EN 13480-4:2017

(Main)Metallic industrial piping - Part 4: Fabrication and installation

Metallic industrial piping - Part 4: Fabrication and installation

This Part of this European Standard specifies the requirements for fabrication and installation of piping systems, including supports, designed in accordance with EN 13480-3:2017.

Metallische industrielle Rohrleitungen - Teil 4: Fertigung und Verlegung

Dieser Teil der Europäischen Norm legt die Anforderungen an die Fertigung und Verlegung, einschließlich der Halterungen, von Rohrleitungssystemen, die nach EN 13480-3:2017 konstruiert sind, fest.

Tuyauteries industrielles métalliques - Partie 4: Fabrication et installation

La présente partie de la présente Norme européenne spécifie les exigences relatives à la fabrication et à l'installation des réseaux de tuyauteries, supports inclus, conçus conformément à l’EN 13480-3:2017.

Kovinski industrijski cevovodi - 4. del: Proizvodnja in vgradnja

Ta del tega evropskega standarda določa zahteve za proizvodnjo in vgradnjo cevnih sistemov, vključno z nosilci, ki so konstruirani v skladu s standardom EN 13480-3:2017.

General Information

- Status

- Withdrawn

- Publication Date

- 27-Jun-2017

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 267 - Industrial piping and pipelines

- Drafting Committee

- CEN/TC 267/WG 8 - Maintenance of EN 13480 series

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 24-Jul-2024

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 08-Jun-2022

- Effective Date

- 08-Jun-2022

- Effective Date

- 05-Jul-2017

- Effective Date

- 15-Feb-2017

- Effective Date

- 15-Feb-2017

- Effective Date

- 19-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 13480-4:2017 is a standard published by the European Committee for Standardization (CEN). Its full title is "Metallic industrial piping - Part 4: Fabrication and installation". This standard covers: This Part of this European Standard specifies the requirements for fabrication and installation of piping systems, including supports, designed in accordance with EN 13480-3:2017.

This Part of this European Standard specifies the requirements for fabrication and installation of piping systems, including supports, designed in accordance with EN 13480-3:2017.

EN 13480-4:2017 is classified under the following ICS (International Classification for Standards) categories: 23.040.01 - Pipeline components and pipelines in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13480-4:2017 has the following relationships with other standards: It is inter standard links to EN 13480-4:2012, EN 13480-4:2012/A2:2015, EN 13480-4:2012/A1:2013, EN 13480-4:2012/A5:2017, EN 13480-4:2012/A3:2016, EN 13480-4:2012/A4:2017, EN 13480-4:2024, EN ISO 15613:2004, EN ISO 15609-6:2013, EN 13480-5:2017, EN ISO 15608:2025, EN ISO 15609-5:2011, EN 10204:2004, EN ISO 14732:2013, EN ISO 15610:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13480-4:2017 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13480-4:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Kovinski industrijski cevovodi - 4. del: Proizvodnja in vgradnjaMetallische industrielle Rohrleitungen - Teil 4: Fertigung und VerlegungTuyauteries industrielles métalliques - Partie 4: Fabrication et installationMetallic industrial piping - Part 4: Fabrication and installation77.140.75Jeklene cevi in cevni profili za posebne nameneSteel pipes and tubes for specific use23.040.10Železne in jeklene ceviIron and steel pipesICS:Ta slovenski standard je istoveten z:EN 13480-4:2017SIST EN 13480-4:2018en,fr,de01-januar-2018SIST EN 13480-4:2018SLOVENSKI

STANDARDSIST EN 13480-4:2012/A3:2017SIST EN 13480-4:2012/A4:2017SIST EN 13480-4:2012/A5:2018SIST EN 13480-4:2012SIST EN 13480-4:2012/A1:2013SIST EN 13480-4:2012/A2:20161DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13480-4

June

t r s y ICS

t uä r v rä r s Supersedes EN

s u v z ræ vã t r s tEnglish Version

Metallic industrial piping æ Part

vã Fabrication and installation Tuyauteries industrielles métalliques æ Partie

v ã Fabrication et installation

Metallische industrielle Rohrleitungen æ Teil

vã Fertigung und Verlegung This European Standard was approved by CEN on

t s June

t r s yä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s y CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s u v z ræ vã t r s y ESIST EN 13480-4:2018

