CEN/TR 16907-8:2024

(Main)Earthworks - Part 8: Alternative materials in earthworks

Earthworks - Part 8: Alternative materials in earthworks

This document informs about the experience of European member state practices for successfully using alternative materials in earthworks. It covers all earthworks, whether for roads, railways, and other infrastructure, including fills, capping layers, transition zones, drainage ribs or others (for details, see EN 16907-1:2018, Clause 1 "Scope").

Alternative materials have properties, on a geotechnical standpoint, which makes them different from the materials (soils and rocks) being normally used in earthworks. Therefore, the objective of this document is:

- to give an overview of the alternative materials that have been successfully used in earthworks in Europe;

- for the alternative materials, for which use in earthworks is adequately documented, to give general information regarding the points of attention that clients, designers and earthwork companies, keep in mind in any attempt to use them in earthworks.

This document does not deal with alternative materials used as aggregate.

This document does not deal with alternative materials used as binders (fly ash, granulated blast furnace slag or others) or binder components.

Erdarbeiten - Teil 8: Alternative Materialien für Erdarbeiten

Terrassements - Partie 8 : Matériaux alternatifs pour les terrassements

Zemeljska dela - 8. del: Alternativni materiali pri zemeljskih delih

Ta dokument obvešča o izkušnjah praks evropskih držav članic glede uspešne uporabe alternativnih materialov pri zemeljskih delih. Zajema vsa zemeljska dela za cestno, železniško in drugo infrastrukturo, vključno s polnili, plastmi za pokrivanje, prehodnimi območji, drenažnimi rebri ali drugim (za podrobnosti glej standard EN 16907-1:2018, točka 1 – »Področje uporabe«).

Z geotehničnega vidika se alternativni materiali zaradi svojih lastnosti razlikujejo od materialov, ki se običajno uporabljajo pri zemeljskih delih (zemljine in kamnine). Zato je cilj tega dokumenta:

– podati pregled alternativnih materialov, ki so bili uspešno uporabljeni pri zemeljskih delih v Evropi;

– za alternativne materiale, katerih uporaba pri zemeljskih delih je ustrezno dokumentirana, zagotoviti splošne informacije o tem, na kaj morajo biti stranke, projektanti in podjetja za zemeljska dela pozorni pri vsakršnem poskusu njihove uporabe pri zemeljskih delih.

Ta dokument ne obravnava alternativnih materialov, ki se uporabljajo kot agregat.

Ta dokument ne obravnava alternativnih materialov, ki se uporabljajo kot veziva (elektrofiltrski pepel, granulirana plavžna žlindra ali drugo vezivo) ali sestavine zanje.

General Information

- Status

- Published

- Publication Date

- 26-Nov-2024

- Technical Committee

- CEN/TC 396 - Earthworks

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 27-Nov-2024

- Due Date

- 18-Apr-2025

- Completion Date

- 27-Nov-2024

Overview

CEN/TR 16907-8:2024 - Earthworks, Part 8: Alternative materials in earthworks is a CEN Technical Report that documents European experience in using alternative (anthropogenic) materials in earthworks. It covers all earthworks applications (roads, railways and other infrastructure) such as fills, capping layers, transition zones and drainage ribs. The report gives an overview of alternative material types, practical points of attention for use in earthworks and national practice examples across several CEN members.

Key exclusions: the document does not cover alternative materials used as aggregate, nor binder materials/components (e.g., fly ash used as a binder).

Key topics and technical content

- Material classification and groups (A–J) - construction & demolition materials, municipal incineration residues, coal combustion products, iron/steel and non‑ferrous industry by‑products, foundry residues, quarry/mine materials, excavated natural materials, other combustion residues and miscellaneous materials.

- Material sheets - consolidated practical information for many specific alternative materials (with a list of materials that currently lack sheets).

- Geotechnical perspective - differences in engineering properties compared with natural soils and rocks; implications for design and performance.

- Environmental assessment - recommended approach and relevant aspects to evaluate (material properties, site‑specific risks, conditions of use).

- Design testing and construction control - testing philosophy including geotechnical and chemical testing in advance of construction and control during works.

- Health & safety - management of dust, runoff, leachate and other occupational/environmental hazards.

- Incorporation of new source materials - guidance for assessing novel or changed waste/material sources.

- Annexes with national practice - informative summaries for countries (e.g., Czech Republic, Germany, France, UK) and results of enquiries among CEN members.

Practical applications and who uses this standard

This Technical Report is practical for:

- Clients and asset owners specifying sustainable or recycled fill and capping solutions.

- Geotechnical designers and engineers assessing suitability and design implications of alternative materials.

- Contractors and earthworks companies implementing construction control and testing regimes.

- Material producers and waste processors preparing material data sheets and supporting approvals.

- Environmental assessors and regulators evaluating site‑specific risks and compliance.

Use cases include reuse of municipal incinerator bottom ash for subbase layers, steel slags for engineered fills, excavated materials in transition zones, and other documented examples where geotechnical and environmental performance has been demonstrated.

