EN 15567-1:2015+A1:2020

(Main)Sports and recreational facilities - Ropes courses - Part 1: Construction and safety requirements

Sports and recreational facilities - Ropes courses - Part 1: Construction and safety requirements

This European Standard applies to permanent and mobile ropes courses and their components.

This European Standard specifies safety requirements for the design, construction, inspection and maintenance of ropes courses and their components.

This European Standard does not apply to temporary ropes courses (see 3.3) and children's play grounds (see EN 1176 all parts).

For the use of ropes courses EN 15567 2 applies.

Sport- und Freizeitanlagen - Seilgärten - Teil 1: Konstruktion und sicherheitstechnische Anforderungen

Diese Europäische Norm gilt für permanente und mobile Seilgärten und deren Bestandteile.

Diese Europäische Norm legt sicherheitstechnische Anforderungen an die Auslegung, Konstruktion, Inspektion und Instandhaltung von Seilgärten und deren Bestandteilen fest.

Diese Europäische Norm gilt nicht für temporäre Seilgärten (siehe 3.3) und für Kinderspielplätze (siehe EN 1176, alle Teile).

Für die Benutzung von Seilgärten gilt EN 15567 2.

Structures de sport et d’activités de plein air - Parcours acrobatiques en hauteur - Partie 1 : Exigences de construction et de sécurité

La présente Norme européenne s’applique aux parcours acrobatiques en hauteur, fixes et mobiles, et à leurs composants.

La présente Norme européenne spécifie les exigences de sécurité concernant la conception, la construction, le contrôle et la maintenance des parcours acrobatiques en hauteur et de leurs composants.

La présente Norme européenne ne s’applique ni aux parcours acrobatiques temporaires (voir 3.3) ni aux aires de jeux pour enfants (voir toutes les parties de l’EN 1176).

En ce qui concerne l’utilisation des parcours acrobatiques en hauteur, l’EN 15567 2 s’applique.

Športni in rekreacijski pripomočki - Vrvni plezalni parki - 1. del: Konstrukcijske in varnostne zahteve

General Information

- Status

- Published

- Publication Date

- 18-Feb-2020

- Withdrawal Date

- 11-Aug-2020

- Technical Committee

- CEN/TC 136 - Sports, playground and other recreational equipment

- Drafting Committee

- CEN/TC 136 - Sports, playground and other recreational equipment

- Current Stage

- 9000 - Start of review/2 Year Review Enquiry - Review Enquiry

- Start Date

- 20-May-2020

- Completion Date

- 20-May-2020

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 18-Jan-2023

- Effective Date

- 09-Feb-2026

- Refers

EN 13411-4:2021 - Terminations for steel wire ropes - Safety - Part 4: Metal and resin socketing - Effective Date

- 28-Jan-2026

- Refers

EN 12927:2019 - Safety requirements for cableway installations designed to carry persons - Ropes - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 12277:2015+A1:2018 - Mountaineering equipment - Harnesses - Safety requirements and test methods - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 15567-1:2015+A1:2020 is the CEN European Standard that sets construction and safety requirements for ropes courses. It applies to both permanent and mobile ropes courses and their components, covering design, manufacture, inspection and maintenance. The standard excludes temporary ropes courses (installed ≤7 days) and children’s playground equipment (see EN 1176). EN 15567‑1 complements EN 15567‑2, which addresses operation requirements.

Key topics and technical requirements

The standard provides a structured framework for safe ropes-course systems, including:

- Scope and definitions - clear terminology for elements such as activity systems, support systems, platforms, zip lines, giant swings, safety lines and landing areas.

- Site selection and structural design (Clause 4.1–4.3) - guidance on choice of site, influence of loads, and requirements for support structures (poles, trees, foundations).

- Materials and components (Clause 4.2) - requirements for wire ropes, synthetic ropes and terminations; durability and suitability of wood and metal components.

- Safety systems and PPE (Clause 4.3–4.4) - specification of collective and individual safety systems (categories A–E), primary braking systems (active and passive), and conformity with PPE standards (e.g., EN 361, EN 358).

- Testing, marking and identification (Clause 5–6) - recommended test methods, element marking and traceability.

- Inspection and maintenance (Clause 7) - regular inspection schedules, maintenance manuals and discard criteria for components.

- Documentation and guidance (Clause 8; normative Annexes) - requirements for user manuals, arboreal assessment reports (Annex A), and informative guidance on risk assessment and relevance of ISO 4309 for wire rope care (Annex C–D).

Practical applications and users

EN 15567‑1 is practical for professionals involved in planning, constructing and maintaining ropes courses:

- Designers and manufacturers - to ensure components and systems meet safety and material requirements.

- Site owners and operators - to implement safe installations, inspection regimes and maintenance manuals.

- Inspectors and certifiers - for conformity assessment, marking and discard criteria.

- Arborists and structural engineers - when trees or natural supports are used.

- Training providers and risk assessors - to align operational practices with the construction standard and to inform EN 15567‑2 evaluations.