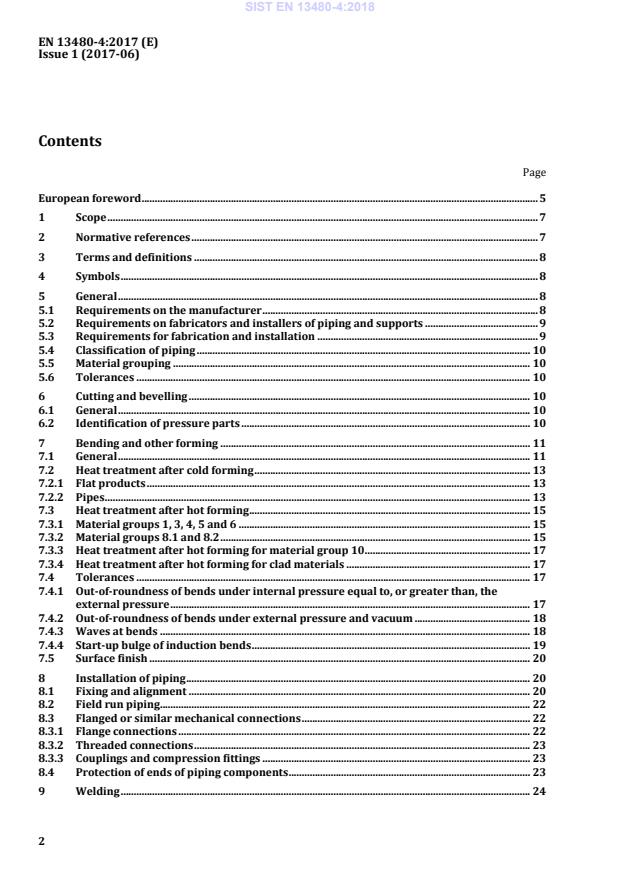

EN13480æ4:2017(E)Issue1(2017æ06)2ContentsFPageFEuropeanforeword.5 1Scope.7 2Normativereferences.7 3Termsanddefinitions.8 4Symbols.8 5General.8 5.1Requirementsonthemanufacturer.8 5.2Requirementsonfabricatorsandinstallersofpipingandsupports.9 5.3Requirementsforfabricationandinstallation.9 5.4Classificationofpiping.10 5.5Materialgrouping.10 5.6Tolerances.10 6Cuttingandbevelling.10 6.1General.10 6.2Identificationofpressureparts.10 7Bendingandotherforming.11 7.1General.11 7.2Heattreatmentaftercoldforming.13 7.2.1Flatproducts.13 7.2.2Pipes.13 7.3Heattreatmentafterhotforming.15 7.3.1Materialgroups1,3,4,5and6.15 7.3.2Materialgroups8.1and8.2.15 7.3.3Heattreatmentafterhotformingformaterialgroup10.17 7.3.4Heattreatmentafterhotformingforcladmaterials.17 7.4Tolerances.17 7.4.1Outæofæroundnessofbendsunderinternalpressureequalto,orgreaterthan,theexternalpressure.17 7.4.2Outæofæroundnessofbendsunderexternalpressureandvacuum.18 7.4.3Wavesatbends.18 7.4.4Startæupbulgeofinductionbends.19 7.5Surfacefinish.20 8Installationofpiping.20 8.1Fixingandalignment.20 8.2Fieldrunpiping.22 8.3Flangedorsimilarmechanicalconnections.22 8.3.1Flangeconnections.22 8.3.2Threadedconnections.23 8.3.3Couplingsandcompressionfittings.23 8.4Protectionofendsofpipingcomponents.23 9Welding.24 SIST EN 13480-4:2018

EN13480æ4:2017(E)Issue1(2017æ06)39.1Weldingpersonnel.24 9.2Weldingprocedurespecifications.24 9.3Weldingprocedures.24 9.3.1Verificationofsuitability.24 9.3.2Application.25 9.4Fillermetalsandauxiliarymaterials.26 9.5Climaticconditions.26 9.6Cleaningbeforeandafterwelding.26 9.7Jointpreparation.27 9.8Edgeprotection.27 9.9Assemblyforwelding.27 9.10Earthing.27 9.11Performanceofwelding.28 9.11.1Preheating.28 9.11.2Strikingmarks.28 9.11.3Externalwelds.28 9.11.4Dissimilarjoints.28 9.12Backingrings.28 9.13Attachments.29 9.13.1General.29 9.13.2Temporaryattachments.29 9.13.3Permanentattachments.29 9.14Postæweldheattreatment.29 9.14.1General.29 9.14.2Equipment.33 9.14.3Temperaturemeasurements.33 9.14.4Controllingthickness.33 9.14.5Rateofheating.35 9.14.6Localheattreatment.35 9.14.7Insulation.36 9.15Weldidentification.36 10Adjustmentandrepair.36 10.1General.36 10.2Adjustment.36 10.2.1Coldhammering.36 10.2.2Adjustmentsbymeansofheat.36 10.2.3Adjustmentbywelding.37 10.2.4Adjustmentbylocalforging.37 10.3Weldrepair.37 11Markinganddocumentation.37 11.1Markingofspoolsandcomponentsforinstallation.37 11.2Markingandidentificationofinstalledpiping.37 11.2.1General.37 11.2.2CEMarkingofinstalledpiping.38 11.2.3Technicalidentificationofinstalledpiping.38 12Additionalrequirements.39 12.1Cleaning.39 12.2Temporarypreservation.39 12.3Externalcorrosionprotection.39 12.4Thermalandacousticinsulation.39 12.5Connectionsforstaticelectricity.40 SIST EN 13480-4:2018

EN13480æ4:2017(E)Issue1(2017æ06)4AnnexA(informative)Contaminationandsurfacequalityofstainlesssteel.41 A.1Introduction.41 A.2Protection.41 A.2.1Handling.41 A.2.2Duringfabricationandinstallation.41 A.3Controlledcleaningmethods.42 A.4Chemicaltreatments.42 A.4.1Acidpickling.42 A.4.2Decontamination,passivation.43 A.5Preparingforshipment.43 AnnexBDimensionaltolerancesforfabricatedspools.44 AnnexYHistoryofEN13480æ4.46 Y.1DifferencesbetweenEN13480æ4:2012andEN13480æ4:2017.46 AnnexZARelationshipbetweenthisEuropeanStandardandtheEssentialRequirementsofEUDirective2014/68/EUaimedtobecovered.47 Bibliography.48 FFFSIST EN 13480-4:2018

EN13480æ4:2017(E)Issue1(2017æ06)5EuropeanforewordpipingFandFpipelinesóáFtheFsecretariatFofFwhichFisFheldFbyFAFNORäFThisFEuropeanFStandardFshallFbeFgivenFtheFstatusFofFaFnationalFstandardáFeitherFbyFpublicationFofFanFidenticalFtextForFbyFendorsementáFatFtheFlatestFbyFDecemberFFtFrFsFyáFandFconflictingFnationalFstandardsFshallFbeFwithdrawnFatFtheFlatestFbyFDecemberFFtFrFsFyäFAttentionFisFdrawnFtoFtheFpossibilityFthatFsomeFofFtheFelementsFofFthisFdocumentFmayFbeFtheFsubjectFofFleFforFidentifyingFanyForFallFsuchFpatentFrightsäFThisFdocumentFhasFbeenFpreparedFunderFaFmandateFgivenFtoFCENFbyFtheFEuropeanFCommissionFandFtheFEuropeanFFreeFTradeFAssociationáFandFsupportsFessentialFrequireForFrelationshipFwithFEUFDirectiáFwhichFisFanFintegralFpartFofFthisFdocumentäFThisFEuropeanFStandardFENFFsFuFvFzFrFforFmetallicFindustrialFpipingFconsistsFofFeightFinterdependentFandFnotFdissociableFPartsFwhichFareãF Part1:General; Part2:Materials; Part3:Designandcalculation; Part4:Fabricationandinstallation; Part5:Inspectionandtesting; Part6:Additionalrequirementsforburiedpiping; CEN/TR13480æ7,Guidanceontheuseofconformityassessmentprocedures; Part8:Additionalrequirementsforaluminiumandaluminiumalloypiping.AlthoughFtheseFPartsFmayFbeFobtainedFseparatelyáFitFshouldFbeFrecognisedFthatFtheFPartsFareFinterædependantäFAsFsuchFtheFmanufactureFofFmetallicFindustrialFpipingFrequiresFtheFapplicationFofFallFtheFrelevantFPartsFinForderFforFtheFrequirementsFofFtheFStandardFtoFbeFsatisfactorilyFfulfilledäFThisFEuropeanFStandardFwillFbeFmaintainedFbyFaFMaintenanceFMHDFworkingFgroupFwhoseFscopeFofFworkingFisFlimitedFtoFcorrectionsFandFinterpretationsFrelatedFtoFENFFsFuFvFzFräFSIST EN 13480-4:2018

