EN 14428:2004

(Main)Shower enclosures - Functional requirements and test methods

Shower enclosures - Functional requirements and test methods

This European Standard specifies requirements for shower enclosures for domestic purposes which ensure that the product, when installed in accordance with the manufacturer's installation instructions, gives satisfactory performance when used as intended.

This standard does not apply to shower cabinets or curtains and does not specify aesthetic and dimensional requirements.

NOTE For the purposes of this standard the term "domestic purposes" includes use in hotels, accommodation for students, hospitals and similar buildings, except when special medical provisions are required.

Duschabtrennungen - Funktionsanforderungen und Prüfverfahren

La présente Norme européenne spécifie les exigences relatives aux parois de douche à usage domestique assurant que le produit, lorsqu'il est installé conformément aux instructions d'installation du fabricant, fonctionne de manière satisfaisante pour l'usage prévu.

La présente norme ne concerne pas les cabines de douche complètes ou les rideaux de douche et ne spécifie pas d'exigences esthétiques et dimensionnelles.

NOTE Pour les besoins de la présente norme l'expression "à usage domestique" comprend les utilisations dans les hôtels, les logements d'étudiants, les hôpitaux et bâtiments similaires, sous réserve de dispositions médicales spéciales.

Parois de douche - Prescriptions fonctionnelles et méthodes d'essai

Zasloni za prhanje – Funkcionalne zahteve in preskusne metode

General Information

- Status

- Withdrawn

- Publication Date

- 23-Nov-2004

- Withdrawal Date

- 22-Jan-2008

- Technical Committee

- CEN/TC 163 - Sanitary appliances

- Drafting Committee

- CEN/TC 163/WG 4 - Baths (W/Pools) - Shower trays (Performance testing)

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 23-Jan-2008

- Completion Date

- 23-Jan-2008

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Nonprofit organization that performs technical evaluations of building products.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

BBA (British Board of Agrément)

UK construction product certification.

Sponsored listings

Frequently Asked Questions

EN 14428:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Shower enclosures - Functional requirements and test methods". This standard covers: This European Standard specifies requirements for shower enclosures for domestic purposes which ensure that the product, when installed in accordance with the manufacturer's installation instructions, gives satisfactory performance when used as intended. This standard does not apply to shower cabinets or curtains and does not specify aesthetic and dimensional requirements. NOTE For the purposes of this standard the term "domestic purposes" includes use in hotels, accommodation for students, hospitals and similar buildings, except when special medical provisions are required.

This European Standard specifies requirements for shower enclosures for domestic purposes which ensure that the product, when installed in accordance with the manufacturer's installation instructions, gives satisfactory performance when used as intended. This standard does not apply to shower cabinets or curtains and does not specify aesthetic and dimensional requirements. NOTE For the purposes of this standard the term "domestic purposes" includes use in hotels, accommodation for students, hospitals and similar buildings, except when special medical provisions are required.

EN 14428:2004 is classified under the following ICS (International Classification for Standards) categories: 91.140.70 - Sanitary installations. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14428:2004 has the following relationships with other standards: It is inter standard links to EN 14428:2004+A1:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14428:2004 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/110. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14428:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Shower enclosures - Functional requirements and test methodsZasloni za prhanje – Funkcionalne zahteve in preskusne metodeParois de douche - Prescriptions fonctionnelles et méthodes d'essaiDuschabtrennungen - Funktionsanforderungen und PrüfverfahrenTa slovenski standard je istoveten z:EN 14428:2004SIST EN 14428:2005en91.140.70ICS:SLOVENSKI

STANDARDSIST EN 14428:200501-marec-2005

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14428November 2004ICS 91.140.70 English versionShower enclosures - Functional requirements and test methodsParois de douche - Prescriptions fonctionelles et méthodesd'essaiDuschabtrennungen - Funktionsanforderungen undPrüfverfahrenThis European Standard was approved by CEN on 2 September 2004.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14428:2004: E

