EN 13979-1:2020

(Main)Railway applications - Wheelsets and bogies - Monobloc Wheels - Technical approval procedure - Part 1: Forged and rolled wheels

Railway applications - Wheelsets and bogies - Monobloc Wheels - Technical approval procedure - Part 1: Forged and rolled wheels

The aim of this document is to define a design assessment procedure of a forged and rolled monobloc wheel (RST). This assessment is carried out before the wheel is commissioned. This document describes, in particular, the assessment to be performed in order to use wheels on a European network which, in addition, have quality requirements in conformity with those defined in EN 13262.

This assessment requires that the conditions of use for the wheel are defined and this standard provides a method for defining those conditions.

The assessment of the design covers four aspects:

- a geometrical aspect: to allow interchangeability of different solutions for the same application;

- a thermomechanical aspect: to manage wheel deformations and to ensure that braking will not cause wheels to fracture;

- a mechanical aspect: to ensure that no fatigue cracks occur in the wheel web and that no permanent deformation occurs under exceptional loading;

- an acoustic aspect: to ensure that the solution chosen is as good as the reference wheel.

This document does not cover assessment of the hub or of the rim.

This document has been drawn up for wheels of non-powered tread-braked wheelsets and applies in full to this type of wheel. For wheels on which disc brakes are mounted or toothed transmission wheels or even wheels with noise reduction devices, the requirements may be amended or supplemented.

For urban railway vehicles, other standards or documents may be used.

Bahnanwendungen - Radsätze und Drehgestelle - Vollräder - Technische Zulassungsverfahren - Teil 1: Geschmiedete und gewalzte Räder

Gegenstand des vorliegenden Dokumentes ist die Bestimmung eines Verfahrens zur Konstruktionsbewertung eines aus Eisenbahnmaterial gewalzten und geschmiedeten Vollrades. Diese Bewertung wird vor der Inbetriebnahme vorgenommen. Das vorliegende Dokument beschreibt insbesondere die Bewertung, die auszuführen ist, um Räder, deren Qualitätsvorschriften angemessener als die sind, die nach EN 13262 festgelegt sind, auf einem europäischen Radbahnnetz zu nutzen.

Diese Bewertung erfordert die Festlegung der Rad-Nutzungsbedingungen und die vorliegende Norm präzisiert, wie diese Bedingungen festzulegen sind.

Die technische Zulassungsbewertung umfasst vier Gesichtspunkte:

- geometrisch: um die Austauschbarkeit verschiedener Lösungen für den gleichen Anwendungsbereich zu ermöglichen;

- thermomechanisch: um die Verformungen des Rades zu beherrschen und sicherzustellen, dass Bremsungen nicht zum Radbruch führen;

- mechanisch: um sicherzustellen, dass kein Dauerschwingriss im Radsteg auftritt;

- akustisch: um sicherzustellen, dass die Lösung so gut wie ein Referenzrad ist.

Dieses Dokument behandelt weder die Bewertung der Nabe, noch die Bewertung des Kranzes.

Dieses Dokument wurde für Räder von Laufradsätzen, die an der Lauffläche gebremst werden, erstellt. Für Räder, an denen Bremsscheiben oder Antriebszahnräder montiert sind, oder für Räder mit Lärmschutzvorrichtungen können die Anforderungen geändert bzw. vervollständigt werden.

Für Schienenverkehrsfahrzeuge des Nahverkehrs können andere Normen oder Dokumente angewendet werden.

Applications ferroviaires - Essieux montés et bogies - Roues monobloc - Procédure d'homologation technique - Partie 1 : Roues forgées et laminées

Le présent document a pour objet de définir une procédure d’évaluation de la conception d’une roue monobloc laminée forgée de matériel ferroviaire (RST). Cette évaluation est effectuée avant sa mise en service. Le présent document décrit en particulier l’évaluation à effectuer afin de pouvoir utiliser sur un réseau européen des roues dont les prescriptions de qualité sont de plus conformes à celles définies par l’EN 13262.

Cette évaluation nécessite de définir les conditions d’utilisation de la roue et la présente norme précise comment définir ces conditions.

L’évaluation de la conception comporte quatre aspects :

- un aspect géométrique : permettre l’interchangeabilité de différentes solutions pour une même application ;

- un aspect thermomécanique : maîtriser les déformations et garantir la non-rupture sous l’effet des freinages ;

- un aspect mécanique : garantir la non-fissuration par fatigue des toiles de roue et l’absence de déformations permanentes sous chargement exceptionnel ;

- un aspect acoustique : assurer que la solution choisie est aussi bonne que la roue prise comme référence.

