EN ISO 16467:2003

(Main)Packaging - Transport packaging for dangerous goods - Test methods for IBCs (ISO 16467:2003)

Packaging - Transport packaging for dangerous goods - Test methods for IBCs (ISO 16467:2003)

ISO 16467:2003 specifies the design type test requirements for Intermediate Bulk Containers (IBCs) intended for use in the transport of dangerous goods.

Verpackung - Verpackungen für die Beförderung gefährlicher Güter - Prüfverfahren für IBC (ISO 16467:2003)

Dieser Europäische Norm-Entwurf legt die Prüfanforderungen für die verschiedenen Bauarten von Großpackmitteln (IBC) fest, die zur Beförderung von gefährlichen Gütern bestimmt sind.

Emballage - Emballages d'expédition de marchandises dangereuses - Méthodes d'essai pour Grands Récipients en Vrac (GRV) (ISO 16467:2003)

L'ISO 16467:2004 spécifie les exigences d'essai d'un modèle de construction de Grands récipients pour vrac (GRV) destinés au transport de marchandises dangereuses.

Embalaža – Transportna embalaža za nevarne snovi – Preskusne metode za vsebnike IBC (ISO 16467:2003)

General Information

- Status

- Withdrawn

- Publication Date

- 30-Sep-2003

- Withdrawal Date

- 06-Aug-2013

- Technical Committee

- CEN/TC 261 - Packaging

- Drafting Committee

- CEN/TC 261/SC 5/WG 16 - Packaging of dangerous goods

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 07-Aug-2013

- Completion Date

- 07-Aug-2013

Relations

- Effective Date

- 28-Aug-2013

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

BRCGS

Global food safety and quality certification programme owner.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN ISO 16467:2003 is a standard published by the European Committee for Standardization (CEN). Its full title is "Packaging - Transport packaging for dangerous goods - Test methods for IBCs (ISO 16467:2003)". This standard covers: ISO 16467:2003 specifies the design type test requirements for Intermediate Bulk Containers (IBCs) intended for use in the transport of dangerous goods.

ISO 16467:2003 specifies the design type test requirements for Intermediate Bulk Containers (IBCs) intended for use in the transport of dangerous goods.

EN ISO 16467:2003 is classified under the following ICS (International Classification for Standards) categories: 13.300 - Protection against dangerous goods; 55.180.10 - General purpose containers. The ICS classification helps identify the subject area and facilitates finding related standards.

EN ISO 16467:2003 has the following relationships with other standards: It is inter standard links to EN ISO 16495:2013, EN 448:2019, EN 15507:2008, EN 253:2019, EN 13941-2:2019; is excused to EN ISO 16467:2003, EN ISO 16467:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN ISO 16467:2003 is associated with the following European legislation: EU Directives/Regulations: 94/55/EC, 96/49/EC, 96/86/EC, 96/87/EC; Standardization Mandates: M/086. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN ISO 16467:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2003

Embalaža – Transportna embalaža za nevarne snovi – Preskusne metode za

vsebnike IBC (ISO 16467:2003)

Packaging - Transport packaging for dangerous goods - Test methods for IBCs (ISO

16467:2003)

Verpackung - Verpackungen für die Beförderung gefährlicher Güter - Prüfverfahren für

IBC (ISO 16467:2003)

Emballage - Emballages d'expédition de marchandises dangereuses - Méthodes d'essai

pour Grands Récipients en Vrac (GRV) (ISO 16467:2003)

Ta slovenski standard je istoveten z: EN ISO 16467:2003

ICS:

13.300 Varstvo pred nevarnimi Protection against dangerous

izdelki goods

55.180.99 Drugi standardi v zvezi z Other standards related to

distribucijo blaga s prevozom freight distribution of goods

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN ISO 16467

NORME EUROPÉENNE

EUROPÄISCHE NORM

October 2003

ICS 13.300; 55.180.10

English version

Packaging - Transport packaging for dangerous goods - Test

methods for IBCs (ISO 16467:2003)

Emballage - Emballages d'expédition de marchandises Verpackung - Verpackungen für die Beförderung

dangereuses - Méthodes d'essai pour Grands Récipients gefährlicher Güter - Prüfverfahren für IBC (ISO

en Vrac (GRV) (ISO 16467:2003) 16467:2003)

This European Standard was approved by CEN on 15 May 2003.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the official

versions.

CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,

Hungary, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Slovakia, Spain, Sweden, Switzerland and United

Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2003 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN ISO 16467:2003 E

worldwide for CEN national Members.

