EN 12451:2012

(Main)Copper and copper alloys - Seamless, round tubes for heat exchangers

Copper and copper alloys - Seamless, round tubes for heat exchangers

This European Standard specifies the composition, property requirements and tolerances on dimensions and form for seamless round drawn copper and copper alloy tubes for heat exchangers, condensers, evaporators and desalination equipment. It gives guidelines for copper and copper alloy tubes supplied in the size range from 6 mm up to and including 76 mm outside diameter and from 0,5 mm up to and including 3 mm wall thickness.

The sampling procedures and the methods of test for verification of conformity to the requirements of this European Standard are also specified.

Kupfer und Kupferlegierungen - Nahtlose Rundrohre für Wärmeaustauscher

Diese Europäische Norm legt die Zusammensetzung, die Anforderungen an die Eigenschaften, Grenzabmaße und Formtoleranzen für nahtlosgezogene Rundrohre aus Kupfer und Kupferlegierungen für Wärmeaus-tauscher, Kondensatoren, Verdampfer und Entsalzungsanlagen fest. Diese Norm gilt für Rohre aus Kupfer und Kupferlegierungen im Maßbereich von 6 mm bis 76 mm Außendurchmesser und von 0,5 mm bis 3 mm Wanddicke. Der Ablauf der Probenentnahme und die Prüfverfahren zur Feststellung der Übereinstimmung mit den Anforderungen dieser Europäischen Norm sind ebenfalls festgelegt.

Cuivre et alliages de cuivre - Tubes ronds sans soudure pour échangeurs thermiques

La présente Norme européenne spécifie la composition, les caractéristiques et les tolérances de dimensions

et de formes des tubes ronds sans soudure en cuivre et alliages de cuivre destinés aux échangeurs

thermiques, aux condenseurs, aux évaporateurs et aux installations de désalinisation. Elle est applicable aux

tubes en cuivre et en alliages de cuivre fournis dans une plage de diamètre extérieur de 6 mm à 76 mm

compris, et d'épaisseur de paroi de 0,5 mm à 3 mm compris.

Les modes opératoires d'échantillonnage et les méthodes d'essai pour la vérification de la conformité aux

exigences de la présente Norme européenne sont également spécifiés.

Baker in bakrove zlitine - Nevarjene cevi z okroglim prerezom za toplotne izmenjevalnike

Ta evropski standard določa sestavo, zahteve glede značilnosti ter odstopanja glede dimenzij in oblike za nevarjene okrogle cevi iz vlečenega bakra in bakrovih zlitin za toplotne izmenjevalnike, kondenzatorje, uparjalnike in opremo za razsoljevanje, ki se dobavljajo z zunanjim premerom velikosti od 6 mm do vključno 76 mm in debelino stene od 0,5 mm do vključno 3 mm. Določeni so tudi postopki vzorčenja in preskusne metode za preverjanje skladnosti tega standarda.

General Information

- Status

- Published

- Publication Date

- 15-May-2012

- Withdrawal Date

- 29-Nov-2012

- Technical Committee

- CEN/TC 133 - Copper and copper alloys

- Drafting Committee

- CEN/TC 133/WG 3 - Copper tubes (installation and industrial)

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 16-Nov-2023

- Completion Date

- 23-Sep-2025

Relations

- Effective Date

- 28-Nov-2009

Overview

EN 12451:2012 - published by CEN - is the European standard for copper and copper alloys - seamless, round tubes for heat exchangers. It specifies composition, mechanical property requirements, and dimensional and form tolerances for seamless round drawn copper tubes used in heat exchangers, condensers, evaporators and desalination equipment. The standard covers tubes with outside diameters from 6 mm to 76 mm and wall thicknesses from 0.5 mm to 3 mm, and includes sampling procedures and test methods for verification of conformity.

Key topics and requirements

- Material Composition: Defines permitted copper and copper-alloy chemistries (material symbols/numbers) for heat-exchanger tubes and notes special composition options for seawater applications.

- Mechanical Properties and Conditions: Specifies tensile, hardness and material-condition designations (R... and H... with optional stress-relieved suffix S) and associated acceptance criteria.

- Dimensions and Tolerances: Sets tolerances on outside diameter, wall thickness, length, and deviation from circular form for seamless round tubes.

- Surface and Technological Requirements: Requirements for surface quality, annealed ends for hard-condition tubes, and technological tests such as drift-expanding.

- Testing and Conformity Verification:

- Sampling plans and test frequencies for chemical analysis, mechanical testing and defect detection.

- Test methods referenced include tensile and hardness tests, eddy-current testing (outer coil and internal probe), stress corrosion resistance, drift-expanding and grain-size estimation.

- Freedom-from-defects testing and retest rules are provided.

