EN 15520:2007

(Main)Thermal spraying - Recommendations for constructional design of components with thermally sprayed coatings

Thermal spraying - Recommendations for constructional design of components with thermally sprayed coatings

This European Standard applies for thermal sprayed coatings. It contains basic recommendations for the design of components, which have to be completely or partially coated. The recommendations apply for new manufacturing as well as for repair of worn components. The coating may be of metallic, metal-ceramic, oxide-ceramic materials or polymers.

Thermisches Spritzen - Empfehlungen zum konstruktiven Gestalten von Bauteilen mit thermisch gespritzten Schichten

Diese Europäische Norm gilt für thermische Spritzschichten. Sie enthält grundsätzliche Empfehlungen zur Gestaltung von Bauteilen, die komplett oder teilweise beschichtet werden müssen. Die Empfehlungen gelten sowohl bei der Neufertigung als auch bei der Instandsetzung von z. B. verschlissenen Bauteilen. Die Beschichtung kann aus metallischen, metallkeramischen, oxidkeramischen Werkstoffen oder aus Kunststoff bestehen.

Projection thermique - Recommandations relatives à la conception des éléments de construction comportant un revêtement déposé par projection thermique

La présente Norme européenne s’applique aux revêtements déposés par projection thermique. Elle comprend des recommandations générales sur la conception des éléments qui doivent être revêtus, que ce soit en totalité ou en partie. Ces recommandations s’appliquent à la fabrication d’éléments neufs mais aussi à la réparation d’éléments usés. Le revêtement peut être en métal, en cermet, en oxyde-céramique ou en polymères.

Vroče brizganje - Priporočila za konstrukcijsko oblikovanje komponent s prevlekami, nanesenimi z vročim brizganjem

General Information

- Status

- Withdrawn

- Publication Date

- 28-Aug-2007

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 240 - Thermal spraying and thermally spraying coatings

- Drafting Committee

- CEN/TC 240 - Thermal spraying and thermally spraying coatings

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 24-Jul-2024

- Completion Date

- 09-Feb-2026

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

EN 15520:2007 is a standard published by the European Committee for Standardization (CEN). Its full title is "Thermal spraying - Recommendations for constructional design of components with thermally sprayed coatings". This standard covers: This European Standard applies for thermal sprayed coatings. It contains basic recommendations for the design of components, which have to be completely or partially coated. The recommendations apply for new manufacturing as well as for repair of worn components. The coating may be of metallic, metal-ceramic, oxide-ceramic materials or polymers.

This European Standard applies for thermal sprayed coatings. It contains basic recommendations for the design of components, which have to be completely or partially coated. The recommendations apply for new manufacturing as well as for repair of worn components. The coating may be of metallic, metal-ceramic, oxide-ceramic materials or polymers.

EN 15520:2007 is classified under the following ICS (International Classification for Standards) categories: 25.220.20 - Surface treatment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15520:2007 has the following relationships with other standards: It is inter standard links to EN 15520:2024, EN ISO 12671:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15520:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Thermal spraying - Recommendations for constructional design of components with thermally sprayed coatingsProjection thermique - Recommandations sur la conception des assemblages d'éléments comportant un revetement déposé par projection thermiqueThermisches Spritzen - Empfehlungen zum konstruktiven Gestalten von Bauteilen mit thermisch gespritzten SchichtenTa slovenski standard je istoveten z:EN 15520:2007SIST EN 15520:2007en,fr25.220.20Površinska obdelavaSurface treatmentICS:SLOVENSKI

STANDARDSIST EN 15520:200701-december-2007

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 15520August 2007ICS 25.220.20 English VersionThermal spraying - Recommendations for constructional designof components with thermally sprayed coatingsProjection thermique - Recommandations sur la conceptiondes assemblages d'éléments comportant un revêtementdéposé par projection thermiqueThermisches Spritzen - Empfehlungen zum konstruktivenGestalten von Bauteilen mit thermisch gespritztenSchichtenThis European Standard was approved by CEN on 20 July 2007.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2007 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 15520:2007: E

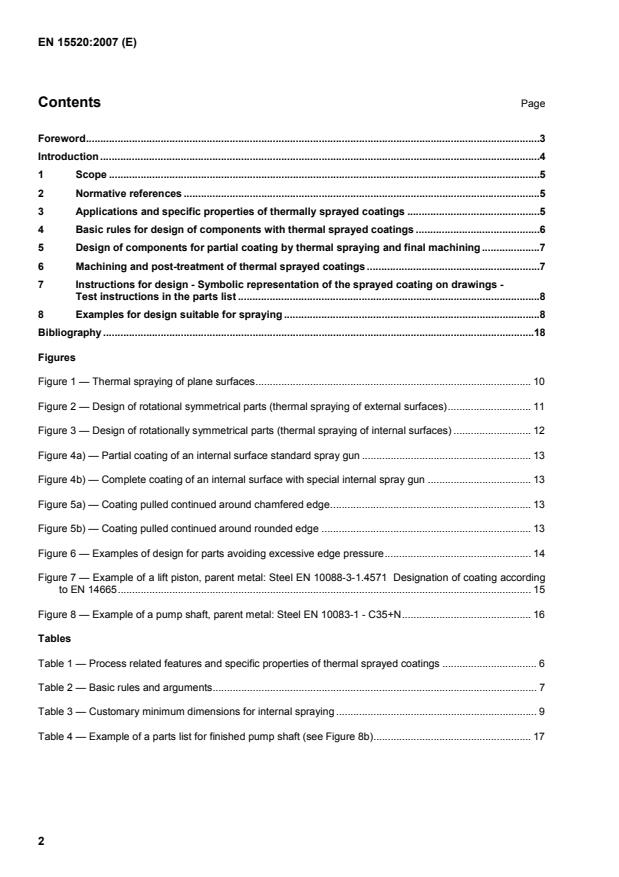

Designation of coating according to EN 14665.15 Figure 8 — Example of a pump shaft, parent metal: Steel EN 10083-1 - C35+N.16 Tables Table 1 — Process related features and specific properties of thermal sprayed coatings.6 Table 2 — Basic rules and arguments.7 Table 3 — Customary minimum dimensions for internal spraying.9 Table 4 — Example of a parts list for finished pump shaft (see Figure 8b).17

Table 1 — Process related features and specific properties of thermal sprayed coatings Process related features Specific properties of thermal sprayed coating Components made of almost every material can be coated by thermal spraying. Not every spraying procedure is appropriate for all applications. Coatings with properties completely different from the parent material are possible. — Coatings can be sprayed with different spraying materials side by side, one upon another, or mixing into one another (graded coatings). Usually the effect of the residual stress in the coating rises with increasing coating thickness. Usually the heat input caused by spraying is so low, that it is possible to avoid structural transformation or deformation.

The heat input by fusing self-fluxing alloys or diffusion annealing may cause structural transformation or deformation.

If the coating is not post heat treated the bond strength mainly depends on mechanical adhesive properties. If the coating is post heat treated the bond strength depends on diffusion and the coating is densified.

The ability to apply the spraying process is practically independent of the size of the component.

Some geometric dimensions e.g. internal bores with too small a diameter may limit the spray ability.

Components

with complicated shapes can be coated, if appropriate spraying equipment is used. Sprayed coatings are susceptible to edge loading, point and line loading and im

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...