EN 360:2023

(Main)Personal fall protection equipment - Retractable type fall arresters

Personal fall protection equipment - Retractable type fall arresters

This document specifies requirements, test methods, marking, manufacturer’s instructions and information for retractable type fall arresters (RTFAs) and applies to a RTFA with a single retractable lanyard and a RTFA with two retractable lanyards (twin RTFA) as components of one of the fall arrest systems covered by EN 363:2018.

This European standard is not applicable to RTFAs and twin RTFAs used in any sport or recreational activity.

Persönliche Absturzschutzausrüstung - Höhensicherungsgeräte

Dieses Dokument legt Anforderungen, Prüfverfahren, Kennzeichnung sowie Anleitungen und Informationen des Herstellers für Höhensicherungsgeräte (RTFA, en: retractable type fall arresters) fest und ist anwendbar für Höhensicherungsgeräte mit einem einzelnen einziehbaren Verbindungsmittel und Höhensicherungsgeräte mit zwei einziehbaren Verbindungsmitteln (Doppel-Höhensicherungsgeräte) als Bestandteile eines der von EN 363:2018 erfassten Auffangsysteme.

Diese Europäische Norm ist nicht anwendbar auf Höhensicherungsgeräte und Doppel-Höhensicherungs-geräte, die bei Sport- oder Freizeitaktivitäten verwendet werden.

Équipement de protection individuelle contre les chutes de hauteur - Antichutes à rappel automatique

Le présent document spécifie les exigences, les méthodes d'essai, le marquage, les instructions et informations fournies par le fabricant concernant les antichutes à rappel automatique (ARA). Il s'applique aux antichutes à rappel automatique munis d'une seule longe rétractable et aux antichutes à rappel automatique munis de deux longes rétractables (ARA doubles) en tant que composants de l'un des systèmes d'arrêt des chutes couverts par l'EN 363:2018.

La présente Norme européenne ne s'applique pas aux ARA et ARA doubles utilisés dans les activités sportives ou de loisirs.

Osebna oprema za varovanje pred padci - Samonavijalna zaustavitvena naprava

Ta dokument določa zahteve, preskusne metode, označevanje, navodila in informacije proizvajalca za samonavijalne zaustavitvene naprave (RTFA) in velja za samonavijalne zaustavitvene naprave z eno uvlečno varovalno vrvico in samonavijalne zaustavitvene naprave z dvema uvlečnima varovalnima vrvicama kot sestavnih delov ene od samonavijalnih zaustavitvenih naprav, zajetih v standard EN 363:2018.

Ta evropski standard se ne uporablja za samonavijalne zaustavitvene naprave z eno ali dvema uvlečnima varovalnima vrvicama, ki se uporabljajo pri športni ali drugi prostočasni

dejavnosti.

General Information

- Status

- Published

- Publication Date

- 19-Dec-2023

- Technical Committee

- CEN/TC 160 - Protection against falls from height including working belts

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 20-Dec-2023

- Due Date

- 06-Jul-2022

- Completion Date

- 20-Dec-2023

- Directive

- Not Harmonized2016/425 - Regulation (EU) 2016/425 of the European Parliament and of the Council of 9 March 2016 on personal protective equipment and repealing Council Directive 89/686/EEC

Not Harmonized89/686/EEC - Personal protective equipment (PPE)

Relations

- Effective Date

- 13-Nov-2017

- Refers

EN ISO 9227:2022 - Corrosion tests in artificial atmospheres - Salt spray tests (ISO 9227:2022) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 360:2023 - Personal fall protection equipment - Retractable type fall arresters (RTFAs) - specifies requirements, test methods, marking, manufacturer’s instructions and information for single and twin retractable lanyard fall arresters. Adopted by the Slovenian standards body (SIST) as the national version of EN 360:2023, this standard supersedes EN 360:2002. It applies to RTFAs used as components of fall arrest systems covered by EN 363:2018 and is not applicable to sport or recreational activities.

Key topics and technical requirements

The standard defines a comprehensive technical and test framework for retractable type fall arresters (RTFAs) and twin RTFAs, including:

- Design and ergonomics: requirements for form, user interaction and safe attachment points.

- Materials and construction: acceptable materials, corrosion resistance and manufacturing quality.

- Retraction tension and function: criteria for lanyard retraction performance in vertical and horizontal applications.

- Static and dynamic strength: static load tests and multiple dynamic performance tests (overhead, foot-level, horizontal, lateral offset) to verify energy-absorption, locking and integrity under fall conditions.

- Conditioning and environmental tests: heat, cold, wet and corrosion conditioning before performance verification.

- Marking and manufacturer’s information: required labelling, user instructions, maintenance, periodic examination and packaging rules.

- Special provisions: additional requirements and test methods for use in mobile elevating work platforms (annex).

The document includes detailed test methods (traction, dynamic, function, strength) and informative annexes explaining changes from the previous edition and EU regulatory relationships.

