . 44

Annex A (informative) Procedure for determination of mean stress factors for non-welded

and welded structures . 46

Annex B (informative) Example specification for permissible of volumetric defects in

castings of steel, iron and aluminium . 49

Annex C (normative) Surface roughness factor for cut edges of steel . 50

Annex D (normative) Reference values of the fatigue strength Δσ and Δτ for notch cases

C C

of welded structures of steel . 51

Annex E (normative) Reference values of the fatigue strength Δσ and Δτ for notch cases of

C C

welded structures of aluminium . 80

Annex F (normative) Thickness influence for welded structures of steel and consideration

of bending for welded structures of steel and of aluminium . 96

Annex G (informative) Enhancement of reference value of the fatigue strength Δσ for load

C

carrying T- and cruciform joints with double fillet weld with or without partial

penetration . 100

Annex H (informative) Application of structural stress assessment for welded structures of

steel and aluminium . 103

Annex I (informative) Application of notch stress assessment for welded structures of steel

and aluminium . 107

Annex J (informative) Example for fatigue assessment . 121

Annex K (informative) Determination of nominal stresses in weld root of single sided

partial penetration welds . 127

Bibliography . 130

European foreword

This document (prEN 17149:2017) has been prepared by Technical Committee CEN/TC 256 “Railway

applications”, the secretariat of which is held by DIN.

This document is currently submitted to the CEN Enquiry.

Introduction

For railway vehicle structures the fatigue strength assessment is necessary. In some cases it is sufficient

to apply an endurance limit approach, i.e. assessing just against the peak stress level and not taking into

account the number of cycles and spectrum shapes of the stress history. Traditionally this endurance

limit approach is used in combination with the normative loads such as those defined in EN 12663

series or EN 13749.

A more detailed evaluation may be obtained using a cumulative damage fatigue assessment taking into

consideration stress spectra with varying amplitudes and cycle numbers or stress time histories.

This European Standard provides the basic procedure and criteria to be applied for fatigue strength

assessment based on cumulative damage approach.

The bibliography lists relevant documents that may be used for reference purposes.

The main body of the standard is based on the nominal stress approach, but the consideration of

variable amplitudes and cycles counts according to methods described in this standard may equally be

applied with the structural stress and the notch stress approach (additional information is included as

informative annexes). A combination of these approaches may be appropriate.

This Standard defines a pragmatic methodology for undertaking fatigue assessments based on

cumulative damage approach. In the application of this standard the use of more detailed information

or other validated methods is permissible under the precondition of a valid justification.

1 Scope

The purpose of this European standard is to specify the procedure for fatigue strength assessment of

railway vehicle structures based on cumulative damage.

This document is applicable to all rail vehicle structures, which are covered by EN 12663 series (car

body) and EN 13749 (bogie frame).

It considers materials used for design of car bodies and bogie frames (steel, aluminium, castings and

forgings) and the manufacturing according to the standards valid for railway applications.

NOTE As a manufacturing standard, EN 15085 series covers the welding of rail vehicle structures.

It is applicable for variable amplitude load data with total number of cycles higher than 10000 cycles.

This document is not applicable for:

— Corrosive conditions or

— Elevated temperature operation in the creep range.

A static strength assessment is outside the scope of this European Standard.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

EN 15085-3:2007/AC:2009, Railway applications - Welding of railway vehicles and components - Part 3:

Design requirements

BS 7608:2014+A1:2015, Guide to fatigue design and assessment of steel products

EN 755-2:2016, Aluminium and aluminium alloys - Extruded rod/bar, tube and profiles - Part 2:

Mechanical properties

EN 485-2:2016, Aluminium and aluminium alloys - Sheet, strip and plate - Part 2: Mechanical properties

EN 586-2:1994, Aluminium and aluminium alloys - Forgings - Part 2: Mechanical properties and

additional property requirements

EN 1706:2010, Aluminium and aluminium alloys - Castings - Chemical composition and mechanical

properties

3 Terms, definitions, symbols and abbreviations

For the purposes of this document, the following terms and definitions apply.