- Product Designation and Ordering: Standardized product designation (Tube - EN 12451 - material - condition - OD × wall thickness) and recommended ordering information to ensure purchaser/supplier clarity.

- Documentation & Regulatory Links: Declaration of conformity, inspection documents (per EN 10204 types), marking/packaging and informative Annex ZA describing the relationship to the EU Pressure Equipment Directive (PED 97/23/EC).

Applications and users

EN 12451 is primarily used for specifying and verifying heat exchanger tubing in:

- HVAC, refrigeration and industrial heat exchangers

- Condensers, evaporators and desalination equipment

- Marine and seawater-cooled systems (when CuNi alloys are specified) Typical users:

- Tube manufacturers and mill quality departments

- Heat exchanger designers, OEMs and fabricators

- Purchasing/specification engineers and procurement teams

- Inspection bodies, testing laboratories and certifiers ensuring conformity to European requirements

Related standards

Relevant companion standards referenced in EN 12451 include:

- EN 1655 (declarations of conformity)

- EN 1971-1 / EN 1971-2 (eddy current testing)

- EN ISO 6892-1 (tensile testing) and EN ISO 6507-1 (Vickers hardness)

- ISO 6957 (ammonia stress corrosion test)

- Other CEN tube standards: EN 1057, EN 12449, EN 12735-1/2

EN 12451:2012 provides a clear, auditable framework for selecting, testing and ordering seamless copper tubes for reliable heat-exchanger performance, aligning material, dimensional and testing requirements with European conformity and safety expectations.

Frequently Asked Questions

EN 12451:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Copper and copper alloys - Seamless, round tubes for heat exchangers". This standard covers: This European Standard specifies the composition, property requirements and tolerances on dimensions and form for seamless round drawn copper and copper alloy tubes for heat exchangers, condensers, evaporators and desalination equipment. It gives guidelines for copper and copper alloy tubes supplied in the size range from 6 mm up to and including 76 mm outside diameter and from 0,5 mm up to and including 3 mm wall thickness. The sampling procedures and the methods of test for verification of conformity to the requirements of this European Standard are also specified.

This European Standard specifies the composition, property requirements and tolerances on dimensions and form for seamless round drawn copper and copper alloy tubes for heat exchangers, condensers, evaporators and desalination equipment. It gives guidelines for copper and copper alloy tubes supplied in the size range from 6 mm up to and including 76 mm outside diameter and from 0,5 mm up to and including 3 mm wall thickness. The sampling procedures and the methods of test for verification of conformity to the requirements of this European Standard are also specified.

EN 12451:2012 is classified under the following ICS (International Classification for Standards) categories: 23.040.15 - Non-ferrous metal pipes; 77.150.30 - Copper products. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12451:2012 has the following relationships with other standards: It is inter standard links to EN 12451:1999. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12451:2012 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU, 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase EN 12451:2012 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Baker in bakrove zlitine - Nevarjene cevi z okroglim prerezom za toplotne izmenjevalnikeKupfer und Kupferlegierungen - Nahtlose Rundrohre für WärmeaustauscherCuivre et alliages de cuivre - Tubes ronds sans soudure pour échangeurs thermiquesCopper and copper alloys - Seamless, round tubes for heat exchangers77.150.30Bakreni izdelkiCopper products23.040.15Cevi iz neželeznih kovinNon-ferrous metal pipesICS:Ta slovenski standard je istoveten z:EN 12451:2012SIST EN 12451:2012en,de01-september-2012SIST EN 12451:2012SLOVENSKI

STANDARDSIST EN 12451:20001DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12451

May 2012 ICS 23.040.15; 77.150.30 Supersedes EN 12451:1999English Version

Copper and copper alloys - Seamless, round tubes for heat exchangers

Cuivre et alliages de cuivre - Tubes ronds sans soudure pour échangeurs thermiques

Kupfer und Kupferlegierungen - Nahtlose Rundrohre für Wärmeaustauscher This European Standard was approved by CEN on 20 April 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12451:2012: ESIST EN 12451:2012