Practical applications - who uses this standard

EN 360:2023 is intended for:

- PPE manufacturers and designers developing or certifying retractable fall arresters.

- Testing laboratories and certification bodies performing static and dynamic tests and compliance verification.

- Health & safety managers, procurement teams and specifiers selecting fall arrest equipment for workplaces.

- Inspectors and maintenance personnel who follow marking, instruction and periodic examination requirements. Common use cases include fall protection systems for construction, industrial maintenance, utilities and work-at-height operations, and integration of RTFAs into EN 363:2018 fall arrest systems. Annex A covers requirements for use in mobile elevating work platforms (MEWPs).

Related standards (normative references)

Key related documents referenced by EN 360:2023:

- EN 363:2018 (Fall arrest system framework)

- EN 361 (Full body harnesses)

- EN 362 (Connectors)

- EN 365 (Instructions, maintenance, periodic examination)

- EN 358 (Belts and lanyards) These references guide compatible components, testing methods and conformity with EU Regulation 2016/425.

Keywords: EN 360:2023, retractable type fall arresters, RTFA, twin RTFA, fall arrest systems, EN 363:2018, personal fall protection equipment, testing and marking.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 360:2023 is a standard published by the European Committee for Standardization (CEN). Its full title is "Personal fall protection equipment - Retractable type fall arresters". This standard covers: This document specifies requirements, test methods, marking, manufacturer’s instructions and information for retractable type fall arresters (RTFAs) and applies to a RTFA with a single retractable lanyard and a RTFA with two retractable lanyards (twin RTFA) as components of one of the fall arrest systems covered by EN 363:2018. This European standard is not applicable to RTFAs and twin RTFAs used in any sport or recreational activity.

This document specifies requirements, test methods, marking, manufacturer’s instructions and information for retractable type fall arresters (RTFAs) and applies to a RTFA with a single retractable lanyard and a RTFA with two retractable lanyards (twin RTFA) as components of one of the fall arrest systems covered by EN 363:2018. This European standard is not applicable to RTFAs and twin RTFAs used in any sport or recreational activity.

EN 360:2023 is classified under the following ICS (International Classification for Standards) categories: 13.340.60 - Protection against falling and slipping. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 360:2023 has the following relationships with other standards: It is inter standard links to EN 360:2002, EN ISO 9227:2022, EN 362:2004, EN 10278:1999, EN 10277:2018, EN 361:2002, EN ISO 683-1:2018, EN 365:2004, EN 358:2018, EN 16307-3:2023, EN 795:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 360:2023 is associated with the following European legislation: EU Directives/Regulations: 2016/425, 89/686/EEC; Standardization Mandates: M/031, M/571, M/571 AMD 1. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 360:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2024

Nadomešča:

SIST EN 360:2002

Osebna oprema za varovanje pred padci - Samonavijalna zaustavitvena naprava

Personal fall protection equipment - Retractable type fall arresters

Persönliche Absturzschutzausrüstung - Höhensicherungsgeräte

Équipement de protection individuelle contre les chutes de hauteur - Antichutes à rappel

automatique

Ta slovenski standard je istoveten z: EN 360:2023

ICS:

13.340.60 Zaščita pred padci in zdrsi Protection against falling and

slipping

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 360

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2023

EUROPÄISCHE NORM

ICS 13.340.60 Supersedes EN 360:2002

English Version

Personal fall protection equipment - Retractable type fall

arresters

Équipement de protection individuelle contre les Persönliche Absturzschutzausrüstung -

chutes de hauteur - Antichutes à rappel automatique Höhensicherungsgeräte

This European Standard was approved by CEN on 20 June 2022.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 360:2023 E

worldwide for CEN national Members.