3.1 Terms and definitions

3.1.1

fatigue

damage of a structural part by the process of initiation and gradual propagation of cracks caused by

time varying repeated applications of stress

3.1.2

fatigue action

time varying repeated loading events which introduces a stress into a structural component

3.1.3

fatigue stress

stress caused by fatigue action

3.1.4

fatigue resistance

structural detail’s resistance to fatigue actions expressed in terms of a S-N curve

3.1.5

fatigue strength

magnitude of stress range leading to a particular fatigue life

3.1.6

component fatigue strength

fatigue strength considering the specific design details

3.1.7

design loads

loads caused by fatigue action under the consideration of partial factor for loads

3.1.8

stress spectrum

fatigue stresses including the partial factor for actions (e.g. loads) and relevant to the fatigue strength

assessment

3.1.9

design value of fatigue strength

strength of a structural detail under the consideration of partial factor for component fatigue strength

and relevant to the fatigue strength assessment

3.1.10

endurance limit

constant amplitude fatigue below which no fatigue damage will occur

3.1.11

nominal stress

stress in a component adjacent to a potential crack location calculated in accordance with elasticity

theory excluding all stress concentration effects (e.g. welds, openings, thickness changes)

3.1.12

modified nominal stress

nominal stress including macro-geometric effects

Note 1 to entry: The macro-geometric effects are the stress raising effects caused by the macro-geometry in the

vicinity of the welded joints (e.g. concentrated load effects, misalignment, eccentricity) but disregarding stress

raising effects of the weld joint itself.

3.1.13

structural stress

surface value of linearly distributed stress across the section thickness adjacent to a welded detail

taking into account the effects of a structural discontinuity

Note 1 to entry: Structural stress is also referred to as geometric stress.

Note 2 to entry: The linear stress distribution includes the effects of gross structural discontinuities (e.g.

presence of an attachment, aperture, change of cross-section, misalignment, intersection of members) and

distortion-induced bending moments. However it excludes the notch effects of local structural discontinuities (e.g.

weld toe, weld end) which give rise to nonlinear stress distributions across the section thickness.

3.1.14

notch stress

calculated stress for a notch of welded joint with a certain assumed notch radius

3.1.15

reference values of fatigue strength

fatigue strength for a particular welded structure detail related to N = 2×10 cycles for a survival

C

probability of P = 97,5 %

s

3.1.16

mean stress

mean value of the algebraic sum of maximum and minimum alternating stress in a cycle

3.1.17

residual stress

permanent stresses in a structure caused by manufacture processes (e.g. rolling, cutting or welding)

and with static equilibrium to itself

3.1.18

membrane stress

average normal stress which is uniform across the thickness of a plate or shell

3.1.19

bending stress

stress in a shell or plate-like part of a component with linear distribution across the thickness

3.1.20

stress range

algebraic difference between the maximum and minimum stresses in a cycle

3.1.21

constant stress range

constant magnitude stress fluctuation between a maximum and minimum value in a stress cycle

3.1.22

variable stress range

variable magnitude stress fluctuation between a maximum and minimum value in a stress cycle caused

by an irregular load time history

3.1.23

stress ratio

ratio of minimum to maximum algebraic value of the stress in a particular stress cycle

3.1.24

partial factor

factor taking into account uncertainties of loads (forces), material, model and geometry

Note 1 to entry: In some of the referred documents the partial factor described with terms as “safety factor” as

in EN 12663 series and EN 13749 or partial factor for variable actions (e.g. loads or forces) and for material,

model and geometric uncertainties as in ISO 2394.

3.1.25

stress cycle

pattern of variation of stress at a point defined by the cycle counting method and consisting of a change

in stress between a minimum (trough) and maximum (peak) values and back again

3.1.26

S-N curve

quantative relationship between the fatigue strength and the number of the cycles corresponding to a

specific survival probability of the failure for a detail, derived from test data

3.1.27

stress (range) spectrum

tabular or graphical presentation of the number of occurrences (cumulative frequency) of different

magnitudes produced by the load spectrum in the design life of a structure detail

3.1.28

stress range block

part of stress spectrum with constant stress range

3.1.29

cut off limit

fatigue strength under variable stress ranges below which the stress cycles are considered to be non-

damaging

3.1.30

damage equivalent stress range

constant stress range which produces an equivalent fatigue damage to that resulted from a variable

amplitude stress spectrum

3.1.31

damage sum

sum of fatigue damage produced by a variable amplitude stress spectrum

3.1.32

cumulative damage sum

linear cumulative damage summation based on the rule devised by Palmgren and Miner of the fatigue

damage due to all cycles in a stress-range spectrum

3.1.33

cumulative damage rule

method for estimating fatigue life under variable amplitude loading from the constant S-N curve

Note 1 to entry: Often referred to as damage accumulation hypothesis, Miner’s rule or Palmgren-Miner rule.

