EN 16750:2017+A1:2020

(Main)Fixed firefighting systems - Oxygen reduction systems - Design, installation, planning and maintenance

Fixed firefighting systems - Oxygen reduction systems - Design, installation, planning and maintenance

This European standard specifies oxygen reduction systems that are used as fire prevention systems by creating an atmosphere in an area which is having a lower permanent oxygen concentration as in ambient conditions. The level of oxygen reduction is defined by the individual risks of these areas (see Annex A). Oxygen reduction is achieved by technical systems which are providing a flux of air containing a reduced concentration of oxygen.

This European standard specifies minimum requirements and defines the specifications governing the design, installation and maintenance of fixed oxygen reduction systems with oxygen reduced air in buildings and industrial production plants. The standard also applies to the extension and modification of existing systems.

This European standard applies to oxygen reduction systems using nitrogen which are designed for continual oxygen reduction in enclosed spaces.

NOTE Nitrogen is today the most suitable gas to be used for oxygen reduction. For other gases this European standard can be used as basis.

This European standard does not apply to oxygen reduction systems that use water mist or combustion gases.

The European standard does not apply to:

- explosion suppression systems;

- explosion prevention systems;

- fire extinguishing systems using gaseous extinguishing agents;

- inertization of portable containers;

- systems in which oxygen levels are reduced for reasons other than fire prevention (e.g. steel processing in the presence of inert gas to avoid the formation of oxide film);

- inerting required during repair work on systems or equipment (e.g. welding) in order to eliminate the risk of fire or explosion.

In addition to the conditions for the actual oxygen reduction system and its individual components this European standard also covers certain structural specifications for the protected area.

The space protected by an oxygen reduction system is a controlled and continuously monitored indoor climate for extended occupation. This standard does not cover unventilated confined spaces that may contain hazardous gases.

Ortsfeste Löschanlagen - Sauerstoffreduktionsanlagen - Auslegung, Einbau, Planung und Instandhaltung

Diese Europäische Norm legt Anforderungen an die Sauerstoffreduktionsanlagen fest, die als Brandvermeidungsanlagen verwendet werden, indem in einem Bereich eine Atmosphäre erzeugt wird, die eine niedrigere ständige Sauerstoffkonzentration aufweist als unter Umgebungsbedingungen. Der Grad der Sauerstoffreduktion ist durch die einzelnen Brandrisiken, die in diesen Bereichen vorherrschen, festgelegt (siehe Anhang A). Die Sauerstoffreduktion wird durch technische Systeme erreicht, die einen Volumenstrom sauerstoffreduzierter Luft erzeugen.

Diese Europäische Norm legt die Mindestanforderungen an die Auslegung, den Einbau und die Instandhaltung von ortsfesten Sauerstoffreduktionsanlagen mit sauerstoffreduzierter Luft in Gebäuden und Industrieanlagen fest und enthält die diesbezüglichen Festlegungen. Die Norm gilt auch für die Erweiterung und Änderung bereits vorhandener Anlagen.

Diese Europäische Norm gilt für Sauerstoffreduktionsanlagen mit Stickstoff zur kontinuierlichen Sauerstoffreduktion in umschlossenen Räumen.

ANMERKUNG Stickstoff ist gegenwärtig das geeignetste Gas für die Sauerstoffreduktion. Bezüglich weiterer Gase kann diese Europäische Norm als Grundlage dienen.

Diese Europäische Norm gilt nicht für Sauerstoffreduktionsanlagen, die Wassernebel oder Verbrennungsgase verwenden.

Diese Europäische Norm gilt nicht für:

Explosionsunterdrückungsanlagen;

Explosionsschutzanlagen;

Feuerlöschanlagen mit gasförmigen Feuerlöschmitteln;

die Inertisierung tragbarer Behälter;

Anlagen, bei denen der Sauerstoffgehalt aus anderen Gründen als der Brandvermeidung reduziert wird (z. B. Stahlverarbeitung unter Inertgas zur Vermeidung der Bildung einer Oxidschicht);

die Inertisierung, die bei Reparaturarbeiten von Anlagen oder Apparaturen (z. B. Schweißen) zur Vermeidung der Brand- oder Explosionsgefahr erforderlich ist.

Neben den Vorgaben für die eigentliche Sauerstoffreduktionsanlage und ihre einzelnen Bauteile behandelt die vorliegende Europäische Norm auch bestimmte bauliche Anforderungen an den Schutzbereich.

Der von einer Sauerstoffreduktionsanlage geschützte Bereich ist ein geregeltes und ständig überwachtes Innenraumklima für längere Nutzung. Diese Norm behandelt keine unbelüfteten engen Räume, in denen sich gefährliche Gase befinden können.

Installations fixes de lutte contre l'incendie - Systèmes d'appauvrissement en oxygène - Conception, installation, planification et maintenance

La présente Norme européenne spécifie les systèmes d’appauvrissement en oxygène qui sont utilisés comme systèmes de prévention incendie en créant, dans les zones protégées, une atmosphère dans laquelle la concentration en oxygène est réduite en permanence par rapport aux conditions ambiantes. Le niveau d’appauvrissement en oxygène est défini par les risques individuels identifiés dans les zones protégées (voir l’Annexe A). L’appauvrissement en oxygène est obtenu au moyen de systèmes qui fournissent un flux d’air ayant une concentration réduite en oxygène.