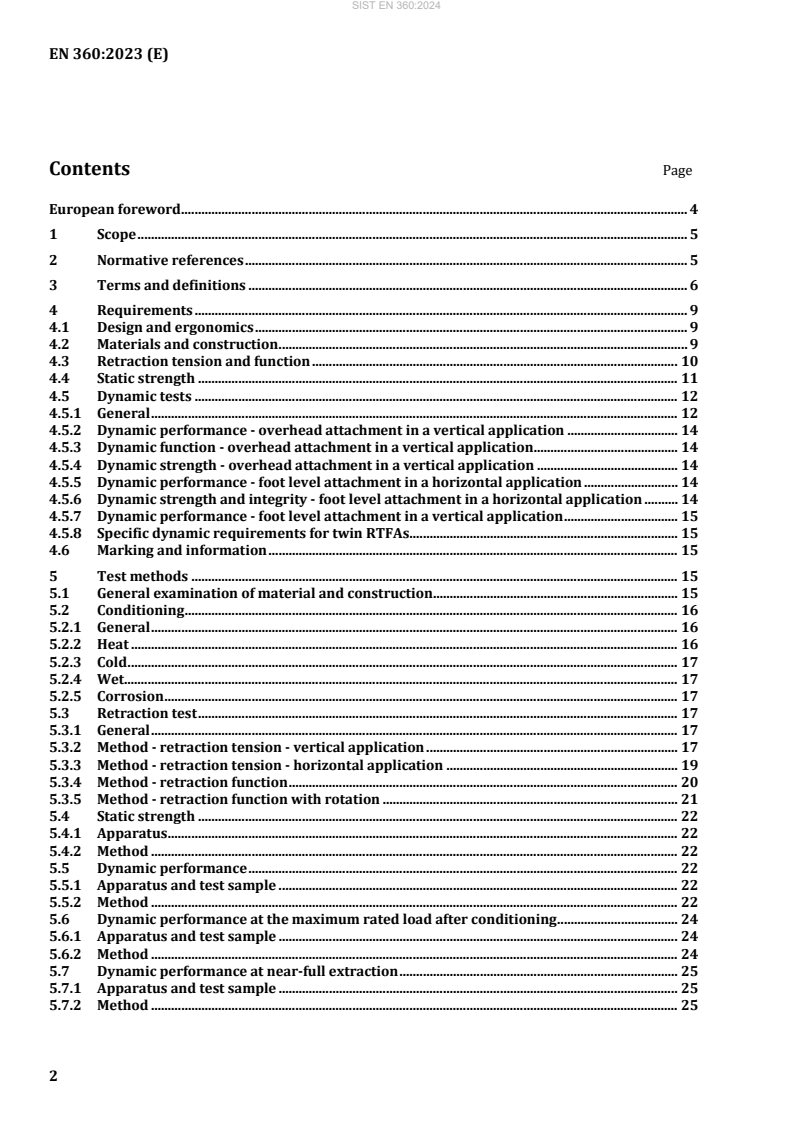

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Requirements . 9

4.1 Design and ergonomics . 9

4.2 Materials and construction . 9

4.3 Retraction tension and function . 10

4.4 Static strength . 11

4.5 Dynamic tests . 12

4.5.1 General . 12

4.5.2 Dynamic performance - overhead attachment in a vertical application . 14

4.5.3 Dynamic function - overhead attachment in a vertical application . 14

4.5.4 Dynamic strength - overhead attachment in a vertical application . 14

4.5.5 Dynamic performance - foot level attachment in a horizontal application . 14

4.5.6 Dynamic strength and integrity - foot level attachment in a horizontal application . 14

4.5.7 Dynamic performance - foot level attachment in a vertical application . 15

4.5.8 Specific dynamic requirements for twin RTFAs . 15

4.6 Marking and information . 15

5 Test methods . 15

5.1 General examination of material and construction. 15

5.2 Conditioning . 16

5.2.1 General . 16

5.2.2 Heat . 16

5.2.3 Cold . 17

5.2.4 Wet. 17

5.2.5 Corrosion . 17

5.3 Retraction test . 17

5.3.1 General . 17

5.3.2 Method - retraction tension - vertical application . 17

5.3.3 Method - retraction tension - horizontal application . 19

5.3.4 Method - retraction function . 20

5.3.5 Method - retraction function with rotation . 21

5.4 Static strength . 22

5.4.1 Apparatus . 22

5.4.2 Method . 22

5.5 Dynamic performance . 22

5.5.1 Apparatus and test sample . 22

5.5.2 Method . 22

5.6 Dynamic performance at the maximum rated load after conditioning . 24

5.6.1 Apparatus and test sample . 24

5.6.2 Method . 24

5.7 Dynamic performance at near-full extraction . 25

5.7.1 Apparatus and test sample . 25

5.7.2 Method . 25

5.8 Dynamic function at the minimum rated load . 27

5.8.1 Apparatus . 27

5.8.2 Method . 27

5.9 Dynamic strength . 27

5.9.1 Apparatus . 27

5.9.2 Method . 27

5.10 Dynamic tests in a horizontal application . 28

5.10.1 Apparatus . 28

5.10.2 Test sample . 29

5.10.3 Method - dynamic performance . 29

5.10.4 Method - dynamic strength and integrity . 30

5.11 Dynamic tests in a horizontal application with a lateral offset . 33

5.11.1 Apparatus . 33

5.11.2 Test sample . 33

5.11.3 Method - dynamic performance . 33

5.11.4 Method - dynamic strength and integrity . 34

5.12 Dynamic performance - foot level attachment in a vertical application . 37

5.12.1 Apparatus and test sample . 37

5.12.2 Method . 37

5.13 Dynamic performance - twin RTFAs with both lanyards in a horizontal opposite

arrangement . 39

5.13.1 Apparatus and test sample . 39

5.13.2 Method . 39

6 Marking . 43

7 Manufacturer’s instructions and information . 45

8 Packaging . 48

Annex A (normative) Additional requirements and test methods for RTFAs and twin RTFAs

for use in mobile elevating work platforms . 49

A.1 Introduction. 49

A.2 Requirements . 49

A.3 Marking and information. 49

A.4 Test method . 49

A.4.1 General examination of materials and construction . 49

A.4.2 Dynamic performance and integrity . 50

A.5 Marking . 53

A.6 Manufacturer’s instructions and information . 54

Annex B (informative) Explanatory information on this edition of EN 360:2023. 55

Annex C (informative) Significant technical changes between this European Standard and

the previous edition EN 360:2002 . 58

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of EU Regulation 2016/425 aimed to be covered . 63

Bibliography . 65

European foreword

This document (EN 360:2023) has been prepared by Technical Committee CEN/TC 160 “Protection

against falls from height including working belts”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2024, and conflicting national standards shall be

withdrawn at the latest by June 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 360:2002.

