EN 12566-3:2005

(Main)Small wastewater treatment systems for up to 50 PT - Part 3: Packaged and/or site assembled domestic wastewater treatment plants

Small wastewater treatment systems for up to 50 PT - Part 3: Packaged and/or site assembled domestic wastewater treatment plants

This European Standard specifies requirements, test methods, the marking and evaluation of conformity for packaged and/or site assembled domestic wastewater treatment plants (including guest houses and businesses) used for populations up to 50 inhabitants. Small wastewater treatment plants according to this European Standard are used for the treatment of raw domestic wastewater.

It covers plants with tanks made of concrete, steel, PVC-U, Polyethylene (PE), Polypropylene (PP) and Glass Reinforced Polyester (GRP-UP).

The test methods specified in this European Standard establish the performance of the plant, needed to verify its suitability for the end use (see 3.1).

This European Standard applies for small wastewater treatment plants for use buried in the ground where no vehicle loads are applied to the product.

This European Standard applies to plants where all prefabricated components are factory or site-assembled by one manufacturer and which are tested as a whole.

NOTE In some countries, domestic wastewater treatment plants are followed by other systems to conform to national regulations.

NOTE In some countries, domestic waste water treatment plants are followed by other systems to conform to national regulations.

Kleinkläranlagen für bis zu 50 EW - Teil 3: Vorgefertigte und/oder vor Ort montierte Anlagen zur Behandlung von häuslichem Schmutzwasser

Dieses Dokument legt Anforderungen an vorgefertigte und/oder vor Ort montierte Anlagen zur Behandlung von häuslichem Schmutzwasser einschließlich solchem aus Gaststätten und Gewerbebetrieben für Gruppen von bis zu 50 Personen sowie Prüfverfahren, die Kennzeichnung und die Konformitätsbewertung fest. Kleinkläranlagen nach diesem Dokument werden für die Behandlung von häuslichem Rohabwasser verwendet.

Dieses Dokument deckt Anlagen mit Behältern aus Beton, Stahl, PVC U, Polyethylen (PE), Polypropylen (PP) und glasfaserverstärktem Kunststoff (GFK) ab.

Die in diesem Dokument spezifizierten Prüfverfahren legen die Ausführung der Anlage fest, die zur Prüfung von deren Eignung für den Verwendungszweck erforderlich ist (siehe 3.1).

Das vorliegende Dokument gilt für Kleinkläranlagen, die in den Boden eingebaut werden und dann keinen Fahrzeuglasten ausgesetzt sind.

Dieses Dokument gilt für Anlagen, bei denen alle vorgefertigten Bauteile im Werk oder vor Ort durch einen Hersteller zusammengebaut werden, und die als Ganzes geprüft werden.

ANMERKUNG In einigen Ländern sind, um den nationalen Vorschriften zu entsprechen, den Anlagen zur Behandlung des häuslichen Abwassers weitere Anlagen nachgeschaltet.

Petites installations de traitement des eaux usées jusqu'à 50 PTE - Partie 3: Stations d'épuration des eaux usées domestiques prêtes à l'emploi et/ou assemblées sur site

Cette partie de la présente norme spécifie certaines exigences, des méthodes d'essais et certaines prescriptions sur le marquage et les contrôles de la production en usine pour les stations d'épuration d'eaux usées domestiques intégrées (micro-station) et/ou assemblées sur site utilisées pour des populations jusqu'à 50 habitants. Ces stations doivent traiter des eaux usées brutes domestiques.

Les méthodes d'essais de cette présente norme établissent les performances des stations requises pour vérifier leur aptitude à l'emploi.

Une station doit être considérée comme un produit si tous les composants sont assemblés par un même fabricant et doit être essayée comme un tout.

Les stations de traitement des eaux usées construites sur site ne sont pas visées par cette norme.