3.1.34

proportional stresses

principal stresses or stress components with constant directions and constant ratios of their values for

time varying loads

3.1.35

non-proportional stresses

principal stresses or stress components with non-constant directions and non-constant ratios of their

values for time varying loads

3.1.36

degree of utilisation

relationship between the design values of fatigue stress and of component fatigue strength expressed as

a ratio of applied stress to component fatigue strength

3.1.37

damage equivalent degree of utilisation

relationship between the design values of fatigue stress and of component fatigue strength for an

extrapolation of stress spectra with compliance to the assessment criteria

3.1.38

misalignment

axial and angular deformation (offset) of welded joints caused by detail design or/and by manufacture

process

3.1.39

NDT

non-destructive test

3.1.40

safety category

consequences of failure of the single welded joint in respect to the effects on persons, facilities and the

environment according to EN 15085-3

3.1.41

weld performance class

performance requirements of the welded joint with respect to weld quality requirements and weld

inspection requirements as defined in EN 15085-3

Note 1 to entry: The weld performance class is abbreviated by “CP” (class of performance)

3.1.42

weld inspection class

inspections to be carried out for a given weld with respect to the frequency and the type of inspection

(e.g. volumetric, surface or visual) as defined by the weld performance class according to EN 15085-3

Note 1 to entry: The weld inspection class is abbreviated by “CT” (class of testing)

3.2 Symbols and abbreviations

A ultimate elongation according to material standards

A stress spectrum shape factor

eq

a throat thickness of fillet weld

a degree of utilisation for stress component

c

a degree of utilisation for plain axial stress state according to von Mises criterion

f

a mean stress sensitivity parameter

m

b exponent in correction term for thickness in case of membrane and bending loading (e.g.

in F.3)

b distance from weld toe or root to the stress assessment location (evaluation point) for a

EP

nominal stress, modified nominal stress or structural stress assessment

b mean stress sensitivity parameter

m

Cσ constant in equation of S-N curve for normal stresses

C constant in equation of S-N curve for shear stresses

τ

c root gap length

D cumulative damage sum of stress spectrum

it

D admissible damage sum

m

D damage sum limit

m,min

e eccentricity between midpoint of weld throat and connected plates (amount of offset to

misalignment)

f anisotropy factor for rolled sheets and extrusions with different strength in rolling or

A

extrusion and transverse directions

fbend enhancement factor for bending

f fatigue strength factor for casting

C

f enhancement factor for NDT-level during manufacture

M,NDT

f mean stress factor for normal stress

m,σ

f mean stress factor for shear stress

m,τ

f enhancement factor for post weld improvement

post

f fatigue strength factor for normal stresses

R,σ

f ratio between fatigue strength of shear stress and of normal stress

R,τ

f residual stress factor for normal stress for stress difference between R = −1 and R = 0,5

res,σ σ σ

under consideration of residual stress state

fres,τ residual stress factor for shear stress for stress difference between Rτ = −1 and Rτ = 0,5

under consideration of residual stress state

f surface roughness factor

SR

f surface roughness factor for normal stress assessment

SR,σ

f surface roughness factor for shear stress assessment

SR,τ

f factor for fatigue strength related to structural stress defined in Annex H

struc

f thickness correction factor

thick

h depth of partial penetration of butt weld

i number of blocks of stress spectrum

j total number of blocks of stress spectrum for which additionally holds: x × Δσ > Δσ

it i L

j basic partial factor according to [2]