The significant technical changes between this document and the previous edition are described in the

informative Annex C.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annex ZA, which is an integral part of this

document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

1 Scope

This document specifies requirements, test methods, marking, manufacturer’s instructions and

information for retractable type fall arresters (RTFAs) and applies to a RTFA with a single retractable

lanyard and a RTFA with two retractable lanyards (twin RTFA) as components of one of the fall arrest

systems covered by EN 363:2018.

This European standard is not applicable to RTFAs and twin RTFAs used in any sport or recreational

activity.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 358:2018, Personal protective equipment for work positioning and prevention of falls from a height —

Belts and lanyards for work positioning or restraint

EN 361:2002, Personal protective equipment against falls from a height — Full body harnesses

EN 362:2004, Personal protective equipment against falls from a height — Connectors

EN 364:1992, Personal protective equipment against falls from a height — Test methods

EN 365:2004, Personal protective equipment against falls from a height — General requirements for

instructions for use, maintenance, periodic examination, repair, marking and packaging

EN 10277:2018, Bright steel products — Technical delivery conditions

EN 10278:1999, Dimensions and tolerances of bright steel products

EN ISO 683-1:2018, Heat-treatable steels, alloy steels and free-cutting steels — Part 1: Non-alloy steels for

quenching and tempering (ISO 683-1:2016)

EN ISO 9227:2022, Corrosion tests in artificial atmospheres — Salt spray tests (ISO 9227:2022)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org

3.1

retractable type fall arrester

RTFA

fall arrester with a self-locking function and an automatic tensioning and return facility with one

retractable lanyard.

Note 1 to entry: Figure 1a shows an example of a RTFA.

Note 2 to entry: Figure 2a, Figure 2b and Figure 2c show directions of use.

Note 3 to entry: An energy dissipating element may be in or at the housing of the RTFA and/or part of the

retractable lanyard.

Note 4 to entry: An RTFA that includes a feature to manually prevent only extraction may require additional

testing, e.g. to EN 358.

3.2

twin RTFA

fall arrester with a self-locking function and an automatic tensioning and return facility with two

retractable lanyards

Note 1 to entry: Twin RTFAs may be two independent devices connected together or may be two retractable

lanyards integrated into a single housing. See Figure 1b and Figure 1c.

Note 2 to entry: An energy dissipating element(s) may be in or at the housing of the twin RTFA and/or part of the

retractable lanyards.

a) b)

c)

Key

L non-retractable section 4 energy dissipating element (if applicable)

1 attachment point 5 swivel

2 housing 6 connector or connection element

3 retractable lanyard(s) 7 permanent connection element

Figure 1 — Examples of RTFAs with one or two retractable lanyards

3.3

retractable lanyard

connecting element of a RTFA, which may be of wire rope, man-made fibre webbing or man-made fibre

rope and may include an energy dissipating element

Note 1 to entry: A retractable lanyard may be any length.

3.4

man-made fibre

fibre obtained by a manufacturing process

Note 1 to entry: Man-made fibres refer to CEN ISO/TR 11827:2016.

3.5

energy dissipating element

element of a RTFA, which is designed to dissipate the kinetic energy developed during a fall from a height

3.6

braking force

maximum force F measured during the dynamic performance test

max

Note 1 to entry: Braking force is expressed in kilonewtons.

3.7

arrest distance

H

AD

vertical distance measured from the initial position of the test mass before its release in a dynamic test

to its final position after arrest

Note 1 to entry: Arrest distance is expressed in metres.

3.8

distance beneath anchor

H

BA

vertical distance measured from the anchor point on the test apparatus to the connection point of the

RTFA to the load cell at its final position after arrest

Note 1 to entry: Distance beneath anchor is expressed in metres.

3.9

minimum rated load

minimum mass of the person, excluding any tools and equipment carried, when using the RTFA, as

specified by the manufacturer

Note 1 to entry: Minimum rated load is expressed in kilograms.

3.10

maximum rated load

maximum mass of the person, including any tools and equipment carried, when using the RTFA, as

specified by the manufacturer

Note 1 to entry: Maximum rated load is expressed in kilograms.

