CEN/TR 15276-1:2009

(Main)Fixed firefighting systems - Condensed aerosol extinguishing systems - Part 1: Requirements and test methods for components

Fixed firefighting systems - Condensed aerosol extinguishing systems - Part 1: Requirements and test methods for components

This document specifies requirements, describes test methods for condensed aerosol extinguishing components and covers solely condensed aerosols.

This document is not intended to indicate approval of the extinguishants listed herein by the appropriate authorities, as other extinguishants may be equally acceptable.

This document is intended as a standard covering solely condensed aerosol.

The condensed aerosol generator typically consists of the following main components:

a) solid aerosol-forming compound;

b) cooling mechanism;

c) ignition device(s);

d) end plate discharge outlet(s);

e) housing;

f) mounting bracket.

This document does not cover dispersed aerosols.

This document requires, as a precaution, that the room is evacuated and sealed off whenever a generator is activated. Precautions include evacuation of the proximity area, criteria for re-entering and other safeguards as stated in Clause 5 of CEN/TR 15276-2:2009.

Ortsfeste Brandbekämpfungsanlagen - Löschanlagen für kondensierte Aerosole - Teil 1: Anforderungen und Prüfverfahren für Bauteile

Dieses Dokument legt Anforderungen fest und beschreibt Prüfverfahren für Bauteile für Aerosol-Löschanlagen,

die ausschließlich kondensierte Aerosole verwenden.

Dieses Dokument ist nicht als Zulassung der hier aufgeführten Löschmittel durch die zuständigen Stellen

vorgesehen, da andere Löschmittel ebenso zulässig sein können.

Dieses Dokument behandelt keine Dispersions-Aerosole.

Installations fixes de lutte contre l'incendie - Systèmes d'extinction à aérosol - Partie 1 : Exigences et méthodes d'essais pour les éléments constitutifs

Le présent document spécifie les exigences, décrit les méthodes d'essai relatives aux composants d'extinction des aérosols de condensation et ne couvre que les aérosols de condensation.

Le présent document n'est pas destiné à indiquer l'approbation des agents extincteurs énumérés ici, par les autorités compétentes, car d'autres agents extincteurs peuvent être également acceptables.

Ce document ne s’applique qu’aux aérosols de condensation.

Le générateur d'aérosol de condensation comprend habituellement les composants principaux suivants :

a) composé solide générateur d’aérosol ;

b) mécanisme de refroidissement ;

c) dispositif(s) d'allumage ;

d) sortie(s) d’émission en plaque d'extrémité ;

e) boîtier ;

f) support de montage.

Le présent document ne couvre pas les aérosols dispersés.

Le présent document exige, comme précaution, que la pièce soit évacuée et que l'accès en soit interdit dès qu'un générateur est activé. Les précautions incluent l'évacuation de la zone à proximité, les critères de retour dans la pièce et autres mesures de sauvegarde, comme cela est indiqué à l'Article 5 du CEN/TR 15276 2:2009.

Vgrajeni gasilni sistemi - Sistemi za gašenje s kondenziranim aerosolom - 1. del: Zahteve in preskusne metode za sestavne dele

General Information

- Status

- Withdrawn

- Publication Date

- 13-Jan-2009

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 191 - Fixed firefighting systems

- Drafting Committee

- CEN/TC 191/WG 6 - Gas extinguishing Systems and components

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 03-Apr-2019

- Completion Date

- 09-Feb-2026

Relations

- Effective Date

- 10-Apr-2019

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 622-5:2009 - Fibreboards - Specifications - Part 5: Requirements for dry process boards (MDF) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 13262:2004/FprA2 - Railway applications - Wheelsets and bogies - Wheels - Product requirements - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

CEN/TR 15276-1:2009 is a technical report published by the European Committee for Standardization (CEN). Its full title is "Fixed firefighting systems - Condensed aerosol extinguishing systems - Part 1: Requirements and test methods for components". This standard covers: This document specifies requirements, describes test methods for condensed aerosol extinguishing components and covers solely condensed aerosols. This document is not intended to indicate approval of the extinguishants listed herein by the appropriate authorities, as other extinguishants may be equally acceptable. This document is intended as a standard covering solely condensed aerosol. The condensed aerosol generator typically consists of the following main components: a) solid aerosol-forming compound; b) cooling mechanism; c) ignition device(s); d) end plate discharge outlet(s); e) housing; f) mounting bracket. This document does not cover dispersed aerosols. This document requires, as a precaution, that the room is evacuated and sealed off whenever a generator is activated. Precautions include evacuation of the proximity area, criteria for re-entering and other safeguards as stated in Clause 5 of CEN/TR 15276-2:2009.

