EN 17069-1:2019

(Main)Railway applications - Systems and procedures for change of track gauge - Part 1: Automatic Variable Gauge Systems

Railway applications - Systems and procedures for change of track gauge - Part 1: Automatic Variable Gauge Systems

This document defines the interfaces and gives guidance for the design of systems and procedures for change of track gauge. It defines also their assessment for technical approval, for the automatic variable-gauge systems.

The document is focused on the change of track gauge among the following nominal track gauges: 1 435 mm, 1 520 mm, 1 524 mm, 1 600 mm and 1 668 mm.

This document is not limited to the aforementioned nominal track gauges but the interfaces to change to/from other nominal track gauges can be different. The established assessment procedures can be used as well.

Bahnanwendungen - Systeme und Verfahren zur Umspurung - Teil 1: Automatische Umspursysteme

Dieses Dokument legt die Schnittstellen fest und gibt für automatische Umspursysteme eine Anleitung für die Konstruktion von Umspursystemen und verfahren vor. Weiter legt es die Bewertung zur technischen Freigabe der automatischen Umspursysteme fest.

Dieses Dokument konzentriert sich auf den Wechsel der Spurweite zwischen den folgenden Nennspurweiten: 1 435 mm, 1 520 mm, 1 524 mm, 1 600 mm und 1 668 mm.

Das Dokument ist nicht auf die zuvor genannten Nennspurweiten beschränkt, aber die Schnittstellen, auf die von/von denen zu anderen Nennspurweiten gewechselt wird, können unterschiedlich sein. Die eingeführten Bewertungsverfahren können ebenso verwendet werden.

Applications ferroviaires - Systèmes et procédures de changement d'écartements de voie - Partie 1 : Systèmes à écartement variable automatique

Le présent document définit les interfaces et donne les lignes directrices pour la conception des systèmes et procédures de changement d'écartement de voie. Elle définit notamment leur évaluation à des fins d'validation technique, dans le cadre des systèmes à écartement variable automatique.

Le présent document porte essentiellement sur le changement d'écartement de voie parmi les écartements de voie nominaux suivants : 1 435 mm, 1 520 mm, 1 524 mm, 1 600 mm et 1 668 mm.

Le présent document ne se limite pas aux écartements de voie susmentionnés, mais les interfaces de changement d'écartements de voie nominaux peuvent être différentes. Les procédures d'évaluation établies peuvent également être utilisées.

Železniške naprave - Sistemi in postopki za spremembo tirne širine - 1. del: Sistemi za samodejno spreminjanje širine

Ta evropski standard določa vmesnike in podaja smernice za projektiranje sistemov in postopkov spreminjanja tirne širine, ki zajemajo tudi njihovo oceno za tehnično odobritev, za sisteme za samodejno spreminjanje tirne širine.

Standard je osredotočen na spremembo tirne širine med naslednjimi nominalnimi tirnimi širinami: 1435 mm, 1520 mm, 1524 mm, 1600 mm in 1668 mm.

Ta dokument ni omejen na prej omenjene nominalne tirne širine, vendar so vmesniki za spremembo v/iz drugih nazivnih tirnih širin lahko različni. Mogoče je uporabiti tudi uveljavljene postopke ocenjevanja.

General Information

- Status

- Published

- Publication Date

- 09-Apr-2019

- Withdrawal Date

- 30-Oct-2019

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 2/WG 11 - Wheels - Wheelsets

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 03-Dec-2024

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN 15877-1:2024 - Railway applications - Markings of railway vehicles - Part 1: Freight wagons - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 17069-1:2019 (CEN) - "Railway applications - Systems and procedures for change of track gauge - Part 1: Automatic Variable Gauge Systems" defines interfaces and provides design guidance and assessment methods for automatic variable-gauge systems. The standard focuses on automatic change of track gauge among the nominal gauges 1 435 mm, 1 520 mm, 1 524 mm, 1 600 mm and 1 668 mm, while noting that the assessment framework can be applied to other gauges where interfaces differ. EN 17069-1:2019 supports technical approval processes and aligns with EU Directive 2008/57/EC requirements for interoperability.

Key Topics

The standard addresses the full lifecycle of automatic variable-gauge systems with emphasis on safety, interoperability and technical approval. Major technical areas include:

- Running gear and running gear dimensions - interfaces and dimensional requirements for variable-gauge bogies and wheelsets.

- Axles and wheels - functional requirements for rotating/non-rotating axles and wheel movement during gauge change.

- Axleboxes / bearings - design, lubrication and monitoring interfaces (linking to axlebox condition monitoring).

- Locking mechanisms - requirements for safe unlocking and re-locking of running elements during the automatic gauge changeover process.

- Running gear frames and braking equipment - structural and braking interfaces affecting gauge-change performance.

- Validation, testing and technical approval - validation plans, acceptance testing, technical files and finalisation steps required for certification.

- Gauge changeover facilities - design, operation, maintenance, track layout and ancillary systems (e.g., de-icing, shelters) for gauge changeover platforms.

- Interfaces with other subsystems - control-command, signalling, energy and trackside equipment (including Hot Axlebox Detector interfaces for non‑1 435 mm gauges).