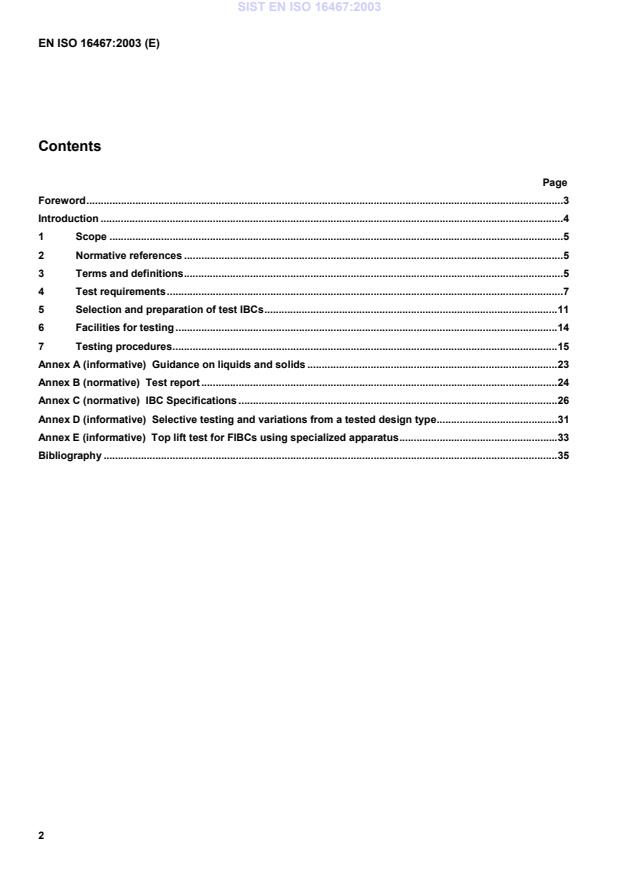

Contents

Page

Foreword.3

Introduction .4

1 Scope .5

2 Normative references .5

3 Terms and definitions.5

4 Test requirements.7

5 Selection and preparation of test IBCs.11

6 Facilities for testing .14

7 Testing procedures.15

Annex A (informative) Guidance on liquids and solids .23

Annex B (normative) Test report.24

Annex C (normative) IBC Specifications .26

Annex D (informative) Selective testing and variations from a tested design type.31

Annex E (informative) Top lift test for FIBCs using specialized apparatus.33

Bibliography .35

Foreword

This document (EN ISO 16467:2003) has been prepared by Technical Committee CEN/TC 261, "Packaging", the

secretariat of which is held by AFNOR in collaboration with Technical Committee ISO/TC 122 "Packaging".

This European Standard EN ISO 16467:2003 shall be given the status of a national standard, either by publication

of an identical text or by endorsement, at the latest by April 2004, and conflicting national standards shall be

withdrawn at the latest by April 2004.

This document has been prepared under a mandate given to CEN by the European Commission and the European

Free Trade Association, and supports the objectives of the framework Directives on Transport of Dangerous

Goods.

This European Standard has been submitted for reference into the RID and/or in the technical annexes of the ADR.

Therefore in this context the standards listed in the normative references and covering basic requirements of the

RID/ADR not addressed within the present standard are normative only when the standards themselves are

referred to in the RID and/or in the technical annexes of the ADR.

Annexes A, D and E are informative. Annexes B and C are normative.

This document includes a Bibliography.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Czech Republic, Denmark, Finland,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal,

Slovakia, Spain, Sweden, Switzerland and the United Kingdom.

Introduction

This Standard was developed to provide requirements and test procedures to meet the multi-modal United Nations

Recommendations on the Transport of Dangerous Goods [1] and successful passing of the tests can lead to the

allocation of an appropriate UN IBC mark. The UN Recommendations have been developed by the United Nations

Committee of Experts on the Transport of Dangerous Goods as a model regulation (referred to in this document as

the UN Recommendations) in the light of technical progress, the advent of new substances and materials, the

exigencies of modern transport systems and, above all, the need to ensure the safety of people, property and the

environment. Amongst other aspects, the UN Recommendations cover principles of classification and definition of

classes, listing of the principal dangerous goods, general packing requirements, testing procedures, marking,

labelling or placarding, and shipping documents. There are in addition special recommendations related to

particular classes of goods.

The UN Recommendations are given legal entity by the provisions of a series of international modal agreements

and national legislation for the transport of dangerous goods. The international agreements include:

The European Agreement Concerning the International Carriage of Dangerous Goods by Road (ADR) (covering

most of Europe). [2]

Regulations concerning the International Carriage of Dangerous Goods by Rail (RID) (covering most of Europe,

parts of North Africa and the Middle East). [3]

The International Maritime Dangerous Goods Code (worldwide). [4]

The International Civil Aviation Organization’s Technical Instructions for the Safe Transport of Dangerous Goods by

Air (ICAO TIs)(worldwide). [5]

The application of this Standard will need to take account of the requirements of these international agreements

and the relevant national regulations for domestic transport of dangerous goods.

It is important to note that there will be certain modal differences from the UN Recommendations and that the

schedule for revision of the Recommendations and modal provisions may lead to temporary inconsistencies with

this Standard, which is regularly updated to the latest version of the UN Recommendations.

It is noted that success in the tests and the allocation of an official UN mark do not on their own authorize the use

of an IBC for any dangerous goods. There are other regulatory provisions that have to be taken into account in

each instance.

This European Standard is based on Revision 12 of the UN Recommendations.

1 Scope

This European Standard specifies the design type test requirements for Intermediate Bulk Containers (IBCs) as

described in 3.2 of this standard and intended for use in the transport of dangerous goods.