La présente Norme européenne spécifie les exigences minimales et définit les spécifications régissant la conception, l’installation et la maintenance des systèmes fixes d’appauvrissement en oxygène dans des bâtiments et dans des usines de production industrielle fonctionnant sous air appauvri en oxygène. La norme s’applique également à l’extension et à la modification des systèmes existants.

La présente Norme européenne s’applique aux systèmes d’appauvrissement en oxygène utilisant de l’azote, qui sont conçus pour assurer un appauvrissement continu en oxygène dans des espaces clos.

NOTE L’azote est à l’heure actuelle le gaz le mieux adapté pour réaliser un appauvrissement en oxygène. Pour les autres gaz, la présente Norme européenne peut être utilisée comme base.

La présente Norme européenne ne s’applique pas aux systèmes d’appauvrissement en oxygène comme le brouillard d’eau ou les systèmes d’extinction gaz.

La présente Norme européenne ne s’applique pas :

- aux systèmes anti-explosion ;

- aux systèmes de prévention des explosions ;

- aux systèmes d’extinction d’incendie utilisant des agents extincteurs gazeux ;

- à l’inertage des réservoirs portatifs ;

- aux systèmes dans lesquels les niveaux d’oxygène sont réduits pour des raisons autres que la prévention incendie (par exemple, transformation de l’acier en présence de gaz inerte pour éviter la formation d’un film d’oxyde) ;

- à l’inertage nécessaire pendant les travaux de réparation des systèmes ou de l’équipement (par exemple, soudage) afin d’éliminer le risque d’incendie ou d’explosion.

En plus des conditions qui s’appliquent au système d’appauvrissement en oxygène proprement dit et à ses composants individuels, la présente Norme européenne couvre également certaines spécifications structurelles relatives à la zone protégée.

Un espace protégé par un système d’appauvrissement en oxygène est une zone à l’intérieur d’un bâtiment dont l’environnement est contrôlé en continu pour permettre une occupation prolongée. A contrario, la présente norme ne concerne pas les espaces confinés non ventilés susceptibles de contenir des gaz dangereux.

Vgrajeni gasilni sistemi - Sistemi z zmanjšano koncentracijo kisika - Projektiranje, vgradnja, načrtovanje in vzdrževanje

General Information

- Status

- Published

- Publication Date

- 18-Aug-2020

- Withdrawal Date

- 27-Feb-2021

- Technical Committee

- CEN/TC 191 - Fixed firefighting systems

- Drafting Committee

- CEN/TC 191/WG 6 - Gas extinguishing Systems and components

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 06-Apr-2023

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 01-Jul-2020

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 16750:2017+A1:2020 is a CEN European standard for fixed firefighting systems - oxygen reduction systems. It defines minimum requirements for the design, installation, planning and maintenance of systems that prevent fire by creating and maintaining a permanently oxygen‑reduced atmosphere in enclosed spaces. The standard applies primarily to systems using nitrogen to supply oxygen‑reduced air and covers continuous inerting solutions in buildings and industrial plants. It does not apply to water‑mist or combustion‑gas systems, gaseous extinguishing agents, explosion‑suppression systems or inerting for non‑fire‑prevention processes.

Key topics and technical requirements

EN 16750 lays out technical and organizational requirements including:

- System requirements and effectiveness - criteria for achieving target oxygen concentration based on assessed ignition thresholds (see Annex A).

- Design - qualification of designers, fire protection concepts, structural specifications for the protected area, safety margins and calculation of oxygen‑reduced air quantities.

- Distribution pipework - installation, components and support requirements for delivery of reduced‑oxygen air.

- Monitoring and controls - continuous oxygen concentration monitoring, alarms (local and external), fault signalling and data recording.

- Control equipment and power - functional and electrical requirements for control panels and supply reliability.

- Operation, maintenance and documentation - inspection, maintenance schedules, training, operations logs and system documentation.

- Health & safety (Annex B) - guidance on occupational safety, risk classification and measures for working in reduced‑oxygen atmospheres.

- National regulatory considerations (Annex C) - awareness that national rules for access and work in low‑oxygen areas vary across EU members.

Applications and who uses this standard

EN 16750 is intended for stakeholders involved in fire prevention by atmospheric control:

- Fire safety engineers and consultants designing oxygen reduction solutions.

- System manufacturers and installers responsible for equipment selection and installation.

- Facility and plant managers deploying continuous nitrogen inerting for archives, data centers, museums, warehouses, chemical or pharmaceutical production areas.

- Maintenance contractors performing inspections, testing and servicing.

- Regulators and safety officers assessing compliance and occupational health impacts.

Practical benefits include reduced ignition risk for stored materials, tailored fire prevention strategies, and clear operational and safety procedures for continuously occupied, controlled atmospheres.