Applications and Who Uses It

EN 17069-1:2019 is practical for organizations involved in cross-border rail operations and rolling-stock design:

- Railway infrastructure managers planning or operating gauge changeover facilities.

- Rolling-stock manufacturers and bogie designers developing automatic variable-gauge running gear.

- Vehicle acceptance authorities and certification bodies performing technical approval and safety assessments.

- System integrators and project engineers implementing trackside interfaces, signalling and maintenance provisions.

- Operators seeking to reduce passenger transhipment and freight handling by enabling through-running across different track gauges.

Related Standards

EN 17069-1 references and complements existing railway standards, including (but not limited to):

- EN 12080 / EN 12081 / EN 12082 (axleboxes and bearings)

- EN 13260 / EN 13261 / EN 13262 (wheelsets, axles, wheels)

- EN 14363 (running behaviour testing)

- EN 15273 series (gauges)

- EN 15437 (axlebox condition monitoring)

- EN 50126 series (RAMS)

For projects involving automatic variable-gauge systems, EN 17069-1:2019 provides the interoperable, safety-focused framework for design, testing and approval.

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

EN 17069-1:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Systems and procedures for change of track gauge - Part 1: Automatic Variable Gauge Systems". This standard covers: This document defines the interfaces and gives guidance for the design of systems and procedures for change of track gauge. It defines also their assessment for technical approval, for the automatic variable-gauge systems. The document is focused on the change of track gauge among the following nominal track gauges: 1 435 mm, 1 520 mm, 1 524 mm, 1 600 mm and 1 668 mm. This document is not limited to the aforementioned nominal track gauges but the interfaces to change to/from other nominal track gauges can be different. The established assessment procedures can be used as well.

This document defines the interfaces and gives guidance for the design of systems and procedures for change of track gauge. It defines also their assessment for technical approval, for the automatic variable-gauge systems. The document is focused on the change of track gauge among the following nominal track gauges: 1 435 mm, 1 520 mm, 1 524 mm, 1 600 mm and 1 668 mm. This document is not limited to the aforementioned nominal track gauges but the interfaces to change to/from other nominal track gauges can be different. The established assessment procedures can be used as well.

EN 17069-1:2019 is classified under the following ICS (International Classification for Standards) categories: 45.040 - Materials and components for railway engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 17069-1:2019 has the following relationships with other standards: It is inter standard links to EN 50126-2:2017, EN 50153:2014, EN 50126-1:2017, EN 15877-1:2024, EN 15437-1:2009+A1:2022, EN 14363:2016+A2:2022, EN 15839:2024, EN 12080:2025, EN 13749:2021+A1:2023, EN 15437-2:2012+A1:2022, EN 13979-1:2023, EN 15273-2:2025, EN 15551:2022, EN 15663:2017+A2:2024, EN 13261:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 17069-1:2019 is associated with the following European legislation: EU Directives/Regulations: 2008/57/EC; Standardization Mandates: M/483. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 17069-1:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-junij-2019

Železniške naprave - Sistemi in postopki za spremembo tirne širine - 1. del:

Sistemi za samodejno spreminjanje širine

Railway applications - Systems and procedures for change of track gauge - Part 1:

Automatic Variable Gauge Systems

Bahnanwendungen - Systeme und Verfahren zur Umspurung - Automatische

Umspursysteme

Applications ferroviaires - Systèmes et procédures de changement d'écartement de voie

- Systèmes à écartement variable automatique

Ta slovenski standard je istoveten z: EN 17069-1:2019

ICS:

45.040 Materiali in deli za železniško Materials and components

tehniko for railway engineering

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17069-1

EUROPEAN STANDARD

NORME EUROPÉENNE

April 2019

EUROPÄISCHE NORM

ICS 45.040

English Version

Railway applications - Systems and procedures for change

of track gauge - Part 1: Automatic Variable Gauge Systems

Applications ferroviaires - Systèmes et procédures de Bahnanwendungen - Systeme und Verfahren zur

changement d'écartements de voie - Partie 1 : Umspurung - Teil 1: Automatische Umspursysteme

Systèmes à écartement variable automatique

This European Standard was approved by CEN on 2 December 2018.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17069-1:2019 E

worldwide for CEN national Members.