2 Normative references

This European Standard incorporates by dated or undated reference, provisions from other publications. These

normative references are cited at the appropriate places in the text, and the publications are listed hereafter. For

dated references, subsequent amendments to or revisions of any of these publications apply to this European

Standard only when incorporated in it by amendment or revision. For undated references the latest edition of the

publication referred to applies (including amendments).

ISO 6789, Assembly tools for screws and nuts — Hand torque tools — Requirements and test methods for design

conformance testing, quality conformance testing and recalibration procedure

EN ISO/IEC 17025, General requirements for the competence of testing and calibration laboratories (ISO/IEC

17025:1999).

3 Terms and definitions

For the purposes of this European Standard the following terms and definitions apply.

3.1

competent authority

any national regulatory body or authority designated or otherwise recognized as such for any purpose in

connection with the regulations specified in the Bibliography.

3.2

Intermediate Bulk Containers (IBCs)

rigid or flexible portable packagings, other than those specified in Chapter 6.1 of the UN Recommendations, that:

have a capacity of:

i) not more than 3,0 m (3,000 l) for solids and liquids of Packing Groups II and III;

ii) not more than 1,5 m for solids of Packing Group I when packed in flexible, rigid plastics, composite,

fibreboard and wooden IBCs;

iii) not more than 3,0 m for solids of Packing Group I when packed in metal IBCs.

iv) not more than 3,0 m for radioactive material of class 7

are designed for mechanical handling;

are resistant to the stresses produced in handling and transport, as determined by tests.

3.3

IBC design type

IBC of one design, size, material and thickness, manner of construction and means of filling and discharging,

including various surface treatments, together with IBCs which differ from the design type only in their lesser

external dimensions

NOTE 1 Attention is drawn to the fact that, when the IBC design type has a maximum capacity greater than 450 l and IBCs

of that type with lesser dimensions bring the capacity below 450 l, additional tests can be necessary.

NOTE 2 For flexible IBCs the design type is specified by the grammage per square metre not by the thickness.

3.4

liquids

o

dangerous goods which at 50 C have a vapour pressure of not more than 300 kPa (3 bar), which are not

o

completely gaseous at 20 C and at a pressure of 101,3 kPa, and which have a melting point or initial melting point

o

of 20 C or less at a pressure of 101,3 kPa

NOTE An expansion of this definition can be found in annex A

3.5

solids

dangerous goods, other than gases, that do not meet the definition of liquids

3.6

capacities

3.6.1

brimful (overflow, maximum) capacity

maximum volume of water in litres held by the IBC when filled through the designed filling orifice to the point of

overflowing in its normal position of filling

3.6.2

nominal capacity

capacity in litres which, by convention is used to represent a class of packagings of similar brimful capacities

3.7

packing groups

group to which substances of most classes of dangerous goods are assigned according to the degree of danger

presented:

Packing Group I Packing Group II Packing Group III

high danger medium danger low danger

NOTE The severity of an IBC test (e.g. the drop height) varies with the packing group of the substance.

3.8

types of IBCs

NOTE Further definitions are found in UN 6.5.1.3:

3.8.1

Rigid IBCs (RIBCs)

metal, rigid plastics, composite, fibreboard and wooden IBCs

3.8.2

Flexible IBCs (FIBCs)

paper, plastics and textile IBCs

3.9

maximum net mass

maximum mass of contents in one IBC expressed in kilograms

3.10

maximum permissible gross mass (for all RIBCs)

mass of the IBC and any service or structural equipment together with the maximum net mass

3.11

filling

3.11.1

under pressure

filling under a pressure of more than 10 kPa (0,1 bar)

3.11.2

under gravity

filling under gravity alone or a pressure of not more than 10 kPa (0,1 bar)

3.12

discharging

3.12.1

under pressure

discharging under a pressure of more than 10 kPa (0,1 bar)

3.12.2

under gravity

discharging under gravity alone or a pressure of not more than 10 kPa (0,1 bar)

4 Test requirements

4.1 Test and sequence requirements

4.1.1 Table 1 sets out the test requirements for IBCs

NOTE 1 The tests required in Table 1 correspond to the applicability provisions of the UN Recommendations but not

necessarily to the tabulation therein.

NOTE 2 Successful design type tests as described in this standard normally lead to the allocation of a UN IBC mark by the

competent authority. It is a requirement of the regulations listed in the Biliography that, before the IBC is used for dangerous

goods, tests are carried out successfully on each IBC design type (see 3.3). It is also a requirement of those regulations that the

tests are successfully repeated after any modification that alters the IBC design type, however the Competent Authority can

waive testing. Some examples of where testing may be waived are given in annex D.

NOTE 3 Where an inner treatment or coating is applied for safety reasons it should retain its protective properties even after

the tests.

NOTE 4 A design type not designed for bottom or top lifting does not meet the definition of an IBC [see 3.2] because, unless

otherwise approved by the competent authority, it is not considered to be suitable for mechanical handling.

4.1.2 One sample RIBC shall be tested in accordance with the relevant test sequence in Table 1 and shall meet

the applicable criteria in 4.2 to 4.7.

