EN 4050-3:2012

(Main)Aerospace series - Test method for metallic materials - Ultrasonic inspection of bars, plates, forging stock and forgings - Part 3: Reference blocks

Aerospace series - Test method for metallic materials - Ultrasonic inspection of bars, plates, forging stock and forgings - Part 3: Reference blocks

This European Standard specifies the requirements for the manufacture, checking and marking of the series of ultrasonic testing reference blocks containing flat bottom holes (FBH) which define the indicated defect size to which reference is made in EN standards.

The application of ultrasonic testing reference blocks containing side drilled holes (SDH) which define an indicated defect size shall be agreed between manufacturer and purchaser.

This standard is applicable to the production of master and standard test blocks to be used when carrying out ultrasonic inspection to the requirements of EN 4050 1 (FBH method).

It is recognized that particular difficulties are encountered with round forging stock and bars due to the wide range of curvatures. For this application, only one block shall be produced to act as both master and standard test block.

Luft- und Raumfahrt - Prüfverfahren für metallische Werkstoffe - Ultraschallprüfung von Stangen, Platten, Schmiedevormaterial und Schmiedestücken - Teil 3: Referenzblöcke

Diese Europäische Norm legt die Anforderungen an Herstellung, Überprüfung und Kennzeichnung der Serie von Ultraschallprüfungs-Referenzblöcken mit Flachbodenbohrungen (FBH) fest, welche die angezeigte Fehlergröße definieren, auf die in EN-Normen verwiesen wird.

Série aérospatiale - Méthode d'essai applicable aux matériaux métalliques - L'inspection par ultrasons des barres, des plaques, des stocks de forgeage et de pièces forgées - Partie 3: Blocs de référence

Aeronavtika - Metode za preskušanje kovinskih materialov - Ultrazvočno preskušanje palic, plošč, kovnih materialov in izkovkov - 3. del: Referenčni ingoti

General Information

- Status

- Published

- Publication Date

- 25-Sep-2012

- Withdrawal Date

- 30-Mar-2013

- Technical Committee

- ASD-STAN - Aerospace

- Drafting Committee

- ASD-STAN/D 4 - Metallic

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 26-Sep-2012

- Completion Date

- 26-Sep-2012

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 4050-3:2012 is a European standard developed by CEN that specifies requirements for the manufacturing, checking, and marking of ultrasonic testing reference blocks used in aerospace materials. These reference blocks contain flat bottom holes (FBH) that represent calibrated defect sizes for ultrasonic inspection of metallic bars, plates, forging stock, and forgings. The standard supports the aerospace series test method for nondestructive ultrasonic inspection techniques, providing traceability and accuracy in defect detection and calibration.

This standard is essential for quality assurance in aerospace manufacturing where ultrasonic inspections are used to detect internal flaws in critical metallic components. EN 4050-3:2012 ensures standardization of reference blocks that serve as calibration benchmarks for ultrasonic equipment, particularly in compliance with the FBH method described in EN 4050-1.

Key Topics

Reference Blocks Types

- Master test blocks: Manufactured from specific aerospace-grade alloys with precise FBH sizes and metal paths for calibration benchmarks.

- Standard test blocks: Produced and calibrated using master blocks, replicating the ultrasonic response necessary for routine inspections.

Materials and Alloys

Materials used for master and standard blocks include aerospace alloys such as aluminium (2024-T3), steel (FE-PM37), titanium alloys (Ti-P64), and nickel-cobalt alloys. The choice depends on the inspected component's material class.Flat Bottom Hole (FBH) Specifications

FBHs are drilled with tight tolerances on diameter, depth, and geometric features to simulate defects accurately. The minimum metal path is generally 3 mm, with adjustments for low-frequency ultrasonic testing.Manufacture and Marking

Blocks are machined to strict ASTM E 127 dimensional tolerances. Each block is identified with a serial number, alloy class, and detailed FBH specifications marked permanently on the block to maintain traceability.Calibration and Checking Procedures

Ultrasonic response characteristics of blocks are verified using immersion technique equipment with probes in the 5-10 MHz range, ensuring consistent defect simulation and amplitude accuracy within ±3 dB. Advanced methods like DGS evaluation or destructive statistical tests may be employed.Special Cases for Round Forgings and Bars

Due to curvature, a single test block may function as both master and standard for these geometries, simplifying inspection protocols while maintaining accuracy.