Related standards

CEN/TR 16907-8 complements the EN 16907 earthworks series (Parts 1–7 and ongoing parts) and should be read alongside EN 16907-1 (principles & scope), EN 16907-2 (classification of materials) and applicable test standards referenced in the report.

Keywords: CEN/TR 16907-8, CEN/TR 16907-8:2024, Earthworks, alternative materials, geotechnical, environmental assessment, material sheets, construction control.

Get Certified

Connect with accredited certification bodies for this standard

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

CEN/TR 16907-8:2024 is a technical report published by the European Committee for Standardization (CEN). Its full title is "Earthworks - Part 8: Alternative materials in earthworks". This standard covers: This document informs about the experience of European member state practices for successfully using alternative materials in earthworks. It covers all earthworks, whether for roads, railways, and other infrastructure, including fills, capping layers, transition zones, drainage ribs or others (for details, see EN 16907-1:2018, Clause 1 "Scope"). Alternative materials have properties, on a geotechnical standpoint, which makes them different from the materials (soils and rocks) being normally used in earthworks. Therefore, the objective of this document is: - to give an overview of the alternative materials that have been successfully used in earthworks in Europe; - for the alternative materials, for which use in earthworks is adequately documented, to give general information regarding the points of attention that clients, designers and earthwork companies, keep in mind in any attempt to use them in earthworks. This document does not deal with alternative materials used as aggregate. This document does not deal with alternative materials used as binders (fly ash, granulated blast furnace slag or others) or binder components.

This document informs about the experience of European member state practices for successfully using alternative materials in earthworks. It covers all earthworks, whether for roads, railways, and other infrastructure, including fills, capping layers, transition zones, drainage ribs or others (for details, see EN 16907-1:2018, Clause 1 "Scope"). Alternative materials have properties, on a geotechnical standpoint, which makes them different from the materials (soils and rocks) being normally used in earthworks. Therefore, the objective of this document is: - to give an overview of the alternative materials that have been successfully used in earthworks in Europe; - for the alternative materials, for which use in earthworks is adequately documented, to give general information regarding the points of attention that clients, designers and earthwork companies, keep in mind in any attempt to use them in earthworks. This document does not deal with alternative materials used as aggregate. This document does not deal with alternative materials used as binders (fly ash, granulated blast furnace slag or others) or binder components.

CEN/TR 16907-8:2024 is classified under the following ICS (International Classification for Standards) categories: 93.020 - Earthworks. Excavations. Foundation construction. Underground works. The ICS classification helps identify the subject area and facilitates finding related standards.

CEN/TR 16907-8:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2025

Zemeljska dela - 8. del: Alternativni materiali pri zemeljskih delih

Earthworks - Part 8: Alternative materials in earthworks

Erdarbeiten - Teil 8: Alternative Materialien für Erdarbeiten

Terrassements - Partie 8 : Matériaux alternatifs pour les terrassements

Ta slovenski standard je istoveten z: CEN/TR 16907-8:2024

ICS:

93.020 Zemeljska dela. Izkopavanja. Earthworks. Excavations.

Gradnja temeljev. Dela pod Foundation construction.

zemljo Underground works

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

CEN/TR 16907-8

TECHNICAL REPORT

RAPPORT TECHNIQUE

November 2024

TECHNISCHER REPORT

ICS 93.020

English Version

Earthworks - Part 8: Alternative materials in earthworks

Terrassements - Partie 8 : Matériaux alternatifs pour Erdarbeiten - Teil 8: Alternative Materialien für

les terrassements Erdarbeiten

This Technical Report was approved by CEN on 25 November 2024. It has been drawn up by the Technical Committee CEN/TC

396.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TR 16907-8:2024 E

worldwide for CEN national Members.

