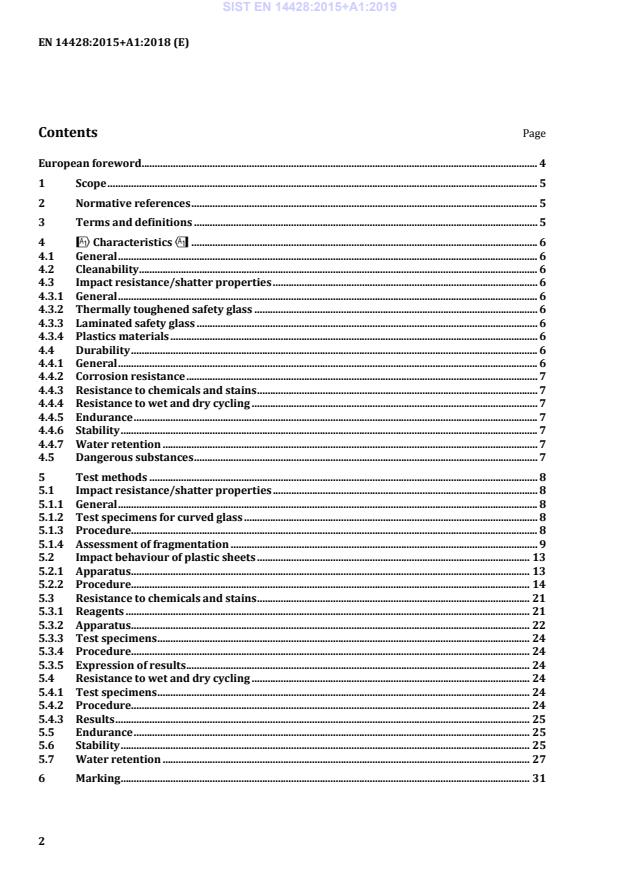

EN 14428:2015+A1:2018

(Main + Amendment)Shower enclosures - Functional requirements and test methods

Shower enclosures - Functional requirements and test methods

This European Standard specifies "characteristics" for shower enclosures for domestic purposes which ensure that the product, when installed in accordance with the manufacturer's installation instructions, gives satisfactory performance when used as intended.

This European Standard does not apply to shower cabinets or curtains and does not specify aesthetic and dimensional "characteristics".

NOTE For the purposes of this document the term "domestic purposes" includes use in hotels, accommodation for students, hospitals and similar buildings, except when special medical provisions are required.

Duschabtrennungen - Funktionsanforderungen und Prüfverfahren

Diese Europäische Norm legt !Eigenschaften" von Duschabtrennungen für den Hausgebrauch fest, die sicherstellen, dass das nach den Einbauanweisungen des Herstellers eingebaute Produkt für den vorgesehenen Verwendungszweck eine zufriedenstellende Gebrauchstauglichkeit aufweist.

Diese Europäische Norm gilt nicht für Einfachduschkabinen oder Duschvorhänge und legt keine ästhetischen und maßlichen !Eigenschaften" fest.

ANMERKUNG Der Begriff für den „Hausgebrauch“ in diesem Dokument schließt die Verwendung in Hotels, Studentenwohnheimen, Krankenhäusern und ähnlichen Einrichtungen ein; ausgenommen ist die medizinische Verwendung.

Parois de douche - Prescriptions fonctionnelles et méthodes d'essai

!La présente Norme européenne" spécifie les "caractéristiques" relatives aux parois de douche à usage domestique assurant que le produit, lorsqu’il est installé conformément aux instructions d’installation du fabricant, fonctionne de manière satisfaisante pour l’usage prévu.

"La présente Norme européenne" ne s’applique pas aux cabines de douche ou aux rideaux de douche et ne spécifie pas de "caractéristiques" esthétiques et dimensionnelles. "texte supprimé"

NOTE Pour les besoins du présent document, l’expression « à usage domestique » comprend les utilisations dans les hôtels, les logements d’étudiants, les hôpitaux et les bâtiments similaires, sauf lorsque des dispositions spéciales médicales sont requises.