Le présent document ne traite pas de l’évaluation du moyeu ni de la jante.

Le présent document a été établie pour les roues d’essieux montés porteurs freinées sur la table de roulement, et s’applique en totalité pour ce type de roue. Pour les roues sur lesquelles sont montés des disques de freins ou des roues dentées de transmission, ou bien les roues comportant des dispositifs de réduction du bruit, les exigences sont susceptibles d'être modifiées ou complétées.

Pour les véhicules ferroviaires urbains, d’autres normes ou documents sont susceptibles d'être utilisés.

Železniške naprave - Kolesne dvojice in podstavni vozički - Monoblok kolesa - Postopek za tehnično odobritev - 1. del: Kovana in valjana kolesa

General Information

- Status

- Withdrawn

- Publication Date

- 21-Jul-2020

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 2/WG 11 - Wheels - Wheelsets

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 20-Dec-2023

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 23-Sep-2020

- Effective Date

- 28-Jan-2026

- Refers

EN 13262:2004+A2:2011 - Railway applications - Wheelsets and bogies - Wheels - Product requirements - Effective Date

- 28-Jan-2026

- Referred By

EN 13262:2020 - Railway applications - Wheelsets and bogies - Wheels - Product requirements - Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

EN 13979-1:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Wheelsets and bogies - Monobloc Wheels - Technical approval procedure - Part 1: Forged and rolled wheels". This standard covers: The aim of this document is to define a design assessment procedure of a forged and rolled monobloc wheel (RST). This assessment is carried out before the wheel is commissioned. This document describes, in particular, the assessment to be performed in order to use wheels on a European network which, in addition, have quality requirements in conformity with those defined in EN 13262. This assessment requires that the conditions of use for the wheel are defined and this standard provides a method for defining those conditions. The assessment of the design covers four aspects: - a geometrical aspect: to allow interchangeability of different solutions for the same application; - a thermomechanical aspect: to manage wheel deformations and to ensure that braking will not cause wheels to fracture; - a mechanical aspect: to ensure that no fatigue cracks occur in the wheel web and that no permanent deformation occurs under exceptional loading; - an acoustic aspect: to ensure that the solution chosen is as good as the reference wheel. This document does not cover assessment of the hub or of the rim. This document has been drawn up for wheels of non-powered tread-braked wheelsets and applies in full to this type of wheel. For wheels on which disc brakes are mounted or toothed transmission wheels or even wheels with noise reduction devices, the requirements may be amended or supplemented. For urban railway vehicles, other standards or documents may be used.

The aim of this document is to define a design assessment procedure of a forged and rolled monobloc wheel (RST). This assessment is carried out before the wheel is commissioned. This document describes, in particular, the assessment to be performed in order to use wheels on a European network which, in addition, have quality requirements in conformity with those defined in EN 13262. This assessment requires that the conditions of use for the wheel are defined and this standard provides a method for defining those conditions. The assessment of the design covers four aspects: - a geometrical aspect: to allow interchangeability of different solutions for the same application; - a thermomechanical aspect: to manage wheel deformations and to ensure that braking will not cause wheels to fracture; - a mechanical aspect: to ensure that no fatigue cracks occur in the wheel web and that no permanent deformation occurs under exceptional loading; - an acoustic aspect: to ensure that the solution chosen is as good as the reference wheel. This document does not cover assessment of the hub or of the rim. This document has been drawn up for wheels of non-powered tread-braked wheelsets and applies in full to this type of wheel. For wheels on which disc brakes are mounted or toothed transmission wheels or even wheels with noise reduction devices, the requirements may be amended or supplemented. For urban railway vehicles, other standards or documents may be used.