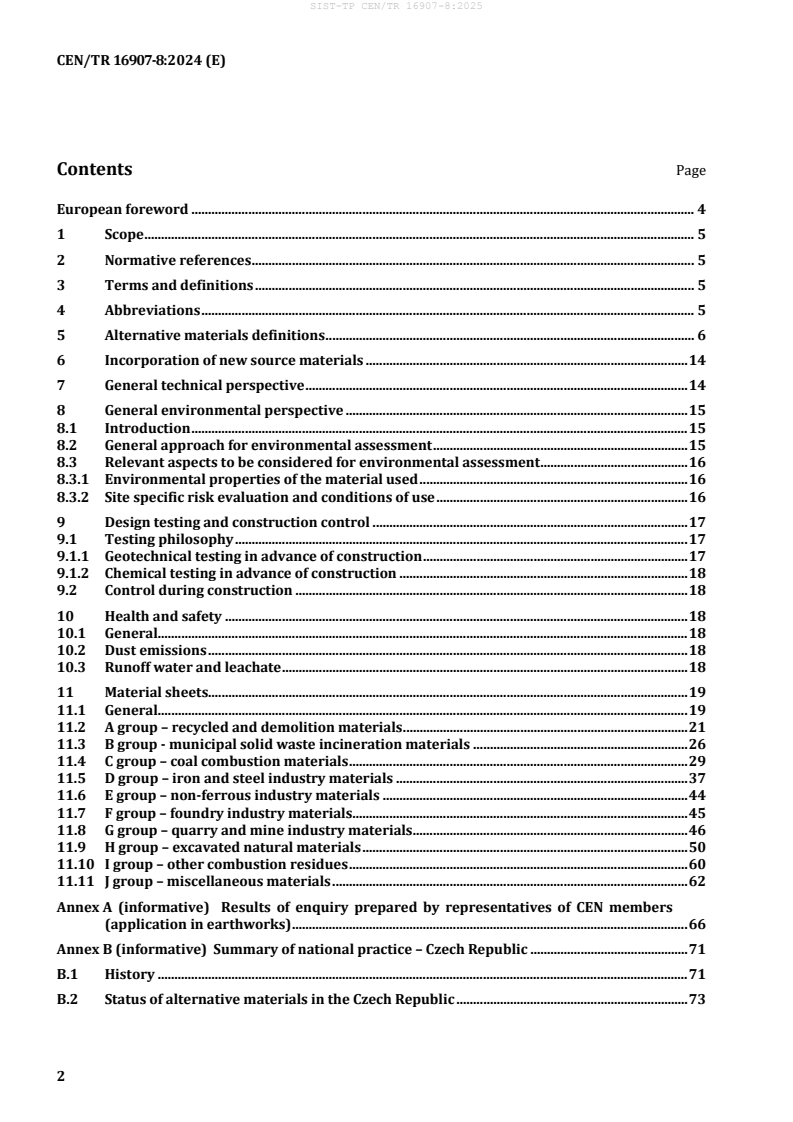

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Abbreviations . 5

5 Alternative materials definitions . 6

6 Incorporation of new source materials . 14

7 General technical perspective . 14

8 General environmental perspective . 15

8.1 Introduction . 15

8.2 General approach for environmental assessment . 15

8.3 Relevant aspects to be considered for environmental assessment . 16

8.3.1 Environmental properties of the material used . 16

8.3.2 Site specific risk evaluation and conditions of use . 16

9 Design testing and construction control . 17

9.1 Testing philosophy . 17

9.1.1 Geotechnical testing in advance of construction . 17

9.1.2 Chemical testing in advance of construction . 18

9.2 Control during construction . 18

10 Health and safety . 18

10.1 General. 18

10.2 Dust emissions . 18

10.3 Runoff water and leachate . 18

11 Material sheets. 19

11.1 General. 19

11.2 A group – recycled and demolition materials . 21

11.3 B group - municipal solid waste incineration materials . 26

11.4 C group – coal combustion materials . 29

11.5 D group – iron and steel industry materials . 37

11.6 E group – non-ferrous industry materials . 44

11.7 F group – foundry industry materials. 45

11.8 G group – quarry and mine industry materials . 46

11.9 H group – excavated natural materials . 50

11.10 I group – other combustion residues . 60

11.11 J group – miscellaneous materials . 62

Annex A (informative) Results of enquiry prepared by representatives of CEN members

(application in earthworks) . 66

Annex B (informative) Summary of national practice – Czech Republic . 71

B.1 History . 71

B.2 Status of alternative materials in the Czech Republic . 73

B.3 Utilization of alternative materials in the Czech Republic . 73

B.4 Conclusion . 77

B.5 Technical specifications in the Czech Republic . 77

B.6 Bibliography . 77

Annex C (informative) Summary of national practice - Germany . 79

C.1 Alternative materials for earthwork constructions - Situation in Germany . 79

C.2 Regulations for earthworks in road constructions . 79

C.3 Possible technical applications in Germany for earthworks according to the ZTV E-

StB (technical possible, if the material fulfils the requirements) . 82

Annex D (informative) Summary of national practice - France . 84

D.1 General context . 84

D.2 Geotechnical specifications . 85

D.3 Environmental specifications . 87

D.4 National specifications . 88

Annex E (informative) Summary of national practice – United Kingdom . 89

E.1 General context . 89

E.2 Geotechnical considerations . 89

E.3 Environmental considerations . 89

E.4 National specifications . 91

Bibliography . 93

European foreword

This document (CEN/TR 16907-8:2024) has been prepared by Technical Committee CEN/TC 396

“Earthworks”, the secretariat of which is held by AFNOR.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document complements the European Standards within the framework series of EN 16907 on

Earthworks:

— EN 16907-1, Earthworks — Part 1: Principles and general rules;

— EN 16907-2, Earthworks — Part 2: Classification of materials;

— EN 16907-3, Earthworks — Part 3: Construction procedures;

— EN 16907-4, Earthworks — Part 4: Soil treatment with lime and/or hydraulic binders;

— EN 16907-5, Earthworks — Part 5: Quality control;

— EN 16907-6, Earthworks — Part 6: Land reclamation earthworks using dredged hydraulic fill;

— EN 16907-7, Earthworks — Part 7: Hydraulic placement of waste;

— CEN/TR 16907-8, Earthworks — Part 8: Alternative materials in earthworks (this document);

— CEN/TR 16907-9, Earthworks — Part 9: Sustainable earthworks (Under preparation).