3.11

connection element

integral element of the RTFA permitting connection between the RTFA and the appropriate fall arrest

attachment point on the suitable full body harness, e.g. a harness conforming to EN 361:2002, and/or the

anchor point

4 Requirements

4.1 Design and ergonomics

4.1.1 When checked in accordance with 5.3.5 the retractable lanyard(s) shall fully retract.

4.1.2 When checked in accordance with 5.1.1, the non-retractable section of the retractable lanyard(s)

(e.g. energy dissipating element, connector), including the largest permissible connector or connection

element specified by the manufacturer’s instructions and information, shall have a maximum length L of

600 mm (see Figure 1).

4.1.3 When checked in accordance with 5.1.1, if the weight of the RTFA or twin RTFA is 15 kg or more

its weight shall equal that marked on the device to the nearest 0,5 kg.

4.1.4 When checked in accordance with 5.1.2, a twin RTFA shall have lanyards of equal length and with

either lanyard fully extracted the maximum length L (see Figure 3) shall not exceed 2,5 m.

max

4.1.5 If the manufacture permits two independent RTFAs to be used as a twin RTFA they shall be tested

in accordance with 5.1.2, with either lanyard fully extracted the maximum length L (see Figure 3) shall

max

not exceed 2,5 m.

4.1.6 If the manufacturer permits use of the RTFA or twin RTFA in a Mobile Elevating Work Platform

(MEWP) it shall additionally meet the requirements of normative Annex A.

4.1.7 If the RTFA or twin RTFA includes a feature to limit extraction of the retractable lanyard the RTFA

or twin RTFA shall additionally conform to relevant requirements of other standards or specifications,

e.g. EN 358:2018, with the feature engaged. The RTFA or twin RTFA shall not include a feature or features

which limits retraction of the lanyard.

4.2 Materials and construction

4.2.1 When checked in accordance with 5.1.1, materials used in the RTFA and twin RTFA that may come

into contact with the skin of the user including the retractable lanyard shall not be known to cause

irritating or sensitization effects when used as intended.

4.2.2 When checked in accordance with 5.1.1, the retractable lanyard(s) shall be a wire rope, a man-

made fibre webbing, man-made fibre rope or a hybrid with a man-made content.

NOTE 1 A retractable lanyard(s) can include a non-load bearing covering material, e.g. non-metallic sheath.

NOTE 2 A hybrid retractable lanyard(s) can be a combination of man-made fibre and metallic elements.

4.2.3 When checked in accordance with 5.1.1, wire ropes for retractable lanyards shall be made either

from stainless steel or galvanised steel. Terminations (e.g. a swaged ferrule) for a retractable lanyard

made from wire rope shall be made from a metallic material and not known to cause an adverse reaction

with the material of the wire rope (e.g. dissimilar metal corrosion, cracking).

4.2.4 When checked in accordance with 5.1.1, webbing or fibre rope and sewing threads for retractable

lanyards shall be made from man-made fibres with a tenacity of at least 0,6 N/tex.

NOTE 0,6 N/tex is based on the information given in EN ISO 9554:2019, Annex A.

4.2.5 When checked in accordance with 5.1.1, exposed edges or corners of elements shall be relieved

either with a radius of at least 0,5 mm or a chamfer of at least 0,5 mm × 0,5 mm.

4.2.6 When checked in accordance with 5.1.1, the termination of the retractable lanyard(s) and the

attachment point (see Figure 1) shall be designed such that they either incorporate a connector

conforming to EN 362:2004, 4.1 to 4.5, or are of such a design that an EN 362 connector can be fitted or

they shall incorporate a specific connection element (e.g. for attachment to a full body harness, tripod)

which shall be so designed that it cannot be disconnected unintentionally and shall require at least two

different deliberate manual actions to disconnect.

4.2.7 When checked in accordance with 5.1.1, the RTFA shall be fitted with a fall indicator.

A RTFA may have more than one fall indicator.

4.2.8 When checked in accordance with 5.1.1, the twin RTFA shall be fitted with a fall indicator in the

connection element, in or at the housing(s) or in each retractable lanyard.

4.2.9 When checked in accordance with 5.1.1, U-bolt clamps including those conforming to EN 13411-

5 shall not be used to form a termination in the retractable lanyard made from wire rope.

4.3 Retraction tension and function

4.3.1 When tested in accordance with 5.3.2, for vertical applications where the maximum angle θ from

the true vertical is not greater than 45° (see Figure 2a), the retraction tension in each lanyard shall not

be less than 5 N or more than 110 N and the lanyard(s) shall fully retract to its original position without

stopping.

4.3.2 If the manufacturer permits use in a horizontal application or where angle θ from the true vertical

is greater than 45° (see Figures 2b and 2c) the RTFA and twin RTFA shall be tested as described in 5.3.3

and the lanyard(s) shall fully retract to its original position without stopping.