EN13480æ4:2017(E)Issue1(2017æ06)6submittingFquestionsFcanFbeFdownloadedFfromFtheFlinkFtoFtheFMHDFwebsiteäFAfterFsubjectFexpertsFhaveFagreedFanFansweráFtheFanswerFwillFbeFcommunicatedFtoFtheFquestioneräFCorrectedFpagesFwillFbeFgivenFspecificFissueFnumberFandFissuedFbyFCENFaccordingFtoFCENFRulesäFInterpretationFsheetsFwillFbeFpostedFonFtheFwebsiteFofFtheFMHDäFThisFdocumentFsupersedesFENFFsFuFvFzFræFvãFtFrFsFtäFThisFnewFeditionFincorporatesFtheFAmendmentsFwhichFhaveFbeenFapprovedFpreviouslyFbyFCENFmembersáFandFtheFcorrectedFpagesFupFtoFIssueFFvFwithoutFanyFfurtherFtechnicalFchangeäFAnnexFYFprovidesFdetailsFofFsignificantFtechnicalFchangesFbetweenFthisFEuropeanFStandardFandFtheFpreviousFeditionäFAmendmentsFtoFthisFnewFeditionFmayFbeFissuedFfromFtimeFtoFtimeFandFthenFusedFimmediatelyFasFalternativesFtoFrulesFcontainedFhereinäFAccordingFtoFtheFCENæCENELECFInternalFRegulationsáFtheFnationalFstandardsForganizationsFofFtheFfollowingFcountriesFareFboundFtoFimplementFthisFEuropeanFStandardãFAustriaáFBelgiumáFBulgariaáFCroatiaáFCyprusáFCzechFRepublicáFDenmarkáFEstoniaáFFinlandáFFormerFYugoslavFRepublicFofFMacedoniaáFFranceáFGermanyáFGreeceáFHungaryáFIcelandáFIrelandáFItalyáFLatviaáFLithuaniaáFLuxembourgáFMaltaáFNetherlandsáFNorwayáFPolandáFPortugaláFRomaniaáFSerbiaáFSlovakiaáFSloveniaáFSpaináFSwedenáFSwitzerlandáFTurkeyFandFtheFUnitedFKingdomäFFFFFFFFFFFFFFFFFFSIST EN 13480-4:2018

EN13480æ4:2017(E)Issue1(2017æ06)71 ScopeThisFPartFofFthisFEuropeanFStandardFspecifiesFtheFrequirementsFforFfabricationFandFinstallationFofFpipingFsystemsáFincludingFsupportsáFdesignedFinFaccordanceFwithFENFFsFuFvFzFræFuãFtFrFsFyäF2 NormativereferencesTheFfollowingFdocumentsáFinFwholeForFinFpartáFareFnormativelyFreferencedFinFthisFdocumentFandFareFindispensableFforFitsFapplicationäFForFdatedFreferencesáFonlyFtheFeditionFcitedFappliesäFForFundatedFreferencesáFtheFlatestENFFsFrFtFrFvãFtFrFrFváFMetallicproducts—TypesofinspectiondocumentsENFFsFtF{FwFtæFwãFtFrFsFsáFWaterætubeboilersandauxiliaryinstallations—Part5:WorkmanshipandconstructionofpressurepartsoftheboilerFENFFsFuFvFzFræFsãFtFrFsFyáFMetallicindustrialpiping—Part1:GeneralENFFsFuFvFzFræFtãFtFrFsFyáFMetallicindustrialpiping—Part2:MaterialsFENFFsFuFvFzFræFuãFtFrFsFyáFMetallicindustrialpiping—Part3:DesignandcalculationFENFFsFuFvFzFræFwãFtFrFsFyáFMetallicindustrialpiping—Part5:InspectionandFtestingENFISOFFuFzFuFvæFuãFtFrFrFwáFQualityrequirementsforfusionweldingofmetallicmaterials—Part3:Standardqualityrequirements(ISO3834æ3:2005)ENFISOFFvFrFxFuãFtFrFsFráFWeldingandalliedprocesses—Nomenclatureofprocessesandreferencenumbers(ISO4063:2009,Correctedversion2010æ03æ01)FENFISOFFwFzFsFyãFtFrFrFyáFWelding—Fusionæweldedjointsinsteel,nickel,titaniumandtheiralloys(beamweldingexcluded)—Qualitylevelsforimperfections(ISO5817:2003,correctedversion:2005,includingTechnicalCorrigendum1:2006)ENFISOFF{FxFrFxæFsãFtFrFsFuáFQualificationtestingofwelders—Fusionwelding—Part1:Steels(ISO9606æ1:2012,FincludingCor1:2012)FENFISOFFsFuF{FtFráFWelding—Generaltolerancesforweldedconstructions—Dimensionsforlengthsandangles—Shapeandposition(ISO13920)ENFISOFFsFvFyFuFtãFtFrFsFuáFWeldingpersonnel—Qualificationtestingofweldingoperatorsandweldsettersformechanizedandautomaticweldingofmetallicmaterials(ISO14732:2013)FSpecificationandqualificationofweldingproceduresformetallicmaterials—WeldingprocedurespecificationFENFISOFFsFwFxFsFrãFtFrFrFuáFSpecificationandqualificationofweldingproceduresformetallicmaterials—Qualificationbasedontestedweldingconsumables(ISO15610:2003)ENFISOFFsFwFxFsFsãFtFrFrFuáFSpecificationandqualificationofweldingproceduresformetallicmaterials—Qualificationbasedonpreviousweldingexperience(ISO15611:2003)SIST EN 13480-4:2018