This document specifies requirements, describes test methods for condensed aerosol extinguishing components and covers solely condensed aerosols. This document is not intended to indicate approval of the extinguishants listed herein by the appropriate authorities, as other extinguishants may be equally acceptable. This document is intended as a standard covering solely condensed aerosol. The condensed aerosol generator typically consists of the following main components: a) solid aerosol-forming compound; b) cooling mechanism; c) ignition device(s); d) end plate discharge outlet(s); e) housing; f) mounting bracket. This document does not cover dispersed aerosols. This document requires, as a precaution, that the room is evacuated and sealed off whenever a generator is activated. Precautions include evacuation of the proximity area, criteria for re-entering and other safeguards as stated in Clause 5 of CEN/TR 15276-2:2009.

CEN/TR 15276-1:2009 is classified under the following ICS (International Classification for Standards) categories: 13.220.20 - Fire protection. The ICS classification helps identify the subject area and facilitates finding related standards.

CEN/TR 15276-1:2009 has the following relationships with other standards: It is inter standard links to EN 15276-1:2019, EN 60068-2-6:2008, EN IEC 60068-2-30:2025, EN 15154-5:2019, EN 622-3:2004, EN 622-5:2009, EN 622-4:2024, EN 622-2:2004, EN 316:2009, EN 622-1:2003, EN 13262:2004/FprA2, CEN/TR 15276-2:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

CEN/TR 15276-1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-april-2009

Vgrajeni gasilni sistemi - Sistemi za gašenje s kondenziranim aerosolom - 1. del:

Zahteve in preskusne metode za sestavne dele

Fixed firefighting systems - Condensed aerosol extinguishing systems - Part 1:

Requirements and test methods for components

Ortsfeste Brandbekämpfungsanlagen - Löschanlagen für kondensierte Aerosole - Teil 1:

Anforderungen und Prüfverfahren für Bauteile

Installations fixes de lutte contre l'incendie - Systemes d'extinction a aérosol - Partie 1 :

Exigences et méthodes d'essais pour les éléments constitutifs

Ta slovenski standard je istoveten z: CEN/TR 15276-1:2009

ICS:

13.220.10 Gašenje požara Fire-fighting

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

TECHNICAL REPORT

CEN/TR 15276-1

RAPPORT TECHNIQUE

TECHNISCHER BERICHT

January 2009

ICS 13.220.20

English Version

Fixed firefighting systems - Condensed aerosol extinguishing

systems - Part 1: Requirements and test methods for

components

Installations fixes de lutte contre l'incendie - Systèmes Ortsfeste Brandbekämpfungsanlagen - Löschanlagen für

d'extinction à aérosol - Partie 1 : Exigences et méthodes kondensierte Aerosole - Teil 1: Anforderungen und

d'essais pour les éléments constitutifs Prüfverfahren für Bauteile

This Technical Report was approved by CEN on 9 September 2008. It has been drawn up by the Technical Committee CEN/TC 191.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,

Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2009 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TR 15276-1:2009: E

worldwide for CEN national Members.

