EN 13925-2:2003

(Main)Non-destructive testing - X-ray diffraction from polycrystalline and amorphous materials - Part 2: Procedures

Non-destructive testing - X-ray diffraction from polycrystalline and amorphous materials - Part 2: Procedures

This standard outlines the basic procedures applied in the X-ray Powder Diffraction (XRPD) method. Many of these procedures are common to most types of diffractometer used and type of analysis mentionen in prEN WI 00138079 (General Principles). In the interests of clarity and immediate usability more detail is given for procedures using instruments with Bragg-Brentano geometry and application to phase identification. Aspects of specimen preparation and data quality assessment are included, but the standard remains non-exhaustive.

Zerstörungsfreie Prüfung - Röntgendiffraktometrie von polykristallinen und amorphen Materialien - Teil 2: Verfahrensabläufe

Diese Europäische Norm stellt grundlegende Verfahrensabläufe dar, die bei der Anwendung der Röntgenpulverdiffraktometrie zur Anwendung kommen. Viele dieser Verfahrensabläufe sind von allgemeiner Bedeutung sowohl für die Mehrzahl der verschiedenen Diffraktometertypen, als auch für die Mehrzahl der verschiedenen Analysenarten, die in prEN WI 00138079 aufgeführt sind. Im Interesse der Übersichtlichkeit und der unmittelbaren Anwendbarkeit der Norm, konzentriert sich die Darstellung auf Arbeitsabläufe, die typisch sind für die Anwendung von Bragg-Brentano Diffraktometern in der Phasenidentifizierung.

Essais non destructifs - Diffraction des rayons X appliquée aux matériaux polycristallins et amorphes - Partie 2: Procédures

La présente Norme européenne spécifie les procédures de base appliquées dans la méthode de diffraction des rayons X par les poudres (DRXP). Beaucoup de ces procédures sont communes à la plupart des types de diffractomètre utilisés et des types d'analyse mentionnés dans l'EN 13925-1. Par souci de clarté et d'utilisation immédiate, plus de détails sont donnés sur les procédures utilisant des instruments à géométrie Bragg-Brentano et avec despour les applications d'identification des de phases. Des Divers aspects de préparation des échantillons et d'évaluation de la qualité des données sont inclus, mais la norme reste non exhaustive. Il est prévu que des normes particulières traitent plus en détail lesde domaines d'application spécifiques.

Neporušitveno preskušanje – Uklon rentgenskih žarkov na polikristalnih in amorfnih materialih – 2. del: Postopki

General Information

- Status

- Published

- Publication Date

- 11-Mar-2003

- Technical Committee

- CEN/TC 138 - Non-destructive testing

- Drafting Committee

- CEN/TC 138 - Non-destructive testing

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 02-Dec-2024

- Completion Date

- 02-Dec-2024

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 13925-2:2003 is a CEN standard that specifies procedures for X‑ray Powder Diffraction (XRPD) used in non‑destructive testing (NDT) of polycrystalline and amorphous materials. It complements EN 13925‑1 (General principles) and gives practical, immediately usable guidance - with greater detail for instruments using Bragg‑Brentano geometry and for phase identification. The standard covers specimen preparation, data collection, and data processing/analysis while recognising that it is non‑exhaustive and that specific applications may require additional standards.

Key topics and technical requirements

- Specimen preparation

- Recommendations on lateral specimen size and ensuring the specimen intercepts the full incident beam.

- Guidance for block specimens (surface flatness, polishing and mounting) and powder specimens (thin-layer preparation, handling of small sample quantities).

- Consideration of specimen displacement, thickness and transparency effects and use of internal standards to detect/correct these effects.

- Treatment of reactive samples and measurements under non‑ambient conditions.

- Data collection

- General considerations for XRPD measurements, choice of angular range, and appropriate mode of data collection.

- Parameters relevant to data quality (counting statistics, instrumental configuration, geometry).

- Data processing and analysis

- Background subtraction, peak searching, profile decomposition and peak‑fitting.

- Phase identification, indexing, lattice‑parameter refinement and other XRPD analyses (e.g., crystallite size, microstrain as outlined in EN 13925‑1).

- Quality assessment and reporting

- Informative annexes include a report form example, a typical procedure scheme, analytical functions for profile fitting, and methods to test internal consistency of XRPD data.

- Radiation protection

- The standard reiterates the need to follow national radiation safety limits or ICRP recommendations where national rules are absent.

Applications and users

- Who uses EN 13925‑2: NDT laboratories, quality assurance and control teams, materials scientists, research laboratories and industrial facilities employing XRPD for routine or research analyses.

- Practical applications: phase identification, routine quality control of powders and bulk materials, verification of crystalline/amorphous phases, preliminary lattice parameter checks and establishing consistent XRPD procedures across laboratories and instruments.

Related standards

- EN 13925‑1:2003 – Non‑destructive testing - X‑ray diffraction - General principles.

- prEN 13925‑3 – Instruments (in preparation).

- prEN 13925‑4 – Reference materials (in preparation).

Keywords: EN 13925‑2, XRPD, X‑ray powder diffraction, Bragg‑Brentano, non‑destructive testing, specimen preparation, phase identification, data processing, diffraction standards.

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

EN 13925-2:2003 is a standard published by the European Committee for Standardization (CEN). Its full title is "Non-destructive testing - X-ray diffraction from polycrystalline and amorphous materials - Part 2: Procedures". This standard covers: This standard outlines the basic procedures applied in the X-ray Powder Diffraction (XRPD) method. Many of these procedures are common to most types of diffractometer used and type of analysis mentionen in prEN WI 00138079 (General Principles). In the interests of clarity and immediate usability more detail is given for procedures using instruments with Bragg-Brentano geometry and application to phase identification. Aspects of specimen preparation and data quality assessment are included, but the standard remains non-exhaustive.