Applications

Aerospace Industry

Critical for inspecting metallic aerospace components, ensuring reliable detection of internal discontinuities such as cracks, voids, or inclusions in bars, plates, forging stock, and forgings.Ultrasonic NDT Calibration

Provides standardized reference materials for calibrating ultrasonic inspection systems, allowing traceable and reproducible defect size indications consistent across production batches.Quality Assurance Programs

Central to aerospace quality management systems that require conformance to EN 4050 series standards establishing test reliability and component acceptance criteria.Material Integrity Verification

Assists in periodic validation of ultrasonic testing equipment and inspector performance, enhancing safety in aerospace manufacturing and maintenance.

Related Standards

EN 4050-1: Ultrasonic inspection - General requirements

Defines overall principles and procedures for ultrasonic testing of metallic aerospace materials.EN 4050-2: Ultrasonic inspection - Performance of test

Details performance criteria and testing methodology for ultrasonic inspections.EN 4050-4: Ultrasonic inspection - Acceptance criteria

Establishes acceptance thresholds for inspected materials based on ultrasonic test results calibrated with reference blocks.EN 2278 / EN 2321 / EN 3311: Aerospace Material Specifications

Define the chemical and mechanical properties of aerospace alloys used in manufacture of test blocks and inspected components.ASTM E 127: Standard practice for fabricating and checking ultrasonic reference blocks

Provides general machining and checking guidelines referenced for geometric tolerance compliance.

Keywords: EN 4050-3, ultrasonic inspection, aerospace materials, metallic bars, forging stock, reference blocks, flat bottom holes, FBH, nondestructive testing, NDT calibration, aerospace standards, ultrasonic testing reference blocks, master test blocks, standard test blocks, ASTM E 127, defect simulation, ultrasonic calibration, aerospace quality assurance

Get Certified

Connect with accredited certification bodies for this standard

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Element Materials Technology

Materials testing and product certification.

Sponsored listings

Frequently Asked Questions

EN 4050-3:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Aerospace series - Test method for metallic materials - Ultrasonic inspection of bars, plates, forging stock and forgings - Part 3: Reference blocks". This standard covers: This European Standard specifies the requirements for the manufacture, checking and marking of the series of ultrasonic testing reference blocks containing flat bottom holes (FBH) which define the indicated defect size to which reference is made in EN standards. The application of ultrasonic testing reference blocks containing side drilled holes (SDH) which define an indicated defect size shall be agreed between manufacturer and purchaser. This standard is applicable to the production of master and standard test blocks to be used when carrying out ultrasonic inspection to the requirements of EN 4050 1 (FBH method). It is recognized that particular difficulties are encountered with round forging stock and bars due to the wide range of curvatures. For this application, only one block shall be produced to act as both master and standard test block.

This European Standard specifies the requirements for the manufacture, checking and marking of the series of ultrasonic testing reference blocks containing flat bottom holes (FBH) which define the indicated defect size to which reference is made in EN standards. The application of ultrasonic testing reference blocks containing side drilled holes (SDH) which define an indicated defect size shall be agreed between manufacturer and purchaser. This standard is applicable to the production of master and standard test blocks to be used when carrying out ultrasonic inspection to the requirements of EN 4050 1 (FBH method). It is recognized that particular difficulties are encountered with round forging stock and bars due to the wide range of curvatures. For this application, only one block shall be produced to act as both master and standard test block.