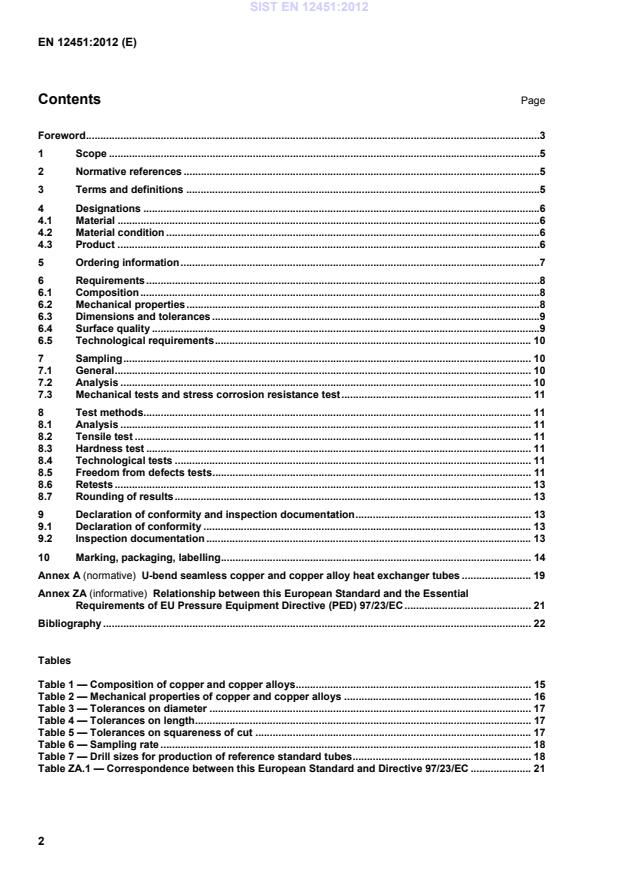

U-bend seamless copper and copper alloy heat exchanger tubes . 19Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Pressure Equipment Directive (PED) 97/23/EC . 21Bibliography . 22 Tables Table 1 — Composition of copper and copper alloys . 15 Table 2 — Mechanical properties of copper and copper alloys . 16 Table 3 — Tolerances on diameter . 17 Table 4 — Tolerances on length . 17 Table 5 — Tolerances on squareness of cut . 17 Table 6 — Sampling rate . 18 Table 7 — Drill sizes for production of reference standard tubes . 18 Table ZA.1 — Correspondence between this European Standard and Directive 97/23/EC . 21

EN 12450, Copper and copper alloys — Seamless, round copper capillary tubes

EN 12452, Copper and copper alloys — Rolled, finned, seamless tubes for heat exchangers

EN 12735-1, Copper and copper alloys — Seamless, round copper tubes for air conditioning and refrigeration — Part 1: Tubes for piping systems

EN 12735-2, Copper and copper alloys — Seamless, round copper tubes for air conditioning and refrigeration — Part 2: Tubes for equipment EN 13348, Copper and copper alloys — Seamless, round copper tubes for medical gases or vacuum EN 13349, Copper and copper alloys — Pre-insulated copper tubes with solid covering EN 13600, Copper and copper alloys — Seamless copper tubes for electrical purposes SIST EN 12451:2012

(ISO 6892-1) EN ISO 8493, Metallic materials — Tube — Drift-expanding test (ISO 8493) ISO 6957, Copper alloys — Ammonia test for stress corrosion resistance 3 Terms and definitions For the purposes of this document, the following terms and definitions apply. 3.1 seamless round tube hollow semi-finished product, circular in cross-section, having a uniform wall thickness, which at all stages of production has a continuous periphery 3.2 mean wall thickness arithmetical mean of the maximum and minimum wall thicknesses at the same cross-section of the tube SIST EN 12451:2012

Material condition designated by the minimum value of tensile strength requirement for the product with mandatory tensile property requirements; H.

Material condition designated by the minimum value of hardness requirement for the product with mandatory hardness requirements. S (suffix)

Material condition for a product which is stress relieved. NOTE 1 Products in the H. condition can be specified to Vickers or Brinell hardness. The condition designation H. is the same for both hardness test methods. NOTE 2 Products in the R. or H. condition can be specially processed (i.e. mechanically or thermally stress relieved) in order to lower the residual stress level to improve the resistance to stress corrosion (see 6.5.2). Exact conversion between material conditions designated R. and H. is not possible. Except when the suffix S is used, the material condition is designated by only one of the above designations. 4.3 Product The product designation provides a standardized pattern of designation from which a rapid and unequivocal description of a product can be conveyed in communication. It provides mutual comprehension at the international level with regard to products which meet the requirements of the relevant European Standard. The product designation is no substitute for the full content of the standard. SIST EN 12451:2012

Tube EN 12451 – CuNi10Fe1Mn – H075 – 22 ×××× 2,0

or

Tube EN 12451 –

CW352H

–

H075

–

22 ×××× 2,0 Denomination Number of this European Standard Material designation Material condition designation Nominal dimensions in millimetres 5 Ordering information In order to facilitate the enquiry, order and confirmation of order procedures between the purchaser and the supplier, the purchaser shall state on his enquiry and order the following information: NOTE 1 Heat exchanger tube can also be supplied as U-bend tube. For specific product and ordering information, see Annex A. a) quantity of product required (number of pieces, length or mass); b) denomination (Tube); c) number of this European Standard (EN 12451); d) material designation (see Table 1); e) material condition designation (see 4.2 and Table 2); f) nominal cross-sectional dimensions (outside diameter × wall thickness); g) nominal length (see 6.3.4). NOTE 2 It is recommended that the product designation, as described in 4.3, is used for items b) to f). SIST EN 12451:2012