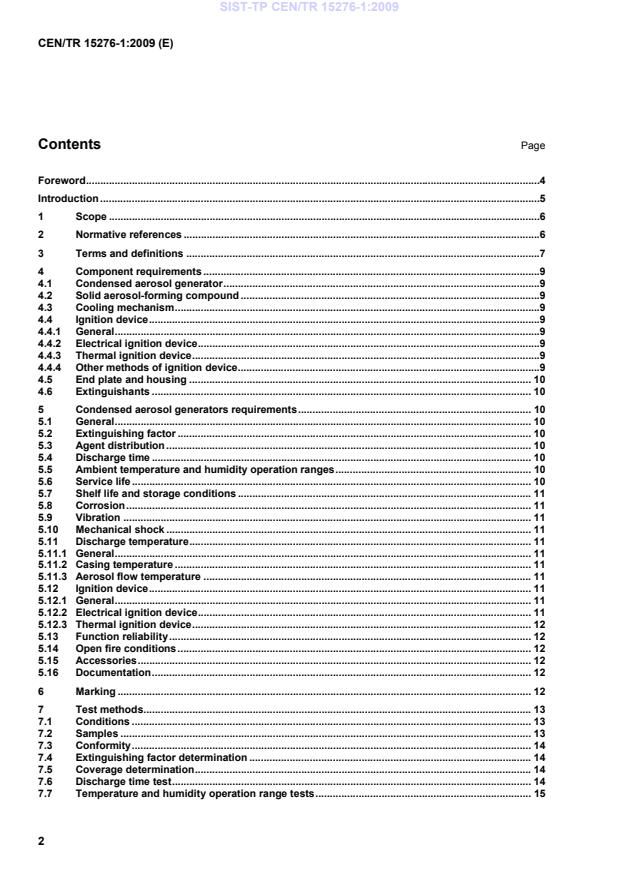

Contents Page

Foreword .4

Introduction .5

1 Scope .6

2 Normative references .6

3 Terms and definitions .7

4 Component requirements .9

4.1 Condensed aerosol generator .9

4.2 Solid aerosol-forming compound .9

4.3 Cooling mechanism .9

4.4 Ignition device .9

4.4.1 General .9

4.4.2 Electrical ignition device .9

4.4.3 Thermal ignition device .9

4.4.4 Other methods of ignition device.9

4.5 End plate and housing . 10

4.6 Extinguishants . 10

5 Condensed aerosol generators requirements . 10

5.1 General . 10

5.2 Extinguishing factor . 10

5.3 Agent distribution . 10

5.4 Discharge time . 10

5.5 Ambient temperature and humidity operation ranges . 10

5.6 Service life . 10

5.7 Shelf life and storage conditions . 11

5.8 Corrosion . 11

5.9 Vibration . 11

5.10 Mechanical shock . 11

5.11 Discharge temperature . 11

5.11.1 General . 11

5.11.2 Casing temperature . 11

5.11.3 Aerosol flow temperature . 11

5.12 Ignition device . 11

5.12.1 General . 11

5.12.2 Electrical ignition device . 11

5.12.3 Thermal ignition device . 12

5.13 Function reliability . 12

5.14 Open fire conditions . 12

5.15 Accessories . 12

5.16 Documentation . 12

6 Marking . 12

7 Test methods . 13

7.1 Conditions . 13

7.2 Samples . 13

7.3 Conformity . 14

7.4 Extinguishing factor determination . 14

7.5 Coverage determination . 14

7.6 Discharge time test . 14

7.7 Temperature and humidity operation range tests . 15

7.7.1 Object of the test . 15

7.7.2 Test procedure . 15

7.7.3 Low temperature Test . 15

7.8 Accelerated ageing test . 15

7.8.1 Test time . 15

7.8.2 Test procedure . 16

7.9 Corrosion test . 16

7.10 Stress corrosion test. 17

7.11 Vibration test . 17

7.12 Impact test . 18

7.12.1 Test procedure . 18

7.12.2 Test apparatus . 18

7.13 Drop test . 20

7.13.1 Impact surface . 20

7.13.2 Procedure . 20

7.13.3 Requirements . 20

7.14 Casing and aerosol flow temperatures test . 20

7.14.1 Casing temperature test . 20

7.14.2 Aerosol flow temperature test . 20

7.15 Ignition performance test . 20

7.16 Function test . 20

7.16.1 Discharge time . 21

7.16.2 Aerosol flow temperatures . 21

7.16.3 Test procedure . 21

7.16.4 Casing temperature test . 21

7.16.5 Discharged mass . 21

7.16.6 Explosive atmosphere actuation test . 21

7.16.7 Requirements . 22

7.17 Heat exposure test . 22

7.17.1 Object of the test . 22

7.17.2 Test procedure . 22

7.17.3 Requirements . 22

7.18 Explosive atmosphere test . 22

7.18.1 Object of the test. . 22

7.18.2 Test procedure . 23

7.18.3 Requirements . 23

Annex A (normative) Extinguishing factor/coverage test procedure . 24

Bibliography . 47

Foreword

This document (CEN/TR 15276-1:2009) has been prepared by Technical Committee CEN/TC 191 “Fixed

firefighting systems”, the secretariat of which is held by BSI.

This document has the general title Fixed fire-fighting systems – Condensed aerosol extinguishing systems

and will consist of the following parts:

Part 1: Requirements and test methods for components;

Part 2: Design, installation and maintenance.

Introduction

It has been assumed in the preparation of this document that the execution of its provisions is entrusted to

appropriately qualified and experienced people in the specification, design, installation, testing, approval,

inspection, operation and maintenance of systems and equipment, for whose guidance it has been prepared,

and who can be expected to exercise a duty of care to avoid unnecessary release of extinguishant.