4.3.3 For twin RTFAs and for RTFAs where the manufacturer permits attachment of the RTFA housing,

i.e. not the retractable lanyard, to the attachment point of the harness, when tested in accordance with

5.3.4 the lanyard(s) shall fully retract to its original position without stopping.

a)

b) c)

Key

L non-retractable section 5 swivel

1 attachment point 6 connector

2 housing 7 additional direction of use

3 retractable lanyard θ angle from true vertical

4 energy dissipating element (if applicable)

Figure 2 — Examples of directions of use for a RTFA attachment

4.4 Static strength

4.4.1 RTFAs and twin RTFAs with a retractable lanyard(s) material entirely of man-made fibre rope or

man-made fibre webbing or which is a hybrid with a man-made content shall sustain a load of at least

15 kN when tested as described in 5.4.2.2.

4.4.2 RTFAs and twin RTFAs with a retractable lanyard(s) material entirely of wire rope shall sustain

a load of at least 12 kN when tested as described in 5.4.2.2.

4.4.3 If any load-bearing element other than the retractable lanyard(s) of the RTFA or twin RTFA, e.g.

an energy dissipating element, is made from non-metallic materials it shall sustain a load of 15 kN when

tested in accordance 5.4.2.3.

4.5 Dynamic tests

4.5.1 General

Table 1 — Overview of applications and product related tests

Attachment(s)

Overhead Twin MEWP

Foot Level Foot Level

(vertical RTFA

(RTFA

Dynamic tests

(horizontal (vertical

application)

and twin

application) application)

RTFA)

Performance 4.5.2, function

4.5.3 and strength 4.5.4

(overhead attachment,

vertical application)

Performance 4.5.5, strength

and integrity 4.5.6 (foot level

attachment, horizontal

application)

Dynamic performance 4.5.7

(foot level attachment,

vertical application)

Dynamic performance 4.5.8

(horizontally opposite

arrangement)

Dynamic performance and

integrity A.2.4 (foot level

attachment, MEWP

application)

Key

required

not required

required if use is claimed by the manufacturer

NOTE 1 For devices that are intended for multiple attachments, select all columns that are applicable.

Table 2 — Overview of the dynamic test requirements

Requirements

Braking Arrest

Fall

Type of test Condition(s) Test mass force distance

indicator Clause

F H

max AD max

activation

kN m

Ambient

100 kg 6 1,4 Yes 4.5.2.1

Dynamic

(as received)

performance

Heat, cold, wet Max. rated

6 1,4 Yes 4.5.2.2

Dynamic

& corrosion load

performance,

function and

Dynamic

strength

Ambient

performance at Max. rated

6 1,4 Yes 4.5.2.3

(overhead

near-full load

(as received)

attachment,

extraction

vertical

Ambient

application) Dynamic Min. rated Not

1,4 Yes 4.5.3

function load applicable

(as received)

Ambient

Dynamic Max. rated Not Not

Yes 4.5.4

strength load applicable applicable

(as received)

Ambient

Dynamic Max. rated

6 4,5 Yes 4.5.5

performance load

(as received)

Dynamic

Dynamic

Ambient

performance Max. rated

performance,

6 4,75 Yes 4.5.5

with a lateral load

strength and

(as received)

offset

integrity (foot

level

Dynamic

Ambient

attachment, Max. rated Not Not Not

strength and 4.5.6

horizontal load applicable applicable applicable

(as received)

integrity

application)

Dynamic

Ambient

strength and Max. rated Not Not Not

4.5.6

integrity with a load applicable applicable applicable

(as received)

lateral offset

Dynamic

performance

Ambient

(foot level Dynamic Max. rated

6 4,5 Yes 4.5.7

attachment, performance load

(as received)

vertical

application)

Dynamic

Dynamic

performance

Ambient

performance Max. rated Not

(horizontally 6 Yes 4.5.8

with twin load applicable

(as received)

opposite

RTFA

arrangement)

NOTE 2 Where specific operating conditions have been identified, additional relevant conditioning and/or

endurance tests can be required.

NOTE 3 For MEWP dynamic test requirements, see Annex A.

4.5.2 Dynamic performance - overhead attachment in a vertical application

4.5.2.1 When tested as described in 5.5 with a rigid steel mass of 100 kg, the braking force F shall

max

not exceed 6 kN, the arrest distance H shall not exceed 1,4 m and the fall indicator shall activate.

AD

4.5.2.2 When tested as described in 5.6 with a rigid steel mass equal to the maximum rated load but

not less than 100 kg the braking force F shall not exceed 6 kN, the arrest distance H shall not exceed

max AD

1,4 m and the fall indicator shall activate.

4.5.2.3 When tested as described in 5.7 with the rigid steel mass equal to the maximum rated load

but not less than 100 kg, the braking force F shall not exceed 6 kN, the arrest distance H shall not

max AD

exceed 1,4 m and the fall indicator shall activate.

4.5.3 Dynamic function - overhead attachment in a vertical application

When tested as described in 5.8 with the rigid steel mass equal to the minimum rated load but not greater

than 100 kg, the arrest distance H shall not exceed 1,4 m and the fall indicator shall activate.

AD

4.5.4 Dynamic strength - overhead attachment in a vertical application

When tested as described in 5.9 with a rigid steel test mass equal to the maximum rated load but not less

than 100 kg the RTFA shall hold the test mass clear of the ground and the fall indicator shall activate.