Keywords: ropes courses, EN 15567‑1, construction and safety requirements, ropes course inspection, PPE, zip line, wire rope maintenance.

Related standards

- EN 15567‑2 (Operation requirements)

- EN 1176 (Playground equipment - excluded scope)

- ISO 4309 (Wire rope care, inspection, discard)

- Relevant PPE and wire‑rope standards cited within EN 15567‑1 (e.g., EN 361, EN 358, EN 13411 series).

Frequently Asked Questions

EN 15567-1:2015+A1:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "Sports and recreational facilities - Ropes courses - Part 1: Construction and safety requirements". This standard covers: This European Standard applies to permanent and mobile ropes courses and their components. This European Standard specifies safety requirements for the design, construction, inspection and maintenance of ropes courses and their components. This European Standard does not apply to temporary ropes courses (see 3.3) and children's play grounds (see EN 1176 all parts). For the use of ropes courses EN 15567 2 applies.

This European Standard applies to permanent and mobile ropes courses and their components. This European Standard specifies safety requirements for the design, construction, inspection and maintenance of ropes courses and their components. This European Standard does not apply to temporary ropes courses (see 3.3) and children's play grounds (see EN 1176 all parts). For the use of ropes courses EN 15567 2 applies.

EN 15567-1:2015+A1:2020 is classified under the following ICS (International Classification for Standards) categories: 97.220.10 - Sports facilities. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15567-1:2015+A1:2020 has the following relationships with other standards: It is inter standard links to EN 15567-1:2015/FprA1, EN 15567-1:2015, ISO 4309:2010, EN 13411-4:2021, EN 12927:2019, EN 13411-2:2001+A1:2008, EN 335:2013, EN 13411-3:2004+A1:2008, EN 15567-2:2015, EN 813:2024, EN 12277:2015+A1:2018, EN 636:2012+A1:2015, EN 358:2018, EN 351-1:2007, EN 1176-1:2017+A1:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15567-1:2015+A1:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2020

Nadomešča:

SIST EN 15567-1:2015

Športni in rekreacijski pripomočki - Vrvni plezalni parki - 1. del: Konstrukcijske in

varnostne zahteve

Sports and recreational facilities - Ropes courses - Part 1: Construction and safety

requirements

Sport- und Freizeitanlagen - Seilgärten - Teil 1: Konstruktion und sicherheitstechnische

Anforderungen

Structures de sport et d’activités de plein air - Parcours acrobatiques en hauteur - Partie

1 : Exigences de construction et de sécurité

Ta slovenski standard je istoveten z: EN 15567-1:2015+A1:2020

ICS:

97.220.10 Športni objekti Sports facilities

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 15567-1:2015+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

February 2020

EUROPÄISCHE NORM

ICS 97.220.10 Supersedes EN 15567-1:2015

English Version

Sports and recreational facilities - Ropes courses - Part 1:

Construction and safety requirements

Structures de sport et d'activités de plein air - Parcours Sport- und Freizeitanlagen - Seilgärten - Teil 1:

acrobatiques en hauteur - Partie 1 : Exigences de Konstruktion und sicherheitstechnische

construction et de sécurité Anforderungen

This European Standard was approved by CEN on 12 March 2015 and includes Amendment 1 approved by CEN on 11 November

2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 15567-1:2015+A1:2020 E

worldwide for CEN national Members.