Product certification: Users of this document are advised to consider the desirability of independent

certification of product conformity with this document based on testing and continuing surveillance, which may

be coupled with assessment of manufacturer quality systems against EN ISO 9001.

Fire-fighting systems covered in this document are designed to provide a supply of fixed condensed aerosol

extinguishing medium to extinguish fire.

The requirements of this document are made in the light of the best technical data known to the working group

at the time of writing but, since a wide field is covered, it has been impracticable to consider every possible

factor or circumstance that might affect implementation of the requirements.

It is important that the fire protection of a building or plant be considered as a whole. Aerosol extinguishant

systems form only a part, though an important part, of the available facilities, but it should not be assumed that

their adoption necessarily removes the need to consider supplementary measures, such as the provision of

portable fire extinguishers or other mobile appliances for first aid or emergency use, or to deal with special

hazards.

Aerosol extinguishants have been recognized as effective media for the extinction of Class A fires (solid

surface burning fires) and Class B and Class C fires according to EN 2, but it should not be forgotten, in the

planning of comprehensive schemes, that there may be hazards for which these mediums are not suitable, or

that in certain circumstances or situations there may be dangers in their use requiring special precautions.

Advice on these matters can be obtained from the appropriate manufacturer of the aerosol generators or the

extinguishing system. Information may also be sought from the appropriate fire authority, the health and safety

authorities and insurers. In addition, reference should be made as necessary to other national standards and

statutory regulations.

It is essential that fire-fighting equipment be carefully maintained to ensure instant readiness when required.

Routine maintenance is liable to be overlooked or given insufficient attention by the owner of the system. It is,

however, neglected at peril to the lives of occupants of the premises and at the risk of crippling financial loss.

The importance of maintenance cannot be too highly emphasised.

Condensed aerosol may contain traces of toxic substances like those produced by a fire, and will obscure

vision like smoke from fire.

1 Scope

This document specifies requirements, describes test methods for condensed aerosol extinguishing

components and covers solely condensed aerosols.

This document is not intended to indicate approval of the extinguishants listed herein by the appropriate

authorities, as other extinguishants may be equally acceptable.

This document is intended as a standard covering solely condensed aerosol.

The condensed aerosol generator typically consists of the following main components:

a) solid aerosol-forming compound;

b) cooling mechanism;

c) ignition device(s);

d) end plate discharge outlet(s);

e) housing;

f) mounting bracket.

This document does not cover dispersed aerosols.

This document requires, as a precaution, that the room is evacuated and sealed off whenever a generator is

activated. Precautions include evacuation of the proximity area, criteria for re-entering and other safeguards

as stated in Clause 5 of CEN/TR 15276-2:2009.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

EN 316, Wood fibreboards – Definition, classification and symbols

EN 622 (all parts), Fibreboards – Specifications

EN 60068-2-6, Environmental testing – Part 2-6: Tests – Test Fc: Vibration (sinusoidal) (IEC 60068-2-6:2007)

EN 60068-2-30, Environmental testing – Part 2-30: Tests – Test Db: Damp Heat, cyclic (12 h + 12 h cycle)

(IEC 60068-2-30:2005)

ISO 209, Aluminium and aluminium alloys – Chemical composition

ISO 5660-1, Reaction-to-fire tests – Heat release, smoke production and mass loss rate – Part 1: Heat

release rate (cone calorimeter method)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

authority

organisation, office or individual responsible for approving equipment, installations or procedures in

determining acceptability

NOTE The authority may base acceptance on conformity to the appropriate standards.

3.2

clearance

3.2.1

electrical clearance

unobstructed air distance between extinguishing system equipment and unenclosed or uninsulated live

electrical components not at ground potential

3.2.2

thermal clearance

air distance between a condensed aerosol generator and any structure or components sensitive to the

temperature developed by the generator

3.3

condensed aerosol

extinguishing medium consisting of finely divided solid particles and gaseous matter, these being generated

by a combustion process of a solid aerosol-forming compound

3.4

condensed aerosol generator

non-pressurised device which, when activated, generates an aerosol. It includes the mounting brackets

3.5

design factor

extinguishing factor multiplied by the safety factor, required for system design purposes

NOTE 1 The design factor is expressed in grams per cubic metre.

NOTE 2 Extinguishing factor and design factor have been introduced as an alternative to extinguishing concentration

and design concentration respectively as concentration of the actual aerosol cannot be measured or even assessed in

some cases (the discharged medium, apart from the condensed aerosol, may contain products of the thermal

decomposition of a chemical coolant).