4.5.5 Dynamic performance - foot level attachment in a horizontal application

If the manufacturer permits use in a horizontal application (see Figure 2b) and where the angle from the

true vertical is greater than 45° (see Figure 2c) the RTFA shall conform to 4.5.2 to 4.5.3 and be tested as

described in 5.10.3 and 5.11.3 with a rigid steel mass equal to the maximum rated load but not less than

100 kg. The braking force F at the test mass shall not be greater than 6 kN, the fall indicator shall

max

activate and the RTFA shall hold the test mass clear of the ground. The arrest distance shall not exceed

4,5 m when tested perpendicular to the edge as described in 5.10.3 or 4,75 m when tested with a lateral

offset as described in 5.11.3.

4.5.6 Dynamic strength and integrity - foot level attachment in a horizontal application

4.5.6.1 If the manufacturer permits use in a horizontal application (see Figure 2b) and where the

angle from the true vertical is greater than 45° (see Figure 2c) the RTFA shall be tested as described in

5.10.4 and 5.11.4 with a rigid steel mass equal to the maximum rated load but not less than 100 kg. The

RTFA shall hold the test mass clear of the ground.

4.5.6.2 The RTFA with a retractable lanyard made from man-made fibre rope or man-made fibre

webbing or in combination with wire rope shall sustain a load of three times the maximum rated load

(static load) when tested in accordance with 5.10.4.3 and 5.11.4.3.

4.5.6.3 The RTFA with a retractable lanyard made entirely from wire rope shall sustain a load of two

times the maximum rated load (static load) when tested in accordance with 5.10.4.3 and 5.11.4.3.

NOTE Testing in a horizontal application in 4.5.5 and 4.5.6 has been introduced to demonstrate a level of

robustness for the RTFA and twin RTFA should accidental loading over a sharp edge occur, however, this does not

mean that an RTFA or twin RTFA can be used over a sharp edge.

4.5.7 Dynamic performance - foot level attachment in a vertical application

If the manufacturer permits use in a vertical application with a foot level attachment the RTFA shall

conform to 4.5.2 to 4.5.3 and be tested as described in 5.12, with a rigid steel mass equal to the maximum

rated load but not less than 100 kg. The braking force F shall not exceed 6 kN, the distance beneath

max

anchor H shall not exceed 3,75 m and the fall indicator shall activate.

BA

4.5.8 Specific dynamic requirements for twin RTFAs

4.5.8.1 Twin RTFAs shall conform to 4.5.2 to 4.5.4. If claimed by the manufacturer twin RTFAs shall

conform to 4.5.5 to 4.5.7.

NOTE 1 For twin RTFAs comprising of two independent devices which are identical (see Figure 1b) the test can

be carried out on one of the devices.

NOTE 2 For twin RTFAs comprising of a single housing with identical retractable lanyards (see Figure 1c) the

test can be carried out on one of the retractable lanyards,

4.5.8.2 Twin RTFAs shall be tested in accordance with 5.13, with a rigid steel mass equal to the

maximum rated load but not less than 100 kg. The braking force F shall not exceed 6 kN, the fall

max

indicator shall activate and the RTFA shall hold the test mass clear of the ground.

4.6 Marking and information

Marking of the RTFA and twin RTFA shall be in accordance with Clause 6.

Manufacturer’s instructions and information shall be supplied with the RTFA and twin RTFA in

accordance with Clause 7.

5 Test methods

5.1 General examination of material and construction

5.1.1 Confirm by reference to appropriate documentation and by normal or corrected vision and/or

tactile/functional examination and/or by measurement and/or by weighing of the RTFA and twin RTFA

that it conforms to 4.1 and 4.2.

5.1.2 Attach the twin RTFA to a suitable fixture and extend one lanyard to its maximum length using

the longest connectors in accordance with the manufacturer’s instructions and information. Apply a static

+01,

load using a rigid steel test mass of 12 kg or equivalent force to the connector of the extended

( )

retractable lanyard. Maintain the load for (60 ± 15) s. Within the next 10 s, with the load still applied,

between the load bearing points on the connectors in

measure and record the twin RTFA length L

max

metres to the nearest 0,01 m (see Figure 3). Repeat the examination for the second retractable lanyard

and check that the length of the twin RTFA measured between load bearings points are same with a

maximum difference of 0,05 m.

Key

L maximum length between load bearing points 5 swivel

max

L non-retractable section 6 connector

1 attachment point 7 permanent connection element

2 Housing 8 anchor point

3 retractable lanyard 9 12 kg test mass or equivalent force

4 energy dissipating element (if applicable)

Figure 3 — Method to determine L with an example of a twin RTFA

max

5.2 Conditioning

5.2.1 General

The conditioning apparatus shall conform to EN 364:1992, 4.8.1 and 4.8.2.