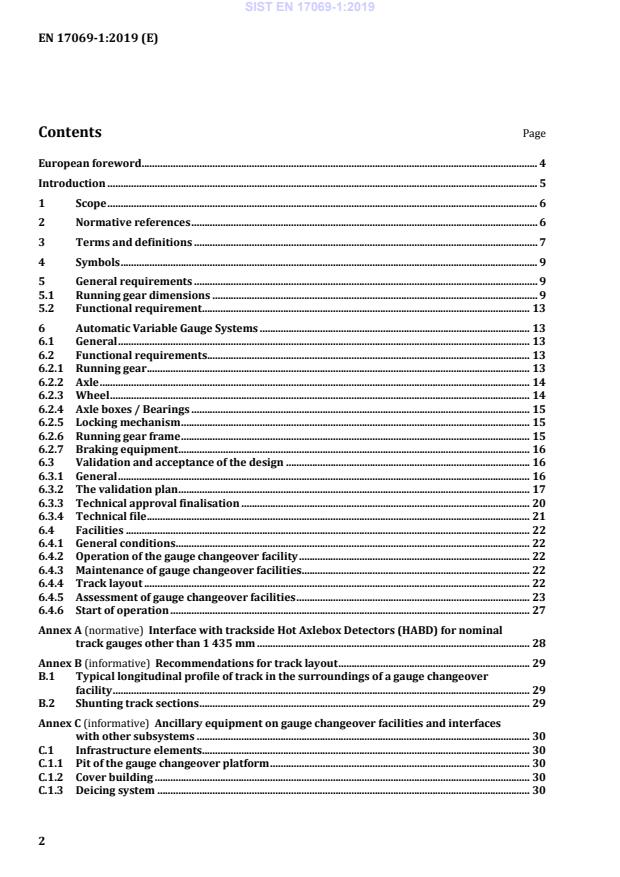

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Symbols . 9

5 General requirements . 9

5.1 Running gear dimensions . 9

5.2 Functional requirement. 13

6 Automatic Variable Gauge Systems . 13

6.1 General . 13

6.2 Functional requirements. 13

6.2.1 Running gear . 13

6.2.2 Axle . 14

6.2.3 Wheel . 14

6.2.4 Axle boxes / Bearings . 15

6.2.5 Locking mechanism . 15

6.2.6 Running gear frame . 15

6.2.7 Braking equipment . 16

6.3 Validation and acceptance of the design . 16

6.3.1 General . 16

6.3.2 The validation plan . 17

6.3.3 Technical approval finalisation . 20

6.3.4 Technical file . 21

6.4 Facilities . 22

6.4.1 General conditions . 22

6.4.2 Operation of the gauge changeover facility . 22

6.4.3 Maintenance of gauge changeover facilities . 22

6.4.4 Track layout . 22

6.4.5 Assessment of gauge changeover facilities . 23

6.4.6 Start of operation . 27

Annex A (normative) Interface with trackside Hot Axlebox Detectors (HABD) for nominal

track gauges other than 1 435 mm . 28

Annex B (informative) Recommendations for track layout . 29

B.1 Typical longitudinal profile of track in the surroundings of a gauge changeover

facility . 29

B.2 Shunting track sections . 29

Annex C (informative) Ancillary equipment on gauge changeover facilities and interfaces

with other subsystems . 30

C.1 Infrastructure elements. 30

C.1.1 Pit of the gauge changeover platform . 30

C.1.2 Cover building . 30

C.1.3 Deicing system . 30

C.1.4 Slab track . 30

C.2 Interfaces with energy subsystem . 30

C.3 Interfaces with control-command and signalling subsystem . 31

C.4 Other ancillary equipment . 31

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive 2008/57/EC aimed to be covered. 32

Bibliography . 37

European foreword

This document (EN 17069-1:2019) has been prepared by Technical Committee CEN/TC 256 “Railway

applications”, the secretariat of which is held by DIN.

This document shall be given the status of a national standard, either by publication of an identical text

or by endorsement, at the latest by October 2019, and conflicting national standards shall be withdrawn

at the latest by October 2019.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document has been prepared under a standardization request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of

Directive 2008/57/EC.

For relationship with Directive 2008/57/EC, see informative Annex ZA, which is an integral part of this

document.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this document: Austria, Belgium, Bulgaria, Croatia, Cyprus,

Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany,

Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

For historical reasons, several track gauges are used on the rail networks in Europe. In order to cross the

borders among these, passengers and goods need to be transferred.

In order to increase comfort of passengers by avoiding transhipments, and to reduce both the risk of

damaging goods and the involved cost of transferring them, several systems and procedures for change

of track gauge have been developed. Nowadays, there are three main possibilities to attain connection

among rail networks with different track gauges:

— automatic variable-gauge systems;

— interchange of complete bogies;

— interchange of complete wheelsets.

The interfaces and the approval methods for such systems were defined in several UIC-leaflets and

national regulations. This document is intended to set all related requirements together in a single

document for automatic variable-gauge systems.

1 Scope

This document defines the interfaces and gives guidance for the design of systems and procedures for

change of track gauge. It defines also their assessment for technical approval, for the automatic variable-

gauge systems.

The document is focused on the change of track gauge among the following nominal track gauges:

1 435 mm, 1 520 mm, 1 524 mm, 1 600 mm and 1 668 mm.

