EN 15595:2009

(Main)Railway applications - Braking - Wheel slide protection

Railway applications - Braking - Wheel slide protection

This European Standard specifies the minimum criteria for system acceptance/type approval of a new wheel slide protection system and implementation of accepted WSP to specific vehicle applications and route requirements. This includes the design, testing and quality assessment of the WSP system and its components.

This European Standard is applicable to wheel slide protection systems for pneumatic braking systems without taking the type of vehicles and track-gauge into consideration. The general principles of this standard can also apply as a reference for other types of braking systems and other kinds of railway vehicles. The system is designed to control the sliding of wheels of railway vehicles during braking under degraded adhesion conditions to prevent wheel damage and to minimize the extension of the stopping distance under degraded adhesion conditions by optimizing the available adhesion between wheel and rail.

This European Standard does not apply to the following categories of vehicles:

1) tramways;

2) light railways;

3) metros on steel wheels;

4) metros on rubber tyred wheels.

Bahnanwendungen - Bremse - Gleitschutz

Diese Europäische Norm legt Anforderungen für die Konstruktion, die Erprobung und die Qualitätssicherung der Gleitschutzanlagen fest. Es liegt daher in der Verantwortung jedes Herstellers, alle notwendigen Schritte zu unternehmen, um sicherzustellen, dass die Qualität der Verarbeitung und die Konstruktion so beschaffen sind, dass sie der guten Ingenieurspraxis entsprechen.

Diese Europäische Norm gilt für Gleitschutzanlagen mit pneumatischen Bremssystemen ohne Berück-sichtigung der Fahrzeugtypen und der Spurbreite. Die Grundlagen der vorliegenden Norm gelten auch als Referenz für andere Arten von Bremssystemen. Das System ist dazu ausgelegt, das Gleiten der Räder von Schienenfahrzeugen zu regeln, um Radschaden zu verhindern und den Bremsweg durch Optimierung des verfügbaren Kraftschlusses zwischen Rad und Schiene auf ein Mindestmaß zu beschränken.

Applications ferroviaires - Freinage - Anti-enrayeur

La présente Norme européenne spécifie les critères minimaux pour l’acceptation du système / la qualification

de type d’un nouveau système d’anti-enrayeur et l’application d’un anti-enrayeur validé à des véhicules

spécifiques et à des exigences de missions. Cela comprend les exigences relatives à la conception, aux

essais et à l’assurance qualité d’un anti-enrayeur et de ses composants.

La présente Norme européenne est applicable aux anti-enrayeurs pour les systèmes de freinage

pneumatique indépendamment du type de véhicule et de l’écartement de la voie. Les principes généraux de

la présente norme s’appliquent également comme référence pour d’autres types de systèmes de freinage ou

d’autres types de véhicules ferroviaires. Le système est conçu pour contrôler le glissement des roues de

véhicules ferroviaires durant le freinage en conditions d’adhérence dégradées afin d’éviter d’endommager les

roues et de réduire le plus possible l’allongement de la distance d’arrêt dans des conditions d’adhérence

dégradées en optimisant l’adhérence disponible entre la roue et le rail.

La présente Norme européenne ne s’applique pas aux catégories suivantes de véhicules :

- tramways ;

- véhicules ferroviaires légers ;

- métros montés sur roues en acier ;

- métros montés sur roues à bandages pneumatiques.

Železniške naprave - Zavore - Preprečevanje zdrsa koles

General Information

- Status

- Withdrawn

- Publication Date

- 24-Feb-2009

- Withdrawal Date

- 10-May-2011

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 3/WG 24 - Components

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 11-May-2011

- Completion Date

- 11-May-2011

Relations

- Effective Date

- 12-Mar-2011

- Referred By

EN 15179:2007 - Railway applications - Braking - Requirements for the brake system of coaches - Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