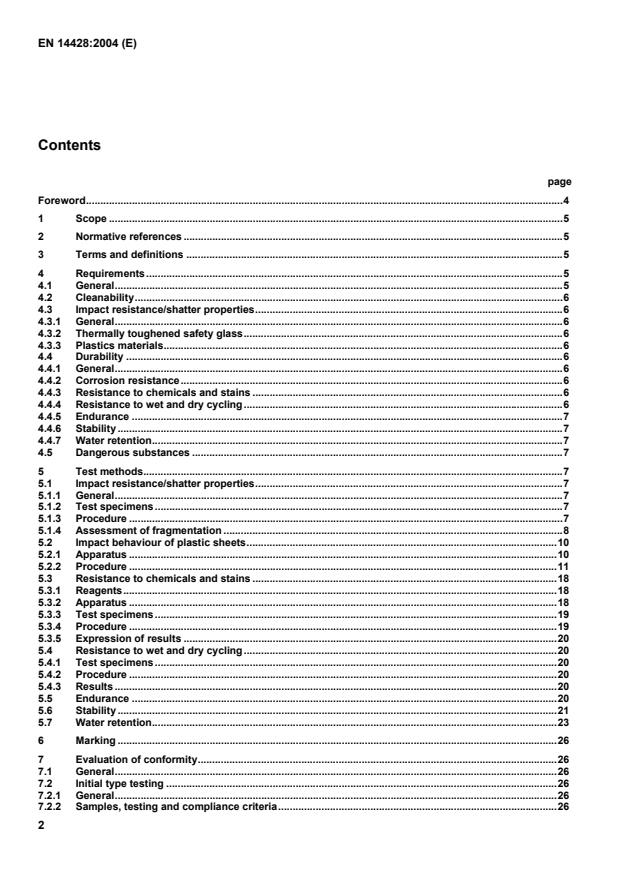

Clauses of this European Standard addressing the provisions of EU Construction Products Directive.28 ZA.1 Scope and relevant characteristics.28 ZA.2 Procedure for attestation of conformity of shower enclosures.29 ZA.2.1 System of attestation of conformity.29 ZA.2.2 Certificate and Declaration of conformity.29 ZA.3 CE marking and labelling.30

4.3.1 General Shower enclosures may be glazed with various materials. Where glass is used, this shall meet the requirements of 4.3.2, and where plastics materials are used, they shall meet the requirements of 4.3.3. 4.3.2 Thermally toughened safety glass Thermally toughened safety glass shall meet the requirements of EN 12150-1:2000, except in respect of Clause 8 which is replaced by 5.1 of this document. When tested in accordance with 5.1, the minimum particle count shall be 40. 4.3.3 Plastics materials When tested in accordance with 5.2, sheets shall not break or they shall break safely. 4.4 Durability 4.4.1 General Products conforming with the requirements of 4.2 and 4.3 and the following are deemed to be durable. 4.4.2 Corrosion resistance All components shall consist of corrosion-proof materials or shall be corrosion-protected. All corrosion protection shall conform with the relevant requirements specified in European and International Standards. For example: the minimum paint adhesion performance for powder-coated or wet-painted surfaces shall comply with a cross-cut value ≤ 2 when tested in accordance with EN ISO 2409; the minimum average thickness of coating on aluminium shall be of grade AA 8 when tested in accordance with one of the methods given in ISO 7599. In no cases shall the minimum local thickness be less than 80 % of the minimum average thickness. 4.4.3 Resistance to chemicals and stains When tested in accordance with 5.3 the glazing materials shall not show permanent staining or deterioration. 4.4.4 Resistance to wet and dry cycling When tested in accordance with 5.4, the glazing materials shall not show any cracks, crazing or discoloration.

Key 1 Impact point Figure 1 — Position of impact point For thermally toughened soda lime silicate safety glass manufactured by vertical toughening, the impact point shall not be on the tong mark edge. 5.1.4 Assessment of fragmentation The particle count and measuring of the dimensions of the largest particle shall be made between 4 min to 5 min after fracture. An area of radius 100 mm, centred on the impact point, and a border of 25 mm, round the edge of the test specimen (see Figure 2), shall be excluded from the assessment.

Dimensions in millimetres

Key 1 Excluded area Figure 2 — Area to be excluded from the particle count determination and largest particle measurement The particle count shall be made in the region of coarsest fracture (the aim being to obtain the minimum value). The particle count shall be made by placing a mask of (50 ± 1) mm x (50 ± 1) mm on the test piece (see Figures 3, 4 and 5). The number of crack-free particles within the mask shall be counted. A particle is ‘crack-free’, if it does not contain any cracks which run from one edge to another (see Figure 6).

Figure 3 — Select the area of coarsest fracture, place the template on the test specimen and draw round the template

NOTE Number of perimeter particles = 32/2 = 16 Figure 4 — Mark and count the perimeter fragments as 1/2 particle each

NOTE Number of central particles

= 53

Total number of particles = 16 + 53 = 69 Figure 5 — Mark and count the central fragments and add these to the perimeter count to obtain the particle count for the specimen

Figure 6 — Examples of crack-free particles and the assessment regarding their number In the particle count, all particles wholly contained within the area of the mask shall be counted as one particle each and all the particles which are partially within the mask shall be counted as 1/2 particle each (see Figure 4). 5.2 Impact behaviour of plastic sheets 5.2.1 Apparatus a) test frame, constructed of securely welded or bolted sections, designed to present a flat face to the sub-frame. The test frame sections and bracing members shall be steel channel 102 mm x 51 mm, or equivalent material of equal or greater strength and rigidity. This frame shall be securely bolted to the floor and securely braced as shown in Figures 7, 8 and 9. b) sub-frame, constructed of wood or other suitable material designed to hold the test piece as shown in

Figure 10 so that the test piece can make contact only with the strips of chloroprene or similar material. These strips shall be capable of being compressed by 10 % to 15 % of their original depth without a permanent set being introduced. The edge cover of the chloroprene on the test pieces shall be such that for the nominal

865 mm x 1 930 mm specimens the central area of (845 ± 3) mm x (1 910 ± 3) mm is unsupported.

450 mm apart and no fewer than two per side. c) impactor, consisting of a leather case of a punch bag type, modified with a central support rod and fitting system as shown in Figure 11, and filled with chilled lead shot. The leather case shall be made from six panels, as shown in Figure 12, which shall be securely stitched together leaving a slit approximately 175 mm long to allow for filling with the lead shot. Lace holes shall be inserted on each side of the slit which is closed by a leather thong. The neck shall be taped separately to cover the wor

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...