3.6

discharge time

time from the generator activation to the end of its discharge

3.7

extinguishing application density

minimum mass of a specific aerosol-forming compound per cubic metre of enclosure volume required to

extinguish fire involving a specific fuel under defined experimental conditions, excluding any safety factors

NOTE The extinguishing factor is expressed in grams per cubic metre.

3.8

family

group of generators with same solid compound, same kind of cooling device, same kind of discharge outlet,

same ignition device, same layout and same internal/external architecture

3.9

ignition device

any device which is able to ignite the solid aerosol-forming compound

3.10

listing authority

recognized fire protection testing and approval body (notified laboratory)

3.11

maintenance

thorough check to give maximum assurance that the extinguishing system will operate as intended

NOTE It includes a thorough examination and any necessary repair or replacement of system components.

3.12

manufacturer

legal person that is responsible for the design, manufacturing, packaging and quality assurance of a device

before it is placed on the market

3.13

monitoring

supervision of the operating integrity of an electrical, mechanical, pneumatic or hydraulic control feature of a

system

3.14

protected volume

volume enclosed by the building elements around the protected enclosure, minus the volume of any

permanent impermeable building element within the enclosure

3.15

release

physical discharge or emission of an aerosol as a consequence of the generator actuation

3.16

safety factor

multiplier of the extinguishing factor to determine the design factor

3.17

solid aerosol-forming compound

mixture of oxidant, combustible component and technical admixtures producing fire extinguishing aerosol

upon ignition

3.18

supplier

legal person that is responsible for the product and is able to ensure that its quality is ensured

3.19

thermal ignition device

device which automatically operates at a rated temperature and is arranged for the ignition of the solid

aerosol-forming compound

3.20

test house

establishment having all relevant test equipment to carry out the required tests

4 Component requirements

4.1 Condensed aerosol generator

The condensed aerosol generator typically consists of the following main components:

a) solid aerosol-forming compound;

b) cooling mechanism;

c) ignition device(s);

d) end plate discharge outlet(s);

e) housing;

f) mounting bracket.

The generator is a non-pressurised canister, because aerosol is generated and distributed by the combustion

process of the solid aerosol-forming compound.

4.2 Solid aerosol-forming compound

Upon actuation of the condensed aerosol generator, the solid aerosol-forming compound shall undergo the

combustion reaction producing a fire extinguishing aerosol.

4.3 Cooling mechanism

The cooling mechanism shall provide an adequate cooling of the hot aerosol prior to its discharge into the

enclosure.

4.4 Ignition device

4.4.1 General

The ignition device is arranged to initiate the aerosol-forming compound.

If the ignition device is a complex device incorporating several components, all such components shall be

specified by the manufacturer.

4.4.2 Electrical ignition device

The electrical ignition device shall be capable of operating via an electrical input and arranged to initiate the

aerosol-forming compound.

4.4.3 Thermal ignition device

The thermal ignition device shall be capable of operating at a rated temperature and arranged to initiate the

aerosol-forming compound.

4.4.4 Other methods of ignition device

Methods capable to ignite the aerosol-forming compound, other than 4.4.2 and 4.4.3, shall be specified.

4.5 End plate and housing

The outer case and all parts inside the generator shall be made of corrosion-resistant material or shall be

suitably treated to resist corrosion. The manufacturer shall ensure that the materials of construction are also

compatible with the solid aerosol-forming compound and the cooling device so that corrosion or chemical

action does not occur.

Materials for non-metallic components that are exposed to ultraviolet light shall be UV-stabilised.

4.6 Extinguishants

The extinguishants referred to in this document are electrically non-conductive media.

5 Condensed aerosol generators requirements

5.1 General

The test samples shall conform to the technical description (drawings, parts list, description of function,

operating instructions) as stated by the manufacturer (see 5.16 and 7.3).

The manufacturer shall specify the minimum distance from the generator outlet to the first obstacle.

The manufacturer shall specify the minimum and maximum mass of aerosol compound discharged from the

generator

5.2 Extinguishing factor

The extinguishing factor for specific fuels under different classes of fires shall be determined by test using the

fire test protocol described in Annex A.

5.3 Agent distribution

The maximum area coverage and the related maximum and minimum height of the protected enclosure for

each aerosol generator unit size shall be determined by test using the fire test protocol described in 7.5.

5.4 Discharge time

The discharge time required to achieve 95 % of the minimum design application density shall be specified by

the manufacturer and shall not exceed 90 s when tested in accordance with 7.6.