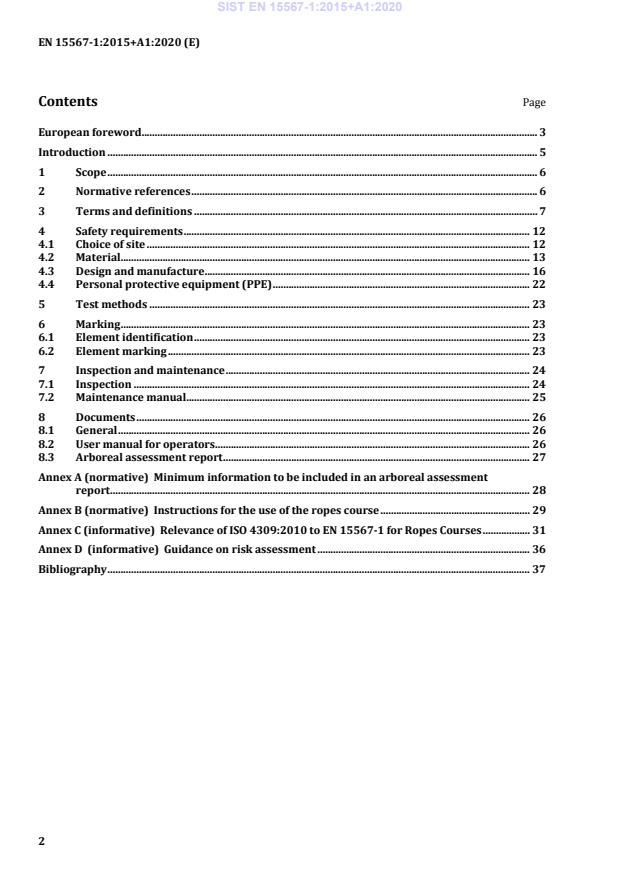

Contents Page

European foreword . 3

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Safety requirements . 12

4.1 Choice of site . 12

4.2 Material . 13

4.3 Design and manufacture . 16

4.4 Personal protective equipment (PPE) . 22

5 Test methods . 23

6 Marking . 23

6.1 Element identification . 23

6.2 Element marking . 23

7 Inspection and maintenance . 24

7.1 Inspection . 24

7.2 Maintenance manual . 25

8 Documents . 26

8.1 General . 26

8.2 User manual for operators. 26

8.3 Arboreal assessment report . 27

Annex A (normative) Minimum information to be included in an arboreal assessment

report . 28

Annex B (normative) Instructions for the use of the ropes course . 29

Annex C (informative) Relevance of ISO 4309:2010 to EN 15567-1 for Ropes Courses . 31

Annex D (informative) Guidance on risk assessment . 36

Bibliography . 37

European foreword

This document (EN 15567-1:2015+A1:2020) has been prepared by Technical Committee CEN/TC 136

“Sports, playground and other recreational facilities and equipment”, the secretariat of which is held by

DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by August 2020, and conflicting national standards shall

be withdrawn at the latest by August 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document includes amendment 1, approved by CEN on 11 November 2019.

This document supersedes !EN 15567-1:2015."

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

EN 15567 consists of the following parts, under the general title, Sports- and recreational facilities —

Ropes courses:

— Part 1: Construction and safety requirements;

— Part 2: Operation requirements.

The main changes to EN 15567-1:2007 are:

a) terms and definitions revised (Clause 3);

b) requirements for wire ropes revised (4.2.4);

c) new clause for synthetic ropes included (4.2.5);

d) influence of loads revised (4.3.2);

e) requirements for trees revised (4.3.3.3);

f) requirements for zip lines revised (4.3.4.2);

g) requirements for safety systems revised (4.3.5);

h) requirements for personal protective equipment revised in accordance with existing standards

(4.4);

i) requirements for inspection and maintenance revised (Clause 7);

j) Annex A revised;

k) Annex B deleted;

l) new Annex C “Relevance of ISO 4309:2010 to EN 15567-1 for ropes courses” added;

m) correction of editorial errors.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

Ropes courses vary considerably and may be used for educational, recreational, training or therapeutic

purposes.

Ropes course activities involve risks that should be managed by the manufacturers and operators. This

is achieved through careful design, manufacture, supervision, training, instruction, information etc.

Ropes course activities should only be undertaken by those who are physically and mentally able to

comply with the safety requirements specified by the operator.

The various safety devices (for protection against falling from a height and collisions) consist of

equipment designed to limit the consequences of falls or collisions. There are inherent risks associated

with ropes courses. These risks should, however, be appropriately managed and reduced to an

acceptable level by the ropes course operator. However, it should be understood that such risks cannot

be eliminated altogether. It should be noted that no safety system can prevent deliberate misuse.

On the basis of a risk assessment, that takes into account the manufacturer's manual, operators should

take reasonably practicable measures to ensure the safety of participants and staff. This means that the

degree of risks in a particular job/work place/facility need to be balanced against the time, trouble,

cost, benefits and physical difficulty of taking measures to avoid or reduce the risk.

Ropes course operators should also consider EN 15567-2, when carrying out risk assessments.

1 Scope

This European Standard applies to permanent and mobile ropes courses and their components.

This European Standard specifies safety requirements for the design, construction, inspection and

maintenance of ropes courses and their components.

This European Standard does not apply to temporary ropes courses (see 3.3) and children's play

grounds (see EN 1176 all parts).

For the use of ropes courses EN 15567-2 applies.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

EN 335, Durability of wood and wood-based products - Use classes: definitions, application to solid wood

and wood-based products

EN 350-2:1994, Durability of wood and wood-based products — Natural durability of solid wood — Part

2: Guide to natural durability and treatability of selected wood species of importance in Europe

EN 351-1:2007, Durability of wood and wood-based products - Preservative-treated solid wood - Part 1:

Classification of preservative penetration and retention

EN 358, Personal protective equipment for work positioning and prevention of falls from a height - Belts

and lanyards for work positioning or restraint

EN 361, Personal protective equipment against falls from a height - Full body harnesses

EN 636, Plywood — Specifications

EN 813, Personal fall protection equipment - Sit harnesses

EN 1176-1, Playground equipment and surfacing - Part 1: General safety requirements and test methods

EN 12277, Mountaineering equipment — Harnesses — Safety requirements and test methods

EN 12927-6, Safety requirements for cableway installations designed to carry persons — Ropes — Part 6:

Discard criteria

EN 13411-1, Terminations for steel wire ropes — Safety — Part 1: Thimbles for steel wire rope slings