Related standards

EN 16750 references and complements other standards, notably:

- EN 54 (Fire detection and alarm systems)

- EN 50104 (Oxygen measuring apparatus)

- EN 12094‑1 (Components for gas extinguishing systems)

Keywords: EN 16750, oxygen reduction systems, fixed firefighting systems, nitrogen inerting, oxygen‑reduced air, design, installation, maintenance, fire prevention.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 16750:2017+A1:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "Fixed firefighting systems - Oxygen reduction systems - Design, installation, planning and maintenance". This standard covers: This European standard specifies oxygen reduction systems that are used as fire prevention systems by creating an atmosphere in an area which is having a lower permanent oxygen concentration as in ambient conditions. The level of oxygen reduction is defined by the individual risks of these areas (see Annex A). Oxygen reduction is achieved by technical systems which are providing a flux of air containing a reduced concentration of oxygen. This European standard specifies minimum requirements and defines the specifications governing the design, installation and maintenance of fixed oxygen reduction systems with oxygen reduced air in buildings and industrial production plants. The standard also applies to the extension and modification of existing systems. This European standard applies to oxygen reduction systems using nitrogen which are designed for continual oxygen reduction in enclosed spaces. NOTE Nitrogen is today the most suitable gas to be used for oxygen reduction. For other gases this European standard can be used as basis. This European standard does not apply to oxygen reduction systems that use water mist or combustion gases. The European standard does not apply to: - explosion suppression systems; - explosion prevention systems; - fire extinguishing systems using gaseous extinguishing agents; - inertization of portable containers; - systems in which oxygen levels are reduced for reasons other than fire prevention (e.g. steel processing in the presence of inert gas to avoid the formation of oxide film); - inerting required during repair work on systems or equipment (e.g. welding) in order to eliminate the risk of fire or explosion. In addition to the conditions for the actual oxygen reduction system and its individual components this European standard also covers certain structural specifications for the protected area. The space protected by an oxygen reduction system is a controlled and continuously monitored indoor climate for extended occupation. This standard does not cover unventilated confined spaces that may contain hazardous gases.

This European standard specifies oxygen reduction systems that are used as fire prevention systems by creating an atmosphere in an area which is having a lower permanent oxygen concentration as in ambient conditions. The level of oxygen reduction is defined by the individual risks of these areas (see Annex A). Oxygen reduction is achieved by technical systems which are providing a flux of air containing a reduced concentration of oxygen. This European standard specifies minimum requirements and defines the specifications governing the design, installation and maintenance of fixed oxygen reduction systems with oxygen reduced air in buildings and industrial production plants. The standard also applies to the extension and modification of existing systems. This European standard applies to oxygen reduction systems using nitrogen which are designed for continual oxygen reduction in enclosed spaces. NOTE Nitrogen is today the most suitable gas to be used for oxygen reduction. For other gases this European standard can be used as basis. This European standard does not apply to oxygen reduction systems that use water mist or combustion gases. The European standard does not apply to: - explosion suppression systems; - explosion prevention systems; - fire extinguishing systems using gaseous extinguishing agents; - inertization of portable containers; - systems in which oxygen levels are reduced for reasons other than fire prevention (e.g. steel processing in the presence of inert gas to avoid the formation of oxide film); - inerting required during repair work on systems or equipment (e.g. welding) in order to eliminate the risk of fire or explosion. In addition to the conditions for the actual oxygen reduction system and its individual components this European standard also covers certain structural specifications for the protected area. The space protected by an oxygen reduction system is a controlled and continuously monitored indoor climate for extended occupation. This standard does not cover unventilated confined spaces that may contain hazardous gases.

EN 16750:2017+A1:2020 is classified under the following ICS (International Classification for Standards) categories: 13.220.20 - Fire protection. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16750:2017+A1:2020 has the following relationships with other standards: It is inter standard links to EN 16750:2017, EN 16750:2017/FprA1, EN IEC 60079-29-0:2026, EN 54-17:2005, EN 54-16:2008, EN 12094-1:2003, EN 54-28:2016, EN 54-4:1997, EN 54-4:1997/A1:2002, EN 54-12:2015, EN 54-30:2015, EN 54-25:2008, EN 54-21:2006, EN 54-5:2017+A1:2018, EN 54-1:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16750:2017+A1:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2020

Nadomešča:

SIST EN 16750:2017

Vgrajeni gasilni sistemi - Sistemi z zmanjšano koncentracijo kisika - Projektiranje,

vgradnja, načrtovanje in vzdrževanje

Fixed firefighting systems - Oxygen reduction systems - Design, installation, planning

and maintenance

Ortsfeste Löschanlagen - Sauerstoffreduktionsanlagen - Auslegung, Einbau, Planung

und Instandhaltung

Installations fixes de lutte contre l'incendie - Systèmes d'appauvrissement en oxygène -

Conception, installation, planification et maintenance

Ta slovenski standard je istoveten z: EN 16750:2017+A1:2020

ICS:

13.220.10 Gašenje požara Fire-fighting

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 16750:2017+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

August 2020

EUROPÄISCHE NORM

ICS 13.220.20 Supersedes EN 16750:2017

English Version

Fixed firefighting systems - Oxygen reduction systems -

Design, installation, planning and maintenance

Installations fixes de lutte contre l'incendie - Systèmes Ortsfeste Löschanlagen - Sauerstoffreduktionsanlagen -

d'appauvrissement en oxygène - Conception, Auslegung, Einbau, Planung und Instandhaltung

installation, planification et maintenance

This European Standard was approved by CEN on 9 July 2017 and includes Amendment 1 approved by CEN on 12 July 2020.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 16750:2017+A1:2020 E

worldwide for CEN national Members.