This standard outlines the basic procedures applied in the X-ray Powder Diffraction (XRPD) method. Many of these procedures are common to most types of diffractometer used and type of analysis mentionen in prEN WI 00138079 (General Principles). In the interests of clarity and immediate usability more detail is given for procedures using instruments with Bragg-Brentano geometry and application to phase identification. Aspects of specimen preparation and data quality assessment are included, but the standard remains non-exhaustive.

EN 13925-2:2003 is classified under the following ICS (International Classification for Standards) categories: 19.100 - Non-destructive testing. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13925-2:2003 has the following relationships with other standards: It is inter standard links to EN 13925-3:2005, EN 15305:2008, EN 15049:2007, EN 13925-1:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13925-2:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Neporušitveno preskušanje – Uklon rentgenskih žarkov na polikristalnih in amorfnih materialih – 2. del: PostopkiZerstörungsfreie Prüfung - Röntgendiffraktometrie von polykristallinen und amorphen Materialien - Teil 2: VerfahrensabläufeEssais non destructifs - Diffraction des rayons X appliquée aux matériaux polycristallins et amorphes - Partie 2: ProcéduresNon-destructive testing - X-ray diffraction from polycrystalline and amorphous materials - Part 2: Procedures19.100Neporušitveno preskušanjeNon-destructive testingICS:Ta slovenski standard je istoveten z:EN 13925-2:2003SIST EN 13925-2:2004en01-marec-2004SIST EN 13925-2:2004SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13925-2March 2003ICS 19.100English versionNon-destructive testing - X-ray diffraction from polycrystallineand amorphous materials - Part 2: ProceduresEssais non destructifs - Diffraction des rayons X appliquéeaux matériaux polycristallins et amorphes - Partie 2:ProcéduresZerstörungsfreie Prüfung - Röntgendiffraktometrie vonpolykristallinen und amorphen Materialien - Teil 2:VerfahrensabläufeThis European Standard was approved by CEN on 29 November 2002.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Hungary, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Slovakia, Spain, Sweden, Switzerland and UnitedKingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2003 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13925-2:2003 ESIST EN 13925-2:2004

(informative)

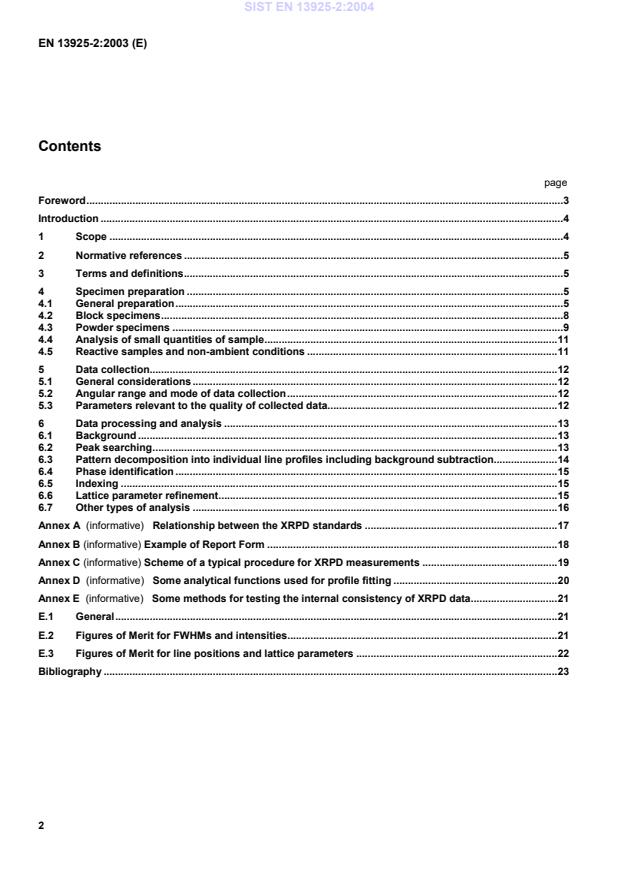

Relationship between the XRPD standards.17Annex B (informative) Example of Report Form.18Annex C (informative) Scheme of a typical procedure for XRPD measurements.19Annex D

(informative)

Some analytical functions used for profile fitting.20Annex E

(informative)

Some methods for testing the internal consistency of XRPD data.21E.1General.21E.2Figures of Merit for FWHMs and intensities.21E.3Figures of Merit for line positions and lattice parameters.22Bibliography.23SIST EN 13925-2:2004

1)a European draft standard (WI 00138078 "Non-destructive testing – X-ray powder diffraction – Terminology") is inpreparationSIST EN 13925-2:2004

2)This equation is similar to that given by Wilson [3].SIST EN 13925-2:2004

(6)wherer is the crystal density, expressed in grams per cubic centimetre;m'

is the mass attenuation coefficient, expressed in square centimetres per gram;l is the crystallite dimension, expressed in centimetres.Values of Um up to about 10%, arising from larger crystallites, often give satisfactory data for phase identification.Smaller values of Um (and hence smaller crystallite sizes) are necessary for quantitative analysis where a higherlevel of reproducibility is needed. However excessive milling, giving crystallite dimensions below about 0,5 mm, maycause line broadening and significant changes to the intrinsic characteristics of the specimen, such as:¾ sample contamination by particles abraded from the milling instruments (e.g. mortar, pestle, balls etc.);¾ partial amorphisation of the near-surface region of the sample particles;¾ transition to different polymorphic crystallographic forms;SIST EN 13925-2:2004

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...