EN 13979-1:2020 is classified under the following ICS (International Classification for Standards) categories: 45.040 - Materials and components for railway engineering; 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13979-1:2020 has the following relationships with other standards: It is inter standard links to EN 13979-1:2003+A2:2011, EN 13979-1:2023, EN 13103-1:2017+A1:2022, EN 13262:2004+A2:2011, EN 13262:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13979-1:2020 is associated with the following European legislation: EU Directives/Regulations: 2008/57/EC, 2016/797/EU; Standardization Mandates: M/483. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13979-1:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2020

Nadomešča:

SIST EN 13979-1:2004+A2:2011

Železniške naprave - Kolesne dvojice in podstavni vozički - Monoblok kolesa -

Postopek za tehnično odobritev - 1. del: Kovana in valjana kolesa

Railway applications - Wheelsets and bogies - Monobloc Wheels - Technical approval

procedure - Part 1: Forged and rolled wheels

Bahnanwendungen - Radsätze und Drehgestelle - Vollräder - Technische

Zulassungsverfahren - Teil 1: Geschmiedete und gewalzte Räder

Applications ferroviaires - Essieux montés et bogies - Roues monobloc - Procédure

d'homologation technique - Partie 1 : Roues forgées et laminées

Ta slovenski standard je istoveten z: EN 13979-1:2020

ICS:

45.040 Materiali in deli za železniško Materials and components

tehniko for railway engineering

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13979-1

EUROPEAN STANDARD

NORME EUROPÉENNE

July 2020

EUROPÄISCHE NORM

ICS 45.040 Supersedes EN 13979-1:2003+A2:2011

English Version

Railway applications - Wheelsets and bogies - Monobloc

Wheels - Technical approval procedure - Part 1: Forged

and rolled wheels

Applications ferroviaires - Essieux montés et bogies - Bahnanwendungen - Radsätze und Drehgestelle -

Roues monobloc - Procédure d'homologation Vollräder - Technische Zulassungsverfahren - Teil 1:

technique - Partie 1 : Roues forgées et laminées Geschmiedete und gewalzte Räder

This European Standard was approved by CEN on 8 April 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13979-1:2020 E

worldwide for CEN national Members.

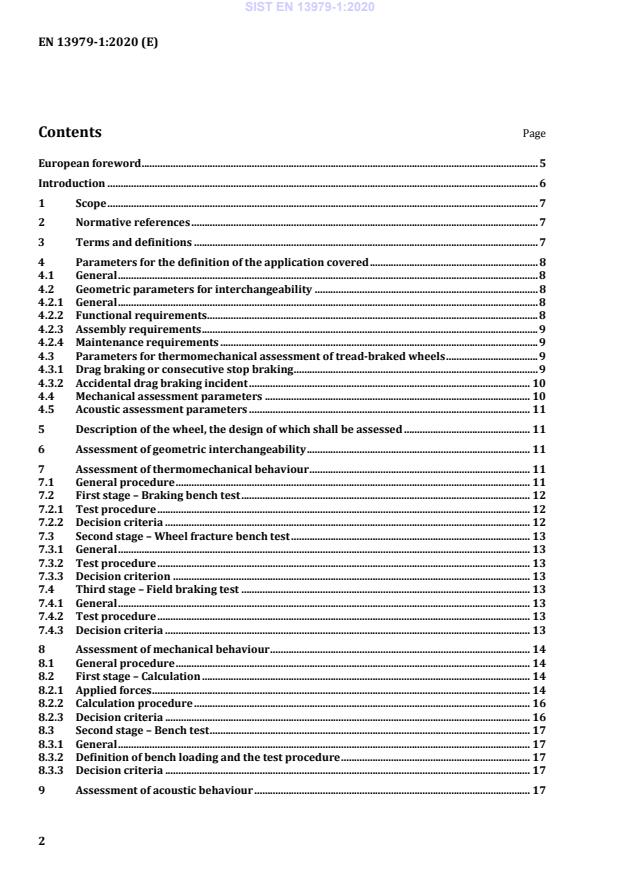

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Parameters for the definition of the application covered . 8