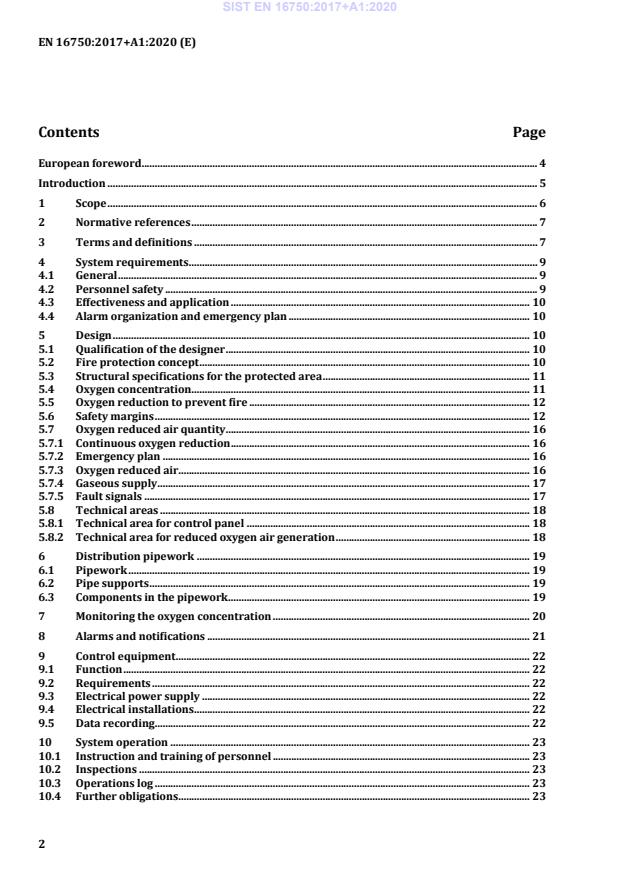

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 7

3 Terms and definitions . 7

4 System requirements . 9

4.1 General . 9

4.2 Personnel safety . 9

4.3 Effectiveness and application . 10

4.4 Alarm organization and emergency plan . 10

5 Design . 10

5.1 Qualification of the designer . 10

5.2 Fire protection concept . 10

5.3 Structural specifications for the protected area . 11

5.4 Oxygen concentration . 11

5.5 Oxygen reduction to prevent fire . 12

5.6 Safety margins . 12

5.7 Oxygen reduced air quantity . 16

5.7.1 Continuous oxygen reduction . 16

5.7.2 Emergency plan . 16

5.7.3 Oxygen reduced air . 16

5.7.4 Gaseous supply . 17

5.7.5 Fault signals . 17

5.8 Technical areas . 18

5.8.1 Technical area for control panel . 18

5.8.2 Technical area for reduced oxygen air generation . 18

6 Distribution pipework . 19

6.1 Pipework . 19

6.2 Pipe supports . 19

6.3 Components in the pipework . 19

7 Monitoring the oxygen concentration . 20

8 Alarms and notifications . 21

9 Control equipment . 22

9.1 Function . 22

9.2 Requirements . 22

9.3 Electrical power supply . 22

9.4 Electrical installations . 22

9.5 Data recording . 22

10 System operation . 23

10.1 Instruction and training of personnel . 23

10.2 Inspections . 23

10.3 Operations log . 23

10.4 Further obligations . 23

11 Maintenance . 24

12 Documentation . 24

13 Installation . 25

13.1 Qualification of the installer . 25

13.2 General specifications, installation . 25

Annex A (normative) Ignition thresholds for oxygen reduction using nitrogen in fire

prevention . 26

A.1 Ignition thresholds . 26

A.2 Tests to ascertain ignition thresholds of unfamiliar materials . 27

A.2.1 Cup burner tests . 27

A.2.2 Ignition threshold tests . 28

A.2.2.1 General . 28

A.2.2.2 Test criteria . 29

A.2.2.3 Test documentation . 29

Annex B (informative) Information for health and safety – Working in oxygen-reduction

atmospheres for reasons of fire prevention . 31

B.1 General . 31

B.2 Principles of occupational health . 31

B.3 Risk classes . 31

B.4 Basic requirements, planning and installation . 32

B.5 Protective measures for all areas with oxygen-reduced atmospheres . 33

B.5.1 Structural and technical measures. 33

B.5.2 Organizational measures . 34

B.6 Risk classes and safety measures . 35

Annex C (informative) Existing national regulations for access and working in areas with

lower oxygen concentration . 36

Bibliography . 37

European foreword

This document (EN 16750:2017+A1:2020) has been prepared by Technical Committee CEN/TC 191

“Fixed firefighting systems”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by February 2021, and conflicting national standards

shall be withdrawn at the latest by February 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes !EN 16750:2017".

This document includes Amendment 1 approved by CEN on 12 July 2020.

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

Introduction

Oxygen reduction systems are designed to prevent fires from starting or spreading, by means of the

introduction of oxygen reduced air. Oxygen reduction systems are not designed to extinguish fires. The

design and installation shall be based on detailed knowledge of the protected area, its occupancy and

the materials in question. It is important to suit the fire protection measures to the hazard as a whole.

It is important to emphasize that across the European Union there are several regulatory and legislative

limitations for access and working in areas with lower oxygen concentration, so it is important to take

these limitations into account. Use of this European Standard can vary based on the national legislation

in each country of the European Union.