D

K fatigue notch factor

f

K stress concentration factor

t

K weld notch shape factor

w

L toe distance or sum of thickness or length of attachment and weld leg lengths

l length of attachment of welded structures or non-load carrying rectangular or circular

pads or plates

l length of strain gauge measurement grid

SG

l total length of strain gauge including backing film

SG,tot

M mean stress sensitivity for normal stresses

σ

M mean stress sensitivity for shear stresses

τ

m exponent of S-N curve

m exponent of S-N curve before knee point

m exponent of S-N curve beyond knee point

N number of cycles

N number of cycles of reference value of fatigue strength

C

N number of cycles of knee point of S-N curve

D

N number of cycles of damage equivalent stress spectrum

eq

N number of cycles of cut-off limit for stress range

L

N total number of cycles in given stress spectrum with Δσ > Δσ

t i OM

n exponent in correction term for thickness in case of membrane loading

n cycle number of stress range block i of stress spectrum

i

P survival probability

s

R stress ratio

R upper yield strength

eH

R tensile strength relevant for determination of fatigue strength of non-welded structures

m

R normative tensile strength according to material standards

m,N

R nominal tensile strength according to drawing or to component specification

m,S

R 0,2 % proof strength

p0,2

R surface roughness

z

R stress ratio for normal stresses

σ

Rτ stress ratio for shear stresses

r actual notch radius of weld toe or weld root

r reference notch radius of weld toe or weld root

ref

t plate thickness

t effective plate thickness in correction term for thickness influence

eff

t reference plate thickness relevant to reference values of the fatigue strength for welded

ref

structural details in Annex D and Annex E

w width of loaded plates with welded longitudinal flat side gusset

x scaling factor for stress range with iteration result D (x ) ≡ D

Dm it Dm m

x scaling factor for stress range during iteration for determination of cumulative damage

it

sum

γ partial factor for stress spectrum based on design loads

L

γ partial factor for design values of fatigue strength

M

γ partial factor for inspection during maintenance

M,I

γ partial factor for safety category

M,S

γ partial factor for degree of validation process

M,V

γ partial factor considering validation of fatigue behaviour by fatigue testing

M,V,FT

γ partial factor considering validation of calculated stress data by measured stress data

M,V,ST

Δσ normal stress range

Δσ applied bending stress range

b

Δσ reference value of fatigue strength of normal stress range for N = 2 × 10 cycles, R = 0,5,

C C

P = 97,5 %

s

Δσ reference value of fatigue strength for normal notch stress assessment

C,e

Δσ reference value of fatigue strength for normal structural stress assessment

C,S

Δσ normal stress range for component fatigue strength at knee point of S-N curve N

D D

Δσ normal stress range for reference value of fatigue strength at knee point of S-N curve N

D,C D

Δσ normal notch stress range transverse to weld line

e

Δσ normal stress range of damage equivalent stress spectrum

eq

Δσ normal stress range of stress spectrum block i related to stress ratio R = −1

i

Δσ normal stress range of stress spectrum block i as a result of rain flow counting

i,RF

Δσ cut-off limit for normal stress range at N

L L

Δσ omission limit of normal stress range

OM

Δσ applied membrane stress range

mem

Δσ component fatigue strength for normal stress range

R

Δσ component fatigue strength for normal notch stress range

R,e

Δσ largest normal stress range of stress spectrum

Δτ shear stress range

ΔτC reference value of fatigue strength of shear stress range for NC = 2 × 10 cycles, R = 0,5,

P = 97,5 %

s

Δτ reference value of fatigue strength for shear notch stress assessment

,C,e

Δτ shear stress range for component fatigue strength at knee point of S-N curve N

D D

Δτ shear stress range for reference value of fatigue strength at knee point of S-N curve N

D,C D

Δτ shear notch stress range

e

Δτ shear stress range of damage equivalent stress spectrum

eq

Δτ shear tress range of stress range block i related to stress ratio R = −1

i

Δτ cut-off limit for shear stress range at N

L L

Δτ omission limit of shear stress range

OM

Δτ component fatigue strength for shear stress range

R

Δτ component fatigue strength for shear notch stress range

R,e

Δτ largest shear stress range of stress spectrum

δ first number of step in stress spectrum with x × Δσ < Δσ

it i D

θ weld flank angle

ν Poisson's ratio

ρ fictitious notch radius of weld toe or of weld root in Annex G

σ normal stress amplitude

a

σ bending stress

b

σ σ linear-elastic calculated normal notch stress transverse to weld line

e e,⊥

σ hot spot stress according to Annex H and Annex I

hs

σ mean stress

m

σ mean stress related to Δσ

m,i,RF i,RF

σ membrane stress

mem

σ nominal normal stress longitudinal to weld line

n,II

σ measured structural stress according to definition in Annex H

SG

σ nominal bending stress related to weld throat section

w,b

σ nominal welded membrane stress related to weld throat section

w,mem

σ nominal stress related to weld throat section due to combined membrane and bending