Zasloni za prhanje - Funkcionalne zahteve in preskusne metode

Ta evropski standard določa »karakteristike« za zaslone za prhanje za domačo uporabo, ki zagotavljajo, da izdelek, ki je vgrajen v skladu z navodili proizvajalca za vgradnjo, pri načrtovani uporabi deluje zadovoljivo.

Ta evropski standard se ne uporablja za omarice ali zavese za prhanje ter ne določa estetskih in dimenzijskih »karakteristik«.

OPOMBA: Za namene tega dokumenta izraz »domača uporaba« vključuje uporabo v hotelih, namestitvah za študente, bolnišnicah in podobnih stavbah, razen če so potrebna posebna medicinska določila.

General Information

- Status

- Published

- Publication Date

- 30-Oct-2018

- Technical Committee

- CEN/TC 163 - Sanitary appliances

- Drafting Committee

- CEN/TC 163/WG 4 - Baths (W/Pools) - Shower trays (Performance testing)

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 06-Dec-2021

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 13-Jun-2018

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN ISO 9227:2022 - Corrosion tests in artificial atmospheres - Salt spray tests (ISO 9227:2022) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 14428:2015+A1:2018 (CEN) – Shower enclosures – Functional requirements and test methods defines the functional characteristics and test procedures for shower enclosures intended for domestic purposes. The standard ensures that, when installed according to the manufacturer's instructions, shower enclosures perform satisfactorily in normal use. It explicitly excludes shower cabinets and curtains and does not prescribe aesthetic or dimensional characteristics. “Domestic purposes” also covers hotels, student accommodation and similar buildings (excluding special medical provisions).

Key topics and technical requirements

- Scope & applicability: Requirements apply to panels and doors around a drained shower place, shower tray or bath; excludes fully prefabricated shower cabinets and curtains.

- Cleanability: Surfaces accessible during use must be free of sharp edges; recommended cleaning agents should not reduce safety or function.

- Impact resistance / shatter properties:

- Thermally toughened glass: Flat glass to conform with prEN 12150‑1; curved toughened glass tested per Clause 5.1 must yield a particle count ≥40 and longest particle ≤100 mm.

- Laminated safety glass: Must meet EN 14449 and EN ISO 12543‑2 and must not have holes for fixings or fittings.

- Plastics: Sheets tested per Clause 5.2 must not break, or if they break, must do so safely.

- Durability:

- Corrosion resistance: Components must be corrosion‑proof or protected; tests and harmonized standards apply (examples given include EN ISO 2409, EN ISO 7599, EN ISO 9227).

- Chemical and stain resistance: Glazing materials tested under Clause 5.3 must show no permanent deterioration.

- Wet/dry cycling, endurance, stability, water retention: Specified test methods in Clauses 5.4–5.7 assess long‑term performance.

- Marking & AVCP: Clause 6 covers marking; Clause 7 details Assessment and Verification of Constancy of Performance and factory production control.

Applications and users

EN 14428 is essential for:

- Shower enclosure manufacturers - design, testing and technical documentation

- Test laboratories - executing Clauses 5.1–5.7 impact, chemical, corrosion and endurance tests

- Product specifiers and procurement teams - ensuring compliant products for residential, hospitality and similar building projects

- Architects, installers and building inspectors - verifying installation instructions, durability and safety claims

- Compliance officers - linking to the Construction Products Regulation via Annex ZA

Related standards

Relevant referenced standards include:

- prEN 12150‑1 (thermally toughened glass)

- EN 14449 / EN ISO 12543‑2 (laminated safety glass)

- EN ISO 2409, EN ISO 7599, EN ISO 9227 (coatings/corrosion tests)

- ISO 7892 (impact test procedures)