EN 13411-2, Terminations for steel wire ropes — Safety — Part 2: Splicing of eyes for wire rope slings

EN 13411-3:2004+A1:2008, Terminations for steel wire ropes - Safety - Part 3: Ferrules and ferrule-

securing

EN 13411-4, Terminations for steel wire ropes - Safety - Part 4: Metal and resin socketing

EN 13411-5, Terminations for steel wire ropes — Safety — Part 5: U-bolt wire rope grips

EN 13411-6, Terminations for steel wire ropes — Safety — Part 6: Asymmetric wedge socket

EN 13411-7, Terminations for steel wire ropes — Safety — Part 7: Symmetric wedge socket

EN 15567-2:2015, Sports- and recreational facilities - Ropes courses - Part 2: Operation requirements

ISO 4309:2010, Cranes — Wire ropes — Care and maintenance, inspection and discard

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

ropes course

constructed facility consisting of one or more activity systems, support systems and, if needed, an

appropriate safety system with restricted access and requiring supervision

Note 1 to entry: See Figure 1.

Key

Activity systems Support systems Belaying systems

A S B

A1 Elements S1 Poles B1 Assisted belaying system

trees

A2 Platforms S2 B2 Safety line

buildings,

A3 Access S3 B3 Safety system (categories A to

rock,

E)

other supporting

structures

Foundations, anchors

Guy lines

Figure 1 — Example of a ropes course

3.2

permanent ropes course

facility installed for more than seven days on the same site

3.3

temporary ropes course

facility that is not a mobile ropes course and is installed for a maximum of seven days

3.4

mobile ropes course

facility constructed in such a way that the support system is transportable from site to site

3.5

support system

artificial and/or natural structure intended for installation of activity and safety systems

Note 1 to entry: See Figure 1 for examples.

3.6

activity system

facility that permits the progression of the participant

EXAMPLE Examples are elements, platforms and access structures, see Figure 1.

3.7

element

activity unit in a ropes course

3.8

platform

raised area usually before or after an element on which participants can stand

3.9

giant swing

activity system where the participant performs guided pendulums (to- and-fro movements)

3.10

zip line

activity system in which the participant glides under gravity in a sloping direction

3.11

landing area

area in which a participant exiting an element can land

3.12

change-over

manual transfer from one part of a safety system to another

3.13

safety line

flexible or rigid, horizontal, vertical or sloping, continuous or discontinuous device used as a protection

against falling from a height

3.14

interlocking device

device with at least two gates whereby an action on the one gate results in an effect on another gate

EXAMPLE The opening of one gate causes the locking of another gate.

3.15

safety system

system used either to prevent, to arrest or cushion a participant's fall

Note 1 to entry: Examples of fall safety systems are guard rails, safety line, landing mat, net, retractable lifeline.

3.16

individual safety system

component(s) connecting the harness to the safety line

Note 1 to entry: Each of the following systems A to E provide adequate levels of safety when used in

combination with appropriate supervision, training, instruction and information. See also EN 15567-2.

3.16.1

individual safety system category A

self-closing device which is not automatically self-locking

EXAMPLE Self-closing or screw gate connector.

3.16.2

individual safety system category B

self-locking device

EXAMPLE Self-locking connector.

3.16.3

individual safety system category C

interlocking device designed to reduce the likelihood of unintentional detaching from the safety system

3.16.4

individual safety system category D

interlocking device designed to prevent unintentional detaching from the safety system

3.16.5

individual safety system category E

device that is permanently attached during operation and can only be opened with a tool

3.17

collective safety system

system which can protect at least one person and, once properly installed or erected, does not require

any action by the user to make sure it will work

Note 1 to entry: Examples include scaffolds, towers, nets, airbags, etc.

3.18

assisted belay system

belaying system where the participant is secured by at least one person

3.19

spotting

one or more persons working to catch, hold or give physical support to other participants

3.20

critical application

application where the consequences of a failure are likely to lead to a serious injury or death

3.21

serious injury

any of the following injuries:

— fractures, other than to fingers, thumbs and toes;

— amputations;

— any injury likely to lead to permanent loss of sight or reduction in sight;

— any crush injury to the head or torso causing damage to the brain or internal organs;

— serious burns (including scalding) which:

— covers more than 10 % of the body;

— causes significant damage to the eyes, respiratory system or other vital organs;

— any scalping requiring hospital treatment;

— any loss of consciousness caused by head injury or asphyxia;

— any other injury arising from working in an enclosed space which:

— leads to hypothermia or heat-induced illness;

— requires resuscitation or admittance to hospital for more than 24 h

3.22

primary brake

braking system engaged during normal operation to arrest the participant which can be either active or

passive

3.22.1

active braking system

braking system operated by the participant or another person

3.22.2

passive braking system

braking system operating without manual intervention

EXAMPLE Examples are bungee, gravity, net, water, impact absorbers, impact absorbent floors, landing mats,

etc.