This document is not limited to the aforementioned nominal track gauges but the interfaces to change

to/from other nominal track gauges can be different. The established assessment procedures can be used

as well.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 12080, Railway applications – Axleboxes - Rolling bearings

EN 12081, Railway applications – Axleboxes – Lubricating greases

EN 12082, Railway applications – Axleboxes – Performance testing

EN 13103-1, Railway applications – Wheelsets and bogies – Part 1: Design method for axles with external

journals

EN 13260, Railway applications – Wheelsets and bogies – Wheelsets – Product requirements

EN 13261, Railway applications – Wheelsets and bogies – Axles – Product requirements

EN 13262, Railway applications – Wheelsets and bogies – Wheels – Product requirements

EN 13749, Railway applications – Wheelsets and bogies – Method of specifying the structural requirements

of bogie frames

EN 13979-1, Railway applications – Wheelsets and bogies – Monobloc wheels – Technical approval

procedure – Part 1: Forged and rolled wheels

EN 14363, Railway applications – Testing and Simulation for the acceptance of running characteristics of

railway vehicles – Running Behaviour and stationary tests

EN 15273-1, Railway applications – Gauges – Part 1: General – Common rules for infrastructure and rolling

stock

EN 15273-2, Railway applications – Gauges – Part 2: Rolling stock gauge

EN 15437-1, Railway applications – Axlebox condition monitoring – Interface and design requirements –

Part 1: Track side equipment and rolling stock axlebox

EN 15437-2, Railway applications – Axlebox condition monitoring – Interface and design requirements –

Part 2: Performance and design requirements of on-board systems for temperature monitoring

EN 15551, Railway applications – Railway rolling stock – Buffers

EN 15663, Railway applications – Vehicle reference masses

EN 15827, Railway applications – Requirements for bogies and running gears

EN 15839, Railway applications – Testing for the acceptance of running characteristics of railway vehicles –

Freight wagons – Testing of running safety under longitudinal compressive forces

EN 15877-1, Railway applications – Marking on railway vehicles – Part 1: Freight wagons

EN 50126-1, Railway applications – The specification and demonstration of Reliability, Availability,

Maintainability and Safety (RAMS) – Part 1: Basic requirements and generic process

EN 50126-2, Railway Applications – The Specification and Demonstration of Reliability, Availability,

Maintainability and Safety (RAMS) – Part 2: Systems Approach to Safety

CLC/TR 50126-3, Railway applications – The specification and demonstration of Reliability, Availability,

Maintainability and Safety (RAMS) – Part 3: Guide to the application of EN 50126-1 for rolling stock RAM

EN 50153, Railway applications – Rolling stock – Protective provisions relating to electrical hazards

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

nominal track gauge

single value which identifies the track gauge, but may differ from the design track gauge

Note 1 to entry: Definition in addition to the EN 15273 series. As example 1 435 mm.

3.2

gauge changeover technology

set of systems and devices specifically designed to perform the automatic gauge changeover process on

certain types of compatible rolling stock fitted with variable-gauge running gear

3.3

automatic variable-gauge running gear

specific type of running gear designed to automatically switch between different track gauges when

passing through a gauge changeover facility

Note 1 to entry: This process does not involve the removal or assembly of any component of the running gear.

3.4

non-rotating axle

axle fixed to bogie frame, that does not rotate and during the service, the wheel can freely-rotate, and

lateral movement between wheels and axle is not possible

Note 1 to entry: Only during the automatic gauge changeover process, the wheels can move laterally to reach the

corresponding track gauge position.

3.5

rotating axle

axle not fixed to bogie frame, during service wheels rotate together with the axle and lateral movement

between wheels and axle is not possible

Note 1 to entry: Only during the automatic gauge changeover process, lateral movements are possible to reach

the corresponding track gauge position.

3.6

automatic gauge changeover process

automatic change of track gauge in variable-gauge running gear, consisting at least of the following

phases:

— unlocking of the rolling elements;

— displacement of the rolling elements while variable-gauge running gear is in the gauge changeover

platform;

— safe locking of the rolling elements in their new position

3.7

gauge changeover facility

facility where the automatic gauge changeover process is performed when passed through by trains at a

given speed

Note 1 to entry: It includes the gauge changeover platform along with all ancillary systems that may be required

to prepare the train for the automatic gauge changeover process (e.g. deicing system) and those for sheltering, if

any.

3.8

gauge changeover platform

core element of a gauge changeover facility in which all systems directly related to change of track gauge

for variable-gauge running gear are installed

3.9

multi-mode gauge changeover facility

gauge changeover facility where several gauge changeover technologies are implemented and thus more

than one mode of change is allowed

3.10

mode of change

configuration of a multi-mode gauge changeover facility for a specific gauge changeover technology

3.11

area of a gauge changeover facility

area between the signals of entrance and exit of a gauge changeover facility, including the gauge

changeover facility itself as well as switches and crossings of shunting track sections

3.12

surroundings of a gauge changeover facility

track section before and after the area of a gauge changeover facility, the considered external limits of

which are the entrance and exit signals of main tracks

3.13

nominal passage speed

vehicle speed during the changeover process at which both the gauge changeover facility and the

variable-gauge running gear are designed

Note 1 to entry: Nominal passage speed depends on the gauge changeover technology.

4 Symbols

For the purposes of this document, the following symbols apply.

Table 1 — Symbols

Symbol Designation

a Back to back dimension

a Front-to-front dimension

e Thickness of flange

h Height of flange

qR Face of the flange

d Wheel diameter

Y Lateral position of the centre of the target area

TA

W Lateral width in mm of the target area

TA

L Longitudinal length in mm of the target area

TA

Y Lateral position of the centre of the prohibitive zone

PZ

W Lateral width in mm of the prohibitive zone

PZ

L Longitudinal length in mm of the prohibitive zone

PZ

NOTE Symbols given in Table 1 come from EN 15313 and EN 15437-1.