5.5 Ambient temperature and humidity operation ranges

Condensed aerosol generators shall operate at ambient temperatures as specified by the manufacturer and

as a minimum requirement from – 20 °C to + 50 °C.

Condensed aerosol generators shall operate at ambient humidity up to 95 %.

These operation ranges shall be verified by the temperature and humidity operation range tests as described

in 7.7.

5.6 Service life

The service life of condensed aerosol generator under specific conditions, as described in 5.5, shall be

specified by the manufacturer and as a minimum requirement shall not be less than 5 years.

The specified service life shall be verified by test using the accelerated ageing test as described in 7.8.

5.7 Shelf life and storage conditions

The shelf life and storage conditions shall be specified by the manufacturer.

5.8 Corrosion

The aerosol generator shall operate according to 7.16 and shall show no sign of damage which could alter the

proper extinguishing action after being subjected to the corrosion test described in 7.9.

Any copper alloy part used in the component shall not crack, when tested in accordance with 7.10 (stress

corrosion test).

5.9 Vibration

The aerosol generator shall operate according to 7.16 after being subjected to a vibration test described in

7.11.

5.10 Mechanical shock

The aerosol generator shall operate according to 7.16 after being subjected to an impact test as described in

7.12.

The aerosol generator shall operate according to 7.16 after being subjected to a drop test as described in

7.13.

5.11 Discharge temperature

5.11.1 General

The requirements of 5.11.2 and 5.11.3 shall be verified by test according to the procedure described in 7.14.

5.11.2 Casing temperature

The manufacturer shall specify the maximum developed temperature for aerosol casing that shall not exceed

400 °C.

5.11.3 Aerosol flow temperature

The manufacturer shall specify the distance from the aerosol generator discharge outlet to the point where the

temperatures do not exceed 75 °C, 200 °C and 400 °C.

5.12 Ignition device

5.12.1 General

The characteristics of the ignition device shall be verified and the reliability of operation tested by using the

test method as described in 7.15.

5.12.2 Electrical ignition device

The manufacturer shall specify at least the minimum activation current and its duration, form of the signal,

maximum monitoring current, range of voltage and the type of connection for a multiple generators

arrangement.

5.12.3 Thermal ignition device

The manufacturer shall specify at least the minimum rated temperature at which the device operates.

5.13 Function reliability

When activated, the aerosol generator shall operate satisfactorily when tested in accordance with the

procedure described in 7.16 (Function test).

Any generator’s family shall be actuated inside an explosive atmosphere. The actuation of the generator shall

not initiate any explosion.

5.14 Open fire conditions

The aerosol generator, when intended for installation inside the protected enclosure, shall pass the function

test after being subjected to the heat exposure test as described in 7.17.

5.15 Accessories

The mounting bracket shall be tested together with the generator for corrosion, vibration and mechanical

shock impacts as described in 7.9, 7.11, 7.12 and 7.13.

5.16 Documentation

The manufacturer shall prepare and maintain documentation.

The manufacturer shall prepare installation and user documentation, which shall be submitted to the testing

authority together with the sample(s). This documentation shall comprise at least the following:

a) a general description of the components;

b) a technical specification including:

1) information mentioned in 5.1 and 7.16.6;

2) sufficient information to permit an assessment of the compatibility with other components of the

system (if applicable e.g. mechanical, electric or software compatibility);

c) installation instructions including mounting instructions;

d) operating instructions;

e) maintenance instructions.

The manufacturer shall prepare design documentation, which shall be submitted to the testing authority

together with the sample(s). This documentation shall include drawings, parts lists, block diagrams (if

applicable), circuit diagrams (if applicable) and a functional description to such an extent that conformity to this

document may be checked and that a general assessment of the design is possible.

6 Marking

Each generator shall be marked with the following information:

a) name of the product;

b) manufacturer's or supplier's name or trade mark;

c) some mark(s) or code(s) (e.g. serial number or batch code), by which, at least, the date or batch and

place of manufacture (if several places of manufacture) can be identified by the manufacturer;

d) mass of aerosol-forming compound;

e) date of manufacture;

f) temperature range;

g) storage humidity range;

h) service life;

i) distances as specified in 5.11.3.

The markings shall be non-detachable, non-flammable, permanent and legible.

7 Test methods

7.1 Conditions

The components shall be tested assembled as recommended for installation by the manufacturer. The tests

shall be carried at a temperature of (25 ± 10) °C, except when otherwise stated.

The tolerance for all test parameters is ± 5 %, unless otherwise stated.