4.1 General . 8

4.2 Geometric parameters for interchangeability . 8

4.2.1 General . 8

4.2.2 Functional requirements . 8

4.2.3 Assembly requirements . 9

4.2.4 Maintenance requirements . 9

4.3 Parameters for thermomechanical assessment of tread-braked wheels . 9

4.3.1 Drag braking or consecutive stop braking . 9

4.3.2 Accidental drag braking incident . 10

4.4 Mechanical assessment parameters . 10

4.5 Acoustic assessment parameters . 11

5 Description of the wheel, the design of which shall be assessed . 11

6 Assessment of geometric interchangeability . 11

7 Assessment of thermomechanical behaviour . 11

7.1 General procedure . 11

7.2 First stage – Braking bench test . 12

7.2.1 Test procedure . 12

7.2.2 Decision criteria . 12

7.3 Second stage – Wheel fracture bench test . 13

7.3.1 General . 13

7.3.2 Test procedure . 13

7.3.3 Decision criterion . 13

7.4 Third stage – Field braking test . 13

7.4.1 General . 13

7.4.2 Test procedure . 13

7.4.3 Decision criteria . 13

8 Assessment of mechanical behaviour . 14

8.1 General procedure . 14

8.2 First stage – Calculation . 14

8.2.1 Applied forces . 14

8.2.2 Calculation procedure . 16

8.2.3 Decision criteria . 16

8.3 Second stage – Bench test . 17

8.3.1 General . 17

8.3.2 Definition of bench loading and the test procedure . 17

8.3.3 Decision criteria . 17

9 Assessment of acoustic behaviour . 17

10 Technical approval documents . 17

Annexe A (informative) Drag braking values . 18

A.1 Freight wagons . 18

A.2 Other types of rolling stock and specific freight wagons . 18

Annexe B (normative) Assessment of thermomechanical behaviour . 19

B.1 Assessment flow chart . 19

B.2 Braking bench test procedure . 20

B.2.1 Test principle . 20

B.2.2 Definition of drag braking . 20

B.2.3 Method for measuring decision criteria . 20

B.2.4 Tests and measurements . 21

B.2.5 Anomalies . 22

B.3 Wheel fracture bench testing procedure . 22

B.3.1 Test principle . 22

B.3.2 Creation of residual stresses in the rim of the wheel . 22

B.3.3 Pre-cracked rim . 22

B.3.4 Definition of drag braking test . 24

B.3.5 Parameters for the wheel fracture bench test . 24

B.3.6 Tests and measurements . 25

B.3.7 Anomalies . 26

B.4 Field braking test procedure . 26

B.4.1 Test principle . 26

B.4.2 Definition of braking . 26

B.4.3 Method for measuring decision criteria . 27

B.4.4 Route type for testing . 27

B.4.5 Tests and measurements . 28

B.4.6 Anomalies . 29

Annexe C (normative) Wheel profile diameter definition . 30

C.1 General . 30

C.2 Diameter after last reprofiling . 30

C.3 Worn diameter . 31

Annexe D (normative) Assessment of mechanical behaviour . 32

D.1 Assessment flow chart . 32

D.2 Calculation procedure in the case of exceptional load. 33

D.2.1 Principle . 33

D.2.2 Load . 33

D.3 Calculation procedure for cases of fatigue load . 33

D.3.1 Principle . 33

D.3.2 Load . 33

D.3.3 Method of calculation . 33

Annexe E (informative) Fatigue loading for narrow gauge tracks (metric or close to a metre) . 35

Annexe F (informative) Fatigue loading for tilting trains . 36

Annexe G (normative) Mechanical behaviour – Finite element calculation assessment . 37

Annexe H (informative) Mechanical behaviour – Bench loading and test procedure . 38

H.1 Principle of bench loading and test procedure . 38

H.2 Definition of loads . 38

H.2.1 General . 38

H.2.2 Measurement of stresses during field tests . 38

H.3 Fatigue bench test . 39

H.3.1 Method 1 – Random fatigue test . 39

H.3.2 Method 2 – Single-stage fatigue test . 40

H.3.3 Examples of benches . 41

Annexe I (informative) Assessment of acoustic behaviour . 42

I.1 General procedure . 42

I.2 Assessment procedure . 42

I.3 Assessment criteria . 43

I.4 Decision criterion . 43

I.5 Assessment flow chart . 44

I.5.1 Preliminary comment. 44

I.5.2 Calculating the wheel modal basis . 45

I.5.3 Defining the reference speeds . 45

I.5.4 Defining the reference combined wheel-rail roughness . 45

I.5.5 Defining the reference track model . 46

I.5.6 Defining the calculation parameters . 47

I.5.7 Calculating sound power . 48

I.5.8 Factoring the weighted spectrum into sound power . 48

I.5.9 Calculating the acceptance criterion . 49

I.5.10 Optional calculations . 49

I.6 Field measurement procedure . 50

I.6.1 General . 50

I.6.2 Environmental conditions . 50

I.6.3 Conditions for the track . 50

I.6.4 Conditions for the train . 50

I.6.5 Positioning the measurement points . 51

I.6.6 Measurement quantities. 52

I.6.7 Test procedure . 52

I.6.8 Data processing . 53

Annexe J (informative) Ultrasonic method for determining residual stresses in the rim

(non-destructive method) . 55

J.1 Procedure. 55

J.2 Measurement uncertainty . 55

J.3 Calibrations . 56

J.4 Verifying measurement parameters . 56

Annexe ZA (informative) Relationship between this European Standard and the relevant

essential requirements of EU Directive 2008/57/EC which it aims to cover . 57

Bibliography . 61

European foreword

This document (EN 13979-1:2020) has been prepared by Technical Committee CEN/TC 256 “Railway

applications”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, by January 2021 at the latest, and all conflicting national standards shall

be withdrawn no later than January 2021.