EN 15595:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Braking - Wheel slide protection". This standard covers: This European Standard specifies the minimum criteria for system acceptance/type approval of a new wheel slide protection system and implementation of accepted WSP to specific vehicle applications and route requirements. This includes the design, testing and quality assessment of the WSP system and its components. This European Standard is applicable to wheel slide protection systems for pneumatic braking systems without taking the type of vehicles and track-gauge into consideration. The general principles of this standard can also apply as a reference for other types of braking systems and other kinds of railway vehicles. The system is designed to control the sliding of wheels of railway vehicles during braking under degraded adhesion conditions to prevent wheel damage and to minimize the extension of the stopping distance under degraded adhesion conditions by optimizing the available adhesion between wheel and rail. This European Standard does not apply to the following categories of vehicles: 1) tramways; 2) light railways; 3) metros on steel wheels; 4) metros on rubber tyred wheels.

This European Standard specifies the minimum criteria for system acceptance/type approval of a new wheel slide protection system and implementation of accepted WSP to specific vehicle applications and route requirements. This includes the design, testing and quality assessment of the WSP system and its components. This European Standard is applicable to wheel slide protection systems for pneumatic braking systems without taking the type of vehicles and track-gauge into consideration. The general principles of this standard can also apply as a reference for other types of braking systems and other kinds of railway vehicles. The system is designed to control the sliding of wheels of railway vehicles during braking under degraded adhesion conditions to prevent wheel damage and to minimize the extension of the stopping distance under degraded adhesion conditions by optimizing the available adhesion between wheel and rail. This European Standard does not apply to the following categories of vehicles: 1) tramways; 2) light railways; 3) metros on steel wheels; 4) metros on rubber tyred wheels.

EN 15595:2009 is classified under the following ICS (International Classification for Standards) categories: 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15595:2009 has the following relationships with other standards: It is inter standard links to EN 15595:2009+A1:2011, EN 15179:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15595:2009 is associated with the following European legislation: EU Directives/Regulations: 2001/16/EC, 2008/57/EC, 96/48/EC; Standardization Mandates: M/275, M/334. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15595:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Bahnanwendungen - Bremse - GleitschutzApplications ferroviaires - Freinage - Anti-enrayeurRailway applications - Braking - Wheel slide protection45.040Materiali in deli za železniško tehnikoMaterials and components for railway engineeringICS:Ta slovenski standard je istoveten z:EN 15595:2009SIST EN 15595:2009en,fr01-junij-2009SIST EN 15595:2009SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 15595February 2009ICS 45.060.01 English VersionRailway applications - Braking - Wheel slide protectionApplications ferroviaires - Freinage - Anti-enrayeurBahnanwendungen - Bremse - GleitschutzThis European Standard was approved by CEN on 3 January 2009.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre:

Avenue Marnix 17,

B-1000 Brussels© 2009 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 15595:2009: ESIST EN 15595:2009