7.2 Samples

The manufacturer shall submit for tests 100 samples from the same batch. From this number, 20 samples

shall be tested according to the function test in 7.16 only.

The order of tests (with the exception of the compliance test and the functional test) may be changed by the

testing authority.

The sequence of tests is shown in Table 1 and is given by the numbers 1, 2, 3 etc. in the Table. A, B etc. are

the different samples.

Table 1 — Test order for samples

Test method Test order for sample

A B C D E F G H

7.3 Conformity 1 1 1 1 1 1 1 1

7.6 Discharge time test 2

7.7.2 Temperature and humidity test 2 2

7.7.3 Low temperature test 3

7.8 Accelerated ageing test 2

7.9 Corrosion test 2

7.10 Stress corrosion test 2

7.11 Vibration test 2

7.12 Impact test 2

7.13 Drop test 2

7.14 Casing and aerosol flow 3

temperatures tests

7.16 Function test 2 4 3 3 3 3 4

7.17 Heat exposure test 2

7.3 Conformity

A visual and measurement check shall be made to determine whether the condensed aerosol generator

corresponds to the description in the technical literature (drawings, parts lists, description of functions,

operating and installation instructions).

7.4 Extinguishing factor determination

NOTE This test relates to the requirements of 5.2.

The extinguishing factor for specific fuels under different classes of fires shall be determined by specific test

using the fire test procedure described in Annex A.

Extinguishing factor tests should be conducted with generator(s) of the same family. Number of aerosol

generator units shall be sufficient to provide needed extinguishing factor in the test enclosure. Mass of

generators unit prior and after discharge shall be registered. Other generators unit sizes which belong to the

same family shall be subjected to a cold discharge. Mass prior to and after discharge shall be registered.

These data shall be compared to results from fire tests to get extinguishing factor for each generator unit type.

7.5 Coverage determination

NOTE This test relates to the requirements of 5.3.

The maximum coverage and maximum and minimum height of the protected enclosure for each aerosol

generator unit size shall be determined by test using the fire test procedures as described in Annex A.

7.6 Discharge time test

NOTE This test relates to the requirements of 5.4.

Discharge time test is integral part of the function test. See 7.16.1 for the discharge time test procedure.

7.7 Temperature and humidity operation range tests

NOTE The tests relate to the requirements of 5.5.

7.7.1 Object of the test

The object of the test is to demonstrate the ability of the equipment to function correctly at high relative

humidity (with condensation) which may occur for short periods in the anticipated service environment.

7.7.2 Test procedure

7.7.2.1 General

The test procedure as described in EN 60068-2-30, using the variant 1 test cycle and controlled recovery

conditions shall be used.

7.7.2.2 Conditioning

Apply the following severity of conditioning:

a) lower temperature: (25 ± 3) °C

b) upper temperature: (55 ± 2) °C

c) relative humidity at lower temperature: (93 ± 3) %

d) relative humidity at upper temperature: (93 ± 3) %

e) number of cycles: 2

7.7.2.3 Final measurements

After the recovery period, the sample shall be visually checked for mechanical damage externally, and shall

be subjected to the function test.

7.7.2.4 Requirements

When subjected to the function test, the sample shall respond correctly.

7.7.3 Low temperature Test

Condition the sample at – 20°C, or the service temperature recommended by the manufacturer whichever is

the lower, for (2 ± 0,5) h.

Then carry out function test immediately. When subjected to the function test, the sample shall respond

correctly.

7.8 Accelerated ageing test

NOTE This test relates to the requirements of 5.6.

7.8.1 Test time

The test time shall be calculated to fulfil requirements as follows:

t

2 ∆∆∆∆T/10

= 2 (1)

t

where

t test time, in days

t expected service life, in days

∆T = T - T

1 2

T test temperature, in degrees Kelvin

T equivalent storage temperature, in degrees Kelvin

Table 2 — Example for the calculation result of formula (1) at T = 25 °C

Test temperature T Test days for 10 years Test days for 5 years

expected service life expected service life

363,15K (90°C) 40 days 20 days

373,15K (100°C) 20 days 10 days

7.8.2 Test procedure

a) Tests are performed on three fully assembled condensed aerosol generators of the selected model

size(s).

b) The manufacturer shall specify the maximum operation temperature and expected service life.

c) The generators shall be subjected to air-oven ageing at temperature T , which shall be at least 10 °C

higher than the specified maximum operation temperature, for a period of t days as calculated by

Equation (1).

d) Following the ageing test the aerosol generators shall be subjected to and pass the function test.