4.1.3 FIBCs shall be tested in accordance with Table 1 and shall meet the applicable criteria in 4.2 to 4.10. For

any one design type, the tests shall be carried out using a different sample for each test, or with a sample which

has passed one test being used for other tests.

NOTE 1 IBCs for solids, which are likely to become liquid during transport, should be tested as for liquids, RIBCs for solids

can also be tested for liquids, specifically leakproofness and / or hydraulic tests.

NOTE 2 IBCs being tested for solids which require phlegmatizing with a liquid for safe transport, such that there is free liquid

in the packaging, should be subjected to the appropriate tests for liquids with the test contents being a representative mixture of

solids and liquids.

Table 1 — Design type tests required and sequential order

Metal IBCs Test required when contents are:

Sequential Requirement Testing Solids filled or Solids filled or

order clause clause discharged by discharged by

gravity pressure and

liquids

a) a)

Bottom lift 1 4.2 7.1 Yes Yes

b) b)

4.3 7.2

Top lift 2 Yes Yes

c) c)

Stacking 3 4.4 7.4 Yes Yes

Leakproofness 4 4.5 7.5 N/A Yes

Hydraulic pressure 5 4.6 7.6 N/A Yes

d) d)

f)

4.7 7.7

6 Yes Yes

Drop

Rigid plastics IBCs Test required when contents are:

Solids filled or Solids filled or

Sequential Requirement Testing

discharged by discharged by

order clause clause

gravity pressure and

liquids

a) a)

4.2 7.1

Bottom lift 1 Yes Yes

b) b)

Top lift 2 4.3 7.2 Yes Yes

c) c)

Stacking 3 4.4 7.4 Yes Yes

Leakproofness 4 4.5 7.5 N/A Yes

Hydraulic pressure 5 4.6 7.6 N/A Yes

f)

6 4.7 7.7 Yes Yes

Drop

Composite IBCs Test required when contents are:

Sequential Solids filled or Solids filled or

Requirement Testing

order discharged by discharged by

clause clause

gravity pressure and

liquids

a) a)

Bottom lift 1 4.2 7.1 Yes Yes

b) b)

Top lift 2 4.3 7.2 Yes Yes

c) c)

4.4 7.4

Stacking 3 Yes Yes

Leakproofness 4 4.5 7.5 N/A Yes

Hydraulic pressure 5 4.6 7.6 N/A Yes

f) d)

d)

Drop

6 4.7 7.7 Yes Yes

Test required when contents are:

Fibreboard and wooden IBCs

Sequential Requirement Testing Solids filled or

order clause clause discharged by

gravity

Bottom lift 1 4.2 7.1 Yes

b)

Top lift 2 4.3 7.2 Yes

c)

4.4 7.4

Stacking 3 Yes

f)

Drop

4.7 7.7

4 Yes

Table 1 (Continued)

Flexible IBCs Test required when contents are:

Sequential Requirement Testing Solids filled or

order clause clause discharged by

gravity

a)d)

4.2 7.1 Yes

Bottom lift N/A

d)e)

Top lift N/A 4.3 7.3 Yes

c)d)

Stacking N/A 4.4 7.4 Yes

d)

f)

N/A 4.7 7.7 Yes

Drop

d)

Tear N/A 4.8 7.8 Yes

d)

4.9 7.9

Topple N/A Yes

d)

Righting N/A 4.10 7.10 Yes

a)

When IBCs are fitted with means of lifting from the base.

b)

When IBCs are designed to be lifted from the top.

c)

When IBCs are designed to be stacked on each other during transport.

d)

The test is required but another IBC of the same design may be used

e)For FIBCs designed to be lifted from the top or the side

f)See 7.7.3 for additional drop tests for IBCs of 0,45m capacity or less

4.2 Criteria for passing the bottom lift test

When tested in accordance with 7.1 there shall be no permanent deformation which renders the IBC, including the

base pallet, if any, unsafe for transport and no loss of contents.

4.3 Criteria for passing the top lift test

4.3.1 When tested in accordance with 7.2 there shall be no permanent deformation which renders the RIBC,

including the base pallet, if any, unsafe for transport and no loss of contents.

4.3.2 When tested in accordance with 7.3 there shall be no damage to the FIBC or its lifting devices which

renders the FIBC unsafe for transport or handling and no loss of contents.

4.4 Criteria for passing the stacking test

4.4.1 When tested in accordance with 7.4 there shall be no permanent deformation which renders the RIBC,

including the base pallet, if any, unsafe for transport and no loss of contents.

4.4.2 When tested in accordance with 7.4 there shall be no deterioration of the body which renders the FIBC

unsafe for transport and no loss of contents.

4.5 Criteria for passing the leakproofness test

When tested in accordance with 7.5 there shall be no leakage of air.

4.6 Criteria for passing the hydraulic pressure test(s)

When tested in accordance with 7.6 there shall be no leakage of liquid.

When a pre-test at 65 kPa is required for metal IBCs there shall be neither permanent deformation which would

render the IBC unsafe for transport nor leakage of liquid.