Male čistilne naprave do 50 PE – 3. del: Predizdelane in/ali na mestu postavitve sestavljene čistilne naprave za gospodinjske odplake

General Information

- Status

- Withdrawn

- Publication Date

- 26-Jul-2005

- Withdrawal Date

- 27-Jan-2009

- Technical Committee

- CEN/TC 165 - Waste water engineering

- Drafting Committee

- CEN/TC 165 - Waste water engineering

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 28-Jan-2009

- Completion Date

- 28-Jan-2009

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 08-Mar-2023

- Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 12566-3:2005 is a standard published by the European Committee for Standardization (CEN). Its full title is "Small wastewater treatment systems for up to 50 PT - Part 3: Packaged and/or site assembled domestic wastewater treatment plants". This standard covers: This European Standard specifies requirements, test methods, the marking and evaluation of conformity for packaged and/or site assembled domestic wastewater treatment plants (including guest houses and businesses) used for populations up to 50 inhabitants. Small wastewater treatment plants according to this European Standard are used for the treatment of raw domestic wastewater. It covers plants with tanks made of concrete, steel, PVC-U, Polyethylene (PE), Polypropylene (PP) and Glass Reinforced Polyester (GRP-UP). The test methods specified in this European Standard establish the performance of the plant, needed to verify its suitability for the end use (see 3.1). This European Standard applies for small wastewater treatment plants for use buried in the ground where no vehicle loads are applied to the product. This European Standard applies to plants where all prefabricated components are factory or site-assembled by one manufacturer and which are tested as a whole. NOTE In some countries, domestic wastewater treatment plants are followed by other systems to conform to national regulations. NOTE In some countries, domestic waste water treatment plants are followed by other systems to conform to national regulations.

This European Standard specifies requirements, test methods, the marking and evaluation of conformity for packaged and/or site assembled domestic wastewater treatment plants (including guest houses and businesses) used for populations up to 50 inhabitants. Small wastewater treatment plants according to this European Standard are used for the treatment of raw domestic wastewater. It covers plants with tanks made of concrete, steel, PVC-U, Polyethylene (PE), Polypropylene (PP) and Glass Reinforced Polyester (GRP-UP). The test methods specified in this European Standard establish the performance of the plant, needed to verify its suitability for the end use (see 3.1). This European Standard applies for small wastewater treatment plants for use buried in the ground where no vehicle loads are applied to the product. This European Standard applies to plants where all prefabricated components are factory or site-assembled by one manufacturer and which are tested as a whole. NOTE In some countries, domestic wastewater treatment plants are followed by other systems to conform to national regulations. NOTE In some countries, domestic waste water treatment plants are followed by other systems to conform to national regulations.

EN 12566-3:2005 is classified under the following ICS (International Classification for Standards) categories: 13.060.30 - Sewage water. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12566-3:2005 has the following relationships with other standards: It is inter standard links to prEN 12566-3, EN 12566-3:2005+A1:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12566-3:2005 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/118. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12566-3:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Small wastewater treatment systems for up to 50 PT - Part 3: Packaged and/or site assembled domestic wastewater treatment plantsPetites installations de traitement des eaux usées jusqu'a 50 PTE - Partie 3: Stations d'épuration des eaux usées domestiques pretes a l'emploi et/ou assemblées sur siteKleinkläranlagen für bis zu 50 EW - Teil 3: Vorgefertigte und/oder vor Ort montierte Anlagen zur Behandlung von häuslichem Schmutzwasser13.060.30Odpadna vodaSewage waterICS:SIST EN 12566-3:2005enTa slovenski standard je istoveten z:EN 12566-3:200501-december-2005SIST EN 12566-3:2005SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12566-3

July 2005 ICS 13.060.30 English version

Small wastewater treatment systems for up to 50 PT - Part 3: Packaged and/or site assembled domestic wastewater treatment plants

Petites installations de traitement des eaux usées jusqu'à 50 PTE - Partie 3: Stations d'épuration des eaux usées domestiques prêtes à l'emploi et/ou assemblées sur site

Kleinkläranlagen für bis zu 50 EW - Teil 3: Vorgefertigte und/oder vor Ort montierte Anlagen zur Behandlung von häuslichem Schmutzwasser This European Standard was approved by CEN on 20 June 2005.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the Central Secretariat or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2005 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12566-3:2005: E