5 General requirements

5.1 Running gear dimensions

Running gear shall comply with minimum and maximum values in Tables 2 and 3 and Tables 4 and 5 for

any service condition. For 1 435 mm nominal track gauge, the values which are given in Tables 2 and 3

and Tables 4 and 5 are the same as in EN 15313.

Table 2 — Limit values for front-to-front and back-to-back dimensions for freight wagons

Designation Wheel diameter Minimum value Maximum value

d [mm] [mm] [mm]

330 ≤ d ≤ 760 1 415 1 426

Front-to-front dimension (a )

760 < d ≤ 840 1 412 1 426

a = a + e + e

2 1 1 2

d > 840 1 410 1 426

1 435 mm

330 ≤ d ≤ 760 1 359 1 363

Back to back dimension (a ) 760 < d ≤ 840 1 358 1 363

d > 840 1 357 1 363

400 ≤ d < 840 1 492 1 514

Front-to-front dimension (a )

a = a + e + e

2 1 1 2

d ≥ 840 1 487 1 514

1 524 mm

400 ≤ d < 840 1 444 1 448

Back to back dimension (a )

d ≥ 840 1 442 1 448

Front-to-front dimension (a )

690 ≤ d ≤ 1 016 1 573 1 592

a = a + e + e

2 1 1 2

1 600 mm

Back to back dimension (a ) 690 ≤ d ≤ 1 016 1 521 1 526

a

330 ≤ d < 840 1 659

1 648

Front-to-front dimension (a )

a = a + e + e

2 1 1 2

a

840 ≤ d ≤ 1 250 1 659

1 643

1 668 mm

330 ≤ d < 840 1 592 1 596

Back to back dimension (a )

840 ≤ d ≤ 1 250 1 590 1 596

e and e are the thicknesses of each wheel.

1 2

a

Two-axle wagons with axle load up to 22,5 t the value shall be taken as 1 651 mm.

Table 3 — Limit values for front-to-front and back-to-back dimensions for rolling stock other

than freight wagons

Designation Wheel diameter Minimum value Maximum value

d [mm] [mm] [mm]

330 ≤ d ≤ 760 1 415 1 426

Front-to-front dimension

(a )

760 < d ≤ 840 1 412 1 426

a = a + e + e

2 1 1 2

d > 840 1 410 1 426

1 435 mm

330 ≤ d ≤ 760 1 359 1 363

Back to back dimension

760 < d ≤ 840 1 358 1 363

(a )

d > 840 1 357 1 363

Front-to-front dimension

(a )

2 400 ≤ d < 1 220 1 487 1 509

a = a + e + e

2 1 1 2

1 520 mm

Back to back dimension

400 ≤ d < 1 220 1 437 1 443

(a )

Front-to-front dimension 400 ≤ d < 725 1 506 1 509

(a )

d ≥ 725 1 487 1 514

a = a + e + e

2 1 1 2

1 524 mm

400 ≤ d < 725 1 444 1 446

Back to back dimension

(a )

d ≥ 725 1 442 1 448

Front-to-front dimension

(a )

690 ≤ d ≤ 1 016 1 573 1 592

a = a + e + e

2 1 1 2

1 600 mm

Back to back dimension

690 ≤ d ≤ 1 016 1 521 1 526

(a )

Front-to-front dimension 330 ≤ d < 840 1 648 1 659

(a )

840 ≤ d ≤ 1 250 1 643 1 659

a = a + e + e

2 1 1 2

1 668 mm

330 ≤ d < 840 1 592 1 596

Back to back dimension

(a )

840 ≤ d ≤ 1 250 1 590 1 596

Table 4 — Limit values for wheel flange and rim for freight wagons

Designation Wheel diameter Minimum Value Maximum Value

[mm]

[mm] [mm]

Width of the rim d ≥ 330 133 140

330 ≤ d ≤ 760 27,5 33

Thickness of flange (e) 760 < d ≤ 840 25 33

d > 840 22 33

1 435 mm

330 ≤ d ≤ 630 31,5 36

Height of flange (h) 630 < d ≤ 760 29,5 36

d > 760 27,5 36

Face of the flange qR d ≥ 330 6,5 -

Width of the rim d ≥ 400 134 140

400 ≤ d ≤ 760 27,5 33

Thickness of flange (e) 760 < d ≤ 840 25 33

d > 840 22 33

1 524 mm

400 ≤ d ≤ 630 31,5 36

Height of flange (h) 630 < d ≤ 760 29,5 36

d > 760 27,5 36

Face of the flange qR d ≥ 400 6,5 -

Width of the rim 690 ≤ d ≤ 1 016 137 139

Thickness of flange (e) 690 ≤ d ≤ 1 016 26 33

1 600 mm

Height of flange (h) 690 ≤ d ≤ 1 016 28 38

Face of the flange qR 690 ≤ d ≤ 1 016 6,5 -

Width of the rim d ≥ 330 133 140

330 ≤ d ≤ 840 27,5 33

Thickness of flange (e)

a

d > 840 33

1 668 mm

330 ≤ d ≤ 630 31,5 36

Height of flange (h) 630 < d ≤ 760 29,5 36

d > 760 27,5 36

Face of the flange qR d ≥ 330 6,5 -

a

Other values may be used. For instance 25 mm in Spain.