EN13480æ4:2017(E)Issue1(2017æ06)8ENFISOFFsFwFxFsFtãFtFrFrFváFSpecificationandqualificationofweldingproceduresformetallicmaterials—Qualificationbyadoptionofastandardweldingprocedure(ISO15612:2004)ENFISOFFsFwFxFsFuãFtFrFrFváFSpecificationandqualificationofweldingproceduresformetallicmaterials—Qualificationbasedonpreæproductionweldingtest(ISO15613:2004)FENFISOFFsFwFxFsFvæFsãFtFrFrFváFSpecificationandqualificationofweldingproceduresformetallicmaterials—Weldingproceduretest—Part1:Arcandgasweldingofsteelsandarcweldingofnickelandnickelalloys(ISO15614æ1:2004)ENFISOFFsFyFxFxFuãFtFrFrF{áFWelding—Qualityrequirementsforheattreatmentinconnectionwithweldingandalliedprocesses(ISO17663:2009)Welding—Guidelinesforametallicmaterialsgroupingsystem(ISO/TR15608)F3 TermsanddefinitionsForFtheFpurposesFofFthisFdocumentáFtheFtermsFandFdefinitionsFgivenFinFENFFsFuFvFzFræFsãFtFrFsFyFtogetherFwithFtheFfollowingFapplyäF3.1fieldrunpipingpipingFinstalledFwithoutFpreplanningFbyFdrawingsFofFtheFpipingFroutingFandFtheFsupportFpointsFFNoteFFsFtoFentryãFTypicalFdimensionsFareFDNFFwFrForFsmalleräF3.2spool(withorwithoutoverlength)prefabricatedFassemblyFofFcomponentsFwhichFformsFpartFofFaFpipingFsystemF3.3coldformingformingFatFambientFtemperatureáFbutFnotFbelowFFªFFwFF¹CFFF3.4hotformingforFferriticFsteelsáFformingFatFtemperaturesFatForFaboveFtheFmaximumFpermissibleFtemperatureFforFpostæweldFheatFtreatmentâFforFausteniticFandFausteniticæferriticFsteelsFatFtemperaturesFaboveFFuFrFrFF¹CF4 SymbolsForFtheFpurposesFofFthisFPartFofFthisFEuropeanFStandardáFtheFsymbolsFgivenFinFENFFsFuFvFzFræFsãFtFrFsFyFapplyäFAdditionalFsymbolsFareFdefinedFinFappropriateFclausesFofFthisFPartäF5 General5.1 RequirementsonthemanufacturerTheFmanufacturerFshallFbeFresponsibleFforFtheFfabricationFandFtheFinstallationáFevenFifFthisFworkFwillFbeFFsubæcontractedFtoFotherFfabrSIST EN 13480-4:2018

EN13480æ4:2017(E)Issue1(2017æ06)95.2 Requirementsonfabricatorsandinstallersofpipingandsupports5.2.1rsFshallFensureFtheFcorrectFtransportáFhandlingáFstorageáFfabricationáFinstallationFandFtestingFofFallFpipingFcomponentsFincludingFsupportsäF5.2.2TheFfabricatorsFandFinstallersFshallFhaveFaccessFtoFfacilitiesFwhichFenableFthemFtoFhandleFtheFpipingFcomponentsFincludingFsupportsFcorrectlyFandFtoFcarryFoutFtheFrequiredFtestsäF5.2.3rsFshallFemployFtheirFownFresponsibleFsupervisorsFandFcompetentFpersonneläFIfFsubæcontractorsFareFemployedáFtheFfabriresponsibleFforFtheirFcompetenceFandFtheFcomplianceFwithFthisFEuropeanFStandardäFNOTEFTheFtaskFandFresponsibilitiesFofFaFweldingFcoæordinatorFareFdescribedFinFENFISOFFsFvFyFuFsäF5.2.4FAllFstagesFofFfabricationFandFinstallationFshallFbeFsupervisedFinFsuchFaFwayFasFtoFmaintainFtheFdesignFintegrityFofFtheFfinishedFsystemäF5.2.5FCoæordinationFbetweenFthoseFresponsibleFforFdesignFandFthoseFresponsibleFforFfabricationFsáFtoFensureFthatFfabricationáFinstallationFandFtestingFisFcarriedFoutFinFaccordanceFwithFtheFdesignFspecificationäF5.2.6ofFtheFpipingFshallFfulfilFtheFrequirementsFofFENFISOFFuFzFuFvæFuäF5.3 Requirementsforfabricationandinstallation5.3.1FPriorFtoFanyFoperationáFaFcheckFshallFbeFmadeFtoFensureFthatFtheFspoolsFandFcomponentsFsuppliedFareFinFaccordanceFwithFth5.3.2FPrefabricatedFspoolsFandFcomponentsFshallFbeFprotectedFduringFhandlingáFtransportáFandFstorageäFF5.3.3FWhenFjoiningFspoolsForFcomponentsáFtheyFshallFnotFbeFstrainedFnorFdeformedFotherFthanFasFmayFbeFrequiredFbyFtheFdesignäFDesignerF5sFinstallationFinstructionsáFifFanyáFshallFbeFobservedäFNOTEFFwäFuäFuFisFdeemedFtoFbeFfulfilledáFwhenFtheFqualityFcharacteristicsFofFtheFmaterialFareFnotFimpairedFbyFcoldForFhotFformingáFeägäFbyFcuttingáFgrindingáFstraighteningForFbendingáFofFtheFcomponentsFandFwhenFtheFdifferentFcomponentsFhaveFbeenFjoinedFsuchFthatFstressesFandFdeformationsFwhichFcanFimpairFtheFsafetyFofFtheFpipingFareFexcludedäF5.3.4AnyFtemporaryFsupportsForFrestraintsFusedFasFanFaidFduringFtransportáFinstallationForFtestingFshallFbeFremovedFpriorFtoFcommissioningäF5.3.5FAppropriateFmeasuresFshallFbeFtakenFtoFavoidFcorrosionæinducingFcontaminationFofFstainlessFsteelFandFnonæferrousFmaterialsäFIfFcontaminationFoccursáFitFshallFbeFproperlyFremovedFasFsoonFasFpracticableáFnotwithstandingFanyFfinalFtreatmentäFNOTEFRecommendedFmethodsFforFtheFpreventionFandFremovalFofFcontaminationFonFstainlessFsteelFareFgivenFinFAnnexFAäF5.3.6FPipingFforFfluidsFwhichFareFlikelyFtoFcauseFcondensationFshallFbeFinstalledFwithFadequateFslopesFandFtrapsäFSIST EN 13480-4:2018