3.23

emergency brake

passive braking system that controls participant deceleration upon failure of the primary brake without

causing serious injury or death

3.24

level 1 supervision

situation whereby an instructor can physically intervene to prevent a misuse of the individual safety

system that would otherwise lead to a significant risk of serious injury or death

3.25

level 2 supervision

situation whereby an instructor is able to see the participant and intervene verbally

3.26

level 3 supervision

situation whereby a participant is in a position to alert an instructor of their need for assistance, who is

able to respond promptly to the alert and provide adequate assistance

Note 1 to entry: It is intended that the role of the instructor is to be available to provide adequate assistance to a

participant if called upon to do so. This is a largely reactive, rather than proactive, role.

3.27

fall factor

the height of the fall or distance fallen divided by the length of the lanyard or rope that is used

3.28

falling space

any space into which a participant may enter during a fall stopped by the safety system

3.29

free space

space in, on or around an element that can accommodate a participant whilst attached to the safety

system

EXAMPLE Examples are oscillating space for a zip line or for a giant swing.

3.30

free height of fall

greatest vertical distance from the clearly intended structure supporting the body to the impact area

below

3.31

dead load

weight of the element when unloaded

3.32

characteristic load

maximum (un-factored) load that can be generated in normal use

3.33

imposed load

load corresponding to the average weight of a participant multiplied by the number of participants

simultaneously authorized on the element

3.34

dynamic load

vertical impact force imposed on the safety system generated by a falling participant

3.35

routine visual check

inspection intended to identify obvious hazards that can result from vandalism, use or weather

conditions

3.36

operational inspection

inspection, more detailed than routine visual inspection, to check the operation and condition of the

equipment

3.37

periodical inspection

verification carried out by an inspection body at least once per calendar year and within a maximum

interval of 15 months intended to establish the level of safety of the ropes course

3.38

functional test

practical test of elements to ensure they are fit for purpose

3.39

inspection body

body that performs inspections

Note 1 to entry: A body can be an organization or part of an organization.

[SOURCE: EN ISO/IEC 17020:2012, 3.5]

Note 2 to entry: EN ISO/IEC 17020 defines inspection bodies of type A, type B and type C, covered by

appropriate professional civil liability insurance.

3.40

arboricultural expert

competent person able to undertake arboreal assessments

Note 1 to entry: Expert covered by appropriate professional civil liability insurance.

3.41

competent person

someone who has the necessary technical expertise, training and experience to carry out the task

3.42

arboreal assessment report

report of a periodical inspection comparing the condition of the trees in relation to the last assessment

4 Safety requirements

4.1 Choice of site

The site of the ropes course shall be chosen to ensure that it is located in an area of reasonable

operating safety. It shall be possible to evacuate participants from any part of the ropes course.

The immediate surrounding area shall not impair the safety of the structure and the activities taking

place on the site.

Local factors (e.g. lightning, humidity, corrosion, flooding, avalanches, soil conditions, weather patterns

and evidence of previous tree failures, etc.) shall be taken into consideration in both the design and the

operation of the facility, see EN 15567-2. Local land managers and foresters may need to be consulted.

Unauthorized access to the ropes course shall be taken into account referring to national regulations.

NOTE In general, the installation and use of ropes courses will cause changes to the environment which are

covered by national legislation in force.

4.2 Material

4.2.1 General

Materials shall conform to 4.2.2, 4.2.3, 4.2.4 and 4.2.5.

Materials shall be fit for purpose.

NOTE 1 The provisions relating to certain materials in this standard do not imply that other equivalent

materials are unsuitable in the manufacture of ropes courses.

The selection of materials and their use should be in accordance with appropriate European Standards.

Materials shall be selected and protected so that the structural integrity of the equipment manufactured

from these materials should not be rendered unserviceable before the next relevant inspection.

NOTE 2 EN 15567-2 gives recommendations on inspections.

Particular care should be taken in the choice of materials where equipment is to be used in extreme

climatic or atmospheric conditions.

In the choice of materials or substances for ropes courses, consideration should be given to the eventual

disposal of the material or substance having regard to any possible environmental toxic hazard.

For all Materials used in critical applications, a competent person shall determine an inspection

procedure or comply with the manufacturer's recommendations.

Consideration should also be given to degradation of structural components through ultraviolet

influences.

4.2.2 Timber and associated products

Timber parts should be designed in such a way that precipitation can drain off freely and water

accumulation is avoided.

In cases of ground contact, one or more of the following methods shall be used to minimize the risk of

rot:

a) use of timber species with sufficient natural resistance in accordance with Classes 1 and 2 of the

natural resistance classification given in EN 350-2:1994, 4.2.2.

b) construction methods, e.g. post shoe;

c) use of timber treated with wood preservatives in accordance with EN 351-1:2007, Figure A.1 and in

accordance with hazard Class 4 of EN 335.

Consideration should also be given to other factors which can be hazardous, such as splintering,

poisoning etc.