w,root

stresses

τ shear stress amplitude

a

τ τ linear-elastic calculated shear notch stress longitudinal to weld line

e e,II

τ mean stress of shear stress

m

Ω degree of bending

ω weld toe angle

4 Stress determination

4.1 General

The stress spectrum used to perform the fatigue strength assessment based on cumulative damage

approach shall be expressed in terms of stress amplitudes, mean stresses and number of cycles to

represent the design life.

The stress spectrum shall be incorporated any necessary allowance to account for uncertainties in their

values. If relevant, this may be achieved by application of a partial factors γ on the characteristic stress

L

spectrum as specified in the application code. In 6.2 recommendations and requirements for the partial

factors γ are given.

L

NOTE EN 12663 series, EN 15827 and EN 13749 contain information on how to determine design loads for

cumulative damage assessment of railway vehicles. For constant amplitude loads as given in EN 12663 and

EN 13749 an assessment against a cumulative damage approach is not mandatory.

4.2 Determination of nominal stresses for non-welded structures

The component stress values shall be determined as a plain stress tensor in a fixed coordinate system

tangential to the component surface.

The component stress values shall be determined for the three components of the plain stress tensor

(i.e. σ , σ , τ ) in terms of amplitude and mean values as well as number of cycles for each component

x y xy

stress spectrum block.

The component stress values for assessment of non-welded structure have to account for local stress

concentrations.

4.3 Determination of nominal stresses related to welded structures

4.3.1 General

The definition of nominal stresses in the welded plate or weld throat excludes the stress concentrations

effects due to the welded joint (e.g. weld shape, thickness changes) and any secondary bending effects

due to the local detail (e.g. eccentricity or misalignment). That shall be considered in the determination

of nominal stresses by calculation or measurements.

The fatigue strength values for notch cases of welded structures defined in Annex D and Annex E fulfil

these general requirements. In cases where effects of eccentricity or secondary bending effects have to

be accounted for, that is explicitly described in these both annexes.

The determination of nominal stresses during the calculation or the measurement with strain gauge

shall be carried out outside the stress concentration field of the welded joint. Appropriate distances

between the stress assessment location and the weld toe or the weld root are defined in 4.3.2.

For the assessment of the weld toe the relevant cross section is the plate section except otherwise

stated in Annex D and Annex E. For the assessment of the weld root the relevant cross section is the

weld throat section. In cases of welds with

— partial penetration or

— eccentricity of the weld throat midpoint to the plate midpoint or

— throat thickness different to the plate thickness

the stresses at the stress assessment location have to be transferred into stresses acting in the throat

section using appropriate techniques. Membrane stresses should be transferred accounting for effects

of eccentricity. Bending stresses should be transferred accounting for the applicable section modulus

against bending for the weld root. For the determination of nominal stresses in welds with partial

penetration welded on one side related to weld root the Annex K contains detailed information.

NOTE Analytical approaches or FE-modelling techniques representing the actual throat thicknesses and

eccentricity of the weld throats are such appropriate procedures.

4.3.2 Stress assessment location

To determine the position for the stress assessment location (evaluation point) the following

recommendations are made:

— The distance b of the assessment location shall be

EP

b = 10 mm ± 5 mm (1)

EP

— In case of non-symmetric weld toe positions at a plate, the weld toe with the higher distance to the

weld or plate centre line is used to determine the distance and the position at the other surface is

directly opposite.

— In case of welds at T joints welded from one side, the distance b at the root side is measured from

EP

the adjacent plate surface.

NOTE For measurements the defined value for bEP of 10 mm correlates to the broadly accepted practice for

strain gauge applications at weld lines.

For evaluation of the nominal stresses in calculations the evaluation point shall be as defined above.