Table 5 — Limit values for wheel flange and rim for rolling stock other than freight wagons

Designation Wheel diameter Minimum Value Maximum Value

[mm] [mm] [mm]

Width of the rim d ≥ 330 133 145

330 ≤ d ≤ 760 27,5 33

Thickness of flange (e) 760 < d ≤ 840 25 33

d > 840 22 33

330 ≤ d ≤ 630 31,5 36

Height of flange (h) 630 < d ≤ 760 29,5 36

d > 760 27,5 36

Face of the flange qR d ≥ 330 6,5 -

5.2 Functional requirement

The design of the earthing system shall comply with EN 50153.

The requirements regarding electrical resistance as set out in EN 13260 shall be applied. If necessary,

specific electrical installation can be mounted.

Vehicles fitted with variable-gauge systems shall fulfil EN 15273-1 and EN 15273-2.

6 Automatic Variable-Gauge Systems

6.1 General

The functionality of the system shall be defined at the design stage, together with its main features

(e.g. how forces are received and transferred) in order to set an appropriate assessment methodology.

6.2 Functional requirements

6.2.1 Running gear

Vehicles fitted with variable-gauge running gear should be capable of being operated with no restrictions

due to the special features of their running gear.

Vehicles equipped with variable-gauge running gear shall be able to negotiate curves with a radius of

150 m when coupled into a train.

Individual wagons shall be able to negotiate curves with a radius of 75 m. Wagons intended to be

operated between the 1 435 mm and 1 520 mm track gauge systems shall be able to negotiate curves

with a radius of 60 m either when empty or loaded.

In order to identify the variable-gauge running gear, rules for marking, as set out in EN 15877-1, shall be

applied to all types of vehicles and nominal track gauges.

NOTE The referred standard was originally intended for wagons only.

For the design of the variable-gauge system, the following points shall be considered:

— suitable combinations shall be chosen in order to avoid frictional corrosion on sliding surfaces

between axle body and wheel hub. Protection against corrosion and dirt of the locking system and

bearing surfaces for axial movement of wheels shall be taken into account;

— vehicles shall be designed to be lifted without dismounting their running gear;

— it should be possible to fit and remove wheelsets with the equipment for lifting and exchange that is

normally used for standard wheelsets;

— reprofiling of wheels should not require any equipment other than that for standard wheelsets;

— checks on wheelset geometry shall be possible and integrity should be possible by using existing

equipment for measuring and testing.

6.2.2 Axle

Depending on the technology, two main types of axles can be distinguished: rotating axles and non-

rotating axles with freely rotating wheels.

Validation of axles shall be documented in a validation plan according to EN 15827:

— Rotating axles:

• methods for calculation as set out in EN 13103-1 shall be applied according to the design of the

system. Requirements from EN 13261 shall also be considered;

NOTE In these cases, the validation plan identifies that EN 13103-1 and EN 13261 are fulfilled and no further

assessment is necessary.

• when design is out of the scope of EN 13103-1, the calculation should follow as far as possible

the methods and load systems provided for in this document. Requirements from EN 13261 shall

be considered when applicable.

— Non-rotating axles with freely rotating wheels:

• non-rotating axles with freely rotating wheels are not subject to rotating bending stresses. In

addition, the number of cycles and the range of dynamic forces that non-rotating axles shall

withstand are much lower. They shall, therefore, be considered as a part of the running gear

frame to be calculated and approved according to EN 13749.

6.2.3 Wheel

Wheels shall comply with EN 13979-1 and EN 13262. When these standards do not apply due to the use

of other type of technology, they should be considered at least as a guide. A validation process according

to 6.3.1 shall be applied in any case.

NOTE When wheels comply with EN 13979-1 and EN 13262, the validation process is defined in EN 13979-1.

Any tread profile may be used, but the dynamic behaviour shall always be in accordance with EN 14363.

6.2.4 Axle boxes / Bearings

Axle boxes, greases and bearings shall comply with EN 12080, EN 12081 and EN 12082. When these

standards are not to be directly applied due to the use of other type of technology, they should be

considered at least as a guide. A validation process according to 6.3.1 shall be applied in any case.

It shall be possible to monitor the axle bearing condition either by:

— track side detection equipment; or

— on-board equipment.

Vehicles intended to be monitored by track side equipment on networks with 1 435 mm nominal track

gauge shall comply with all requirements regarding target zone and prohibitive zone as set out in

EN 15437-1.

For vehicles intended to be monitored by track side equipment on networks with nominal track gauges

of 1 520 mm, 1 524 mm, 1 600 mm or 1 668 mm, the corresponding requirements for target zone and

prohibitive zone are established in Annex A.

When hot-box detection is not possible at track-side, on-board systems according to EN 15437-2 shall be

installed.