1 Scope

This European standard specifies oxygen reduction systems that are used as fire prevention systems by

creating an atmosphere in an area which is having a lower permanent oxygen concentration as in

ambient conditions. The level of oxygen reduction is defined by the individual risks of these areas (see

Annex A). Oxygen reduction is achieved by technical systems which are providing a flux of air

containing a reduced concentration of oxygen.

This European standard specifies minimum requirements and defines the specifications governing the

design, installation and maintenance of fixed oxygen reduction systems with oxygen reduced air in

buildings and industrial production plants. The standard also applies to the extension and modification

of existing systems.

This European standard applies to oxygen reduction systems using nitrogen which are designed for

continual oxygen reduction in enclosed spaces.

NOTE Nitrogen is today the most suitable gas to be used for oxygen reduction. For other gases this European

standard can be used as basis.

This European standard does not apply to oxygen reduction systems that use water mist or combustion

gases.

The European standard does not apply to:

— explosion suppression systems;

— explosion prevention systems;

— fire extinguishing systems using gaseous extinguishing agents;

— inertization of portable containers;

— systems in which oxygen levels are reduced for reasons other than fire prevention (e.g. steel

processing in the presence of inert gas to avoid the formation of oxide film);

— inerting required during repair work on systems or equipment (e.g. welding) in order to eliminate

the risk of fire or explosion.

In addition to the conditions for the actual oxygen reduction system and its individual components this

European standard also covers certain structural specifications for the protected area.

The space protected by an oxygen reduction system is a controlled and continuously monitored indoor

climate for extended occupation. This standard does not cover unventilated confined spaces that may

contain hazardous gases.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

EN 54 (all parts), Fire detection and fire alarm systems

EN 12094-1, Fixed firefighting systems — Components for gas extinguishing systems — Part 1:

Requirements and test methods for electrical automatic control and delay devices

EN 50104, Electrical apparatus for the detection and measurement of oxygen — Performance

requirements and test methods

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

Alarms

3.1.1

external alarm

alarm to emergency services such as fire brigade or permanently attended location

3.1.2

local alarm

acoustic and possibly additional visual alarm in protected areas or their immediate surroundings

3.1.3

internal alarm

acoustic and visual displays at the detection panel, possibly with additional displays at other signalling

equipment

3.1.4

alarm threshold

value of a process parameter which, when reached, triggers an alarm and, where necessary, initiates

automatic protection measures

3.1.5

alarm signal

signal to warn people at risk and/or to summon help from the emergency services and/or to provide

information about automatic response measures

3.2

design concentration

ingnition threshold including a safety margin

Note 1 to entry: See also Figure 1.

Note 2 to entry: The design concentration represents the maximum oxygen concentration which cannot be

exceeded in any time.

3.3

emergency situation

deviation from normal operation

EXAMPLE For example a significant deviation from the threshold value (scale of risk).

3.4

operating pressure

pressure of a system under normal operating conditions

3.5

combustible material

A material capable of combustion or being ignited

Note 1 to entry: For the purposes of this standard, whether the quantity of a combustible material is to be

regarded as significant or not can be determined by means of a risk analysis as part of the fire protection design.

3.6

ignition threshold

maximum oxygen concentration in a mixture of a combustible material with air and inert gas, in which

there can be no ignition, determined under established test conditions

Note 1 to entry: This is a specific characteristic of combustible material and inert gas (see A.1).

3.7

detection and alarm installation

remote detection system for the reliable detection of risk to people and property

Note 1 to entry: It creates alarm reports from automatic or manually input information, issues these and detects

any faults. The transmission channels for information and alarms are monitored. Special measures are in place to

prevent any malfunction as far as possible, which may be powered electrically or otherwise. Detection and alarm

systems cover facilities for the input, transmission (through wires or wirelessly), processing and issuing of alarms,

including the necessary power supply. This standard applies to detection and alarm systems which detect and

report the scale of the risk at an early stage.

3.8

measuring zones

virtual separation of the protected volume for oxygen measuring

3.9

normal operation

situation in which the equipment, protection systems and components are able to carry out their

designated functions within their design parameters

3.10

oxygen reduced air

ambient air with an oxygen concentration lower than natural air

3.11

oxygen reduced air supply

nitrogen enriched air stream with an oxygen concentration of less than natural air ready to be

introduced into a protected volume

3.12

oxygen reduction

reduction of oxygen which increases the nitrogen concentration to prevent the ignition or spread of fire

3.13

protected volume

effective volume of the space to be protected

3.14

system

combination of components whose function and compatibility guarantees the safety of the installation

3.15

technical areas

areas where either or the control panel, nitrogen production unit and other relevant system

components are placed

3.16

control panel

electrical device for monitoring, controlling and alarm of the oxygen reduction system

4 System requirements

4.1 General

An oxygen reduction system shall consist basically of:

a) a supply of oxygen reduced air;

b) a fixed pipework system with fittings, valves, nozzles, outlets;

c) oxygen sensors and control panel;

d) alarms.

Oxygen reduced air is produced by air separation or by injecting inert gas or gas mixture into the

protected area.

The oxygen concentration in the protected area shall be monitored by means of measuring equipment.

During operation, the supply of nitrogen shall be controlled automatically according to demand. Where

necessary as a result of a risk analysis additional means shall be provided to operate the supply

manually or an additional supply operated manually or automatically.

The oxygen reduction system can be equipped with automatic equipment designed to shut down

machinery and to close fire doors and other equipment, with the aim of creating and maintaining the

required oxygen concentration.