These “Earthworks standards” do not apply to the environmental planning and geotechnical design that

determines the required form and properties of the earth-structure that is to be constructed. They

apply to the design of the earthwork's materials, execution, monitoring and checking of earthworks

construction processes to ensure that the completed earth-structure satisfies the geotechnical design.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

1 Scope

This document informs about the experience of European member state practices for successfully using

alternative materials in earthworks. It covers all earthworks, whether for roads, railways, and other

infrastructure, including fills, capping layers, transition zones, drainage ribs or others (for details, see

EN 16907-1:2018, Clause 1 “Scope”).

Alternative materials have properties, on a geotechnical standpoint, which makes them different from

the materials (soils and rocks) being normally used in earthworks. Therefore, the objective of this

document is:

— to give an overview of the alternative materials that have been successfully used in earthworks in

Europe;

— for the alternative materials, for which use in earthworks is adequately documented, to give general

information regarding the points of attention that clients, designers and earthwork companies, keep

in mind in any attempt to use them in earthworks.

This document does not deal with alternative materials used as aggregate.

This document does not deal with alternative materials used as binders (fly ash, granulated blast

furnace slag or others) or binder components.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp/

4 Abbreviations

ABS air-cooled blast furnace slag

ASAM Asociace stavebních alternativních materiálů (Association of construction alternative

materials in Czechia)

BOS basic oxygen furnace slag

CBR California Bearing Ratio

CCP coal combustion products

CO carbon dioxide

CSH calcium silicate hydrates

ECOBA European Coal Combustion Products Association

EAF S electric arc furnace slag from stainless/high alloy steel production

EAFC electric arc furnace slag from carbon steel production

EPB earth pressure balance

FBC fluidized bed combustion

FBCFA fluidized bed combustion fly ash

FGD flue gas desulphurisation

GBS granulated blast furnace slag

LA Los Angeles coefficient (see EN 1097-2)

LOI loss on ignition

MDD maximum dry density (see EN 13286-2)

MIBA municipal incinerator bottom ash

MIFA municipal incinerator fly ash

OMC optimum moisture content (see EN 13286-2)

PAH polyaromatic hydrocarbons

PFA pulverized fuel ash

pH decimal logarithm of the reciprocal of the hydrogen ion activity

SMS secondary metallurgical slags

SNCR selective non-catalytic reduction (method of denitrification)

TBM tunnel boring machine

UIC International Union of Railways (Union internationale des chemins de fer - French)

UKQAA UK Quality Ash Association

UPS Polska Unia Ubocznych Produktów Spalania (Polish Association of Coal Combustion

Products)

WG7 working group 7 “Alternative materials in earthworks” of CEN/TC 396 “Earthworks”

5 Alternative materials definitions

Alternative materials are considered as anthropogenic materials according to EN 16907-2. In Table 1,

groups of alternative materials are grouped according to the Table 5 of EN 16907-2:2018.

Table 1 — The groups of alternative materials by groups in EN 16907-2

Group Source EN 16907-2

A Construction and demolition recycling industries AR

B Municipal solid waste incineration industry AM

C Coal Power generation industry AM

D Iron and steel Industry AM

E Non-ferrous industry AM

F Foundry industry AM

G Mining and quarry industry AN (AM)

H Excavated natural materials AN

I Other combustion residues AM

J Miscellaneous AM (AR)

Key

AN – natural materials processed mechanically;

AM – manufactured materials (including secondary manufactured materials);

AR – recycled materials.

The definitions for the alternative materials described in document are listed in Table 2. They were

inspired by the CEN/TS 17438, however for earthworks additional materials are defined (see Table 2).

Material sheets were prepared for majority of materials described in Table 2. In case of no or not

enough practical applications in earthworks no material sheets have been prepared. A list of materials

without material sheet is below:

— A1 Reclaimed asphalt

— B2 Municipal incinerator fly ash (MIFA)

— E2 Ferromolybdenum slag

— E3 Zinc slag

— E4 Phosphorous slag

— E5 Lead slag

— E6 Ferrochromium slag

— F2 Foundry cupola furnace slag

— I2 Sewage sludge incineration ash (municipal)

— I4 Oil shale ash

— J2 Cement and lime kiln dust

— J4 FGD artificial gypsum

— J5 Industrial artificial gypsum

— J6 Marginal materials

Dredged material – coarse (class H2b) for application as hydraulic fill is described in EN 16907-6.

Reclaimed natural soil (without processing) is assessed according to EN 16907-1 to EN 16907- 6.

NOTE Marginal materials represent local sources (e.g. China clay residues, peat ash, etc.). They are assessed

individually.

Table 2 — Definitions of alternative materials

EN 16907–2 Subnumber

Group Source Group Specific material Definition

Group (CEN/TS 17438)

A Construction AR A1 A1 Reclaimed asphalt Material resulting from processing bituminous layers.

and demolition

A2 A2 Reclaimed concrete Material resulting from processing concrete.

recycling

industries

A3 A3 Reclaimed bricks, masonry Material resulting from processing demolition brick work and

masonry.