6.2.5 Locking mechanism

The locking mechanism, which is an integral part of the variable-gauge running gear, shall reliably

perform the following functions, allowing for static and dynamic forces, the effects of weather, wear, and

possible heating due to braking:

— locking of wheels of variable-gauge running gear at the corresponding position for a given track

gauge, irrespective of the operating conditions outside the gauge changeover facility;

— release and locking of wheels while passing through the gauge changeover facility.

Correct locking of the system shall be verified after every passage through the gauge changeover facility

by means of controlling the correct position of the locking system by using at least one of the following

methods:

— visual control;

— on-board control system;

— infrastructure/facility control system.

Arrangements shall be made in order to prevent the intrusion of rain, snow or dust, which can jeopardize

safety and increase wear.

The correct performance of axial movement of wheels shall be ensured. This shall be verified during in-

service tests.

During in-service operation and maintenance, the locking mechanism of variable-gauge running gear

shall not show any defect that could cause displacement of one or both wheels. Defects on the sealing

elements of wheels and/or the locking mechanism of variable-gauge running gear are permissible insofar

wheels are properly locked.

6.2.6 Running gear frame

The running gear frame shall comply with EN 13749. When this document does not apply due to the use

of other type of technology, it should be considered at least as a guide. A validation process according to

6.3.1 shall be applied in any case. According to the design, the locking mechanism can be part of the

running gear frame.

6.2.7 Braking equipment

In the case that the braking system is displaced during the automatic gauge changeover process, an

adapting system shall be used. This system shall automatically switch the position of braking elements

within the automatic gauge changeover process. After the referred switching process is completed, the

braking system shall stay in its correct position.

The correct position of the braking system can be ensured by means of a locking system. It shall be

possible to supervise the locking system, if any, by a visual check or by any other means.

6.3 Validation and acceptance of the design

6.3.1 General

Validation plans are intended to prove that the design of variable-gauge running gear fulfils the

specifications defined in the relevant standards. This document includes the request of a validation plan

according to the state of the art in 6.3.2. When the characteristics or the conditions of use of a previously

approved system are changed, the scope of the assessment shall be established on the basis of a risk

assessment.

When, for the novelty of the applied concepts, design is so different from conventional solutions that

common railway standards cannot be directly applied, a defined engineering process shall be followed in

order to ensure that variable-gauge running gear, together with its associated systems and subsystems,

have the same level of reliability, availability, maintainability and safety as conventional running gear

designed and validated according to the relevant European railway standards in force.

NOTE An engineering process that is consistent with EN ISO 9001 is recognized as satisfying the minimum

requirements specified by this clause.

This process shall be based on EN 15827, which brings together in a single document the design

requirements (i.e. structural and dynamic behaviour), the validation procedures, the maintenance plans

and the quality requirements for all systems and subsystems. It is also defined therein what information

is needed for the technical specification of systems and interfaces, together with the relevant European

standards.

For some elements of variable-gauge systems (e.g. locking systems, non-conventional axles, wheels), it

may not be possible to apply existing standards due to its novelty. It shall hence follow a specific

procedure to analyse failure modes and criticality of each (e.g. FMECA, HAZOP) in order to determine

their possible causes, the severity of their consequences and their probability of occurrence. The

EN 50126 series details how to perform this analysis in the context of RAMS Management along the whole

life cycle of the product.

The acceptance process shall cover the following stages:

— validation plan (e.g. combination of load cases for analysis and static tests, programs for fatigue tests,

routes for track tests);

— values for every load case;

— acceptance criteria (e.g. treatment of measured or calculated values, limiting stresses, criteria for

completion of fatigue tests).

6.3.2 Validation plan

6.3.2.1 Content

The validation plan shall include a list of the planned validation steps in order to demonstrate compliance

with this document.

The procedure for the validation of the variable-gauge running gear against the defined acceptance

criteria shall be established on the basis of:

— design analysis;

— laboratory tests;

— on track tests;

— in service tests.

6.3.2.2 Design review

The design review shall include the following documents:

— technical specification of the variable-gauge system, including the operational and climatic

conditions for which it has been designed, shall define the requirements and acceptance criteria to

be achieved. It shall be explained how the system works, how forces are received and transferred

and, if necessary, the reasons why the referred railway standards do not apply;

— calculations:

• EN standards shall be followed for the calculation of those elements that have been designed in

accordance therewith (e.g. wheels and bogie frames). Where validated components are used,

these calculations are only required if there is a significant variation in the climatic or operation

conditions in operational use;

• axle;

• running gear stiffness: The assembly shall be stiff enough to maintain the back-to-back distance

within the limits, in any operational condition;

• locking mechanism;

• maximum permissible component wear from the standpoint of functional and operational safety;

— thermal effect of braking on the variable-gauge systems. It shall be studied whether any additional

test is needed;

— study of safe running. It shall be proven that wheels are not accidentally released in the following

situations:

• when passing over twisted track as defined in EN 14363;

• during buffing tests in accordance with EN 15551;

• under high longitudinal compression forces as defined in EN 15839;

• when passing over rail mounted brakes in shunting yard tracks;

— maintenance plan shall be included in the validation file;

— study of functional reliability (RAMS - Reliability, Availability, Maintainability, and Safety) of the

wheel locking and release mechanism, to be performed in accordance with EN 50126-1, EN 50126-2

and CLC/TR 50126-3. Additionally, these studies shall determine whether or not the following

measures are necessary:

• additional calculations on the strength of locking mechanism components;

• further tests than those defined in 6.3.2.3 and 6.3.2.4;

• stricter limit values for maximum component wear;

• application of a special maintenance cycle.