EN13480æ4:2017(E)Issue1(2017æ06)105.4 ClassificationofpipingTheFpipingFsystemsFshallFbeFclassifiedFintoFdifferentFcategoriesFdependingFonFtheFfluidFcarriedáFdiameterFandFpressureäFTheseFareFgivenFinFENFFsFuFvFzFræFsäF5.5 MaterialgroupingMaterialFgroupingFisFgivenFinFENFFsFuFvFzFræFtäF5.6 TolerancesTolerancesFshallFcomplyFwithFENFISOFFsFuF{FtFráFclassFCFandFclassFGáFexceptFwhereFotherFclassesFareFspecifiedFinFthisFEuropeanFStandardForFbyFdesignäFAngularFtolerancesFforFfabricatedFpipeworkFshallFbeFdeterminedFbyFtheFdimensionalFtoleranceFforFtheFterminalFpointsFofFtheFfinishedFpartäFAlternativeFtolerancesFforFfabricationFandFinstallationFofFpipeworkFshallFbeFdeterminedFandFinFallFcasesFtheseFshallFbeFidentifiedFinFtheFspecificationäFDimensionalFtolerancesFforFfabricatedFspoolsFshallFcomplyFwithFAnnexFBäF6 Cuttingandbevelling6.1 GeneralCuttingFandFbevellingFbyFmachiningFshallFbeFpermittedFforFallFmaterialsäFFlameFcuttingFshallFbeFpermittedFforFmaterialFgroupsFFsáFFtáFFuáFFvFandFFwFonlyFwithFpreheatingFasFspecifiedFforFweldingäFFNOTEFFlameFcuttingFforFmaterialFgroupsFFsFandFFtFcanFbeFusedFforFbevellingáFifFtheFrequiredFbevelFformsFandFtolerancesFcanFbeFachievedFandFtheFheatFaffectedFzoneFhasFnoFdetrimentalFeffectsFonFtheFqualityFofFtheFweldäFFForFmaterialFgroupsFFuáFFvFandFFwáFtheFheatFaffectedFzoneFshallFbeFremovedFbyFmachiningForFgrindingäFPlasmaFcuttingFshallFbeFpermittedFforFallFmaterialFgroupsFgivenFinFthisFEuropeanFStandardäFPlasmaFcuttingFshallFbeFprecededFbyFpreheatingáFasFspecifiedFforFweldingäFOtherFcuttingFandFbevellingFprocessesFareFpermittedáFprovidedFtheirFsuitabilityFisFdemonstratedäF6.2 IdentificationofpressurepartsForFpressureFpartsáFidentificationFofFmaterialsFshallFremainFpossibleáFeitherFbyFretainingForFbyFtransferringFtheFmarkFstipulatedFbyFtheFproductFstandardáForFbyFusingFaFuniqueFcodeFkeptFinFtheFrecordsFofFtheFpipingFfabricatoräFStampingFshallFnotFintroduceFaFnotchingFeffectáFthereforeFlowæstressFstampingFisFrecommendedäFIfFanyFmethodFofFmarkingFotherFthanFhardæstampingáFedgingForFenfabricatorFshallFensureFthatFconfusionFbetweenFdifferentFmaterialsFisFnotFpossibleäFSIST EN 13480-4:2018

EN13480æ4:2017(E)Issue1(2017æ06)117 Bendingandotherforming7.1 General7.1.1FFabricatorsFofFformedFpressureFpartsFshallFhaveFadequateFproceduresáFequipmentFandFtoolsFforFtheFformingFandFtheFsubsequentFheatFtreatmentäFTheFprocedureFforFbendingFshallFbeFqualifiedFaccordingFtoFENFFsFtF{FwFtæFwãFtFrFsFsáFAnnexFAáFwithFregardFtoFexaminationFandFrangeFofFqualificationäFPipesFwithFinternalFcoatingFsuchFasFglassáFrubberForFplasticsFshallFnotFbeFformedFunlessFitFhasFbeenFdemonstratedFthatFtheFformingFprocessFisFnotFdetrimentalFtoFtheFliningäFNOTEFThereFareFtwoFkindsFofFformingFwithinFtheFscopeFofFthisFEuropeanFStandardãFcoldFformingFandFhotFformingäFTheFthicknessFafterFbendingForFformingFshallFbeFnotFlessFthanFthatFrequiredFbyFtheFdesignäFLongitudinalFweldsFshouldFbeFlocatedFatFtheFneutralFzoneäFTheFrangeFofFtheFneutralFzoneFafterFbendingFisFgivenFinFFigureFFyäFsäFsæFsäFKeyFsFextradosFFtFintradosFngitudinalFweldFatFbendingFFigure7.1.1æ1—OptimalrangeforthelongitudinalweldatbendingF7.1.2TheFformingFandFpostæformingFheatFtreatmentFofFthermomechanicalFsteelsFshallFbeFgivenFindividualFconsiderationäFAccountFshallFbeFtakenFofFtheFrecommendationsFofFtheFsteelmakersäFPipesFwhoseFpropertiesFhaveFbeenFgeneratedFbyFthermomechanicalFmeansFsuchFasFcontrolledFrollingFcanFbeFformedFbyFcoldFmethodsäFSuchFmaterialsFmayFbeFsubstantiallyFchangedFbyFtheFformingFprocessFandFrequireFparticularFconsiderationFtoFensureFthatFtheFspecifiedFpropertiesFareFrecoveredFafterFformingäFF7.1.3TheFfollowingFformulaeFshallFbeFusedFforFtheFcalculationFofFtheFpercentageFdeformationFforFcoldFformedFcylindersFandFconeFproducSIST EN 13480-4:2018

EN13480æ4:2017(E)Issue1(2017æ06)12 ForFcylindersFandFconesFrolledFfrmfordd50reVF ForFcylindersFandFconesFrolledFfrmimfmfintd150rrreVwhereFordeFisFtheForderedFthicknessâFinteFFisFtheFthicknessFofFtheFintermediateFproductâFmfrFFisFtheFaverageFradiusFofFtheFfinishedFproductâFmirFFisFtheFaverageFradiusFofFtheFintermediateFproductâFVdFFisFtheFdeformationFasFaFpercentageäFNOTEFIfFnoFintermediateFqualityFheatFtreatmentFisFappliedFbetweenFindividualFformingFstepsáFtheFdeformationFisFtheFtotalFamountFofFdeformationFofFtheFindividualFstepsäFIfFintermediateFqualityFheatFtreatmentFisFappliedFbetweenFtheFformingFstepsáFtheFdeformationFisFthatFdeformationFappliedFafterFtheFlastFtreatmentäFFttFFigure7.1.3æ1—FormingofcylindersandconesF7.1.4ToolsFandFequipmentFusedFforFformingFshallFbeFmaintainedFtoFensureFaFsmoothFprofileFfreeFfromFstressæraisingFdefectsáFeägäFscoresäFSIST EN 13480-4:2018