4.2 Personnel safety

Oxygen reduced air can be dangerous for personnel.

Adherence to this European Standard does not remove the user's statutory responsibility to comply

with the relevant national bodies and laws. In case no national laws exist, further information can be

found in Annex B.

Code requirements for unventilated confined spaces do not apply to space protected by oxygen

reduction system that control and continuously monitor indoor climate for extended occupation.

Personnel safety measures shall be made for the fact that neighbouring volumes can have a reduced

oxygen concentration. These areas may also need to be monitored and/or personnel safety measures

may need to be taken.

Technical or organizational measures shall be taken to prevent unauthorized people from entering

protected areas with permanently reduced oxygen levels.

The measurement system shall be designed in such a way that a loss of function or a measurement

error can in no event lead to the minimum oxygen threshold not being detected.

The spreading of the oxygen-reduced atmosphere to other areas not intended for this (e.g. through wall

openings, cable ducts, floor drainages, leaking doors, conveyor belts, etc.) shall be prevented.

4.3 Effectiveness and application

A fire risk assessment detailing the key fire protection factors shall be done. The important aspects are:

— the type and quantity of material/materials requiring protection;

— the area(s) requiring protection;

— the right dimension of the oxygen reduced air supply to maintain the reduced oxygen concentration

on its design value;

— a back-up oxygen reduced air supply, if provided;

— alarm equipment.

Oxygen reduction systems provide preventive fire protection. The introduction of nitrogen reduces the

oxygen concentration of the air, thereby preventing the ignition or spread of fire except for the

following:

— chemicals containing their own supply of oxygen, such as cellulose nitrate;

— mixtures containing oxidizing materials, such as sodium chlorate or sodium nitrate;

— chemicals cable of undergoing auto-thermal decomposition, such as some organic peroxides;

— reactive metals (such as sodium, potassium, magnesium, titanium and zirconium), reactive

hydrides or metal amides, some of which may react violently.

4.4 Alarm organization and emergency plan

An alarm organization is required for the following purposes:

— to alert affected and responsible persons;

— to alert the permanently attended location;

— to initiate other necessary protective measures.

The responsibilities for the alarm organization shall be defined.

The emergency plan should cover keywords to designate the basic measures that need to be taken in

case of emergency, too low oxygen level or fire signal.

5 Design

5.1 Qualification of the designer

The designer shall be sufficiently technically qualified to ensure effective protection.

5.2 Fire protection concept

The system design shall be part of the fire safety concept of the building.

As part of the system design a fire risk assessment might lead to further fire protection measures.

EXAMPLE Since the oxygen reduction system cannot prevent or detect smouldering or pyrolizing processes

(e.g. overheated cables) suitable smoke detection systems for the protected volume e.g. high sensitive smoke

detection systems according to EN 54–20 class A, are recommended and should be part of the main fire alarm

system of the facility.

Where special circumstances deviate from what is covered in this standard, for example spatial

configuration, structure, installations, combustible materials, altitude different from sea level,

temperature different from normal, fumes or gases, require special measures, the designer shall take

these into account. In these cases the appropriate authorities shall be consulted.

5.3 Structural specifications for the protected area

Structural partitions shall comply with the criteria governing the protection target, as shown in Table 1.

Building regulation specifications are unaffected by these measures.

Table 1 — Structural partitions

Level Protection target Protected Specification Achieved by

volume

Enclosing elements (walls,

floor and roof) shall be

The contents of a room

a

1 shall be protected Room —

sufficiently air tight over the

from internal fires.

life time to protect from

internal fires.

Enclosing elements (walls,

The contents of a room The construction

floor and roof) shall be

shall be protected of fire

a

sufficiently air tight over the

from internal fires and compartments

2 Room

life time and provide

from fires spreading according to the

protection against the spread

from an external relevant

of fire from the surrounding

source. guidelines.

area.

a

Openings shall be constantly sealed or sealable; otherwise the openings shall be reflected in the

calculation of the nitrogen production.

The user should be aware of the relationship between leakage, reduced oxygen air supply and the

system duty cycle.

In the case of oxygen reduction systems all operational openings that are not included in the calculation

of the required levels of oxygen shall be provided with closing mechanisms or monitored via limit

switches. These operational openings include emergency exit doors and other doors, gates etc.

5.4 Oxygen concentration

The following information should be used (where relevant) to determine the design concentration:

— combustible material present (in normal operation and in the case of maintenance work or faults);

— geometry of the combustible materials (e.g. hollow items, thin walls etc.);

— volume of gas contained in combustible materials (e.g. hollow parts, densely packed storage items);

— temperatures and pressures in the protected area;

— safety margin between oxygen concentrations established experimentally and the oxygen

concentrations required for the design of the oxygen reduction system.

5.5 Oxygen reduction to prevent fire

NOTE Ignition can only be prevented in protected areas if the oxygen concentration within the protected area

does not exceed the design concentration. If this level is exceeded, the protection objective of “fire prevention” can

no longer be guaranteed.

If different combustible materials are present in the protected area the lowest ignition threshold (i.e.

the most ignitable material in its most ignitable geometry) shall be taken as the basis for determining

the design concentration. In individual cases additional tests can be carried out to establish ignition

thresholds for combustible materials in the forms and geometry in which the materials are actually

present.