6.3.2.3 Laboratory tests

As a minimum, the following laboratory testing shall be performed:

— EN standards shall be followed for testing of those elements that have been designed in accordance

therewith (e.g. wheels, bogie frames). Where validated components are used, these tests are only

required if there is a significant variation in the climatic or operation conditions in operational use.

Determination of the fatigue strength of variable-gauge running gear shall be made by means of a

rotational bending test at a speed equal to or greater than 50 km/h. This test shall be in accordance with

stages, number of cycles and forces as set out in Table 6.

Table 6 — Stages for fatigue testing of variable-gauge running gear

Vertical force [kN] Transverse force [kN]

Stage No. of cycles

static dynamic static dynamic

I 6 P ±0,5 P at 4 Hz 0 ±0,3 P at 2 Hz

II 2 P ±0,6 P at 4 Hz 0 ±0,36 P at 2 Hz

III 2 P ±0,7 P at 4 Hz 0 ±0,42 P at 2 Hz

It is allowed to perform this fatigue test at a higher speed. In this case, all frequencies shall be multiplied

by the following ratio: speed/50.

P load, that represents the static axle load corresponding to design mass under normal payload as defined

in EN 15663.

load cycles without

This test shall be regarded as completed when the running gear has withstood 10

suffering damage (positive test) or when a crack or fracture has occurred (negative test).

The non-rotating axle with freely-rotating wheels and non-rotating locking system shall be considered as

a part of the bogie frame to be tested as such according to EN 13749.

6.3.2.4 Tests on track gauge changeover facility

Before starting in service tests, the functional reliability of the locking mechanism shall be demonstrated.

A minimum of 500 automatic gauge changeover processes shall be made without servicing or inspection

at the nominal passage speed and under conditions representative of those in-service. After these 500

automatic gauge changeover processes, the locking system should be checked:

— back-to-back dimension shall be in accordance with Tables 2 and 3 when the sum of guiding forces

ƩY limit as set out in EN 14363 is applied;

max

— verify that all exerted forces during the automatic gauge changeover process are in the defined range;

— measured wear of components for maintenance purposes.

Further tests can result from the study of functional reliability.

Once all of these tests are successful, it is allowed to perform in-service tests.

6.3.2.5 In-service test

Once all the previous tests are successful, and, after the necessary tests of the behaviour of the vehicle

with the system to run on track has been undertaken, it is allowed to perform in-service tests.

For Phases 1 and 2, tests shall be representative of in-service conditions for the vehicle:

— operational mass under normal payload according to EN 15663. Freight wagons shall also be tested

under dead mass conditions, as defined in EN 15663. In order to consider both load conditions for

freight wagons, the total mileages defined below include both load conditions;

— speeds of up to the maximum design speed of the vehicle, when possible;

— tracks for testing as similar as possible to those on which the vehicle shall run.

For in-service tests, at least 4 variable-gauge sets of running gear shall be used (8 for multiple units). The

variable-gauge running gear shall cover the following distances:

— a phase 1 of 50 000 km on one of the track gauges. No automatic gauge changeover processes shall

be made until the end of this stage.

— a phase 2 of 50 000 km in both track gauges. Not less than 20 % of this distance shall be covered in

any of the track gauges for which the vehicle is being tested. At least 50 automatic gauge changeover

processes shall be performed evenly distributed during this phase.

The controls to be performed during the phases 1 and 2 should be the following as given in Table 7:

a) visual control every 1 000 km of all parts of the running gear that are visible without dismounting

any part of the vehicle. Any incidence should be reported.

b) running gear control (i.e. qR, flange width and flange height, back to back dimension, front to front

dimension and electrical resistance).

c) control of axle stiffness: Back-to-back dimension shall be measured after applying lateral forces

according to EN 14363 at the height of the wheel flange.

d) measurement of translational forces during the automatic gauge changeover process: The maximum

and the average force per wheel shall be measured. The results of these measurements shall be

according to the design.

Table 7 — Controls for in-service test phase 1 and 2:

Phase Running Running Running gear Translational

distance gear stiffness force comments

control measurement measurement

0 x x x

2 000 x

5 000 x

No automatic gauge

10 000 x x

Phase 1 changeover process will be

20 000 x

made at this stage.

30 000 x x

40 000 x

50 000 x x x

60 000 x x

70 000 x x x

At least 50 automatic gauge

Phase 2 80 000 x x changeover processes shall

be performed.

90 000 x x

100 000 x x x

Reports shall be created.

After all these tests are successfully performed, the running gear shall be granted a provisional technical

approval.

This approval may be used to cover in-service tests as required in phase 3, which can involve a

commercial use. Phase 4 is authorized to start once the referred in-service tests of phase 3 are completed.

6.3.3 Technical approval finalisation

Following the issuance of the provisional approva

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...