All components made of timber and associated products, other than those species conforming to a), that

affect the stability of the structure and are in constant contact with the ground shall be treated in

accordance with c).

When selecting metal fastenings, consideration should be given to the species of timber and chemical

treatments used as some will accelerate corrosion of metals if there is contact.

Plywood used for outdoor installations shall conform to EN 636.

EN 14229 may be used for ropes courses where timber poles are used for the support system.

4.2.3 Metals

Consideration shall be given to the corrosion of metal components.

Metals that produce toxic oxides shall be protected by a non-toxic coating.

4.2.4 Wire ropes

The choice of the wire rope shall be appropriate for the application. For wire safety lines only

galvanized or stainless steel wire ropes shall be used. Synthetic core wire ropes may also be

appropriate.

Wire ropes with natural fibre core shall not be used in critical applications.

A wire rope discard criteria shall be in accordance with the relevant sections of ISO 4309:2010. For

guidance see Annex C. For cables which are not covered by ISO 4309:2010, EN 12927-6 applies.

All wire rope terminations shall conform to EN 13411-1, EN 13411-2, EN 13411-3, EN 13411-4,

EN 13411-5, EN 13411-6 and EN 13411-7 or an appropriate documented test shall be carried out.

Only the following conditions are considered to be acceptable variations from EN 13411-3 in relation to

the use of ferrules on wire rope termination used on ropes courses.

a) The fatigue test (EN 13411-3:2004+A1:2008, 5.1.2.3) is not required if a second ferrule-secured

termination is applied. In such cases, the second ferrule shall be applied in such a way that the end

of the cable is at least flush with the end of the compressed ferrule-secured termination and in a

manner that is consistent with the design provided by the ferrule-secured system designer.

b) All ferrules used for wire rope termination on ropes courses shall display (legibly) the ferrule-

secured termination manufacturer’s mark/identity. A mark for individual traceability, as would

normally be required by EN 13411-3:2004+A1:2008, 7.1 b), is waived.

c) A record shall be kept by the ropes course owner of the ferrule-secured termination manufacturer’s

details. There shall be no requirement to certificate the ferrule-secured termination as is required

by EN 13411-3:2004+A1:2008, 7.2.

If other types of wire rope terminations are used they shall be used in accordance with the

manufacturer's guidelines.

Terminations shall consider the effects of the closure angle. An angle α ≤ 60 ° is recommended (see

Figure 2, e.g. trees and poles).

Key

α = angle of

termination

Figure 2 — Angle of termination

If angles α > 60 °are applied, sufficient measures shall be taken to protect the termination from

inappropriate radial loading.

If the angle α is > 120 °, particular care shall be taken to ensure the strength of the wire rope is

sufficient.

If it is necessary to use rope clamps to make an in line connection of two separate wire rope

terminations, Figure 3 provides an example of an inline connection.

a) Correct and wrong placement of rope grips when connecting parallel rope ends

b) Double-lug head fittings

Figure 3 — Placement of wire rope grips

NOTE Figure 3 indicates only the position of wire rope grips. The number of wire rope grips according to

EN 13411-5 will depend on the nature and the diameter of the wire rope and the types of wire ropes and grips

used.

Plastic covered wire ropes shall not be used for zip lines.

If plastic covered wire ropes are used for a critical application they shall be constructed of galvanized or

stainless steel and an appropriate inspection process shall be applied to take account of difficulties in

their visual inspection. If during an inspection damage to the coating is observed (except for the dead

ends) sufficient to allow water ingress the wire rope shall be discarded.

Either of the following test methods for plastic covered ropes shall be undertaken every two years with

2 samples of the oldest or most subject to fatigue wire ropes used in the course:

1) breaking test, in which the minimum design calculation shall be reached;

2) interior wire rope inspection.

Points of attachment on wire ropes are liable to create changes in local curvature of wire rope and

might therefore create local fatigue, therefore these points shall be given special attention during

inspection and examination.

Care shall be taken to ensure that the torque settings of wire rope grips comply with EN 13411-5.

4.2.5 Synthetic ropes

The choice of the synthetic rope shall be appropriate for the application.

4.2.6 Synthetics and composites

If, in maintenance, it is difficult to determine at what point material becomes brittle, manufacturers

shall give an indication of the time period after which the part or equipment should be replaced.

It should be possible to identify excessive wear of the gelcoat of GRP (glass-reinforced plastics)

products intended for sliding before the participant becomes exposed to the glass fibres. (This can be

achieved for example by the use of different coloured layers in the sliding surface.)

4.2.7 Dangerous substances

Dangerous substances shall not be used in ropes courses in such a way that they can cause adverse

health effects to the user of the equipment.

NOTE Attention is drawn to the provisions of Directive 76/769/EEC. Such materials include, for example,

asbestos, lead, formaldehyde, coal tar oils, carbolineums and polychlorinated biphenyls (PCB).