EN13480æ4:2017(E)Issue1(2017æ06)137.1.5HeatFtreatmentFafterFformingFshallFbeFinFaccordanceFwithFtheFrespectiveFmaterialFstandardäF7.1.6FWeldingFonFtoFformedFareasFshallFnotFbeFperformedFuntilFheatFtreatmentFisFcompleteäF7.2 Heattreatmentaftercoldforming7.2.1 FlatproductsFlatFproductsFshallFbeFheatFtreatedFafterFcoldFformingFasFrequiredFinFTableFFyäFtäFsæFsäFFForFspecialFdesignFreasonsáFforFexampleFcyclicFloadingForFstressFcorrosionFcrackingáFheatFtreatmentFinFexcessFofFthatFinFTableFFyäFtäFsæFsFmayFbeFspecifiedFafterFcoldFformingäFNoFheatFtreatmentFforFausteniticFsteelsFisFrequiredãF ForFausteniticFsteelsFhavingFaFdocumentedFminimumFvalueFofFelonAFwFequalFtoForFgreaterFthanFFuFrFF¨áFaFmaximumFlevelFofFFsFwFF¨FcoldFdeformationFshallFbeFacceptableäFFAFgreaterFdeformationFmayFbeFacceptedFifFtheFevidenceFisFsuppliedFthatFthereFisFaFminimumFFFSuchFevidenceFshallFbeFdeemedFsuppliedáFifFtheFacceptanceFcertificateFshowsFthatFelongationFafterFAFwFisFnotFlessFthanFFuFrFF¨äFThisFshallFbeFapplicableFonlyFinFcasesFwhereFthereFisFnoFriskFofFstressFcorrosionFcrackingâFAFwFlessFthanFFuFrFF¨áFevidenceFshallFbeFsuppliedFthatFthereFisFaFminimumFelongationFofFFsFwFF¨FafterFcoldFformingâFFrFF¨FifFtheFworkingFtemperatureFisFbelowFæFsF{FxFF¹CäFTable7.2.1æ1—HeattreatmentaftercoldformingofflatproductsMaterialgroupsaccordingtoCENISO/TR15608FDeformationHeattreatmentFsäFsáFFsäFtáFFsäFuáFFtäFsáFFtäFtFaáFFuáFFvFbáFFwäFsáFFwäFtbáFFwäFuFbáFFwäFvFbáFFxFbáFFyäFsáFFyäFtáFFyäFuáFF{äFsáFF{äFtáFFsFrFFFwFF¨FnoFFµFFwFF¨FyesFFzäFsáFFzäFtFcFFFdFFFaFIfFnotFheatFtreatedáFqualificationFtestsFareFrequiredFtoFdemonstrateFthatFtheFmaterialFpropertiesFareFnotFimpairedäFbFHeatFtreatmentFrequiredFinFaccordanceFwithFtheFmaterialFstandardsFwhereFtheFminimumFmetalFtemperatureFisFbelowFæFFsFrFF¹CäFcFdFSolutionFannealedFandFquenchedForFstabilisedFmaterialsFdoFnotFrequireFheatFtreatmentFafterFcoldFformingäF7.2.2 PipesPipesFshallFbeFheatFtreatedFafterFcoldFformingFinFaccordanceFwithFTableFFyäFtäFtæFsäFSIST EN 13480-4:2018

EN13480æ4:2017(E)Issue1(2017æ06)14ForFspecialFreasonsáFforFexampleFcyclicFloadingForFstressFcorrosionáFheatFtreatmentFmayFbeFspecifiedFafterFcoldFformingäFTable7.2.2æ1—HeattreatmentaftercoldformingofpipesMaterialgroupsaccordingtoCENISO/TR15608FMeanbendingradiusofthepipeFFrm OutsidediameterofthepipeFFdoFHeattreatmentFsäFsáFFsäFtáFFsäFuáFFtäFsáFFFtäFtFbáFFuFbáFFvFaáFFwäFsáFFwäFtFaáFFwäFuFaáFFwäFvFaáFFxFaáFFyáFFzáFF{áFFsFrFFrmFFFsáFuFdoFFallFdiametersFFyesFFsáFuFdoFF´FrmFF´FFtáFwFdoFFdoFFFsFvFtFmmFFnoFFdoFFµFFsFvFtFmmFFyesFcFFFFtáFwFdoFFrmFallFdiametersFnoFNOTEFForFdoFand rmáFseeFFigureFFyäFtäFtæFsäFaFHeatFtreatmentFrequiredFinFaccordanceFwithFtheFmaterialFstandardsFwhereFtheFminimumFmetalFtemperatureFisFbelowFæFsFrFF¹CäFbFIfFnotFheatFtreatedáFqualificationFtestsFareFrequiredFtoFdemonstrateFthatFtheFmaterialFpropertiesFareFnotFimpairedäFcFNotFrequiredFforFmaterialFgroupsFFzäFsáFFzäFtäFFFFigure7.2.2æ1—PipebendingSIST EN 13480-4:2018