Attention is drawn to the fact that some elements of this document may be the subject of patent rights or

similar rights. CEN and/or CENELEC shall not be held responsible for identifying all or some of these

patent rights.

This document replaces EN 13979-1:2003+A2:2011.

This document has been prepared in the context of a standardization request given to CEN by the

European Commission and the European Free Trade Association, and supports essential requirements of

EU Directive 2008/57/EC.

For the relationship with Directive 2008/57/EC, see informative Annex ZA, which is an integral part of

this document.

According to the CEN/CENELEC Internal Regulations, the national standards organisations of the

following countries are required to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, the Czech Republic, Denmark, Estonia, Finland, the Former Yugoslav Republic of

Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg,

Malta, the Netherlands, Norway, Poland, Portugal, the Republic of Serbia, Romania, Slovakia, Slovenia,

Spain, Sweden, Switzerland, Turkey and the United Kingdom.

Introduction

An assessment of the two following aspects is carried out before a wheel is commissioned:

— assessment of the design as described in this standard;

— assessment of the quality of the product (EN 13262).

1 Scope

The aim of this document is to define a design assessment procedure of a forged and rolled monobloc

wheel (RST). This assessment is carried out before the wheel is commissioned. This document describes,

in particular, the assessment to be performed in order to use wheels on a European network which, in

addition, have quality requirements in conformity with those defined in EN 13262.

This assessment requires that the conditions of use for the wheel are defined and this standard provides

a method for defining those conditions.

The assessment of the design covers four aspects:

— a geometrical aspect: to allow interchangeability of different solutions for the same application;

— a thermomechanical aspect: to manage wheel deformations and to ensure that braking will not cause

wheels to fracture;

— a mechanical aspect: to ensure that no fatigue cracks occur in the wheel web and that no permanent

deformation occurs under exceptional loading;

— an acoustic aspect: to ensure that the solution chosen is as good as the reference wheel.

This document does not cover assessment of the hub or of the rim.

This document has been drawn up for wheels of non-powered tread-braked wheelsets and applies in full

to this type of wheel. For wheels on which disc brakes are mounted or toothed transmission wheels or

even wheels with noise reduction devices, the requirements may be amended or supplemented.

For urban railway vehicles, other standards or documents may be used.

2 Normative references

The following documents referred to in the text constitute, for all or part of their content, requirements

of this document. For dated references, only the cited edition applies. For undated references, the last

edition of the reference document applies (including any amendments).

EN 13103-1, Railway applications — Wheelsets and bogies — Part 1: Design method for axles with external

journals

EN 13262:2004+A2:2011, Railway applications – Wheelsets and bogies – Wheels – Product requirements

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: http://www.electropedia.org/

• ISO Online browsing platform: http://www.iso.org/obp

3.1

technical specification

document describing specific parameters and/or design assessment procedure requirements as an

addition to the requirements of this standard

3.2

diameter after last reprofiling

nominal value defined by a 5 x 5 mm nominal chamfer and the slope of the new tread profile

Note 1 to clause: Adapted values can be defined, for example, in the maintenance plan or in the technical

specification. See Figure C.1.

3.3

worn diameter

theoretical minimum diameter in service, and cylindrical profile from the outer side of the rim to D and

then original new profile to the inner side of the rim

Note 1 to clause: See Figure C.1.

4 Parameters for the definition of the application covered

4.1 General

The application for which a wheel is to be assessed shall be defined by the parameters set out below.

If the application parameters are changed for an assessed wheel, the assessment shall be reviewed.

4.2 Geometric parameters for interchangeability

4.2.1 General

The application shall be defined by geometric parameters for interchangeability, which can be split into

three categories according to whether they are related to functional requirements, assembly

requirements or maintenance requirements.

NOTE For rolling stock wheels that have to conform to the Directive, some of the geometrical parameters are

given in the TSIs concerned.