For evaluation of the nominal stresses in measurements the dimension of the strain gauge, especially

the length of strain gauge measurement grid l , and the application distance from the weld toe has

SG

relevant influence on the results. The maximum length of the used strain gauge shall not exceed

— l ≤ 6 mm for measurements on bogie frames

SG

— l ≤ 10 mm for measurements on car body structures.

SG

NOTE The reason for defining different maximum strain gauge lengths is that bogie frames usually have

higher stress gradients than car body structures.

For typical welded joints the stress assessment location of nominal stress assessment is given in

Figure 1, Figure 2 and Figure 3.

Figure 1 — Stress assessment locations for a butt joint

Figure 2 — Stress assessment locations for a T joint

Figure 3 — Stress assessment locations for a cruciform joint

In the case of a weld end assessment the stress state may be regarded as a single axial stress state at the

recommended distance b to the weld toe oriented in direction of the weld line. Such weld ends are for

EP

example:

— weld ends of longitudinal attachments or gussets (see Figure 4 and Table D.42, Table D.46,

Table D.47 and Table E.57),

— weld ends of intermittent welds in T- or cruciform joints (see Figure 5 and Table D.41)

— weld ends in case of a transition of a both-sided weld to a single-sided weld type in T- or cruciform

joints (see Figure 5).

For the assessment location of these weld ends a combination of the stress components as given in 7.6

is not necessary.

Stresses in the remaining weld line have to be separately assessed with the notch cases applicable for

the appropriate notch cases of a continuous weld line.

NOTE At flat attachments like pads or doubling plates the stress state at the welds is not regarded as a single

axial stress stage. For these cases an assessments of all directions and a combination of the stress components is

necessary (see for normal stress assessment transverse to weld line in Table D.42 and longitudinal to weld line in

Table D.39).

Key

1 stresses to be used for assessment of weld ends

2 assessment location for weld end of longitudinal attachment or gusset

3 weld line area to be assessed like a continuous weld line

Figure 4 — Stress assessment locations for a structural detail with non-loaded-carrying

attachments

Key

1 stresses to be used for assessment of weld ends

2 assessment location for weld end

3 weld line area to be assessed like a continuous weld line

Figure 5 — Stress assessment locations for T- or cruciform joint with intermittent fillet weld

The stresses determined as described in this clause are usually higher than the nominal stresses.

Therefore the assessment using these stresses, with the allowable strength values defined in Annex D

and Annex E, may be assumed to be sufficiently conservative.

4.4 Determination of structural stresses and notch stresses related to welded structures

For the fatigue assessment of welded joints the structural stress approaches and the notch stress

approach may be applied. For the application of these approaches the requirements for the calculation

of the relevant stresses and fatigue resistance is described in the following informative annexes:

— Annex H for the structural stress approach and

— Annex I for the notch stress approach.

5 Fatigue resistance

5.1 Fatigue strength of non-welded structures

5.1.1 General

This clause describes the method for a fatigue strength assessment of non-welded structures under the

following conditions:

— materials used for fabricated constructions such as construction steel, weldable cast steel, ductile

cast iron, cast and wrought aluminium,

— application temperature up to 100°C for aluminium and up to 200°C for steel,

— plain stress tensor on the components surface (no significant stress component perpendicular to

the surface, e.g. press fit connection).

The restrictions defined above are met with most applications of non-welded structures for railway

vehicles, in such cases a simplified assessment method is appropriate. If the scope of the application is

exceeded, an assessment method has to be chosen which accounts for the specific application (e.g. high

temperatures and 3 dimensional stress states).

5.1.2 Component fatigue strength

The fatigue strength is specified by S-N curves, which define the values of component fatigue strength

Δσ and Δτ related to

R R

— N = 10 ,

C

— stress ratio R = R = −1,

σ τ

— survival probability of P = 97,5 %,

s

— membrane stresses.

The values of the component fatigue strength are determined with the following formulas:

Δσ (N = 10 , R = −1) = R × f × f × f (2)

R C σ m R,σ SR,σ C

Δτ (N = 10 , R = −1) = R × f × f × f × f (3)

R C τ m R,τ R,σ SR,τ C

where

R tensile strength relevant f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...