For rigid plastics and composite IBCs when tested in accordance with 7.6 there shall be no permanent deformation

which would render the IBC unsafe for transport and no leakage.

4.7 Criteria for passing the drop test

4.7.1 For metal IBCs, when tested in accordance with 7.7 there shall be no loss of contents.

4.7.2 For rigid plastics, composite, fibreboard and wooden IBCs when tested in accordance with 7.7 there shall

be no loss of contents. A slight discharge from a closure upon impact shall not be considered to be a failure of the

IBC provided that no further leakage occurs.

4.7.3 For FIBCs when tested in accordance with 7.7 there shall be no loss of contents. A slight discharge, e.g.

from closures or stitch holes, upon impact shall not be considered to be a failure of the FIBC provided that no

further leakage occurs after the FIBC has been lifted clear of the ground.

4.8 Criteria for passing the tear test

Following the test, which shall be carried out in accordance with 7.8, the original 100 mm long cut shall not have

extended by more than 25 % of its original length.

4.9 Criteria for passing the topple test

When tested in accordance with 7.9, there shall be no loss of contents. A slight discharge, e.g. from closures or

stitch holes, upon impact shall not be considered to be a failure of the FIBC provided that no further leakage

occurs.

4.10 Criteria for passing the righting test

When tested in accordance with 7.10 there shall be no damage to the FIBC or its lifting devices which renders the

FIBC unsafe for transport or handling.

4.11 Equivalent testing

The test methods described in this standard shall be considered to be the reference test methods. Alternative

methods may be used provided that:

their equivalence to the reference test method can be demonstrated;

their use is recorded in the test report;

prior approval is obtained from the competent authority.

4.12 Test report

All IBCs tested for conformity with this standard shall be the subject of a test report and specification check

prepared in accordance with annexes B and C. It shall be possible to specifically identify the IBC relative to each

test report, either by the retention of uniquely referenced IBCs or by inclusion of sufficient photographs and/or

drawings with unique references to enable identification of the IBC and all its components.

NOTE 1 Each test report should be available to the users of the IBC.

NOTE 2 Retention and/or disposal procedures for test IBCs can be established by the competent authority.

5 Selection and preparation of test IBCs

5.1 Selection of IBCs

Sufficient IBCs per design type shall be submitted for testing in accordance with Table 1 and shall be:

a) marked with a test reference which shall also be entered on the test record and later used in the test report;

b) individually weighed to establish the tare or filled mass.

NOTE 1 The form of such weighing can be varied to correspond with whether the IBCs have been supplied full or empty to

the test station. Where the tare masses of individual IBCs are recorded it is recommended to record only a typical filled mass (or

vice-versa).

c) examined for damage which might invalidate the tests, in which event the IBC shall be replaced.

NOTE 2 Under some circumstances it can be desirable to have a range of IBCs tested, for example:

— in a number of different sizes but of the same construction;

— with a variety of closures;

— for use with a range of solid contents.

In such situations it may not be necessary to carry out testing for every possible permutation. This selective testing procedure is

recognized but only after agreement with the competent authority who will advise on options available. Guidelines are set out in

annex D.

5.2 Information to be provided with IBCs

5.2.1 General

Each IBC type shall be accompanied by specification(s) for that design type containing the information set out in

annex C and by the additional information in 5.2.2 to 5.2.6 as relevant.

5.2.2 Water and other non-dangerous substances as test contents

Where the tests are to be carried out using water or other non-dangerous substances a statement of the packing

group for which the IBC is to be tested together with data enabling appropriate selection of inert test contents and

levels shall be provided. For liquids such data shall include the required maximum relative density for the tests

together with data on, for instance, the internal pressure test required. For solids such data shall include mass,

grain size and any other relevant characteristic, for example, bulk density, angle of repose etc., to clearly show

equivalence of physical characteristics.

5.2.3 The dangerous substance as test contents

Where the tests are to be carried out using the dangerous substance(s) to be transported, a statement of their

packing group and their physical characteristics shall be provided. Liquids shall be defined by their relative density

together with viscosity and the method of determination. Solids shall be defined by their mass and grain size and

any other relevant characteristic, for example, bulk density, angle of repose, etc. to ensure physical characteristics

are sufficiently identified and included. This data shall be recorded in the test report (see annex B).

NOTE Where tests are carried out using the actual substance to be transported then the test report is applicable for other

substances having the same or equivalent characteristics.

5.2.4 Vapour pressure

For liquids, the vapour pressure of the substance to be carried or the hydraulic pressure to be achieved during the

tests shall be stated.

5.2.5 Special instructions

Any special filling or closing instructions including, where relevant, for example the closure torque shall be

provided.

5.2.6 Handling characteristics

Each IBC design type shall be accompanied by a statement of its mechanical handling characteristics. This shall

relate to bottom lift, top lift or both as applicable.

EXAMPLE A composite IBC with a pallet base has an outer casing with each side formed from metal mesh within a metal

frame. Where the mesh is complete the IBC is unlikely to be lifted from the top and the accompanying statement covers bottom

lifting only. Where, however, the mesh is cut away in places under the upper frame members for convenience in lifting from the

top, it is appropriate for a top lift characteristic to be included in the statement unless otherwise explained.