EN13480æ4:2017(E)Issue1(2017æ06)157.3 Heattreatmentafterhotforming7.3.1 Materialgroups1,3,4,5and6AfterFhotFformingáFincludingFinductionFbendingáFtheFpartsFshallandFtemperingáFquenchingFandFtemperingForFannealingFasFapproprispecificationFtoFensureFthatFtheFpropertiesFmeetFthoseFrequiredFbyFtheFmaterialFstandardáForFotherFappropriateFspecificationäFSpecialFconsiderationFshallFbeFgivenFtoFmaterialsFdesignedFtoFoperateFatFelevatedForFsubæzeroFtemperaturesForFotherFspecialFconditionsäFIfFtheFhotFformingFofFmaterialsFofFgroupsFFsáFFuáFFwFupFtoFFtFF¨FCrFhasFbeenFstartedFandFendedFwithinFtheFtemperatureFrangeFfixedFinFtheFmaterialFspecificationãF quenchedFandFtemperedFsteelsFneedFonlyFbeFtemperedFprovidedFthatFtheyFhaveFbeenFrapidlyFcooledFbyFwaterForFairFfromFtheFformingFtemperatureäFtreatmentFduringFbendingFbyFtheFapplicationFofFwaterForFairFquenchesäFFusingFtheFinductionFbendingFprocessFwithFairForFwaterFquenchingFmayFbeFsuitableFinFtheFasæbentFconditionFforFapplicationsFwhereFhighFimpactFresistanceFandFductilityFareFnotFrequiredäFSuchFbendsFmayFbeFsuppliedFwithoutFpostæbendingFheatFtreatmentFprovidedFthatFbendFhardnessFdoesFnotFexceedFFtFzFwFHVäFHeatFtreatmentsFforFhighFalloyedFferriticFmaterialFshouldFfollowFasFsoonFafterFformingFasFpracticableáFtoFminimiseFtheFriskFofFhydrogenFinducedFcrackingäFTheFmanufacturerFshallFdemonstrateFthatFtheFrequisiteFpropertiesFareFachievedFinFtheFfinalFproductFbyFtheFexaminationFandFtestingFofFoneForFmoreFsampleFbendsäFTheseFbendsFshallFbeFmadeFinFaccordanceFwithFallFtheFrelevantFparametersFtoFbeFusedFinFproductionFbendsäFTheseFparametersFincludeáFbutFareFnotFlimitedFtoáFchemicalFcompositionáFformingFtemperatureáFformingFrm do7.3.2 Materialgroups8.1and8.2AusteniticFsteelsFwhichFhaveFbeenFrapidlyFcooledFfromFaboveFtheFsolutionFannealingFtemperatureFusingFwaterForFairFduringFtheFformingFprocessFshallFnotFrequireFpostæformingFheatFtreatmentäFStabilisedFausteniticFsteelsFformedFaboveFtheFsolutionFannealingFtemperatureFshallFbeFsubjectedFtoFpostæformingFstabilisingFtreatmentäFStabilisedFausteniticFsteelsFformedFinFtheFstabilisingFtemperatureFrangeáFshallFnotFrequireFsubsequentFtreatmentäFHeatFtreatmentFshallFbeFcarriedFoutFinFaccordanceFwithFTableFFyäFuäFtæFsäFSIST EN 13480-4:2018

EN13480æ4:2017(E)Issue1(2017æ06)16Table7.3.2æ1—HeattreatmentofausteniticsteelsafterhotformingMaterialtypeTypicalsteelgradesConditionsunderwhichpostæformingheattreatmentmaybewaivedTemperaturerangeforheattreatmentwhenstabilisingaSolutionannealingtemperaturebácFNameFNumberFNonæweldedFpartsFWeldedFpartsFNonæweldedFpartsFF¹CFWeldedFpartsFF¹CFFF¹CFStabilisedFsteelsFnonæMoæalloyedFXFFxFCrNiTiFFsFzæFsFrFXFFxFCrNiNbFFsFzæFsFrFFsäFvFwFvFsFFsäFvFwFwFrFFormingFstartedFatFFFFFFFFFFsFFrFrFrFF¹CFfFtoFFsFFsFwFrFF¹CFandFfinishedFatFFµFFyFwFrFF¹CFFormingFstartedFatFFsFFrFrFrFF¹CFtoFFsFFsFwFrFF¹CFandFfinishedFatForFnonæstabilisedFfillersFwithFFFráFrFvFF¨FCFinFweldFmetalFF{FrFrFF¬FFtFrFFcFF{FtFrFF¬FFtFrFFFFsFFrFtFrFFMoæalloyedFXFFxFCrNiMoTiFFsFyæFsFtæFtFXFFxFCrNiMoNbFFsFyæFsFtæFtFFsäFvFwFyFsFFsäFvFwFzFrFnotFpermittedFdFnotFpermittedFdFFeFFsäFvFwFrFwFFFFFsFFrFwFrFFnonFstabilisedFsteelsFnonæMoæalloyedFXFFtFCrNiFFsF{æFsFsFXFFtFCrNiNFFsFzæFsFrFFsäFvFuFrFxFFsäFvFuFsFsFF{FrFrFF¬FFtFrFFcFF{FtFrFF¬FFtFrFFcáFgFFFsFFrFrFrFFMoæalloyedFXFFtFCrNiMoFFsFyæFsFtæFtFXFFtFCrNiMoFFsFzæFsFvæFuFXFFtFCrNiMoNFFsFyæFsFsæFtFFsäFvFvFrFvFFsäFvFvFuFwFFsäFvFvFrFxFF{FxFrFF¬FFtFrFF¹CFcáFeFF{FzFrFF¬FFtFrFFcáFgáFhFFFsFFrFtFrFFXFFtFCrNiMoNFFsFyæFsFuæFuFXFFtFCrNiMoFFsFzæFsFwæFvFXFFtFCrNiMoNFFsFyæFsFuæFwFFsäFvFvFtF{FFsäFvFvFuFzFFsäFvFvFuF{FFFFFsFFrFvFrFFnonFMoæalloyedFXFFvFCrNiFFsFzæFsFrFXFFvFCrNiFFsFzæFsFtFFsäFvFuFrFsFFsäFvFuFrFuFFormingFstartedFatFFFsFFrFrFrFF¹CFfFtoFFsFFsFwFrFF¹CFeFandFfinishedFatFFµFFzFyFwFF¹CFwaterFforFwallFthicknessesFFormingFstartedFatFFsFFrFrFrF¹CFtoFFsFFsFwFrFF¹CFeFandFfinishedFatFwaterFforFwallFthicknessesForFnonæstabilisedFfillersFwithFFFráFrFxFF¨FCFnotFpermittedFnotFpermittedFFFsFFrFrFrFFMoæFalloyedFXFFwFCrNiMoFFsFyæFsFtæFtFXFFuFCrNiMoFFsFyæFsFuæFuFFsäFvFvFrFsFFsäFvFvFuFxFFFFFsFFrFwFrFFaFFStabilisingForFcorrespondingFannealingFinFtheFcaseFofFnonæstabilisedFsteelsFwithFapproximatelyFFuFrminFcriticalFintervaläFbFFForFeordF≥FFxFmmFtheFtypeFofFcoolingFshallFcFFForFeordFdFFUnlessFrequiredFbyFprocessFconditionsäFeFFMinimalFcriticalFintervalFisFFwFminäFfFFFStartingFtemperatureFofFFsFFrFrFrFF¹CFmayFbeFloweredFifFpartFwasFinFtheFquenchedFstateFpriorFtoFhotFformingäFgFFStabilisingFnotFpermissibleFifFstabilisedFfillersFareFusedäFhFFSteelsFNoäFFsäFvFvFrFxFandFFsäFvFvFtF{FmayFbeFstabilisedFatFlowerFtemperaturesFifFtheFsameFmaterialFcharacteristicsFwillFbeFreachedäFSIST EN 13480-4:2018