A4 A4 Hydraulically bound and Material resulting from processing hydraulically bound and unbound

unbound materials materials.

A5 A5 Mix of A1, A2, A3 and A4 Material resulting from processing a mix of bituminous layers

and/or concrete and/or demolition brick work and masonry.

A6 A6 Reclaimed railway ballast Material resulting from recycling of railway ballast.

b

B Municipal solid AM B1 B1 Municipal incinerator bottom Material resulting from processing ‘bottom ash’ following the

a

waste ash incineration of Municipal Solid Waste (domestic and commercial) by

a 'moving grate' or 'fluidised bed' or gasification' process. Today also

incineration (excluding fly ash) (MIBA)

referred to as MIBA (Municipal Incinerator Bottom Ash).

industry

B2 B2 Municipal Material resulting from flue gas following the incineration of

municipal solid waste (municipal and commercial) by a 'moving

incinerator fly ash (MIFA)

grate' or 'fluidised bed' or gasification' process, captured by flue gas

treatment (FGT) systems and in some cases electrostatic

precipitators’. Today also referred to as MIFA (Municipal Incinerator

Fly Ash).

EN 16907–2 Subnumber

Group Source Group Specific material Definition

Group (CEN/TS 17438)

C Coal Power AM C1a C1 Coal fly ash - siliceous Material resulting from flue gas following the burning of pulverised

generation hard (or bituminous) coal, with or without co-combustion materials,

industry captured by electrostatic precipitators.

C1b C1 Coal fly ash - Material resulting from flue gas following the burning of pulverized

calcareous lignite with or without co-combustion materials, captured by

electrostatic precipitators.

C2 C2 Fluidized bed Material resulting from flue gas following coal burning with or

without co-combustion in fluidized bed combustion boilers at

combustion fly ash (FBCFA)

temperatures of 750 °C to 900 °C.

C3 C3 Boiler slag Material resulting from coal combustion in boilers at temperatures

of 1 500 °C to 1 700 °C, followed by wet ash removal of wet bottom

furnaces.

C4a C4 Coal bottom ash- Material resulting from the bottom of dry boilers, derived from the

siliceous combustion of (hard or bituminous coal) coal with or without co-

combustion.

C4b C4 Coal bottom ash - Material resulting from the bottom of dry boilers, derived from the

calcareous combustion of lignite with or without co-combustion.

C5 Fluidized bed combustion Material resulting from the bottom of fluidized bed combustion

bottom ash (FBC bottom ash) boilers at temperatures of 800 °C to 900 °C, derived from the

burning of coal with or without co-combustion.

EN 16907–2 Subnumber

Group Source Group Specific material Definition

Group (CEN/TS 17438)

D Iron and steel AM D1 D1 Granulated blast furnace slag Material resulting from the manufacture of iron by thermochemical

industry (GBS) (vitrified) reduction in a blast furnace and subsequently rapidly-cooled to form

a glassy material.

The rapid cooling (quenching) of the liquid slag generates the glassy

granulated blast furnace slag.

D2 D2 Air-cooled blast furnace slag Material resulting from the manufacture of iron by thermochemical

(ABS) (crystallized) reduction in a blast furnace and subsequently air-cooled to form a

crystalline aggregate.

D3 D3 Basic oxygen furnace slag Material resulting from the conversion of liquid iron (hot metal) and

(converter slag, BOS) steel scrap into steel during a batch process in a basic oxygen

furnace.

D4 D4 Electric arc furnace slag (from Material resulting from melting steel scrap into steel during a batch

carbon steel production, process in an electric arc furnace.

EAFC)

D5 D5 Electric arc furnace slag (from Material resulting from the manufacture of stainless or high alloy

stainless/high alloy steel steel in different metallurgical vessels, e.g. electric arc furnace,

production, EAF S) converter and ladles.

D6 Secondary metallurgical slags Material resulting from the manufacture of carbon steel in different

(SMS) metallurgical vessels, e.g. ladles.

E Non-ferrous AM E1 E1 Copper slag Material resulting from the manufacture of copper in a furnace

industry process.

E2 E2 Ferromolybdenum slag Material resulting from a metallo-thermic reduction process to

produce ferromolybdenum from roasted molybdenite concentrate

and other raw materials.

E3 E3 Zinc slag Material resulting from the pyrometallurgical step when treating

zinc-bearing materials.

E4 E4 Phosphorous slag Material resulting from the manufacture of phosphorus in an electric

arc furnace process.

E5 E5 Lead slag Material resulting from the manufacture of lead.

E6 E6 Ferrochromium slag Material resulting from ferrochromium production. Slag product

processing starts from melt phase.

EN 16907–2 Subnumber

Group Source Group Specific material Definition

Group (CEN/TS 17438)

F Foundry AM F1 F1 Foundry sand Material obtained in iron, steel and malleable iron foundries as well

as in non-ferrous foundries during core making, preparation of

industry

moulding material and after casting and shake out of the moulds.

F2 F2 Foundry cupola Material resulting from operation of a cupola furnace in iron

furnace slag foundries.