4.3 Design and manufacture

4.3.1 General safety requirements

Ropes Courses shall be designed with consideration for the size and the body weight of the participants.

Moving parts shall be designed to limit the risk of injury.

There shall be no sharp edges or burrs on the facility within reach of the user.

The installation shall be constructed and the equipment shall be chosen so that any openings that can

be reached in normal use do not create hidden entrapment hazards.

The free and falling space shall not contain any unprotected obstacles that a person manoeuvring or

falling might crash into, other than the constituent parts of the activity system.

If there is a likelihood of a participant sustaining injury from collision with an obstacle located in the

vicinity of the element (for example a tree), an appropriate safety device should be installed (for

example a pad should be fitted over part of the tree).

On safety system categories A to C a clear distinction between the safety line and the activity system

(hauling system, handlines) shall be made.

It shall be impossible to connect to the dead end of any wire rope.

Ropes courses shall be designed with regard for course evacuation and the rescue of individual

participants (access, anchor location, egress).

Elements located one above the other shall be designed so that lowering of a person who has to be

rescued is not prevented.

It shall not be possible to undo critical components without a tool.

4.3.2 Influence of loads

4.3.2.1 General

The influence of loads needs to be taken into account during design and manufacture of ropes courses.

Such loads can be permanent or variable.

4.3.2.2 Permanent loads

The permanent loads consist of the dead load of the built structure.

4.3.2.3 Variable loads

4.3.2.3.1 General

The variable loads consist of:

a) user loads (static and dynamic);

b) snow loads;

c) wind loads;

d) effects of temperature;

e) special loads.

4.3.2.3.2 User loads

Empirical evidence suggests that it is impossible to have two or more users/participants create a peak

impact force simultaneously due to a fall. The user loads are given in Table 1.

Table 1 — User loads

Description Characteristic Characteristic Characteristic

Vertical Load Vertical Load Horizontal Load

(component) (component) (component, only if

needed)

F q q

v h

Weight of user 0,8 kN — 0,08 kN (1/10 F)

User Load on platforms

and elements where an

2 2

independent, — 1,6 kN/m 0,16 kN/m (1/10 q )

v

individual, or collective

safety system exists

User load on zip lines

where the fall factor is 3,0 kN — 0,6 kN (1/5 F)

less than 0,5

User load for all other 6,0 kN — 1,2 kN (1/5 F)

types of safety systems

User load on elements

where a fall factor

cannot occur e.g. when 3,0 kN — 0,6 kN (1/5 F)

participant is enclosed

within a net

4.3.2.3.3 Snow loads, wind loads and effects of temperature

Data for snow loads, wind loads and effects of temperature can be found in the Eurocodes for actions on

structures (EN 1991-1-1, EN 1991-1-2, EN 1991-1-3, EN 1991-1-4 and EN 1991-1-5) or appropriate

national standard.

4.3.2.3.4 Special loads

These may include earthquakes or unusual emergency procedures.

NOTE User Loads are not special loads.

4.3.2.3.5 Calculations

The calculation of artificial supporting structures shall be in accordance with relevant Eurocodes.

Design calculations shall be provided for all artificial supporting structures.

Loads provided in Table 1 are characteristic loads (un-factored) and therefore relevant factors of safety

shall be applied (i.e. dependent on the materials used).

For the purposes of design a safety factor of 3 of the minimum breaking load shall be applied to wire

ropes. For a belaying system this shall be in accordance with the loads defined in Table 1. The

calculation shall take into account the weakness coefficient caused by wire rope termination (see

EN 13411 all parts).

For the assessment of natural supporting structures (e.g. trees and rock) see 4.3.3.3.

4.3.3 Support system

4.3.3.1 General

The support system shall have the stability and resistance appropriate for the loads given in 4.3.2.3.

The support system may include:

a) Artificial elements like:

1) framework with foundation;

2) guys;

3) foundations;

4) tension bars and compression bars;

5) mounting parts on or in buildings.

b) Natural elements like:

1) trees;

2) rocks.

4.3.3.2 Safety requirements for artificial components

4.3.3.2.1 General

Hauling systems, retrieval systems and guys shall either be inaccessible for participants or clearly

identified as not being a safe connection point.

4.3.3.2.2 Guys

Careful attention shall be given to the position of guys.

When they are accessible from the ground they shall be clearly visible or protected to avoid injury.

Guys shall either be made inaccessible to participants or, when guys are accessible on a belaying system

or from the ground, they shall have a device that discourages misuse.

4.3.3.2.3 Existing supporting structures

Before attaching elements to an existing supporting structure, it shall be evaluated for structural

strength, hazards (e.g. electrical) and accessibility.

In instances where the ropes course transmits loads to the existing supporting structure (e.g. a host

building) care shall be exercised to ensure that the existing supporting structure can bear the loads

created by the ropes course.

Design calculations shall confirm that the existing supporting structure is fit for purpose.

The manufacturer of the ropes course shall provide the owner of the existing supporting structure (or

their agent) with all the relevant information relating to the loads and forces that the ropes course and

associated equipment may apply to the existing supporting structure.