1 000 m Tube EN 12451 – CuNi10Fe1Mn – H075 – 22 ×××× 2,0

– nominal length 3 000 mm

or

1 000 m Tube EN 12451 – CW352H – H075 – 22 ×××× 2,0

– nominal length 3 000 mm 6 Requirements 6.1 Composition The composition shall conform to the requirements for the appropriate material given in Table 1. 6.2 Mechanical properties The properties shall conform to the appropriate requirements given in Table 2. The tests shall be carried out in accordance with either 8.2 (tensile test) or 8.3 (hardness test). Products in stress relieved condition shall conform to the same mechanical property requirements as for non-stress relieved material. SIST EN 12451:2012

...

표준 EN 12451:2012는 열교환기, 응축기, 증발기 및 담수화 장비용으로 seamless(무접합) 형태의 동 및 동 합금 원형 튜브에 대한 요구 사항을 규정하고 있습니다. 이 표준의 범위는 외경이 6mm에서 76mm까지, 벽 두께가 0.5mm에서 3mm까지의 동 및 동 합금 튜브의 성분, 물성 요구 사항 및 치수와 형태에 대한 허용오차를 포함합니다. 이 표준의 강점은 명확한 물성 및 성분 요구 사항을 제시하여 제조업체가 적합한 제품을 생산할 수 있도록 하는 데 있습니다. 또한, 표준은 샘플링 절차와 적합성 확인을 위한 시험 방법을 명시함으로써 품질 관리 및 안전성을 높입니다. 이러한 요소들은 열교환기 및 관련 장비의 효율성과 신뢰성을 보장하는 데 중요한 역할을 합니다. EN 12451:2012는 특히 산업계에서의 응용이 매우 중요하며, 에너지 효율성과 자원 관리 측면에서 기여할 수 있는 표준입니다. 따라서, 이 표준은 동 및 동 합금 튜브를 사용하는 모든 분야에 있어서 필수적인 지침서로 자리잡고 있습니다.

The EN 12451:2012 standard is an essential European guideline that addresses the production and quality assessment of seamless, round tubes made from copper and copper alloys specifically designed for use in heat exchangers, condensers, evaporators, and desalination equipment. Covering a size range from 6 mm to 76 mm in outside diameter and wall thicknesses from 0.5 mm to 3 mm, this standard provides a comprehensive framework that ensures the tubes meet rigorous performance criteria and industry needs. One of the primary strengths of EN 12451:2012 is its detailed composition and property requirements, which help maintain the high quality and durability of the tubes used in critical applications. By defining tolerances on dimensions and form, the standard ensures that manufacturers can produce products that fit seamlessly into existing systems, thereby minimizing installation issues and enhancing operational efficiency. Moreover, the inclusion of specific sampling procedures and testing methods adds a layer of reliability, ensuring that products not only meet theoretical specifications but also adhere to practical performance expectations. This aspect of the standard is particularly relevant for industries that rely heavily on the performance and reliability of heat exchangers and related equipment. The relevance of EN 12451:2012 extends beyond mere compliance; it fosters innovation and improvement in manufacturing processes for copper and copper alloy tubes. By standardizing these critical parameters, the document aids manufacturers in aligning their production capabilities with market demands, thereby enhancing competitiveness in the sector. Overall, the EN 12451:2012 standard stands out as a comprehensive and thorough guideline that plays a significant role in ensuring the quality, reliability, and efficiency of seamless round tubes for heat exchangers, making it a critical reference for manufacturers and industry stakeholders alike.

標準EN 12451:2012は、熱交換器、コンデンサー、蒸発器、及び脱塩装置用の無縫製の丸銅および銅合金チューブに関する包括的な規範を提供しています。この欧州標準は、チューブの組成、特性要件、寸法・形状の許容範囲について明確に定義しており、特に直径6mmから76mmまで、壁厚0.5mmから3mmまでのサイズ範囲に適応しています。 この標準の強みは、その明確な仕様にあります。材料の構成や性能、耐久性に関する要求を明示的に示し、その結果として高い品質の確保が可能となります。特に熱交換器や他の機器における効率的な運用を求める場面において、これらの基準は重要な役割を果たします。また、サンプリング手順や試験方法も詳細に記載されており、標準に適合しているかを確認するための信頼性高い手段を提供しています。 このような明確で有用なガイドラインは、製造業者が市場での競争力を高めるために必要不可欠であり、銅および銅合金の無縫製チューブの利用を推進する大きな要因となります。したがって、EN 12451:2012は、技術の進歩や規制の変化に対応した、業界における信頼できる基準としての重要性を持ち続けています。この標準は、規格に従うことで製品の品質向上や顧客満足度の向上にも寄与するのです。

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...