G Mining and AN G1 G1 Red coal shale Material resulting from uncontrolled burning of colliery spoil on tips

quarry industry Burnt colliery spoil after of bituminous coal.

burning

G2 G2 Refuse from hard coal mining Material from black coal shale (black minestone).

(black coal shale). Unburnt

colliery spoil from hard coal

mining.

G3 G3 Pre-selected all-in Material from the quarry or the mining industry which has

from quarry/mining processed mechanically. It includes quarry spoils.

G4 G4 Spent oil shale Material resulting from oil shale processing by heating under poorly

oxidizing conditions to extract the oil.

EN 16907–2 Subnumber

Group Source Group Specific material Definition

Group (CEN/TS 17438)

H Excavated AN H1a Tunnel arisings from hard Coarse material excavated by blasting in hard rock by the traditional

natural rocks traditional method method (e.g. NATM – New Austrian tunnelling method).

materials

H1b Tunnel arisings from hard Material excavated with a Tunnel Boring Machine in a hard rock.

rocks with TBM

H1c Tunnel arising from soft Material excavated with a slurry shield TBM.

material

Slurry shield

H1d Tunnel arising from soft Material excavated with a TBM with earth pressure balance (EPB).

material

Earth pressure

H2a H1 Dredge spoil - fine Fine material excavated in lakes, dams, ports or rivers exhibiting a

very moisture content and very low bearing capacity even after

stockpiling.

H2b H1 Dredge spoil - coarse Sandy or gravelly material excavated in lakes, dams, ports or rivers

with permeability high enough to allow departure of free water after

stockpiling.

H3 Processed reclaimed natural Material resulting from a screening or treatment process which

soil leaves a residue of natural soils.

I Other

AM I1 I1 Paper sludge ash Material resulting from the incineration of paper sludge (from

combustion deinking process).

residues

I2 I2 Sewage sludge incineration Material resulting from the incineration of sewage sludge (mostly

ash (municipal) communal sludge) by a fluidised bed process.

I3 I3 Biomass ash Material resulting from the incineration of biomass.

I4 Oil shale ash Material resulting from incineration of oil shale.

EN 16907–2 Subnumber

Group Source Group Specific material Definition

Group (CEN/TS 17438)

J Miscellaneous AM J1 I4 Crushed glass Material resulting from the crushing of old glass products e.g.,

bottles.

J2 Cement and lime kiln dust Old tips of dust collected from the flue gas stream of cement or lime

calcining operations

J3a Shredded tyres Shreds resulting from mechanical process of tyres.

J3b Tyre bales Processed tyres to get boxes.

J4 FGD artificial gypsum Material resulting from the desulphurisation process of coal-fired

power plants.

J5 Industrial artificial gypsum Industrial gypsum is a by-product from industrial process. It

contains mainly hydrated CaSO plus Fe and Ti oxides.

J6 Marginal materials These alternative materials are meet very locally and are not part of

(local experience) this guide. They encompass e.g. China clay, peat ashes.

NOTE Shaded materials are without material sheet.

a

Requirements on MIBA are based on experience with grated installations.

b

Bottom ash can include as a small component ‘boiler ash’.

6 Incorporation of new source materials

A request for the incorporation of new source materials into this document will be considered when

this request is made by at least one of the CEN members and the request is based on the actual routine

application of material from this new source.

The request is formally taken into consideration by CEN/TC 396 after evaluation and recommendation

of WG 7.

Basic information on the following items is provided as an input for the request (Table 3).

Table 3 — Information requested for new source materials

Subject General information to be given by applicant

CEN Member From one or more CEN Members

Definition Clear description of the source material

Field of application(s) Applicable CEN/TC 396 standard(s)

Technical information Material characteristics and end use information

Experience/quantity/demonstration Existing applications, not only laboratory

experience

Criteria used to control the quality of material Factory production control, national

regulation(s) or private assessment

Additional requirements necessary to consider

7 General technical perspective

Utilization of alternative materials ranks among the fundamental tasks of the developed world. The use

of alternative materials in earthworks helps to protect the environment and reduces the need to use

natural resources. Earthworks using alternative materials reduces the carbon footprint of construction

and makes a significant contribution to the circular economy.

The use of alternative materials in earthworks is subject to the fulfilment of the same technical

requirements as for natural materials, to achieve the design requirements of bearing capacity,

serviceability, constructability and durability for earthworks. Geotechnical and technical requirements

are defined in the earthwork project.

In earthworks, only such materials that have been suitability verified and fulfil the project requirements

are used. In case of non-homogenous materials their usability according to the design are verified based

on laboratory and full-scale trials or in situ testing.

Regarding the possible significant variability of properties and behaviour inside each class of

alternative materials due to the non-homogeneous composition, the project design specifies the

conditions under which their use is allowed. When using alternative materials in an earthwork project

it defines the following items:

— description of the alternative material to be used;

— technology of their processing;

— mechanical/engineering properties (given by intrinsic and state properties);

— environmental properties;

— durability of mechanical properties (e.g. volume stability, etc.);

— quality control, including frequency of tests.