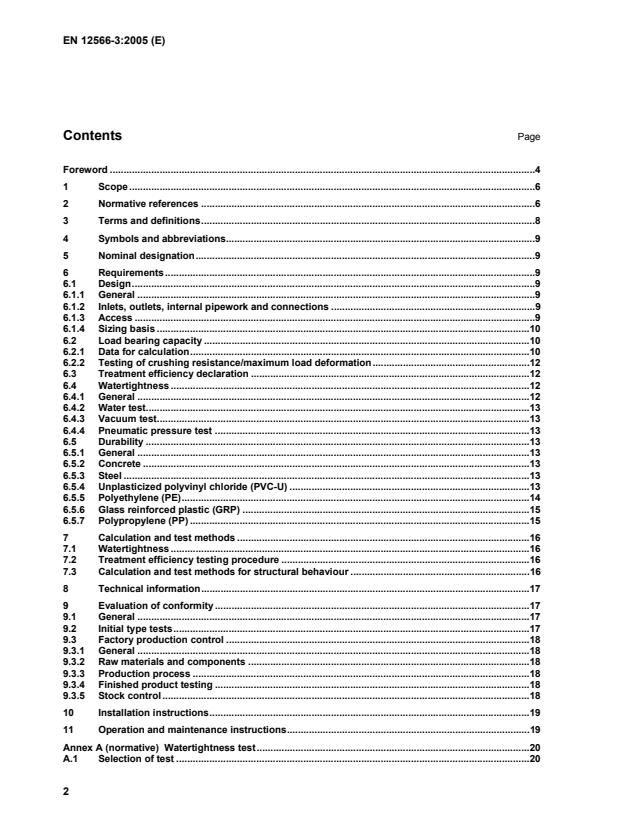

Watertightness test.20 A.1 Selection of test.20

Treatment efficiency test procedure.23 B.1 Responsibility and testing location.23 B.2 Plant selection and preliminary evaluation.23 B.2.1 General.23 B.2.2 Installation and commissioning.23 B.2.3 Operation and maintenance procedures during testing.23 B.2.4 Data to be monitored.24 B.3 Test procedure.24 B.3.1 Time for establishment.24 B.3.2 Influent characteristics.24 B.3.3 Daily flow pattern for testing.25 B.3.4 Test procedure.25 B.3.5 Influent and effluent samplings.27 B.4 Sample analysis.28 B.5 Test report.28 Annex C (normative)

Calculation and test methods for structural behaviour.30 C.1 General.30 C.2 Concrete plant.30 C.2.1 Crushing test methods.30 C.2.2 Test procedures.31 C.3 Polyethylene and polypropylene plant.34 C.3.1 Vertical load test.34 C.4 Determination of mechanical characteristics of test samples used for calculation.35 C.4.1 Concrete.35 C.4.2 Glass reinforced plastic (GRP).35 C.4.3 PVC-U.35 C.4.4 PE, PP.36 C.4.5 Steel.36 C.5 Vacuum test for Glass Reinforced Plastic.36 C.6 Pit test.37 C.6.1 Sample.37 C.6.2 Procedure.37 C.6.3 Expression of results.38 Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive.39 ZA.1 Scope and relevant characteristics.39 ZA.2 Procedure of attestation of conformity of plants.40 ZA.2.1 System of attestation of conformity.40 ZA.2.2 Declaration of conformity.41 ZA.3 CE Marking.42 Bibliography.45

The following Parts are in preparation:

Part 4: Septic tanks built in situ from prefabricated kits – Execution standard; Part 5: Pre-treated Effluent Filtration systems. Figure 1 shows the relationship between the parts of EN 12566. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

Key

A Domestic waste water (influent) B Pre-treated waste water C Infiltration into the ground D

Outlet of treated waste water (effluent) 1 Prefabricated septic tank (see Part 1) 2 Infiltration system (into the ground) (see Part 2;) 3 Waste water treatment plant (see Part 3) 4

Septic tank built in situ (see Part 4; in preparation) 5 Filtration systems (see Part 5; in preparation)

National regulations may specify different arrangements between the products described in the standards series EN 12566. Figure 1 – Scheme related to the arrangement of the parts of EN 12566

EN 1085:1997, Wastewater treatment – Vocabulary EN 1905, Plastics piping systems – Unplasticized poly(vinyl chloride) (PVC-U) pipes fittings and material – Method for assessment of the PVC content based on total chlorine content EN 12255-1, Wastewater treatment plants – Part 1: General construction principles

NOTE 1 It permits accessibility and maintenance work.

NOTE 2 It may be either a vertical extension piece of the tank, or components, which are fitted only over certain points for example to allow maintenance or observation.