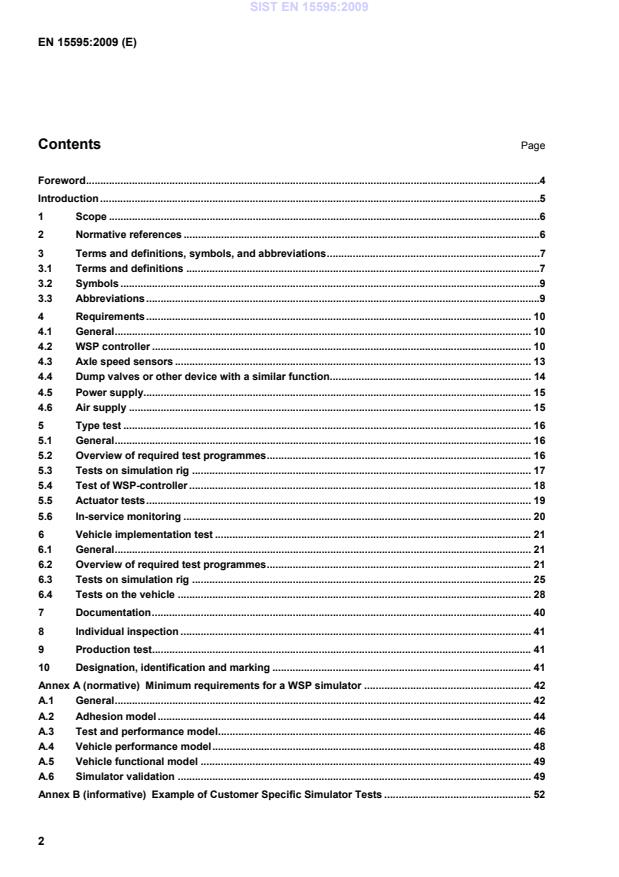

Minimum requirements for a WSP simulator . 42 A.1 General . 42 A.2 Adhesion model . 44 A.3 Test and performance model . 46 A.4 Vehicle performance model . 48 A.5 Vehicle functional model . 49 A.6 Simulator validation . 49 Annex B (informative)

Example of Customer Specific Simulator Tests . 52 SIST EN 15595:2009

Optional tests . 58 C.1 Sander system tests . 58 C.2 Dynamic braking system tests . 59 C.3 Peripheral output tests . 59 Annex D (informative)

Stages of a braking test . 61 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 96/48, as modifed by Directive 2004/50/EC . 63 Annex ZB (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2001/16 of the European Parliament and of the Council of 19 March 2001 on the interoperability of the trans-European conventional rail system, as modified by EU Directive 2004/50/EC of 29 April 2004 . 64 Bibliography . 66

vref signal generated and generally used by the WSP or WRM (wheel rotation monitoring system) to determine an approximation to the true train speed 3.1.1.12 duty cycle percentage of time which the WSP and brake control element is active compared with the total operational time 3.1.1.13 nominal train speed

v specified speed at start of braking during brake tests NOTE Real speed may slightly differ. 3.1.1.14 uncoupled test slip test method of brake testing where the vehicle under test is uncoupled from the rear of the test train and brakes separately 3.1.1.15 absolute wheel slide difference between true train speed and circumferential speed 3.1.1.16 relative wheel slide absolute wheel slide divided by true train speed 3.1.1.17 undesired venting reduction in braking force not justified by behaviour of wheelsets 3.1.1.18 drag braking test test with auxiliary tractive unit performed as a braking with constant brake application and constant speed 3.1.1.19 dynamic brake blending curve curve describing the characteristics of blending of dynamic brake as function of speed 3.1.2 Components 3.1.2.1 WSP rack/controller device having the power supply interface with the vehicle control supply and the electronic hardware and software to receive the signals from the speed sensors and provide the outputs to the WSP brake control elements, for example dump valves enabling the modulation of the brake cylinder pressure 3.1.2.2 WSP dump valve device used to control the amount of air within the brake cylinder in relation to the adhesion level perceived by the WSP controller SIST EN 15595:2009

3.3 Abbreviations AR auxiliary reservoir BP brake pipe BSR brake supply reservoir; for an air brake system with distributor valve, referred to as auxiliary reservoir DNRA detection of non-rotating axle (same as WRM) EB emergency brake ER anticipated event – used in safety analysis FS full service brake G brake mode G: brake mode used for freight trains with specified brake application time and brake release time. MRP main reservoir pipe Nl normal litre P brake mode: brake mode for passenger and freight trains with specified brake application time and brake release time and specified brake mass percentage P(SS) brake mode P(SS): brake mode for passenger and freight trains with specified brake application time and brake release time and specified brake mass percentage equipped with a self adjusting load-proportional brake system R brake mode R: brake mode for passenger trains and fast freight trains with specified brake application time and brake release time as for braking mode P and specified minimum brake mass percentage RAMS reliability, availability, maintainability and safety WRM wheel rotation monitoring system (sometimes called DNRA) WSP wheel slide protection SIST EN 15595:2009

The WSP shall not alter the demanded braking force at reference speed less than a predefined threshold and if the brake force has been reduced by the WSP system then the brake force shall be raised to the demanded value.

This reference speed threshold shall not be higher than 3 km/h. The WSP shall not be capable of applying a greater brake force than that demanded.