EN 14428 provides a practical, test‑based framework for ensuring shower enclosures are safe, durable and fit for intended domestic applications. Keywords: EN 14428, shower enclosures, test methods, functional requirements, impact resistance, durability, CEN.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 14428:2015+A1:2018 is a standard published by the European Committee for Standardization (CEN). Its full title is "Shower enclosures - Functional requirements and test methods". This standard covers: This European Standard specifies "characteristics" for shower enclosures for domestic purposes which ensure that the product, when installed in accordance with the manufacturer's installation instructions, gives satisfactory performance when used as intended. This European Standard does not apply to shower cabinets or curtains and does not specify aesthetic and dimensional "characteristics". NOTE For the purposes of this document the term "domestic purposes" includes use in hotels, accommodation for students, hospitals and similar buildings, except when special medical provisions are required.

This European Standard specifies "characteristics" for shower enclosures for domestic purposes which ensure that the product, when installed in accordance with the manufacturer's installation instructions, gives satisfactory performance when used as intended. This European Standard does not apply to shower cabinets or curtains and does not specify aesthetic and dimensional "characteristics". NOTE For the purposes of this document the term "domestic purposes" includes use in hotels, accommodation for students, hospitals and similar buildings, except when special medical provisions are required.

EN 14428:2015+A1:2018 is classified under the following ICS (International Classification for Standards) categories: 91.140.70 - Sanitary installations. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14428:2015+A1:2018 has the following relationships with other standards: It is inter standard links to EN 14428:2015/prA1:2017, EN 14428:2015, ISO 7892:1988, EN 14449:2005, EN 12150-1:2015, EN ISO 7599:2018, EN ISO 2409:2020, EN ISO 12543-2:2021, EN ISO 9227:2022, CEN/TR 17221:2018, EN 12150-1:2015+A1:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14428:2015+A1:2018 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/110. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14428:2015+A1:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Zasloni za prhanje - Funkcionalne zahteve in preskusne metodeDuschabtrennungen - Funktionsanforderungen und PrüfverfahrenParois de douche - Prescriptions fonctionnelles et méthodes d'essaiShower enclosures - Functional requirements and test methods91.140.70Sanitarne napraveSanitary installationsICS:Ta slovenski standard je istoveten z:EN 14428:2015+A1:2018SIST EN 14428:2015+A1:2019en,fr,de01-januar-2019SIST EN 14428:2015+A1:2019SLOVENSKI

STANDARDSIST EN 14428:20151DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14428:2015+A1

October

t r s z ICS

{ sä s v rä y r Supersedes EN

s v v t zã t r s wEnglish Version

Shower enclosures æ Functional requirements and test methods Parois de douche æ Prescriptions fonctionnelles et méthodes d 5essai

Duschabtrennungen æ Funktionsanforderungen und Prüfverfahren This European Standard was approved by CEN on

s { March

t r s w and includes Amendment

s approved by CEN on

s y May

t r s zä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s z CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s v v t zã t r s w ªA sã t r s z ESIST EN 14428:2015+A1:2019

!Relationship of this European Standard with Regulation (EU) No. 305/2011" . 35 ZA.1 Scope and relevant characteristics . 35 ZA.2 System of Assessment and Verification of Constancy of Performance (AVCP) . 35 ZA.3 Assignment of AVCP tasks . 35 Bibliography . 37

2 when tested in accordance with EN ISO 2409; — the minimum average thickness of coating on aluminium is of grade AA5 when tested in accordance with one of the methods given in EN ISO 7599. In no cases is minimum local thickness less than 80 % of the minimum average thickness. — Compliance with the neutral salt spray (NSS) test e.g. as specified in EN ISO 9227 corrosion test in artificial atmospheres - salt spray tests with a minimum exposure time of 200 h; The defect surface area A is less than or equal to 0,1 % (A