4 Symbols and abbreviations BOD5 (or BOD7) Biochemical oxygen demand at 5 or 7 days (definition 3110 in EN 1085:1997) SS

Suspended solids (definition 3160 in EN 1085:1997) KN

Kjeldahl Nitrogen (definition 3210 in EN 1085:1997) NH4-N

Ammonium nitrogen COD

Chemical oxygen demand (definition 3120 in EN 1085:1997) PE

Polyethylene PVC-U

Unplasticized Poly-vinyl Chloride GRP

Glass reinforced plastic 5 Nominal designation The manufacturer shall state the nominal hydraulic daily flow QN expressed in cubic metres per day or the nominal organic daily load expressed in kg of BOD5 (or BOD7) per day. 6 Requirements 6.1 Design 6.1.1 General Plants shall be structurally stable, durable, watertight and corrosion resistant. Plants shall be provided with an alarm to indicate operational failure (for example electrical, mechanical or hydraulic failure). The manufacturer shall indicate which kind of failure is detected with the alarm. 6.1.2 Inlets, outlets, internal pipework and connections The minimum internal diameter of inlet and outlet pipes for gravity flow is specified below: 100 mm for nominal hydraulic daily flow ≤ 4 m3/d; 150 mm for nominal hydraulic daily flow > 4 m3/d. The hydraulic design of the equipment, the internal pipework and connections shall ensure that no back-flows, blockage or surcharging occur during normal operation. 6.1.3 Access Plants shall be designed to prevent unauthorised access and ensure operational safety. The design shall provide access to the inlet and outlet areas; this access may allow routine maintenance sampling, removal of sludge, cleaning and maintenance.

total depth of the plant

1 inlet H w

height of exterior water level (groundwater)

2 outlet K

coefficient of horizontal soil pressure h

depth of the backfill from the top of the tank to ground level Figure 2 – Definition of parameters 6.2.1.2 Backfill load Calculation of backfill loads shall take account of the effect of ground conditions, backfill materials and tank shape factors. A vertical and a horizontal component shall be calculated as follows: vertical component: h x 18 (expressed in kN/m2), where 18 (kN/m3) is the specific weight of the soil; horizontal component: K x D x 18 (expressed in kN/m2), where D is the distance from the ground level to the point where the load applies: sand: K

= 0,33; gravel: K

= 0,27; other backfill materials: K

= 0,5. 6.2.1.3 Hydrostatic loads A vertical and a horizontal component shall be calculated as follows: vertical component: Hw x 10 (expressed in kN/m2), where 10 (kN/m3) is the action resulting from the specific weight of water; horizontal component: D x 10 (expressed in kN/m2). On sites where the groundwater table is significant (the highest level of the groundwater table is above the bottom of the tank), the stability conditions of the product in relation to the water pressure shall be indicated in the manufacturer's instructions. In this case, the specific load of soil is 10 kN/m3 and shall be added to the water load.

is the efficiency ratio for a given parameter (COD, BOD, SS…); Pi

is the value of the given parameter at the inlet; Po

is the value of the same given parameter at the outlet. The ratio declared by the manufacturer shall not be greater than those obtained by the test made according to Annex B. In addition, another way of expression of the efficiency may be used for BOD, COD and suspended solid. EXAMPLE Minimum and maximum concentrations of the effluent and/or the influent. NOTE The ratios obtained do not automatically mean that the regulatory requirements on effluent qualities in a given country are met. A calculation should be made to indicate the final effluent qualities which should be compared to the requirements valid in the place of use. These ratios may not always be obtained when the plant is operating in practice. In addition, the following parameters shall be declared by the manufacturer: hydraulic daily flow and total power consumption if applicable. Where required, i.e. by national regulations, parameters described in B.2.4 shall be declared. 6.4 Watertightness 6.4.1 General The plant shall be watertight up to the height declared by the manufacturer; the minimum declared height shall be the top of the tank (see Figure A.1). The plant shall be tested according to at least one of the requirements given in 6.4.2 to 6.4.4 when tested according to the methods described in Annex A.

6.5.6 Glass reinforced plastic (GRP) The characteristics of the GRP used for the plant shall be: material shall be constructed using resins, reinforcement materials, processing agents and other materials in accordance with EN 976-1:1997, Clause 3; creep factor (.material) shall be ≥ 0,3. It is determined by using the following equation: iEfEtmaterial,=α (2) where initial flexural modulus (Ef,i) is determined at (23 ± 5) °C according to EN ISO 14125:1998, method A and corrigendum 1; long term flexural modulus (Et) is determined according to EN ISO 899-2 (temperature (23 ± 5)°C; extrapolation procedure according to EN ISO 9967); ageing factor () shall be ≥ 0,3. It is determined by using the following formula: iEfEf,,aged=β (3) where Ef,aged and Ef,i are determined according to the following procedure: a) specimen samples of laminate from the plant shall be prepared. The exposed edges shall be coated with the resin used in the manufacture of the plant. The samples shall be post-cured in air at (50 ± 2) °C for a minimum of 72 h; b) half of the specimen samples shall be immersed in water for (1 000 ± 16) h at (50 ± 1) °C or alternatively for (3 000 ± 16) h at (40 ± 1) °C. The flexural modulus (Ef,aged) shall be determined according to method A of EN ISO 14125:1998 at (23 ± 5) °C; c) half of the specimen samples shall be stored for the time as above at (23 ± 5) °C. The flexural modulus (Ef,i) shall be determined according to method A of EN ISO 14125:1998 at (23 ± 5) °C. 6.5.7 Polypropylene (PP) 6.5.7.1 Injection moulding The characteristics of the PP-injection moulding used for the plant shall be: MFR (230/2,16) = (5,0 ± 3,0 g)/10 min according to EN ISO 1133; density ≥ 905 kg/m3 according to EN ISO 1133; yield stress ≥ 30 MPa according to EN ISO 527-2, test temperature (23 ± 2) °C.