5.3 Selection of test contents and filling of IBCs prior to testing

5.3.1 General

NOTE Further specific requirements for preparation are given in clause 7.

5.3.1.1 RIBCs

For the bottom and top lift tests, IBCs shall be prepared as set out in 7.1 and 7.2

For the stack test, IBCs shall be prepared as set out in 7.4.

For the hydraulic pressure and leakproofness tests, IBCs shall be prepared as set out in 7.5 and 7.6.

For the drop test, IBCs shall be filled in accordance with 5.3.3.1 for liquids, or 5.3.3.2 for solids.

IBCs for liquids, or those capable of containing them, shall have their capacity determined as in 5.3.3. Otherwise

the capacity shall be determined by other suitable means e.g. by calculation.

5.3.1.2 FIBCs

For the bottom and top lift tests, IBCs shall be prepared as set out in 7.1 and 7.3.

For the stack test, drop, tear, topple and righting tests IBCs shall be prepared as set out in 5.3.4.

5.3.2 Test contents

Where non-dangerous substances are to be used as test contents, they shall be selected to accord with the data in

5.2.2. Water or a water/anti-freeze mixture may be used to represent any liquid.

For solids, additives, such as bags of lead shot, may be used to adjust the mass if required, but if used they shall

be placed in such a manner that the test results are not affected. The test contents used shall be recorded in the

test report.

5.3.3 Filling

5.3.3.1 RIBCs to contain liquids – filling for the drop test

An RIBC intended to contain liquids, shall be filled for the drop test to not less than 98 % of the brimful capacity.The

brimful (overflow) capacity is determined by weighing the empty RIBC and then weighing the RIBC full, filling the

RIBC with water until the water just overflows and then fitting the closure. Any surplus water is mopped up. No

steps shall be taken, e.g. by tilting or tapping the RIBC, to enable water to penetrate into a hollow lifting feature or

other design feature above the closure.

5.3.3.1.1 The following formula expresses the brimful capacity:

b = W – m

d

where

b is the brimful capacity in litres (l);

d is density of water (=1) (in kg per litre)

W is the brimful mass in kilograms;

m is the empty mass in kilograms

5.3.3.1.2 The calculation of required volume of liquids for testing shall be:

b98

C =

where

C is the required volume of water in litres;

b is the brimful capacity in litres

5.3.3.2 RIBCs to contain solids – filling for the drop test

5.3.3.2.1 RIBCs intended to contain solids shall be filled to not less than 95 % of the brimful capacity. Where the

IBC is capable of containing liquids the capacity shall be determined as defined in 5.3.3.The calculation of required

mass of solids for testing shall be:

b d95

M =

where

M = the required mass of solids in kilograms

d = the bulk density of the test contents in grams per cubic centimetre (g/cm ).

b= the brimful capacity in litres

Alternatively, for cylindrical IBCs the level of fill required to fill the IBC to not less than 95 % of its brimful capacity

shall be calculated from its internal height, taking into account any reduction in height caused by the fitting of the

closure.

5.3.4 Flexible IBCs to contain solids: filling for stack, drop, tear, topple and righting tests.

Flexible IBCs shall be filled to the required testing mass at which the designer of the packaging intends it to be

used or, if known, to the capacity which the user intends to employ, using either the substance to be transported or,

solids of similar characteristics in respect of mass, grain size and flow characteristics; the test contents used shall

be recorded in the test report.

5.4 Closing IBCs

IBCs shall be closed as for transport and in accordance with any special instructions. Screw type closures shall be

tightened to the recommended torque where appropriate. The torque applied shall be recorded in the test report.

Closure torque shall not differ from one test to another in the test report. If it is necessary to revise a closure torque

following a failure in one test, then all tests shall be completed using the revised torque setting.

5.5 Conditioning

Fibreboard IBCs and composite IBCs with fibreboard outer casings and IBCs made of paper shall be conditioned

before test for at least 24 h in an atmosphere having a controlled temperature and relative humidity (r.h.) There are

three options, one of which shall be chosen. The preferred atmosphere is (23 ± 2) C and (50 ± 2) % r.h. The two

other options are (20 ± 2) C and (65 ± 2) % r.h., and (27 ± 2) C and (65 ± 2) % r.h.

NOTE 1 These values correspond to average values. In the short term the r.h. values can vary by 5 % without this having

an influence on the test.

NOTE 2 The purpose of conditioning in this way is not to replicate any ambient condition likely to be met during actual

transport. The purpose is to standardize the tests and enable them to be reproducible by stabilizing the moisture content of the

paper or fibreboard. It is further noted that:

a) the IBC should be relatively dry before being placed in the controlled atmosphere;

b) the minimum of 24 h can be insufficient to stabilize the moisture content of thick material even if the IBC is open so that

moisture can be transferred via outer and inner faces;

c) the moisture content of the paper or fibreboard can be significantly affected by the moisture content and temperature of the

test contents.

5.6 Check of IBC specification against constructional requirements

Following receipt of the sample(s) and their specification (see 5.2.1), a check shall be made that the design type

corresponds with the definition of an IBC and the constructional requirements set out for that type of IBC in the UN

Recommendations.