The WSP shall not alter the demanded braking force at standstill except during test. WSP-actuators (e.g. WSP dump valves) are able to reduce braking force. 4.2.2 WSP watchdog (safety timer)

The independent monitoring or watchdog function shall be provided for all systems. The watchdog function shall remain permanently active including WSP tests, in order to restore the braking force required by the command if sustained release of the brake occurs. Actuation of this function other than during a test shall be indicated and recorded as a fault. If the watchdog function is activated, it shall be able to revert automatically to its stand-by position when the WSP resumes normal functioning. The reliability of the watchdog device shall conform to ER1 in 4.2.3.4. An independent monitoring or watchdog function, independent from the control algorithm and processor, shall support the automatic control system. The function shall prevent triggering of the actuator if total release of the brake, friction or dynamic brake (or a combination of them during blending), continues uninterrupted for a set SIST EN 15595:2009

4.2.4 Functional characteristics 4.2.4.1 Wheel diameter differences The system shall tolerate permitted differences of the wheel diameter differences on a given vehicle when evaluating speed. 4.2.4.2 Special features of WSPs for dynamic and mixed braking systems The characteristics according to 4.1.1 to 4.2.3 are also mandatory for WSP of dynamic brakes if applicable (except 4.2.2). Wheel slide shall be kept within the tolerance range as specified for friction brake in Clause 6.4.3.2 in the case of tractive units where the dynamic brake can be used independently of the friction brake (particularly for drag SIST EN 15595:2009

It is also recommended that the rotation monitor takes over the principal functions of the WSP if this is defective. 4.3 Axle speed sensors 4.3.1 Integration The WSP sensors shall be an integral part of the WSP system. 4.3.2 Electrical connection The sensor shall be easy to disconnect for bogie or axle maintenance. The sensor should connect into a junction box or should be fitted with a plug. SIST EN 15595:2009

– 25 °C and + 70 °C the WSP dump valve shall not leak at a rate greater than 0,01 Nl/min when tested at a pressure of 7 bar. This requirement shall be tested in accordance with subclause 5.5.5.1. Between – 40 °C and – 25 °C a WSP dump valve shall have a leakage rate of not greater than 0,1 Nl/min when tested at a pressure of 4 bar in accordance with subclause 5.5.5.2. SIST EN 15595:2009

4.5 Power supply Where the design of the vehicle requires the WSP to have a standby option, the power supply to the WSP shall be designed to ensure that the WSP powers up and that power is available when the vehicle is set in motion. WSP systems require a power supply to function and this can be provided by the vehicles or by the WSP itself. WSP systems shall be designed to function correctly allowing for fluctuations in voltage as permitted in EN 50155, Clause 3.1.2. If the voltage fluctuation exceeds this limit, the WSP shall either operate normally or shut down without disturbing all connected systems (such as brake system, door control). The WSP shall automatically return to normal functioning if it shuts down during the voltage fluctuation as soon as the supply voltage reverts to the permitted range. If the WSP does not supply its own power, fluctuations in voltage as permitted in EN 50155, Clause 3.1.2 shall not affect its functioning. The WSP installation for friction brake shall have its own protected electrical circuit except if it is an integrated part of the brake control. Power supply for WRM shall be protected by its own circuit breaker in order to make it independent.

A WSP installation on a trailing (non-powered) vehicle, which is not part of a fixed formation multiple unit, shall have its own protected circuit. Fuses or circuit breakers for the WSP shall be separated from others on the vehicle so that they cannot be confused with or operated in the same manner. The WSP shall be supplied whenever there is power available. Automatic cut-off of the supply is only permissible in the case of sleep-mode (no vehicle movement) or battery protection for battery safety reasons (degraded battery situation or low voltage caused by long-term lack of supply). 4.6 Air supply 4.6.1 Air consumption The WSP shall be designed to minimize the additional air consumption due to its operation. The vehicle’s air equipment shall be dimensioned such that the air consumption of the WSP does not impair the performance of the pneumatic brake. In particular, operation of the WSP shall not give rise to BSR pressures below the demanded brake application pressure. As an option, the WSP shall be inhibited if the BSR pressure falls below a fixed pressure. For vehicles with limited air supply, for example single brake pipe freight wagons the WSP shall be disabled when the Brake supply reservoir (AR) pressure drops to the minimum emergency brake pressure. 4.6.2 Air quality It shall be possible to operate the WSP dump valve or control device without restrictions with compressed air quality according to the following classes defined by ISO 8573-1 or better: Class 4 – for the maximum particle size and the maximum concentration of solid contaminants; SIST EN 15595:2009