NOTE Conditioning and corrosion tests are applicable to the retraction test and the dynamic performance test

at the maximum rated load.

5.2.2 Heat

Place the RTFA in a heated chamber for at least 2 h at a temperature of (50 ± 2) °C and at a relative

humidity of (85 ± 5) %.

5.2.3 Cold

Place the RTFA in a refrigerated chamber for at least 2 h at the minimum temperature claimed by the

manufacturer but not warmer than (−30 ± 2) °C.

5.2.4 Wet

Maintain the RTFA at ambient temperature for 24 h. Fully immerse the RTFA in fresh water within the

+5

temperature range (10 to 30) °C for ( 60 ) min, in such a way that water can enter the housing (e.g. with

retractable type fall arrest on its side). Remove the RTFA from the water, suspend it from its upper

attachment point and allow it to drain for (15 ± 1) min.

5.2.5 Corrosion

Expose the RTFA suspended from its upper attachment point to the neutral salt spray test in accordance

+05, +5

with EN ISO 9227:2022 for a period of ( 24 ) h. Dry for ( ) min at (20 ± 2) °C. Repeat the procedure,

0 0

+05, +5

so that the RTFA is subjected in total to ( 24 ) h exposure and ( 60 ) min drying plus another

0 0

+05,

+5

( 24 ) h exposure and ( 60 ) min drying.

0 0

5.3 Retraction test

5.3.1 General

5.3.1.1 The tension test gauge shall be capable of measuring static tensile loads in the range from 4 N

to 130 N with an accuracy of ± 5 %.

5.3.1.2 Carry out the tests using the heaviest connector in accordance with the manufacturer’s

instructions and information.

5.3.1.3 For heat and cold conditioning tests for an RTFA or twin RTFA with a maximum mass of 4 kg

the time between the end of conditioning and the end of the test sequence shall be less than 5 min. For

RTFAs and twin RTFAs with a mass greater than 4 kg the time between the end of conditioning and the

end of the test sequence shall be less than 10 min. The time between the end of wet conditioning and the

end if the test sequence shall be less than 10 min. The time between the end of corrosion conditioning

and the end of the test sequence shall not exceed 60 min.

NOTE 1 For twin RTFAs comprising of two independent devices (see Figure 1b) the mass is based on one of the

devices.

NOTE 2 For twin RTFAs comprising of a single housing (see Figure 1c) the mass is based on the complete device.

NOTE 3 The time allowed for the test sequence can be used for testing to 5.3.2, 5.3.3 and 5.3.4 in the same time

frame, i.e. the same time period, where possible.

5.3.2 Method - retraction tension - vertical application

5.3.2.1 The test shall be carried out for conditions described in 5.2.2, 5.2.3 and 5.2.5 for RTFAs and

twin RTFAs with wire rope retractable lanyards. For RTFAs and twin RTFAs with man-made fibre

webbing or man-made fibre rope retractable lanyards carry out the tests for each condition described in

5.2.

5.3.2.2 Suspend the RTFA in accordance with the manufacturer’s instructions and information and

fully extract the retractable lanyard and allow the lanyard to fully retract in a controlled manner.

5.3.2.3 Extract (300 ± 10) mm of the retractable lanyard. Connect the tension test gauge and align

the test gauge with the vertical. With the gauge against the gauge platform allow the lanyard retraction

tension to be borne by the gauge. See Figure 4.

5.3.2.4 Record the gauge reading within 30 seconds of the lanyard tension being borne by the gauge

and check the result in accordance with the requirements in 4.3.1. Disconnect the gauge and allow the

lanyard to fully retract back under its own power. The lanyard retraction shall be unassisted and

controlled by hand resistance to prevent uncontrolled take-up of the lanyard by the RTFA.

5.3.2.5 Repeat the procedure with the lanyard fully extracted. The weight of the lanyard, including

any connection element, is to be accounted for by allowing it to be suspended during the test. It is

allowable to secure the lanyard into a coil. To attach the tension gauge, a clamp may be used. Allow the

retractable lanyard to retract a maximum of 100 mm before measuring the retraction tension and record

the result.

5.3.2.6 For a twin RTFA with identical retractable lanyards carry out the test on one of the retractable

lanyards. If the retractable lanyards are not identical carry out the test on each of the retractable lanyards

and record the result(s).

Key

1 RTFA 4 gauge platform

2 extracted lanyard L length of extracted lanyard

3 tension gauge

Figure 4 — Example of the retraction test arrangement in a vertical application

5.3.3 Method - retraction tension - horizontal application

5.3.3.1 The test shall be carried out for conditions described in 5.2.2, 5.2.3 and 5.2.5 for RTFAs and

twin RTFAs with wire rope retractable lanyards. For RTFAs and twin RTFAs with man-made fibre

webbing or man-made fibre rope retractable lanyards carry out the tests for each condition described in

5.2.

5.3.3.2 Connect the RTFA horizontally in accordance with the manufacturer’s instructions and

information. Support the housing of the RTFA and fully extract the retrac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...