5.7 Check of IBC specification against sample

The specification of the IBC to be tested shall be checked by visual inspection and actual measurements as

detailed in annex C. Aspects such as external dimensions shall be checked at this preparatory stage. A record of

each specification check shall be included in the test report.

NOTE Aspects (other than external dimensions) - such as measurement of material thickness requiring sectioning, can be

carried out on completion of the test(s).

6 Facilities for testing

6.1 Testing of design types

Tests shall be carried out at a testing facility capable of meeting the operational provisions of EN ISO/IEC 17025.

NOTE 1 This does not imply a requirement for third party certification or accreditation but if appropriate such external

approval can be obtained from either a national accreditation body or from the competent authority.

NOTE 2 Testing staff should have knowledge of the principles of the dangerous goods regulations as set out in the UN

Recommendations.

6.2 Accuracy of measurement equipment

The accuracy of measurement equipment shall be more precise than the accuracy of the measurements in testing

as specified in 6.3, unless otherwise approved by the competent authority. The measurement equipment shall be

calibrated in accordance with the relevant provisions of EN ISO/IEC 17025.

6.3 Accuracy of measurements in testing

Measurement equipment shall be selected such that individual measurement results, including errors in reading

and calibration, shall not exceed the following:

Mass in kilograms (kg): ± 2 %

Pressure in kilopascals (kPa): ± 3 %

Distance/length in millimetres (mm) ± 2 %

Temperature in degrees Celsius (C) ± 1 C

Humidity in percentage (%) Tolerances are as specified in 5.5

Time in minutes (min): ± 3 %

Torque in newton metres (Nm) ± 3 Nm or 10 %, whichever is the greater in accordance with ISO 6789

NOTE For some measurements the tolerances can be lower in order to have meaningful measurements, e.g. when

measuring masses or dimensions of empty packagings. Where only maximum or minimum values are specified in the text,

tolerances are one-sided e.g. 7.5.2 requires that the leakproofness test be carried out for a period of at least 10 min. The period

should be equal to or greater than 10 min.

6.4 Climatic conditions

There shall be adequate climatic facilities to meet the requirements in 5.5 and clause 7.

6.5 Impact surfaces for drop and topple tests

The drop and/or topple area impact surface shall be horizontal and flat, massive enough to be immovable and rigid

enough to be non-deformable under test conditions and sufficiently large to ensure that the test IBC falls entirely

upon the surface.

7 Testing procedures

7.1 Bottom lift test

7.1.1 Special preparation of IBCs for the test

The IBC shall be filled as for transport. A load shall be added and evenly distributed. The mass of the filled IBC and

the load shall be 1,25 times its maximum permissible gross mass.

7.1.2 Method of testing

The IBC shall be raised and lowered twice by a lift truck with the forks centrally positioned and spaced at three

quarters of the dimension of the side of entry (unless the points of entry are fixed). The forks shall penetrate to

three-quarters the depth of the IBC in the direction of entry. The test shall be repeated from each possible direction

of entry.

NOTE 1 Failure, when it occurs, often takes place during the initial acceleration of a lift. Neither the height nor the rate of

elevating is specified. It is normally adequate (taking safety into account) to raise the IBC for a distance of some 200 mm. A

convenient rate of lifting results in a 200 mm lift being completed in between 5 s and 10 s. It is recommended that, after the final

test, the IBC should then be lowered, the forks placed fully underneath it and the IBC lifted to a convenient height for

examination of the base.

NOTE 2 When a design of rectangular pallet can be entered from each of four sides a total of eight elevations and lowerings

is undertaken.

7.2 Top lift test for RIBCs

7.2.1 Special preparation of the IBC for the test

The IBC shall be filled as for transport and then be loaded to a total of twice its maximum permissible gross mass,

the load being evenly distributed.

7.2.2 Method of testing

7.2.2.1 The rigid plastics or composite IBC shall be lifted:

a) by each pair of diagonally opposed lifting devices, so that the hoisting forces are applied vertically, for a period

of 5 min; and

b) by each pair of diagonally opposed lifting devices, so that the hoisting forces are applied towards the centre at

45° to the vertical, for a period of 5 min.

On each of the four lifts the IBC shall be maintained in that position for 5 min.

7.2.2.2 All other RIBCs shall be lifted in the manner for which they are designed until clear of the floor and

maintained in that position for 5 min.

7.2.2.3 When equivalence can be demonstrated from previous tests on IBCs of similar design and with the

approval of the competent authority, the test on rigid plastics and composite IBCs shall be carried out in

accordance with 7.2.2.1 b) only. Two lifts shall be carried out using each pair of lifting devices in turn to make four

lifts in all. The use of this method shall be recorded in the test report.

7.3 Top lift test for FIBCs

7.3.1 Special preparation of the IBC for the test

The IBC shall be filled to six times its maximum permissible load, the load being evenly distributed.