4.2.2 Functional requirements

— the nominal tread diameter that influences the buffer height and the loading gauge;

— the maximum rim width linked to the switches and crossings and the track brakes;

— the tread profile outside the conical part of the tread;

— the position of the inner side of the rim relative to the corresponding side of the hub;

— the conicity of the hub bore;

— the space required for disc brakes mounted on the wheel;

— the space required on the bogie frame, braking equipment and suspension equipment.

4.2.3 Assembly requirements

— the bore diameter;

— the hub length to ensure the hub overhangs on the wheelseat.

4.2.4 Maintenance requirements

— the wear limit diameter or the last reprofiling diameter;

— the wear groove shape, if necessary;

— the geometry of the area for wheel clamping on reprofiling machines;

— the position and shape of the hole and groove for displacement under oil pressure;

— the general rim shape to allow ultrasonic measurement of residual stresses in tread-braked wheels.

4.3 Parameters for thermomechanical assessment of tread-braked wheels

4.3.1 Drag braking or consecutive stop braking

4.3.1.1 General

The application shall be defined based on the maximum braking energy (P nominal braking power, t

a a

application time (duration of the test) and V average speed of the vehicle) generated by the friction of

a

the brake shoes on the tread, as well as the type of brake shoes applied to the wheel (the type – cast iron

brake shoe or composite brake shoe – dimensions and number).

The braking test with composite brake shoes covers the braking test with cast iron brake shoes. The

braking test with two opposing brake shoes covers the braking test with a single brake shoe. The braking

test is independent of the manufacturing origin of the brake shoes.

4.3.1.2 freight rolling stock

When monobloc wheels are fitted to wagons that are 100% tread braked, the parameters in Table A.1 of

Annex A shall apply, unless the technical specification defines them differently.

NOTE This table is the same as the table in the freight wagons TSI.

When a wagon is not 100% tread braked, nominal power, P , shall be adapted as defined in the technical

b

specification.

For specific wagons or traffic, the power and/or application time and/or running speed values can be

modified to check the thermomechanical behaviour of these wheels in the context of the requirements of

the technical specification and in accordance with Table A.2 ofAnnex A.

4.3.1.3 Other types of rolling stock

Thermomechanical behaviour shall be verified for the worst braking case. This shall be done using drag

braking in conformity with the parameters in Table A.2 of Annex A and/or the worst consecutive stop

braking for this application.

This choice can be made taking into account the level of displacement and residual stresses calculated

using numerical simulation for each of the braking scenarios considered.

The average slope and/or application time and/or average speed of consecutive stop braking and/or

energy values shall be defined in the technical specification. Table A.2 of Annex A provides examples of

values.

NOTE The values of the Loc & Pas TSI clause 4.2.4.5.4 are valid for the assessment of the braking system, not

for the wheel.

4.3.2 Accidental drag braking incident

4.3.2.1 General

The thermomechanical behaviour shall be defined based on the maximum braking energy (P braking

a

power, t application time (duration of the test) and V average speed of the vehicle) generated by the

a a

friction of the brake shoes on the tread that the wheel to be assessed must be able to dispel when there

is an accidental drag braking incident.

4.3.2.2 100% tread-braked wheels

For freight wagons, the parameters for the accidental drag braking incident are identical to those defined

for drag braking (see Table A.1 of Annex A).

For other types of rolling stock, the parameters for the accidental drag braking incident are identical to

those of drag braking (see Table A.2 of Annex A) for 100% tread braking.

4.3.2.3 Non-tread-braked wheels

For all types of rolling stock, the parameters for the drag braking incident shall be:

a) Parameters for the accidental drag braking incident test for a 100% tread-braked wheel (see

subclause 4.3.2.2);

b) Or the parameters for the wheel fracture bench test (see subclause 7.3)

4.4 Mechanical assessment parameters

The application shall be defined by:

— the maximum vertical static force per wheelset (according to EN 13103-1);

— the type of route to be provided by the vehicles that will be fitted with the wheels to be assessed:

1. description of the lines: geometric quality of the tracks, curve parameters, maximum speeds,

etc. ;

2. running times on these lines;

— the estimated service life of the wheel, in kilometres.

In the case of a mechanical assessment solely by means of calculation, the parameters of subclause 8.2

shall be taken into consideration.

4.5 Acoustic assessment parameters

The application shall be defined by all the parameters influencing the noise emitted by the wheel and not

directly involved in the design of the wheel to be assessed, such as:

1) the reference track on which the wheel shall run;

2) the reference wheel to which the design will be compared;

3) the reference rolling stock and one or more reference speeds;

4) a surface roughness spectrum, representative of the operational tread condition (cast iron or

composite tread braked or not tread braked) of the wheel under test, to be used on both the reference

wheel and the new wheel.