4.3.3.3 Safety requirements for natural supporting structures

4.3.3.3.1 Trees

4.3.3.3.1.1 Tree strength assessment

A tree strength assessment shall be undertaken to consider the suitability of each tree in relation to its

intended use and loads applied. The use of additional supports (e.g. guys) shall be considered.

4.3.3.3.1.2 Arboreal assessment

An assessment shall be undertaken of each intended site to consider its general suitability. The general

condition of other trees in the vicinity of the course shall be considered, in order that a reasonably safe

environment can be achieved.

Following initial selection by the course designer, all trees used should be subject to inspection by a

competent arboriculturist to assess their physiological condition and suitability for the intended use.

The assessment shall be carried out post course design and preferably before construction commences.

In any event, the inspection should take place before the course is inaugurated.

Tree selection shall be based primarily on visual assessment of external features to determine each

tree’s physiological and structural condition. Initial assessment may prompt further investigation using

simple tools (such as soft-headed hammers and rigid probes) or more complex methods (such as micro

drilling and sonic tomography) to evaluate internal stem condition.

The inspection shall include an assessment of each tree's diameter, estimated height, vitality and form.

Consideration should also be given to the effect on tree roots from compaction, erosion and physical

damage during the construction phase and continued use. Suitable remedial action should be taken

where necessary. Where assessment identifies work required to trees on site, to improve their

suitability or to remove a danger, this should be carried out by competent arboriculturists before

inauguration.

4.3.3.3.1.3 Periodic arboreal assessment and inspection

For periodic arboreal assessment and inspection Annex A applies.

4.3.3.3.1.4 Tree and root system protection

The systems used to fix the platforms, safety lines and elements shall be designed to minimize any

damage to the trees.

Measures should be taken to protect the root system, particularly against compaction.

4.3.3.3.2 Rocks

When rocks are used as supporting structures the anchor pull out strength shall be at least 4 times the

applied load. The choice of anchor should take into account the environmental conditions of the site.

4.3.4 Activity system

4.3.4.1 General

The activity systems shall be designed to accommodate the imposed loads.

The activity system may include for example:

a) ropes, chains and straps;

b) beams, ladders, bridges;

c) landings and platforms;

d) nets; and

e) descending devices.

4.3.4.2 Zip lines

4.3.4.2.1 General

Zip lines shall have no exposed broken wire ends within the reach of the participants.

If any part of the zip line or the landing area is not visible from the starting point, a departure regulation

system shall be used.

Appropriate training and equipment shall be provided if participants are required to brake actively

during the descent.

A passive braking system shall always be in place.

4.3.4.2.2 Special case: zip line with safety line

If a zip line is designed with a supporting cable for the trolley and another cable for the belay then each

cable shall be calculated according to 4.3.2.3.2.

4.3.4.2.3 Single rope zip lines

If a zip line consists of a single rope that is used both as a progression rope and a safety line, the safety

line calculation rules shall be applied, see 4.3.2.3.2.

For single rope zip lines different fall factors and user loads shall be considered (see Figure 4).

a) fall factor > 0,5, user load = 6 kN b) fall factor ≤ 0,5, user load = 3 kN

Figure 4 — Fall factors and user loads for single ropes zip lines

4.3.4.2.4 Protection at zip line arrival areas

A primary brake shall be in place to control the rate of deceleration in the arrival area thereby reducing

the risk of injury to an acceptable level.

An emergency brake shall be in place where failure of the primary brake would result in a significant

risk of serious injury or death.

4.3.4.3 Platform

The characteristics of the platforms used for an activity system shall:

a) ensure a stable position of balance;

b) withstand the load for which they are designed.

4.3.5 Safety system

4.3.5.1 General

Each safety system and its constituent equipment shall be fit for purpose when combined with the

appropriate levels of design, manufacture, information, instruction, training and supervision as set out

in EN 15567-2.

Evidence of appropriate welding shall be provided when welding forms part of a critical application.

Evidence of suitability shall be supplied for any non-certified component, e.g. type examinations, design

calculations, etc.

Specific attention should be given to the frequency of use. When equipment is provided to participants,

the manufacturer's instructions and the requirements specified in this document shall be observed on

all the used safety systems.

EXAMPLE A device conforming to EN 341 may be suitable for a rescue of a fall from a tower. However, it may

not be fit for purpose for everyday use in a ropes course.

Safety systems can be:

a) collective:

1) guard rails and railings;

2) nets, landing mats and impact absorbent floors appropriate to the potential fall height;

b) individual:

1) safety systems categories A to E: in this case, participants shall wear a harness attached to a

safety line;

2) safety systems categories A to E shall conform to the relevant clauses of European PPE

standards;

c) assisted belaying system: in this case participants shall wear a harness attached to a rope, belayed

by one or more persons using appropriate techniques. assisted belaying systems shall conform to

the relevant clauses of European PPE

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...