6.5.7.2 Extrusion The characteristics of the PP-extrusion used for the plant shall be: MFR (230/2,16) = (0,5 ± 0,1) g/10 min according to EN ISO 1133; density ≥ 908 kg/m3 according to EN ISO 1133; yield stress ≥ 30 MPa according to EN ISO 527-2, test temperature (23 ± 2) °C. 6.5.7.3 Injection moulding with foam The characteristics of Injection moulding with foam shall be: MFR (230/2,16) = (5,0 ± 3,0) g/10 min according to EN ISO 1133; density ≥ 720 kg/m3 according to EN ISO 1133; yield stress ≥ 24 MPa according to EN ISO 527, flexural strength ≥ 30 MPa according to EN ISO 178, compressive strength ≥ 450 MPa according to EN ISO 179, test temperature (23 ± 2) °C. 7 Calculation and test methods 7.1 Watertightness Plants shall be tested to at least one of the tests described in Annex A. 7.2 Treatment efficiency testing procedure The treatment efficiency of a plant shall be tested according to the method described in Annex B. 7.3 Calculation and test methods for structural behaviour Plants shall be subjected to a test or to a calculation taking into account the loads given in 6.2.1. Test methods for plants or mechanical characteristics used for calculation are given in Annex C. Where plants include watertight extension shafts, the loads at the maximum installed depth shall be taken into account and appropriate tests or calculations made to prove the structural adequacy.

8 Technical information The manufacturer shall provide the following information for each product: a) manufacturer and product identification; b) number of this European Standard, EN 12566-3; c) nominal hydraulic daily flow (m3/d) or nominal organic daily load BOD5 or BOD7 (kg/d); d) conditions of use; e) date of manufacture; f) name of laboratory (where appropriate); g) test report number (where appropriate); h) electrical supply (if required). Where ZA.3 requires the same information, the requirements of this clause are met. 9 Evaluation of conformity 9.1 General The conformity of the products with the requirements of this European Standard shall be demonstrated by: a) initial type tests (see 9.2); b) factory production control (see 9.3), including finished product test (see 9.3.4). NOTE For CE marking, Annex ZA applies. For the purposes of testing, products may be grouped into ranges. 9.2 Initial type tests Initial type tests shall be performed to demonstrate conformity with this European Standard. Tests previously performed in accordance with provision of this European Standard (same product, same characteristics, test methods, sampling procedure and system of attestation of conformity) may be taken into account. In addition, when a new product (outside an existing range) or product range is developed, appropriate initial type tests shall be carried out in accordance with the Table 1 to confirm that its final properties conform to the requirements of this European Standard. If a modification, likely to alter the functional properties of the finished product, takes place, the initial type tests shall be repeated. The results of the initial type tests shall be recorded and available for inspection, and shall be kept for at least 10 years after the date of last production of the plants to which they relate.

1 Accessibility X — 2 Watertightness X — 3 Structural behaviour — Xa 4 Treatment efficiency — Xb

5 Durability — Xc

a The biggest size will normally be selected assuming this size represents the worst structural behaviour. b The smallest size will normally be selected assuming this size represents the worst treatment efficiency. c Where the manufacturer uses materials for which the properties are already known (e.g. from the supplier), no durability testing is necessary.

9.3 Factory production control 9.3.1 General A factory production control system shall be established and documented. The factory production control system shall consist of procedures for the internal control of production to ensure that products placed on the market conform to this European Standard. 9.3.2 Raw materials and components The specifications of incoming raw materials and components shall be verified. 9.3.3 Production process The relevant features of the plant

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...