Ignition thresholds for oxygen reduction using nitrogen for various applications are given in A.1. Values

obtained with mixtures of other gas components can differ from these figures. These concentrations are

determined under the specific test conditions described in A.2.

Concentrations other than those shown in Table A.1 can be achieved and allowed when national

legislation (if applicable) are met and the test is validated by test reports in accordance with A.2.

Materials not listed in Table A.1 should be tested in accordance with the test in A.2 and validated by test

reports. Users of this European Standard are advised to inform themselves of the applicability or non-

applicability for this European Standard by their national responsible authorities. If the procedures

described in A.2 is not applicable the ignition threshold shall be determined by the national responsible

authorities. The design of oxygen reduction systems shall take into account the ignition levels and the

safety margins described in 5.6. This design concentration shall not be exceeded anywhere in the

protected area. In case of any fault arising action shall be taken according to the emergency plan (see

5.7.2).

WARNING — Where stored goods may allow a large amount of oxygen to enter the warehouse, the test

structure and the test described in A.2 may not be sufficient. In such cases an appropriate design

concentration shall be agreed with the national responsible authorities. Such cases might include e.g.

warehouses containing toilet paper or clothing in bales.

5.6 Safety margins

The safety margin for oxygen reduction systems shall be set at 0,75 % oxygen by volume.

The difference between the design concentration and the warning threshold or warning threshold and

operating range is established according to the combustible materials, operation and fault related

fluctuations in time and place of the inert gas concentration, the time needed for protection measures

and emergency action to take effect and the tolerance of the oxygen monitoring facilities.

Definitions of concentration levels shown in Figure 1:

a) Ignition threshold

Safety margin, 0,75 % oxygen by vol.

b) Design concentration

Oxygen sensor tolerance: This margin covers the technical measuring errors.

c) Warning threshold for maximum oxygen concentration

Operating margin 1: this margin takes into account the operational fluctuations in time and place of

the oxygen concentration to avoid false warnings, related to the warning threshold for maximum

oxygen concentration (see Clause 4).

Operating margin 2: this margin takes into account the delay before protective measures take effect

and alarm delays of the measuring device monitoring the oxygen concentration. Operation margin

2 is dependent on the system configuration, the emergency concept and the expected hold time.

d) Oxygen reduced air ON

Working range high: this margin ensures a sufficient cycle time for the operation of the oxygen

reduced air supply.

e) Target value for the oxygen concentration

Working range low: this margin ensures a sufficient cycle time for the operation of the oxygen

reduced air supply.

f) Oxygen reduced air OFF

Operating margin 3: this margin takes into account the delay before protective measures take effect

and alarm delays of the device monitoring the oxygen concentration. Operation margin 3 is

dependent on the system configuration and the emergency concept.

g) Pre-alarm threshold for minimum oxygen concentration

Operating margin 4: this margin determines the alarm value for the minimum oxygen

concentration to avoid false alarms.

h) Alarm threshold for minimum oxygen concentration.

NOTE The alarm threshold for minimum oxygen concentration is defined by national regulations and laws.

For further information see Annex B.

Key

X time Y O concentration

1 design values a safety margin

2 ignition threshold b oxygen sensor tolerance

3 maximum design concentration c design operation range

4 minimum design concentration d oxygen sensor tolerance

5 risk classification for human beings e altitude correction

6 alarm and warning levels f supply on

7 O max warning g supply off

a

8 optional O max pre-warning

a

9 optional O min pre-alarm

10 O min alarm

a

required, if distribution valves are not monitored, see 5.7.3

Figure 1 — Control diagram for oxygen reduction

Table 2 provides an example for the calculation of the oxygen concentration with different design

values at an altitude of 300 m.

Table 2 — Example for the calculation of the oxygen concentration

O -

Design values Margin Remarks

Concentration

Vol.-% Vol.-%

Ignition threshold 16,0

Safety margin - 0,75

Design concentration 15,25

Oxygen sensor tolerance - 0,2

Maximum O concentration 15,05 O max warning

2 2

Operating Margin 1warning - 0,2

Pre-warning O 14,85 O max pre warning (optional)

2 2

concentration

Operating margin 2 pre- - 0,2 (optional)

warning

Oxygen reduced air supply 14,65

ON

Working range high - 0,2

Target value 14,45

Working range low - 0,2

Oxygen reduced air supply 14,25

OFF

Operating Margin 3 pre-alarm - 0,2 (optional)

Pre-alarm O concentration 14,05 O min pre alarm (optional)

2 2

Operating margin 4 alarm - 0,2

Minimum O concentration 13,85 O min alarm

2 2

Oxygen sensor tolerance −0,2

Altitude correction None Altitude 300 m (less than

700 m)

Risk classification 13,65 a

Risk class 2

a

See Annex B.

5.7 Oxygen reduced air quantity

5.7.1 Continuous oxygen reduction

When determining the oxygen reduced air flow required for continuous oxygen reduction the following

factors shall be taken into account:

— the target design concentration;

— the leak rate under normal operating conditions (including door openings, air locks and sluices and

frequency of the operation of those openings per day);

— the concentration of the oxygen reduced air;

— the period of operation.

To determine the necessary capacity for the protected volume (under normal operating conditions) an

additional 25 % shall be added to the calculated flow rate.