The simulator testing (type test) may be replaced partially by track test on a vehicle. A track test, as part of the vehicle implementation test, shall be performed except where there is previous evidence of track testing. The requirement for re-testing (type-test) if hardware or software is modified, is derived from EN 50128. 5.1.2 Conditions of test Testing shall include vehicle types as coaches, wagons and tractive units, depending on the intended applications for the equipment. Slip tests shall be performed in accordance with Tables 3, 4 and 5 dependent upon the vehicle type and speed. The simulator facility shall be capable of testing a range of vehicle types and conditions. The general design requirements for the simulator facility are identified in Annex A. 5.1.3 Ambient temperature for track testing The vehicle WSP tests shall be performed at moderate ambient temperatures (between 5 °C and 25 °C), and shall not be performed in snow. The temperature on the rail surface shall be recorded after every test and shall lie between 5 °C and 35 °C. 5.1.4 Air supply For the tests, measures shall be taken to ensure that the auxiliary reservoir provides sufficient air so that there is maximum pressure in the brake cylinders in all brake positions under dry conditions. 5.2 Overview of required test programmes The function of the WSP shall be tested as in Table 1 below: SIST EN 15595:2009

Test facility simulation possible b

For adhesion-independent brakes

5.3 Tests on simulation rig 5.3.1 General Simulator facility tests should, where technically possible, be used both as part of the verification process and also to validate WSP changes. Simulator facility tests are intended to reduce the number of track tests required and are particularly valuable for the following requirements: 1) initial optimization of the WSP equipment prior to any track testing; 2) as a replacement for track tests which present operational difficulties, for example, high speed tests, or operational track access limitations; 3) to modify the WSP parameters when changes are required to suit a variation in the vehicle design, for example when there are significant variations in wheelset inertia between a trailer vehicle and a motored vehicle of the same basic unit type; 4) to modify the WSP parameters when the WSP is used on a different type of vehicle than that for which it was originally approved; 5) to evaluate the implication of sanding or other system that could impact upon the WSP performance; 6) as part of a post incident investigation. The design requirements for simulation facilities are set out Annex A. This subclause details the simulation testing of WSP systems. The performance criteria that are to be met by the WSP system under evaluation are outlined in 6.3.1 and 6.3.2. 5.3.2 Simulation Validity Test Prior to the commencement of the testing programme, the accuracy of the vehicle model simulation shall be validated by comparing the braking performance predicted by the computer model to actual track test data for SIST EN 15595:2009

The simulation validity test shall be performed on an adhesion profile representing a level of adhesion consistently greater than that which will sustain the vehicle’s maximum braking rate (i.e. equivalent to good, dry conditions). If track test figures are unavailable (e.g. for new rolling stock), predicted/calculated dry rail stopping distances provided by the train braking designer/supplier may be used for the validation process. The adhesion profile shall be described in terms of the coefficient of railhead friction against distance along the running line. This will vary with the level of wheel slide. The test(s) shall be performed for at least one vehicle condition (tare/laden) for each vehicle type, from a braking speed based upon track test measurements or calculation data. This shall be the train’s maximum operating speed. The vehicle model simulation shall be deemed acceptable provided the predicted stopping distance(s) concur to within ± 5 % of the dry rail stopping distances achieved by the track tests or by the braking equipment suppliers' calculations.

5.3.3 Simulator Tests For simulation testing it is highly desirable to be able to recreate the characteristics of: 1) track based detergent (6.3); 2) leaf film (6.3.3.1); 3) presence of water

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...