NOTE When using this method, rather than an equivalent one, primary attention often needs to be directed towards

obtaining test contents of sufficient bulk density; it may not be possible to fully take account of other important characteristics

such as the angle of repose of dangerous solids to be transported. The filling level cannot normally be controlled.

EXAMPLE An FIBC 1,2 m x 0,9 m x 0,9 m is designed to transport 1 000 kg of fine granules, so for test the FIBC is filled

with 6 000 kg of test contents. Using 1 mm diameter lead shot with a bulk density of 7,6 g/cm and 3 mm diameter polyethylene

granules with a bulk density of 0,54 g/cm , an 80/20 mixture is required as test contents to give the correct load.

7.3.2 Method of testing

The FIBC shall be lifted in the manner for which it is designed until clear of the floor and maintained in that position

for 5 min.

NOTE With the approval of the competent authority, an equivalent method related to national standards and international

industry standards can be used. It can involve the use of a specialized tensile or compression test machine. The method is

described in annex E.

7.4 Stacking test

7.4.1 Special preparation of the IBC for the test

RIBCs shall be filled as for transport and then loaded to their maximum permissible gross mass.

FIBCs shall be filled in accordance with 5.3.4.

7.4.2 Method of testing

The IBC shall be placed on its base on level hard ground and subjected to a uniformly distributed superimposed

load.

The test load shall be calculated as 1,8 times the combined maximum permissible gross mass of the number of

similar IBCs that may be stacked on top of the IBC during transport.

7.4.2.1 The test load shall be applied by any one of the following:

a) for RIBCs, one or more RIBCs of the same type filled to the maximum permissible gross mass and stacked on

the test RIBC;

b) for FIBCs, one or more FIBCs of the same type filled to the maximum permissible load and stacked on the test

FIBC;

c) appropriate weights loaded on to either a flat plate or a reproduction of the base of the IBC, which is stacked on

the test IBC;

d) an appropriate compression test machine.

7.4.2.2 Metal IBCs shall be stacked for 5 min in ambient conditions.

Rigid plastics IBCs and composite IBCs where the stack load is supported entirely by plastics material shall be

stacked for a period of 28 days at a temperature of not less than 40 °C.

o

NOTE Temperatures outside the range 40° C – 44 C should be pre-arranged and recorded in the test report.

7.4.2.3 Other types of IBC shall be stacked for 24 h in ambient conditions.

7.5 Leakproofness test

7.5.1 Special preparation of the IBC for the test

Vented closures shall either be replaced by similar non-vented closures or the vent shall be sealed.

The design type leakproofness test shall be carried out on the complete IBC and before the fitting of any thermal

insulation equipment.

Alternatively, for composite IBCs, the inner receptacle may be tested without the outer casing provided the test

results are not affected. When the test is carried out on the inner receptacle in this way, the fact shall be recorded

in the test report.

7.5.2 Method of testing

The test shall be carried out for a period of at least 10 min using air at a constant gauge pressure of not less than

20 kPa.The airtightness of the IBC shall be determined by one of the three following methods:

a) by immersing the IBC under water and observing air bubbles. A correction factor shall be applied to the test

pressure to take account of the hydrostatic pressure as illustrated in the example following.

EXAMPLE After immersion, the total depth of water is 2,5 m when the hydraulic pressure is 25 kPa the test pressure is

therefore not less than 45 kPa.

NOTE 1 Air bubbles considered to arise from entrained air (e.g. air held initially in seams or in the thread of closures) should

not be considered as leakage — this includes any bubbles produced which do not appear regularly. If necessary the test period

can be extended to allow entrained air to be expelled.

b) by covering the seams and joints with a suitable soap solution and observing any air bubbles released;

NOTE 2 When using this method it is desirable to take special care with closures.

c) by using an air-pressure differential test.

The method used and the pressure differential shall be documented in the test report.

7.6 Hydraulic pressure test(s)

The IBCs shall be pressurized continuously and gradually up to the required test pressure.

NOTE This should be within the time of not less than 5 min and not more than 30 min.

7.6.1 Special preparation of the IBC for the test

The test shall be carried out before the fitting of any thermal insulation material. Any pressure relief devices shall be

removed and their apertures plugged or they shall be rendered inoperable.

7.6.2 Method of testing and pressures to be applied

The IBCs shall be pressurised continuously and gradually up to the required test pressure.

NOTE This should be within the time of not less than five minutes and not more than 30 min.

The IBC shall be subjected to one or two hydraulic pressure tests each for a period of at least 10 min. The IBC

shall not be mechanically restrained during the test. The test pressures and number of tests are as follows:

metal IBCs for Packing Group I solids loaded or discharged at a pressure of more than 10 kPa shall be

subjected to one test at a gauge pressure of 250 kPa;

metal IBCs for Packing Group II or III solids loaded or discharged at a pressure of more than 10 kPa shall be

subjected to one test at a gauge pressure of 200 kPa;

metal IBCs for Packing Group II or III liquids shall be subjected to two tests in sequence, the first at a gauge

pressure of 65 kPa and the second at a gauge pressure of 200 kPa;

rigid plastics or composite IBCs for solids loaded or discharged at a pressure of more than 10 kPa shall be

subjected to one test at a pre

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...