7.9 Corrosion test

NOTE The tests relate to the requirements of 5.8.

The sample shall be exposed to a salt spray within a fog chamber.

The essential components and properties of the reagents and the test configuration are:

Solution consisting of NaCl in distilled water;

Concentration of the solution: (5 ± 1) %;

pH Value: 6,5 to 7,5;

Spray pressure: 0,6 bar to 1,5 bar;

Spray volume: 1 ml/h to 2 ml/h on an area of 80 cm ;

+1,0

Temperature in test cabinet: (35 ) °C;

−1,7

Position of the sample: 15° to the vertical axis;

Spray time: (240 ± 2) h;

Drying time: (168 ± 5) h at a humidity of maximum 70 %.

The sample shall be inspected for external mechanical damage and shall be subjected to a function test in

accordance with 7.16.

7.10 Stress corrosion test

The aqueous ammonia solution shall have a specific weight of (0,94 ± 0,02) kg/l. The sample shall be filled

with (10 ± 0,5) ml of the solution for each litre of container volume.

The sample shall be degreased for the test and shall be exposed for 10 days to the moist atmosphere of

ammonia and air, at a temperature of (34 ± 2) °C. The samples shall be positioned (40 ± 5) mm above the

level of the liquid.

After testing, the samples shall be cleaned and dried and subjected to careful visual examination. To make

cracking clearly visible, the liquid penetration method shall be used.

7.11 Vibration test

NOTE This test relates to the requirements of 5.9.

The drawings and the technical data shall be checked to determine whether vibration could have an adverse

effect on the performance of the non-electrical disable device.

If necessary, vibration tests shall be carried out either in the standby position, loaded position or unlocked

position.

The sample is attached to a vibration table using fixing materials provided by the manufacturer.

The test apparatus and procedure shall be as described in EN 60068-2-6, Test F :

c

Frequency range: 10 Hz to 150 Hz

Acceleration amplitude for components which are designed to be attached to machinery:

10 Hz to 50 Hz: 9,81 m/s (= 1,0 g )

n

50 Hz to 150 Hz: 29,43 m/s (= 3,0 g )

n

Acceleration amplitude for components which are designed to be attached to walls:

10 Hz to 50 Hz: 1,962 m/s (= 0,2 g

n)

50 Hz to 150 Hz: 4,905 m/s (= 0,5 g

)

n

Sweep rate: 1 octave per 30 min

Number of sweeps: 0,5 per axis

Number of axes: 3 mutually perpendicular

The sample shall not operate during the test as a result of the vibrations.

No deterioration or detachment of parts shall occur. The sample shall be inspected for external mechanical

damage and shall be subjected to a function test in accordance with 7.16.

7.12 Impact test

NOTE This test relates to the requirements of 5.10.

7.12.1 Test procedure

The test apparatus shall consist of a swinging hammer incorporating a rectangular-section aluminium alloy

head (Aluminium alloy AlCu SiMg conforming to ISO 209, solution treated and precipitation treated condition)

with the plane impact face chamfered to an angle of (60 ± 1)° to the horizontal, when in the striking position. A

suitable apparatus is described in Figure 1 – Impact test apparatus.

The specimen shall be rigidly mounted to the apparatus by its normal mounting means and shall be positioned

so that it is struck by part of the upper half of the impact face of the hammer (i.e. above the centre line), when

the hammer is in the vertical position (i.e. when the hammer-head is moving horizontally). The direction of

impact relative to the specimen shall be chosen as the most likely to impair the normal functioning of the

specimen.

A horizontal blow shall be delivered to the specimen at an impact energy level of (1,9 ± 0,1) J by a hammer

velocity of (1,5 ± 0,125) m/s.

7.12.2 Test apparatus

The tolerance for all dimensions in this test apparatus shall be 0,5 mm, unless otherwise specified.

The test apparatus (see Figure 1) shall consist essentially of a swinging hammer comprising a rectangular

section head (striker), with a chamfered impact face, mounted on a tubular steel shaft. The hammer shall be

fixed into a steel boss, which runs on ball bearings on a fixed steel shaft mounted in a rigid steel frame, so that

the hammer can rotate freely around the axis of the fixed shaft. The design of the rigid frame shall be such as

to allow complete rotation of the hammer assembly when the specimen is not present.

The striker shall be of dimensions 76 mm wide, 50 mm deep and 94 mm long (overall dimensions) and shall

be manufactured from aluminium

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...