EN13480æ4:2017(E)Issue1(2017æ06)177.3.3 Heattreatmentafterhotformingformaterialgroup10AfterFhotFformingáFtheFpartsFshallFbeFheatFtreatedFinFaccordanceFwithFtheFmaterialFspecificationsäF7.3.4 HeattreatmentafterhotformingforcladmaterialsIfFformingFcannotFbeFavoidedáFthenFtheFprocessFofFformingFandFheatFtreatmentFshallFbeFdemonstratedFasFgivingFspecifiedFpropertiesäF7.4 Tolerances7.4.1 Outæofæroundnessofbendsunderinternalpressureequalto,orgreaterthan,theexternalpressureTheFoutæofæroundnessáFuF1002minomaxominomaxodddduwhereFFmaxodFisFtheFmaximumFoutsideFdiameterFmeasuredáFinFmmâFFminodFisFtheFminimumFoutsideFdiameterFmeasuredFatFtheFsameFcrossFsectionFasFmaxodáFinFmmäFTheFoutæofæroundnessFofFtheFbendFshallFnotFexceedFtheFlimitsFgivenFinFFigureFFyäFväFsæFsäFTheFendsFofFtheFbentFpipesFshallFcomplyFwithFtheFtolerancesFforFtheFbaseFpipeäFFFFSIST EN 13480-4:2018

EN13480æ4:2017(E)Issue1(2017æ06)18FKey odFFisFtheFoutsideFdiameterFâmrFFisFtheFmeanFbendingFradiusFâFuFFisFtheFoutæofæroundnessFFigure7.4.1æ1—AcceptableoutæofæroundnessF7.4.2 OutæofæroundnessofbendsunderexternalpressureandvacuumValuesFforFoutæofæroundnessFshallFconformFtoFtheFvaluesFstatedFinFtheFdesignäF7.4.3 WavesatbendsWavesFatFbendsFareFacceptableFasFlongFasFtheyFcomplyFwithFbothFofFtheFfollowingFconditionsãF01m03,0dhFwhereFFhmFisFtheFmeanFheightFofFadjacentFwavesáFcalculatedFasFfollowsãF030402m2dddhwhereFdFrFsáFdFrFtáFdFrFuáFdFrFvFareFasFshownFinFFigureFFyäFväFuæFsäFFFFSIST EN 13480-4:2018

EN13480æ4:2017(E)Issue1(2017æ06)19m12haFwhereFFaFisFtheFwaveFdistanceâFhmFisFtheFmeanFheightFofFadjacentFwavesáFcalculatedFasFinFFormula NOTEFFFFForFclarityáFwavesFhaveFbeenFexaggeratedäFigure7.4.3æ1—Wavesatbends7.4.4 StartæupbulgeofinductionbendstheFnominalFwallFthicknessáFandFtheFmaximumFdimensionFofFitsFbaseFshallFbeFatFleastFeightFtimesFitsFheightFandFshallFblendFsmoothlyFintoFtheFTheFoutæofæroundnessFtoleranceFspecifiedFinFFyäFväFsFshallFalsoFbeFapplicableFonFaFcrossæsectionFtakenFatFtheFpointFofFirregularityäFSIST EN 13480-4:2018

EN13480æ4:2017(E)Issue1(2017æ06)20FKeyFaFFFzFhF4ehFwhereFeFisFtheFnominalFwallFthicknessFFigure7.4.4æ1—Startæupbulge7.5 SurfacefinishTheFsurfaceFofFtheFbendFshallFbeFsuchFasFtoFpermitFaFvisualFexaminationäFAllFbendsFshallFbeFfreeFfromFsurfaceFimperfectionsFsuchFasFcracksáFindentationsáFlapsFandFscabsäFWhereFsurfaceFimperfectionsFareFgroundFoutáFtheFwallFthicknessFshallFnotFbeFreducedFbelowFtheFcalculatedFminimumFwallFthicknessäFAreasFwhichFareFgroundFtoFremoveFimperfectionsFshallFbeFexaminedFbyFsurfaceFcrackFdetectionFmethodsFappropriateFtoFtheFmaterialFtoFensureFcompleteFremovalFofFtheFimperfectionsäFRepairsFbyFweldingFshallFnotFbeFpermittedäF8 Installationofpiping8.1 FixingandalignmentTheFpipingFshallFbeFinstalledFinFaccordanceFwithFtheFdesignFrequirementsFgivenFinFENFFsFuFvFzFræFuäFForFspecialFoperationsáFeägäFbalancingFandFcoldFpulláFinstructionsFshallFbeFspecifiedäFTheFslopeFofFtheFpipingFshallFbeFcheckedFtoFensureFthatFcontinuousFslopeFisFachievedFinFaccordanceFwithFtheFdesignäFWhereFnecessaryáFduringFassemblyFofFpipingFsectionsáFtheFinstallerFshallFuseFtemporaryFsupportsFtoFensureFthatFnoFunacceptableFstressForFdeformationFoccursFinFtheFpipingFandFconnectedFequipmentFasFaFconsequenceFofFtheFcantileverFeffectFofFunsupportedFweightFdistributionäFTemporaryFauxiliaryFsupportsFshouldFbeFusedFtoFreplaceFtheFsupportingFeffortFofFconnectedFequipmentäFPipingFshallFnotFbeFdistortedFforFtheFpurposeFofFalignmentFforFjointFassemblyäFSuchFdistortionFcanFintroduceFdetrimentalFstrainsFinFtheFpipingForFconnectedFequipmentäFFFFFSIST EN 13480-4:2018

EN13480æ4:2017(E)Issue1(2017æ06)21LongitudinalFweldsFshallFbeFlocatedFsoFasFtoFavoidFopeningsForFattachmentsFwhereverFpossibleäFLongitudinalFweldsFinFadjoiningFcomponentsFshallFbeFstaggeredFbyFtwiceFtheFnominalFwallFthicknessáFwithFaFminimumFdistanceFofFFtFrFmmäFSupportsFshallFbeFinstalledFtoFensureFthatFtheFidentificat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...