5 Description of the wheel, the design of which shall be assessed

The assessment documentation of the design of the wheel shall include:

1. the description of the manufacturing process (forging, rolling, heat treatment, etc.);

2. the definition of the wheel geometry (drawing);

3. the following manufacturing parameters, if they differ from those defined in EN 13262:

— geometric tolerances;

— surface finishes;

— steel grade;

4. the parameters for defining the application for which the design assessment is requested.

6 Assessment of geometric interchangeability

The wheel design shall conform to the requirements of subclause 4.2.

7 Assessment of thermomechanical behaviour

7.1 General procedure

This assessment comprises of three stages. The transition from one stage to the next depends on the

results obtained.

The flowchart for this assessment is shown in Annexe B (normative).

For each of the three stages, the tests shall be carried out on a new rim (nominal diameter) and at a

diameter after last reprofiling (see Annexe C).

7.2 First stage – Braking bench test

7.2.1 Test procedure

The test method and the measurements to be taken are given in normative Annex B.

For freight wagons the requirements in subclause 4.3.1.2 shall apply. For other vehicles, the power to be

applied during this test shall be equal to 1.2 P (P is defined in 4.3). The duration of each drag braking

a a

period and the average train speed are those defined in 4.3 and in Annexes A and B (t and V ).

a a

7.2.2 Decision criteria

Three criteria shall be met simultaneously for the wheel with the new rim and the wheel diameter after

last reprofiling.

a) Wheel with new rim:

1) maximum lateral displacement of the rim while hot during braking: + 3/– 1 mm;

2) level of residual stress in the rim after cooling:

σ ≤ +∑ N /mm

rn r

i) as the average of three measurements;

ii) σ ≤ + (Σ + 50) N/mm for each of the measures;

in r

3) maximum lateral displacement of the rim while cold: + 1.5/– 0.5 mm.

b) Wheel at a diameter after last reprofiling:

1) maximum lateral displacement of the rim while hot during braking: + 3/– 1 mm;

level of residual stress in the rim after cooling:

i) σ ≤ + (Σ + 75) N/mm for the average of the three measures;

rw r

ii) σ ≤ + (Σ + 100) N/mm for each of the measures;

iw r

2) maximum lateral displacement of the rim while cold: + 1.5/– 0.5 mm.

The value of Σ shall be defined according to the criteria of the steel grades of the wheel rim. For grades

r

ER6 and ER7 of EN 13262, Σ = 200 N/mm .

r

Displacement is positive when it corresponds to a wide gauge of the internal faces of the two wheels of

the wheelset.

For wheels on rolling stock that do not have to satisfy the requirements of the Interoperability Directive,

if the track tolerances differ from the general tolerances used in Europe, other values of displacement

may be defined in the technical specification.

7.3 Second stage – Wheel fracture bench test

7.3.1 General

This second stage shall be proceeded with if the residual stress levels measured during the first stage

exceed the decision criteria, or in application of subclause 4.3.2.3.

7.3.2 Test procedure

The test procedure is given in Annex B (normative).

7.3.3 Decision criterion

The wheels must not fracture during the test.

7.4 Third stage – Field braking test

7.4.1 General

This third stage shall be proceeded with if one of the results of the first stage does not respect the decision

criteria and if the wheel is not rejected after stage two.

7.4.2 Test procedure

The test method and the measurements to be taken are given in Annex B (normative).

The power to be taken into account for these tests is 1.2 P (P is defined in 4.3). The duration of each drag

a a

braking and the average running speed of the vehicle are those defined in 4.3 (t and V ).

a a

7.4.3 Decision criteria

Three criteria shall be met simultaneously for the wheel with the new rim and the wheel at a diameter

after last reprofiling.

a) Wheel with new rim:

1) maximum lateral displacement of the rim while hot during braking: + 3/– 1 mm;

level of residual stress in the rim after the tests and after cooling:

i) σ ≤ + (Σ – 50) N/mm for the average of the three measures;

rn r

ii) σ ≤ + Σ N/mm for each of the measures;

in r

2) maximum lateral displacement of the rim while cold after the tests: + 1.5/– 0.5 mm.

b) Wheel at a diameter after last reprofiling:

1) maximum lateral displacement of the rim while hot during braking: + 3/– 1 mm;

level of residual stress in the rim after the tests and after cooling:

i) σ ≤ + Σ N/mm for the average of the three measures;

rw r

ii) σ ≤ + (Σ + 50) N/mm for each of the measures;

iw r

2) maximum lateral displacement of the rim while cold after the tests: + 1,5/– 0,5 mm.