0,1 %). The defects do not exceed a dimension of 0,3 mm. This list is not exhaustive. 4.4.3 Resistance to chemicals and stains When tested in accordance with 5.3 the glazing materials shall not show permanent staining or deterioration. 4.4.4 Resistance to wet and dry cycling When tested in accordance with 5.4, the glazing materials shall not show any cracks, crazing or discoloration. Uncoated and unpainted thermally toughened safety glass is deemed to be resistant to wet and dry cycling and need not be tested. 4.4.5 Endurance When tested in accordance with 5.5, shower enclosures shall not show any functional deterioration after 20 000 closing-opening cycles. 4.4.6 Stability When tested in accordance with 5.6, shower enclosures shall withstand an energy representing the impact of a human body on a large impact area (e.g. blow from shoulder, fall) without any functional deterioration which could result in injury to the user. 4.4.7 Water retention When tested in accordance with 5.7, shower enclosures shall retain water. A few small drops of water on the outside of the water retaining area are acceptable. Where shower enclosures are intended for installation in wet room environments (where watertightness is not required), water may temporarily pass outside the water retaining area as long as it is drained to the water retaining area. 4.5 Dangerous substances National regulations on dangerous substances may require verification and declaration on release, and sometimes content, when construction products covered by this standard are placed on those markets. In the absence of European harmonized test methods, verification and declaration on release/content should be done taking into account !deleted text" provisions in the place of use. SIST EN 14428:2015+A1:2019

Key 1 impact point Figure 1 — Position of impact point SIST EN 14428:2015+A1:2019

Key 1 excluded area Figure 2 — Area to be excluded from the particle count determination and largest particle measurement The particle count shall be made in the region of coarsest fracture (the aim being to obtain the minimum value). The particle count shall be made by placing a mask of (50 ± 1) mm x (50 ± 1) mm on the test piece (see Figures 3, 4 and 5). The number of crack-free particles within the mask shall be counted. A particle is ‘crack-free’, if it does not contain any cracks which run from one edge to another (see Figure 6). SIST EN 14428:2015+A1:2019

Figure 3 — Select the area of coarsest fracture, place the template on the test specimen and draw round the template SIST EN 14428:2015+A1:2019

NOTE Number of perimeter particles = 32/2 = 16. Figure 4 — Mark and count the perimeter fragments as 1/2 particle each SIST EN 14428:2015+A1:2019

NOTE Number of central particles = 53;

Total number of particles = 16 + 53 = 69. Figure 5 — Mark and count the central fragments and add these to the perimeter count to obtain the particle count for the specimen SIST EN 14428:2015+A1:2019

Figure 6 — Examples of crack-free particles and the assessment regarding their number In the particle count, all particles wholly contained within the area of the mask shall be counted as one particle each and all the particles which are partially within the mask shall be counted as 1/2 particle each (see Figure 4). 5.1.4.2 Selection of the longest particle The longest particle shall be chosen from the body of the test specimen. It shall not be in the excluded area. 5.2 Impact behaviour of plastic sheets 5.2.1 Apparatus 5.2.1.1 Test frame, constructed of securely welded or bolted sections, designed to present a flat face to the sub-frame. The test frame sections and bracing members shall be steel channel 102 mm x 51 mm, or equivalent material of equal or greater strength and rigidity. This frame shall be securely bolted to the floor and securely braced as shown in Figures 7, 8 and 9. 5.2.1.2 Sub-frame, constructed of wood or other suitable material designed to hold the test piece as shown in Figure 10 so that the test piece can make contact only with the strips of chloroprene or similar material. These strips shall be capable of being compressed by 10 % to 15 % of their original depth without a permanent set being introduced. The edge cover of the chloroprene on the test pieces shall be such that for the nominal 865 mm x 1 930 mm specimens the central area of (845 ± 3) mm x (1 910 ± 3) mm is unsupported. In order to limit the compression of the chloroprene strips to within approximately 15 %, spacers of appropriate thickness and material are recommended (see Figure 10). The components of the sub-frame shall b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...