The basis for determining the leak rate of the protected volume can be for example a Door Fan Test

according to EN 15004-1:2008, Annex E, the fan pressurization method according to EN ISO 9972 or a

test for determination of local mean ages of air in buildings for characterizing ventilation conditions

according to ISO 16000-8. In addition air leakage due to normal operation (e.g. through airlock

entrances) shall be taken into account.

5.7.2 Emergency plan

An emergency plan shall be formulated that describes the progress of the oxygen concentration in the

event of a failure of the oxygen reduced air. If there is a risk that after activation of the O max warnings

the design concentration is reached and a danger situation in the protected area cannot be ruled out,

contingency measures shall be taken. Contingency measures can be either technical or organizational

measures.

The emergency plan shall be discussed with all those responsible for fire protection and, where

applicable, personnel safety.

5.7.3 Oxygen reduced air

!The oxygen reduced air shall be free of dangerous impurities and have a minimum concentration of

nitrogen that is necessary to ensure that the necessary injected volume to reduce the oxygen

concentration from 0,5 Vol.% above the target concentration down to the target concentration does not

exceed 20 % of the protected room volume. The pressure and temperature in the protected room needs

to be considered.

The maximum oxygen concentration is to be calculated as follows:

cc+−0,5 %

O O

22,Target Residual

ln > 20 %

cc−

O O

2,Target 2Residual

0,5 %

cc< +

O O

20 %

2Residual 2,Target

1− e

cc< − 23, %

O Residual O

2 2,Target

where

c

is the target oxygen concentration;

O

2,Target

c

is the residual oxygen concentration.

O

2Residual

"

The system and if applicable the reserve supply of oxygen reduced air shall be monitored, see also

Clause 7. Measures to be taken in the event of a fault shall be detailed in the emergency plan.

NOTE The reliability can be achieved for example by:

— monitoring the operating position of the manual stop valves located in the gas flow;

— monitoring the function of the oxygen reduced air production system and/or supply;

— monitoring the oxygen reduced air flow by means of flow monitors.

The oxygen reduced air shall be free of dangerous impurities and have a minimum volumetric

concentration of 90 % of nitrogen.

5.7.4 Gaseous supply

5.7.4.1 In containers

If the oxygen reduced air is stored in containers the reliable quantity of oxygen reduced air shall be

available for the required demand.

A fault alarm shall be issued as soon as this quantity is no longer sufficient to maintain the design

concentration for the period required for refill.

5.7.4.2 Vaporizer

The necessary oxygen reduced air shall be available at all times and if it is a stand-alone system no

other uses shall be allowed for the vaporizer and the supply. If it is a back-up system, additional uses for

the supply can be allowed.

The oxygen reduced air supply shall be monitored for faults. Should there be a problem with the oxygen

reduced air supply a fault alarm shall be displayed on the control panel.

5.7.4.3 Oxygen reduced air production equipment

The necessary oxygen reduced air production equipment shall be available at all times and shall be

dedicated only to the fire prevention purpose.

If back-up solutions (e.g. liquid nitrogen) are used, they shall ensure at all time to have the necessary

availability of oxygen reduced air.

The oxygen reduced air production equipment shall be monitored for faults.

5.7.5 Fault signals

All relevant deviations from the normal operation of the oxygen reduced air system shall trigger a fault

signal on the control panel. These include:

— failure of the oxygen reduced air supply;

— measured oxygen concentration in the protected volume out of design operating range;

— the possible misalignment of section valves from their operating positions or as an alternative the

oxygen concentration in the protected zone could be used. In this case a pre-warning and pre-alarm

level shall be implemented;

— abnormal operating range of the generator (e.g. by low or too high pressure, concentration below

10 % of the normal operating range, high temperatures);

— short-circuit or open-circuit of all operation and alarm lines;

— failure of any oxygen sensor;

— breakdown of power supply.

5.8 Technical areas

5.8.1 Technical area for control panel

The control panel should be located in a designated area, which is not subject to major fire risk and

should not be set up in the protected volume itself. If the control panel is located inside the protected

volume, a display for the actual oxygen concentration shall be visible from outside close to the entrance

of the protected volume and it shall be possible to switch off the oxygen reduced air supply from the

outside.

The location of the control panel shall comply with the following minimum requirements:

— be easily accessible;

— be protected against unauthorized access;

— maintain a minimum temperature range between 0 °C and +50 °C or specified by the manufacturer;

— be designed such that maintenance work and inspections can be carried out easily;

— have electrical lighting.

The operating instructions shall always be displayed in a prominent position.

5.8.2 Technical area for reduced oxygen air generation

The technical area for reduced oxygen air generation shall:

— have ventilation or in the case of closed volumes, the technical area should be equipped with an

oxygen sensor;

— be easily accessible;

— be protected against unauthorized access;

— maintain a minimum temperature range between 0 °C and +35 °C or specified by the manufacturer;

— be designed such that maintenance work and inspections can be carried out easily;

— have electrical lighting.

Components installed in the technical area shall be protected against excessively high temperatures

caused by exposure to the sun or other heat sources.

The technical area shall be separated from neighbouring volumes such that any components of the

oxygen reduction system located in that space are protected against mechanical and chemical

influences.

The following information about the oxygen reduction system shall be provided by the installer:

— name of the installer, where applicable the name of the maintenance company;

— year of installation or of any significant changes;

— operating and main

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...