The value of Σ shall be defined according to the criteria of the steel grades of the wheel rim. For grades

r

ER6 and ER7 of EN 13262, Σ = 200 N/mm .

r

Displacement is positive when it corresponds to a wide gauge of the internal faces of the two wheels of

the wheelset.

For wheels on rolling stock that do not have to satisfy the requirements of the Interoperability Directive,

if the track tolerances differ from the general tolerances used in Europe, other values of displacement

may be defined in the technical specification.

8 Assessment of mechanical behaviour

8.1 General procedure

This assessment comprises of two stages. The second stage is carried out depending on the results of the

first. The purpose of this assessment is to ensure that there will be no risk of fatigue cracking either in

the wheel web or in the connections with the hub or the rim during the service life of the wheel. Another

purpose is to ensure that there is no permanent deformation under exceptional loading, in accordance

with subclause 8.2.1.1. All other parts of the wheel are excluded from this assessment (e.g. oil injection

hole).

The oil injection hole should be positioned in an area with low dynamic stresses.

For the calculation, the geometry of a worn wheel (according to clause C.3) is the most favourable with

regard to the mechanical behaviour. For the tests, the diameter of the wheel shall be specified in the

technical specification.

The flowchart for this assessment is shown in Annex D (normative).

8.2 First stage – Calculation

8.2.1 Applied forces

8.2.1.1 Exceptional loading

Vertical force (in kN) Fz = 90 + P, limited to 200 kN.

lim

Lateral force (in kN) Fy = 10 + 2 P/3.

lim

Load case 2 shall be considered:

— Case 2 : curve (flange pressed against the rail)

lim

Fz = Fz

lim

Fy2 = Fy

lim

8.2.1.2 Fatigue loading

The forces are calculated on the basis of the value of load P. Load P is defined in EN 13103-1. It

corresponds to half of the vertical force on the rail per wheelset.

The fatigue load cases for narrow gauge tracks are defined in Annex E.

The fatigue load cases for tilting rolling stock are defined in Annex F.

On the basis of the parameters necessary for the mechanical assessment defined in subclause 4.4,

additional forces shall be used, as specified in the technical specification, if these parameters generate

greater forces (e.g. curve parameters, etc.).

Three load cases should be considered (see Figure 1):

— Case 1: straight track (centred wheelset)

Fz = 1.25 P

Fy1 = 0

— Case 2: curve (flange pressed against the rail)

Fz = 1.25 P

Fy2 = 0.6 P for non-guiding wheelsets

Fy2 = 0.7 P for guiding wheelsets

— Case 3: negotiation of switches and crossings (inner side of flange applied to the guardrail)

Fz = 1.25 P

Fy3 = 0.6 Fy2 = 0.36 P for non-guiding wheelsets

Fy3 = 0.6 Fy2 = 0.42 P for guiding wheelsets

Figure 1 shows, for the general case, the application points of the different forces.

The terms “guiding wheelsets” and “non-guiding wheelsets” are defined in EN13103-1.

Key

1 straight track

2 curve

3 negotiation of switches and crossings

F Vertical force on a straight track (centred wheelset)

Z1

FZ2 Vertical force on a curve (flange pressed against the rail)

FZ3 Vertical force at the negotiation of switches and crossings (inner side of the flange applied to the guardrail)

F Lateral force on a curve (flange pressed against the rail)

Y2

F Lateral force at the negotiation of switches and crossings (inner side of the flange applied to the guardrail)

Y3

Figure 1 — Application points of the different forces

8.2.2 Calculation procedure

8.2.2.1 General

A finite element calculation code shall be used to determine the stresses.

The validity of the code shall be demonstrated and the choice of parameters that exert a critical influence

on the results shall be justified. Annex G (normative) defines the method of demonstrating this.

8.2.2.2 For exceptional loading

The stresses shall be analysed by determining the principal stresses at all points in the mesh (nodes) and

treated to assess the von Mises equivalent stress.

8.2.2.3 For fatigue loading

The stresses shall be analysed in the following way:

— determination of the principal stresses at all points in the mesh (nodes) for each of the three load

cases;

— assessment, for each node, of the maximum principal stress for the three load cases (σ ) and of the

max

direction of this principal stress;

— assessment, for each

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...