EN 4050-3:2012 is classified under the following ICS (International Classification for Standards) categories: 49.025.05 - Ferrous alloys in general; 49.025.15 - Non-ferrous alloys in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 4050-3:2012 has the following relationships with other standards: It is inter standard links to EN 4050-4:2012, EN 3311:2023, EN 4050-2:2012, EN 4050-1:2012, EN 12392:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 4050-3:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.YRþQRLuft- und Raumfahrt - Prüfverfahren für metallische Werkstoffe - Ultraschallprüfung von Stangen, Platten, Schmiedevormaterial und Schmiedestücken - Teil 3: ReferenzblöckeSérie aérospatiale - Méthode d'essai applicable aux matériaux métalliques - L'inspection par ultrasons des barres, des plaques, des stocks de forgeage et de pièces forgées - Partie 3: Blocs de référenceAerospace series - Test method for metallic materials - Ultrasonic inspection of bars, plates, forging stock and forgings - Part 3: Reference blocks49.035Sestavni deli za letalsko in vesoljsko gradnjoComponents for aerospace construction49.025.01Materiali za letalsko in vesoljsko gradnjo na splošnoMaterials for aerospace construction in generalICS:Ta slovenski standard je istoveten z:EN 4050-3:2012SIST EN 4050-3:2014en01-marec-2014SIST EN 4050-3:2014SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 4050-3

September 2012 ICS 49.025.05; 49.025.15 English Version

Aerospace series - Test method for metallic materials - Ultrasonic inspection of bars, plates, forging stock and forgings -Part 3: Reference blocks

Série aérospatiale - Méthode d'essai applicable aux matériaux métalliques - L'inspection par ultrasons des barres, des assiettes, des stocks de forgeage et de pièces forgées - Partie 3: Blocs de référence

Luft- und Raumfahrt - Prüfverfahren für metallische Werkstoffe - Ultraschallprüfung von Stangen, Platten, Schmiedevormaterial und Schmiedestücken - Teil 3: Referenzblöcke This European Standard was approved by CEN on 15 July 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 4050-3:2012: ESIST EN 4050-3:2014

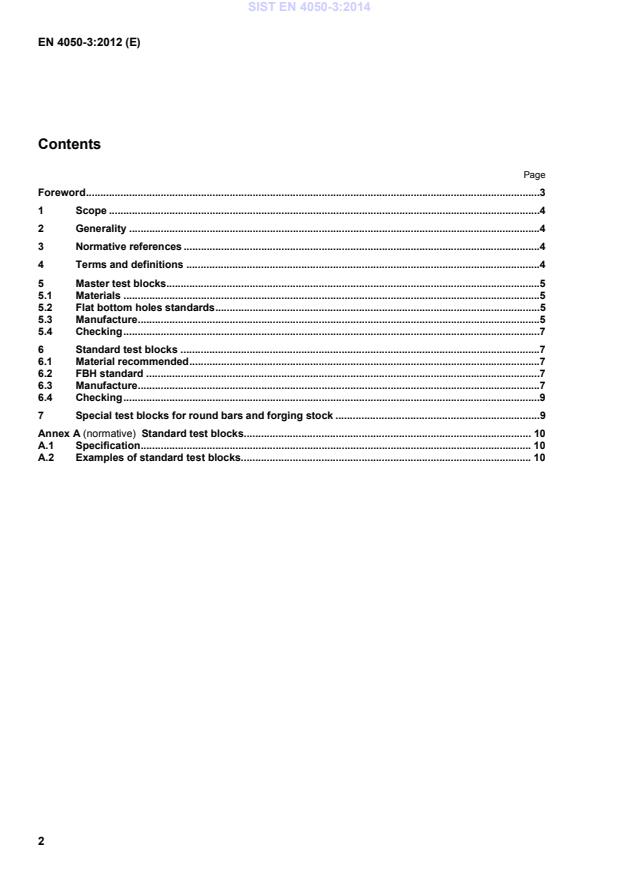

Standard test blocks. 10A.1Specification . 10A.2Examples of standard test blocks. 10 SIST EN 4050-3:2014

1) Published as ASD-STAN Standard at the date of publication of this standard. 2) Published as ASD-STAN Prestandard at the date of publication of this standard. 3) Published by: American Society for Testing and Materials (ASTM) 1916 Race Street, Philadelphia, PA. SIST EN 4050-3:2014

5.2 Flat bottom holes standards Flat bottom holes in the master test blocks shall be used to calibrate standard test blocks. The master test blocks shall have FBH at different metal paths to suit the product range to be inspected. It shall be ensured however that there is sufficient number with a minimum of three different metal paths to accurately produce the required distance/amplitude curve (see 5.4.2.2). 5.3 Manufacture 5.3.1 Material procurement Material for each set of master test blocks shall be obtained from the same cast, forging and heat treatment batch.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...