Achievement of designed parameters is supported by laboratory tests with respect to real conditions in

earth construction and verified by relevant testing.

Most relevant physical, chemical and mechanical properties of alternative materials potentially utilized

in earthworks are presented for each class material in material sheets (see Clause 11). More

information concerning characteristics, testing and utilization of alternative materials in several

countries (Czech Republic, France, Germany, United Kingdom) are presented in Annexes B to E. Apart

from national specifications, the principal testing needs and evaluation schemes are provided in

EN 16907-2.

8 General environmental perspective

8.1 Introduction

The use of alternative materials in earthworks is an important contribution to the European circular

economy policy, aiming to increase resource efficiency in the field of building operations and contribute

to the sustainability of construction. Following the principles of the circular flow economy, transport

journeys can be minimized, CO emissions reduced, and destructive land use downsized.

The use of materials in earthworks, either from natural or alternative origin, needs to take into account

and manage potential impacts on environment and health, to ensure a safe use of the material. This part

describes the main issues to consider in order to guarantee environmental performance consistent with

the use of the material, in the same way as technical performances are required for building

construction of earthworks.

NOTE This document does not deal with the Waste Framework Directive or the material’s legal status in the

different Member States.

8.2 General approach for environmental assessment

Management of the potential environmental impacts of materials – natural or alternative – for

earthworks is based on a general risk assessment approach, to determine if the characteristics of the

material are compatible with the conditions of use and with the sensitivity of the environment where

the earthworks are to be constructed.

The potential environmental impacts which are considered for earthworks are either in the short-term,

or in the long term:

— Short term environmental impacts in conjunction with the application of the materials:

— The potential contamination during application (wind transport of fine particles or leaching

during temporary storage before the final application);

— The potential risks to working security, e.g. because of dust emissions;

— Long-term environmental impacts due to the use of the materials:

— The potential contamination of ground (which is next to, under or over the application area)

through short or long-term leaching or transfer of chemical substances with rainwater, flooding

or wind transportation;

— The potential contamination of water (ground water, surface water) either directly or after

leaching and transfer of chemical substances with rainwater or through flooding.

Finally, when answering the question as to whether a material can be used for earthworks (or not), two

main issues are taken into consideration:

— The evaluation of environmental properties of the material used (see subclause 8.3.1);

— The exposure scenario and conditions of use, considering environmental sensitivity of the area

(protection areas, ground water vs. industrial areas) and the type of application.

8.3 Relevant aspects to be considered for environmental assessment

8.3.1 Environmental properties of the material used

Different approaches exist in national regulations to determine or estimate the environmental

properties, or the material used:

— Determination of the total content of relevant chemical substances,

— Determination of the leachable amount of chemical substances by

— simple and short batch compliance leaching tests (e.g. liquid/solid ratio 1:2 or 1:10), or

— more complex and longer leaching tests (percolation test, pH-stat test),

— Evaluation in selected media: ecotoxicity-tests (daphnia, water plants, algae),

— Pilot scale/Full-scale experiments/trials.

For all these approaches, the sampling strategy used has very high importance, aiming at delivering

representative samples for the (normally high amount of) material used. As a first approach, the

sampling method can follow the procedure described in EN 932-1. Two main sampling strategies can be

distinguished:

— Batch sampling: a specific amount of material is sampled and analysed, the quality for the specific

mass of material can be determined;

— Continuous sampling: samples are taken at fixed intervals, either after a certain mass of material or

after a certain time. The tested material is homogeneous during these intervals.

The main issues for some classes of alternative materials can be the homogeneity. Materials resulting

from controlled industrial processes tend to have a good homogeneity, in this case continuous testing

can be sufficient. Materials resulting from recycling process (especially construction and demolition

waste, excavation material, tunnel arisings) can be very non-homogeneous, therefore batch sampling

can be the most suitable method.

8.3.2 Site specific risk evaluation and conditions of use

The environmental sensitivity of the area, where earthworks are being undertaken, is one important

factor which is taken into consideration when alternative materials are proposed. Different sensitive

areas/targets can be identified and considered from the environmental perspective:

— water protection areas,

— groundwater,

— areas with contact to surface waters,

— areas subject to flooding,

— nature protection areas,

— areas with active agricultural production (plants, livestock farming).

Therefore, environmental properties of materials used in earthworks are considered and are evaluated

to ensure compatibility in these (vertical and horizontal) sensitive areas.

Another key factor is the exposure to run-off rainwater, which can cause emissions of substances and

transport these emissions to distant areas or water bodies (ground water, soil, surface water). The

exposure can be different if the material is used under a non-permeable layer (for example, asphalt

layers in road construction or under building constructions, etc.) or open to run-off rainwater (for

example, dam construction, road shoulders, etc.).

NOTE The above-mentioned principles are finally set in national regulations.

9 Design testing and construction control

9.1 Testing philosophy

9.1.1 General

Like natural materials, alternative materials can be used in the construction of earth structures,

provided they comply with the specification in place for the intended use. In all cases, they meet the

following requirements:

— Provisions of the national legislation about the environment, health and safety, and storage,

handling and transport of construction products;

— Physical and chemical properties of the materials for short and long-term stability and service

conditions of the earth structure.

The selection of tests to be undertaken will be linked to the proposed use of the materials, their

anticipated behaviour and the environmental regulations at the place of the use.

Testing of the materials will fall into two categories:

— geotechnical and

— chemical/environmental.

Parameters and intensity of testing vary in relation to the risks associated with the material used, the

homogeneity of the material in relation to geotechnical and chemical properties and the site where the

material will be placed. The proposed testing is in compliance with national regulations and practice.

9.1.2 Geotechnical testing in advance of construction

Geotechnical testing is carried out in order to determine the short-term and long-term characteristics of

the materials.

The choice of geotechnical tests would be the same as for a natural soil and include for sufficient tests in

order to accurately represent the behaviour of the material (some specific tests are in material sheets).

CEN Standards, where applicable, are used for the geotechnical testing of alternative materials.

9.1.3 Chemical testing in advance of construction

In addition to the geotechnical testing, chemical testing is undertaken to determine if there is a

potential risk to the environment through the use of an alternative material.

The choice of chemical tests is made in relation to the potential risks associated with the alternative

material and any identified risks associated with the intended location of use. Reference is made to

Clause 7 for different approaches and methods to determine the risks to the environment.

The duration of the chemical testing is considered, particularly for leachate testing as the leachate levels

will normally change over time.

CEN Standards, where applicable, are used for the chemical testing of alternative materials.

9.2 Control during construction

Geotechnical and chemical compliance testing, where applicable, is carried out during construction to

ensure the material used is in accordance with the project specification. The choice and frequency of

testing are specified in the project. Their specification could be based on the client requirements, on a

risk assessment and considers the nature and intended use of the alternative materials.

Compliance testing, where applicable, allows for the potential variable nature of alternative materials.

Compliance testing could also be used to assess the variance of the material from that tested in advance

of construction.

All test locations are recorded in both horizontal and vertical position and each test give a unique

reference.

European Standards, where applicable, are used.

10 Health and safety

10.1 General

There are both European and national legal frameworks relating to Health and Safety, and these are

followed as applicable to the country of work. This section gives current best practice guidance to aid

the management of risk to operatives and others.

The use of alternative materials in earthworks requires that operators working with them have

adequate personal protection. The type of personal protection required will depend on the

classification and risk assessment for the material being used. Typical personal protection equipment

could include dust masks, overalls, gloves, goggles, etc.

10.2 Dust emissions

One of the biggest potential risks to Health and Safety is from airborne dust during earthworks

operations.

Water bowsers or similar equipment are used to keep surfaces damp where vehicles will traffic the

earthworks to reduce the risk of dust, particularly in environmentally sensitive and urban areas.

10.3 Runoff water and leachate

Runoff water and leachate can lead to potential health and safety issues both on the site and offsite.

Precautions, if necessary, are taken to avoid any leachate or run off from of the site. This is normally in

the form of cut off ditches and silt tanks/water treatment depending on the risk of the material being

used.

11 Material sheets

11.1 General

Material sheets contain basic information on individual alternative materials that are used in

earthworks, including:

— material definition;

— description of the material;

— typical applications in earthworks;

— specific technical properties – chemical, mineralogical, physico-mechanical;

— specific environmental properties;

— considerations during construction;

— long-term considerations;

— recommended specific tests;

— overview of countries that use the material;

— case studies.

Typical applications were adopted from other EN 16907 series standards:

• capping layer

Specific transition layer, part of the upper zone of the fill, placed below the superstructure. The

capping layer is part of the earth structure (EN 16907-1:2018, 3.1.4).

• fill

Collective term used in EN 16907-1 to describe all earth-structures formed by the placement of fill

material in a controlled manner for an engineering purpose (including embankment, infill, platform,

etc.) (EN 16907-1:2018, 3.1.24). The fill can be divided into the following zones. The tables in this

document for typical use only refer to fill rather than any sub division:

• base

Fill zone in direct contact with the existing ground. This zone can be divided into layers, e.g. for

drainage, working platform, impervious protection layer. It includes replacement of existing

foundation ground to some depth or improvement of existing ground by binders or installation

of geosynthetics (EN 16907-1:2018, 6.2.2.2).

• core

Fill zone located between any base layers and the upper zone (where the embankment is of

sufficient height). The core can be protected from water or isolated to limit pollution of the

environment (EN 16907-1:2018, 6.2.2.2).

• shoulders (side zones)

Lateral zones of fills. These zones can have various functions, e.g. enable steeper slopes, protect

the core, serve as filters, protect from erosion (EN 16907-1:2018, 6.2.2.2).

• upper zone

Zone located between the core and the superstructure (pavement, track). This zone can

comprise different layers such as the “upper part of fill“, the "capping layer", a "transition layer"

to separate rock fill from the upper granular layers, an impermeable layer, or another layer with

a particular function. It does not include the superstructure layers (EN 16907-1:2018, 6.2.2.2).

• transition zones

Embankments can comprise different types of transition zones: longitudinal tr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...